Spin-Up from Rest of a Liquid Metal with Deformable Free Surface in a Cylinder under the Influence of a Uniform Axial Magnetic Field

Abstract

:1. Introduction

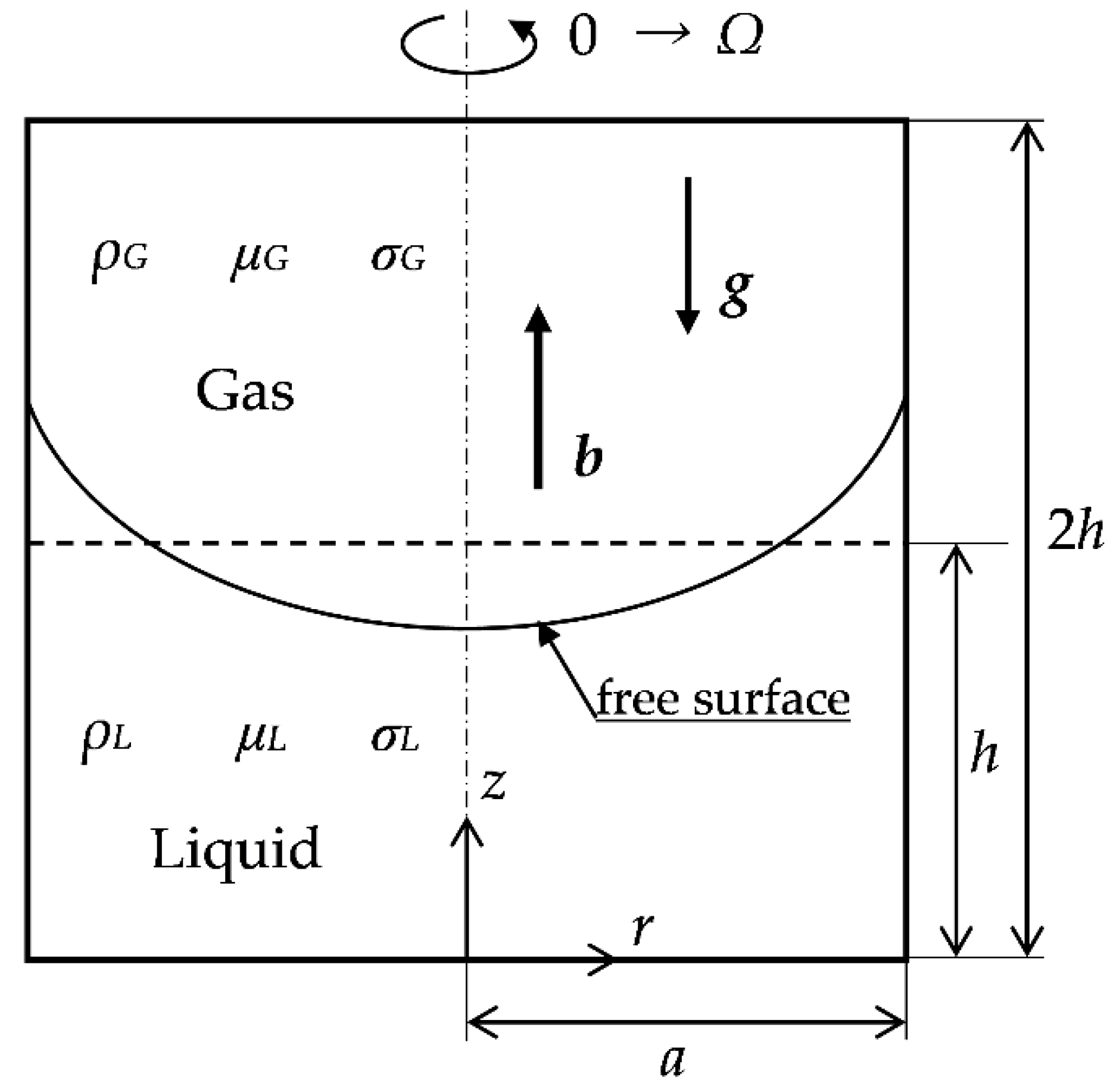

2. Mathematical Formulations

2.1. Schematic Model for Spin-Up

2.2. Governing Equations

2.3. Dimensionless Equations

2.4. Numerical Methodology

3. Results

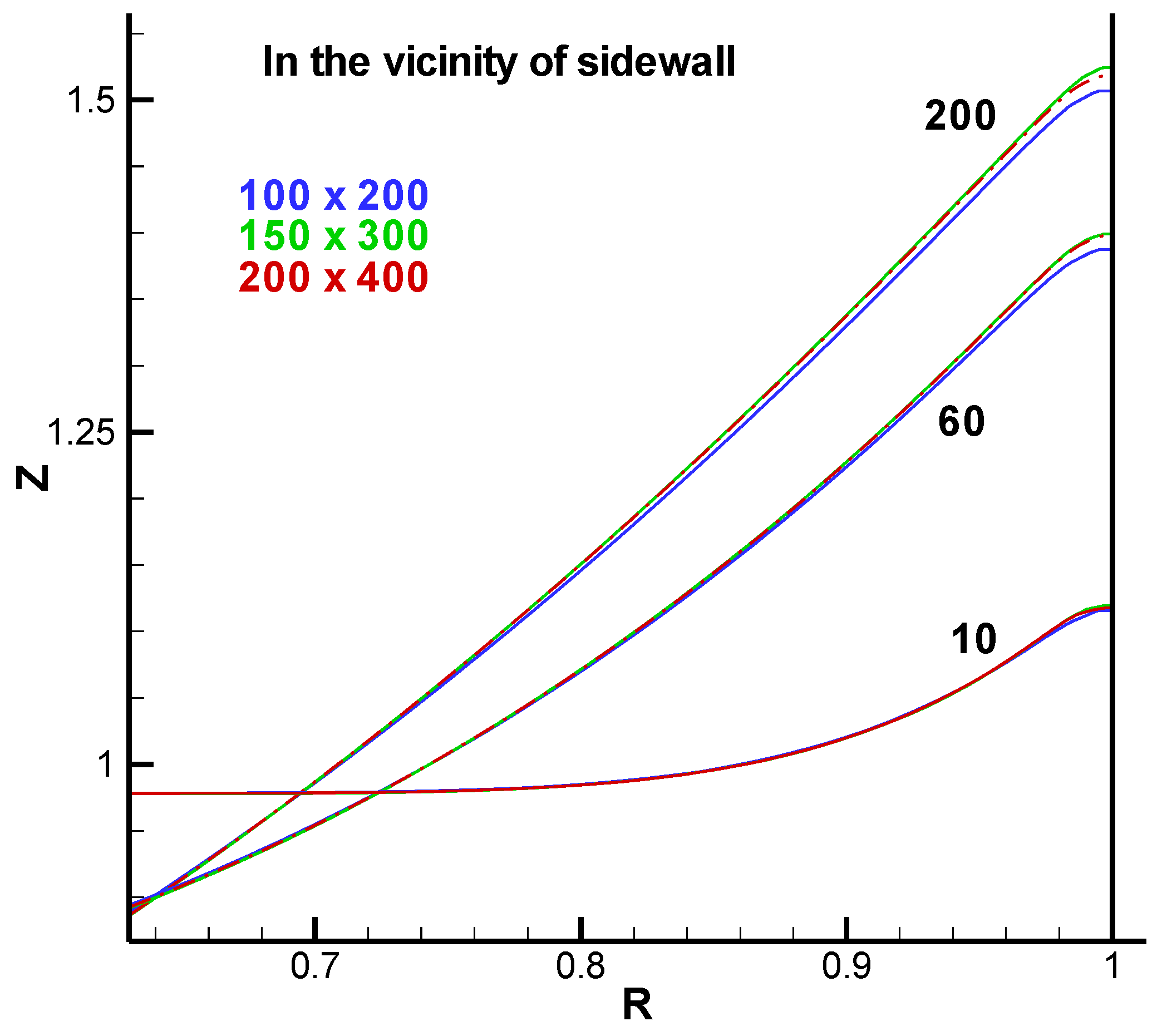

3.1. Grid Dependency

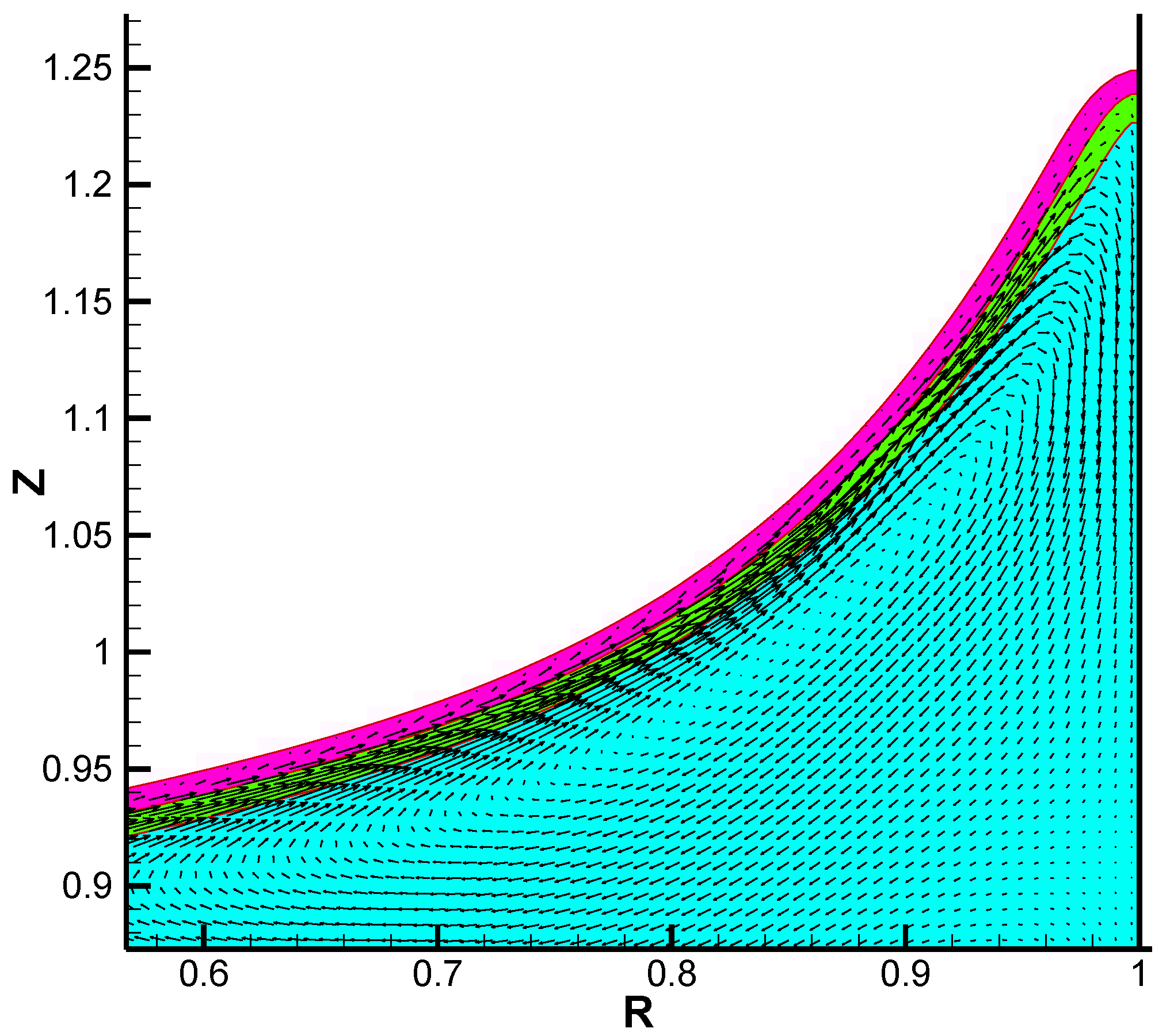

3.2. Effect of Surface Tension

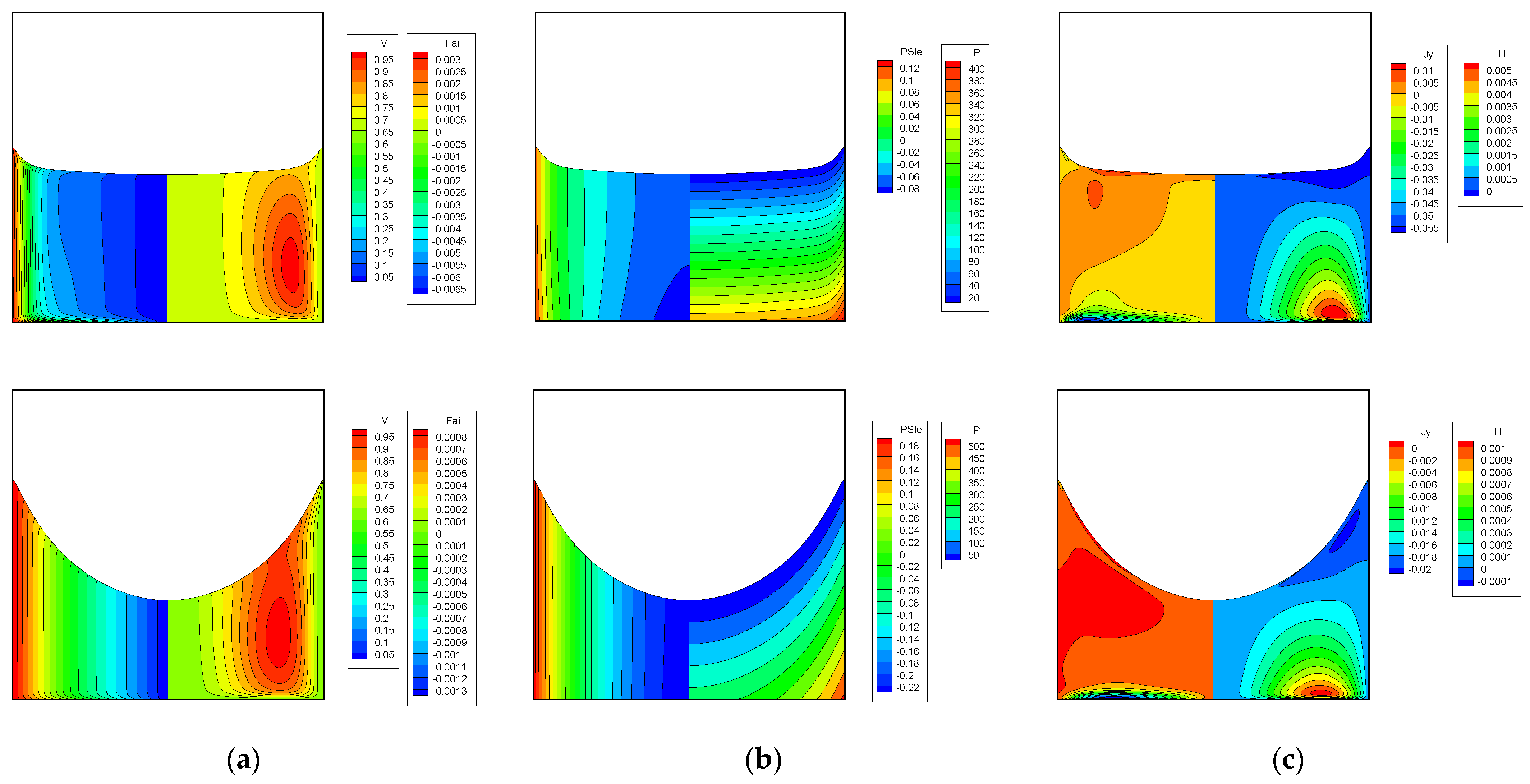

3.3. Effect of the Ekman Number

3.4. Spin-Up in the Axial Uniform Magnetic Field

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| a | radius of cylindrical enclosure (m) |

| Ar | aspect ratio = a/h (-) |

| b0 | absolute value of magnetic flux density (T) |

| b | magnetic flux density (T) |

| E | Ekman number (-) |

| eR | unit vector in radial direction (-) |

| eZ | unit vector in axial direction (-) |

| eθ | unit vector in azimuthal direction (-) |

| fst | surface normal force (N/m3) |

| Fr | Froude number (-) |

| g | gravitational acceleration (m/s2) |

| g | absolute value of gravitational acceleration (m/s2) |

| h | initial height of liquid (m) |

| Ha | Hartmann number (-) |

| Hε(φ) | smoothed Heaviside step function (-) |

| j | electric current density = (jr, jθ, jz) (A/m2) |

| jr | radial component of electric current density (A/m2) |

| jz | axial component of electric current density (A/m2) |

| jθ | azimuthal component of electric current density (A/m2) |

| J | dimensionless electric current density (-) |

| JR | dimensionless radial component of electric current density (-) |

| JZ | dimensionless axial component of electric current density (-) |

| Jθ | dimensionless azimuthal component of electric current density (-) |

| p | pressure (Pa) |

| P | dimensionless pressure (-) |

| r | radial coordinate (m) |

| R | dimensionless r coordinate (-) |

| t | time (s) |

| u | velocity = (u, v, w) (m/s) |

| u | radial velocity component (m/s) |

| U | dimensionless radial velocity component (-) |

| v | azimuthal velocity component (m/s) |

| V | dimensionless azimuthal velocity component (-) |

| w | axial velocity component (m/s) |

| W | dimensionless axial velocity component (-) |

| We | Weber number (-) |

| z | axial coordinate (m) |

| Z | dimensionless z-coordinate (-) |

| Greek symbols | |

| γ | surface tension (N/m) |

| δε(φ) | smoothed Dirac delta function (1/m) |

| κ | curvature of interface (1/m) |

| μ | viscosity (Pa·s) |

| ν | kinematic viscosity = μ/ρ (m2/s) |

| ρ | density (kg/m3) |

| σ | electric conductivity (1/(Ω·m)) |

| τ | dimensionless time (-) |

| φ | level-set function (m) |

| Φ | dimensionless level-set function (-) |

| ψe | electric potential (V) |

| Ψe | dimensionless electric potential (-) |

| ΨJ | Stokes stream function for electric current density (-) |

| ΨS | Stokes stream function for velocity (-) |

| Ω | angular velocity (rad/s) |

| Subscripts or superscripts | |

| G | gas |

| i,k | grid point |

| L | liquid |

| n | time step |

| m | iteration number |

| Φ | dependence of level-set function |

References

- Greenspan, H.P.; Howard, L.N. On a time-dependent motion of a rotating fluid. J. Fluid Mech. 1963, 17, 385–404. [Google Scholar] [CrossRef]

- Wedemeyer, E.H. The unsteady flow within a spinning cylinder. J. Fluid Mech. 1964, 20, 383–399. [Google Scholar] [CrossRef] [Green Version]

- Watkins, W.B.; Hussey, R.G. Spin-up from rest in a cylinder. Phys. Fluids 1977, 20, 1596–1604. [Google Scholar] [CrossRef]

- Hyun, J.M.; Leslie, F.; Fowlis, W.W.; Warn-Varnas, A. Numerical solutions for spin-up from rest in a cylinder. J. Fluid Mech. 1983, 127, 263–281. [Google Scholar] [CrossRef]

- Park, J.S.; Hyun, J.M. Review on open-problems of spin-up flow of an incompressible fluid. J. Mech. Sci. Technol. 2008, 22, 780. [Google Scholar] [CrossRef]

- Hyun, J.M.; Park, J.S. Spin-up from rest of a compressible fluid in a rapidly rotating cylinder. J. Fluid Mech. 1992, 237, 413–434. [Google Scholar] [CrossRef]

- Henderson, D.M.; Lopez, J.M.; Stewart, D.L. Vortex evolution in non-axisymmetric impulsive spin-up from rest. J. Fluid Mech. 1996, 324, 109–134. [Google Scholar] [CrossRef]

- Van de Konijnenberg, J.A.; Van Heijst, G.J.F. Free-surface effects on spin-up in a rectangular tank. J. Fluid Mech. 1997, 334, 189–210. [Google Scholar] [CrossRef]

- Hyun, J.M. Axisymmetric flows in spin-up from rest of a stratified fluid in a cylinder. Geophys. Astrophys. Fluid Dyn. 1983, 23, 127–141. [Google Scholar] [CrossRef]

- Duck, P.; Foster, M. Spin-up of homogeneous and stratified fluids. Annu. Rev. Fluid Mech. 2001, 33, 231–263. [Google Scholar] [CrossRef] [Green Version]

- Homicz, G.F.; Gerber, N. Numerical model for fluid spin-up from rest in a partially filled cylinder. J. Fluids Eng. 1987, 109, 194–197. [Google Scholar] [CrossRef]

- Choi, S.; Kim, J.W.; Hyun, J.M. Experimental investigation of the flow with a free surface in an impulsively rotating cylinder. J. Fluids Eng. 1991, 113, 245–249. [Google Scholar] [CrossRef]

- Maas, L.R.M. Nonlinear and free-surface effects on the spin-down of barotropic axisymmetric vortices. J. Fluid Mech. 1993, 246, 117–141. [Google Scholar] [CrossRef]

- Kim, K.Y.; Hyun, J.M. Spin-up from rest of a two-layer liquid in a cylinder. J. Fluids Eng. 1994, 116, 808–814. [Google Scholar] [CrossRef]

- Nikrityuk, P.A.; Ungarish, M.; Eckert, K.; Grundmann, R. Spin-up of a liquid metal flow driven by a rotating magnetic field in a finite cylinder: A numerical and an analytical study. Phys. Fluids 2005, 17, 067101. [Google Scholar] [CrossRef]

- Nikrityuk, P.A.; Eckert, S.; Eckert, K. Spin-up and spin-down dynamics of a liquid metal driven by a single rotating magnetic field pulse. Eur. J. Mech. B/Fluids 2008, 27, 177–201. [Google Scholar] [CrossRef]

- Vogt, T.; Grants, I.; Eckert, S.; Gerbeth, G. Spin-up of a magnetically driven tornado-like vortex. J. Fluid Mech. 2013, 736, 641–662. [Google Scholar] [CrossRef]

- Lee, C.H.; Tagawa, T.; Ozoe, H.; Hyun, J.M. Spin-up from rest in a cylinder of an electrically conducting fluid in an axial magnetic field. Acta Mech. 2006, 186, 203–220. [Google Scholar] [CrossRef]

- Galazka, Z. Czochralski method. In Gallium Oxide: Materials Properties, Crystal Growth, and Devices; Higashiwaki, M., Fujita, S., Eds.; Springer: Cham, Switzerland, 2020; Volume 293, pp. 15–36. [Google Scholar]

- Ozoe, H.; Szmyd, J.S.; Tagawa, T. Magnetic fields in semiconductor crystal growth. In Magnetohydrodynamics; Molokov, S., Moreau, R., Moffatt, K., Eds.; Springer: Dordrecht, The Netherlands, 2007; pp. 375–390. [Google Scholar]

- Moreau, R.; Molokov, S. Julius Hartmann and his followers: A review on the properties of the Hartmann layer. In Magnetohydrodynamics; Molokov, S., Moreau, R., Moffatt, K., Eds.; Springer: Dordrecht, The Netherlands, 2007; pp. 155–170. [Google Scholar]

- Scardovelli, R.; Zaleski, S. Direct numerical simulation of free-surface and interfacial flow. Annu. Rev. Fluid Mech. 1999, 31, 567–603. [Google Scholar] [CrossRef] [Green Version]

- Sussman, M.; Smereka, P.; Osher, S. A level set approach for computing solutions to incompressible two-phase flow. J. Comput. Phys. 1994, 114, 146–159. [Google Scholar] [CrossRef]

- Sussman, M.; Puckett, E.G. A coupled level set and volume-of-fluid method for computing 3D and axisymmetric incompressible two-phase flows. J. Comput. Phys. 2000, 162, 301–337. [Google Scholar] [CrossRef] [Green Version]

- Inamuro, T.; Ogata, T.; Tajima, S.; Konishi, N. A lattice Boltzmann method for incompressible two-phase flows with large density differences. J. Comput. Phys. 2004, 198, 628–644. [Google Scholar] [CrossRef]

- Morley, N.; Smolentsev, S.; Munipalli, R.; Ni, M.-J.; Gao, D.; Abdou, M. Progress on the modeling of liquid metal, free surface, MHD flows for fusion liquid walls. Fusion Eng. Des. 2004, 72, 3–34. [Google Scholar] [CrossRef]

- Takatani, K. Mathematical modeling of incompressible MHD flows with free surface. ISIJ Int. 2007, 47, 545–551. [Google Scholar] [CrossRef] [Green Version]

- Tagawa, T. Numerical simulation of a falling droplet of liquid metal into a liquid layer in the presence of a uniform vertical magnetic field. ISIJ Int. 2005, 45, 954–961. [Google Scholar] [CrossRef] [Green Version]

- Tagawa, T. Numerical simulation of two-phase flows in the presence of a magnetic field. Math. Comput. Simul. 2006, 72, 212–219. [Google Scholar] [CrossRef]

- Tagawa, T. Numerical simulation of liquid metal free-surface flows in the presence of a uniform static magnetic field. ISIJ Int. 2007, 47, 574–581. [Google Scholar] [CrossRef] [Green Version]

- Tagawa, T.; Ozoe, H. Effect of external magnetic fields on various free-surface flows. Prog. Comput. Fluid Dyn. Int. J. 2008, 8, 461–468. [Google Scholar] [CrossRef]

- Shibasaki, Y.; Ueno, K.; Tagawa, T. Computation of a rising bubble in an enclosure filled with liquid metal under vertical magnetic fields. ISIJ Int. 2010, 50, 363–370. [Google Scholar] [CrossRef]

- Brackbill, J.U.; Kothe, D.B.; Zemach, C. A continuum method for modeling surface tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Francois, M.; Cummins, S.J.; Dendy, E.D.; Kothe, D.B.; Sicilian, J.M.; Williams, M.W. A balanced-force algorithm for continuous and sharp interfacial surface tension models within a volume tracking framework. J. Comput. Phys. 2006, 213, 141–173. [Google Scholar] [CrossRef]

- Hirt, C.; Nichols, B.; Romero, N. A Numerical Solution Algorithm for Transient Fluid Flows; Los Alamos Scientific Laboratory Report: Santa Fe, NM, USA, 1975. [Google Scholar]

- Tagawa, T.; Ozoe, H. Effect of Prandtl number and computational schemes on the oscillatory natural convection in an enclosure. Numer. Heat Transf. Part A Appl. 1996, 30, 271–282. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tagawa, T.; Song, K. Spin-Up from Rest of a Liquid Metal with Deformable Free Surface in a Cylinder under the Influence of a Uniform Axial Magnetic Field. Fluids 2021, 6, 438. https://doi.org/10.3390/fluids6120438

Tagawa T, Song K. Spin-Up from Rest of a Liquid Metal with Deformable Free Surface in a Cylinder under the Influence of a Uniform Axial Magnetic Field. Fluids. 2021; 6(12):438. https://doi.org/10.3390/fluids6120438

Chicago/Turabian StyleTagawa, Toshio, and Kewei Song. 2021. "Spin-Up from Rest of a Liquid Metal with Deformable Free Surface in a Cylinder under the Influence of a Uniform Axial Magnetic Field" Fluids 6, no. 12: 438. https://doi.org/10.3390/fluids6120438

APA StyleTagawa, T., & Song, K. (2021). Spin-Up from Rest of a Liquid Metal with Deformable Free Surface in a Cylinder under the Influence of a Uniform Axial Magnetic Field. Fluids, 6(12), 438. https://doi.org/10.3390/fluids6120438