Abstract

An important step toward automation and digitization in Industry 4.0 is the automobile sector’s use of smart manufacturing integrated systems (SMISs). Although this change increases productivity and competitiveness, it also creates new hazards for workplace safety. Key issues include ergonomic and cognitive strain from greater human–machine interactions, particularly with collaborative robots (cobots), and cybersecurity threats from the IIoT and cyber–physical systems. This paper looks at these hazards and stresses the value of safety precautions like predictive maintenance, traceability, and real-time monitoring. This case study investigates how the integration of smart manufacturing integrated systems (SMISs) and cyber–physical systems (CPSs) within Industry 4.0 frameworks enhances workplace safety in the automotive sector. Through a comprehensive case study of the final assembly line, this research explores how these technologies contribute to predictive maintenance, real-time monitoring, and human–machine collaboration, leading to significant reductions in ergonomic and cybersecurity risks.

1. Introduction

The Fourth Industrial Revolution, known as Industry 4.0, has profoundly transformed the manufacturing sector by integrating advanced digital technologies, cyber–physical systems (CPSs), the Industrial Internet of Things (IIoT), and artificial intelligence (AI) into production processes [,]. These innovations have led to the development of smart manufacturing integrated systems (SMISs), which enhance efficiency, flexibility, and customization, particularly in small-series automotive production. However, the adoption of these technologies also introduces new challenges related to occupational safety, cybersecurity risks, and human–machine interactions [,].

Moreover, a systematic literature review underlines the current gaps and challenges in terms of Maintenance 4.0 adoption, reinforcing the importance of aligning safety strategies with evolving maintenance frameworks [].

The integration of smart manufacturing involves the use of autonomous robots, real-time data analytics, and interconnected production systems, which, while improving productivity, may expose workers to unforeseen risks. These include cybersecurity threats to operational safety, ergonomic hazards associated with human–machine collaboration and increased cognitive workload due to complex automated workflows [,]. Studies suggest that risk mitigation strategies, including predictive maintenance, adaptive safety measures, and AI-driven decision-making models, are essential for ensuring a safe working environment [,].

Cybersecurity issues are particularly relevant in Industry 4.0 environments, where automated assembly lines and smart sensors rely on real-time data exchange. Unauthorized access to industrial control systems may lead to production disruptions and workplace hazards [,]. Therefore, robust cybersecurity frameworks must be integrated alongside occupational safety protocols to protect both infrastructure and personnel. Additionally, collaborative robots (cobots) require strict safety measures to prevent unintended physical interactions that could endanger human workers [,].

This paper investigates the occupational safety challenges posed by Industry 4.0 technologies in the automotive sector, with a particular focus on the implementation of smart manufacturing integrated systems (SMISs). By analyzing case studies on automated production lines, our aim is to identify the key risks and propose strategies for reducing workplace hazards while maintaining the efficiency and competitiveness of modern manufacturing environments. Focusing on the final assembly line as a representative case study, this research highlights the interplay between advanced automation and occupational health, providing empirical insights into real-time monitoring, predictive maintenance, and ergonomic risk mitigation. Unlike previous studies that primarily emphasize productivity, this work places equal importance on Safety 4.0 principles, demonstrating how digital transformation can be aligned with human-centered safety strategies. Through a combination of field observations, expert interviews, and safety performance data, this study contributes novel evidence on how digital technologies reshape risk perception, worker–machine interactions, and the effectiveness of proactive safety management in smart factory contexts.

2. Literature Review—Workplace Safety Issues in Industry 4.0

The evolution of Industry 4.0 has transformed manufacturing processes by integrating digital technologies, automation, and data-driven decision-making systems. In the automotive sector, the adoption of smart manufacturing systems (SMSs) has led to the development of interconnected and intelligent production lines that enhance efficiency, flexibility, and customization. However, alongside these advancements, new challenges related to occupational safety have emerged, requiring innovative approaches to risk assessment and mitigation strategies.

The concept of Industry 4.0 is characterized by the digitalization of manufacturing systems, where cyber–physical systems (CPSs), the Internet of Things (IoT), and artificial intelligence (AI) work together to optimize production processes. This integration allows for real-time monitoring, predictive maintenance, and improved decision-making, significantly reducing production downtime and resource waste [].

In the automotive industry, smart manufacturing systems (SMSs) facilitate seamless communication between machines, products, and operators. These systems incorporate robotics, AI-driven process control, and IoT-enabled monitoring devices to ensure optimal performance. The ability of smart factories (Figure 1) to self-adjust and adapt to changing production demands has proven to be a significant advantage in meeting the increasing demand for mass-customized vehicles [].

Figure 1.

Industry 4.0 pillars.

Despite these benefits, the increased reliance on automation introduces complex challenges in terms of workplace safety, particularly in relation to human–machine collaboration, cybersecurity vulnerabilities, and ergonomic considerations.

As manufacturing systems become more autonomous, the interaction between human workers and robotic systems becomes a critical area of concern. Collaborative robots (cobots) are increasingly being used in automotive assembly lines to perform repetitive tasks and reduce the physical strain on workers. However, inadequate safety measures or system malfunctions may result in workplace accidents [].

Additionally, the integration of IoT-based devices exposes manufacturing systems to cybersecurity threats. Unauthorized access to industrial control systems can lead to production disruptions, data breaches, and potential safety hazards for workers operating in automated environments. The complexity of interconnected networks makes it challenging to implement foolproof security measures, requiring continuous monitoring and system updates [].

Beyond cybersecurity, ergonomic risks remain a major concern in smart factories. While automation reduces manual labor, certain production tasks still require human intervention. The design of workstations, repetitive motion patterns, and the cognitive load associated with monitoring advanced digital interfaces must be carefully managed to prevent musculoskeletal disorders and mental fatigue [].

To address the safety concerns associated with Industry 4.0, manufacturers are increasingly adopting advanced technologies aimed at improving workplace conditions and reducing occupational hazards.

One of the most promising developments is the use of intelligent hazard detection systems that employ real-time data analytics, virtual reality (VR), and artificial intelligence (AI) to identify potential risks before they escalate into serious incidents. These systems provide predictive insights that help manufacturers proactively address safety issues, thereby reducing workplace injuries and operational disruptions [].

Another innovation is the integration of wearable sensor technology for monitoring workers’ physiological and biomechanical conditions. These devices track movement, posture, and exertion levels, providing real-time feedback on ergonomic risks. Such systems help optimize workstation design and prevent musculoskeletal injuries, particularly during repetitive motion tasks [].

In addition, workplace environment monitoring through IoT-connected sensors enables continuous tracking of the temperature, humidity, and air quality. These smart sensors facilitate early detection of hazardous conditions, allowing manufacturers to take preventive actions before workers are exposed to harmful environments [].

For smart manufacturing systems to be effectively implemented in the automotive sector, several key factors must be considered.

One of the most important aspects is production flexibility, which ensures that manufacturing systems can adapt to changing market demands while maintaining cost-efficiency. The ability to shift between different production modes, adjust assembly line parameters in real time, and integrate customer-specific customization is crucial for competitiveness [].

Another critical factor is traceability management, which enables manufacturers to track components throughout the production process. Smart traceability systems, powered by blockchain technology and real-time data analytics, provide end-to-end visibility, reducing errors and enhancing quality control [].

Lastly, the integration of digital technologies such as big data analytics, machine learning, and AI-driven automation plays a fundamental role in optimizing production workflows. By leveraging digital twins and predictive modeling, manufacturers can simulate different operational scenarios to identify the most efficient production strategies [].

2.1. Workplace Safety Issues in Industry 4.0

Industry 4.0 is revolutionizing industrial operations through the integration of big data, robotics, artificial intelligence (AI), the Internet of Things (IoT), and cyber–physical systems. While these technologies significantly enhance productivity and operational efficiency, they also introduce new and complex workplace safety challenges. This section outlines the primary concerns related to occupational safety in Industry 4.0 environments.

The incorporation of advanced technologies such as the IoT, AI, robotics, and virtual reality into existing safety infrastructures can be technically demanding and may inadvertently introduce new risks, including cybersecurity vulnerabilities [,,]. Furthermore, Wu et al. [] propose a risk-informed framework for the functional safety design of human–robot collaboration systems, which offers valuable guidance for ensuring safer interactions between humans and machines in smart factories. As industrial processes become more automated, it is essential to consider the physical, psychological, and cognitive well-being of workers, which can be adversely affected by poorly managed transitions to new technologies [].

Although these technologies can mitigate traditional physical and mechanical hazards, they may simultaneously generate new psychosocial and ergonomic risks [,]. For example, changes in job roles and task structures can lead to increased stress and mental fatigue. Moreover, occupational exposure to vibrations—often underestimated in automated settings—can now be effectively monitored and reduced through digital solutions, as shown by Darabont et al. []. In addition, the perceived uncertainty and insecurity associated with technological change may negatively impact employee health and morale.

2.2. Proactive Safety Management (Safety 4.0)

A contemporary and forward-thinking approach to occupational health and safety, referred to as “Proactive Safety Management” or Safety 4.0, prioritizes the anticipation and prevention of incidents before they occur, rather than reacting to them after the fact. This approach is rooted in the principles of Industry 4.0, which advocate for the integration of advanced technologies into industrial systems to enhance both efficiency and safety.

One of the core components of this model is predictive maintenance, which leverages the capabilities of the IoT and AI to detect early signs of equipment malfunction and operational disruption, allowing preemptive action to be taken []. Closely related is real-time monitoring, achieved through the deployment of sensors and wearable devices that continuously track worker conditions and environmental factors, issuing alerts when hazards are detected [,].

Integrated safety systems play a vital role by consolidating various safety functions—such as monitoring, reporting, and signal processing—into unified platforms that support faster and more effective decision-making [].

In parallel, human-centric approaches remain fundamental. Training and upskilling ensure that employees are equipped to operate new technologies safely and are aware of emerging occupational risks. Additionally, employee empowerment—through active involvement in safety initiatives and decision-making—contributes to building a strong organizational safety culture [].

Regulatory and organizational support also underpins the successful implementation of Safety 4.0. This includes the development of government policies that incentivize the adoption of smart manufacturing technologies, alongside a demonstrated commitment from top management to embed safety into strategic planning and operational procedures.

Several enabling technologies further strengthen Safety 4.0:

- Artificial intelligence (AI): Enhances the predictive and analytical capacity of safety systems, allowing for early risk identification and prevention [,].

- Internet of Things (IoT): Enables real-time data collection and condition monitoring across equipment, processes, and personnel [,].

- Robotics and automation: Minimize direct human exposure to hazardous tasks, though their implementation must be carefully managed to avoid new categories of risk [,].

- Virtual and augmented reality (VR/AR): Offer immersive training environments where workers can experience and respond to simulated hazardous situations without actual exposure [].

As highlighted by Martinetti et al. [], the integration of advanced maintenance strategies—such as predictive and condition-based maintenance—plays a crucial role in the success of Industry 4.0 implementations. These approaches not only enhance system reliability but also contribute significantly to proactive safety management in smart manufacturing environments.

By embracing these technologies and principles, the automotive industry can significantly enhance workplace safety in the context of Industry 4.0. However, addressing new and complex risks requires a balanced safety strategy that combines technological solutions with human-centered practices. In this evolving industrial landscape, the promotion of a strong safety culture, continuous education, and supportive regulations are essential to ensuring a secure and sustainable working environment

3. Research Methodology

The methodology of this study is structured to analyze the automation of the final assembly line named VW-FES, focusing on its integration into Industry 4.0 manufacturing systems related to Safety 4.0. In line with the Safety 4.0 concept, this study focuses on assessing how automation technologies, cyber–physical systems (CPSs), and smart monitoring tools influence production efficiency and occupational safety. This study is based on a case study analysis, incorporating direct industrial observations, expert interviews, workplace safety reports, and operational data analysis [].

By leveraging insights from smart manufacturing frameworks, this research evaluates the key technological components, automation strategies, and risk mitigation techniques employed in modern automotive production. The findings will contribute to an improved understanding of the role of digitalization in enhancing production reliability, minimizing human error, and ensuring worker safety in highly automated environments [].

The VW-FES final assembly line was chosen as the subject of this case study due to its high level of automation and advanced integration of real-time monitoring systems, which enable continuous supervision of production operations. As a state-of-the-art automotive manufacturing facility, it incorporates key components such as programmable logic controllers (PLCs), human–machine interfaces (HMIs), and digital traceability tools to optimize the efficiency and safety of its assembly processes.

This case study presents a valuable opportunity to examine how the Safety 4.0 concept is applied within a modern automotive context. Key aspects analyzed include the efficiency of automated control systems in reducing production delays and defects, the contribution of cyber–physical systems (CPSs) to predictive maintenance and failure prevention, the role of real-time monitoring tools in enhancing occupational safety and managing operational risks, and the advantages of digital traceability in identifying defects and ensuring consistent quality control in the production line [].

By focusing on a well-documented industrial environment, this research enables a detailed exploration of the technical, operational, and safety-related dimensions involved in the implementation of smart manufacturing.

To support this analysis, a comprehensive mixed-methods approach was adopted. Both quantitative and qualitative data were collected to offer a nuanced understanding of how digital transformation influences modern automotive manufacturing systems [].

A series of direct industrial observations were conducted at the VW-FES assembly line. These field assessments documented the real-time interactions between workers and automated systems, with a focus on human–machine collaboration, system performance, and adherence to safety standards. Patterns of operation were recorded to identify potential hazards and inefficiencies related to automation [].

Complementing the observational data, structured interviews were held with key personnel, including plant managers, automation engineers, and occupational safety experts. These interviews provided insights into cybersecurity challenges, the integration of AI-based monitoring technologies, and strategies aimed at reducing human error in automated environments [].

A review of workplace safety records and incident reports further contributed to the analysis. This review highlighted recurring safety concerns such as machine malfunctions, ergonomic challenges, and the effectiveness of automated safety systems [].

Additionally, operational data gathered from smart manufacturing systems, including real-time sensor readings, equipment logs, and predictive maintenance outputs, offered valuable information on the system reliability, the error detection capabilities, and the overall impact of automation on production uptime and safety outcomes [].

To evaluate and manage risks effectively, this study applied a structured framework aligned with the Safety 4.0 model, integrating technologies like automation, big data, AI, and the IoT into occupational health and safety (OHS) strategies. Risk assessment methodologies such as hazard identification and risk analysis (HIRA) and failure mode and effects analysis (FMEA) were used to identify and categorize hazards in the smart manufacturing environment [].

Key risks identified within the VW-FES assembly line include mechanical failures due to robotic malfunctions, cybersecurity threats linked to unauthorized access to control systems, cognitive strain from complex human–machine interfaces, and limitations in sensor precision that could lead to false or delayed alerts.

Each risk was evaluated based on the following:

Severity (S): The potential impact on worker safety.

Occurrence (O): The likelihood of the event under normal conditions.

Detection (D): The capacity of existing systems to detect and respond before incidents occur.

Based on this analysis, several safety enhancement strategies were proposed, including AI-powered predictive maintenance to minimize downtime, improved real-time monitoring systems for prompt hazard detection, stronger cybersecurity protocols to protect industrial networks, and ergonomic improvements in workstation design to reduce physical strain and injury risks.

To ensure alignment with international safety standards, this study was conducted in accordance with the following:

ISO 45,001 (the international standard for Occupational Health and Safety (OH&S) management systems)—For occupational health and safety management.

ISO 13849-1(Safety of machinery—Safety-related parts of control systems—Part 1: General principles for design)—Guiding safety-related control system design.

IEC 61,508—Addressing functional safety of programmable systems [,,].

Ethical considerations were strictly followed, including the protection of confidential industrial data, obtaining informed consent for interviews and site observations, and minimizing disruption to operations through non-intrusive research methods.

In conclusion, this case study offers a structured, data-driven assessment of the automation process at the VW-FES final assembly line. It illustrates how Industry 4.0 technologies, when implemented under the principles of Safety 4.0, can lead to meaningful improvements in both production efficiency and occupational safety [].

The findings of this research support the development of safer and more intelligent human–machine interaction models, reinforce predictive and real-time safety mechanisms, and contribute to the optimization of risk management strategies in highly automated environments. Ultimately, this work advances the understanding of how digital transformation in automotive manufacturing can simultaneously drive productivity and elevate safety performance.

4. Case Study on the Automation of the VW-FES Final Assembly Line

The automation of the VW-FES final assembly line represents a pivotal advancement in the integration of Industry 4.0 principles within the automotive sector.

VW-FES final assembly line automation, especially considering the Safety 4.0 framework, complies with a number of important rules and guidelines to guarantee worker safety and efficiency. This transformation aims to optimize production efficiency, quality control, and occupational safety through the deployment of smart manufacturing systems, cyber–physical technologies, and real-time monitoring tools.

According to the Safety 4.0 concept, which combines Industry 4.0 technologies with contemporary safety regulations, the automation of the VW-FES final assembly line offers a number of advantages:

- Reduced human exposure to hazardous tasks

- Real-time safety monitoring and predictive maintenance

- Collaborative robotics (cobots) enhance human safety

- Digitization enhances transparency and compliance

- AI-driven risk assessment and safety decision support

- Fewer people on the line = Lower overall risk

The case study on the VW-FES final assembly line provides an in-depth examination of the benefits, challenges, and best practices associated with the integration of automation technologies in modern automotive manufacturing.

This analysis contributes to a broader understanding of how Industry 4.0 innovations are shaping the future of highly efficient, adaptive, and secure production environments regarding Safety 4.0.

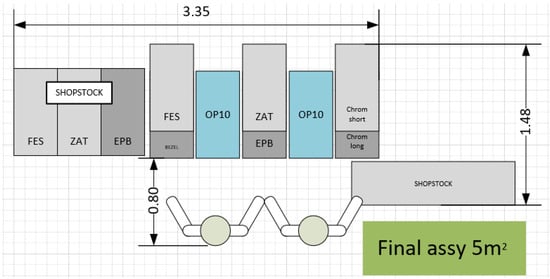

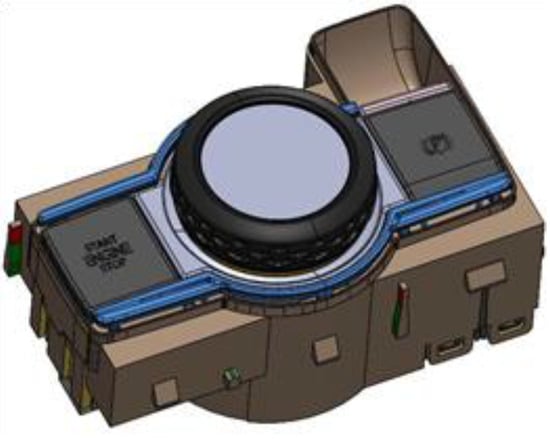

The complete VW-FES module (front electronic system) (Figure 2) consists of multiple components that work together to control various electronic functions in Volkswagen vehicles, as can be observed in Figure 3.

Figure 2.

VW-FES module.

Figure 3.

Automation line.

The automation line analyzed in this study integrates several key components—FES, EPB, and ZAT switches—each fulfilling a specific function within the vehicle’s electronic system architecture.

The FES switch (front electronic switch) is responsible for managing multiple electronic features located at the front of the vehicle. These include essential systems such as the headlights, windshield wipers, electric side mirrors, and infotainment controls. The FES is embedded within a central module that brings together several driver interface functions, contributing to a more streamlined and efficient vehicle control layout.

The EPB (electronic parking brake) replaces the traditional manual handbrake with a digital switch, enabling the parking brake to be engaged or released electronically. This not only improves driver convenience but also enhances vehicle safety by ensuring precise and consistent activation. The EPB works in coordination with other onboard electronic systems to support a secure and reliable braking process.

The ZAT switch (zentral antriebssperre taster), or central drive lock button, allows the driver to control functions related to traction management. Depending on the specific vehicle model, it can be used to activate or deactivate features such as centralized drive locking, differential locks, or all-wheel drive systems, thus contributing to improved drivability and safety under various road conditions.

In addition to these vehicle-specific components, the automation line also incorporates programmable logic controllers (PLCs), which play a fundamental role in coordinating industrial processes. PLCs are widely used across manufacturing environments—including in assembly automation, HVAC control, and robotics—due to their high reliability, adaptability, and real-time processing capabilities. Their integration into the production system enhances both operational efficiency and process stability, forming the backbone of modern automotive and industrial automation.

Programmable Logic Controller (PLC)

A programmable logic controller (PLC) is an industrial-grade electronic system specifically designed to automate and manage complex industrial operations. Functioning as a robust and highly reliable industrial computer, the PLC orchestrates production equipment and automated processes through a network of logical input and output signals. Its primary role is to ensure accurate, repeatable, and adaptable control over machinery and production lines.

For successful implementation, several key aspects must be considered. First, the selection of the PLC system is critical. Manufacturers such as Siemens, Beckhoff, and Omron are generally preferred due to their proven performance, flexibility, and support infrastructure. Alternative systems may be used but typically require customized programming to ensure compatibility and functionality.

Scalability is another essential requirement. Each PLC setup should allow for future functional expansion, meaning that it must have a sufficient reserve of inputs and outputs. As a baseline, each station or machine should include at least eight digital inputs/outputs (DIOs) and four analog inputs/outputs (AIOs) to accommodate system modifications or process extensions.

Comprehensive and well-documented project files must accompany any PLC implementation. These should include clear comments and annotations, facilitating ease of maintenance, debugging, and future updates. Such documentation plays a vital role in ensuring the transparency and long-term operability of the automation system.

Modern PLCs must also feature LAN connectivity, enabling real-time communication with central database servers. This connection allows for the secure and efficient storage of operational data, such as serial numbers and production outcomes, contributing to full traceability within smart manufacturing environments.

Furthermore, a centralized PLC architecture can be employed to control multiple assembly stations simultaneously. This not only reduces hardware redundancy but also simplifies the overall automation structure, improving the system coordination and reducing the installation and maintenance complexity.

Through these functionalities and requirements, PLCs represent a foundational component of Industry 4.0 manufacturing systems, supporting the integration of digital technologies into efficient and intelligent production environments.

Human–Machine Interface (HMI)

The human–machine interface (HMI) plays a critical role as the communication bridge between operators and automated systems. It enables real-time monitoring and control over industrial processes, facilitating seamless interaction between humans and machinery through a graphical user interface (GUI). Designed for usability and efficiency, the HMI ensures that operators can intuitively access and manage automation tasks on the production floor.

One of the essential features of the HMI system is its touchscreen interface, which must include a 7-inch display to allow straightforward access to various control functions. This interface offers operators a responsive and centralized platform to monitor processes and execute commands with ease.

To support standardized workflows and operator guidance, the HMI must provide visual support and process-monitoring capabilities. Through video-based guides and real-time feedback, the system assists workers in following predefined procedures and verifying each step of the operation. This is particularly important in relation to workstations such as OP20, where the HMI is required to display test sequences in a clear, step-by-step format, thereby eliminating ambiguity and reducing the risk of human error.

Each workstation must be equipped with a dedicated HMI. Shared interfaces between stations are not permitted, as individualized control is essential for maintaining safety and efficiency. At the same time, the system must enable quality monitoring and production tracking, using a part counter that distinguishes between compliant (OK) and non-compliant (NOK) products, while also recording the total output of each unit.

In support of global operations and a diverse workforce, the HMI must offer multilingual interface support. A minimum of five languages should be included, with all interface labels stored in editable language files. Importantly, the system should permit easy updates or uploads of these files without requiring assistance from the equipment vendor.

To facilitate efficient process management, the HMI must also include a recipe selection menu. Either a single master station must be designated to control the recipe distribution, or the system should be capable of retrieving recipe identifiers directly from the end-of-line testing (EOLT) system via TCP/IP communication. For added security, manual or service mode access must be password-protected, ensuring that only authorized personnel can modify system settings or perform diagnostics and maintenance [].

The integration of the PLC and HMI systems within the automation architecture significantly enhances the process reliability, traceability, and operational safety. Together, they form a foundational layer of smart manufacturing systems, supporting dynamic production needs with adaptable and user-friendly control environments.

An equally vital component of this system is traceability—the ability to track a product or batch from initial component insertion to final delivery, and vice versa. In industries like automotive manufacturing, where quality and compliance are critical, this functionality ensures transparency across the entire production lifecycle. Each component introduced onto the assembly line must be verified against the database, with the operational results and serial numbers being recorded along with the part markings.

Within this case study, two key operational procedures, OP10 and OP20, illustrate how the Safety 4.0 concept is applied in practice. These procedures represent distinct phases of the assembly process, each governed by a structured workflow and integrated safety measures. OP10 typically marks the first step in the assembly sequence, varying slightly depending on the component being processed. Together, OP10 and OP20 form the foundation of the case study’s methodological framework, demonstrating full alignment with Safety 4.0 principles and deliverables.

Description of OP10—Installation of Switches into the Frame

Assembly steps:

- 1.

- The operator picks up the EPB switch, scans the DMC code, and places it into the fixture.

- ○

- Poka-yoke device for part orientation.

- ○

- Presence detection system to ensure correct positioning.

- ○

- DMC code scanner for traceability verification.

- 2.

- The operator takes the frame and inserts it into the fixture through the EPB switch.

- ○

- Poka-yoke device for correct part orientation.

- ○

- Presence detection system to confirm proper insertion.

- ○

- Verification of the external clip dimensions on the frame.

- ○

- Inspection of “stop” dimensions to ensure proper fitting.

- ○

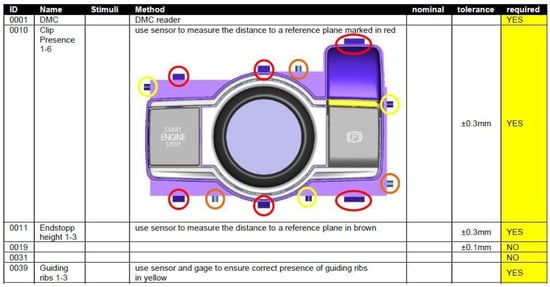

- Guiding rib inspection to detect structural integrity issues (Figure 4).

Figure 4. Product verification.

Figure 4. Product verification.

This structured traceability and assembly verification system ensures product quality, compliance with manufacturing standards, and process efficiency, supporting automation and smart manufacturing initiatives in the automotive sector.

- 3.

- The operator picks up the FES switch, scans the DMC code of the switch, and places it into the frame.

- Presence detection

- DMC code scanner

- 4.

- The operator inserts the drawer/starts the pressing process.

- The machine presses all the switches into the frame.

- The final pressing position is controlled by a sensor for each switch/component individually.

- The machine generates a serial number for the entire assembly, known as the FAZIT string, and stores it in the database. This serial number links the DMC codes of the individual switches and the operation result. It will be part of the marking of the entire assembly for the next operation.

- 5.

- The operator transfers the completed pre-assembly to the next operation (Figure 5).

Figure 5. The completed pre-assembly of the product.

Figure 5. The completed pre-assembly of the product.

- 6.

- Station specifications

- Poka-yoke design products.

- All the cylinders must be equipped with sensors at both end positions—if the cylinder size allows.

- Material and design of the pushers must prevent damage to the parts.

- The station must be equipped with an intake air pressure sensor (max. 8 bar) and must evaluate whether the pressure remains within the specified limits.

- If multiple cylinders are used for pressing, each cylinder must have its own pressure regulator.

- All the cylinders must be equipped with throttle valves.

- A stationary Keyence, Cognex, or SICK DMC code reader must be placed on the machine.

- The foundation bed and all the materials within 30 cm of the designated product must be ESD-compliant in design.

Description of OP20—Final Assembly and Testing Steps

- 1.

- The operator takes the pre-assembly from the previous operation and places it into the fixture.

- ○

- Poka-yoke jig preparation to maintain part orientation.

- ○

- DMC readers for scanning all the codes.

- ○

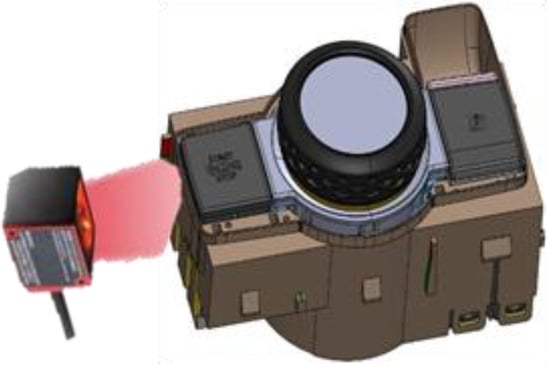

- Data processing: After scanning the ZAT DMC code, the machine verifies in the database whether the previous operation was completed successfully (Figure 6).

Figure 6. Product testing.

Figure 6. Product testing.

- 2.

- The operator picks up the chrome molds and fits them into the frame.

- Detection of the presence of chrome strips (Figure 7).

Figure 7. Detection of chrome strips.

Figure 7. Detection of chrome strips. - Detection of the chrome strip variant (color).

- 3.

- The operator inserts the drawer/starts the machine.

- Chrome strips are crimped.

- Press height verification using an analog sensor on the pressing cylinder, mechanical dosing sensor, or an equivalent system.

- Verification of the switch positions within the frame by checking the symbol positions (nominal values will be defined by the TBD drawing).

- Verification of the gaps between switches is not yet fully defined, but the vision system should be capable of performing such tests.

- 4.

- The operator removes the drawer and performs a manual functional test.

- The purpose is to detect possible button blockage in extreme positions.

- The machine verifies that none of the buttons remain closed.

- 5.

- If the switch is evaluated as OK, the operator inserts the drawer.

- The product is laser-marked. The marking format will be defined for a procedure and will follow the recommendation of the manufacturer.

After part marking, the station must verify the readability of the DMC code according to the ISO/IEC TR 29158:2011 (DPM), ISO/IEC 15415, and ISO/IEC 16022 (LABEL) standards. The operator removes the part from the stacker, checks the part marking, and transfers the product to the packaging [,,].

- 6.

- If the switch is evaluated as NOK (non-conforming).

- The product will not be laser-marked.

- The machine prints a label containing the defect number (test stage), a brief defect description, the lower tolerance limit, the measured value, and the upper tolerance limit.

- For label printing, use the Zebra GK420t printer (Zebra Technologies, Lincolnshire, IL, USA).

- Label format: 25 × 15 mm.

- The machine releases the defective part from the stacker and instructs the operator to apply the NOK label to the product. Simultaneously, an alert prompts the operator to place the product in the NOK bin.

- In the NOK bin, the machine scans one of the product’s DMC codes to verify that the correct part is being discarded.

- The NOK bin opens, and after the product passes through the sensor, it closes again.

- A sensor must be used to check if the NOK bin is full.

- 7.

- The operator transfers the finished OK product to packaging.

- Station specifications

- Poka-yoke preparation.

- For contacting all the switches:

- ○

- Contact masks made of ceramic material (e.g., Doceram), or optionally, ceramic or stainless-steel inserts in a plastic mask.

- ○

- Flexible “pogo-pin” contact probes (brands: Ingun or Feinmetall).

- ○

- Contact in a so-called “floating” bearing to compensate for tolerance inaccuracies in the product and improve alignment.

- ○

- Contact masks with ramps for better guidance to the connector.

- CAN interface for communication with the FES module.

- DMM (digital multimeter) for measuring the electrical characteristics of switches.

- For the vision tests, use a Cognex color camera with sufficient resolution to measure the symbol positions and gap widths and detect the presence of chrome parts or button colors.

- Material and design of the pushers must prevent damage to parts.

- The station must be equipped with an intake air pressure sensor (max. 8 bar) and must assess whether the pressure remains within limits.**

- If multiple cylinders are used for pressing, each cylinder must have its own pressure regulator.

- All the cylinders must be equipped with throttle valves.

- For laser marking, FOBA lasers are preferred—other options must be agreed upon (FOBA laser marking tests conducted).

- DMC readers—Keyence or Cognex.

- NOK part sensor chute—designed to prevent damage to visible parts of the assembly.

This structured approach ensures quality control, compliance with industry standards, and process efficiency in smart manufacturing environments.

- 8.

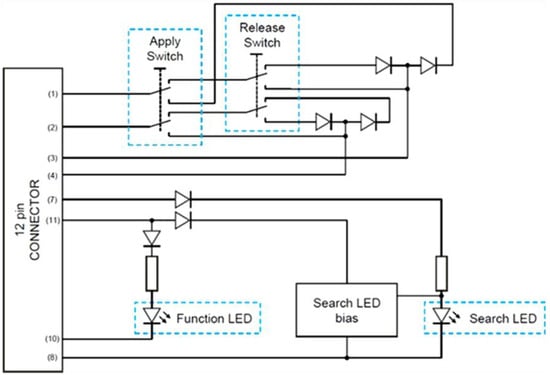

- Connecting the ZAT switches.

The connection of ZAT switches (Figure 8) is a crucial step in the final assembly process, ensuring that all the components function properly within the electronic system of the vehicle. This stage involves electrical integration, functional verification, and alignment with the vehicle’s central control module.

Figure 8.

ZAT switch connection.

Regarding the conditions of the Safety 4.0 concept and the conditions imposed by the beneficiary, the stations must comply with local safety regulations and standards, including EN ISO 4414 (Pneumatic fluid power—General rules and safety requirements for systems and their components), EN ISO 12100 (Safety of machinery—General principles for design—Risk assessment and risk reduction), EN ISO 13849-1 (Safety of machinery—Safety-related parts of control systems), EN ISO 13855 (Safety of machinery—Positioning of safeguards with respect to the approach speeds of parts of the human body), EN ISO 13857 (Safety of machinery—Safety distances to prevent hazard zones being reached by upper and lower limbs), EN ISO 14120 (Safety of machinery—Guards—General requirements for the design and construction of fixed and movable guards), EN 1837+A1 (Safety of machinery—Integral lighting of machines), EN 60204-1 ed.2 (Safety of machinery—Electrical equipment of machines—Part 1: General requirements), EN 60825-1 ed.3 (The Standard for Safety of laser products—Equipment classification and requirements.), EN 61310-1 ed.2 (Safety of machinery—Indication, marking and actuation—Part 1: Requirements for visual, auditory and tactile signals), and EN 61496-1 ed.3 (Safety of machinery—Electro-sensitive protective equipment—Part 1: General requirements and tests) [,,,,,,,,,].

Considering the Safety 4.0 concept and the conditions imposed by the beneficiary, the delivery must include complete documentation, which consists of the following:

- Electrical diagram

- Pneumatic diagram

- List of recommended spare parts

- Equipment operation and maintenance instructions

- Risk assessment report

- Declaration of conformity

- Electrical review

The VW-FES final assembly line ensures its products meet various international safety standards, including the Federal Motor Vehicle Safety Standards (FMVSS) in the United States and the European New Car Assessment Program (Euro NCAP). Additionally, the VW-FES final assembly integrates ISO 26262, focusing on the functional safety of automotive electronic systems, into its development processes to mitigate risks associated with electronic malfunctions. By adhering to these principles and regulations, the VW-FES final assembly line aims to enhance the safety and efficiency of its automated assembly lines, aligning with the objectives of Safety 4.0 [].

5. Conclusions

This case study demonstrates how the automation of the front electronic system (FES) connector production line significantly improved the efficiency, product quality, and process reliability. The transformation was achieved through the integration of industrial robots, programmable logic controllers (PLCs), sensors, and automated testing stations, enabling a highly precise, consistent, and adaptable manufacturing process.

A structured automation approach was applied, beginning with a comprehensive analysis of the production phases—material supply, assembly, testing, and packaging—to identify the most suitable areas for automation and real-time monitoring.

The PLC and sensor integration played a central role in coordinating the robotic operations, quality control units, and other subsystems. The PLCs facilitated automatic adaptation to changes in production, while the sensors and FES-specific switches ensured task precision and enhanced workplace safety.

In the advanced assembly and testing stage, the robotic systems reduced human error during assembly, while the automated testing stations ensured that each unit met strict quality specifications. The FES switches were used to support efficient and consistent quality checks.

The monitoring and safety systems were enhanced through the SCADA platforms, which enabled real-time data acquisition, anomaly detection, and quick fault response. The safety was further reinforced by automatic shutdown procedures and built-in protections against electrical hazards.

The material handling was optimized using automated conveyors and autonomous guided vehicles (AGVs), which streamlined the internal logistics and reduced the dependency on manual labor.

The main benefits of automation are as follows:

- Increased production speed and accuracy

- Greater flexibility to accommodate various product types

- Reduced long-term operational costs

- Strengthened quality assurance and regulatory compliance

- The following notable innovations have been implemented:

- A 20% reduction in the automated optical inspection (AOI) cycle time

- Programmable presses with fully customizable settings

- High-precision screwdrivers and automated tool changers

- Cameras for grease application detection

- Polyurethane casting sensors with up to 2-micron accuracy

- End-to-end process traceability

- Automated CAN-based functional testing systems

- Laser marking for unique product identification (VW-compliant)

- The measurable effects of the automation processes are as follows:

- Shorter production cycle times

- Fewer quality issues and customer complaints

- Improved traceability and compliance with industry standards

- Enhanced defect prevention and process control

Overall, the automation of the FES connector production line modernized the manufacturing system, making it more efficient, adaptable, and quality-focused. This case study highlights how strategic integration of automation technologies can bring sustainable, long-term benefits to complex industrial operations.

By integrating these Industry 4.0 technologies and the Safety 4.0 concept, Volkswagen in the VW-FES final assembly line aims to create a safer, more efficient, and adaptable manufacturing environment that prioritizes both productivity and worker well-being.

While this study focuses specifically on the VW-FES final assembly line, many of the safety issues identified—such as the ergonomic risks, cybersecurity vulnerabilities, and human–machine interaction challenges—are common across various smart manufacturing environments. The findings, including the benefits of predictive maintenance, real-time monitoring, and AI-driven safety systems, are broadly applicable to other industrial contexts where Industry 4.0 technologies are implemented. However, the degree of applicability may vary depending on the level of automation, the type of industry, and the specific operational procedures involved. Therefore, the VW-FES case study serves as a representative model, offering transferable insights while also highlighting the need for contextual adaptation in different manufacturing settings.

Author Contributions

Conceptualization, A.N., A.Ț. and O.R.C.; methodology, A.F., O.R.C. and I.C.E.; writing—original draft preparation, M.G. and C.B.; writing—review and editing, A.F. and M.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study was approved by the Ethics Committee of the Quality Engineering and Industrial Technologies, National University of Science and Technology Politehnica Bucharest, Splaiul Independentei Nr. 313, 060042 Bucharest, Romania (Decision no. 1 of 2025).

Informed Consent Statement

Not applicable.

Data Availability Statement

All the data generated or analyzed during this study are included in this published article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Almada-Lobo, F. The Industry 4.0 revolution and the future of Manufacturing Execution Systems (MES). J. Innov. Manag. 2015, 3, 16–21. [Google Scholar] [CrossRef]

- Alsafi, Y.; Vyatkin, V. Ontology-based reconfiguration agent for intelligent mechatronic systems in flexible manufacturing, Robot. Comput. Integr. Manuf. 2010, 26, 381–391. [Google Scholar] [CrossRef]

- Armengaud, E.; Sams, C.; von Falck, G.; List, G.; Kreiner, C.; Riel, A. Industry 4.0 as Digitalization over the Entire Product Lifecycle: Opportunities in the Automotive Domain. In Proceedings of the EuroSPI 2017, Ostrava, The Czech Republic, 6–8 September 2017; pp. 334–351. [Google Scholar] [CrossRef]

- Bi, Z.; Zhang, W.J.; Wu, C.; Luo, C.; Xu, L. Generic Design Methodology for Smart Manufacturing Systems from a Practical Perspective. Machines 2021, 9, 207. [Google Scholar] [CrossRef]

- Martinetti, A.; Demichela, M.; Singh, S.; Soares, G.M.; Castro Silva, J. Maintenance 4.0: Where Are We? A Systematic Literature Review. In Applications and Challenges of Maintenance and Safety Engineering in Industry 4.0; Martinetti, A., Demichela, M., Singh, S., Eds.; IGI Global Publisher: Hershey, PA, USA, 2020; pp. 1–30. [Google Scholar] [CrossRef]

- Chrysolouris, G.; Mavrikios, D.; Papakostas, N.; Mourtzis, D.; Michalos, G.; Georgoulias, E.K. Digital manufacturing: History, perspectives, and outlook. J. Eng. Manuf. 2009, 223, 451–462. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2018, 6, 6505–6519. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 49th Hawaii International Conference on System Sciences, Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative Industrie 4.0; Forschungsunion, Acatech: Darmstadt, Germany, 2013. [Google Scholar]

- Kusiak, A. Smart Manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Lee, S.; Ryu, K. Development of the Architecture and Reconfiguration Methods for the Smart, Self-Reconfigurable Manufacturing System. Appl. Sci. 2022, 12, 5172. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- ElMaraghy, H.; Monostori, L.; Schuh, G.; ElMaraghy, W. Evolution and future of manufacturing systems. CIRP Ann. 2021, 70, 635–658. [Google Scholar] [CrossRef]

- Leng, J.; Liu, Q.; Ye, S.; Jing, J.; Wang, Y.; Zhang, C.; Zhang, D.; Chen, X. Digital twin-driven rapid reconfiguration of the automated manufacturing system via an open architecture model. Robot. Comput.-Integr. Manuf. 2020, 63, 101895. [Google Scholar] [CrossRef]

- ISO 13849-1:2015; Safety of Machinery—Safety-Related Parts of Control Systems. ISO: Geneva, Switzerland, 2015.

- Hermann, F. The Smart Factory and Its Risks. Systems 2018, 6, 38. [Google Scholar] [CrossRef]

- Kagermann, H. Chancen von Industrie 4.0 nutzen. In Industrie 4.0 in Produktion, Automatisierung und Logistik; Bauernhansl, T., ten Hompel, M., Vogel-Heuser, B., Eds.; Springer Vieweg: Wiesbaden, Germany, 2014; pp. 603–614. [Google Scholar]

- Koren, Y.; Gu, X.; Guo, W. Reconfigurable manufacturing systems: Principles, design, and future trends. Front. Mech. Eng. 2018, 13, 121–136. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Jiang, P. Digital twin-based designing of the configuration, motion, control, and optimization model of a flow-type smart manufacturing system. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- IEC 61508:2010; Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems. TC/SCs: London, UK, 2010.

- Vijayakumar, K.; Robert, P. Human Factor Index Measurement Using an ISM-SEM-Fuzzy Approach. Sustainability 2022, 14, 7635. [Google Scholar] [CrossRef]

- Syed, H.; Vivek, V. Paradigm of integrating technology to reach zero safety risks. Proceedings of Society of Petroleum Engineers—SPE Americas E and P Health, Safety, Security, and Environmental Conference, Galveston, TX, USA, 18 March 2013; pp. 96–99. [Google Scholar]

- Yousif, I.; Samaha, J.; Ryu, J.; Harik, R. Safety 4. 0: Harnessing computer vision for advanced industrial protection, Manuf. Lett. 2024, 41, 1342–1356. [Google Scholar] [CrossRef]

- Wu, J.; Ren, J.; Ravn, O.; Nalpantidis, L. A Risk-Informed Design Framework for Functional Safety System Design of Human–Robot Collaboration Applications. Safety 2025, 11, 24. [Google Scholar] [CrossRef]

- Darabont, D.C.; Cioca, L.-I.; Badea, D.O. Digital Approaches for Mitigating Occupational Vibration Exposure in the Context of Industry 4.0. Safety 2025, 11, 31. [Google Scholar] [CrossRef]

- ISO 45001:2018; Occupational Health and Safety Management Systems—Requirements with Guidance for Use. ISO: Geneva, Switzerland, 2015.

- Roussel, S.; King, N.J. Safety management system—Workplace activities at toyota motor manufacturing, Texas. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 17 August 2012; pp. 467–473. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M.; Singh, R.P. Encouraging Safety 4.0 to enhance industrial culture: An extensive study of its technologies, roles, and challenges. Green. Technol. Sustain. 2025, 3, 100158. [Google Scholar] [CrossRef]

- Rînjea, C.; Chivu, O.R.; Darabont, D.-C.; Feier, A.I.; Borda, C.; Gheorghe, M.; Nitoi, D.F. Influence of the Thermal Environment on Occupational Health and Safety in Automotive Industry: A Case Study. Int. J. Environ. Res. Public Health 2022, 19, 8572. [Google Scholar] [CrossRef] [PubMed]

- ISO/IEC TR 29158:2011; Information Technology—Automatic Identification and Data Capture Techniques—Direct Part Mark (DPM) Quality Guideline. ISO: Geneva, Switzerland, 2011.

- ISO/IEC 15415; Information Technology—Automatic Identification and Data Capture Techniques—Bar Code Symbol Print Quality Test Specification—Two-dimensional symbols. ISO: Geneva, Switzerland, 2011.

- ISO/IEC 16022; Information Technology—Automatic Identification and Data Capture Techniques—Data Matrix Bar Code Symbology Specification. ISO: Geneva, Switzerland, 2024.

- EN ISO 4414; Pneumatic Fluid Power—General Rules and Safety Requirements for Systems and Their Components. ISO: Geneva, Switzerland, 2010.

- EN ISO 12100; Safety of Machinery—General Principles for Design—Risk Assessment and Risk Reduction. ISO: Geneva, Switzerland, 2010.

- EN ISO 13855; Safety of Machinery—Positioning of Safeguards with Respect to the Approach Speeds of Parts of the Human Body. ISO: Geneva, Switzerland, 2024.

- EN ISO 13857; Safety of Machinery—Safety Distances to Prevent Hazard Zones Being Reached by Upper and Lower Limbs. ISO: Geneva, Switzerland, 2019.

- EN ISO 14120; Safety of machinery—Guards—General Requirements for the Design and Construction of Fixed and Movable Guards. ISO: Geneva, Switzerland, 2015.

- EN 1837+A1; Safety Of Machinery—Integral Lighting Of Machines. CEN: Brussels, Belgium, 2009.

- EN 60204-1 ed.2; Safety of Machinery–Electrical Equipment of Machines—Part 1: General Requirements. CEN: Brussels, Belgium, 2007.

- EN 60825-1 ed.3; The Standard for Safety of Laser Products—Equipment Classification and Requirements. CEN: Brussels, Belgium, 2014.

- EN 61310-1 ed.2; Safety of Machinery—Indication, Marking and Actuation—Part 1: Requirements for Visual, Auditory and Tactile Signals. CEN: Brussels, Belgium, 2007.

- 4EN 61496-1 ed.3; Safety of Machinery—Electro-Sensitive Protective Equipment—Part 1: General Requirements and Tests. CEN: Brussels, Belgium, 2012.

- ISO 26262; The International Functional Safety Standard for the Development of Electrical and Electronic Systems in Road Vehicles. ISO: Geneva, Switzerland, 2011.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).