Abstract

Ammonothermal synthesis is a method for synthesis and crystal growth suitable for a large range of chemically different materials, such as nitrides (e.g., GaN, AlN), amides (e.g., LiNH2, Zn(NH2)2), imides (e.g., Th(NH)2), ammoniates (e.g., Ga(NH3)3F3, [Al(NH3)6]I3 · NH3) and non-nitrogen compounds like hydroxides, hydrogen sulfides and polychalcogenides (e.g., NaOH, LiHS, CaS, Cs2Te5). In particular, large scale production of high quality crystals is possible, due to comparatively simple scalability of the experimental set-up. The ammonothermal method is defined as employing a heterogeneous reaction in ammonia as one homogenous fluid close to or in supercritical state. Three types of milieus may be applied during ammonothermal synthesis: ammonobasic, ammononeutral or ammonoacidic, evoked by the used starting materials and mineralizers, strongly influencing the obtained products. There is little known about the dissolution and materials transport processes or the deposition mechanisms during ammonothermal crystal growth. However, the initial results indicate the possible nature of different intermediate species present in the respective milieus.

1. Introduction

Ammonothermal synthesis has gained increasing research interest over the last 20 years. The first ammonothermal syntheses were carried out in analogy to the hydrothermal synthesis of oxides in the 1960s by Juza and Jacobs and pursued by Jacobs and co-workers over the following decades [1,2,3]. Since ammonia resembles water in its physical properties, water was replaced by ammonia in order to obtain amides, imides and nitrides in place of hydroxides and oxides. Using ammonia instead of nitrogen for nitridation allows less harsh temperature and pressure conditions, since ammonia is more reactive. Furthermore, an abundance of further materials like hydroxides, chalcogenides and hydrogen sulfides can be also obtained from supercritical ammonia.

Both hydrothermal and ammonothermal synthesis are part of the large group of solvothermal methods. The use of the term solvothermal is not defined unambiguously. Definitions vary from “any heterogenous chemical reaction in the presence of a solvent (whether aqueous or non-aqueous) above room temperature and at pressure greater than 1 atm in a closed system” [4] to sub- or supercritical conditions of the solvent [5]. Rabenau’s definition for hydrothermal conditions is frequently used “an aqueous medium over 100 C and 1 bar” [6] and transferred to solvothermal conditions in general by adjusting 373 K to “the boiling point of the solvent” [7]. The characteristics of ammonothermal synthesis and its products are mainly influenced by high pressure and temperature and usually syntheses are carried out under supercritial conditions. Above the critical point, solvents exist as homogeneous supercritical fluids, where gas and liquid phase can no more be distinguished and consequently the properties of the different phases converge. However, the properties of a supercritical fluid in its proper meaning and those of a fluid, with only one physical quantity above the critical state and the other one slightly below it, are hardly distinguishable. Hence, we define ammonothermal synthesis as a reaction in ammonia as one homogenous fluid next to or under supercritical conditions.

Various solvents showing distinct different chemical properties are used for solvothermal syntheses. This comprises (i) polar protic solvents like H2O, NH3, HF, HCl, HBr; (ii) polar non-protic solvents like tetrahydrofuran and (iii) non-polar solvents like benzene, xylene and CO2. Table 1 gives some examples for solvents used in solvothermal techniques and the obtained products. Over recent years, the research interest in solvothermal methods has greatly increased, due the constantly raising demand of crystal growth of functional materials, like, for example, semiconductors (CuInSe2 [8], InAs [9], GaN [10], AlN [11] and ZnO [12]), piezoelectrics (α-quartz [13], GaPO4 [14]), electrodes for lithium batteries (LiMnO [15]), magnetic and catalytic materials (LaCa/Sr/BaMnO [16]) and fine dielectric ceramics (BaTiO3 [17]).

Table 1.

Examples for solvothermal solvents and obtained products (see text).

| Solvent | Examples for products | References | |

|---|---|---|---|

| (i) | H2O | ZnO, α-quartz, α-Al2O3, GaPO4 | [12,13,14,18] |

| H2O + isopropyl alcohol | BaTiO3 | [17] | |

| H2O + C2H3Cl3 | Diamond | [19] | |

| NH3 | GaN, AlN, Cu3N, Cs2S2, NaOH | [10,11,20,21,22] | |

| HCl, HBr, HI | BiSCl, BiTeBr, SbSeI | [23] | |

| Ethanol | LiMnO | [15] | |

| Benzyl alcohol | LaCa/Sr/BaMnO | [16] | |

| (ii) | Ethylendiamine | Cu7Te4, CuInSe2 | [8,24] |

| Diethylamine | CuInSe2 | [8] | |

| THF | β-MnS | [25] | |

| (iii) | C6H6 | Se, c/h-BN, γ-MnS | [25,26] |

| Xylene | InAs | [9] | |

| Toluene | CuCr2Se4 | [27] | |

| CO2 | Poly vinyl chloride | [28] | |

| Br2 | SbSBr | [23] |

The choice of the solvent considerably influences the obtained product. Even different modifications occur depending on the solvent. For the reaction of MnCl2 · 4H2O with thiourea, SC(NH2)2, to MnS, for example, the use of tetrahydrofuran (THF) as solvent leads to metastable β-MnS, with benzene as solvent exclusively metastable γ-MnS and with water or ethylenediamine the stable α-MnS occur. Thus, the crystallization of the different modifications depends on the formed complexes of the solvent with the substrate, e.g., [Mn(H2O)6]2+. The knowledge of the chemical nature of the dissolved species is the crucial information to understand the formation mechanism of MnS [25]. Those observations manifest the importance of the complex intermediates present in the solvent for the formed product and for the structure of the product.

The best explored solvothermal method is the hydrothermal synthesis, owing to its commercial application for the synthesis of oxides and hydroxides. Nowadays, the hydrothermal method is used, for example, in the industrial synthesis of over 3000 t α-quartz single crystals per year, due to their piezoelectric properties and of Al2O3 from more than 90 million t of bauxite per year, for processing to metal [4].

Already in 1839, Bunsen carried out experiments with liquids at high temperatures and high pressures (473 K, 150 MPa) [29]. For this purpose he used sealed glass tubes with integrated mercury manometer. Later, in 1848, he succeeded in the growth of BaCO3 and SrCO3 millimeter-long crystals from an aqueous solution at 473 K and 1.52 MPa using NH4Cl as mineralizer [30]. Similar experiments for recrystallization of apophyllites were apparently conducted by Wöhler earlier [30]. Already in 1845 Schafhäutl obtained for the first time micro crystalline quartz crystals from hydrothermal conditions [31]. In 1851 Sénarmont laid the foundation for hydrothermal mechanisms in geology. He already realized the importance of pressure and temperature ...pressure to maintain the gaseous reactants in a forced dissolution and temperature to favorite certain combinations or decompositions... for the formation of the minerals and synthesized a great number of natural minerals under high temperature and high pressure conditions, in order to elucidate the natural formation conditions. Using a similar experimental setup as Bunsen did, he applied high temperatures and high pressures in sealed glass tubes. To avoid explosion of the sealed glass tubes containing the reactants and the solvent (water), he placed them inside water filled autoclaves [32].

The ammonothermal method was established inter alia in order to synthesize high quality crystals of amides for XRD structure determination and of deuteroamides for neutron diffraction [3]. The first compounds obtained from ammonothermal conditions (up to 507 MPa and 823 K) were binary amides (Be(NH2)2, Mg(NH2)2 [2]) and binary nitrides (Be3N2 [1]), later also imides (Th(NH)2 [33]), ternary compounds and other than nitrogen containing materials were synthesized [3].

Over the last twenty years the research interest in the ammonothermal method has increased considerably, since it is one of the few techniques leading to group III bulk nitrides. In comparison to other techniques, the ammonothermal method allows crystal growth on native substrate and growth of the initial native substrate itself in a very high quality. Increasing commercial efforts are directed to the ammonothermal growth of GaN and AlN on native substrates. GaN and AlN are semiconductors with wide band gaps used as base for optoelectronic and electronic devices (e.g., light-emitting diodes (LEDs), high electron mobility transistors, lasers with high optical storage capacity). The growth of group III nitrides as bulk crystal is much more difficult than as micro crystalline powder, but necessary for the use in optoelectronic and electronic devices [34,35].

There are several other methods known for the synthesis of bulk GaN and AlN. Up to now the most popular technique is hydride or halide vapor phase epitaxy, which is used for commercial purposes. Vapor-phase GaCl or GaCl3 obtained from metallic Ga and gaseous HCl is carried in a gas flow and reacts with gaseous NH3 to form GaN. The formed GaN deposits usually on a non-native substrate like sapphire, silicon or GaAs. At ambient pressure, growth temperatures of 1000–1100 °C are typical and growth rates of up to 0.5 mm/h are reported. Wafers are cut from the formed bulk material and subsequently polished. They can be used in devices or as a substrate for further syntheses [36].

Metal organic vapor phase epitaxy allows the growth of thin epitaxial layers used for devices. Metalorganic precursors (e.g., triethyl or trimethyl-gallium) react with NH3 forming GaN on a substrate. Growth rates vary from 1–2 μm/h for thin layers and up to 50 μm/h for bulk growth [36].

The advantages of devices made from ammonothermal GaN are the lower defect, strain and bowing level due to the growth on native substrate, the possibility of high scalability and no tilt boundaries, which occur even at GaN grown on a native seed by hydride/halide vapor phase epitaxy. If the substrate shows tilt boundaries, even if it is a native substrate but grown itself on a foreign substrate, the tilt boundaries will appear in the grown material, too [10,37,38,39,40,41,42]. High quality of the substrate is very important, since it allows the production of more devices per substrate and devices made of low-defect-density GaN or AlN promise longer working periods at higher power without breakdown [43]. Solvothermal methods in general are known for their reliable and scalable process, which permits the efficient growth of a great number of crystals within one synthesis, e.g., 1400 quartz crystals, 1700 g each [36,44].

Slow growth rates were one of the disadvantages of the ammonothermal method in the past. According to the latest research results this problem seems to overcome. Recently, researchers increased growth rates for GaN by ammonothermal method from 24–106 μm/d [45] to 250 (c-plane) and 300 μm/d (m-plane) in the presence of NH4F, used as so-called mineralizer [46]. Even m-plane growth rates of up to 40 μm/h (=960 μm/d) with rates of 10–30 μm/h (=240–720 μm/d) for all planes were reported recently [39].

2. Ammonia as Solvent

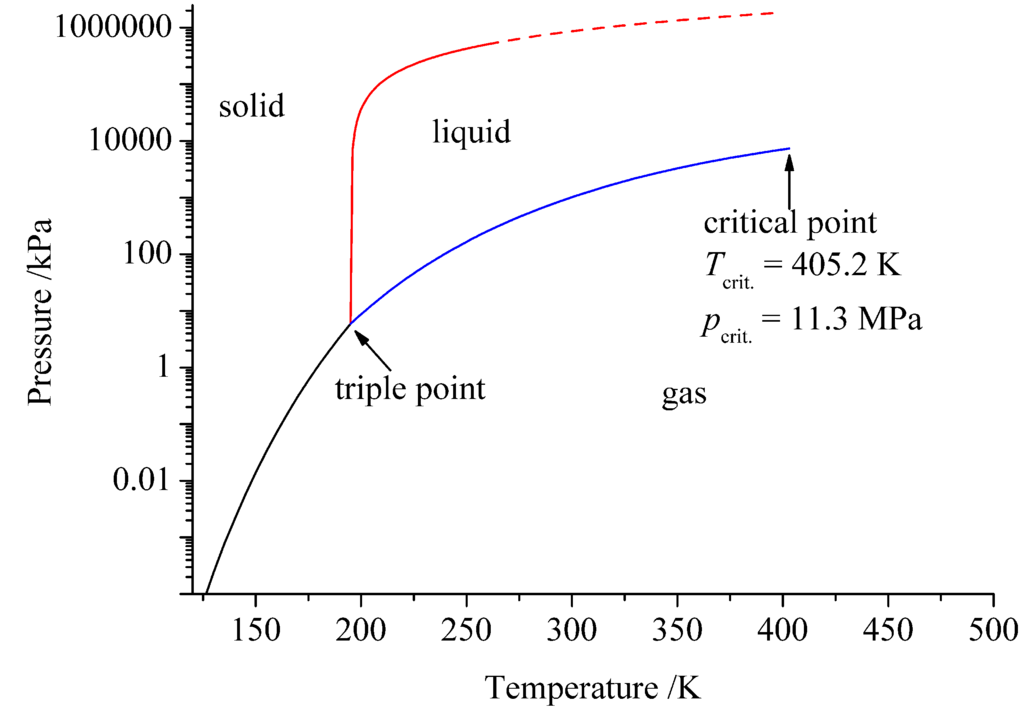

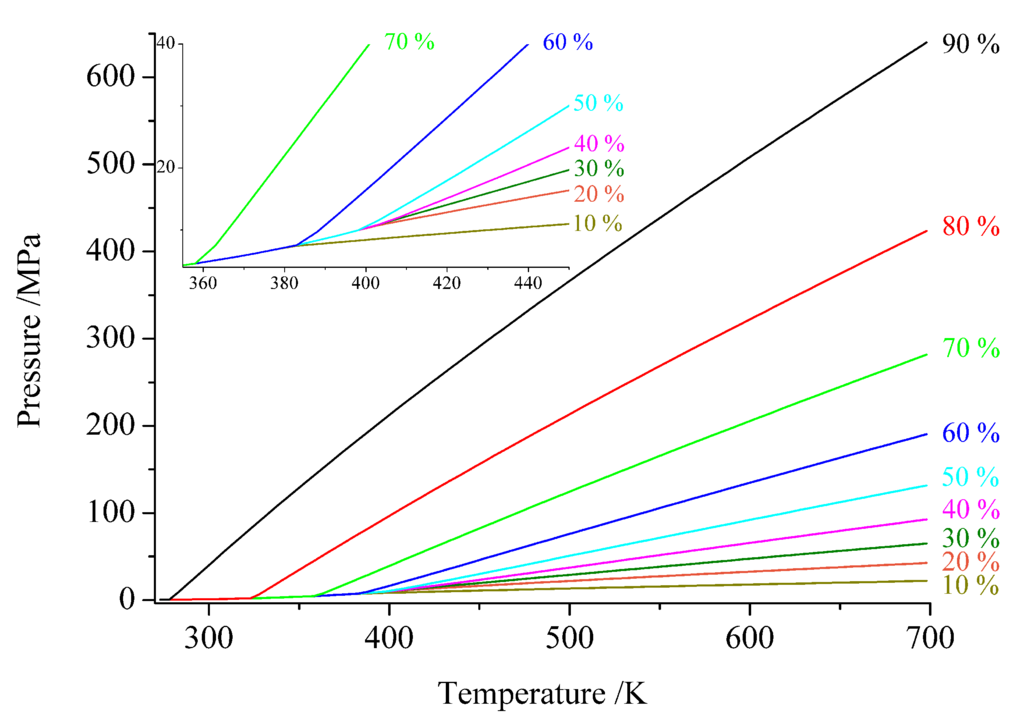

Ammonia and water show quite similar properties (see Table 2). Hence, the parallel from supercritical water to supercritical ammonia, drawn and realized by Juza and Jacobs, who established the ammonothermal synthesis, is not surprising [1,2]. Ammonia is a non-aqueous ionizing solvent, that means pure ammonia has a low specific electrical conductivity and dissolved electrolytes are partially or completely dissociated [47]. Ammonia was the first ionizing solvent, except for water, which has been studied thoroughly. Already at the beginning of the 20th century, inter alia Franklin, Kraus and Bronn studied the ammono-system of compounds, e.g., metal solutions in liquid ammonia [48,49,50]. Still, supercritical and liquid ammonia is a far less explored solvent than water. Compared to water ammonia is less protic and polar, at ambient pressure and temperature it is gaseous and shows much higher pressures at high temperatures [51]. Liquid ammonia has only small solubilities for many inorganic compounds, which yields often poorly crystallized or amorphous solids on precipitation, due to inhibited nucleation and crystal growth. Using supercritical ammonia rather than liquid ammonia overcomes this problem: Under ammonothermal conditions (supercritical fluid above a pressure of 11.3 MPa and a temperature of 405.2 K [52] see Figure 1 and Figure 2 [53]) the solubility is high enough to dissolve a large number of inorganic compounds. To dissolve a solid the relative permittivity of the solvent has to be higher than the lattice energy of the solid. Due to the rising relative permittivity of solvents with increasing density, which occurs at higher pressure, the solubility of mostly ionic solids increases with increasing pressure [3,54]. Water has a higher relative permittivity than ammonia; therefore, solids dissolve better in water than in ammonia at similar conditions (see Table 2).

Table 2.

Comparison of selected properties of ammonia and water [47,52,55].

| Water | Ammonia | |

|---|---|---|

| T/K | 647.65 | 405.2 |

| p/MPa | 22.1 | 11.3 |

| 78.3 (298 K) | 16.9 (298 K) | |

| Autoprotolysis | 2H2O ⇄ H3O+ + OH− | 2NH3 ⇄ NH + NH |

| Ionic product | (298 K) | (239 K) |

| pk | 15.7 | 4.75 |

| Proton affinity/eV | −7.9 | −9.2 |

Ammonia has a higher proton affinity than water ((NH3) = –9.2 eV; (H2O) = –7.9 eV [47]; the energy released when a proton is attached to the molecule in the gas phase). Hence, ammonia is a more basic solvent than water (see pk(NH3) = 4.8 and pk(H2O) = 15.7 [47]). Both water and ammonia show autoprotolysis since they possess at least one non-bonding pair of electrons and acidic hydrogen atoms, leading to formation of H3O+ or NH cations and OH− or NH anions, respectively. Due to the endothermic nature of the autoprotolysis reactions, the magnitude of autoprotolysis increases with increasing temperature. In the same way as water is a suitable solvent for the synthesis of oxides, ammonia is a unique and excellent solvent for nitride synthesis. Additionally, liquid and supercritical ammonia find application as solvent for water sensible compounds, which do not necessarily contain nitrogen, e.g., sulfides, hydrogen sulfides [3,56,57] and hydroxides [22].

Figure 1.

Pressure-temperature phase diagram of ammonia. The dashed line is extrapolated [58].

Figure 2.

Pressure-temperature diagram of ammonia in dependence on the filling degree of the reaction vessel (in %). The inset shows an enlarged view in the range around the critical point (T 405.2 K, p = 11.3 K) [53].

3. Technical Details for Ammonothermal Reactions

There are different installations for the realization of ammonothermal synthesis, starting with the materials and construction of the reaction vessel, the inner shape, liner and geometry of the reaction vessel via the filling of the reaction vessel with ammonia to the heating of the reaction vessel. In general, two types of ammonothermal syntheses can be distinguished, covering different aims: the research on fundamental questions and the research on application of the method for crystal growth. The former research branch investigates new compounds, new synthesis routes for compounds and the processes during crystal growth. The latter investigates and applies the conditions for an optimal crystal growth, including low defect and crack concentration, high growth rates and large crystal size, aiming at a commercial application. The different objectives require different laboratory installations, not only of size but also of type.

The reaction vessel is referred to as autoclave, since most of the installations use steel autoclaves and even the techniques with metallic capsules and glass tubes as reaction containers usually use steel autoclaves for mechanical stabilization of the capsule.

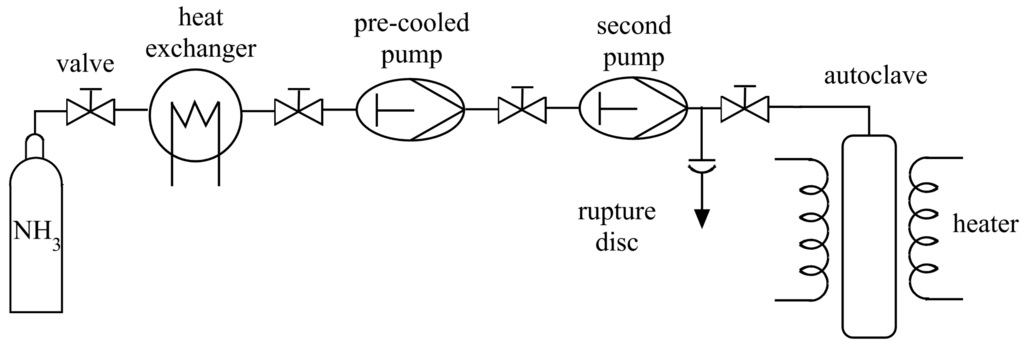

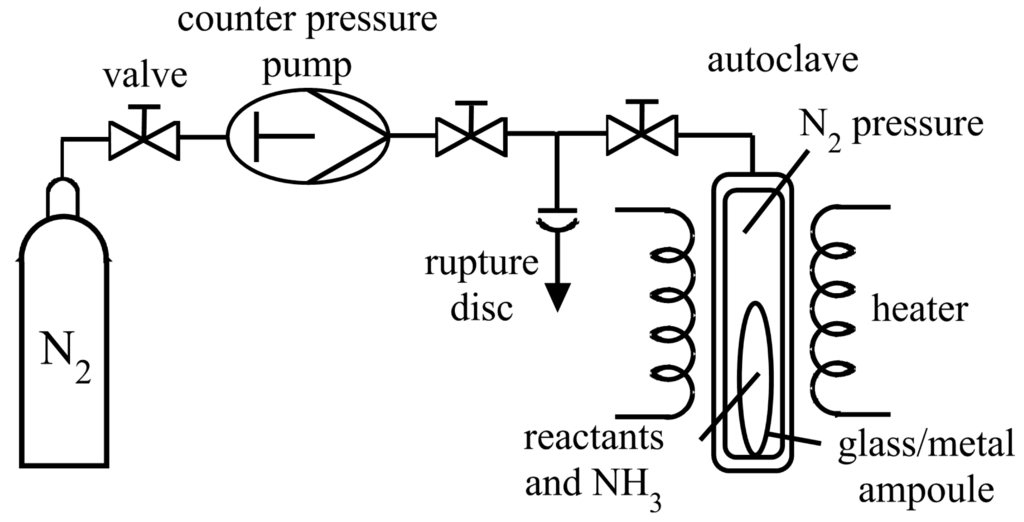

Figure 3.

Flow chart of an ammonothermal reaction setup for the simultaneous pressure and temperature control during reaction using two pumps. The heat exchanger is used for pre-cooling one pump and the supply pipe [59,60].

Different approaches find application to fill the autoclave with ammonia: Condensing ammonia into the autoclave by cooling, adding solid ammonia or filling the autoclave sequentially with ammonia by high pressure pumps. Condensing ammonia into the autoclave historically is realized by the help of a tensieudiometer, an apparatus for the simultaneous measurement of pressure and volume, developed by Hüttig [61]. The autoclave, already loaded with the solid reactants, can be connected to the tensieudiometer and is cooled down below the boiling point of ammonia ( K at ambient pressure [52]) and ammonia condenses in the autoclave. Since volume and pressure in the tensieudiometer, which realizes a closed system including the autoclave, are known an exact amount of ammonia can be filled inside the autoclave. To cool the autoclave down, usually the autoclave body is placed in a cooling bath of acetone or ethanol and dry ice. Adding solid ammonia, solidified by cooling in liquid nitrogen is an other option, which is necessary if glass tubes are used, since the glass tubes are sealed at high temperatures after filling. Liquid ammonia would evaporate too fast at those temperatures. Both filling methods only allow limited control of the pressure during synthesis, by the amount of added ammonia before the synthesis and the applied temperature during synthesis. Pressure control during synthesis is possible using high pressure pumps, which compress ammonia prior to reaction and control the pressure during synthesis. A system of two high pressure pumps with a pre-cooled compressor and supply pipe (258–263 K) guarantees the condensation of the gaseous ammonia, using only one pump allows the system to reach pressures of 5–30 MPa, since the pressure increases with increasing temperature (see Figure 3). The use of a second pump permits the variation of the pressure during synthesis and pressures of up to 450 MPa [3,59,60].

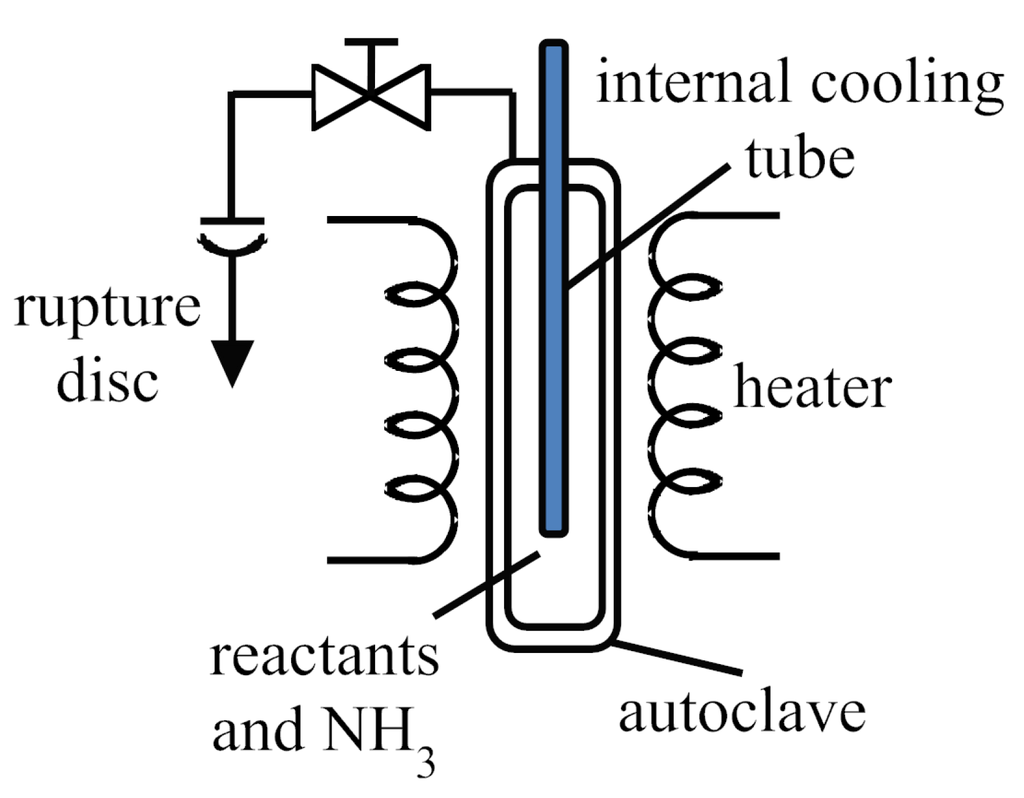

Concerning the temperature at least two different temperature zones inside the reaction chamber have to be achieved in order to obtain a temperature gradient. The temperature gradient contributes via convection to the mass transport of the dissolved species during synthesis and is essential for the crystallization process (see section Crystallization Process). The temperature gradient can be applied by different heaters around or integrated into the autoclave, by not heating or even cooling one part of the autoclave. Autoclave models with integrated cooling were also reported, see Figure 4 [3,39].

Figure 4.

Flow chart of an ammonothermal autoclave with integrated cooling and external heating [3].

3.1. Reaction Vessels

The first reaction vessels for supercritical syntheses were sealed thick-walled glass tubes with integrated mercury manometer, which withstand temperatures of up to 473 K and pressures of upto 15 MPa [29]. Sénarmont was the first to apply a counter-pressure to avoid explosion of the sealed glass tubes containing the reactants, by placing them inside water filled autoclaves [32]. Similar counter pressure systems are still in use for ammonothermal synthesis. Sealed glass, silver or gold ampoules are used as reaction vessels for ammonothermal synthesis, containing the starting materials and supercritical ammonia. To avoid explosion, the ampoules are placed in a steel autoclave, connected to a high pressure pump, which produces a counter-pressure of nitrogen inside the autoclave (see Figure 5). The counter-pressure should only be slightly lower than the pressure inside the ampoule. However, in order to simplify the handling the counter-pressure is usually higher than the pressure inside the ampoule. For supercritical conditions, the autoclave containing the ampoule is placed in a heater. In this way, pressures and temperatures of up to 280 MPa and 470 K for glass ampoules are realized, metal ampoules enable the application of higher temperatures [3]. Recently, a similar construction was used for large scale GaN crystal growth in a vessel with internal heating. The reaction is carried out in a welded capsule, containing the starting materials and supercritical ammonia. The capsule is coated directly by a heater, followed by a ceramic shell and an externally-cooled steel shell. The inner heater reaches temperatures of up to 1023 K at 600 MPa, while the temperature of the outer steel shell remains below 473 K, due to the insulating ceramic shell. The use of an internal heating allows the application of higher temperatures and higher pressures compared to autoclaves made of nickel based superalloys, additionally the use of conventional steel is less expensive in production and processing [39]. Nickel based superalloys, for example, Inconel 750 [6], Vacumelt ATS 340 [3], Inconel 718 [59] and Rene 41 [36] are used for the construction of high pressure autoclaves with external heating. Those superalloys almost resist corrosion in ammonobasic milieu up to temperatures of ∼873 K at ≥3000 MPa (Inconel 750) and can stand even ≤1123 K at ≤150 MPa (Rene 41) [62]. Autoclaves made of those alloys are loaded directly with the starting materials and ammonia and are heated up with an external direct heater. This explains the milder working conditions.

Figure 5.

Flow chart of an ammonothermal reaction setup using a glass or metal ampoule filled with ammonia and the reactants placed in a steel autoclave connected to a high pressure pump, applying a counter-pressure of nitrogen [3].

Depending on the reaction conditions, the use of a liner may be necessary. Ammonobasic conditions are usually less corrosive than ammonoacidic conditions. Thus, a nickel based superalloy as autoclave material is often sufficient. However, in ammonobasic conditions, nickel based alloys can also be affected and a supplementary liner can be useful. We have observed the formation of nickel compounds from the autoclave material at T ≥ 840 K with zinc or gallium as reactant. Indium metal used as reactant passed the autoclave material by diffusion along the grain boundaries and leads to the destruction of the autoclave. For ammonoacidic conditions, liners are used to protect the products from metal impurities originating from the autoclave material. Especially chromium and nickel impurities in the compounds or even chromium and nickel based compounds are observed. Precious metals are used as liner materials, particularly silver, gold and platinum, although the choice of liner material restricts the choice of the mineralizer. However, the formation of a nitride layer on the surface of the autoclave material at T ∼ 800 K in supercritical ammonia during synthesis, resulting in a hard surface of nitrides, seems to protect the autoclave material in some cases to a certain amount from corrosion [3].

According to the use of the autoclave, the inner geometry is constructed differently. Ammonothermal syntheses on a fundamental research level, investigating new compounds, synthesis routes and processes do not obligatory require special inner shapes of the autoclave. Only the starting materials, including mineralizer, are loaded into the autoclave in one of the two temperature zones, subsequently the formed products, the crystallization spot and the dependence on temperature and pressure are investigated. However, ammonothermal syntheses exploring the crystal growth usually use seed crystals and a feedstock of micro crystalline powder, both containing the same metal (mostly GaN or AlN but also metal amides, metal halides or pure metal) and placed in different temperature zones of the reaction vessel. The micro crystalline powder is diluted with the help of a mineralizer and transported to the seed crystals, where it deposits. In this way, large crystals are obtained. The epitaxial growth on the seed crystal can be heteroepitaxial on foreign substrate or homoepitaxial on native substrate. This method is suitable for large scale commercial synthesis of AlN and GaN [63]. Often a baffle is used, in order to optimize the heat and mass transport inside the autoclave, since it is capable of controlling the flow pattern in the system. Different baffle designs are used, depending on the transport direction in the system.

4. Crystallization Process

The ammonothermal synthesis corresponds, in its thermodynamical fundaments and many chemical aspects, to the well studied Chemical Vapor Transport. The definition of the Chemical Vapor Transport by Binnewies et al. applies on a fundamental level: “textita condensed phase, typically a solid, is volatilized in the presence of a [...] transport agent, and deposits elsewhere, usually in the form of crystals” [64]. For the ammonothermal method this means: A solid phase is dissolved in supercritical ammonia initiated by chemical reaction with the added mineralizer forming complex ions, the complex ions are transported into the crystallization zone and deposit there under reformation of the solid as micro crystalline powder or single crystals. Crucial for the transport is the solubility of the compound (≥3% [65]) and the presence of a gradient. In principle, the gradient may concern any state variable leading to a difference in solubility. Typically, temperature gradients are used in crystal growth due the most simple realization by applying two or more different heaters realizing different temperatures and consequently producing two or more different temperature zones inside the reaction vessel.

There are currently many research efforts in maximizing growth rates and crystal sizes and in minimizing defects and strain/bowing levels. However, there appears only very little work done in order to understand the reasons for the achieved improvements. Knowledge and understanding of the physical and chemical processes during ammonothermal crystal growth allows a controlled and efficient improvement of the crystal growth process. Due to the influence of various parameters, this process is very complex. Two groups of parameters can be distinguished: Chemical parameters like the solvent, the chemical nature and the concentration of nutrient and mineralizer, and thermodynamical parameters like the pressure, the temperature in dissolution and crystallization zone and the temperature gradient contribute to the crystal growth [5]. Over the last years, there have been some initial studies carried out clarifying the processes during ammonothermal synthesis and especially the formation mechanism of GaN from supercritical ammonia. The research efforts cover different points of both groups of parameters, yet the influence of most parameters are not well examined and require further intense research efforts.

By isolation of intermediate compounds, evaluation of crystallization and dissolution zone, and determination of solubility of Ga species, important information for the formation mechanism of GaN from supercritical ammonia are obtained. Additionally, spectroscopic data of the intermediate compounds were collected representing the base for future in-situ measurements for further exploration of the GaN formation mechanism [66,67]. Special optical cells for in-situ monitoring during ammonothermal process were developed [59,60,68]. A combination of the in-situ monitoring technology and preliminary work on intermediate compounds allows to obtain further information for a complete unravelment of the ammonothermal synthesis. In order to understand the role of applied temperature, temperature gradient and baffle design for an optimized transport and consequently for the crystal growth first theoretical 3-D simulations for the ammonothermal process were furnished, revealing a strong dependence of the flow pattern by the baffle shape. A positive inclination of the baffle leads to an upward directed jet stream through the baffle opening and vice versa. The baffle shape not only influences the flow pattern but also the temperature profile. These information may be used to control specifically the crystallization and the mass transport from dissolution to crystallization zone, and to avoid parasitic crystal growth [69].

4.1. Thermodynamical Parameters

Knowledge about thermodynamical parameters (temperatures, pressure and reaction time) during ammonothermal crystal growth is crucial to adjust the growth conditions. High pressure allows us to decrease the temperature so that comparatively mild conditions can be applied. Depending on the desired product, temperature and pressure have to be adapted. In general, high temperature and low pressure favors the formation of binary nitrides and low temperatures and high pressures the stabilization of ternary amides, ternary ammoniates or mixed ternary compounds. Regarding the temperature, different aspects have to be respected: the dissolution temperature, the growth temperature and the temperature gradient. Generally speaking, increasing temperature and pressure yields a higher solubility of the starting materials, but the nature of the reactants and the products’ solubility (negative or positive temperature dependance) have to be considered. For the transport of the mobile species, a gradient, typically in temperature, is necessary, determining the transport of the mobile species in solution and the kinetics. The transport can be performed dominated by convection or by diffusion, with convection by a gradient being much faster. A vertical gradient, typically meaning a vertical position of the reaction vessel, favors the transport via convection, while a horizontal position minimizes almost entirely the transport to diffusion, which leads to much slower transport rates. However, higher transport rates often yields higher defect densities. Thus, the kinetics have to be adapted according to the advantages of a high growth rate and the disadvantages of increased defect densities [5,7]. A temperature gradient can easily be applied by different heaters, by the lack of a heater on some parts of the reaction vessel or by an induced cooling.

The influence of the thermal decomposition of ammonia obeying reaction Equation (1) during ammonothermal synthesis at temperatures up to 873 K is expected to be small. H2 formed from the dissociation or as by-product of chemical reactions during dissolution or recrystallization has been shown to diffuse through the autoclave wall [3,70]. Jacobs and Schmidt concluded that equilibrium Equation (1) has to lie more on the left side, as they could not detect any N2 after reaction and their autoclaves would not have stand pressures as high as the extrapolated values [3].

4.2. Chemical Parameters

Chemical parameters have previously been studied for solvothermal methods using other solvents than ammonia. We will limit ourselves to few examples: For the basic hydrothermal synthesis of wurtzite-type ZnO (starting materials: Zn(NO3)2(aq), NH4OH in H2O at ambient pressure and 373 K) the mechanism starts with dissolution of the ZnO nutrient by means of a mineralizer forming different soluble intermediate species [ZnOOH]−, [Zn(OH)4]2− and [ZnO2]2−, which occur in different concentrations depending on OH− concentration and temperature and the solid ϵ-Zn(OH)2, which crystallizes as solid intermediate [44]. h-ZnO was shown to form via the crystalline intermediate ϵ-Zn(OH)2, where the conversion takes place interior solid ϵ-Zn(OH)2. Simultaneously, on the outer surface layers exposed to the solution, h-ZnO is formed directly from ϵ-Zn(OH)2, or exchanged with solution. ϵ-Zn(OH)2 crystallizes from soluble species ([Zn(OH)(HO); ) [12]. A possible ZnO formation mechanism for the growth on a ZnO seed crystal is shown in reaction Equation (2), while reaction Equation (3) shows the solid-solid transformation from spontaneously nucleated ϵ-Zn(OH)2 to h-ZnO.

Extensive research has also been done on the mechanism during hydrothermal growth of zeolites. It has been shown, e.g., that the dissolved species taking part in the crystallization process are small and of simple structure. The growth from larger and more complex species is too time consuming and has a higher defect probability due to different docking possibilities on the crystal surface. A high defect concentration may slow down or even entirely stop the crystal growth [71]. [Si(OH)3O]− and [Al(OH)4]− monomers are taken to represent the building species in zeolite crystal growth [71,72].

During ammonothermal synthesis, various ionic species may occur. The nature of these species is strongly related to the acidity of the system. Three types of milieus arise, evoked by the used starting materials: ammonoacidic (NH present), ammononeutral (e.g., NO present) and ammonobasic (NH present). The milieu determining ions (NH and NH) derive from the acidic or basic mineralizer and the autoprotolysis of ammonia. Mineralizers added to the reactants are applied to establish a defined milieu. Sometimes a tiny amount of a co-mineralizer (e.g., alkali metal halides) is added to activate the reaction. Although the role of mineralizers in chemical reactions is not always known, they are used in ammonothermal synthesis [66,67] as well as in various further methods (gas phase transport reactions [64], hydrothermal synthesis [4], synthesis in liquid ammonia [54,73,74]). Similar applies to the so-called co-mineralizers. The mineralizers fulfill different functions in the growth process: to convey the solubility of the starting material by inducing the formation of soluble and consequently mobile species, to enable and enhance the formation of new chemical bonds and compounds, and finally to detach from the desired compound to be able to act like a catalyst (especially in case of growth of binary compounds). The importance of the choice of the mineralizer can be seen in the fact that they determine the transportation direction of the product in the gradient within the autoclave (see paragraph Intermediate Species controlling Solubility and Growth Rates).

4.2.1. Ammonobasic Systems

Typically, alkali metal amides A(1)NH2, alkali metals or alkali metal azides are use as ammonobasic mineralizers. Ammonia reacts with alkali metals and alkali metal azides according to reactions Equations (4) and (5) to form NH, such that the solution turns basic. The same applies for alkaline-earth metals and some rare-earth metals. However, alkali metal amides and azides are easier to handle due to their powder shape and lower reactivity compared to the metal bulk material. Alkali metal amides are favorable if no formation of hydrogen or additional nitrogen pressure is desired.

During ammonothermal synthesis, in analogy to the experience from hydrothermal research, it is expected that the metal dissolves by help of the mineralizer, forming intermediate species of the type [B(NH2)], possibly also as complex imides or amide imides. Those complex anions are transported in the supercritical ammonia from the dissolution to the crystallization zone, where the crystallization takes place.

Ammonobasic mineralizers like KNH2 are known from syntheses of binary metal amides in liquid ammonia for a long time. The latter binary amides are formed from metal salt solutions in liquid ammonia with KNH2 as a little soluble precipitate. An example for this synthesis is the formation of Cd(NH2)2 from Cd(SCN)2 in liquid ammonia with KNH2 as mineralizer. The application of alkali metal amides as mineralizers only work, if there are no ternary alkali metal amides formed. Often with small amounts of mineralizer binary amides, with large amounts ternary amides are obtained. Beryllium and zinc always form ternary amides [74].

There is a large number of ternary amides of two metals synthesized in supercritical ammonia from the metals (see paragraph Ternary Amides) at comparatively high pressures and low temperatures. Ternary amides decompose to imides and further to nitrides, under release of ammonia. Before the formation of pure nitrides is completed, metal hydrides and mixed hydride nitrides may be obtained as shown in the systems Th/H/N [33], Zr/H/N [75] and Ce/H/N [76], especially at temperatures below the formation temperature for pure nitrides.

It is also known that various bulk binary nitrides are formed from the metal in supercritical ammonia using an ammonobasic mineralizer (see paragraph Nitrides), from technological point of view, the most interesting examples currently being the semiconductors GaN [77] and AlN [78]. Recent research in ammonobasic conditions indicates that the binary nitrides are formed via ternary amides functioning as intermediate species [67,79] following the assumed reaction Equation (6). K[Ga(NH2)4] and Na[Ga(NH2)4] convert to h-GaN at higher temperatures [80,81]. For GaN synthesis from Ga with LiNH2 in supercritical ammonia, Li[Ga(NH2)4] was proposed as possible intermediate compound [79] and was indeed recently found to crystallize in two modifications in the hot zone of the autoclave [67]. In the system Ga/Na/NH3 two ternary amides are known, namely Na[Ga(NH2)4] [81] and Na2[Ga(NH2)4]NH2 [67,82] to form under ammonothermal conditions. The former predominates at high pressures, whereas the latter is obtained mainly at lower pressures. With potassium only one solid compound K[Ga(NH2)4] [80] and an intriguing liquid “KGa(NH)NH3” were reported [65]. Decomposition of Na[Al(NH2)4] under release of ammonia at temperatures below 373 K is known to proceed via a liquid compound. An intermediate “NaAl(NH2)2(NH)” was proposed according to volumetric measurements of released ammonia. Further heating leads to a mixture of AlN and NaNH2 [81]. Knowledge about those intermediate compounds is not only interesting for the formation mechanism, but also for understanding the temperature dependance of the solubility of GaN in supercritical ammonia.

4.2.2. Ammonoacidic Systems

Ammonothermal synthesis in ammonoacidic milieu is a powerful method to obtain ammoniates, nitrides and even amides. The effect of ammonacidic milieu is due to the presence and increased concentration of ammonium ions NH. Ammonoacidic milieu is well known from syntheses in liquid ammonia [54,73], where, e.g., NH4I is used as ammonoacidic catalyst for the precipitation of Mg(NH2)2 from magnesium according to the following reaction [73]:

Typical ammonoacidic mineralizers comprise ammonium halides (X = F, Cl, Br, I) and metal halides (X = F, Cl, Br, I; B = for example, Al, Ga, Fe, Zn).

Several aluminum halide ammoniates are known [Al(NH3)5 (X = F [83], Cl, Br, I [84]), obtained from different synthetic approaches. Ammoniates of aluminum halides are supposed to represent intermediate compounds in the ammonoacidic AlN synthesis. Analogously, there are ammoniates from gallium halides with different amounts of ammonia molecules per gallium kown. In GaN hydride or halide vapor phase epitaxy these occur as volatile precursors, accomplishing the gallium transport to the crystallization zone.

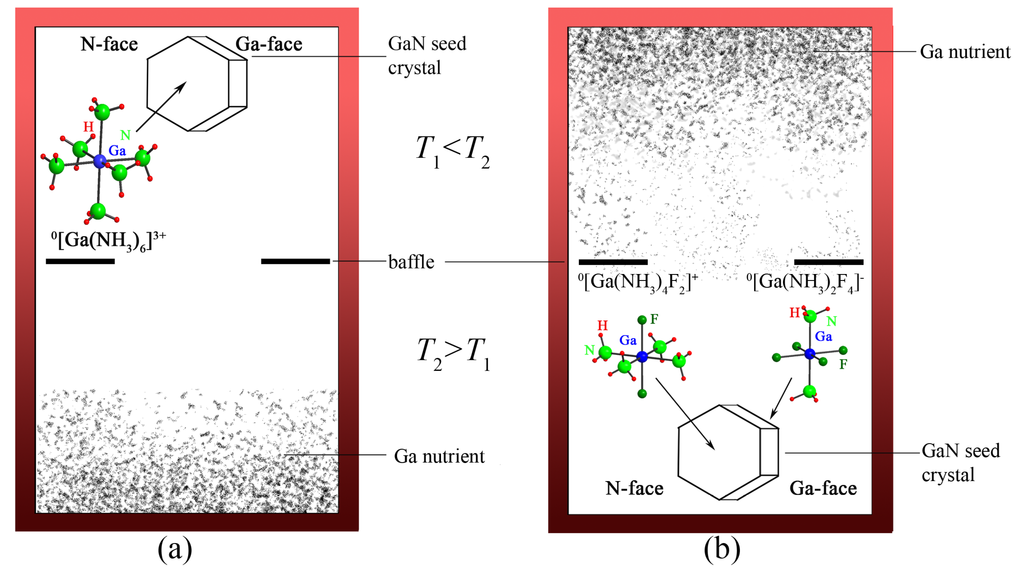

In liquid ammonia gallium halides form hexammoniates such as [Ga(NH3)6]Br3 · NH3 and [Ga(NH3)6]I3 · NH3 [66,85]. Those ammoniates contain octahedrally surrounded Ga3+ forming positively charged complex ions [Ga(NH3)6]3+, which may represent the mobile Ga-containing species in solution. At higher temperature and pressure gallium metal reacts with ammonium halides NH4x (X = F, Cl) to the ammoniates [Ga(NH3)5Cl]Cl2 or Ga(NH3)3F3 and GaN [66]. Obtaining [Ga(NH3)5Cl]Cl2 and Ga(NH3)3F3 during ammonothermal crystal growth of GaN next to GaN confirms the assumption of their role as intermediate species in the GaN synthesis from supercritical ammonia. [Ga(NH3)5Cl]Cl2 contains octahedral units [Ga(NH3)5Cl]2+, which may again represent the Ga-transporting species in solution. In solid Ga(NH3)3F3 gallium occurs in two different species, namely [Ga(NH3)4F2]+ and [Ga(NH3)2F4]−. Thus, in solution cationic [Ga(NH3)4F2]+ and anionic [Ga(NH3)2F4]− complex ions may be present. This observation may be the key to the enravelment of solubility and crystallization processes during GaN crystal growth.

4.2.3. Intermediate Species controlling Solubility and Growth Rates

There is little known about the solubility of group III nitrides in supercritical ammonia. We believe it to strongly depend on the present intermediate compounds and thus on mineralizer, temperature and pressure. In the system Ga/NH3 a retrograde solubility for GaN in supercritical ammonia using KNH2 as mineralizer was found, meaning that the solubility of GaN decreases with increasing temperature. This results from experiments, where a Ga nutrient was placed at the midpoint of an autoclave, presenting a temperature gradient with a hot and a cold zone, and observing the crystallization spot are shown. At T K, GaN crystallizes in the hot zone [65,67,86]. An equivalent behavior was observed for AlN, which can be formed from Al and KNH2 probably via the intermediate K[Ga(NH2)4] [78]. This observation might be attributed to dynamic temperature dependant equilibria of different potassium amides and imides of gallium as intermediate species. K[Ga(NH2)4], with tetrahedrally coordinated Ga, is known from synthesis in liquid ammonia [80]. At 853 K and 100 MPa we obtain from Ga and KNH2 pure h-GaN. At 733 K and 50 MPa the same starting materials yield a liquid with the composition “KGa(NH2)2(NH)”, which was earlier reported as “KGa(NH)NH3” [65]. This liquid is supposed to behave similarly to the intermediate “NaAl(NH2)2(NH)”, which occurs during thermal decomposition of Na[Al(NH2)4] under release of ammonia (see paragraph Ammonobasic Systems) [81]. The coordination of gallium in this liquid is not yet known. Initial results assume a similar behavior for the system Na/Ga/NH3, where the compounds Na[Ga(NH2)4] [81] and Na2[Ga(NH2)4]NH2 [67,82] are known and the existence of an equivalent liquid phase is possible.

In ammonoacidic milieu, negative and positive temperature dependance of the solubilities are observed. For the temperature range 473–823 K GaN shows a positive temperature dependance of the solubility in ammonoacidic milieu, using NH4X (X = Cl, Br, I) as mineralizer [87,88]. This is observed for the syntheses of c-GaN and h-GaN with Ga metal or GaN as nutrient [88]. Additionally, there are two examples of GaN manifesting a negative solubility in ammonoacidic milieu reported: A change in the temperature dependance of the solubility of GaN from positive to negative, using NH4Cl has been noticed at temperatures above 923 K with pressures of 110 MPa [62]. Also, a negative solubility has been revealed in the temperature range 823–923 K using NH4F as mineralizer [46]. Up to now NH4F and NH4Cl are the only acidic mineralizers known to evoke a negative solubility for GaN and consequently the crystallization in the hot zone.

Different growth rates for the negatively charged (000) N-face and the positively charged (0001) Ga-face of the GaN seed crystal were observed. It is assumed that the nature of the intermediate species determines the predominant growth on one of the faces. Thus, the existence of positively charged complex ions such as [Ga(NH3)6]3+ and [Ga(NH3)5Cl]2+ may explain a higher growth rate on the negatively charged face (see Figure 6a) [87]. Furthermore, a growth on both c-faces, the negatively charged N-face and the positively charged Ga-face, is observed using NH4F as mineralizer [46]. The presence of both cationic [Ga(NH3)4F2]+ and anionic [Ga(NH3)2F4]− complex ions as intermediates in solution, which should deposit each on the opposite charged face of the GaN seed, may explain this phenomenon (see Figure 6b). Consequently, the solubility, the crystallization zone and the deposition on the seed crystal of group III nitrides dependent strongly on the formed intermediate compounds.

Figure 6.

Schematic crystallization of GaN on a seed crystal under ammonoacidic conditions. (a) by cationic [Ga(NH3)4F2]+ and anionic [Ga(NH3)2F4]− intermediates, (using NH4F as mineralizer), manifesting a negative temperature dependance of the solubility of GaN; (b) by cationic [Ga(NH3)6]3+ intermediates (using NH4Br or NH4I as mineralizer), manifesting a positive temperature dependance of the solubility of GaN.

5. Compounds from Ammonothermal Synthesis

5.1. Ammoniates of Metal Halides

Ammoniates of metal halides can be grown from metal halides or from the metal and ammonium halides in supercritical ammonia (see Table 3). Such ammoniates of metal halides are suggested to represent crystallized intermediate compounds during ammonoacidic III-nitride growth [66], since ammoniates are expected to have a high solubility in supercritical ammonia (see paragraph Ammonoacidic Systems). In liquid and supercritical ammonia, one typically obtains the ammoniates with highest ammonia content known, for example, [Al(NH3)6]I3 · NH3 [89], [Al(NH3)5Cl]Cl2, [Al(NH3)5Br]Br2, [Al(NH3)5I]I2 [84], [Ga(NH3)6]I3 · NH3, [Ga(NH3)6]Br3 · NH3, [Ga(NH3)5Cl]Cl2, Ga(NH3)3F3 [66], [Fe(NH3)6]I2 and [Mn(NH3)6]I2 [90].

Other synthesis methods leading to metal ammoniates are reaction of metal halides with gaseous ammonia or reaction of metals with ammonia donors (e.g., NH4HF2, NH4Cl, NH4Br) producing compounds such as Mg(NH3)2Cl2, Mg(NH3)2Br2, Mg(NH3)2I2 [91], [Zn(NH3)4]Br2, [Zn(NH3)4]I2 [92], Ga(NH3)2F3 [93], Fe(NH3)2Cl2, [Fe(NH3)6]Cl2, [Fe(NH3)6]Br2 [94,95,96] and [B(NH3)5Cl]Cl2 with B = Al [84], Cr [97], Co [97,98], Rh [97,99], Ru [97], Os [97]. Further ammoniates may be obtained by thermal decomposition of higher ammoniates. The step-wise ammonia release on heating of [Fe(NH3)6]Cl2 via Fe(NH3)2Cl2 and amorphous Fe(NH3)Cl2 to ϵ-Fe3N illustrates the formation of different metal halide ammoniates by thermal decomposition [94,95,96].

Table 3.

Conditions for the ammonothermal crystal growth of metal halide ammoniates and of ammoniates of metal amides.

| Compound | Reactants + mineralizer | T/K | p/MPa | t/d | References |

|---|---|---|---|---|---|

| Al(NH3)2F3 | AlN + NH4F | 673 | – | 3 | [83] |

| [Al(NH3)5Cl]Cl2 | AlCl3 | 603 | – | 3–6 | [84] |

| [Al(NH3)5Br]Br2 | AlBr3 | 623 | – | 3–6 | [84] |

| [Al(NH3)5I]I2 | AlI3 | 673 | – | 3–6 | [84] |

| [Al(NH3)6]I3 · NH3 | Al + NH4I | 393 | 9 | 1 | [89] |

| Ga(NH3)3F3 | Ga + NH4F | 753 | 238 | 3 | [66] |

| [Ga(NH3)5Cl]Cl2 | Ga + NH4Cl | 853 | 95 | 1 | [66] |

| [Ga(NH3)6]Br3 · NH3 | GaBr3 | 197–373 | ≤6 | – | [66] |

| [Ga(NH3)6]I3 · NH3 | GaI3 | 197–373 | ≤6 | – | [66] |

| [Mn(NH3)6]I2 | Mn + I2 | 673–873 | 600 | ≤7 | [90] |

| [Fe(NH3)6]I2 | Fe + I2 | 673–873 | 600 | ≤7 | [90] |

| Cs3La(NH2)6 · NH3 | Cs + La | 490–570 | 400–600 | 31–103 | [100] |

| Cs4La(NH2)7 · NH3 | Cs + La | 490–570 | 400–600 | 31–103 | [100] |

| BaAl2(NH2)8 · 2NH3 | Al + BaAl2 | 823 | 245 | 29 | [101] |

| InF2(NH2) · NH3 | InN + NH4F | 673 | 220 | 1 | [83] |

5.2. Binary Amides and Deuteroamides

Several binary amides were obtained from the metals dissolved in liquid ammonia at ambient temperature. In 1891, Joannis had already discovered liquid ammonia as useful solvent to obtain single crystals of metal amides. He obtained colorless NaNH2 crystals from a solution of Na in liquid ammonia [102]. Europium, ytterbium, alkali and alkaline-earth metals dissolve in liquid ammonia at ambient temperature and form intensely blue or bronze colored solutions, if in higher concentration [103]. The solutions are metastable and react to metal amides in form of colorless crystals, hydrogen and a colorless solution [104]. The formation of amides can be enhanced by higher temperatures, higher pressures, exposure to light or addition of a catalyst, e.g., elemental platinum or Fe(II)-compounds like iron oxide [49,73,74,105,106].

5.2.1. Alkali Metal Amides

The alkali metal amides LiNH2 [107], NaNH2 [108], KNH2, RbNH2 and CsNH2 [73] can be obtained from the metals in liquid ammonia at ambient temperature. The presence of a catalyst (platinum net) or exposure to light enhances the reaction rate. The reaction duration depends on the solubility of the metal in liquid ammonia, which rises with increasing atomic weight of the alkali metal. Higher temperatures accelerate the reactions considerably. For KNH2, RbNH2 and CsNH2 the reaction can be carried out within a few hours even at low temperatures (T ≤ 273 K), usually yielding micro crystalline powders [106]. The formation of LiNH2 from lithium metal and liquid ammonia at ambient temperature takes 8 days or more [73,107]. At 400 K and 20 MPa the reaction can be carried out within one day without any catalyst [109], after seven days at 583 K and 71 MPa crystals were obtained [1]. NaNH2 shows similar behavior [108]. To shorten the reaction time and to grow alkali metal amide crystals, it is favorable to work under ammonothermal conditions (see Table 4) [1].

Table 4.

Conditions for the ammonothermal synthesis of binary amides and deuteroamides (synthesized using ND3).

| Compound | Reactants + mineralizer | T/K | p/MPa | t/d | Sample | References |

|---|---|---|---|---|---|---|

| LiND2 | Li | 473 | 304 | – | m.c. | [110] |

| NaNH2 | Na | 393 | ≤10 | 14 | s.c. | [111] |

| NaND2 | Na | 423–473 | 405 | 8 | m.c. | [111] |

| KND2 | K | 320 | ≤10 | 4 | m.c. | [112] |

| CsNH2 | Cs | 423 | 180 | 2 | m.c. | [113] |

| CsND2 | Cs | 423 | 180 | 2 | m.c. | [113] |

| Be(NH2)2 | Be | 633 | 253 | 5 | s.c. | [2] |

| Be(NH2)2 | Be + NaN3 | 643 | 355 | 20 | s.c. | [114] |

| Mg(NH2)2 | Mg | 613–653 | 10 | 2 | m.c. | [115] |

| Mg(NH2)2 | Mg + NaN3 | 523 | 253 | 2–4 | s.c. | [1,2] |

| Mg(NH2)2 | Mg3N2 | 633–648 | 1 | ≤7 | m.c. | [115] |

| Mg(NH2)2 | Mg + NaNH2 | 623–653 | 212–345 | 2–4 | s.c. | [115] |

| Ca(NH2)2 | Ca | 370 | 6 | 14 | s.c. | [116] |

| Sr(NH2)2 | Sr + K | 625 | 550 | 7 | s.c. | [117] |

| Sr(ND2)2 | Sr | 625 | 550 | 9 | m.c. | [117] |

| Ba(NH2)2 | Ba | 533 | 324 | 3 | s.c. | [1] |

| Ba(NH2)2 | Ba | 398 | ≤20 | 120 | s.c. | [118] |

| Mn(NH2)2 | Mn + Na2[Mn(NH2)4] | 393 | 10 | 10 | s.c. | [119] |

| Zn(NH2)2 | Zn + Na2[Zn(NH2)4]·0·5NH3 | 523 | 380 | 60 | s.c. | [119] |

| La(NH2)3 | La + KNH2 | 623 | 405 | 6 | s.c. | [120] |

| Sm(NH2)3 | Sm | 403–493 | 200–500 | – | – | [121] |

| Eu(NH2)2 | Eu + K | 523–673 | 500–557 | 7–9 | s.c. | [122] |

| Eu(NH2)2 | Eu | 323 | ≥0.9 | 3 | m.c. | [123] |

| Yb(NH2)3 | Yb | 453 | 507 | 32 | m.c. | [123] |

s.c. means single crystal, m.c. micro crystalline.

Although crystals of the heavier alkali metal amides were obtained from liquid ammonia, the atomic positions of hydrogen could not be determined with X-ray diffraction. This stems back to the low scattering contribution of hydrogen in combination with these metals. Neutron diffraction of the corresponding deuteroamides allows determination of the atomic position for hydrogen. Under ammonothermal conditions, deuteroamides can be grown with small amounts of expensive ND3, while getting fast a comparatively large yield per synthesis. The exact atomic position provided the base for the interpretation of the interesting electrostatic interactions between the protons and the cations, due to an asymmetric distribution of the charge on NH [110,111,117,124,125]. An increasing interaction with rising charge density of the cation was observed, i.e., for the amides of the lighter alkali and alkaline-earth metals (Li, Na, Be, Mg) those interactions are stronger than for the heavier ones. In the amides of Li, Na, Be and Mg, the anions form the motif of a cubic closed packing with the cations occupying tetrahedral holes. The resulting structures show an occupation of specific tetrahedral holes within the anion substructure by the cations and can even lead to layered structures similar to LiOH [126]. In lithium amide, Li occupies alternatingly 3/4 of the tetrahedral holes within one layer and 1/4 within the next. Due to strong proton–cation interactions, the anion is hindered in vibration. For the heavier metals the coordination number increases to six for K, Rb, Ca and Sr and eight for Cs. The interatomic interactions decrease resulting in the realization of several modifications, depending on the vibrational and rotational freedom of the amide ions influenced by temperature, as can be seen in the case of KNH2 [3,124,125,127,128].

Alkali metal amides are important starting materials in ammonothermal synthesis, due to their application as ammonobasic mineralizers. NaNH2 and KNH2 are the most used ones, since they are less reactive than RbNH2 and CsNH2, but show a higher solubility as LiNH2. The solubility of alkali metal amides in liquid ammonia increases with increasing atomic weight. LiNH2 is only very poorly soluble in liquid ammonia, NaNH2 is poorly soluble (0.144 g/100 g NH3 at 253 K), KNH2 is well soluble (65.8 g/100 g NH3 at 241 K), RbNH2 is very soluble (several hundred grams/100 g NH3 at 241 K) and CsNH2 is little less soluble as RbNH2 [73,129].

5.2.2. Alkaline-Earth Metal Amides

The alkaline-earth metal amides Mg(NH2)2, Ca(NH2)2, Sr(NH2)2 and Ba(NH2)2 are obtained from the metals in liquid ammonia at ambient temperature with reaction times of two days (Ba(NH2)2), eight days (Sr(NH2)2), four months (Ca(NH2)2) [130] and up to 1.5–2 years (Mg(NH2)2) [115]. Mg(NH2)2 and Ba(NH2)2 crystals, produced in this way, were not suitable for X-ray diffraction and no Be(NH2)2 could be obtained. For the heavier alkaline-earth metals (Ca, Sr, Ba) temperatures and pressures somewhat below the critical point of ammonia are sufficient to obtain well crystallized amides and deuteroamides. For the synthesis of Ca(NH2)2, Ca(ND2)2, Sr(NH2)2 and Sr(ND2)2 370 K and 6 MPa were applied for two weeks starting from the metal and ammonia [116], Ba(NH2)2 crystals were obtained at 398 K and ≤20 MPa after four months [118]. Nevertheless, working under ammonothermal conditions reduces the reaction time considerably and micro crystalline Ba(NH2)2 and Sr(NH2)2 can be obtained from the respective metals in supercritical ammonia after 2 days at 573 K and 60 MPa. Increasing the reaction conditions for Mg(NH2)2 from ∼0.09 MPa and ambient temperature to ∼10 MPa and 613–653 K reduces the reaction time from 1.5–2 years to two days and forms a micro crystalline product suitable for powder X-ray diffraction [115]. Mg(NH2)2 crystals were obtained from Mg metal under ammonobasic conditions (using NaNH2 or NaN3 as mineralizers) at 523–653 K and 10–345 MPa [1,2,115]. The reaction of Mg3N2 at elevated temperatures of 633–648 K and NH3 pressure of 1 MPa also yields micro crystalline Mg(NH2)2 [115]. First synthesis of Be(NH2)2 proceeded under ammonothermal conditions: Single crystals were obtained from the reaction of beryllium metal and ammonia with NaN3 as mineralizer at 643 K and 355 MPa after 20 days [114].

5.2.3. Lanthanum Amide, Samarium Amide, Europium Amide and Ytterbium Amide

Apart from Yb(NH2)3 [123] and Sm(NH2)3 [121], La(NH2)3 [120] is the only binary trivalent rare-earth metal amide so far. Colorless single crystals are obtained from the reaction of lanthanum metal and potassium (molar ratio 80:1) in supercritical ammonia at 623 K and 405 MPa after six days. The use of a mineralizer is crucial for the crystal growth, without only micro crystalline powder is produced. Using NH4I as mineralizers leads to smaller crystals than presented for the reaction in presence of the potassium mineralizer [120,131]. Sm(NH2)3 was obtained from samarium metal and potassium (molar ratio 23:1) in supercritical ammonia at 403–493 K and 200–500 MPa as micro crystalline powder [121]. A solution of europium in liquid ammonia already forms micro crystalline EuII(NH2)2 at 323 K and ≥ MPa. Increasing the temperature and pressure to 523–673 K and 500–557 MPa and using optionally potassium as mineralizer leads to dark red crystals. The amount of mineralizer is crucial for the formation of the binary amide, since two ternary amides, namely K[EuII(NH2)3] and K3[EuIII(NH2)6], can be obtained in the same temperature and pressure range [122,123]. There are two binary ytterbium amides known, Yb(NH2)2 and Yb(NH2)3, which were so far only obtained as micro crystalline powders. Yb(NH2)2 was prepared from ytterbium metal in liquid ammonia at ambient temperature within some hours and forms with ammonia Yb(NH2)3, already before all metal has reacted to Yb(NH2)2 [123]. Nearly pure Yb(NH2)3 was obtained from ammonothermal conditions (453 K, 507 MPa, 32 days), however, no successful crystal structure determination for Yb(NH2)3 was presented so far [123].

5.2.4. Transition Metal, Group III and Group IV Metal Amides

There are various synthetic methods leading to binary transition metal amides. Some transition metal amides precipitate from metal salt solutions in liquid ammonia in presence of KNH2, e.g., Cd(NH2)2 can be obtained from Cd(SCN)2 [74,132]. Earlier, binary metal amides were obtained from the reaction from the metal with gaseous or liquid ammonia or of a metal ethyl compound with ammonia, e.g., Zn(NH2)2 [133]. As a result of these synthesis techniques conducted at comparably low temperatures, the products are often amorphous or poorly crystallized. Under ammonothermal conditions, such poorly crystallized or amorphous binary amides can be recrystallized in form of single crystals or well crystallized powders. Alternatively, they yield from the metal in presence of a mineralizer under ammonothermal conditions: Amorphous zinc amide can be recrystallized at 723 K and 30.4 MPa [1]. Zinc amide was first crystallized under ammonothermal conditions, subsequently the crystal structure was determined. Crystals were obtained from zinc powder and ammonia with Na2[Zn(NH2)4]· 0.5 NH3 as mineralizer at 523 K and 380 MPa [119]. The analogous reaction of Mn and ammonia at 393 K and 10 MPa (slightly lower than the critical pressure) using Na2[Mn(NH2)4] as mineralizer yielded Mn(NH2)2 [119].

Binary group III amides are potential precursors during ammonothermal synthesis of group III nitrides. However, the correctness of the reported formula B(NH2)3 (B = B, Al, Ga, In) was questioned or could not be reproduced. The lack of crystal structure data for these compounds hinders an unequivocal chemical assignment. B(NH2)3 obtained from BCl3 or BBr3 with NH4Cl in liquid ammonia [134] is suspected to represent polymeric B(NH) (see paragraph Imides, Nitride Imides, Nitride Amides and Amide Azides) [135]. The reaction of AlBr3 and KNH2 in liquid ammonia did not yield Al(NH2)3, but a mixed polymeric aluminum amide imide [Al(NH)(NH)] (see paragraph Imides, Nitride Imides, Nitride Amides and Amide Azides) [135,136,137]. The reaction of A(1)[Ga(NH2)4] with NH4Cl in liquid ammonia at 237 K yields an amorphous product, with the proposed formula Ga(NH2)3. Due to the lack of diffraction data no crystal structures are proposed, although the composition was determined by chemical analysis [80]. Polymeric gallium imide [Ga(NH] was reported from the reaction of [Ga(NMe2)3]2 with liquid ammonia in reflux for 8 h (see paragraph Imides, Nitride Imides, Nitride Amides and Amide Azides) [135].

In(NH2)3 crystals were obtained from KNH2 and InI3 or K3In(NH2)6 in liquid ammonia after one day. Several ternary alkali metal indium amides are known from snythesis in liquid ammonia, e.g., Li3In(NH2)6, K2In(NH2)5, K3In(NH2)6 [138]. However, since no structural information on these compounds is available, the compositions might be questioned.

Si(NH2)4 is obtained from SiCl4 in liquid ammonia at T 273 K and decomposes at T ≥ 373 K to Si(NH)2 [139,140]. Again, no crystal structure data for Si(NH2)4 and Si(NH)2 are reported due to the lack of crystalline products. The chemical nature of the compounds for now remains to be proven.

5.3. Ternary Amides

There were various ternary amides of the formulas A(1)A(1), A(1)A(2), A(1)B/R (A(1) = alkali metal, A(2) = alkaline-earth metal, M = transition metal, R = rare-eart metal, B = main group metal; n = 1, 2, 3; m = 1, 3, 7) obtained from liquid or supercritical ammonia. Usually, they contain two different metals, from which at least one is an alkali or alkaline-earth metal. Examples for ternary amides were reported from syntheses in liquid ammonia, e.g., A(1) (with A(1) = Na, K, Cs) [81,141], Na2Al(NH2)5 [82], Na[Ga(NH2)4] [81], KBe(NH2)3 [142], RbBe(NH2)3 [142], Li[Al(NH2)4] [143], α-K[Al(NH2)4] and β-K[Al(NH2)4] [144]. By increasing temperature and pressure the list of ternary amides was extended and the structure determination often was possible (see Table 5, Table 6 and Table 7), since crystal growth was realized only under ammonothermal conditions, e.g., for Na2[Ga(NH2)4]NH2 [67,82]. Such compounds are expected to exhibit significantly higher solubilities in supercritical NH3. Therefore, they are suggested as intermediates formed from the reactant and the mineralizer during nitride crystal growth of, for example, GaN. The isolation and crystallization of such compounds sheds light on the formation mechanism of the nitride crystal growth.

For the preparation of ternary alkali and alkaline-earth metal amides some tendencies has been established, which can often also be applied to other ternary amides. Thus, it is recommendable to use a surplus of the less soluble metal. In general, alkali metals possess a higher solubility in ammonia than alkaline-earth metals. The same applies for amides of the heavier metals compared to their lighter homologues. The thermal stability of ternary amides decreases with increasing charge density of the cations. At higher temperatures nitrides of the A(2), M, R or B metal and binary amides of the alkali metals are formed. The water and oxygen sensitivity of the ternary amides increases with increasing atomic weight of the metal. In the case of ternary alkali metal alkaline-earth metal amides they depend more of the alkali metal than of the alkaline-earth metal [3].

Table 5.

Conditions for the ammonothermal synthesis of alkali metal alkaline-earth metal ternary amides and coordination numbers of the metal atoms by amide ions.

| Compound | CN A(1), A(1)/A(2) by NH | Reactants | T/K | p/MPa | t/d | References |

|---|---|---|---|---|---|---|

| K2Li(NH2)3 | 6, 4 | K + Li 2:1 | 333 | 70 | 60 | [145,146] |

| KLi(NH2)2 | a, 4 | K + Li 1:1 | 333–473 | 70–210 | 4 | [145] |

| KLi3(NH2)4 | 8, 4 | K ≤ Li | 333–473 | 70–210 | 4 | [145] |

| KLi7(NH2)8 | 8, 4 | K ≤ Li | 333–473 | 70–210 | 4 | [145] |

| K2[Mg(NH2)4] | 7, 4 | K + Mg | 423 | 200 | 3 | [147] |

| Rb2[Mg(NH2)4] | 7, 4 | Rb + Mg | 423 | 200 | 3 | [147] |

| Cs[Mg(NH2)4] | 9/11, 4 | Cs + Mg | 415 | 200 | 2 | [148] |

| NaCa(NH2)3 | 6, 6 | Na + Ca 5:1–1:2 | 740–773 | 500 | 60 | [149,150] |

| KCa(NH2)3 | 6, 6 | K + Ca 1:1 | 573 | 500 | 20 | [151] |

| RbCa(NH2)3 | 8, 6 | Rb + Ca 1:2–3:1 | 573 | 500 | 17 | [152] |

| CsCa(NH2)3 | 8, 6 | Cs + Ca | 573–773 | 500–600 | 10–35 | [153] |

| KSr(NH2)3 | 6, 6 | K + Sr 1:1 | 570 | 500 | 7 | [149] |

| RbSr(NH2)3 | 6, 6 | Rb + Sr 3:1–1:1 | 540–573 | 800 | 8 | [150] |

| CsSr(NH2)3 | 8, 6 | Cs + Sr | 573–673 | 500–600 | 14–55 | [153] |

| KBa(NH2)3 | 6, 6 | K + Ba 3:1–1:1 | 540–573 | 500 | 7 | [150] |

| RbBa(NH2)3 | 6, 6 | Rb + Ba 3:1–1:1 | 540–573 | 500 | 7 | [150] |

| CsBa(NH2)3 | 8, 6 | Cs + Ba | 473 | 500 | 11 | [154] |

| Na2Sr3(NH2)8 | 6, 6 | Na + Sr 1:2 | 570 | 500 | 4 | [149] |

a Coordination number uncertain cf. [3].

Table 6.

Conditions for the ammonothermal synthesis of ternary amides containing rare-earth metals and coordination numbers of the metal atoms by amide ions.

| Compound | CN A(1), R by NH | Reactants | T/K | p/MPa | t/d | References |

|---|---|---|---|---|---|---|

| Na3[La(NH2)6] | 6, 6 | Na + La 1:1 | 523 | 507 | 30 | [131] |

| KLa2(NH2)7 | 6, 8 | K + La 1:2 | 623 | 507 | 6 | [155] |

| K3[La(NH2)6] | 6, 6 | K + La | 473 | 405 | – | [156] |

| RbLa2(NH2)7 | a | [3] | ||||

| Rb3[La(NH2)6] | 6, 6 | Rb + La 3:1 | 573 | 400–450 | 6–12 | [157] |

| CsLa2(NH2)7 | 9, 8 | Cs + La | 470–570 | 400–600 | 3–100 | [3,158] |

| Na3[Ce(NH2)6] | a | [3] | ||||

| KCe2(NH2)7 | 6, 8 | K + Ce 1:1 | 455 | 400–500 | 5–10 | [76] |

| K3[Ce(NH2)6] | 6, 6 | K + Ce 3:1 | 455 | 400–500 | 5–10 | [76] |

| Cs3Ce2(NH2)9 | 12, 6 | Cs + Ce | 490 | 600 | 21 | [159] |

| Cs3Ce2(NH2)9 | 12, 6 | Cs + Ce | 490 | 200 | 21 | [159] |

| Na3[Nd(NH2)6] | 6, 6 | a | [3] | |||

| KNd2(NH2)7 | 6, 8 | a | [3] | |||

| K3[Nd(NH2)6] | 6, 6 | a | [3] | |||

| Rb3[Nd(NH2)6] | 6, 6 | Rb + Nd 3:1 | 573 | 400 | 7 | [157] |

| Cs3Nd2(NH2)9] | 12, 6 | Cs + Nd | 430–530 | 300 | 7–100 | [159] |

| Na3[Sm(NH2)6] | 6, 6 | a | [3] | |||

| KSm2(NH2)7 | 6, 8 | K + Sm 1:2 | 403–493 | 200–500 | – | [121] |

| K3[Sm(NH2)]6 | 6, 6 | K + Sm 3:1 | 403–493 | 200–500 | – | [121] |

| Cs3Sm2(NH2)9 | 12, 6 | Cs + Sm | 470 | 600 | 60 | [159] |

| KEu(NH2)3 | 6, 6 | K + Eu 1:1 | 573 | 500 | 3 | [122] |

| RbEu(NH2)3 | 6, 6 | Rb + Eu 1:1-2:1 | 540–73 | 500 | 28 | [150] |

| Rb3[Eu(NH2)6] | 10, 6 | Rb + Eu 10:1 | 423 | 500 | 40 | [160] |

| CsEu(NH2)3 | 6, 6 | Cs + Eu | 573 | 500–600 | 9–14 | [153] |

| K3[Eu(NH2)6] | 6, 6 | K + Eu 12:1 | 573 | 500 | 3 | [122,149] |

| Na2Eu3(NH2)8 | 6, 6 | Na + Eu 1:1 | 570 | 500 | 8 | [149] |

| NaGd(NH2)4 | 4, 6 | NaNH2 + Gd 1:1 | 493 | 507 | 20 | [161] |

| Na3[Gd(NH2)6] | 6, 6 | NaNH2 + Gd 3:1 | 573 | 304 | 51 | [3,161] |

| K3[Gd(NH2)6] | 6, 6 | a | [3] | |||

| Cs3Gd2(NH2)9 | 12, 6 | Cs + Gd | 440 | 600 | 160 | [162] |

| NaY(NH2)4 | 6, 6 | Na + Y 1:1 | 523 | 507 | 7 | [163] |

| KY(NH2)4 | 6, 6 | K + Y 1:4–6 | 485–505 | 600 | 22 | [164] |

| RbY(NH2)4 | 11, 6 | Rb + Y 1:4–6 | 485–505 | 600 | 22 | [164] |

| Na3[Y(NH2)6] | 6, 6 | Na + Y 3:1 | 523 | 507 | 7 | [163] |

| Cs3Y2(NH2)9 | 12, 6 | Cs + Y | 490 | 600 | 70 | [162] |

| Rb3[Y(NH2)6] | 10, 6 | Rb + Y 3:1 | 473 | 500 | 14 | [157,160] |

| K3[Y(NH2)6] | 10, 6 | K + Y 3:1 | 473 | 500 | 14 | [157,160] |

| NaYb(NH2)4 | 4, 6 | Na + Yb 1:1 | 413–463 | 507 | 14 | [163] |

| Na3[Yb(NH2)6] | 6, 6 | Na + Yb 3:1 | 453 | 608 | 8 | [165] |

| KYb(NH2)7 | a | [3,121] | ||||

| K3[Yb(NH2)6] | 10, 6 | K + Yb 3:1 | 473 | 500 | 14 | [157,160] |

| Rb3[Yb(NH2)6] | 8, 6 | Rb + Yb 3:1 | 473 | 500 | 14 | [157,160] |

| Cs3Yb2(NH2)9 | 12, 6 | Cs + Yb | 450 | 600 | 160 | [162] |

a No further information in literature.

Table 7.

Conditions for the ammonothermal synthesis of ternary amides of main group and transition metals and coordination numbers of the metal atoms by amide ions.

| Compound | CN A(1), B/M by NH | Reactants | T/K | p/MPa | t/d | References |

|---|---|---|---|---|---|---|

| Li[Ga(NH2)4] | 4, 4 | Ga + LiNH2 | 673 | 250 | 3 | [67] |

| Li[Ga(NH2)4] | 4, 4 | Ga + LiNH2 | 673 | 250 | 3 | [67] |

| Na2[Ga(NH2)4]NH2 | 4, 4 | Ga + NaNH2 | 853 | 130 | 2 | [67,82] |

| Na[Ga(NH2)4] | 4, 4 | Na + Ga | 853 | 130 | 2 | [67,81] |

| Rb[Al(NH2)4] | 12, 4 | Rb + Al | 393–473 | 80–120 | 20 | [166] |

| Cs[Al(NH2)4] | 12, 4 | Cs + Al | 423–473 | 120–600 | 15 | [166] |

| Na2[Mn(NH2)4] | 4/6, 4 | Na + Mn | 373 | 10 | – | [167] |

| K2[Zn(NH2)4] | 7, 4 | Zn + KNH2 | 720 | 249 | 2 | [168] |

Both the nature of the A(1) and the A(2), M, R or B metal have an impact on the crystal structure, the number of compounds formed and the composition of the ternary amide. The charge density of both cations is crucial for the realized structure. Increasing the size of the alkali metal leads in the case of ternary lanthanum amides to different structures for Na3[La(NH2)6] [131], K3[La(NH2)6] [156] and Rb3[La(NH2)6] [157]: In Na3[La(NH2)6] all cations occupy octahedral sites in a close packing of amide ions with ABC stacking. In K3[La(NH2)6] both types of cations occupy octahedral sites in a close packing of amide ions with ABC stacking, one layer of octahedral voids is fully occupied by K cations, in the next layer one third of the octahedral voids is filled with La atoms. For K(NH2)6] (R = Y, La, Ce, Nd, Sm, Eu, Gd, Yb) two structure types were observed, one for rare-earth metals from La to Gd and one for Y and Yb. The first group crystallizes in C with all cations in octahedral holes of a close packing of amide groups, occupying layers of octahedral holes alternately. The second group consists of K3[Y(NH2)6] and K3[Yb(NH2)6], which are isotypes of Rb3[Eu(NH2)6] and Rb3[Y(NH2)6] [160]. Those compounds crystallize in R32. R cations occupy octahedral holes in a close packing of amide groups, while A cations are surrounded by a larger number of amide groups. In Rb3[La(NH2)6] [157] again the cations are surrounded octahedrally, realizing layers. Perhaps surprisingly, there is no such compound as Cs3[La(NH2)6] known, but two amide ammoniates Cs3La(NH2)6 · NH3 and Cs4La(NH2)7 · NH3 [100], where cesium and amide ions together with ammonia molecules form the motif of a cubic close packing with lanthanum cations in octahedral voids, exclusively formed by amide groups. A change of the structure for compounds of the same composition can be observed with changing charge density of both cation types, as can be seen from alkali metal rare-earth metal amides. Thus, compounds with small charge density realize close packings of amide ions with all cations situated in octahedral holes. With increasing size of the alkali metal, layered structures of the cations are preferred and the rare-earth cations form structural units with the amide groups similar to the binary amides. In the cesium amides cesium is surrounded by twelve amide ions, the R ions occupy also octahedral sites in a close packing. A(1)-rich phases manifest lower coordination numbers at A(2), M, R or B metal, as can be seen in K3[La(NH2)6] [156] and KLa2(NH2)7 with CN(La) of 8 and 6 respectively [155]. In Table 5 the coordination numbers of the cations by amide ions in ternary alkali metal alkaline-earth metal amides are listed and the change of the surrounding depending on the size of the metals can be compared.

Four different types of ternary alkali metal amides can be distinguished according to their crystal structures: The first group consists of the isotypic compounds NaCa(NH2)3 [149,150], KSr(NH2)3 [149], KBa(NH2)3 [150], RbBa(NH2)3 [150], KEu(NH2)3 [122], RbEu(NH2)3 [150] and NaY(NH2)4 [163]. The amide groups arrange in the motif of a cubic closed packing, the cations occupy octahedral holes. Na2Sr3(NH2)8 [149], Na2Eu3(NH2)8 [149], Na3La(NH2)6 [131] and Na3Y(NH2)6 [163] crystallize in the same structure, irrespective of the different composition. This is possible, since in Na(NH2)6 with R = La, Ce, Nd, Sm, Gd, Y the sites are occupied completely and ordered, whereas for all other compounds a statistical occupation of the sites with different cations is observed [148,150]. Compared to the ternary amides of the smaller alkaline-earth metals, those compounds are more ionic.

In the second group the difference of the radii of the two types of cations is larger, which results in different coordination numbers. Those ternary amides crystallize in the space groups C (RbCa(NH2)3 [152]) and P2 (KCa(NH2)3 [151]). Both structures are related by a close structural relationship, since P2 is a translationengleiche maximal subgroup of C. The change of the space group is a result of the influence of the radii of the alkali metals. For potassium a distorted octahedral surrounding is realized, however rubidium and cesium require higher coordination numbers. This group also contains the compounds CsCa(NH2)3, CsSr(NH2)3 and CsEu(NH2)3 [153]. The resulting crystal structures are described as distorted hexagonal perovskites, where cesium and NH form the motif of a hexagonal close packing. Ca occupies face-sharing octahedral voids exclusively surrounded by amide ions. In this way, one-dimensional chains of [Ca(NH2)] result [153]. The change from group one to group two may surprise: One could expect the same crystal structure for KCa(NH2)3 and KEu(NH2)3, because the binary amides Ca(NH2)2 and Eu(NH2)2 are isotypes [149].

The third group includes K[Be(NH2)3] and Rb[Be(NH2)3], where nearly trigonal planar complex anions [Be(NH2)3]− appear. Up to now, no amide of this group was obtained from ammonothermal conditions [142].

Finally, the fourth group contains isolated tetrahedral complex anions of the type [B(NH2)4]−. Examples, obtained from supercritical ammonia are one modification of dimorphic K2[Zn(NH2)4] [168,169] and CsMg(NH2)4 [148]. The divalent cation is surrounded by four amide groups, whereas the monovalent cations show coordination with larger numbers of amide groups. Various ternary amides of this type containing two metals were synthesized from liquid ammonia, e.g., Na2[Mn(NH2)4] [169], Li[Al(NH2)4] [143,170], Na[Al(NH2)4] [81], Na[Ga(NH2)4] [81,141], K2[Mn(NH2)4] [171] and Rb2[Zn(NH2)4] [171].

There was a remarkable change of the valence state of Eu from +2 to +3 observed, when a large surplus of KNH2 was used in ammonothermal synthesis of ternary amides. Apparently, an increased NH concentration provokes formation of K3[EuIII(NH2)6] rather than KEuII(NH2)3 [122]. Divalent europium is known to behave similarly to divalent strontium and thus it is not surprising that KEuII(NH2)3 is an isotype of KSrII(NH2)3 [149]. Trivalent europium behaves rather similar to the trivalent lanthanides: K3[EuIII(NH2)6] is an isotype of K3[LaIII(NH2)6] [156]. The same applies for the respective ternary rubidium europium amide. Due to the lower solubility of NaNH2 and the resulting lower NH concentration in this system a product with lower sodium content Na2Eu(NH2)8 was obtained in this system [149].

5.4. Imides, Nitride Imides, Nitride Amides and Amide Azides

Certain imides and nitrides can be formed via thermal decomposition of amides under release of ammonia. From in-situ powder X-ray diffraction it is known that during decomposition compounds containing N3−, NH and NH2− ions may occur. Examples are Li2NH, CaNH, MgNH [73,114] and Th2N2(NH) [33]. There are binary imides of lithium, beryllium, magnesium, calcium, strontium and barium known [73,114]. A few imides and nitride imides were obtained from ammonothermal conditions, but only in the form of micro crystalline powders, see Table 8. From the thermal degradation of ternary rare-earth metal amides the formation of Yb0.66(NH) [123], Ce3(NH)3N [76] and La0.667NH [172] was reported.

Table 8.

Conditions for the ammonothermal synthesis of micro crystalline binary imides, nitride imides and amide azides.

| Compound | Reactants mineralizer | T/K | p/MPa | t/d | References |

|---|---|---|---|---|---|

| MgNH | Mg3N2 | 773 | ≥5 | 7 | [115] |

| Th(NH)2 | Th + Li/Na/K | 573 | 608 | 29 | [33] |

| Th2N2NH | Th | 823 | 507 | 2 | [1] |

| ThN(NH2) | ThNJ + A(1)NH2 | 573 | 405 | 2 | [33] |

| Th3N2(NH)3 | ThNJ + A(1)NH2 | 623 | 608 | 27 | [33] |

| Si2N2NH | Si + KNH2 | 873 | 600 | 5 | [173] |

| ZrN(NH2) | ZrNI + KN3 | 633 | 507 | 10 | [75] |

| Cs2(NH2)N3 | Cs + Y | 463–493 | 500–600 | 21–26 | [174] |

The reaction of Mg3N2 with NH3 at T ≥ 773 K and p ≥ 5 MPa yields MgNH with Mg(NH2)2 and Mg3N2 impurities after one week. This finding may be explained by the following equations [115]:

MgNH can also be obtained by thermal decomposition of Mg(NH2)2 at 513–638 K. At 633 K a micro crystalline powder suitable for X-ray diffraction is produced [115]. Th(NH)2 is formed from thorium metal and ammonia at 613 K and 304 MPa after 4 days as micro crystalline powder [1]. At higher temperatures of 823 K and 507 MPa a micro crystalline nitride imide with the composition Th2N2NH is formed [1].

A cesium amide azide Cs2(NH2)N3 is reported from the reaction of Cs and ammonia in presence of Y at 463–493 K and 500–600 MPa. The appearance of azide ions may be regarded somewhat surprising under the applied conditions, as the nitrogen of the ammonia would become oxidized during formation. Jacobs et al. explained this effect by a drastically reduced volume of the obtained Cs2(NH2)N3 compared to the volume of CsNH2 and NH3, assuming release of hydrogen by diffusion through the autoclave wall and perhaps also by formation of yttrium hydride. Following reaction Equation (10) a volume reduction of ∼29% occurs when Cs2(NH2)N3 is formed. In addition, the formation of the mixed amide azide in contrast to two compounds (Cs(NH2) + CsN3) is favorable due to a smaller volume of ∼3% [174].

However, in the past several cyanamides (or carbodiimides, respectively), formed by reaction with unintenional carbon impurities, were initially misinterpreted as representing azide compounds [175,176]. Since any carbon impurity under ammonothermal conditions in presence of alkali or alkaline-earth metals will readily form cyanamide ions [177], it may be regarded as likely that this compound rather represents an amide carbodiimide.