Abstract

Many products from the fine chemicals and pharmaceuticals industries are currently manufactured batch-wise in multi-product plants. However, this processing scheme suffers from severe drawbacks, such as a high specific energy demand, cleaning costs and high staff requirements. Transferring batch into continuous campaign productions may overcome these drawbacks. Using the case of writing ink, such a continuous manufacturing scheme was developed employing micro- and milli-structured components in order to intensify certain unit operations. In this paper, an ecological and economic assessment of both production concepts considering all lifecycle stages is presented. The aim of our work is to highlight the advantages and disadvantages of the two multi-product plants and to derive recommendations for the most efficient design and operation of a continuous campaign manufacturing plant. The results show that lower environmental impacts are related to continuous processing, which is due to the option for energy integration in this case. Furthermore, in the economic assessment, continuous processing proved to be economically viable. In this case, reduced staff requirements based on a highly automated manufacturing plant are the key to lower personnel costs. In general, the results emphasize the importance of such micro-/milli-continuous multi-product plants for the future manufacturing of newly developed products in the mentioned industries.

1. Introduction

Ecological sound production concepts have become increasingly sought after. This is mainly due to the associated cost savings, as an Internet survey of 177 environmental experts by the Institut der Deutschen Wirtschaft Köln (Cologne Institute for Economic Research) [1] revealed. Batch processing is one of the manufacturing strategies currently reviewed both for the environmental implications and the associated costs [2]. Since the vessels and reactors are mostly used as multi-product plants, their cleaning frequency is high, resulting in a large specific amount of cleaning agents. Further disadvantages of discontinuous processing include high personnel requirements and low repeatability, as well as inhomogeneity in terms of product quality. These variations can lead to up to 20% of the product being discarded as waste, as highlighted in an example of Suzuki-polycondensation producing organic light emitting diode (OLED) colorants [3]. Moreover, batch vessels are often connected to a low surface-to-volume-ratio, which poses a limitation to the heat transfer, resulting in long heating/cooling times and a high specific energy demand. Since heating and cooling periods occur at different time intervals, heat integration can only be realized via heat pumps or heat reservoirs. Both solutions are technologically complex and, therefore, often not economically viable, according to Schnitzer and Titz [4].

Using continuous instead of batch processing, the mentioned drawbacks may potentially be overcome and more efficient heat integration accomplished. Continuous manufacturing has therefore attracted much attention in the industries largely characterized by batch processing, namely the pharmaceutical and fine chemical sector. A collaboration between Massachusetts Institute of Technology (MIT) and Novartis on the continuous processing of active pharmaceutical ingredients started in 2007 [5] and resulted in the construction of a pilot plant at Novartis’s headquarters in 2012 [6]. Yet, in 2010, Stitt and Rooney [7] concluded in their review that only moderate progress to continuous manufacturing had been made despite the economic and operating advantages demonstrated. Nevertheless, continuous processing has been voted the top green engineering research area by an expert group from several pharmaceutical and fine chemicals manufacturers [8], highlighting the importance and potential of the technology.

Merely transferring the protocols from discontinuous to continuous manufacturing does not however necessarily lead to more ecological sound processes, as pointed out by Kralisch et al. [9]. When designing continuous processes, it is therefore crucial to review each step in terms of its necessity and conditions, such as pressure, temperatures and concentrations, potentially opening up novel process windows [10]. According to Charpentier [11], also process intensification measures should be considered, which include micro- and milli-structured components.

In order to preserve the flexibility of batch processing for low-volume products, continuous campaign manufacturing schemes should be considered. During one campaign, a single product is synthesized continuously in a multipurpose plant allowing for a high degree of automation. Having reached the desired production quantity, a product change procedure is run during which the plant may be cleaned and prepared for the next campaign. However, open literature information suggests that so far, mainly dedicated continuous manufacturing schemes employing micro- and milli-structured components have been developed. To the best of the authors’ knowledge, there are only two exceptions: The first one is a plant that has been developed for the production of two water soluble synthetic polymers in the F3 factory project [12]. The other one is a multi-purpose lab plant for the production of different writing inks designed by the authors [13,14]. Therein, it was shown that a multi-product continuous plant employing micro- and milli-structured components is technically feasible. However, continuous production requires more elaborate equipment than a batch plant. This leads both to a high environmental impact on the production side of the equipment itself and to high capital investment. Employing only macro-components, a continuous campaign production was deemed economically viable only for production capacities of a few 1000 t per year [15]. More in-depth analysis of multi-purpose production facilities for small production volumes is however highly sought after, according to Schaber et al. [16]. This paper addresses this issue by analyzing a continuous campaign production scheme involving a volume of around 150 t/a for a product group of different colored writing inks. In this analysis, the continuous production scheme is compared to the traditional batch process, both in regards to the economic and ecological implications. Special attention was paid to the specific aspects of a multi-product plant: product qualities during the start-up and shut-down of the plant, the time required for reaching a steady state and the required cleaning procedures.

2. Methods and Assessment Approach

2.1. Case Study of Writing Ink

A product group of writing ink, currently produced batch-wise in jacketed stirred tank reactors, serves as a model system. It is comprised of 5 different colored inks, although only 4 were considered for continuous manufacturing. This is due to one color being a mixture of two others. The recipes differ mainly in the amount and type of pigments and dyes added. The traditional manufacturing scheme utilizes two 1-m3 stirred vessels in which an aqueous dye solution and a binder mixture as premixes are prepared. The binder solution is then transferred into the dye solution, mixed, heated up to the reaction temperature, maintained for a specific holding time and then cooled. Subsequently, different additives and preservatives are added. This manufacturing scheme suffers from the following drawbacks: Firstly, a high specific amount of cleaning agents is needed to clean the two production vessels after each run. Fouling layers at the vessel walls are removed manually with 1 L of ethanol and 1 L of a 10% aqueous sodium hydroxide solution. Then, the two vessels are flooded twice with water in order to flush the remnants out. Secondly, a high specific energy demand is connected with the two heating steps: Heating of the whole vessel volume is required both for dissolving the powdery reactants during the preparation of the color premixes, as well as for initiating the color reaction. Cooling the vessel to ambient conditions is simply achieved by opening up the vessel lid; thus, heat integration is not realized.

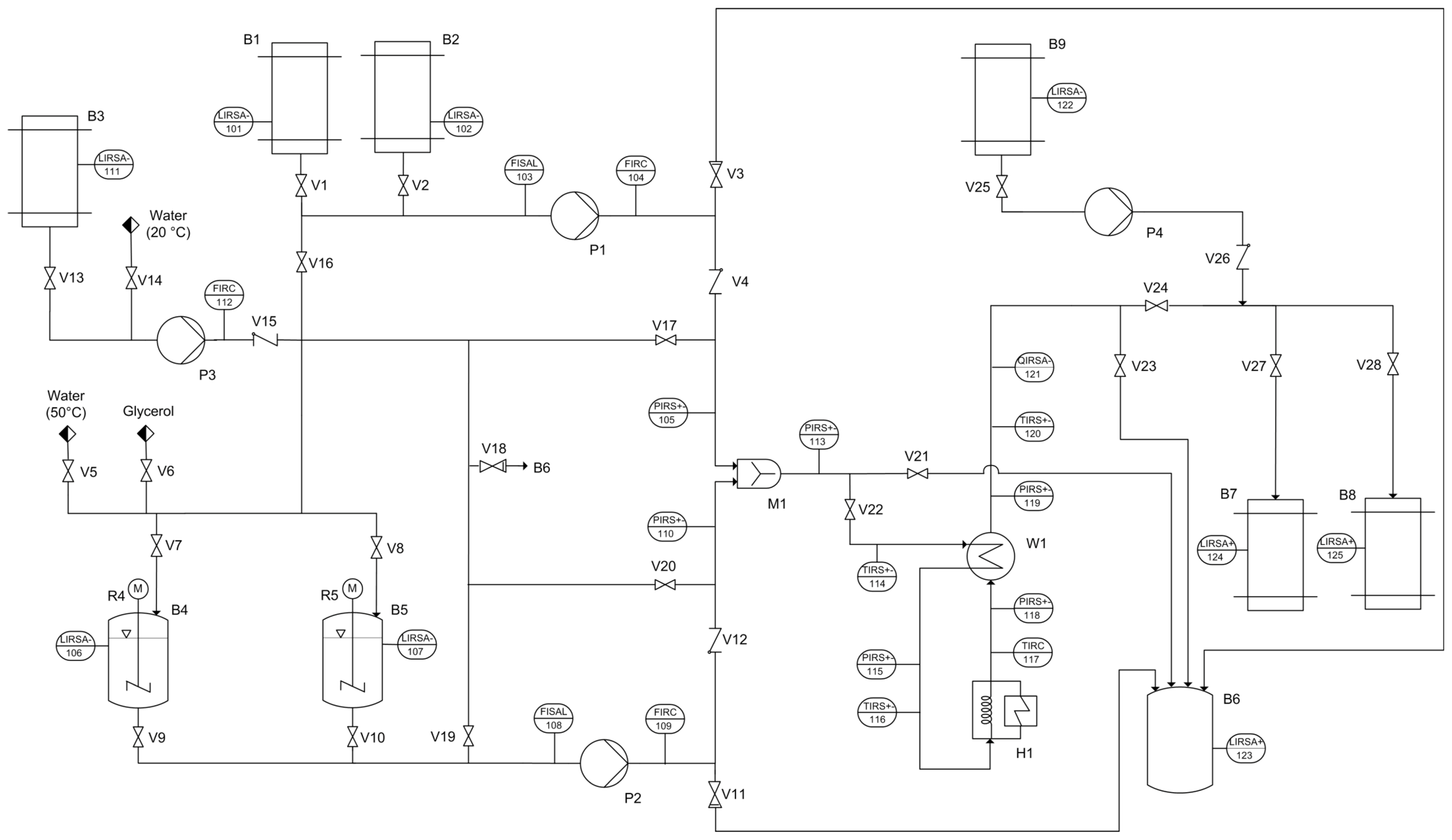

In order to evaluate the technical feasibility of a micro-/milli-continuous campaign manufacturing scheme, a lab plant was set up as shown in Grundemann et al. [13,14]:

- Feeding two reactant streams, a color premix and a binder, a maximum flow rate of 13 L·h−1 could be achieved.

- A micro-structured mixer and micro-structured heat exchanger were employed.

- The hold-up of the plant was determined as 0.93 L considering all conduits.

- The lab plant was designed in order to allow for the investigation of product change, as well as cleaning procedures.

Adapting the recipe to a continuous processing scheme and employing hot water during the preparation of the color premixes, we could refrain from heating the whole reactor volume during this processing step. In addition, instead of flooding the premix vessels during cleaning, a high pressure cleaning device was employed, reducing the amount of water needed per cycle and vessel. The continuous flow production of different inks in a multi-product plant requires dealing with dynamic events: the start-up and shut-down phases, as well as product change procedures with or without cleaning cycles. During start-up, it is important to follow a strict procedure, described in Table 1, in order to avoid agglomerates and blockages of the two opposing reactant inlet nozzles. The ink produced is fed into a micro-heat exchanger for preheating in counterflow with the reacted ink. At the beginning of the weekly production period lasting for 100 h in total (e.g., Monday, 8:00 h to Friday, 12:00 h), it takes around 40 min to reach steady state in the micro-heat exchanger. Afterwards, the ink meets the specifications, both in regard to the particle size distribution, as well as the color properties.

The procedure for the product change is determined by the production sequence and the lot size. Ideally, product changes do not involve any cleaning. In this case, a blend of successively produced colors is created. When feeding this blend to the subsequent product drum, whether the color specifications are still met depends on the lot size. We reported that a minimum lot size of 20 times the plant hold-up relating to the product change is sufficient to gain in-spec ink adhering to the optimum production sequence [14]. Therefore, cleaning of the micro-/milli-continuous plant can be curtailed until shut-down at the end of the weekly production period. Maximum contamination levels have also been defined for cleaning procedures in order to ensure that colors produced directly after cleaning procedures are not contaminated by remnants of the previously produced inks. These levels are reached after the exchange of twice the partial plant hold-up relevant for cleaning.

Based on the experimental results obtained on the lab plant scale, a concept for a production plant was developed. This paper describes the results of the process development and assessment using an exemplary production capacity of 30 L h−1. A flowchart of the production plant is presented in the Appendix A. A floor plan was also drawn in order to estimate the required length of the pipes and tubing. Appendix B contains the equipment list of both plants. In contrast to the lab plant, a macro-heat exchanger was included, due to the lower risk of fouling and clogging, as well as the lower investment. Based on the information from the suppliers, the hold-up of the production plant was estimated to be 7.2 L, of which 4.8 L can be accounted for by the macro heat exchanger. As a first estimate during this early project stage, similar residence times, mixing and heat transfer characteristics were assumed for the production plant as experimentally determined for the lab plant. This resulted in the amounts of fluid to be considered during start-up, shut-down and product change as listed in Table 1.

Table 1.

The procedures and amount of fluids to be considered during start-up, shut-down and product change for the drafted continuous multi-product production plant at a volumetric flow rate of 30 L h−1.

| Event | Procedure (based on experiments with the lab plant) | Amount of fluids (derived by extrapolation from the lab plant based on the relevant plant hold-up) |

|---|---|---|

| Start-up at the beginning of the weekly production period | Feeding water with both reactant pumps for 5 min. | 2.5 L of water |

| Connecting the two reactants step-wise; 5-min waiting period until the second stream is connected; production of agglomerate-laden ink for 10 min. | 5 L mixture of water/binder/color premix in total | |

| Until stationary mode of heat exchanger is achieved after 40 min, the ink does not meet specifications regarding the color value. | 20 L of ink | |

| Cleaning during shut-down procedures at the end of the weekly production period | Replacing twice the cleanable plant hold-up. | 14.2 L mixture of water and ink |

| Product change procedure without cleaning | Replacing 20 times the plant hold-up relevant for product changes. | 120.9 L product (minimum lot size) |

2.2. Ecological Assessment

The ecological study has been conducted with a lifecycle perspective, following the lifecycle assessment (LCA) approach defined in ISO 14040 [17] and ISO 14044 [18]. LCA is a systematic methodology covering the whole lifecycle of a product or process from the cradle to the grave, thereby avoiding a shift of environmental impacts from one lifecycle stage to the next [19]. LCA studies consist of four phases: In the first phase, the goal and scope are defined, including the system boundaries and the functional unit. Secondly, a flow diagram is developed, helping to identify all material and energy flows within the defined system boundaries. These flows are then converted to the functional unit forming the LCA inventory. In the third phase, the potential environmental impacts associated with all flows inside the inventory are assessed. Finally, the results are evaluated to choose the most beneficial product or process.

2.2.1. Goal and Scope Definition of the Ecological Assessment

This study aims to derive the potential environmental impacts of both process alternatives to highlight their advantages and disadvantages, as well as to derive recommendations on whether to change the manufacturing scheme. The functional unit was chosen to be a yearly output of 148,200 L of writing ink. This amount is based on a production period of 52 weeks per year, each covering 100 h. Implying a plant occupancy rate of 95% and a production capacity of 30 L h−1, the functional unit was determined. During batch manufacturing, however, up to 2% of the annual output needs to be discarded, due to quality defects. For the continuous campaign production, it is assumed that all fluids arising during start-up, shut-down and product change procedures as listed in Table 1 are also discarded as waste. Both aspects were taken into account by increasing the reactant streams accordingly.

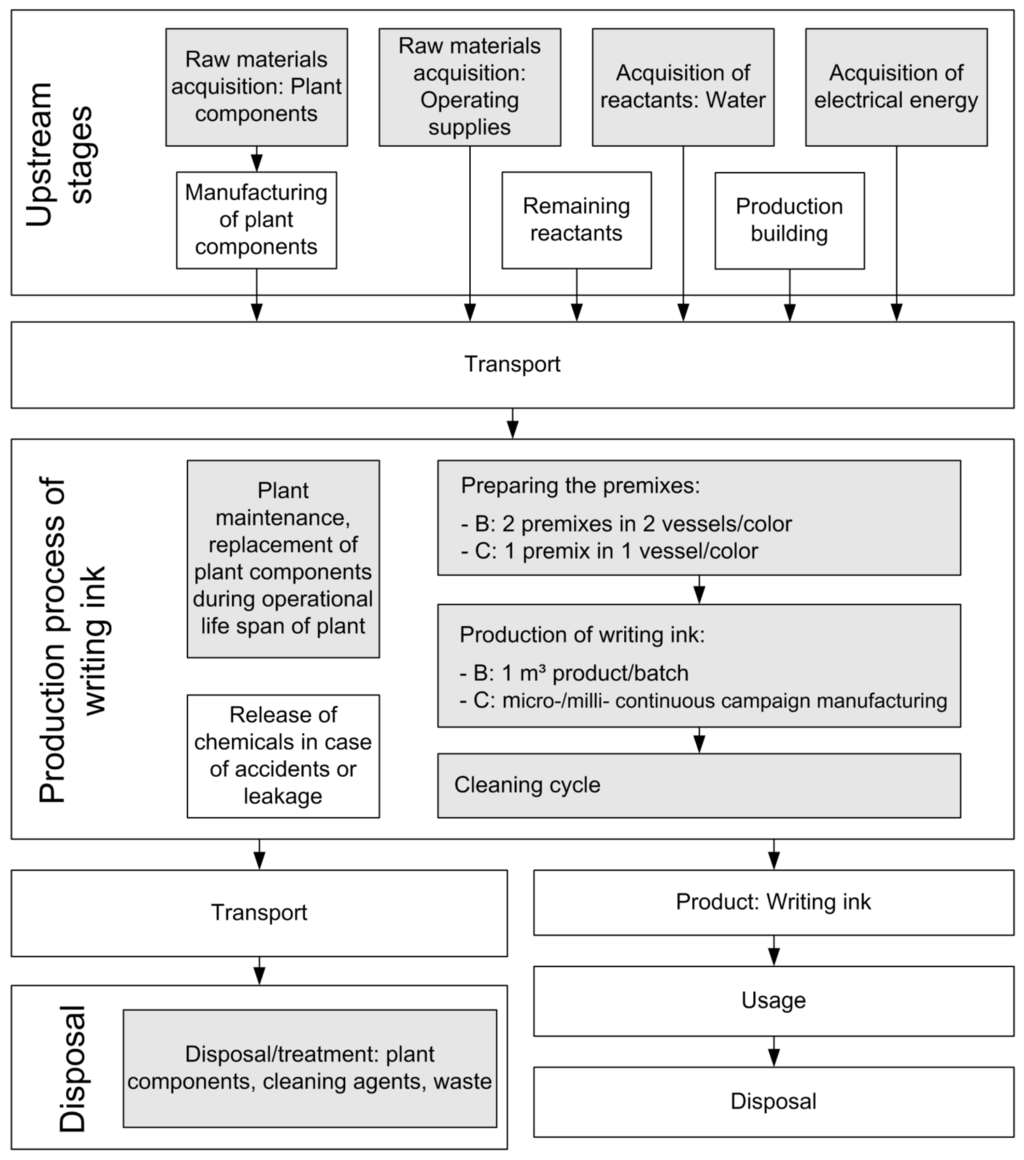

In order to comply with the LCA methodology, the system boundaries encompassed both upstream and disposal stages in addition to the production stage itself, as shown in Figure 1. However, the so-called black-box method proposed by Klöpffer and Grahl [20] was followed. This implies that only those lifecycle and process stages were included that differ between the two process alternatives, minimizing the costs and effort for data collection during process development. The results presented in this paper are therefore only valid for this particular comparative study and do not represent absolute values. Regarding the inputs and outputs of the LCA inventory, the following approach was taken:

- All material and energy flows were considered that differ by more than 2% between the two alternatives. Except for the reactant water, the differences in the amount of the reactants lie below this threshold and their acquisition therefore outside of the system boundaries.

- Manufacturing differently colored inks, the same process steps are performed, adjusting the same process conditions, so that the material flow model is valid for all colors under the assumptions described above. Merely the frequency and type of cleaning cycles of the continuous campaign manufacturing scheme are differing depending on the product sequencing and capacities of the different colors. A sensitivity analysis has been included in the study to evaluate this aspect (see Section 2.3.2).

- The LCA inventory of both process alternatives excluded all material transports, since reliable data were not available. According to Wernet et al. [21], these material transports account for a maximum. of 5% of the environmental impacts, though, and, therefore, play a minor role.

In order to derive the overall material and energy balances of the two process alternatives, process models were set up with the software, Umberto 5.6 [22]. Modeling the traditional batch process, data from the existing plant was used, whereas the production concept presented in Section 2.1 was taken as the data basis for the micro-/milli-continuous campaign manufacturing scheme. For the base scenario, it was assumed that 1 m3 of a certain color premix is created and consumed for ink production. After having emptied the tank, it is cleaned with a high-pressure cleaner. Furthermore, the binder feed lines are rinsed.

Figure 1.

System boundaries for the ecological assessment of both process alternatives [23]. The included lifecycle stages and components are shaded in grey.

The geographical scope of this study is the writing ink production industry in Germany. In order to include the upstream and disposal stages, generic datasets from the ecoinvent database [24] were used. Where possible, datasets applicable to Germany were selected. In cases in which the origins of the raw materials were unknown, datasets generated for Europe were chosen.

The temporal scope is one year, according to the functional unit. An operational life span of 20 years was, however, chosen for both plants, a time frame which is typical for batch plants in Germany as laid down in a joint report by VDI/VDE (Verein deutscher Ingenieure/Verband der Elektrotechnik Elektronik Informationstechnik) and NAMUR (Normen-Arbeitsgemeinschaft Mess- und Regeltechnik) [25]. Required materials and components for plant maintenance were specified for this time frame. The associated environmental impacts were depreciated on a straight-line basis over the 20 years, so that only the share for one year was taken into consideration during material and flow modeling.

Estimating the potential environmental impacts of the material and energy flows listed in the inventory, the CML (Centrum voor Milieukunde, Universiteit Leiden) 2001 impact assessment method [26] was applied. The environmental impacts were first calculated for all 15 impact categories of the CML 2001 method, as recommended by Azapagic and Perdan [27]. Afterwards, eight categories were chosen for detailed analysis, as well as for an effective comparison and presentation of the results. We refrained from using extra endpoint indicators, since ISO 14044 [17] does not permit their use for comparative analyses. Additionally, Huppes et al. [28] stress that the procedure of weighing different impact categories in order to derive an endpoint indicator is still controversial. In this paper, all material and energy flows are combined in so-called modules according to their function, e.g., “upstream stages of operating supplies”. The respective environmental impacts are therefore also expressed depending on these modules.

2.2.2. Description of the Sensitivity Analysis: Cleaning Agent Demand of Micro-/Milli-Continuous Campaign Manufacturing

Regarding the cleaning agent demand for continuous production, it was hypothesized in the first approximation that the results from cleaning experiments conducted on the lab plant can be extrapolated to the production plant based on the plant hold-up.

Furthermore, assumptions were made concerning the required amount of cleaning agents for rinsing the color premix vessels and the binder feeding lines. The influence of all these assumptions on the results of the ecological assessment of the micro-/milli-continuous campaign manufacturing was evaluated by means of a sensitivity analysis. All options considered are listed in Table 2.

The case C-2W-1 is similar to the base scenario requiring only one cleaning cycle at the end of the weekly production period, assuming that the minimum production output per color is exceeded and the optimum production sequence adhered to. However, twice the amount of cleaning agents is used per cycle. C-W-4 describes the production of all four ink colors each week, not adhering to the optimum production sequence or at lower amounts than the minimum production output. Therefore, cleaning of one premix vessel and of the micro-/milli-continuous plant shall be required during each product change procedure. C-EW-1 stands for the option of using 14.2 L of ethylene glycol for discoloring the tubes and rinsing the plant afterwards with three times the amount of water. It is further assumed that 1 L of ethanol is employed for an efficient pre-clean of the color premix vessel walls prior to cleaning the vessel with a high-pressure device. The worst case is represented by the abbreviation C-EW-4, requiring cleaning of the continuous flow plant and of the color premix vessels according to the procedure of C-EW-1, however, increasing the cleaning frequency to four times per week.

Table 2.

Options of the sensitivity analysis regarding the required amount of cleaning agents for the micro-/milli-continuous campaign manufacturing.

| Name | Assumptions for cleaning of | ||

|---|---|---|---|

| Micro-/Milli-continuous flow plant | Color premix vessel | Binder feeding lines | |

| C-Base scenario | 14.2 L water, 1× per week | High-pressure cleaner, 135 L/event, after emptying of vessel | 10 L/event, after emptying of drum |

| C-2W-1 | 28.4 L water, 1× per week | High-pressure cleaner, 270 L/event, after emptying of vessel | 20 L/event, after emptying of drum |

| C-W-4 | 14.2 L water, 4× per week | High-pressure cleaner, 135 L/event, 4× per week | 10 L/event, after emptying of drum |

| C-EW-1 | 14.2 L ethylene glycol, 42.6 L water, 1× per week | Preliminary cleaning with 1 L ethanol/event; afterwards, use of high-pressure cleaner, 135 L/event, 1× per week | 10 L/event, after emptying of drum |

| C-EW-4 | 14.2 L ethylene glycol, 42.6 L water, 4× per week | Preliminary cleaning with 1 L ethanol/event; afterwards, use of high-pressure cleaner, 135 L/event, 4× per week | 10 L/event, after emptying of drum |

2.3. Economic Assessment

In this section, the methods for the economic assessment will be presented. A cost analysis was chosen as the method, since no data concerning the expected sales was available. Note that the system boundary was conformed to the lifecycle costing approach described in the VDI guideline 2884 [29]. In this study, only those costs are included that are directly related to the two processing methods. According to Klöpffer and Grahl [20], overhead costs are therefore disregarded. The static payback period was added as a further means of assessment.

2.3.1. Goal and Scope Definition of the Economic Assessment

The purpose of this study was to compare the two process alternatives, both in regard to the ecological, as well as the economic implications. Therefore, the assessments were based on the same material and energy flow balances with identical boundary conditions. In the following, the information given for the ecological assessment in Section 2.2.1. is specified regarding the requirements of the cost analysis.

We aimed at determining the total production costs per year for a capacity of 148.200 L a−1 for both alternatives and identifying the main cost factors along the lifecycle. The costs for off-spec batches in the case of the batch plant and waste arising during the start-up and shut-down phases of the continuous process were thus included. The analysis was conducted from the producer’s point of view in order to support a decision for or against the transfer of the traditional batch to a novel micro-/milli-continuous campaign manufacturing scheme. This corresponds to a replacement investment. As a second option, it was evaluated whether it is better to invest in either a batch or a continuous campaign plant in the case of a capacity increase to produce special writing inks. Again, the influence of data uncertainties and assumptions made for the continuous process regarding the cleaning frequency was assessed by a sensitivity analysis.

During the production phase, costs arise from the provision of electrical energy, the reactants and operating supplies, the plant operator, personnel for quality control and for maintenance services. These are part of the variable costs and are listed in Appendix C. Analogous to the ecological assessment, changes in deionized water and tap water, respectively, are the only reactants considered due to the minor changes of all other reactants, falling below the threshold value. The assessment is thus again valid for all ink colors. All waste streams are included in the assessment; the disassembly and end-of-life of the plant was, however, excluded, since no reliable data were available. Moreover, all transport was left out of the evaluation.

For both manufacturing schemes, the costs for reactants, operating supplies and electricity were calculated with the yearly amounts resulting from the material and energy flow modeling and their respective prices. Personnel costs were derived from the required work time. During batch operation, an operator without formal vocational training prepares the premixes, dispenses the binder premix to the color premix, is responsible for operating control, filling the ink into drums and cleaning the stirred vessels after each production. On average, 3–7 h are required per batch for the plant operator depending on the amount manufactured, as well as 1 hour for the chemical laboratory assistant. During continuous manufacturing, the following tasks are carried out by the plant operator:

- Premix preparation: The color premixes are prepared taking 1 h on a 1 m3 scale. As described in Section 2.1, the recipe adaption allows for a simplified preparation procedure. For the base scenario, it is assumed that two color premixes are consumed per weekly production procedure. During reactant mixing, the plant operator is also responsible for supplying new binder drums and for refilling of the preservatives.

- Monitoring of the plant: According to Wichmann [30], the start-up phase of micro-/milli-continuous plants ought to be monitored by an operator, whereas the production phase can be automated. In addition, shut-down and cleaning procedures can also be automated. Therefore, a plant operator needs to be on-site for merely 1 h, observing the start-up.

- Cleaning: After the color premix has been used up, the operator uses a high-pressure cleaner to clean the vessel for 15 min.

In total, a plant operator is required for 3.5 h per week for the continuous manufacturing of a single ink color per week. A trained laborer was included in the calculations for plant control in contrast to an untrained laborer for premix preparation and cleaning. The process control system guarantees that the product specifications are met, rendering any additional quality control in the laboratory superfluous. The costs for maintenance services were added to the variable costs. The costs for equipment exchanged during the 20 years of plant life (see Section 2.2.1.) were calculated based on data from the suppliers. The associated personnel costs were added, assuming that the ratio of wages to material costs is 43.5:56.5, as stated by Kölbel and Schulze [31].

Besides the variable costs, the fixed costs for all plant equipment were determined based on current quotations from existing suppliers; see Appendix B. The costs for construction and assembly of the plants were added. In the case of the batch plant consisting mainly of stirred vessels and equipment made of non-alloy steel, 10% of the investment may be taken on according to Helfrich and Schubert [32]. Due to the more elaborate equipment in the case of the continuous process, the recommendation from Ullrich [33] was accepted, who deems a value of 15% of the investment realistic for the construction and assembly of chemical plants with a heterogeneous composition. Furthermore, costs for the programming of the process control system and the testing of the automatic measurement of the color values arise for continuous manufacturing. These costs were also included based on a supplier’s quotation. For both plants, the investment and costs for construction were summed up and depreciated on a straight line basis over 20 years. Depreciation on a straight line basis is customary during pre-calculation, as Ullrich [33] postulates. Other fixed costs, such as taxes and interests, were not included in the cost analysis.

2.3.2. Description of the Sensitivity Analysis: Cleaning Agent Demand of the Micro-/Milli-Continuous Campaign Manufacturing

For sensitivity analysis of the cleaning frequency and, therefore, the cleaning agent demand, the same cases as in the ecological assessment are considered. This sensitivity analysis influenced all cost positions of the variable costs: The type and amount of the cleaning agent is varied for the two cases, C-2W-1 and C-EW-1, which influences the raw material costs, as well as the costs for disposal. In case C-2W-1, the cleaning period of the color premix vessels is duplicated, which increases the labor costs per cleaning cycle accordingly. Furthermore, the energy costs are slightly higher compared to the base scenario of the continuous manufacturing scheme, since the cleaning cycles are lengthened.

In cases C-W-4 and C-EW-4, it is assumed that four cleaning cycles are required for both the continuous flow plant, as well as the color premix vessels, which leads to higher raw material, disposal and personnel costs. Although the share of solvents in the waste is considerably higher than in the other cases, the same disposal costs were applied for all cases, since no other was available. Note that four color premixes shall be prepared in contrast to the cases with only one cleaning cycle. During start-up after cleaning, the same amount of off-spec ink is produced and disposed of as in the C base scenario, leading to higher reactant costs. In order to compensate for this amount of ink, the total production period for the required output is prolonged, which also increases the energy costs.

3. Assessment Results and Discussion

The results of the ecological, as well as the economic assessment will be described in this chapter. The results from both base scenarios, as well as sensitivity analyses will be analyzed and discussed in regard to their significance and validity. Afterwards, conclusions will be drawn with respect to the defined goal of the study.

3.1. Ecological Assessment

3.1.1. Ecological Assessment of the Base Scenarios

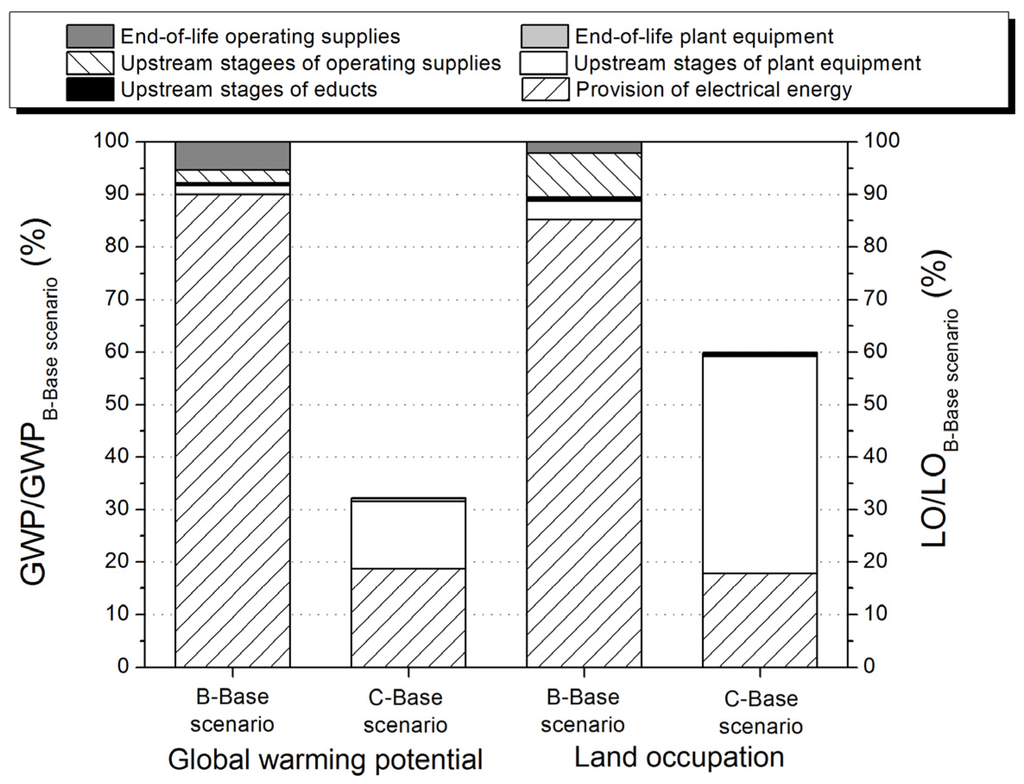

The potential environmental impacts of the eight categories chosen for a detailed analysis from the CML 2001 method are presented in this section. Figure 2 gives an overview of the results for the impact categories, global warming potential and land occupation, each related to the values of the base scenario of the batch process. The global warming potential (GWP) associated with continuous manufacturing is decreased by 68% compared to batch processing. In both cases, more than 92% of the GWP are related to the two modules “provision of electrical energy” and “upstream stages of plant equipment”. Each time, the module mentioned first is associated with the highest impact by far. Savings in electrical energy during the continuous production of writing ink are therefore decisive for the GWP reduction. These are realized by eliminating energy-intensive heating periods in the vessels, enabled both by recipe adaption and effective mixing of the reactants in the micro-mixer. Such a recipe adaption seems not feasible for the batch process, since the premixes have been explicitly designed and adjusted to the production conditions in the stirred tank reactors in order to reach the lowest probability of agglomeration. Besides, the cleaning process of the vessels is shortened by employing a high pressure cleaning device, thus reducing the energy demand for cleaning. Heat integration with a heat exchanger leads to a further decrease in comparison with the batch process. The energy demand of the continuous process is therefore mainly influenced by the power of the electrically operated equipment, whereas it is resulting from long heating periods and the associated heat losses to the environment for the batch process. The second most important component is the module “upstream stage of plant equipment” in which a higher GWP value is derived for the continuous rather than for the batch process. This is mainly caused by more elaborate plant equipment and the use of polytetrafluorethylene (PTFE) for tubing and pipes as the highest single value.

Figure 2.

Comparison of the global warming potential (GWP) and land occupation (LO) of batch and micro-/milli-continuous campaign manufacturing.

Regarding land occupation, the reduction achieved by changing from batch to continuous processing is lower than for the GWP. This fact can be ascribed to the module “upstream stage of plant equipment”, therein to the use of varnished medium-density fiberboards as plant shelves, accounting for around 86% of the category’s value. According to Frühwald et al. [34], wood is both used as the raw material for the fiberboards, as well as the energy source for generating the process energy, therefore resulting in significant land occupation.

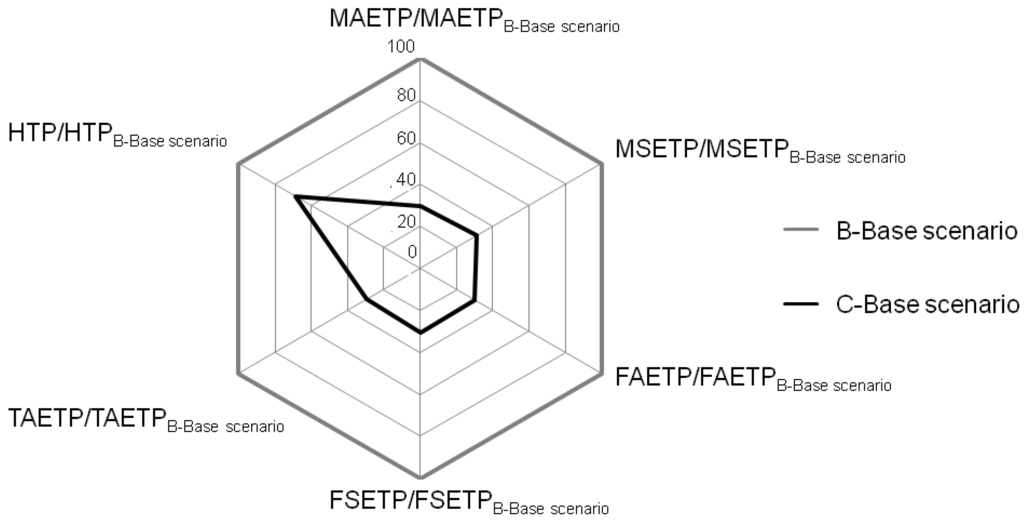

The results of all six toxicity impact categories are illustrated in Figure 3. The values of the continuous process are reduced by 68% to 71% compared to batch manufacturing, with the exception of the human toxicity potential being reduced by only 31%. This lower reduction rate is due to the module “upstream stages of plant equipment” being mainly responsible for this impact category, as well as to the fact that stainless steel is provided in similar amounts for both plants. In all other toxicity categories, the provision of electrical energy causes the highest impacts. These findings support the results of Wernet et al. [21], after which generally more than half of the environmental impacts are caused by the energy-related inputs in chemical industries producing organic and inorganic products.

Figure 3.

Toxicity potentials of batch and micro-/milli-continuous campaign manufacturing. MAETP, marine aquatic eco-toxicity potential; HTP, human toxicity potential; TAETP, terrestrial aquatic eco-toxicity potential; MSETP, marine sediment eco-toxicity potential; FAETP, fresh water aquatic eco-toxicity potential; FSETP, fresh water sediment eco-toxicity potential.

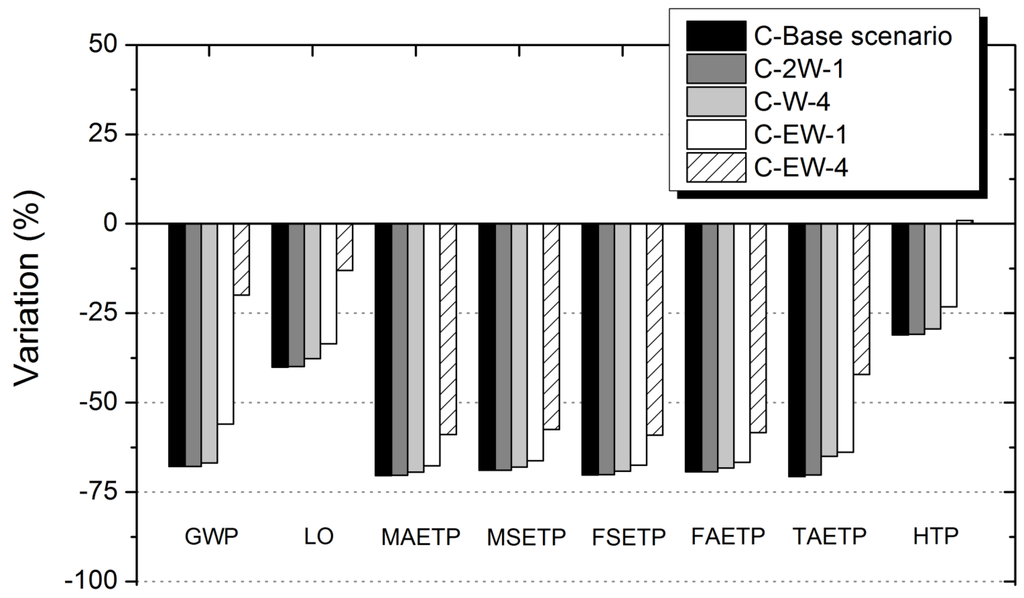

3.1.2. Ecological Assessment of the Sensitivity Analysis

A sensitivity analysis of the cleaning agent demand was conducted in order to examine the reliability of the study. The results of this sensitivity analysis are illustrated in Figure 4. It is evident that the increased amount of water required for cases C-2W-1 and C-W-4 has only minor influences on the impact categories. Decoloring the plant with ethylene glycol and rinsing it afterwards with water at the end of each weekly production period, represented by case C-EW-1, is also ecologically tolerable. However, if this intensive cleaning is required during each of the four cleaning procedures, then the indicator values would be affected very negatively (C-EW-4). In this case, the human toxicity potential is drastically increased and even 1% higher than the equivalent value for batch processing. The deterioration compared to the case C-W-4 with the same cleaning frequency is mainly caused by the calculated amount of ethylene glycol.

Figure 4.

The change in the potential environmental impacts of the continuous process in comparison with the batch production scheme varying the cleaning agent demand.

3.1.3. Significance and Validity of the Results of the Ecological Assessment

This study comprises the comparison of the current batch and the novel micro-/milli-continuous campaign manufacturing scheme, whereas an optimized batch process was not included. However, it cannot be ruled out that a fully or partially automated batch plant leads to similar advantages in regard to energy and cleaning agent demand, as well as personnel requirements as the automated continuous plant. Such an optimized batch production may therefore be the subject of future studies, as, for example, described in Oldenburg et al. [35].

When discussing the significance and validity of these results, the focus should be mainly on their overall robustness.

That is influenced by data uncertainties during material and energy flow modeling caused both by errors in modeling, as well as by the quality of the data used. Regarding the process models, it should again be stressed that a black-box model was employed. The level of detail of both process models is therefore similar: in both cases, the acquisition of raw materials, as well as the end-of-life stages were included as generic datasets, whereas the ink production was modeled on the basis of measurement results, calculations and assumptions.

The quality of the data used for the modeling of the batch production stage can be graded as 1–2, according to the Pedigree matrix presented by Weidema and Wesnaes [36], wherein 1 is the best and 5 the worst classification. This is due to the fact that the lifecycle inventory is mainly based on primary data, which at the time of the study, was not older than three years. In contrast, the quality of the data used for the continuous process can be rated as 4–5. In this case, the results achieved with the continuous lab plant were extrapolated to the production stage, which then served as a basis for the lifecycle inventory analysis. This approach leads to higher data uncertainties. However, several scenario and sensitivity analysis, described in Grundemann [23], as well as for the cleaning agent demand in this paper, showed that only minor variations in the indicator values are resulting from the plausible scenarios. Additional worst cases helped to allow for the deriving of the recommendations.

It can therefore be concluded that the quality of the model and the data employed are adequate for a solid comparison of the two processing schemes.

3.2. Economic Assessment

3.2.1. Economic Assessment of the Base Scenarios

The total annual production costs to manufacture the desired amount of ink are summarized for both processing alternatives in Table 3. It shows that the fixed costs of the continuous production scheme are almost three times higher than those of the batch production scheme, which is due to the more elaborate plant equipment with more electrically-driven parts and sensors. As a result of this, the costs for maintenance services are also increased.

Table 3.

Total annual production costs of the base scenarios of the batch production (B base scenario) and the micro-/milli-continuous campaign manufacturing scheme (C base scenario) for a total production output of 148,200 L of writing ink.

| B-base scenario | C-base scenario | |

|---|---|---|

| Data of both plants | ||

| Investment (€) | 21,315 | 52,018 |

| Costs for construction and assembly of plant (€) | 2,132 | 7,803 |

| Costs for programming and testing of the process control system (€) | / | 6,850 |

| Sum of total investment (a) | 23,447 | 66,671 |

| Operational life span (a) | 20 | 20 |

| Recovery value (€) | 0 | 0 |

| Fixed costs (€ a−1) | ||

| Depreciation | 1,172 | 3,334 |

| Variable costs (€ a−1) | ||

| Raw materials | ||

| Water for ink production | 114 | 94 |

| Operational supplies (cleaning, start-up) | 1,855 | 25 |

| Disposal of waste water and solvents | 1,478 | 37 |

| Energy | 4,319 | 898 |

| Personnel | ||

| Plant operator | 16,235 | 3,263 |

| Chemical laboratory assistant | 4,025 | / |

| Maintenance services | 646 | 3,241 |

| Sum of variable costs | 28,672 | 7,558 |

| Total production costs (€ a−1) | 29,844 | 10,892 |

| Specific manufacturing costs (€ L−1) | 0.2014 | 0.0735 |

However, all other variable costs are decreased when transferring the production scheme. This is mainly caused by reducing the labor costs by 84%, realized both during the production itself and the automated quality control. The energy demand and, hence, the energy costs can be lowered by 79%, a similar percentage as the labor costs. However, the energy costs have less influence on the total production costs, because of the lower prices per unit. This effect is even more pronounced for the costs of the operating supplies and their disposal. Transferring a batch to a continuous process would lead to a reduction of both items by 94% to 98%. Since they are associated with a very low price per unit, though they play only a minor role in the cost analysis.

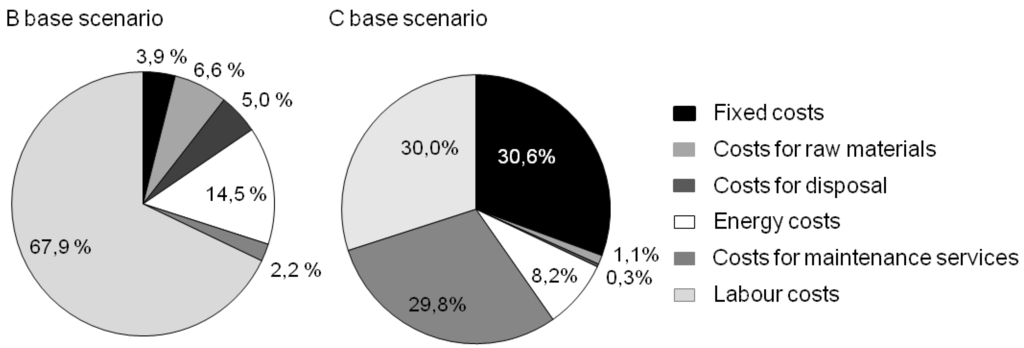

The cost structure is therefore altered by transferring the manufacturing strategy, as Figure 5 illustrates. The largest share of the total production costs per year of the batch plant is related to personnel costs, followed by the costs for electricity, raw materials and disposal. Meanwhile, the fixed costs account for only 4% of the total production costs per year. For the continuous process, the labor costs still have a very high impact, decreasing, however, by 68% to 30%. Since the total production costs are lower than for the batch process, the share of the fixed costs and those for maintenance rise.

Figure 5.

The change in the potential environmental impacts of the continuous process varying the cleaning agent demand in comparison with the batch production scheme.

The cost structure, however, is influenced by the system boundaries chosen. If all reactants were included in the calculation of the costs for raw materials, these would dominate the variable costs for both manufacturing strategies. The latter was also found by Krtschil et al. [37] for the continuous production of 4-cyanophenylboronic acid with micro-components, as well as by Benaskar et al. [38], who have conducted an economic assessment of the Ullmann C–O cross-coupling reaction using both microprocessing and microwave heating. In the case of writing ink, the only reactant included in this study, water, would have the lowest share in the raw material costs, due to its low price.

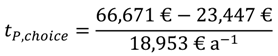

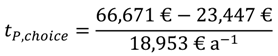

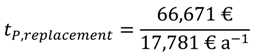

The comparison of the total production costs per year shows that the cost advantage of the continuous manufacturing scheme is mainly based on lower variable costs. This was predicted by Roberge et al. [39] for dedicated micro-/milli-continuous processes. Investing in either a batch or a continuous plant for ink manufacturing, a cost advantage of 18,953 € arises when choosing the continuous instead of the batch regime. Dividing the difference in the total production costs per year of both processes by the cost advantage mentioned according to:

results in a payback time of 2.3 years. However, if the current batch process is replaced by a new micro-/milli-continuous campaign manufacturing scheme, it is assumed that the batch plant is already written off. Only the variable costs have to be considered in this case. The cost advantage of the continuous processing scheme is reduced to 17,781 €. The payback time then follows from to 3.8 years.

results in a payback time of 2.3 years. However, if the current batch process is replaced by a new micro-/milli-continuous campaign manufacturing scheme, it is assumed that the batch plant is already written off. Only the variable costs have to be considered in this case. The cost advantage of the continuous processing scheme is reduced to 17,781 €. The payback time then follows from to 3.8 years.

3.2.2. Economic Assessment of the Sensitivity Analysis

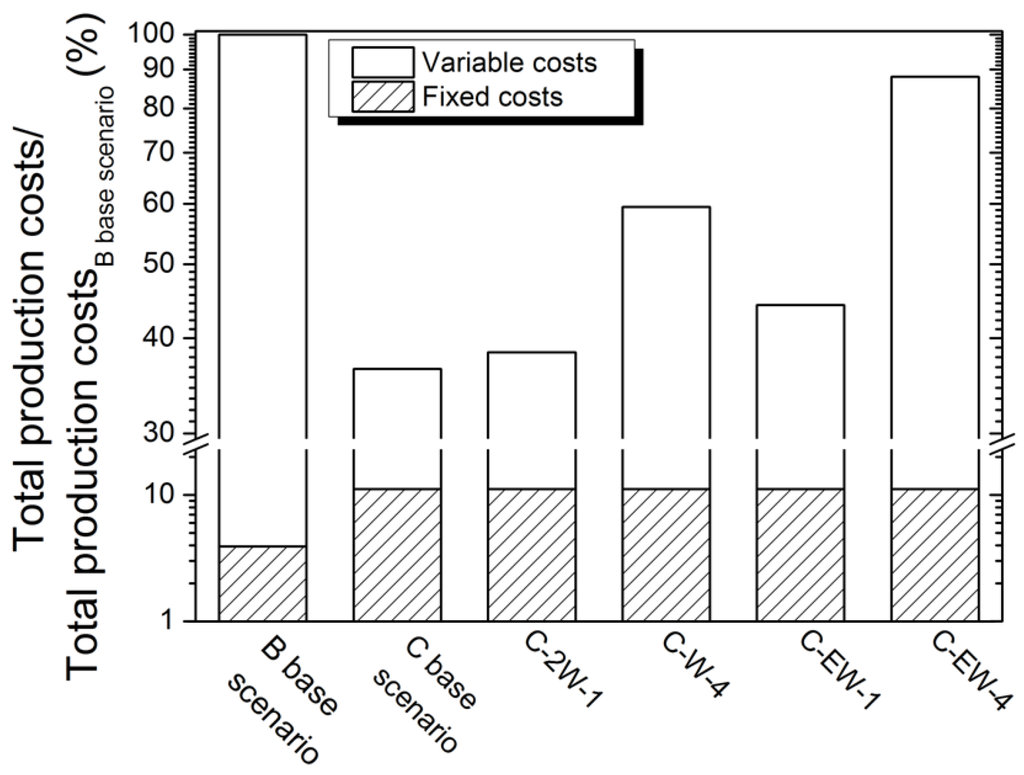

Figure 6 shows that a cost advantage can be realized compared to batch processing for all cases considered. However, this cost advantage strongly depends on the assumptions and the resulting variable costs, as described below.

Figure 6.

Total annual production costs of the batch and the micro-/milli-continuous campaign manufacturing process for writing ink varying the cleaning agent demand.

Using twice the amount of water for cleaning in case C-2W-1 has a negligible impact on the total production costs. Despite their rise by 5.2% compared to the C base scenario, they are still 62% lower than in the batch scenario. The rise mentioned is mainly due to the doubled personnel requirements during the cleaning of the premix vessels. The costs for tap water and its disposal have only a minor impact. The payback time is similar to the C base scenario.

If additional solvents are used for cleaning (C-EW-1), then the total production costs are lowered by 55% compared to the batch scheme. Due to the high costs of ethylene glycol, they are higher than in case C-2W-1; the personnel requirements are, however, equivalent to those of the base scenario. The investment in a new continuous plant is amortized after 2.6 years, whereas exchanging the existing production facilities leads to a payback period of 4.3 years.

Four cleaning cycles are required per week in C-W-4 with production costs 40% lower than for the batch process. The rise compared with the base scenario is caused by the increased personnel requirements for the separate preparation of four premixes and the on-site control of each of the four start-up phases. As a result of this, the payback period is 3.6 years when investing in a new plant and 6.1 years when exchanging the existing plant. This illustrates that even the production of specialties at low volumes or without adhering to the optimum production sequence is economically viable in the case of a capacity increase or the production of new products.

If, however, four intensive cleaning cycles are required per week, then the total production costs are only 12% lower than those of the batch plant. These high production costs are determined by the high labor costs and the high costs for providing the cleaning agent, ethylene glycol. The low cost advantage compared to batch processing renders this version not economically viable: the payback period in the case of a new investment is increased to 12.2 years and to 28.1 years in the case of a plant exchange.

3.2.3. Significance and Validity of the Results of the Economic Assessment

The economic assessment was based on the comparison of the total production costs per year and the payback periods of both process alternatives. The total production costs were calculated with data from an existing batch plant, however, derived from a production concept of the continuous manufacturing scheme. Again, it is stressed that an optimized batch plant is not considered in this paper. Such an optimization might lead to similar cost advantages, as described here for the continuous manufacturing scheme. In order to calculate the fixed costs, detailed equipment lists served as a basis for specific supplier quotations. The fixed costs are therefore regarded as reliable based on the system boundaries chosen and the assumptions made. The calculation of the variable costs is dependent on the material and energy streams derived by flow modeling and the respective prices per unit. For flow modeling, please refer to the constraints and comments listed in Section 3.1.3. All prices employed are valid for the specific production location.

Based on the data basis described, the data quality for the economic assessment of the batch process can be awarded grade 2 following the Pedigree matrix by Ciroth [40], the continuous process, however, only grades 3–4. The grades range from 1 for the best to 5 for the worst data quality. The main influencing factors on the economic viability of the micro-/milli-continuous campaign manufacturing scheme were identified by sensitivity analysis. It was shown that the results are reliable, even when varying critical parameters. Critical limits led to recommendations for an efficient continuous campaign production, as described in the following section.

3.3. Interpretation of All Results and Recommendations

Based on the results of the base scenarios and the sensitivity analysis of the cleaning agent demand of both the ecological, as well as the economic assessment, the following recommendations can be given regarding the operation of a continuous campaign production plant for writing ink:

- If different ink colors are to be produced during one production week, it is advised to adhere to the optimum production sequence, as well as to the minimum production volume of 121 L. In this way, the cleaning frequency can be limited to one cycle at the end of the weekly production period, decreasing the amount of cleaning agents, as well as the disposal effort required and the labor costs associated with it.

- However, if cleaning is required several times a week, due to very tight product specifications, the best option is to use only water (see case C-W-4). It is generally suggested to aim at minimizing the use of ethylene glycol, ethanol or sodium carbonate solution, both from the ecological and economic point of view. Of these three fluids, sodium carbonate solution is the preferred cleaning medium if decoloration is necessary. One cleaning cycle per week using additional solvents to fully clean and decolor the continuous flow plant seems, however, ecologically tolerable and economically viable according to C-EW-1.

- Since the personnel costs are the main influencing factor on the annual production costs, preparing several premixes per week in order to produce various specialties therefore carries weight. It is recommended to prepare at least two premixes in parallel if the type and amount of vessels available permit. Conducting a cost analysis, it is assumed that the same sales can be realized by common inks and special inks of very small production volumes. The additional personnel costs could be taken into consideration during pricing, though.

- From an ecological point of view, the amount of waste should be minimized by its reuse. Particularly, the waste water arising during the cleaning of the premix vessels could be reused as the reactant for the production of the same or similar inks, like is proposed for the waste water of dying processes by Shams-Nateri [41]. The rest of the cleaning agents should, however, be discarded, due to their contamination with a binder, a potential source of agglomerate formation. From an economic point of view, reusing the waste water is not absolutely necessary, due to the low water price, and might even lead to higher labor costs, because of additional handling steps.

4. Conclusions

Based on this study, it can be concluded that a continuous campaign manufacturing scheme is both an ecologically and economically viable alternative to the traditional batch production of writing ink. Lower environmental impacts in all impact categories result from the new production strategy. The key to ecological viability is the reduced energy demand during continuous processing, resulting from more intensive mixing in the micro-mixer, as well as from recipe adaption, thus eliminating the long heating periods in the vessels. The reduced energy demand also outweighs the additional environmental impacts, due to the more elaborate plant equipment. Furthermore, a cost advantage can be realized with the micro-/milli-continuous campaign manufacturing scheme compared to batch processing. In this case, the reduced personnel requirements resulting from a mostly automated production are decisive. Overall, this leads to lower variable costs compared to batch production. The scope of this paper does not include a fully or partially automated batch plant, which might lead to similar advantages in regard to energy demand and personnel requirements. However, intensified heat and mass transfer in micro- and milli-structured components greatly enhances the process repeatability and product quality in comparison with processing in batch vessels. Due to the high investment, continuous campaign production is especially suited for a capacity increase of existing or the introduction of new products.

Nomenclature

| a | Year (Latin: annum) |

| ABS | Acrylonitrile butadiene styrene |

| B | Batch processing of writing ink |

| C | Micro-/milli-continuous campaign manufacturing of writing ink |

| CML | Centrum voor Milieukunde, Universiteit Leiden |

| EPDM | Ethylene propylene diene monomer |

| FAETP | Fresh water aquatic eco-toxicity potential |

| FSETP | Fresh water sediment eco-toxicity potential |

| FU | Functional unit |

| GWP | Global warming potential |

| HTP | Human toxicity potential |

| LCA | Lifecycle assessment |

| LO | Land occupation |

| MAETP | Marine aquatic eco-toxicity potential |

| MSETP | Marine sediment eco-toxicity potential |

| NAMUR | Normen-Arbeitsgemeinschaft Mess- und Regeltechnik |

| OLED | Organic light emitting diode |

| PET | Polyethylene terephtalate |

| PTFE | Polytetrafluorethylene |

| tP | Payback time in years |

| TAETP | Terrestrial aquatic eco-toxicity potential |

| VDI/VDE | Verein deutscher Ingenieure/Verband der Elektrotechnik Elektronik Informationstechnik |

Acknowledgments

This work has been partially funded by the Deutsche Bundesstiftung Umwelt, Germany, under grant no. AZ 25833 within the funding cluster “Novel Process Windows”. We gratefully acknowledge the financial support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mahammadzadeh, M. Unternehmen investieren in den Umweltschutz. UmweltMagazin 2013, 43, 36–39. [Google Scholar]

- Yue, D.; Fengqi, Y. Sustainable scheduling of batch processes under economic and environmental criteria with MINLP models and algorithms. Comp. Chem. Eng. 2013, 54, 44–59. [Google Scholar]

- Mitropetros, K.; Bazzanella, A. Leitfaden Mikroverfahrenstechnik: µVTGuide; Dechema e.V.: Frankfurt, Germany, 2010. [Google Scholar]

- Schnitzer, H.; Titz, M. Technology wedges for low carbon-strategies in industry. In Energy Options Impact on Regional Security; Barbir, F., Ulgiati, S., Eds.; Springer: Dordrecht, The Netherlands, 2010; pp. 109–122. [Google Scholar]

- MIT news. MIT and Novartis in new partnership aimed at transforming pharmaceutical manufacturing. Available online: http://web.mit.edu/newsoffice/2007/novartis-0928.html (accessed on 12 December 2013).

- MIT news. Continuous drug manufacturing offers speed, lower costs. Available online: http://web.mit.edu/newsoffice/2012/manufacturing-pharmaceuticals-0312.html (accessed on 12 December 2013).

- Stitt, E.H.; Rooney, D.W. Switching from batch to continuous processing for fine and intermediate-scale chemicals manufacture. In Novel Concepts in Catalysis and Chemical Reactors: Improving the Efficiency of the Future; Cybulski, A., Moulijn, J.A., Stankiewicz, A., Eds.; Wiley-VCH: Weinheim, Germany, 2010; pp. 309–330. [Google Scholar]

- Jiménez-González, C.; Poechlauer, P.; Broxtermann, Q.B.; Yang, B.S.; am Ende, D.; Baird, J.; Bertsch, C.; Hannah, R.E.; Dell’Orco, P.; Noorman, H.; et al. Key green engineering research areas for sustainable manufacturing: A perspective from pharmaceutical and fine chemicals manufacturers. Org. Proc. Res. Dev. 2011, 15, 900–911. [Google Scholar] [CrossRef]

- Kralisch, D.; Streckmann, I.; Ott, D.; Krtschil, U.; Santacesaria, E.; di Serio, M.; Russo, V.; de Carlo, L.; Linhart, W.; Christian, E.; et al. Transfer of the epoxidation of soybean oil from batch to flow chemistry guided by cost and environmental issues. ChemSusChem 2012, 5, 300–311. [Google Scholar] [CrossRef]

- Hessel, V. Novel process windows—Gate to maximizing process intensification via flow chemistry. Chem. Eng. Technol. 2009, 32, 1655–1681. [Google Scholar] [CrossRef]

- Charpentier, J.-C. In the frame of globalization and sustainability, process intensification, a path to the future of chemical and process engineering (molecules into money). Chem. Eng. J. 2007, 134, 84–92. [Google Scholar] [CrossRef]

- F3 Factory. Third Newsletter published on 27th August 2012. Available online: http://www.f3factory.com/scripts/pages/en/newsevents/F3_Factory_Newsletter_3.pdf (accessed on 12 December 2013).

- Grundemann, L.; Fischer, N.; Scholl, S. From macro batch to micro-conti manufacturing: A new eco-friendly production process for writing ink employing micro-process engineering. Chem. Eng. Technol. 2009, 32, 1748–1756. [Google Scholar] [CrossRef]

- Grundemann, L.; Gonschorowski, V.; Fischer, N.; Scholl, S. Cleaning waste minimization for multi-product plants: transferring macro batch to micro conti manufacturing. J. Cleaner Prod. 2012, 24, 92–101. [Google Scholar] [CrossRef]

- Fürer, S.; Rauch, J.; Sanden, F.J. Konzepte und Technologien für Mehrproduktanlagen. Chem. Ing. Tech. 1996, 68, 375–381. [Google Scholar] [CrossRef]

- Schaber, S.D.; Gerogiorgis, D.I.; Ramachandran, R.; Evans, J.M.B.; Barton, P.I.; Trout, B.L. Economic analysis of integrated continuous and batch pharmaceutical manufacturing: a case study. Ind. Eng. Chem. Res. 2011, 50, 10083–10092. [Google Scholar]

- Environmental management—Life cycle assessment—Principles and framework. 2006; ISO 14040:2006.

- Environmental management—Life cycle assessment—Requirements and guidelines. 2006; ISO 14044:2006.

- Curran, M.A. Life Cycle Assessment: Principles and Practices. By Scientific Applications International Corporation (SAIC), Contract No. 68-C02–067,Work Assignment 3–15–on behalf of: United States Environmental Protection Agency, National Risk Management Research Laboratory, Cincinnati, OH, USA; 2006. Available online: http://www.epa.gov/nrmrl/std/lca/lca.html (accessed on 12 December 2013). [Google Scholar]

- Klöpffer, W.; Grahl, B. Ökobilanz (LCA): Ein Leitfaden für Ausbildung und Beruf; Wiley-VCH: Weinheim, Germany, 2009. [Google Scholar]

- Wernet, G.; Mutel, C.; Hellweg, S.; Hungerbühler, K. The environmental importance of energy use in chemical production. J. Ind. Ecol. 2011, 15, 96–107. [Google Scholar] [CrossRef]

- Umberto 5.6; ifu Hamburg: Hamburg, Germany, 2011.

- Grundemann, L. Zur Umstellung von chargenweise betriebenen Mehrproduktanlagen auf kontinuierliche Kampagnenfertigung; Cuivillier: Göttingen, Germany, 2013. [Google Scholar]

- Ecoinvent database v 2.2; Swiss Centre for Life Cycle Inventories: Zürich, Switzerland, 2010.

- VDI/VDE, NAMURVDI/VDE-Gesellschaft Mess- und Automatisierungstechnik; NAMUR. Roadmap Prozess-Sensoren 2015+: Technologie-Roadmap für Prozess-Sensoren in der chemisch-pharmazeutischen Industrie, 11/2009. Available online: http://www.vdi.de/fileadmin/vdi_de/redakteur_dateien/gma_dateien/Prozess-Sensoren_2015+.pdf (accessed on 12 December 2013).

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Klein, R.; de Koning, A.; van Oers, L.; Wegener Sleeswijk, A.; Suh, S.; de Haes, U.H.A.; et al. Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Azapagic, A.; Perdan, S. Indicators of sustainable development for industry. Process Saf. Environ. 2000, 78, 243–261. [Google Scholar] [CrossRef]

- Huppes, G.; van Oers, L.; Pretato, U.; Pennington, D.W. Weighting environmental effects: Analytic survey with operational evaluation methods and a meta-method. Int. J. Life Cycle Assess. 2012, 17, 876–891. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure. Richtlinie 2884. In Beschaffung, Betrieb und Instandhaltung von Produktionsmitteln unter Anwendung von Life Cycle Costing (LCC); Beuth: Berlin, Germany, 2005. [Google Scholar]

- Wichmann, M. Field report about MRT pilot-application in specialty & fine chemicals production. In Proceedings of the Symposium: Micro process technologies—From mg to tons, Hannover, Germany, 26 November 2008.

- Kölbel, H.; Schulze, J. Projektierung und Vorkalkulation in der Chemischen Industrie; Springer: Berlin, Germany, 1960. [Google Scholar]

- Helfrich, F.; Schubert, W. Ermittlung von Investitionskosten, Einfluss auf die Wirtschaftlichkeitsrechnung. Chem. Ing. Tech. 1973, 65, 891–897. [Google Scholar] [CrossRef]

- Ullrich, H. Wirtschaftliche Planung und Abwicklung verfahrenstechnischer Anlagen; Vulkan-Verlag: Essen, Germany, 1996. [Google Scholar]

- Frühwald, A.; Scharai-Rad, M.; Hasch, J. Ökologische Bewertung von Holzwerkstoffen. Universität Hamburg, Bundesforschungsanstalt für Forst- und Holzwirtschaft Hamburg, 11/2000. Schlussbericht März 2000, ergänzt in den Bereichen Spanplattenrecycling und OSB-Bilanzen. Available online: http://www.Bfafh.de/bibl/pdf/scharai_pub1.pdf (accessed on 12 December 2013).

- Oldenburg, J.; Schlegel, M.; Cruse, A.; Marquardt, M. Batch process modeling and optimization. In Batch Processes; Korovessi, E., Linniger, A.A., Eds.; CRC Press: Boca Raton, FL, USA, 2005; pp. 305–387. [Google Scholar]

- Weidema, B.P.; Wesnaes, M.S. Data quality management for life cycle inventories—An example using data quality indicators. J. Cleaner Prod. 1996, 4, 167–174. [Google Scholar] [CrossRef]

- Krtschil, U.; Hessel, V.; Kralisch, D.; Kreisel, G.; Küpper, M.; Schenk, R. Cost analysis of a commercial manufacturing process of afine chemical compound using micro process engineering. Chimia 2006, 60, 611–617. [Google Scholar] [CrossRef]

- Benaskar, F.; Ben-Abdelmoumen, A.; Patil, N.G.; Rebrov, E.V.; Meuldijk, J.; Hulshof, L.A.; Hessel, V.; Krtschil, U.; Schouten, J.C. Cost analysis for a continuously operated fine chemicals production plant at 10 kg/day using a combination of microprocessing and microwave heating. J. Flow Chem. 2011, 1, 74–89. [Google Scholar] [CrossRef]

- Roberge, D.M.; Ducry, L.; Bieler, N.; Cretton, P.; Zimmermann, B. Microreactor technology: A revolution for the fine chemical and pharmaceutical industries? Chem. Eng. Technol. 2005, 28, 318–323. [Google Scholar] [CrossRef]

- Ciroth, A. Cost data quality considerations for eco-efficiency measures. Ecol. Econ. 2009, 68, 1583–1590. [Google Scholar] [CrossRef]

- Shams-Nateri, A. Reusing wastewater of madder natural dye for wool dyeing. J. Cleaner Prod. 2011, 19, 775–781. [Google Scholar] [CrossRef]

- Landesbetrieb für Statistik und Kommunikationstechnologie (LSKN): Trink- und Abwasserentgelte nach Gemeinden. Available online: http://www.lskn.niedersachsen.de (accessed on 12 December 2013).

- Bundesverband der Energieabnehmer e.V. (VEA); Bundesverband der Energie- und Wasserwirtschaft (BDEW). BDEW-Strompreisanalyse 05/2012: Haushalte und Industrie. Berlin, 04.05.2012. Available online: http://bdew.de/internet.nsf/id/0E5D39E2E798737FC1257A09002D8C9C/$file/120525%20BDEW-Strompreisanalyse%202012%20Chartsatz%20gesamt.pdf (accessed on 12 December 2013).

- WSI-Tarifarchiv der Hans-Böckler-Stiftung. Tarife in der chemischen Industrie. Available online: http://www.boeckler.de/index_wsi_tarifarchiv.htm (accessed on 12 December 2013).

Appendix A: Flow Chart of the Continuous Manufacturing Plant

Appendix B: Equipment List and Investment for Both Process Alternatives

Table B-1.

Equipment list and costs for the batch plant. PTFE, polytetrafluoroethylene.

| Equipment | Supplier and model | Technical data, comments | Main material | Price/piece (€) | Amount | Total costs (€) |

|---|---|---|---|---|---|---|

| Jacketed stirred vessel | HAB Heiland Apparatebau | V = 1 m3 | 1.4301 | 6,820 | 2 | 13,640 |

| Stirrer | Stelzer SM-63, propeller stirrer | Pmax = 2.2 kW | 1.4571 | 1,940 | 2 | 3,880 |

| Level sensor | E.L.B. Füllstandsgeräte, magnetic level gauge | PTFE sealing: Tmax = 150 °C | 1.4571 | 1,046 | 2 | 2,092 |

| Centrifugal pump | Linn-Pumpen T65E with frequency converter VF S11S 2004 PLE- |  = 8–50 L min−1, Pmax = 0.45 kW = 8–50 L min−1, Pmax = 0.45 kW | 1.046 | 922 | 1 | 922 |

| Tube | Haarmann pressure hose | 2 × l = 1.5 m, 2 × l = 4 m | EPDM | 568 | 1 | 568 |

| Portable thermometer | Ebro TFX 410 | T = −50–300 °C | ABS | 213 | 1 | 213 |

| Total investment | 21,315 |

Table B-2.

Equipment list and costs for the micro-/milli-continuous campaign plant.

| Equipment | Code | Supplier and model | Technical data, comments | Main material | Price/piece (€) | Amount | Total costs (€) |

|---|---|---|---|---|---|---|---|

| Stirred vessel | B4, B5 | HAB Heiland Apparatebau | V = 1 m³ | 1.4301 | 4,140 | 2 | 8,280 |

| Stirrer | R4, R5 | Stelzer SM-63, propeller stirrer | Pmax = 2.2 kW | 1.4571 | 1,940 | 2 | 3,880 |

| Level sensor | LIRSA-101/2, 106/7, 124/5 | Waycon UFP-1600-M18-2P-SA | / | PET | 178 | 6 | 1,068 |

| Tube | / | Haarmann pressure hose | 2 × l = 1.5 m, 2 × l = 4 m | EPDM | 568 | 1 | 568 |

| Pump for feeding of reactants | P1, P2 | Knoll MX10S-10/20 |  = 10-25 L·h−1, Pmax = 0.37 kW = 10-25 L·h−1, Pmax = 0.37 kW | 1.4571 | 1,868 | 2 | 3,736 |

| Limit switch | FISAL 103, 108 | Infra CS15 | / | Brass | 94 | 2 | 188 |

| Flow meter | FIRC 109 | Krohne OPTIMASS 3300 C, MFC 300 C | / | 1.4404 | 3,647 | 1 | 3,647 |

| Flow meter | FIRC 104 | PKP DV01 | / | Aluminum | 878 | 1 | 878 |

| Pressure sensor | PIRS+- | tecsis DD701 | Flush-mounted membrane | 1.4301 | 240 | 6 | 1,440 |

| Mixer | M1 | Synthesechemie MicroJetReactor | / | Hastelloy | 3,190 | 1 | 3,190 |

| Thermo couple | TIRS+-114, 116, 120 | TMH | Type K | 2.4816 | 39 | 3 | 117 |

| Heat exchanger | W1 | API Schmidt-Bretten SIGMA M 9 NBL | A = 1.7 m³ | 1.4404 | 1,100 | 1 | 1,100 |

| Thermostat | H1 | Fisher Scientific FBH 712 | Pmax = 2.25 kW | 1.0037 | 1,344 | 1 | 1,344 |

| Resistance thermometer | TIRC 117 | TMH | Pt100/A | 1.4541 | 82 | 1 | 82 |

| Measurement of the color value | QIRSA-121 | Premosys PR0126-C4, PR0137, Durchflussküvette | / | Aluminum | 1,626 | 1 | 1,626 |

| Pump for feeding of preservative | P4 | Medorex TL/15E |  = 0.36-36 mL h−1, Pmax = 0.015 kW = 0.36-36 mL h−1, Pmax = 0.015 kW | 1.4301 | 1,340 | 1 | 1,340 |

| Limit switch | LIRSA 111, 122/3 | Honeywell LLE 102000 | / | Polysulf. | 41 | 3 | 123 |

| Centrifugal pump | P3 | Linn-Pumpen T 65E, frequency converter VF S11S 2004 PLE- |  = 8–50 L h−1, Pmax = 0.45 kW = 8–50 L h−1, Pmax = 0.45 kW | Cast steel | 922 | 1 | 922 |

| Flow meter | FIRC 112 | PKP DOZ01 | / | PTFE | 232 | 1 | 232 |

| Valves | V1–V28 | END Automation, Bürkert: div. models (28 in total) | / | 1.4404 | 2,059 | 1 | 2,059 |

| Fittings | / | Swagelok div. | / | 1.4404 | 2,088 | 1 | 2,088 |

| Tubing | / | Bola div. | din = 2.4 mm/6 mm/8 mm | PTFE | 440 | 1 | 440 |

| Suction lance | / | Franck und Warnecke | din = 8 mm | 1.4404 | 23 | 2 | 46 |

| High-pressure cleaning device | / | Nilfisk-Alto Poseidon 2-22XT |  max = 9 L min−1, Pmax = 2.3 kW max = 9 L min−1, Pmax = 2.3 kW | Cast steel | 577 | 1 | 577 |

| Rockwool | / | Rockwool Klimarock KR50 | A = 2.5 m²,λ = 0.04 W m−1·K−1 | Rockwool | 18 | 1 | 18 |

| Plant Framework | / | Rose + Krieger profiles, Modulor Medium Density Fibre shelves, Jaera perforated plates made of stainless steel | / | Aluminum | 2,948 | 1 | 2,948 |

| Process control unit | / | Delphin TopMessage device | / | Electronics | 9,369 | 1 | 9,369 |

| Computer, screen, mouse | / | Ateclo including assembly | / | / | 653 | 1 | 653 |

| Power supply unit | / | Voltcraft FSP 1207 | / | Polystyrene | 59 | 1 | 59 |

| Total investment | 52,018 |

Appendix C: Prices

Table C-1.

Adopted prices for operating supplies, reactants and electricity for the cost analysis.

| Name | Price | Unit | Comment | Source |

|---|---|---|---|---|

| Tap water | 1.62 | € m−3 | City of Peine, 2008 | Landesbetrieb für Statistik und Kommunikationstechnologie (LSKN) [42] |

| Waste water | 2.43 | € m−3 | City of Peine, 2008 | LSKN [42] |

| Electricity | 0.1233 | € kWh−1 | Average price without tax for German industries, 2012 | Bundesverband der Energieabnehmer e.V. (VEA), Bundesverband der Energie- und Wasserwirtschaft (BDEW) [43] |

| Deionized water | 1.93 | € m−3 | Assumption that price is 20% higher than tap water | / |

| Sodium carbonate | 4.02 | € kg−1 | Packing unit: 25 kg; quotations from 2012 | Each time price average based on three quotations |

| Ethanol | 2.24 | € l−1 | Packing unit: 100–190-L drum; quotations from 2012 | |

| Ethylene glycol | 2.68 | € L−1 | Packing unit: 205–220-L drum; quotations from 2012 |

Table C-2.

Adopted prices for personnel costs for the cost analysis.

| Name | Price | Unit | Comment | Source |

|---|---|---|---|---|

| Plant operator (unskilled) | 15.65 | € h−1 | Assumed pay grade: E5, after 6 years | Labor agreement of the chemicals industries in Niedersachsen, Germany. From Wirtschafts- und Sozialwissenschaftliches Institut (WSI) archive [44] |

| Plant operator | 18.61 | € h−1 | Assumed pay grade: E7, after 6 years | |

| Chemical laboratory assistant | 27.16 | € h−1 | Assumed pay grade: E11, after 6 years |

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).