1. Introduction

Due to the declining birthrate and aging population, the number of skilled workers in Japan’s manufacturing industry is decreasing, resulting in a serious labor shortage. In product inspection processes, there is an ever-increasing need to automate the task of detecting defective products, which has traditionally been achieved visually by human eyes. In order to solve the issues related to product quality control faced by the manufacturing industry, the authors are developing an application that can easily and effectively design and train a machine learning model that has the same or more ability to identify defective products as skilled inspectors.

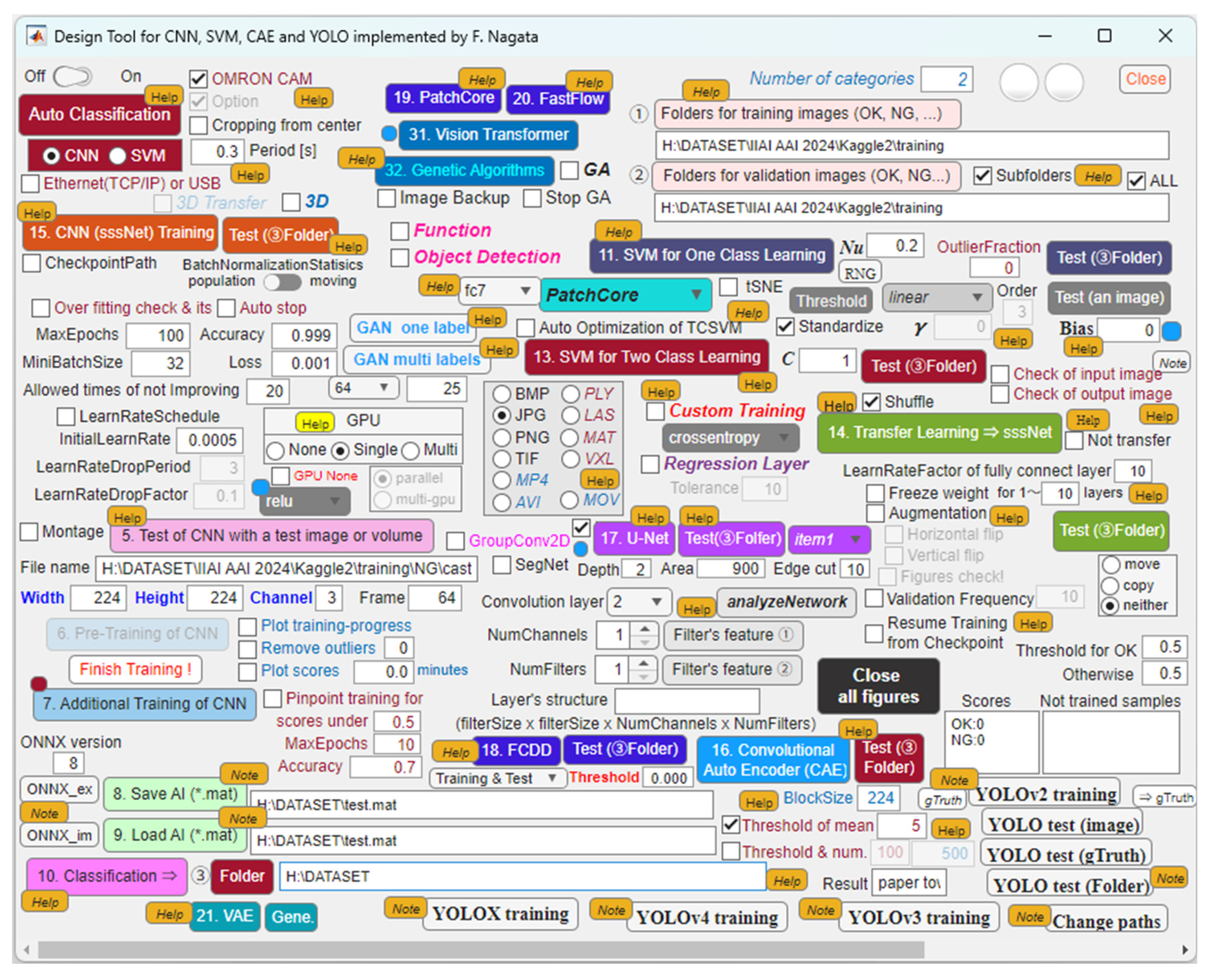

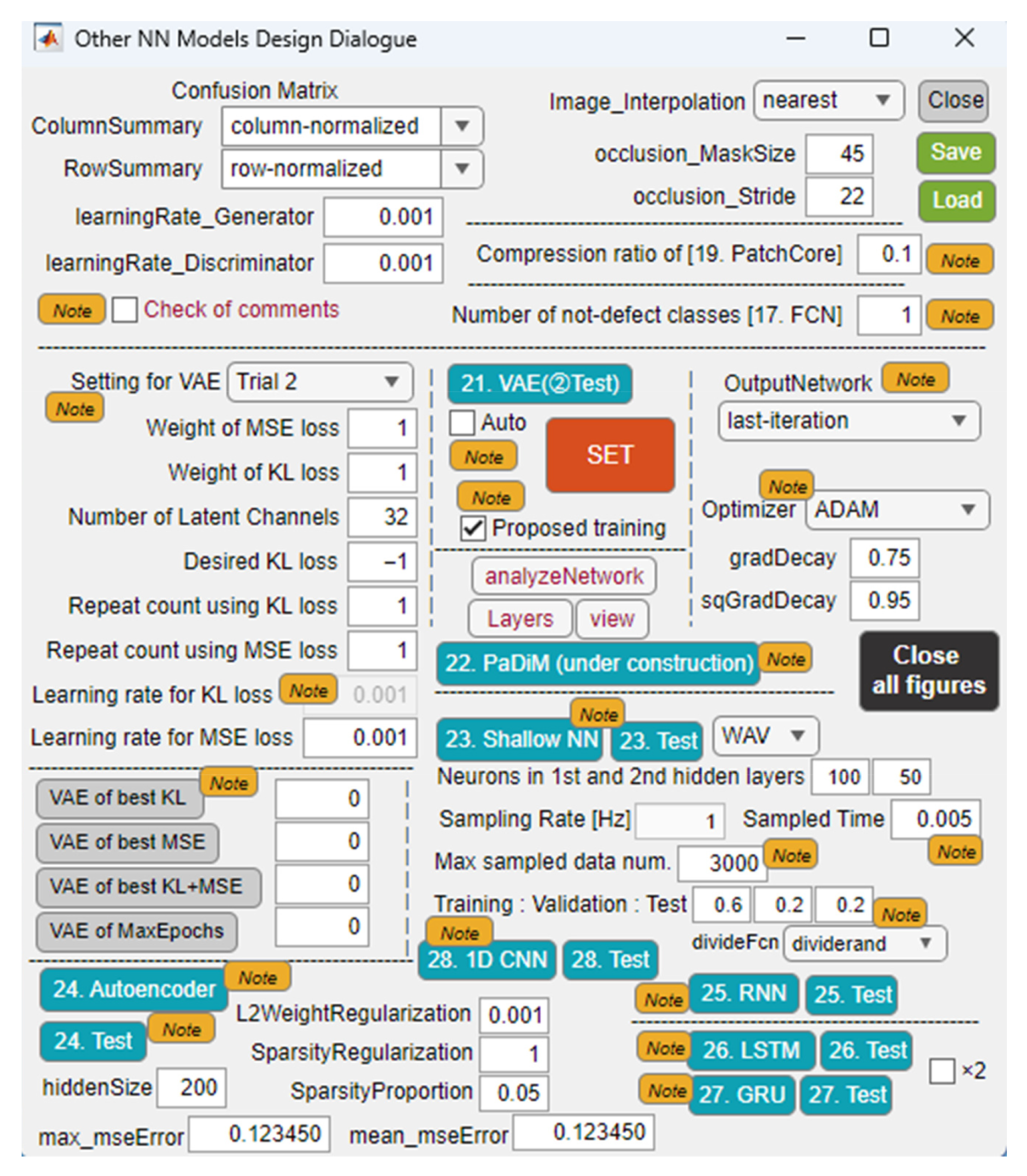

Figure 1 and

Figure 2 show the main and sub dialogs developed on MATLAB R2025a. By using the proposed application, the authors are supporting engineers to build their desired machine learning models for defect detection of industrial products and materials included in images and movies. Available models are convolutional neural network (CNN), convolutional autoencoder (CAE), support vector machine (SVM), you look only once (YOLO) [

1,

2], U-Net, segmenting objects by locations (SOLO) [

3,

4], mask region-based CNN (Mask R-CNN) [

5], fully convolutional data description (FCDD) and so on [

6]. In fact, in manufacturing industries, there is a strong need for flexible anomaly detection systems that allow workers to easily cope with all the processes from setting up the environment to operating the system so that we are evaluating and improving the application through trial use and expanding functionality based on feedback from users.

Up to now, much relevant research on anomaly detection systems based on sound data has been proposed. However, when monitoring the operating status of CNC machine tools and other equipment based on time series data, there does not seem to be sufficient discussion about anomaly detection and concurrent visualization of prediction. In addition, many systems require preprocessing, such as converting time-domain data into the frequency domain. For example, Harada et al. proposed a baseline system for first-shot-compliant unsupervised anomaly detection for machine condition monitoring, in which a simple autoencoder-based implementation combined with a selective Mahalanobis metric is implemented as a baseline system. The performance is evaluated to set the target benchmark for the forthcoming Detection and Classification of Acoustic Scenes and Events (DCASE2023T2) [

7]. Zhou et al. proposed an incremental learning-based anomaly sound detection model that enhances the model’s capacity to learn from continuous data streams, reduces knowledge forgetting, and improves the stability of the model in the anomaly sound detection task. Experiments using Task 2 data from the DCASE2020 challenge show that the proposed method effectively improves the average AUC and average pAUC by 7% to 10% when compared to the fine-tuning strategy [

8]. Also, Dong et al. proposed a self-encoder model combining a residual CNN and a long and short-term memory (LSTM) network to extract features in both spatial and temporal dimensions, respectively, to make full use of the information of the audio signal [

9]. In addition, Sekhar et al. proposed texture analysis-based transfer learning CNN models so that they can be applied to a three-class (high/medium/low tool wear) classification task of tool wear based on the noise generated during mild steel machining. Machining acoustics were converted to spectrogram images so that they can be given to the input layer of each CNN, in which four pre-trained models, SqueezeNet, ResNet50, InceptionV3, and GoogLeNet, were used for the backbone. More recently, Liao et al. proposed an enhanced contrastive ensemble learning method for anomaly sound detection, in which the log-mel transform for frequency domain feature analysis and the Mel spectrogram are used to represent the features of the statistical domain [

10]. It is reported that the method is effective in automatically monitoring the operating conditions of the production equipment by detecting the sounds emitted by the machine.

It is known that spectrograms, MFCCs (Mel-Frequency Cepstrum Coefficients), and Mel-spectrograms are promising practices for audio analysis. For example, Abdul and Al-Talabani reported that MFCCs have been designed to model features of audio signals and have been widely used in various fields. MFCCs are one of the most widely used features in speech recognition and speech processing. Their research aimed to review the applications that the MFCC has been used for in addition to some issues that were facing the MFCC computation and its impact on the model performance [

11]. Dossou and Gbenou used mel-spectrograms over conventional MFCCs features and assessed the abilities of CNNs to accurately recognize and classify emotions from speech data. Their designed speech emotion recognition model trained on four valid speech databases achieved a high classification accuracy of 95.05%, over eight different emotion classes: anger, anxiety, calm, disgust, happiness, neutral, sadness, and surprise [

12]. Also, Islam and Tarique considered two spectral images of voice signals called spectrograms and mel-spectrograms to detect dysphonic voices. It is known that the spectrogram is a convenient representation of voice signals on a time-frequency scale and has been popularly investigated in pathological voice detection algorithms. It is reported from simulation results that the mel-spectrogram was superior to the spectrogram in terms of classification accuracy [

13]. Furthermore, Ninevski et al. proposed a new approach to analyze acoustic emission data in the phase domain. In addition, the use of psychoacoustics was evaluated. Both approaches were applied to monitoring the condition of a CNC milling tool [

14]. However, when the above approaches are applied, it seems that raw time-series sound data must be transformed into frequency domain.

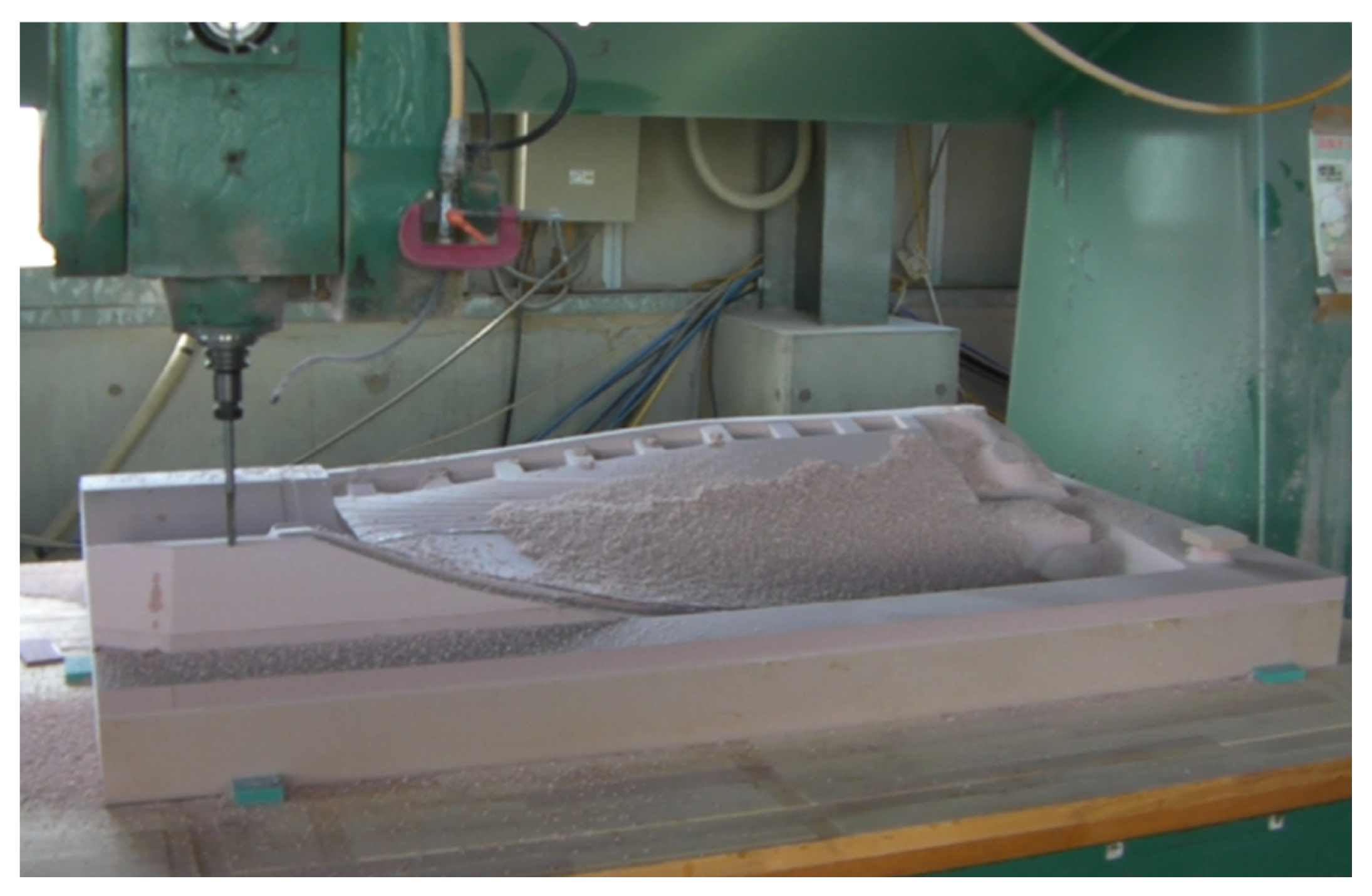

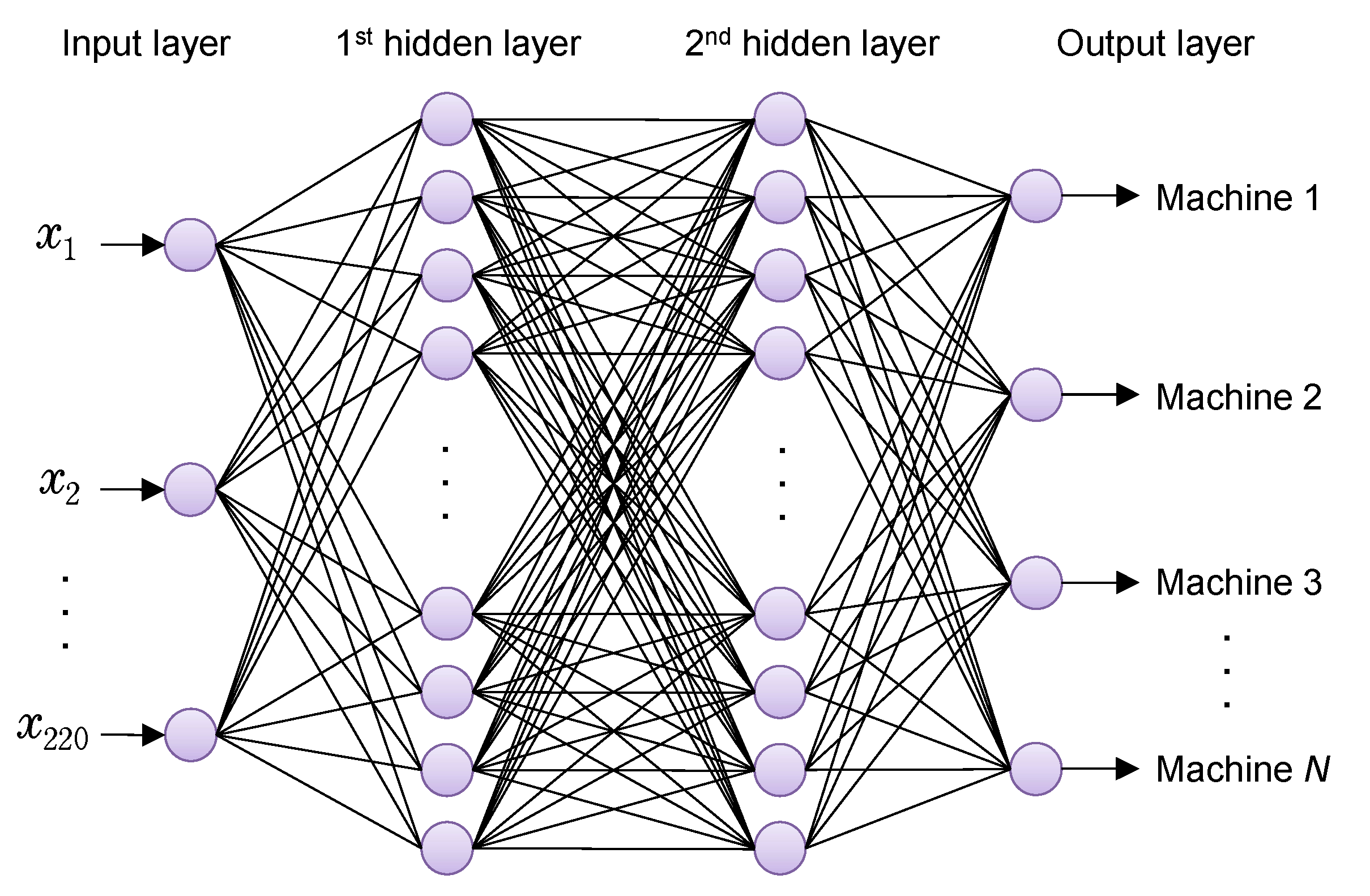

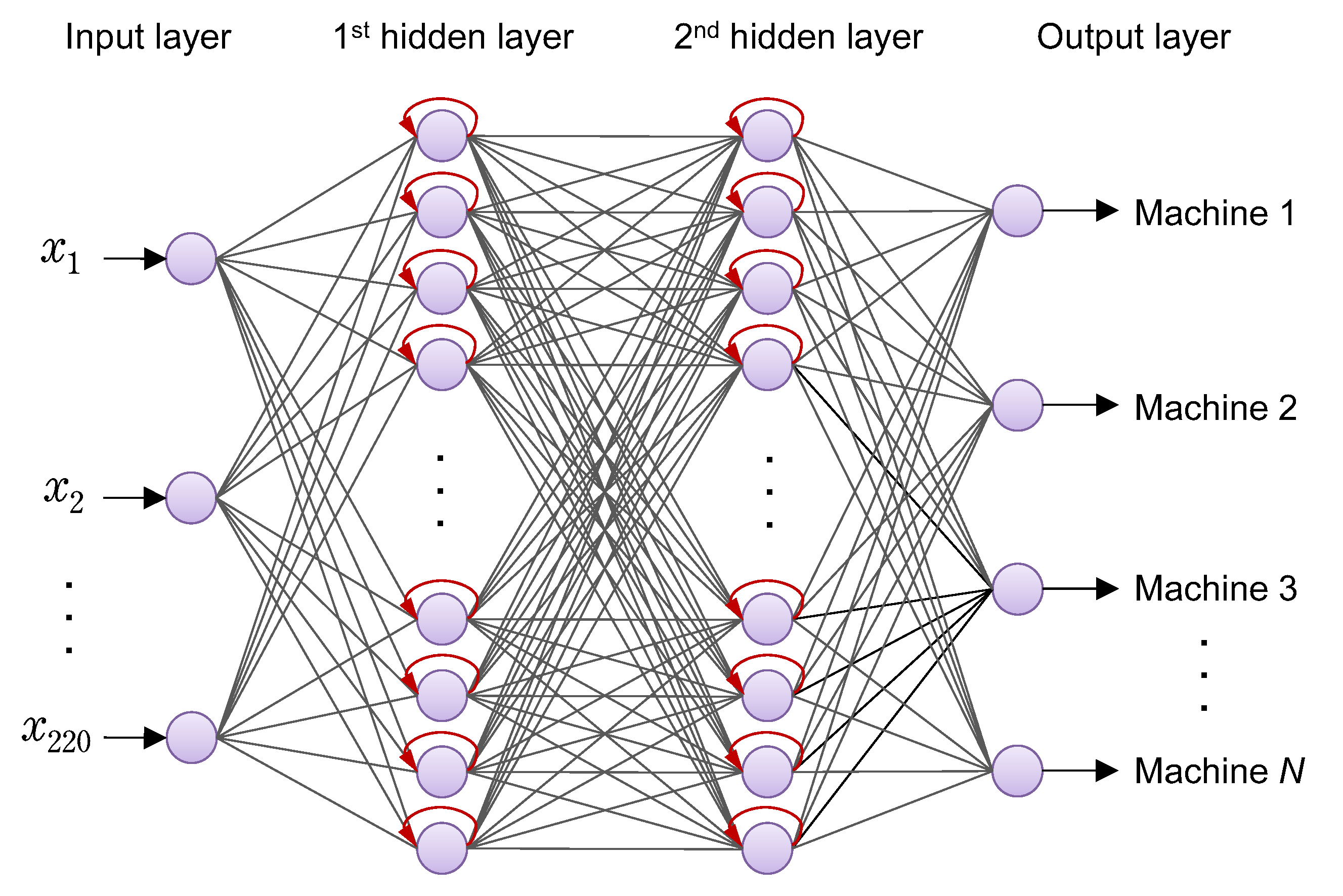

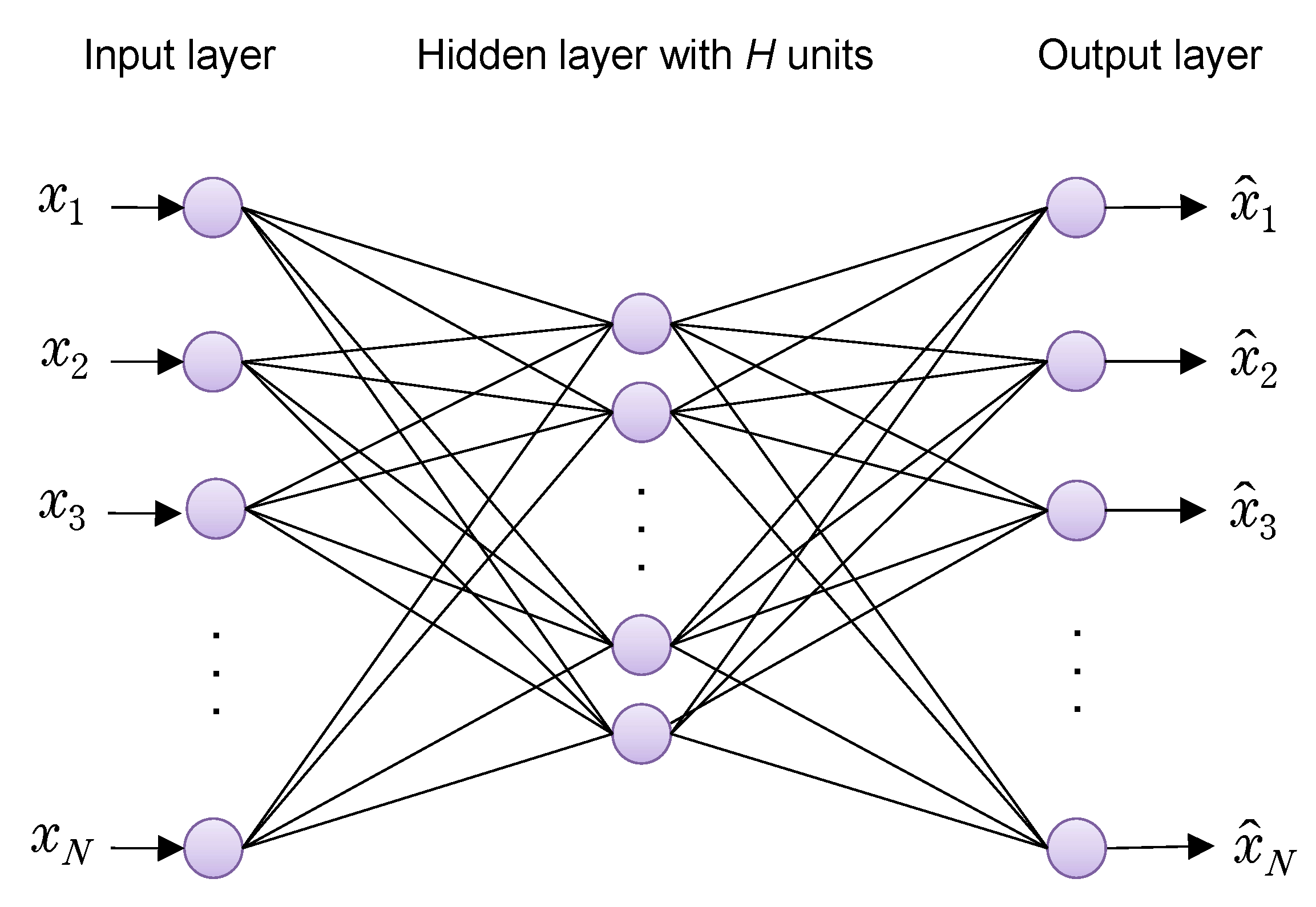

The main objective of this paper is to establish an identification system based on machine tools’ sounds without using conventional frequency domain information, but only raw time series data are used. As surveyed above, there seems to be almost no discussion about the optimal way to design time series sound data-based machine learning models. Also, it seems that concurrent visualization of understanding is not well realized when NN models are applied to anomaly detection of time series data such as mechanical sound data. In this paper, the authors have considered neural network systems that can be easily applied to classification, anomaly detection and prediction of CNC machine tools, as shown in

Figure 3. In addition to images and videos used for training, in order that time series data such as mechanical sounds and vibrations can be used as multidimensional vector data, design functions for shallow NN, recurrent NN, 1D CNN, and AE are implemented in the application shown in

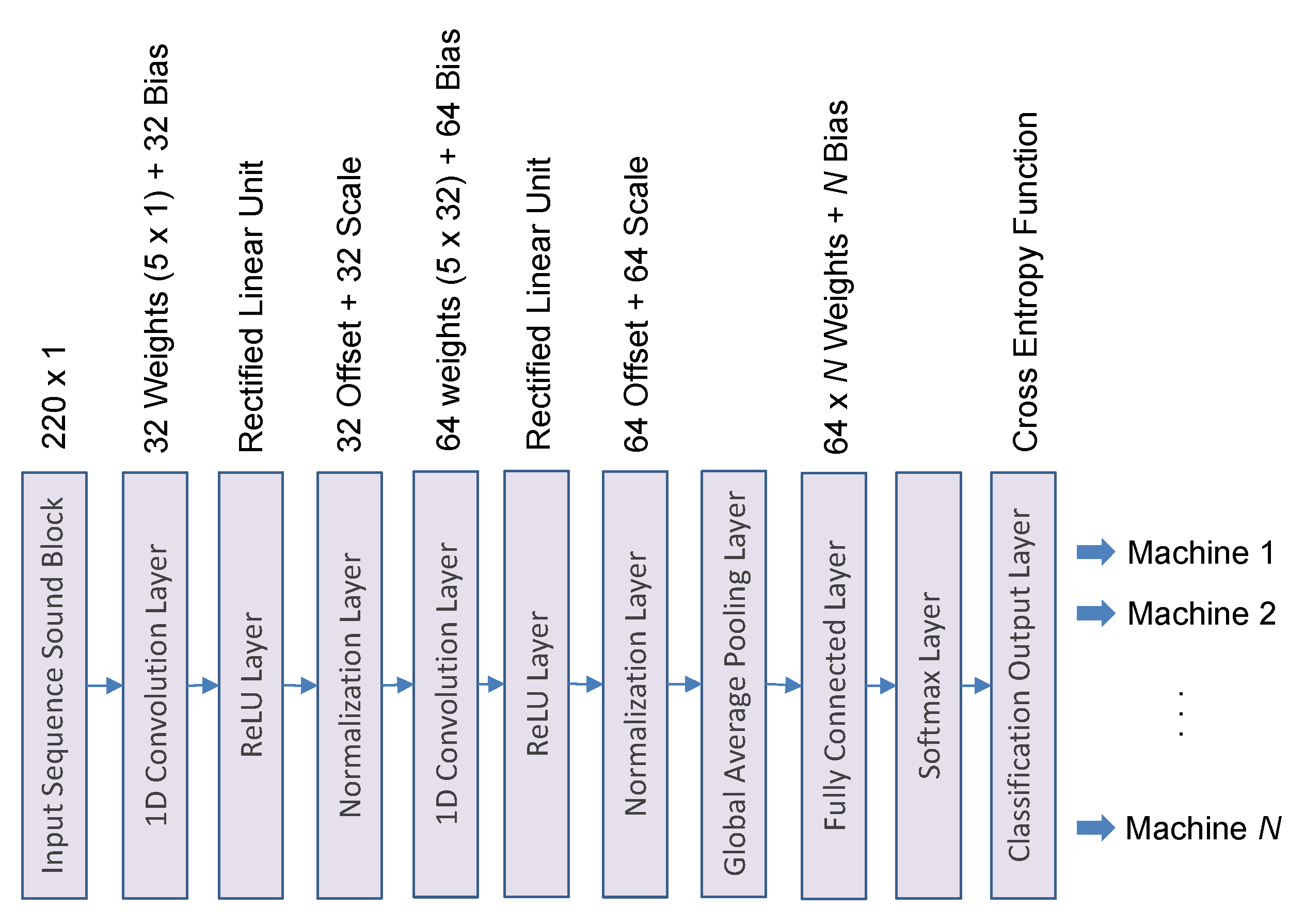

Figure 2. For training machine learning models, many sound block (SB) data extracted with a designated sampling time are generated from nine categories of mechanical sounds collected from multiple machine tools. We report on the evaluation of the classification performance of each model on test data while changing the extraction time, which determines the length of the sound block, and the number of sound blocks used for training.

Finally, SB data-based FCDD is proposed for multi-dimensional vector data to realize anomaly detection of time-series data and its concurrent visualization of understanding, in which for example, time-series sound data are converted to one-line gray-scale images followed by BMP images for training FCDD. The effectiveness of the proposed model is evaluated by experiments.

2. Machining Tool Operating Sound and SoundBlocks

In the experiment, multiple machine tools installed at the university’s machine design and manufacturing center were operated, and nine categories of operating sounds were collected for 10 s each using a sampling rate of 44,100 [Hz]. No special sensor was used, but a microphone on a handheld smartphone was used. Recorded sounds were saved in each WAV file. When a smartphone’s microphone is used to measure SB data, problems such as picking up background noise and depending on placement may sometimes occur. In this experiment, the measurements were conducted by a microphone in hand just around the target machine tools so that such undesirable phenomena were not observed. However, if multiple machine tools are operating nearby, such problems should be noted.

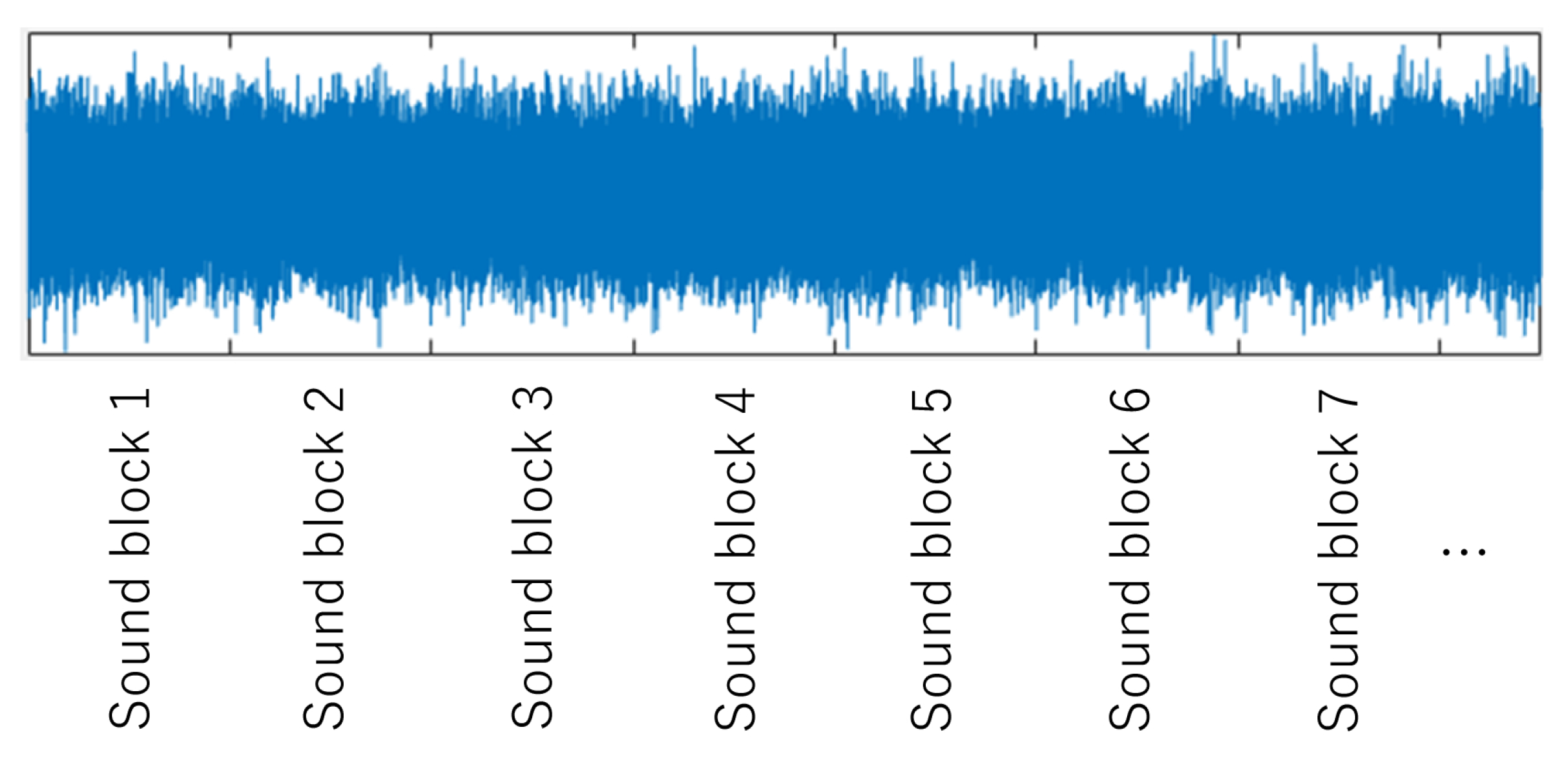

Sound blocks extracted from WAV files are used for training neural network models.

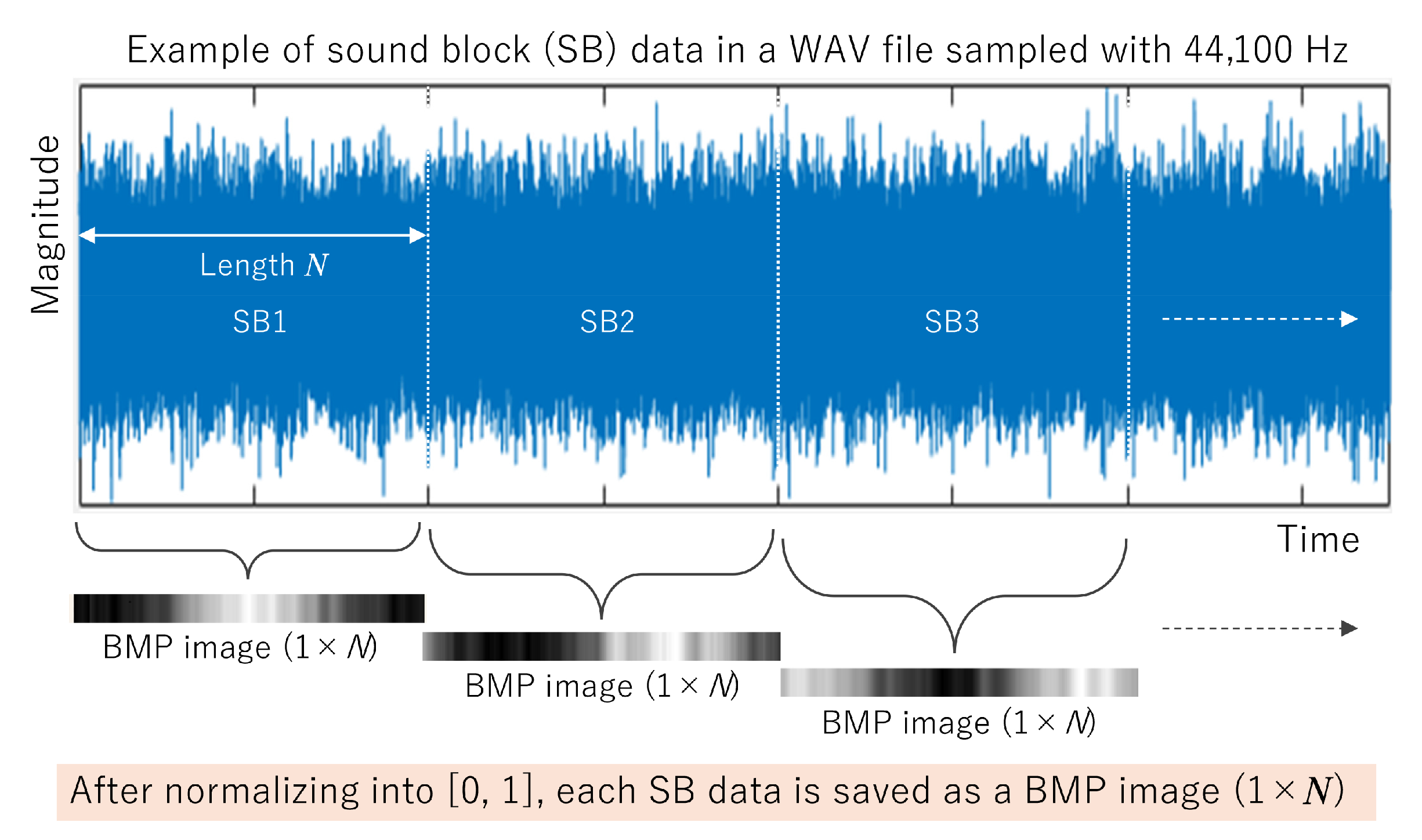

Figure 4 shows an example of extraction of time-series sound block (SB) data from a WAV file, which is recorded from a general milling machine. In this experiment, SB data are sampled with 0.005 [s], so that the length of an SB data file is 44,100 × 0.005 = 220. According to the length, the number of input layer’s neurons is designed as 220. Also, in this case, the number of SB data extracted from a WAV file becomes 2000, whose 80%, 10%, and 10% are assigned for training, validation, and test, respectively. Details, including labels, are tabulated in

Table 1. It has been empirically confirmed that it is important to determine the length of SB data used for training and testing. Note that the size of the dataset, the organization for training, validation and testing, and the length of one SB data were empirically determined in this case. It seems to be required to reconsider those values if conditions, including target materials, cutting tools, and machine tools, are changed.

4. SB Data-Based FCDD Model for Anomaly Detection and Visualization of Time SeriesData

It has been confirmed from the experiments up to the previous sections that 1D CNN and autoencoder are effective for classification and identification of SB data, respectively. As can be expected, 1D CNN is also applied to anomaly detection tasks by redesigning the output layer for binary classification, i.e., normal and anomaly.

As for the data type processed by conventional anomaly detection systems, abnormality diagnosis systems, or fault diagnosis systems for CNC machine tools, original time-series sound data measured seem to need complicated transformation to the frequency domain to obtain, e.g., a spectrogram. For example, Jauregui et al. presented a methodology for the detection of tool wear based on frequency and time-frequency analysis of the cutting force and vibration signals [

17]. Zhang et al. proposed a multi-modal fusion feature extraction method in which support vector machines, random forests, and deep NNs are employed to handle time-domain, frequency-domain, and joint time-frequency domain features, respectively, to build tool wear prediction models [

18]. Also, Rahman et al. proposed vibration-based tool condition monitoring for the CNC grinding process, in which key features indicating tool wear and faults are extracted from the frequency domain using an image embedding technique [

19]. On the other hand, our proposed SB data-based FCDD has only to directly deal with time-series data extracted from, e.g., cutting sound by a router bit. As for the network structure, for example, Kunitake et al. proposed an anomaly detection system using four models consisting of an SVM and three NNs for predicting machining troubles [

20]. On the other hand, our proposed SB data-based FCDD can be simply designed based on pretrained powerful CNN models such as AlexNet and VGG19.

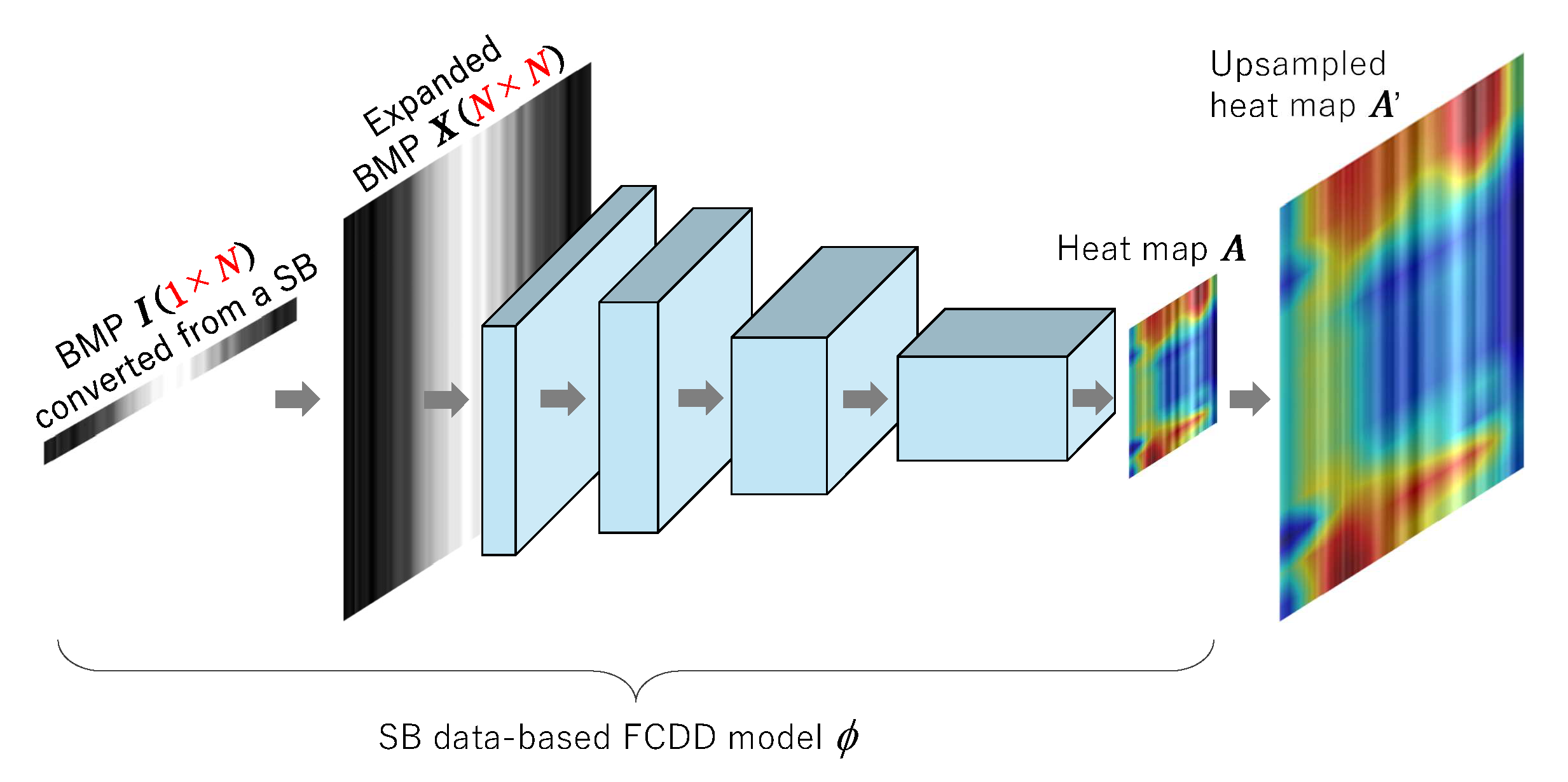

4.1. The Proposed FCDD for Time Series Data Such as SBData

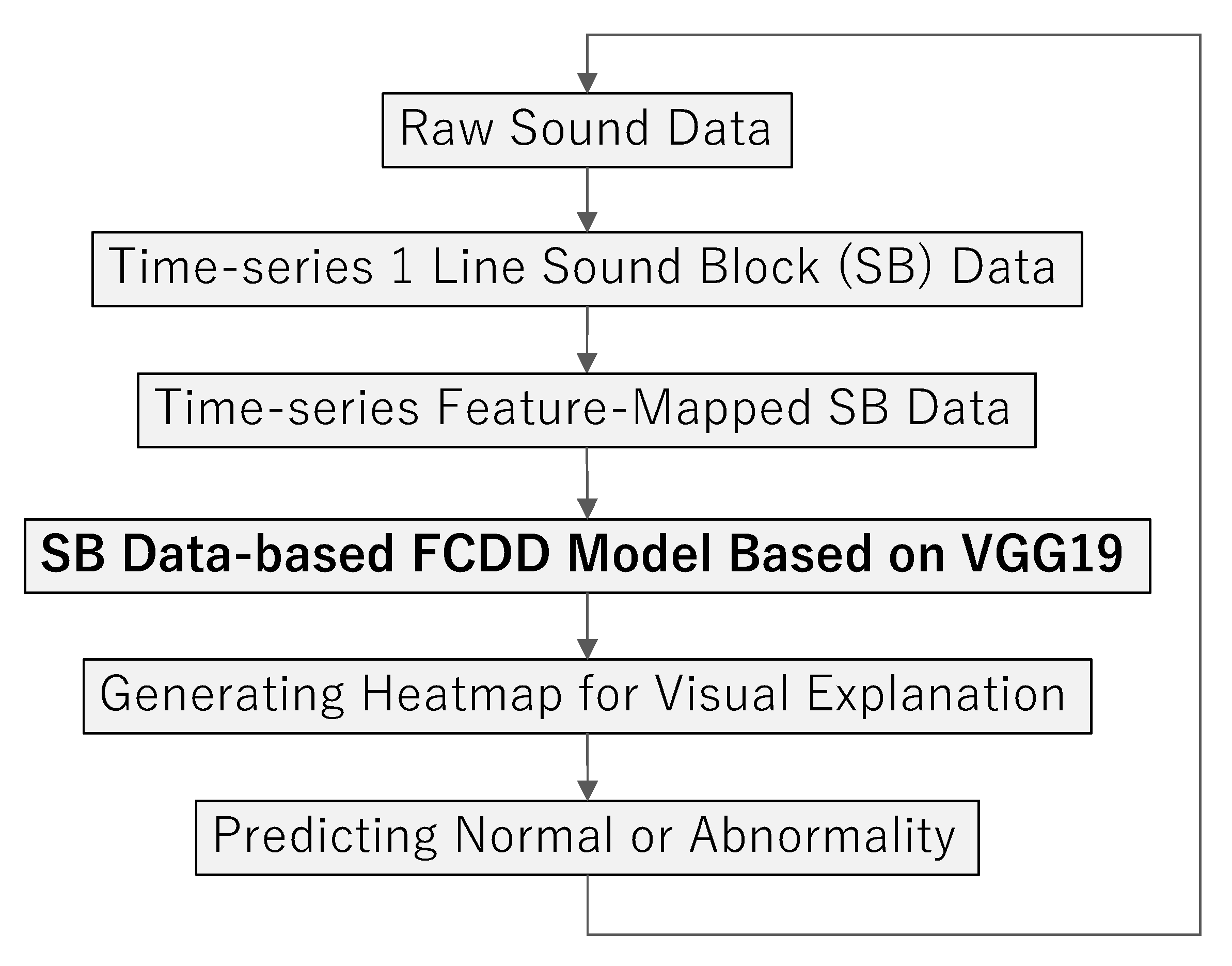

At this stage, one of the serious problems in dealing with the time series data such as SB data is how clearly and concurrently anomaly areas should be visualized and understood. In this paper, to cope with the need, an SB data-based FCDD model is further proposed as shown in

Figure 9 to perform anomaly detection and its concurrent visualization without secondly using Grad-CAM [

21] or Occlusion Sensitivity [

22]. The FCDD model is designed based on VGG19, whose input layer’s resolution is

. The proposed method allows us to construct an FCDD-based anomaly detection system for time series data such as SB data.

The objective function of FCDD [

23] is briefly introduced. In Liznerski’s paper, an FCN model

ϕ employed in the former part performs

ϕ: ℝ

c×h×w → ℝ

u×v, by which a feature map

downsized into

is generated from an input image

X. A heat map of defective regions can be produced based on the feature map. The pseudo-Huber loss

[

24] in terms of an output matrix from the FCN part, i.e., a feature map, is given by

where the calculation is performed with element-wise operation, i.e., pixel-wise, to be able to form a heat map. The object function in training an FCDD model is given by

The first term has a valid value in case that the label of a training image is negative, i.e., , where the L1 norm is divided by the total pixels of a feature map. The value can be considered as the average per one pixel. Therefore, when normal images are given to the network in training, the weights are adjusted so that each pixel forming a heat map can approach to 0.

On the other hand, the second term becomes effective when the label of a training image is an anomaly (

), and

has a value close to 0 with the increase in the average loss per one pixel, so that the value of the log function

also approaches 0 with the lapse of training time. It is confirmed from the above discussion that Equation (

5) using Equation (

4) enables both to minimize the sum of the averages of

of non-defective images and to maximize those of defective images. The main dialog shown in

Figure 1 enables the user-friendly training, testing, and building of FCDD models.

4.2. How to Generate Image Data from SBData

An FCDD model with the backbone consisting of VGG19 is tried to be applied to an identification task of machine tools’ sounds and their concurrent visualization, so that time-series SB data must be transformed into image maps with the same resolution as VGG19’s input layer. To cope with this indispensable process with the simplest method, SB data are simply copied into rows.

In this subsection, it is explained how to generate input images

for FCDD from SB data in the time-series domain. As shown in

Figure 9,

X has the same resolution as the input layer of FCDD. As already explained, SB data

is directly extracted from a WAV file with a designated extraction time

[s]. For example, if the sampling frequency of a WAV file is

f [Hz], then the length

N of SB data becomes

. One line of SB data

is transformed to 1 line gray-scale BMP image

as shown in

Figure 10 through normalization by

where

and

are the maximum and minimum values of elements in

s, respectively. Then, an expanded bitmap image

to be given to the input layer of FCDD can be constructed as

Note that

in the following experiments.

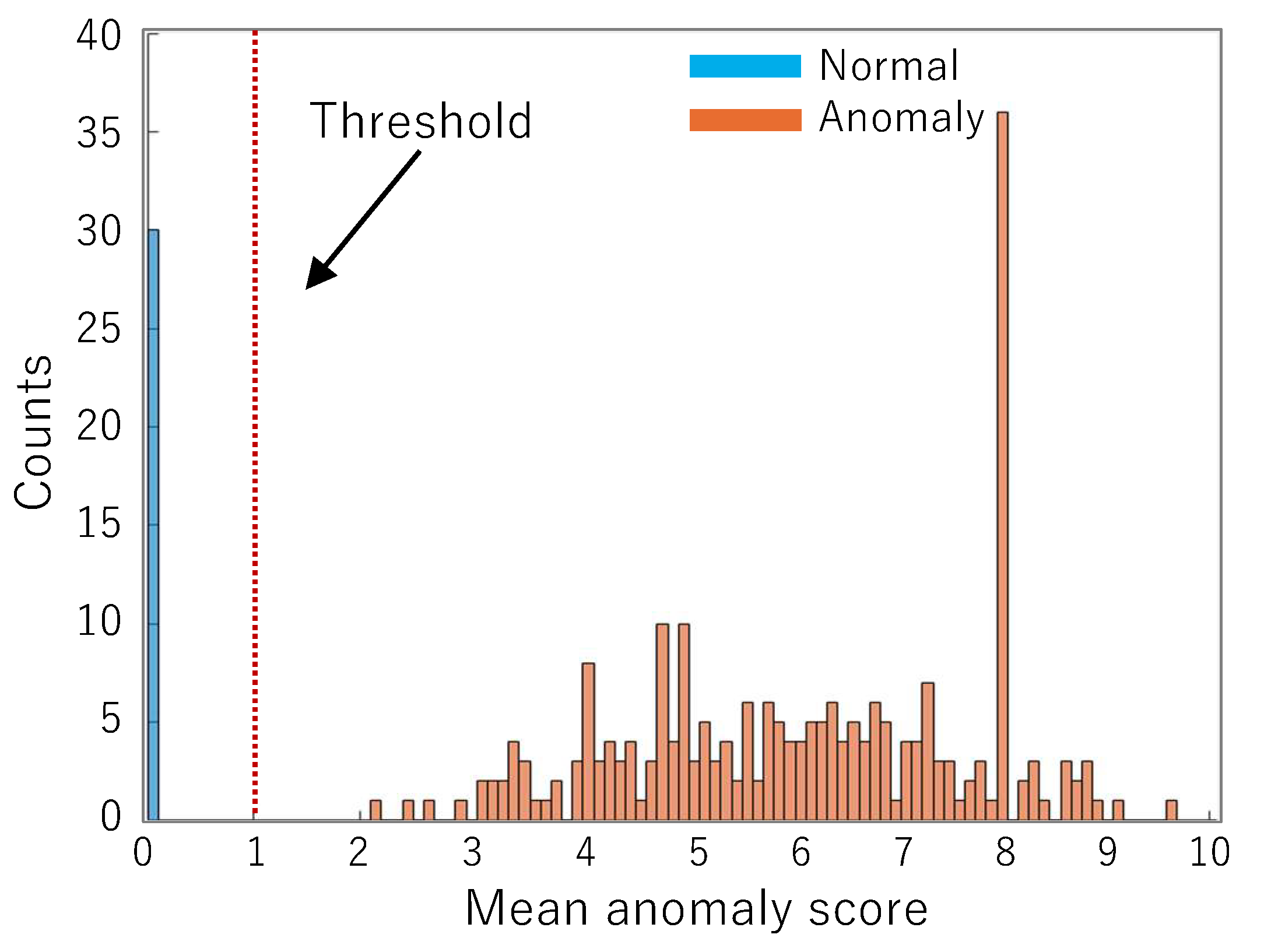

4.3. Experiment of Identification of Machine Tools’ Sound Data and Its Concurrent Visualization Using an FCDDModel

In this subsection, an identification experiment is conducted using the nine kinds of SB data as shown in

Table 4, in which it is assumed that the sound of the band saw is normal and the other eight kinds of sounds are anomaly, so that 30 normal SBs and 30 × 8 = 240 anomalous SBs are used for training the FCDD model. After 200 epochs of training, all the training data were scored as shown in

Figure 11. As can be seen, it is observed from the histogram given by

Figure 11 that SB data extracted from band saw are scored with values close to 0; on the other hand, SB data except for band saw are scored with values far from 0. The mean anomaly score

is calculated by

which is the mean value of each pixel in a predicted map

given by Equation (

4). In order to use the trained FCDD as an anomaly detector, a threshold value for criteria has to be set. In this case, a threshold value of 1 of the anomaly score can be easily determined from the distribution in

Figure 11.

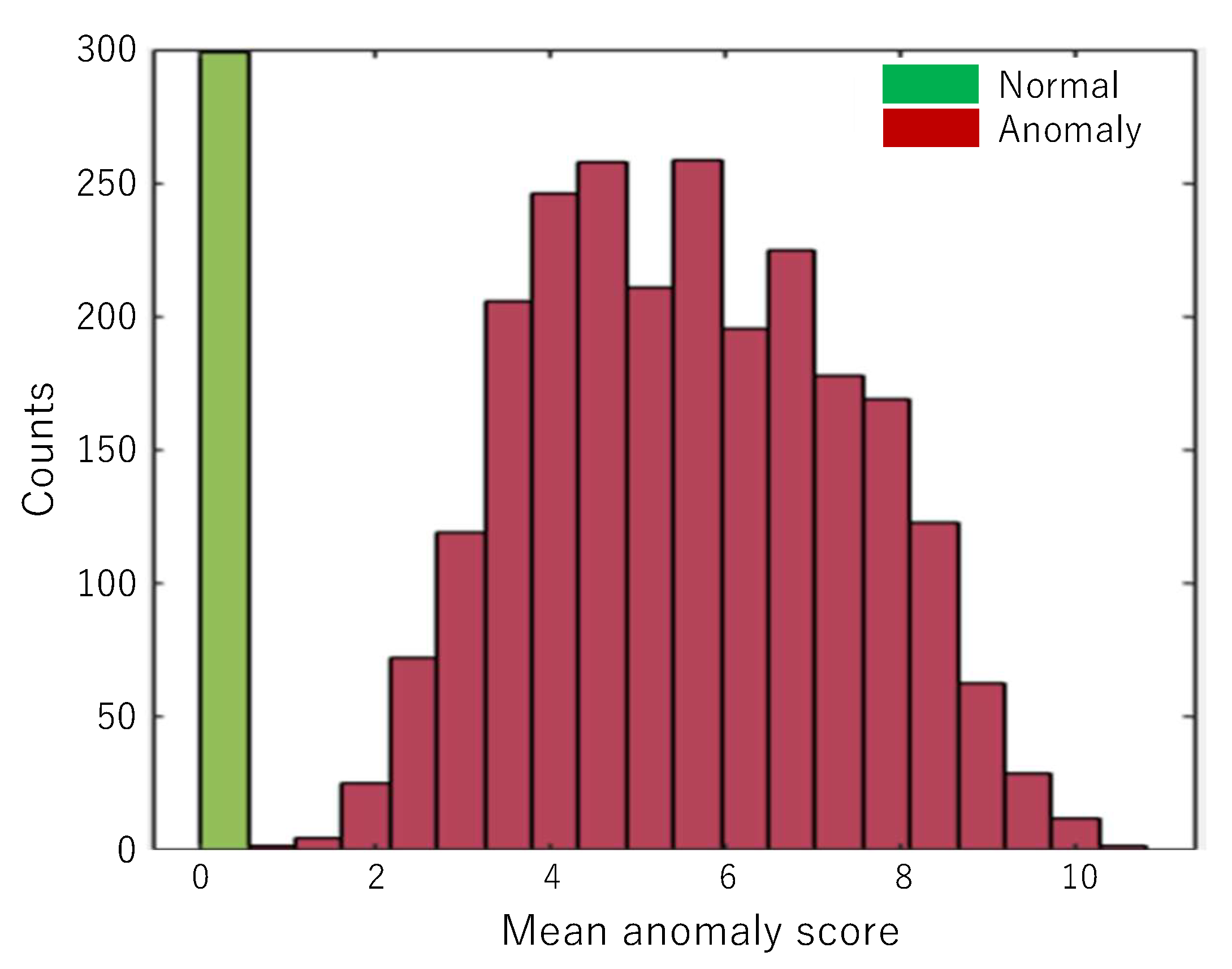

After setting 1 to the threshold value, the generalization ability of the trained FCDD was checked using test SB data. A total of 300 normal SBs and 300 × 8 = 2400 anomaly SBs were used for testing so that all the images could be accurately classified as normal (band saw) or anomaly (except for band saw) as shown in

Table 5.

Figure 12 shows the histogram of the test SB data’s mean anomaly scores predicted by the FCDD model. Incidentally,

Figure 12 is the distribution of scores in which the trained FCDD predicted the test SB data for confirming the generalization. Although the distance between two class groups becomes smaller for test SB data, the test SB data could be successfully identified as shown in

Table 5 by setting the threshold value to 1.

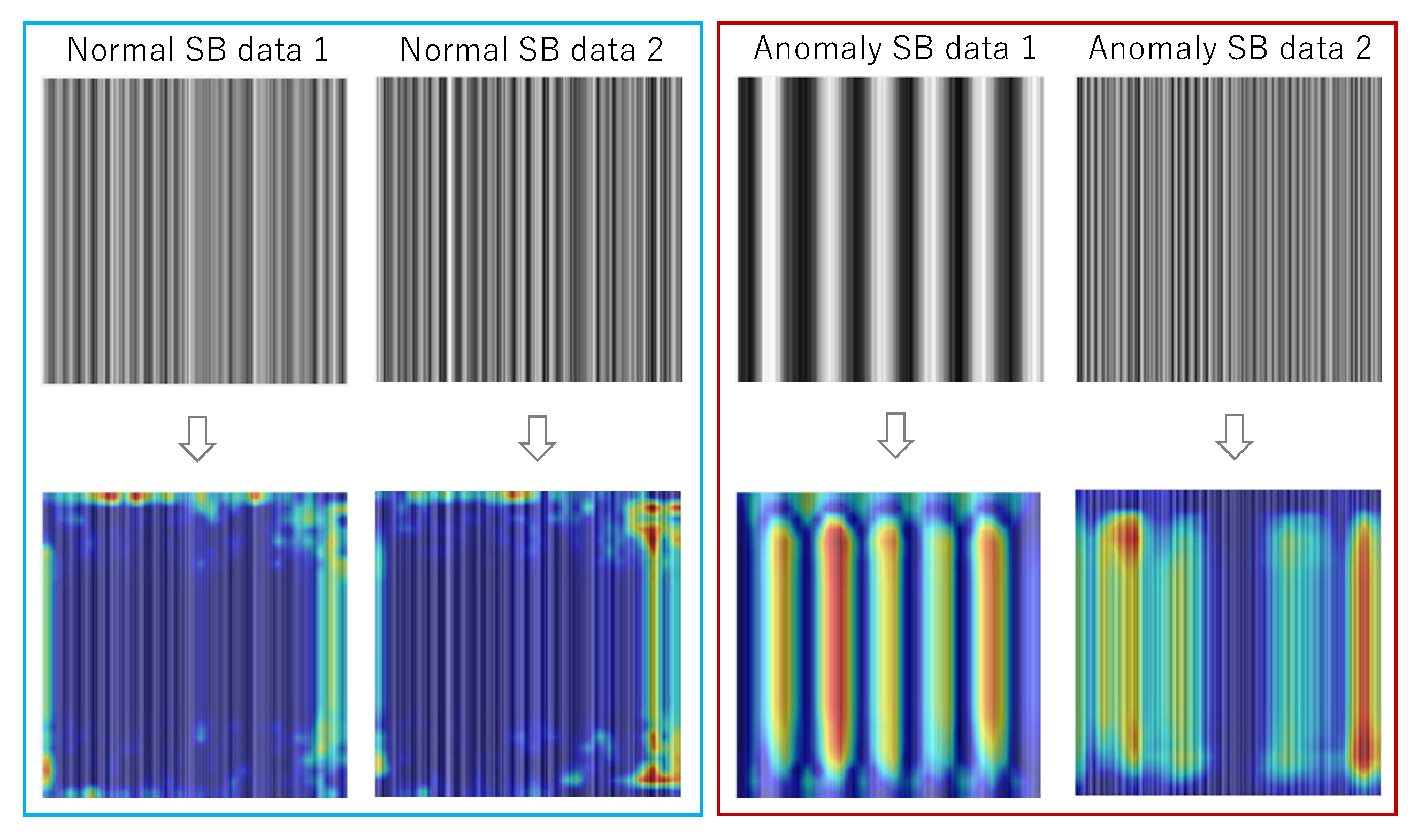

Figure 13 also shows examples of predicted maps generated by the FCDD, in which it is observed that anomaly regions within the time series data are validly visualized. Note that upper and lower figures are examples of inputs to and outputs from the trained FCDD model, respectively. The output from the FCDD model is a map with the same resolution as the input layer, so that heatmaps as shown in

Figure 13 can be concurrently produced from the map without calling other visualizers such as Grad-CAM and Occlusion Sensitivity as a post-process.

Figure 14 shows the flow when the trained SB data-based FCDD model is applied to a real-time monitor of a CNC machine tool. Note that, in this experiment to test SB data tabulated in

Table 4, one feature-mapped SB data for the input layer was concurrently visualized and predicted through one flow.

It is known that smaller training datasets tend to lead to overfitting. However, if almost the same generalization performance is obtained, the smaller the dataset size, the better to reduce training time. It is observed from

Table 5 that the FCDD model trained with only 30 samples per class can perform the promising generalization ability to 300 test samples per class. Naturally, for implementation in an actual machining process, it seems that the dataset needs more SB data with different sound features to enhance the generalization performance.

4.4. Discussions

As can be seen, the form of time-series SB data is not a map but multi-dimensional vectors, so that it cannot be directly given to the input layer of CNN models and CNN-based SVM models. Also, those models seem to not equip the function for concurrent visualization of understanding in predicting test images. As a post process, a visualizer such as Grad-CAM or Occlusion Sensitivity must be optionally called to make a heatmap, which shows the regions where CNN is interested in while classifying images. On the other hand, our proposed SB data-based FCDD model shown in

Figure 9 can perform both prediction and visualization at the same time because the FCDD model can directly generate a heatmap.

The conversion to a 2D image by Equation (

7) may seem to be redundant. However, the input layer’s resolution of FCDD depends on that of the CNN model used as the backbone network. The backbone network works as a feature extractor. The proposed SD-based FCDD model employs VGG19 for the backbone, so that the resolution of training and test images has to be fitted to that of VGG19. That is the reason why feature-mapped images for giving the FCDD are simply created by duplicating one line of SB data.

In the experiments introduced in this paper, the multi-class classification ability of SB data by NN, RNN, and 1D CNN, and the identification ability by AE are shown. Then, the binary-class classification ability of FCDD is evaluated. The binary-class classification task can be regarded as an anomaly detection task by setting two classes as normal and anomaly. It is suggested from the experiment results shown in

Table 3 and

Table 5 that the AE and FCDD models can be applied to anomaly detection tasks. As for 1D CNN, it is also possible to apply it to anomaly detection tasks by training it for binary classification using normal and anomaly SB data.

It is confirmed from

Figure 11 that the FCDD model is well trained using the less training SB data shown in

Table 1, in which it is assumed that SB data of the band saw and other machine tools are normal and abnormal, respectively. The valid threshold value for classification of test SB data can be easily determined by observing both distributions in

Figure 11, e.g., by setting the center value between the maximum of normal scores and the minimum of anomaly ones. Judging from the results shown in

Table 5, it seems that the classification of mapped test images in

Table 1 was not particularly difficult. Because, in this evaluation, each machine tool’s WAV file that is the source of extracted SB data is a recording of relatively monotonous operating sound. However, it is observed from

Figure 12 that the distance between two distributions of mean anomaly scores is close even for these test SB data, so that generalization to other test SB data that are extracted from different domains, e.g., such as different machine tools, materials, and machining conditions, may not be well performed. In the actual machining process, more complex operating sounds, including the sound of cutting material, are generated, so that additional training to enhance the generalization ability of the FCDD model is continuously required while increasing more training SB data with a variety of sound features of machine tools.

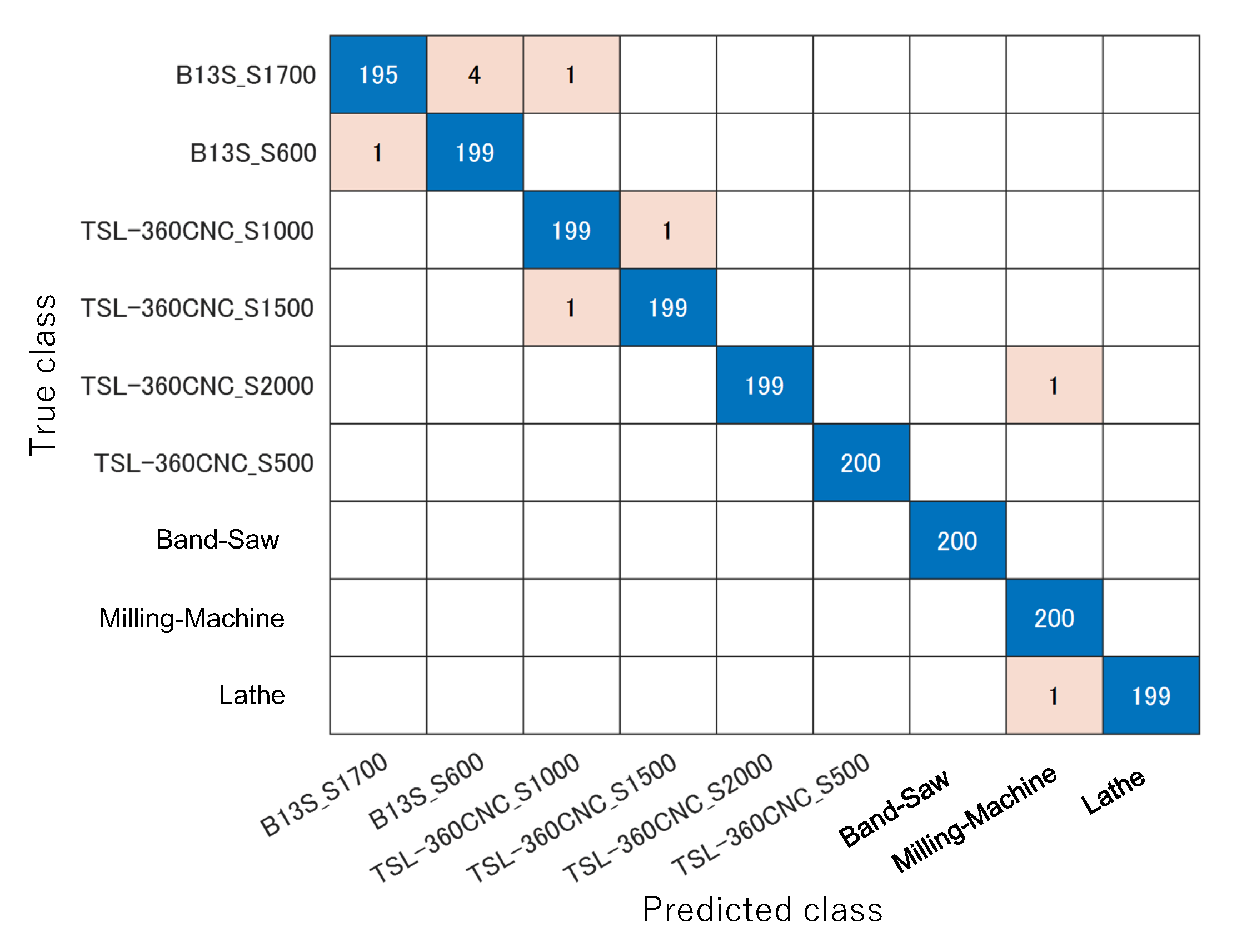

Compared with the above FCDD as an identifier, in

Section 3.1, neural networks were applied to a classification task of nine kinds of SB data shown in

Table 1 and were basically evaluated, in which the designed 1D CNN performed 99.5% classification result as shown in

Figure 15, but some misclassifications were observed. It seems that continuous additional training is also necessary for 1D CNN to enhance its generalization ability. Also, as described at the end of

Section 3.1, although 1D CNN can be used for binary classification, i.e., as an identifier or anomaly detector, post-processing such as Grad-CAM and Occlusion Sensitivity is additionally required for visualization of understanding.

5. Conclusions

The authors have been developing a design, training and building application with a user-friendly operation interface for CNN, CAE, SVM, YOLOX, SOLOv2, FCDD, and so on, which can be used for the defect detection of various kinds of industrial products even without deep skills and knowledge concerning information technology. In those models, images are basically used for training data. In this paper, an intelligent anomaly diagnosis system for CNC machine tools is considered, i.e., what structures of neural networks should be applied to the task. Mechanical sound and vibration generated from machine tools themselves or machining sound and vibration generated from router bits, i.e., end mill cutters, are recorded as wave files and used for training data. Extracted SB data from wave files are used for training NN models. It is confirmed from experiments that a 1D CNN and an autoencoder are effective for classification and identification of SB data, respectively. Then, an SB data-based FCDD model is further proposed for anomaly sound detection of removal machining by CNC machine tools and its concurrent visualization, in which time series data such as SB data can be directly applied to training and testing without converting them to other domains such as frequency. The effectiveness of the proposed method is shown through experiments.

In this paper, the dataset only consists of time-series SB data extracted from limited numbers of machine tools’ operating sounds. In future work, the proposed SB data-based FCDD model is planned to be applied to real-time monitoring of abnormality during endmill cutting by other CNC machine tools and their concurrent visualizations of understandings.