Proposed Design of a Mobile Lift Device to Reduce the Risk of Musculoskeletal Injuries Among Fire Extinguisher Inspectors

Abstract

1. Introduction

2. Materials and Methods

2.1. Participants

2.2. Design of a Mobile Lift Device

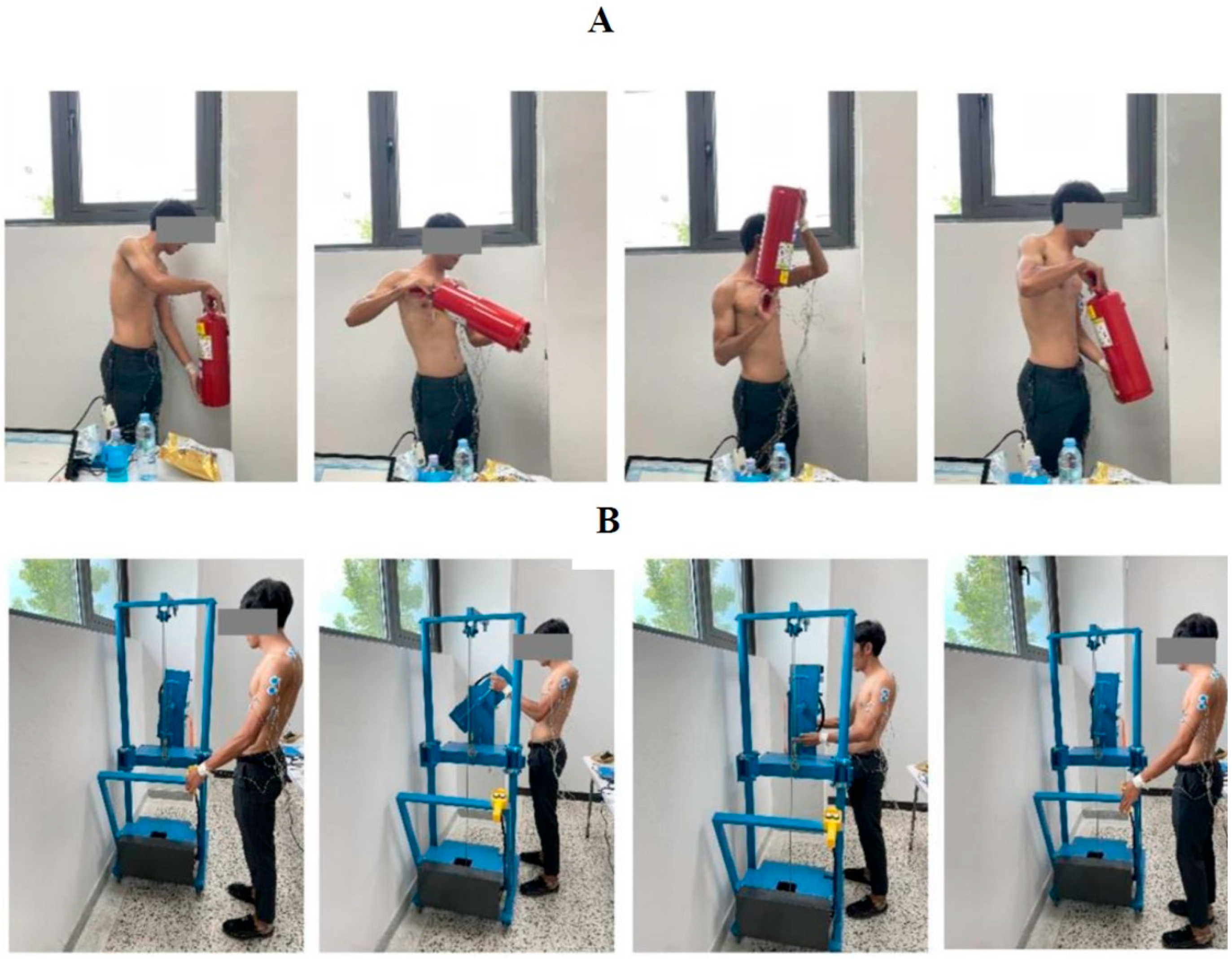

2.2.1. Phase 1: Prototype Development of the Mobile Lift Device as Shown in Figure 1 Prototype Design

2.2.2. Phase 2: Prototype Evaluation of the Mobile Lift Device

- Approach the Fire Extinguisher: Begin by maneuvering the lifting device close to the fire extinguisher. Ensure that the device is positioned correctly to facilitate easy lifting.

- Lift the Fire Extinguisher: Press the button on the lifting device to raise the fire extinguisher from its hanging bracket. This action should be smooth and controlled to avoid any damage.

- Lock the Fire Extinguisher: Once the extinguisher is lifted, engage the locking mechanism on the device to secure the extinguisher in place. This ensures that it remains stable during the inspection process.

- Move the Extinguisher Away from the Wall: Carefully push the lifting device to move the fire extinguisher away from the wall.

- Rotate the Fire Extinguisher: Grasp the handle of the extinguisher and tilt it to turn it upside down.

- Weigh the Fire Extinguisher: Use a scale to check the weight of the extinguisher. This step is important to ensure that it is full and has not lost any extinguishing agent.

- Lift to Lock Position: Press the button again to lift the extinguisher to the designated locking point on the device.

- Return to Installation Position: Push the lifting device back to the original installation location of the fire extinguisher. Ensure that the path is clear and safe for movement.

- Unlock and Rehang the Fire Extinguisher: Finally, unlock the extinguisher from the lifting device and hang it back onto its bracket. Ensure that it is properly secured and ready for use.

- Remove the Lifting Device: Once the extinguisher is safely in place, maneuver the lifting device away from the area, completing the inspection process.

2.3. Statistical Analysis

3. Results

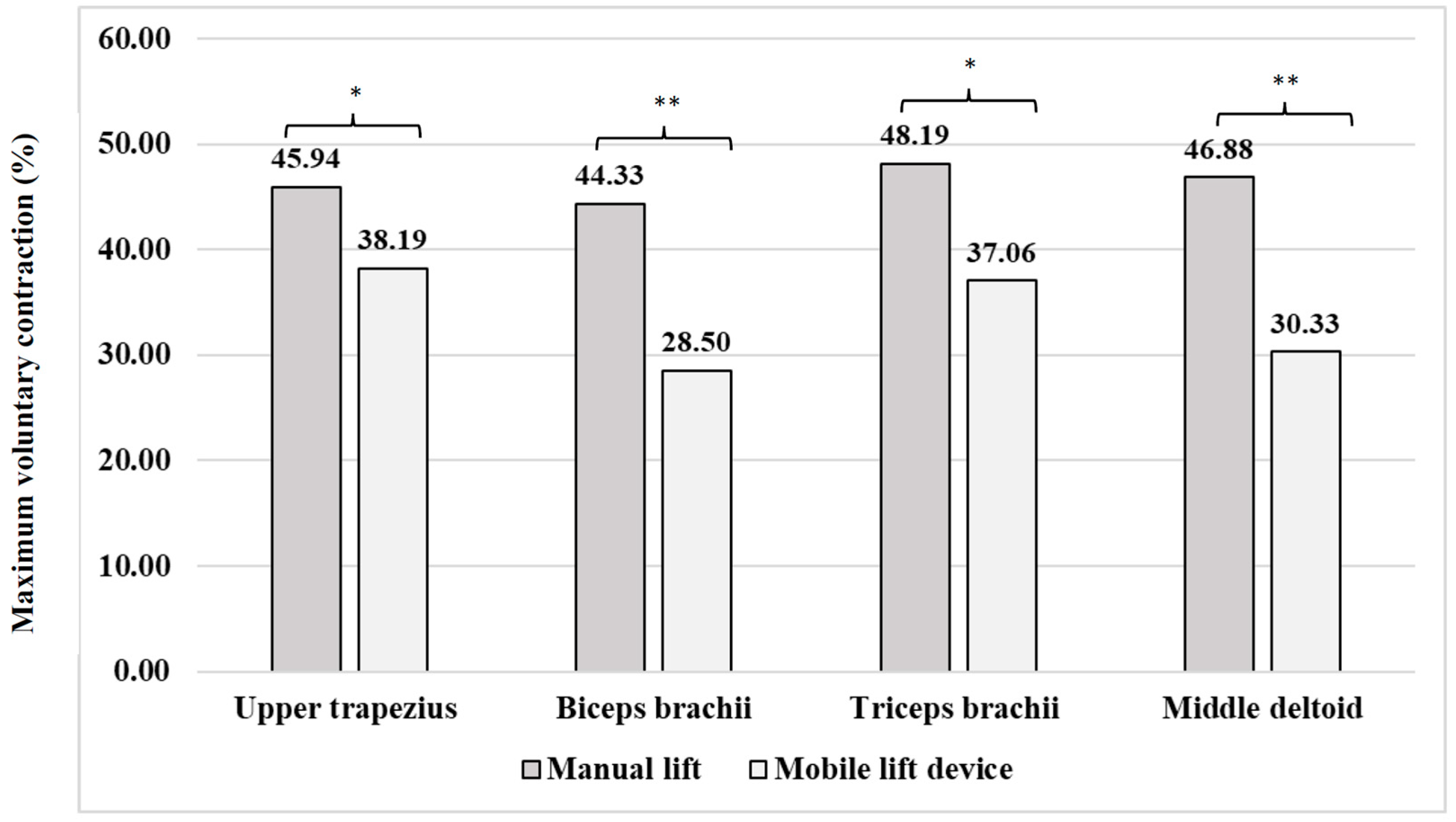

3.1. Muscle Activity

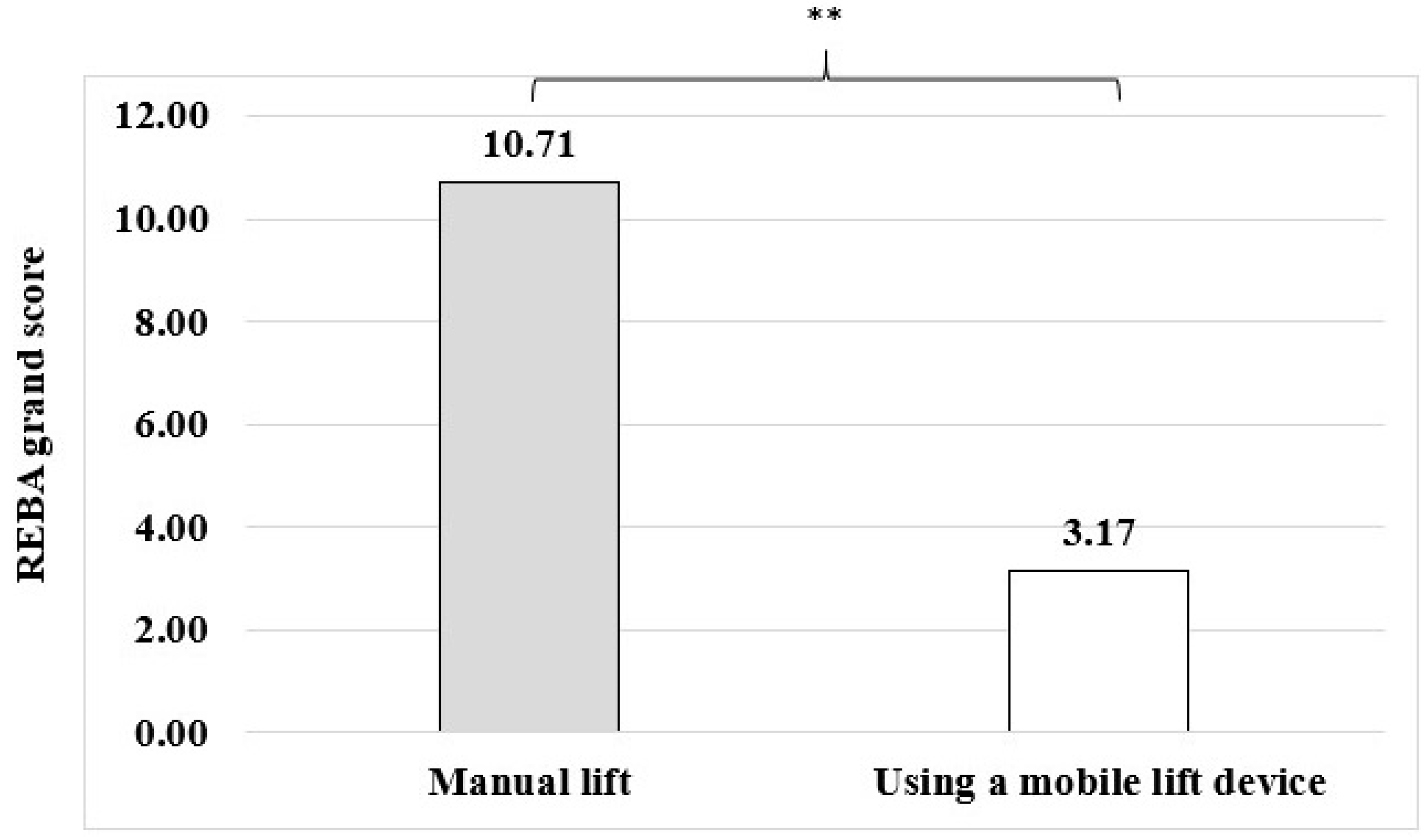

3.2. Postural Analysis

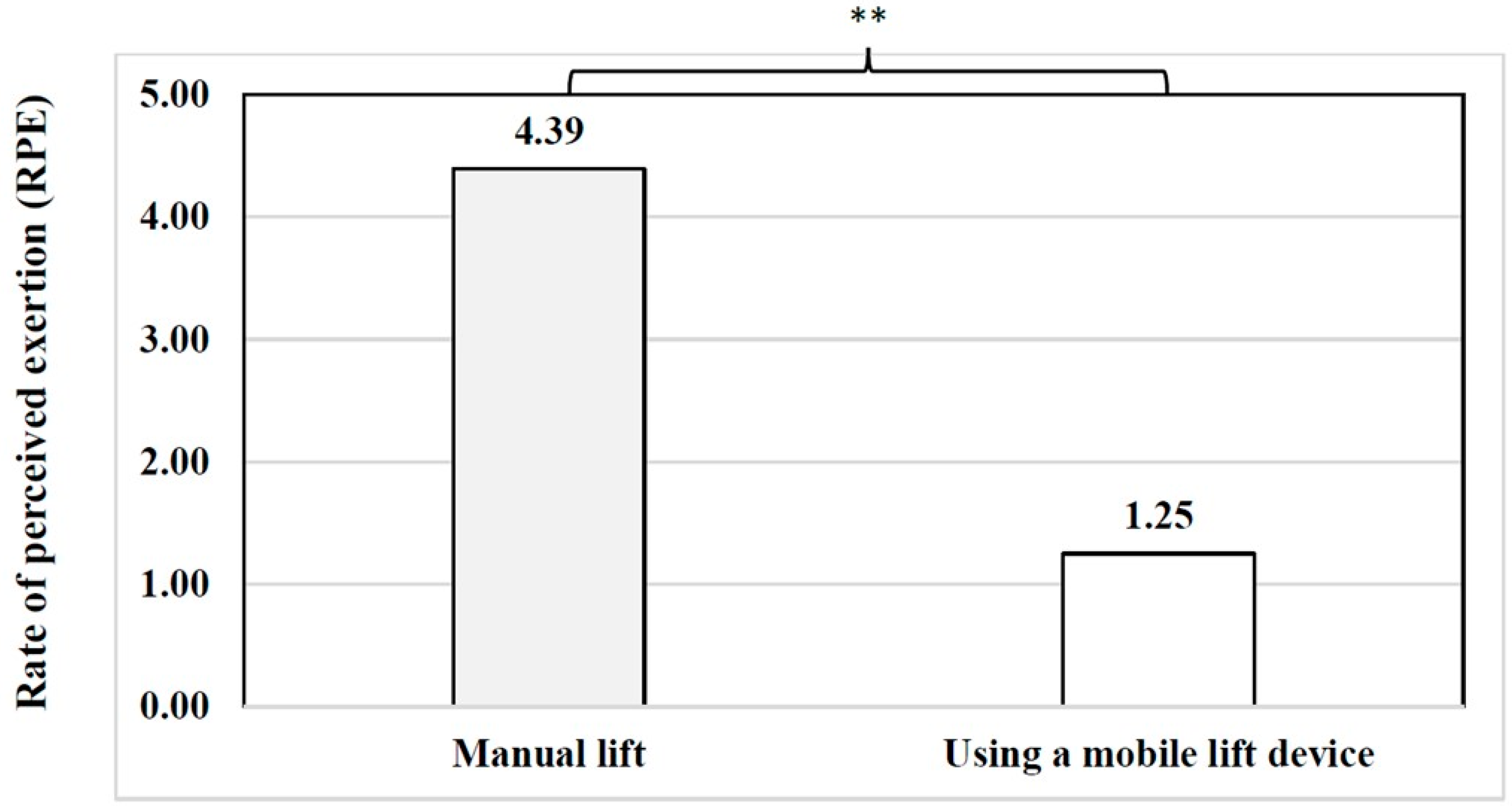

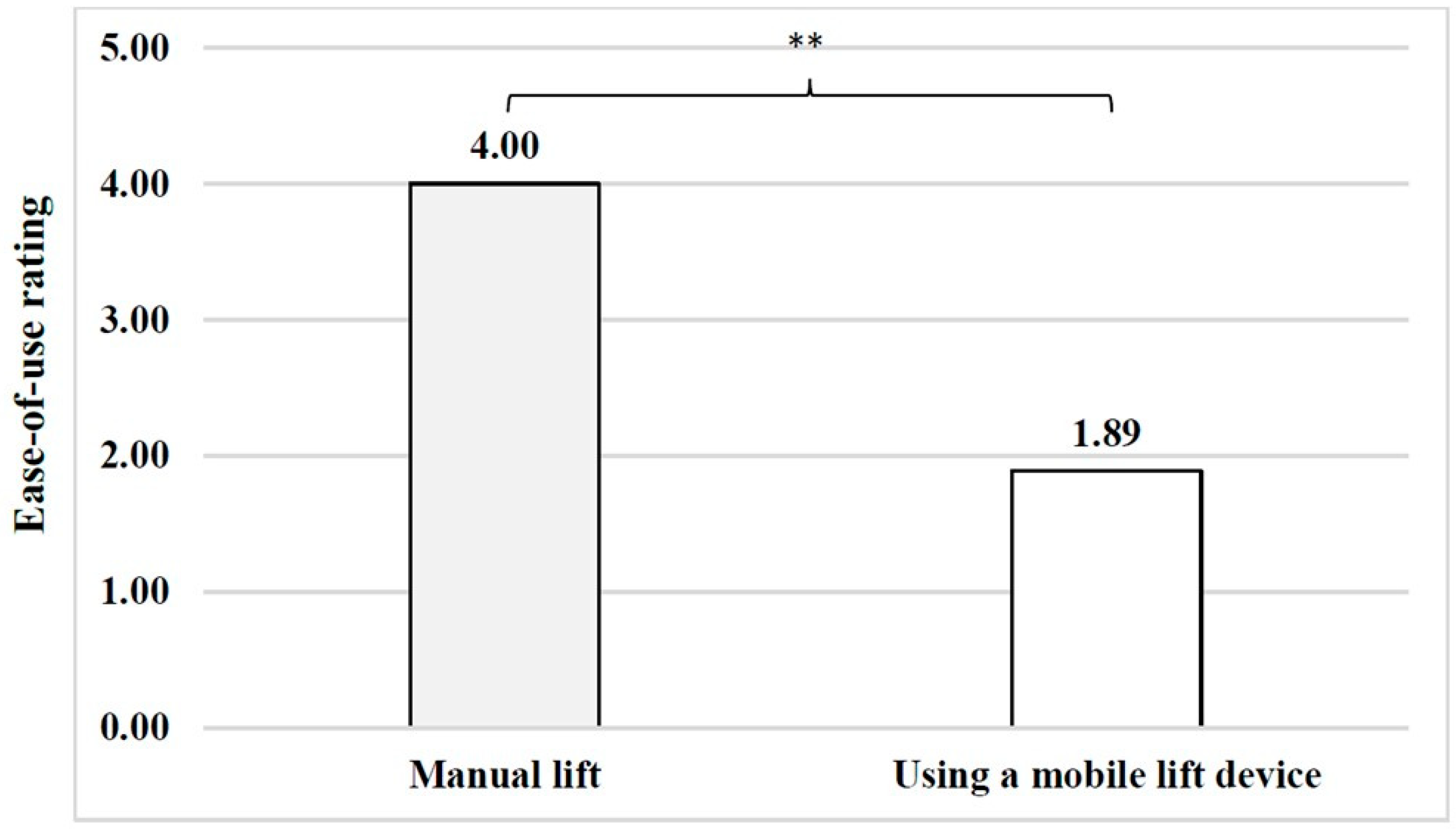

3.3. Perceived Usability

4. Discussion

5. Study Limitations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amos, M.; Lawson, G. User-Centered Design of a Portable Fire Extinguisher. Ergon. Des. 2017, 25, 20–27. [Google Scholar] [CrossRef]

- Srinuangla, P.; Nookua, W.; Srisawat, W.; Thongtang, N.; Phuangchoosakdi, S. Legal Measures On Building Control Act in Thailand. J. Namib. Stud. 2023, 33, 3772–3789. [Google Scholar]

- BUILDING CONTROL ACT, B.E. 2522, 1979. Available online: https://www.iibh.org/kijun/pdf/Thai_01_ACT.combined%20by%20H.pdf (accessed on 2 June 2025).

- Notification of Ministry of Industry Re: Fire Protection and Settlement in Factory, B.E. 2552, 2009. Available online: https://www.issehs.com/additional-resources/emergency-management.pdf (accessed on 2 June 2025).

- Abdul Karim, N.N.; Mahmood, S.; Mustafa El Bakri, H.; Rahman, I.A.; Badulrudin, M.F. The Impact of Rolling Hose Activities: Assessing Musculoskeletal Disorders (MSDs) Among Firefighters. Malays. J. Public Health Med. 2024, 24, 36–46. [Google Scholar]

- Changmuenwai, S.; Wongweragiat, S. Design of dry chemical fire extinguisher inspection equipment in order to reduce ergonomic risks for fire extinguisher inspectors. Thai J. Ergon. 2021, 28, 36. [Google Scholar]

- Isamudin, A.; Mahmood, S. Design of An Ergonomic Portable Fire Hose Roller: A Simulation Study. Prog. Eng. Appl. Technol. 2021, 2, 1016–1025. [Google Scholar]

- The Health and Safety Executive (HSE). Work-Related Musculoskeletal Disorders Statistics in Great Britain, 2024: Annual Statistics; The Health and Safety Executive (HSE): Bootle, UK, 2024.

- Yang, S.T.; Park, M.H.; Jeong, B.Y. Types of manual materials handling (MMH) and occupational incidents and musculoskeletal disorders (MSDs) in motor vehicle parts manufacturing (MVPM) industry. Int. J. Ind. Ergon. 2020, 77, 102954. [Google Scholar] [CrossRef]

- Tahernejad, S.; Farahi-Ashtiani, I.; Veisani, Y.; Ghaffari, S.; Sahebi, A.; Makki, F. A systematic review and meta-analysis of musculoskeletal disorders among firefighters. J. Saf. Res. 2024, 88, 374–381. [Google Scholar] [CrossRef]

- So, B.C.L.; Hua, C.; Chen, T.; Gao, Q.; Man, S.S. Biomechanical assessment of a passive back-support exoskeleton during repetitive lifting and carrying: Muscle activity, kinematics, and physical capacity. J. Saf. Res. 2022, 83, 210–222. [Google Scholar] [CrossRef]

- Radin Umar, R.Z.; Ahmad, N.; Halim, I.; Lee, P.Y.; Hamid, M. Design and Development of an Ergonomic Trolley-Lifter for Sheet Metal Handling Task: A Preliminary Study. Saf. Health Work. 2019, 10, 327–335. [Google Scholar] [CrossRef]

- Kong, Y.-K.; Choi, K.-H.; Park, S.-S.; Shim, J.-W.; Shim, H.-H. Evaluation of the Efficacy of a Lift-Assist Device Regarding Caregiver Posture and Muscle Load for Transferring Tasks. Int. J. Environ. Res. Public Health 2023, 20, 1174. [Google Scholar] [CrossRef]

- Posluszny, K.M.; Ho, D.C.; Veerasammy, S.; Taylor, C.; McDougall, R.; Fischer, S.L. A mixed methods approach to describe the efficacy of lift assist device use to reduce low back musculoskeletal disorder risk factors during three common patient extrication scenarios. Appl. Ergon. 2024, 121, 104361. [Google Scholar] [CrossRef] [PubMed]

- Niyomphant, S. Design and Work Improvement by Ergonomics Principles; Ubon Ratchathani University: Ubon Ratchathani, Thailand, 2014. (In Thai) [Google Scholar]

- ABC of EMG—A Practical Introduction to Kinesiological Electromyography [Internet]. Noraxon INC. USA. 2005. Available online: https://hermanwallace.com/download/The_ABC_of_EMG_by_Peter_Konrad.pdf (accessed on 15 June 2023).

- Lim, J.; Lu, L.; Goonewardena, K.; Liu, J.Z.; Tan, Y. Assessment of Self-report, Palpation, and Surface Electromyography Dataset During Isometric Muscle Contraction. Sci. Data 2024, 11, 208. [Google Scholar] [CrossRef]

- Florimond, V. The Basics of Surface Electromyography Applied to Physical Rehabilitation and Biomechanics; Thought Technology Ltd.: Montreal, QC, Canada, 2009. [Google Scholar]

- Hignett, S.; McAtamney, L. Rapid Entire Body Assessment (REBA). Appl. Ergon. 2000, 31, 201–205. [Google Scholar] [CrossRef] [PubMed]

- Sancibrian, R.; Redondo-Figuero, C.; Gutierrez-Diez, M.C.; Gonzalez-Sarabia, E.; Manuel-Palazuelos, J.C. Ergonomic evaluation and performance of a new handle for laparoscopic tools in surgery. Appl. Ergon. 2020, 89, 103210. [Google Scholar] [CrossRef]

- Lin, K.; Wink, C.; Dolan, B.; Osann, K.; Habib, A.A.; Gehrig, J.; Wilder-Smith, P. A Novel Ergonomic Curette Design Reduces Dental Prophylaxis-Induced Muscle Work and Fatigue. Dent. J. 2023, 11, 272. [Google Scholar] [CrossRef] [PubMed]

- International Ergonomics Association (IEA). Ergonomics Guidelines for Occupational Health Practice in Industrially Developing Countries 2010. Available online: https://www.icohweb.org/site/multimedia/pubblicazioni/ICOH%20and%20IEA%20Ergonomics%20Guidelines%20April%202010.pdf (accessed on 20 December 2023).

- Qu, X.; Qu, C.; Ma, T.; Yin, P.; Zhao, N.; Xia, Y.; Qu, S. Effects of an industrial passive assistive exoskeleton on muscle activity, oxygen consumption and subjective responses during lifting tasks. PLoS ONE 2021, 16, e0245629. [Google Scholar] [CrossRef]

- Richarz, H.-U.; Tamayo, A.; Rahmig, J.; Siepmann, T.; Barlinn, J. The impact of mechanical devices for lifting and transferring of patients on low back pain and musculoskeletal injuries in health care personnel—A systematic review and meta-analysis. J. Occup. Health 2023, 65, e12423. [Google Scholar] [CrossRef]

- Bernard, A.; Varaprasad, G. Ergonomic risk assessment of lifting operations by mud mixing operators at oil rigs. Int. J. Occup. Saf. Ergon. 2024, 31, 231–239. [Google Scholar] [CrossRef]

- Gumasing, M.J.J.; Casela, R.C.J. (Eds.) A Biomechanical Risk Assessment of Lifting Tasks in the Logistics Industry in the Philippines. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Dubai, United Arab Emirates, 10–12 March 2020; IEOM Society International: Southfield, MI, USA, 2020. [Google Scholar]

- Karwowski, W. International Encyclopedia of Ergonomics and Human Factors; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Graham, R.B.; Agnew, M.J.; Stevenson, J.M. Effectiveness of an on-body lifting aid at reducing low back physical demands during an automotive assembly task: Assessment of EMG response and user acceptability. Appl. Ergon. 2009, 40, 936–942. [Google Scholar] [CrossRef]

- Veisi, H.; Choobineh, A.; Ghaem, H.; Shafiee, Z. The effect of hand tools’ handle shape on upper extremity comfort and postural discomfort among hand-woven shoemaking workers. Int. J. Ind. Ergon. 2019, 74, 102833. [Google Scholar] [CrossRef]

- Nakata, C. Design thinking for innovation: Considering distinctions, fit, and use in firms. Bus. Horiz. 2020, 63, 763–772. [Google Scholar] [CrossRef]

- Motamedzade, M.; Afshari, D.; Soltanian, A. The Impact of Ergonomically Designed Workstations on Shoulder EMG Activity during Carpet Weaving. Health Promot. Perspect. 2014, 4, 144–150. [Google Scholar] [PubMed]

- Dianat, I.; Nedaei, M.; Mostashar Nezami, M.A. The effects of tool handle shape on hand performance, usability and discomfort using masons’ trowels. Int. J. Ind. Ergon. 2015, 45, 13–20. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khunburan, Y.; Kaewdok, T. Proposed Design of a Mobile Lift Device to Reduce the Risk of Musculoskeletal Injuries Among Fire Extinguisher Inspectors. Safety 2025, 11, 53. https://doi.org/10.3390/safety11020053

Khunburan Y, Kaewdok T. Proposed Design of a Mobile Lift Device to Reduce the Risk of Musculoskeletal Injuries Among Fire Extinguisher Inspectors. Safety. 2025; 11(2):53. https://doi.org/10.3390/safety11020053

Chicago/Turabian StyleKhunburan, Yonlada, and Teeraphun Kaewdok. 2025. "Proposed Design of a Mobile Lift Device to Reduce the Risk of Musculoskeletal Injuries Among Fire Extinguisher Inspectors" Safety 11, no. 2: 53. https://doi.org/10.3390/safety11020053

APA StyleKhunburan, Y., & Kaewdok, T. (2025). Proposed Design of a Mobile Lift Device to Reduce the Risk of Musculoskeletal Injuries Among Fire Extinguisher Inspectors. Safety, 11(2), 53. https://doi.org/10.3390/safety11020053