Abstract

This study proposes a data-driven optimization framework to enhance emission control performance in diesel engine selective catalytic reduction (SCR) systems under transient operating conditions. A one-dimensional SCR model was constructed in GT-Power, and simulation datasets were generated using experimentally measured inputs from the World Harmonized Transient Cycle (WHTC), with representative emission responses obtained by varying fixed ammonia-to-NOx (A/N) ratios. Building on these datasets, a hybrid prediction model combining Long Short-Term Memory (LSTM) networks and multi-head attention mechanisms was developed to accurately forecast SCR outlet NH3 leakage and NOx emissions. The model exhibited high predictive accuracy, achieving R2 values exceeding 0.977 and low RMSE across training, validation, and test sets. Based on the model predictions, a constrained dynamic multi-objective optimization strategy was implemented to adaptively adjust ammonia dosing, aiming to simultaneously minimize NH3 leakage and NOx emissions. The optimized NH3 injection profiles were validated through reapplication in the GT-Power simulation environment. Compared to the baseline fixed-ratio control strategy, the proposed approach reduced NH3 leakage and NOx emissions by 34.40% and 11.15%, respectively, as determined for the transient segment of the WHTC cycle. These results demonstrate the effectiveness of integrating physics-based simulation, deep learning prediction, and dynamic optimization for improving aftertreatment adaptability and emission compliance in real-world diesel engine applications. All reported values are based on a single simulated WHTC cycle without statistical uncertainty analysis.

1. Introduction

Diesel engines remain dominant in heavy-duty transportation owing to their high efficiency and durability [1,2]. However, increasingly stringent emissions regulations, particularly the China VI standard, impose substantial challenges on aftertreatment systems [3]. China VI mandates significant reductions in nitrogen oxides (NOx) and ammonia (NH3) emissions, enforced not only under laboratory conditions but also through real-driving emissions (RDE) testing [4]. Achieving compliance necessitates advanced aftertreatment technologies. Urea-based selective catalytic reduction (SCR) is widely used to control NOx emissions in diesel engines [5]. However, too much urea can cause NH3 leakage, while too little reduces NOx removal efficiency. Achieving the right balance under changing engine conditions is technically challenging [6,7].

Accurate, control-oriented modeling of selective catalytic reduction (SCR) catalysts is crucial for developing effective emission control strategies. Researchers have proposed various SCR kinetic models, typically accounting for NH3 adsorption/desorption and distinct fast and slow NOx reduction sites [8,9,10]. One prevalent method employs one-dimensional PDE or lumped ODE models with Eley–Rideal kinetics, enabling integration into platforms like GT-Suite (GT-Power) for engine and aftertreatment co-simulation. Holmer and Eriksson [8] demonstrated that a quasi-static gas-phase model achieved better NH3 leakage prediction and computational efficiency compared to CSTR models. Furthermore, SCR models calibrated against standard cycles, such as the hot FTP, have shown strong agreement with measured tailpipe NOx and NH3 emissions across varying operating conditions. Collectively, GT-Power-based SCR models, often coupled with Simulink controllers, provide high-fidelity transient predictions that are essential for control development under dynamic driving cycles [11,12].

Controlling urea injection to balance NOx and NH3 emissions has been an active research focus [13,14,15]. Early feedforward maps and lookup tables based on steady-state calibration cannot adapt to catalyst aging or dynamic disturbances. Consequently, feedback controllers and adaptive observers have been proposed. Closed-loop strategies utilizing tailpipe NOx (and occasionally NH3) measurements help compensate for catalyst degradation, fuel variations, and sensor drift. Wang et al. [7] identified NH3 cross-sensitivity in NOx sensors and proposed a model-based adjustment using the ammonia-to-NOx ratio (ANR) to decouple dosing from sensor bias, achieving NOx control errors below 2%. Additionally, neural network-based observers have been employed to infer unmeasured catalyst ammonia storage states, enabling improved feedback control [16,17]. Despite these advances, many existing control strategies still depend heavily on steady-state assumptions or require case-specific tuning, limiting their effectiveness under real-world transients.

In parallel, data-driven approaches, particularly deep learning, have gained traction for emission prediction under dynamic conditions [17,18,19]. Long Short-Term Memory (LSTM) networks have demonstrated strong performance in modeling time-series engine emissions. For example, Shen et al. [20] developed a CNN-LSTM hybrid to predict NOx emissions over the WHTC cycle, achieving significant improvements in RMSE and R2 compared to standalone LSTM networks. Guo and Mao [21] proposed a parallel LSTM-Transformer architecture, yielding 19–28% improvements in long-range NOx prediction. Sun et al. [22] further demonstrated that integrating multi-layer self-attention with CNN-LSTM architectures enhances temporal feature extraction. These developments suggest that attention-augmented deep networks can more effectively model the complex temporal dynamics of emissions. However, most existing deep-learning applications focus on NOx prediction, with limited efforts on modeling NH3 leakage or jointly forecasting both NOx and NH3 emissions.

Optimizing SCR operation involves inherent trade-offs between maximizing NOx conversion and minimizing NH3 leakage and urea consumption [23]. Multi-objective optimization techniques, such as NSGA-II and Pareto-based methods, have been applied to address these challenges [24,25,26]. Liu et al. [26] combined support vector regression with genetic algorithms to develop Pareto-optimal dosing strategies, achieving high NOx conversion with acceptable NH3 leakage levels. Fan et al. [27] integrated 3D-CFD simulations with response surface modeling and VIKOR decision-making, optimizing injector parameters to enhance NH3 uniformity (+8.4%) and conversion efficiency (+81.7%) while reducing undesired wall film formation (−75.2%). Nevertheless, many existing optimization studies focus on static or quasi-steady conditions, lacking real-time adaptability for transient operations. Despite these advancements, notable research gaps persist. Most current models and control strategies are primarily validated under steady-state or simple transient conditions, with limited integration of physics-based simulation and machine learning for highly dynamic cycles. Furthermore, deep learning models have rarely been employed to jointly predict NOx and NH3 under transient conditions, nor fully incorporated into closed-loop optimization frameworks. Additionally, few studies account for dynamic system constraints, such as catalyst thermal behavior, in real-time optimization.

To address these challenges, this study proposes a comprehensive framework integrating physics-based simulation, hybrid deep learning prediction, and dynamic multi-objective optimization. A GT-Power-based diesel engine and SCR model is developed and validated against experimental bench data. An LSTM predictor augmented with self-attention mechanisms is trained on simulation datasets to forecast transient SCR outlet NH3 leakage and NOx emissions. These predictions are embedded within a constrained optimization layer that dynamically adjusts urea injection in real-time to simultaneously minimize tailpipe NH3 leakage and NOx emissions, subject to operational constraints. This integrated framework aims to significantly enhance SCR control performance under real-world transient driving conditions.

2. Experimental Setup and Methods

2.1. Modeling of the SCR System

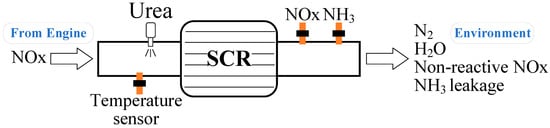

Figure 1 shows a schematic of a catalytic converter illustrating how NOx emissions are converted into nitrogen gas and water. Figure 1 also indicates the possible emissions of non-reactive NH3 (NH3 leakage) and non-reactive NOx.

Figure 1.

Working principle of urea SCR technology.

2.1.1. Reaction Mechanism of SCR

Based on the Eley–Rideal mechanism, the selective catalytic reduction (SCR) process involves the adsorption of ammonia, generated through urea thermolysis, onto active catalytic sites. The adsorbed NH3 then reacts with gaseous NOx species to form N2 and H2O through redox reactions. In addition to the primary SCR reactions, side reactions such as ammonia oxidation, NO oxidation, and the formation of nitrous oxide (N2O) may also occur. In this study, the SCR reaction kinetics are based on the Cu-zeolite mechanism proposed by Pant et al. [28], and a one-dimensional kinetic model of the SCR system was constructed using GT-Power software (version 2019). The model assumes that the urea decomposition process is not explicitly considered; instead, gaseous ammonia is directly introduced upstream of the SCR catalyst. The kinetic mechanism consists of eight key reactions, as summarized in Table 1, which include ammonia adsorption/desorption, standard SCR, fast SCR, ammonia oxidation, and N2O formation pathways. The symbol “S” denotes a vacant active site on the catalyst surface. This reaction set enables accurate simulation of SCR performance under dynamic conditions and forms the core of the GT-Power model used in this study.

Table 1.

Reaction of SCR.

2.1.2. Diesel SCR System Simulation Model

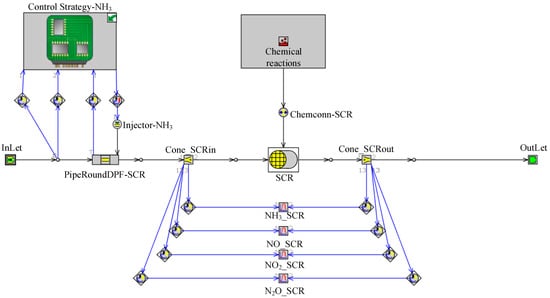

The overall SCR reaction kinetics model, illustrated in Figure 2, was constructed using GT-Power and consists of six main modules: inlet gas processing, catalyst reactor configuration, surface reaction kinetics, outlet gas analysis, sensor acquisition, and data processing. The model considers both heat and mass transfer between the catalyst coating and the laminar flow within the reactor channels, allowing for accurate simulation of transient SCR reaction behavior. This structure enables GT-Power to dynamically capture the interactions between flow, temperature, and chemical conversion processes during NOx reduction and NH3 leakage prediction.

Figure 2.

SCR system simulation model.

2.2. Data Collection

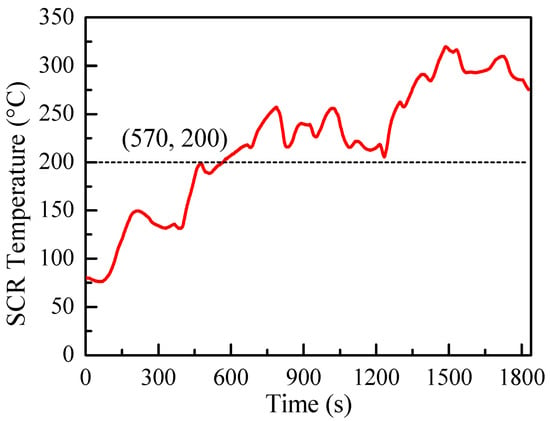

To investigate the NOx emission and other exhaust parameters during cold-start and mid- to low-load working conditions, a diesel engine emission experiment was carried out using the World Harmonized Transient Cycle (WHTC) at a time resolution of 0.1 s. The collected data included engine speed, intake temperature and pressure, NOx mass flow rate at the SCR inlet, urea injection volume, and the outlet concentrations of NH3 and NOx. The urea solution used for all experiments was commercial-grade automotive urea (AdBlue®, 32.5% purity, produced by Tianjin Kunhua Chemical Co., Ltd., Tianjin, China). The concentrations of NH3 and NOx used for calibration and validation were obtained from experimental bench measurements. NO and NOx concentrations were measured using a HORIBA MEXA-ONE-RS analyzer (Horiba, Ltd., Kyoto, Japan; chemiluminescence detection, CLD), and NH3 concentrations were measured using a BRUKER OMEGA-5 analyzer (Bruker, Billerica, MA, USA; Fourier transform infrared spectroscopy, FTIR). Both analyzers have a measurement range of 0–10,000 ppm and an accuracy of ±2% of reading, ensuring the high reliability of the emission data used in this study. The total duration of the WHTC cycle was 1829 s, resulting in 18,290 data points representing dynamic engine operating conditions. Among the recorded parameters, the exhaust temperature upstream of the SCR system was continuously monitored and is shown in the temperature curve depicted in Figure 3. During the initial cold-start phase (0–570 s), the exhaust temperature remained consistently below 200 °C. This low-temperature condition necessitated the suspension of urea injection to prevent the risk of urea crystallization within the SCR system. Consequently, SCR outlet NO and NO2 concentrations during this period closely matched the inlet levels, indicating the absence of NOx conversion reactions. After approximately 570 s, the exhaust temperature gradually increased as the engine warmed up, reaching levels sufficient to enable urea injection and initiate standard SCR operation. For the purposes of our LSTM-attention study, the analysis focused primarily on the period between 570 and 1829 s.

Figure 3.

SCR inlet temperature profile during the WHTC cycle.

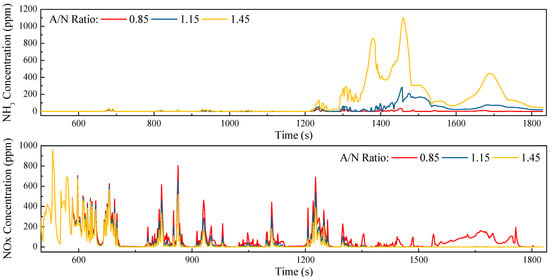

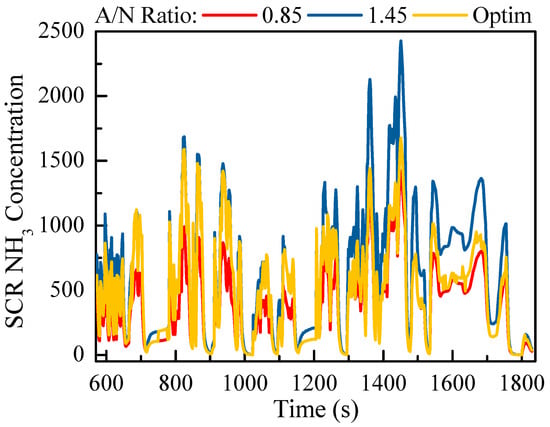

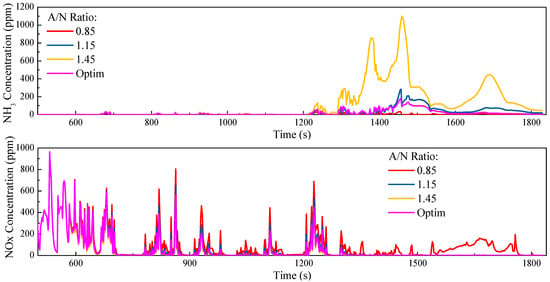

Based on the developed SCR model and using experimentally measured inputs from the WHTC cycle, a series of simulations were performed to evaluate the impact of different ammonia injection strategies. The simulations were designed by scaling the NH₃ dosing rate relative to the instantaneous NOx mass flow at the SCR inlet, resulting in five representative A/N ratios: 0.85, 1.00, 1.15, 1.30, and 1.45. The A/N ratio is defined as the molar ratio of ammonia supplied (as injected or available NH3) to the total NOx entering the SCR catalyst. The results are summarized in Figure 4, which illustrates the time-resolved profiles of NH3 leakage and NOx emissions for each dosing scenario.

Figure 4.

Time-series comparison of NH3 and NOx emissions under different fixed A/N ratios.

As the A/N ratio increased, a clear trade-off was observed between NOx reduction and NH3 leakage. At a low A/N ratio of 0.85, NH3 emissions were negligible throughout the cycle; however, NOx conversion efficiency was substantially compromised, particularly during high-load transients. With increasing A/N ratio, NOx emissions progressively decreased due to higher NH3 availability, but this came at the cost of increased NH3 leakage, especially under deceleration and low-temperature conditions. The intermediate A/N ratio of 1.15 achieved a relatively balanced performance, effectively reducing NOx emissions while keeping NH3 leakage within acceptable limits across most of the transient cycle. In contrast, higher dosing ratios led to marginal NOx improvement but significantly elevated NH3 breakthrough levels, indicating over-injection beyond the catalyst’s storage and conversion capacity. These simulation results demonstrate the sensitivity of SCR system performance to ammonia dosing strategy and underscore the importance of dynamic, condition-dependent control to balance competing emission targets. The insights gained from this parametric study provide a foundation for the data-driven predictive modeling and optimization framework proposed in subsequent sections.

2.3. Method

2.3.1. Time-Series Modeling with LSTM and Multi-Head Attention

This study combines LSTM networks and multi-head attention to model time-series emission data. The LSTM captures long-term dependencies, while attention enables the model to focus on the most relevant moments for more accurate predictions. Importantly, this architectural choice was not made for novelty but for targeted alignment with the SCR emission control problem. The model is compact and control-oriented, relying on four real-time measurable inputs, and the attention mechanism is tuned to emphasize short-term transients, which are critical in dynamic SCR environments. This ensures both interpretability and computational efficiency for real-time deployment. By combining the strengths of LSTM and Multi-Head Attention, the model can better understand the dynamics of the system and make more accurate predictions for emission optimization. Four variable factors are selected as the input layer of the neural network, such as NOx concentration in exhaust gas, inlet temperature of SCR upstream, exhaust flow, and urea injection amount. The output of the neural network is NH3 leakage concentration and NOx emission. From the original data set, 70% is used for training models, 15% is used for validation, and 15% is set aside for testing. This split ensures that the model is exposed to sufficient data for training while reserving unseen samples for robust evaluation. The input sequence length was fixed at 50 time steps based on empirical testing, which provided a good trade-off between capturing dynamic dependencies and maintaining computational efficiency. Hyperparameters such as the number of attention heads (2, 4, 8), hidden dimensions (64–256), and dropout rate (0–0.5) were selected using Optuna optimization guided by validation RMSE. The final model architecture selected for best generalization uses 8 attention heads, 128 hidden units, 3 layers, a dropout of 0.0009, a learning rate of 0.00097, and a batch size of 32.

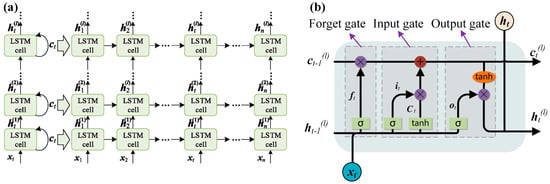

2.3.2. LSTM Neural Network

The long short-term memory (LSTM) network is a specialized form of recurrent neural network (RNN) designed to learn long-term dependencies by mitigating the vanishing gradient problem. An LSTM cell contains internal gating mechanisms, including the input gate, forget gate, and output gate, which regulate the flow of information through the network [29]. The standard architecture of the LSTM neural network and the structure of a typical LSTM cell are illustrated in Figure 5.

Figure 5.

(a) The standard architecture of LSTM neural network with multiple hidden layers; (b) the architecture of an LSTM cell of lth LSTM layer at time step t.

At any time step t in layer l, the LSTM receives an input vector denoted as xt(0), a hidden state ht−1(l), and a cell state ct−1(l). The input gate it(l) regulates the incorporation of new information into the cell state, the forget gate ft(l) controls the retention of information from previous time steps, and the output gate ot(l) determines the extent to which the updated cell state influences the hidden state passed to the next layer.

The internal computations within an LSTM cell can be expressed as follows:

This gating mechanism allows LSTM to selectively maintain or discard information across time steps, enabling effective modeling of complex sequential dependencies (Figure 5).

Although LSTM networks capture long-term dependencies, they may lose sensitivity to distant inputs in long sequences. Therefore, multi-head attention is introduced to adaptively focus on the most relevant time steps, enhancing the model’s ability to capture critical patterns for accurate prediction.

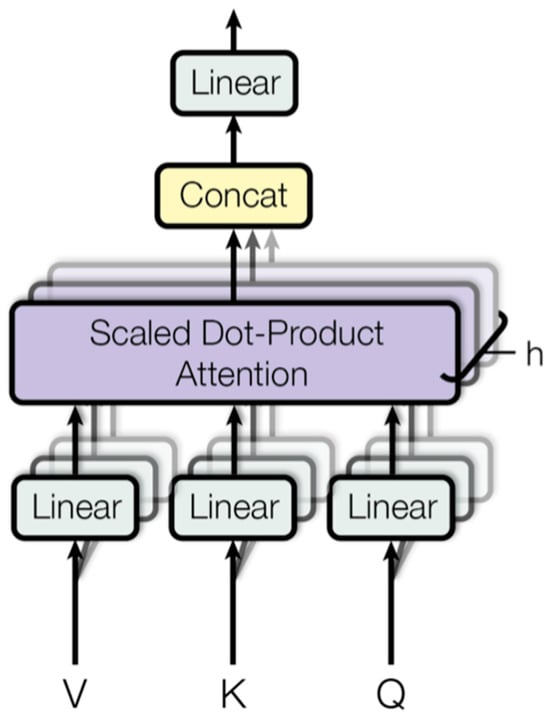

2.3.3. Multi-Head Attention Mechanism

To further improve temporal feature extraction, a multi-head attention layer is integrated with the LSTM, enabling the model to adaptively prioritize the most informative time steps during prediction. This selective focus is especially valuable for capturing critical variations in dynamic emission data. The multi-head attention mechanism is mathematically formulated as follows:

where Q (query), K (key), and V (value) represent the input matrices, and is the dimension of the key vectors. By using multiple attention heads, the model can attend to different parts of the input sequence in parallel, allowing for a richer understanding of the sequence dynamics. Figure 6 illustrates the structure of the Multi-Head Attention Mechanism [30].

Figure 6.

Multi-head attention mechanism structure.

2.4. Constrained Optimization Framework

The optimization of SCR NH3 concentration is formulated as a constrained dynamic problem. The challenge lies in adjusting the control variable while ensuring that emissions are minimized and all system parameters stay within their physical limits. This problem is solved using a constrained dynamic exploration approach.

Let u(t) represent the control inputs (specifically the SCR NH3 concentration) at time t. The adjustment set δ = {−250, −150, −50, −10, 0, 10, 50, 150, 250} was designed to span a practical range of dosing variations, reflecting both small adjustments for fine-tuning and large changes for transient response correction. These values were selected based on observed variability in dosing requirements under the WHTC cycle and optimized empirically to ensure real-time computational feasibility.

For each candidate adjustment, the resulting emissions are predicted using the trained model, and the corresponding loss function is computed:

where and are the predicted emissions for each candidate adjustment.

The optimal adjustment is then selected as the one that minimizes the loss over a predefined future horizon ℎ. At each optimization step, the loss function is evaluated as a weighted sum of predicted NH3 and NOx emissions, representing the control objectives. The candidate adjustment yielding the minimum total loss while satisfying all physical and operational constraints is selected as the control input for that time step. This decision-making rule is applied in a receding-horizon manner throughout the cycle.

Furthermore, the adjustment must satisfy physical constraints on the SCR NH3 concentration, which are defined by the bounds .

This ensures that the optimized control inputs remain feasible within the physical constraints of the SCR system.

Evaluation Metrics

The effectiveness of the optimization is assessed by comparing the emissions before and after the optimization process. The reduction in emissions of both NH3 and NOx is quantified as

where and are the mean values of NH3 and NOx emissions before optimization, and are the corresponding mean values after optimization.

3. Result Analysis and Discussion

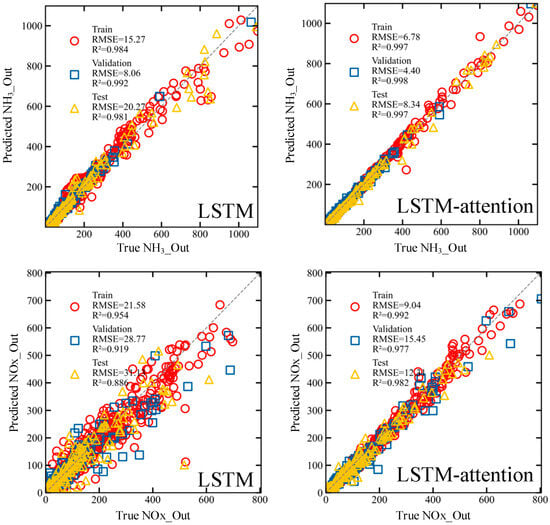

3.1. Evaluation of LSTM-Attention-Based Emission Prediction Models

Figure 7 presents the regression performance of two deep learning models, namely the standard LSTM and the LSTM model integrated with an attention mechanism, in predicting NH3 and NOx emissions. The top row shows the prediction results for NH3, while the bottom row corresponds to NOx. In each subplot, the predicted values are plotted against the true measurements for the training set (red circles), the validation set (blue squares), and the test set (yellow triangles). Quantitative evaluation metrics, including the root mean square error (RMSE) and the coefficient of determination (R2), are reported within each subplot. The LSTM-attention model consistently demonstrates superior predictive performance compared to the standard LSTM model, as evidenced by lower RMSE values and higher R2 scores across all data subsets. For NH3 prediction, the attention-based model achieves RMSE values of 6.78, 4.40, and 8.34 for the training, validation, and test sets, respectively, with corresponding R2 values exceeding 0.997. In comparison, the standard LSTM model exhibits higher RMSEs and slightly lower R² values.

Figure 7.

Regression results of LSTM and LSTM-attention models for NH3 and NOx predictions on training, validation, and test datasets.

Similarly, for NOx prediction, the LSTM-attention model significantly reduces the RMSE, particularly on the test set (12.31 compared to 31.13), and achieves better linear agreement between the predicted and measured values. Moreover, both models exhibit high overall predictive accuracy, with R2 values generally exceeding 0.95 across all phases. The incorporation of the attention mechanism effectively enhances the model’s ability to capture complex temporal dependencies, thereby improving its precision and robustness. Furthermore, we report the Mean Absolute Error (MAE) for all datasets to provide a more intuitive evaluation of the average prediction error. For NH3 prediction, the LSTM-attention model achieves MAE values of 1.78, 1.47, and 2.66 for the training, validation, and test sets, respectively. For NOx prediction, the corresponding MAE values are 3.32, 5.21, and 4.77. These MAE results, together with RMSE and R², demonstrate that the LSTM-attention model maintains superior accuracy and robust generalization compared to the standard LSTM across all dataset splits.

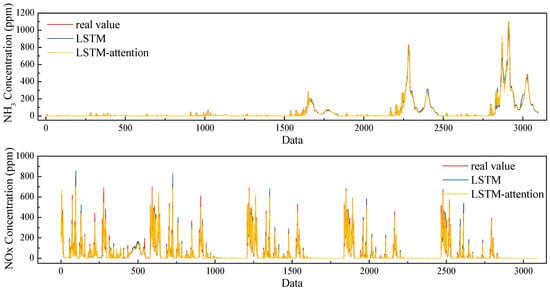

To further validate the temporal prediction performance, Figure 8 presents the time-series evolution of predicted and true NH3 and NOx concentrations using the trained models. The left subplot depicts the NH3 concentration profile, while the right subplot corresponds to the NOx concentration profile. In both cases, the LSTM-attention model predictions exhibit a closer alignment with the real measurements compared to the standard LSTM, particularly in capturing peak values and dynamic fluctuations. These results further confirm that incorporating an attention mechanism enhances the model’s ability to capture complex temporal dependencies, improves predictive precision, and ensures robust generalization across various emission prediction scenarios.

Figure 8.

Time-series comparison of true and predicted NH3 and NOx concentrations using LSTM and LSTM-attention models.

3.2. Dynamic Multi-Objective Optimization for SCR Emission Control

Based on the LSTM-Attention model previously developed, a dynamic emission optimization was conducted by adjusting the input feature SCR NH3 within a constrained optimization framework. In this framework, SCR NH3 values were not statically scaled but dynamically adjusted within a bounded range defined by the minimum and maximum products of SCR NOx and preset A/N ratio coefficients. This dynamic adjustment strategy was employed to simultaneously optimize both NH3 and NOx emissions while maintaining the model’s predictive accuracy.

Conventionally, SCR_NH3 values are estimated by dividing the SCR NOx concentration by a fixed coefficient. To explore the effects of different input scaling strategies, five distinct A/N ratio coefficients were considered, specifically 0.85, 1.00, 1.15, 1.30, and 1.45. Among these, an A/N ratio of 1.15 was selected as the baseline for subsequent comparisons. To ensure feasible and physically meaningful adjustments during optimization, SCR NH3 was dynamically varied within a constrained interval determined by the corresponding coefficient bounds. The optimized SCR NH3 trajectory is shown in Figure 9, where it can be observed that, rather than following a simple proportional scaling, the optimized SCR NH3 concentration exhibits significant dynamic fluctuations within the defined range. This flexibility allows the model to better adapt to instantaneous variations in system conditions, thereby enhancing the overall emission control performance.

Figure 9.

Time-series profiles of SCR NH3 concentrations under different A/N ratios and optimized control. The red line represents a fixed A/N ratio of 0.85, the blue line denotes a fixed A/N ratio of 1.45, and the yellow line corresponds to the dynamic optimized control strategy. Note: All time series correspond to a single simulated WHTC cycle.

Figure 10 presents the time-series comparison of NH3 and NOx emissions under different A/N ratios, including the results obtained from the optimized control strategy. As shown, compared to traditional approaches where SCR NH3 is determined by directly applying fixed coefficients to SCR NOx, the optimization strategy achieves more favorable emission profiles. For NH3 emissions, the optimized strategy achieves a substantial reduction compared to the cases with A/N ratios of 1.15 and 1.45. In particular, the optimized profile exhibits significantly lower NH3 concentration peaks, especially during periods of high emission fluctuations around 1400–1800 s, where the A/N = 1.45 case shows sharp and excessive ammonia leakage. Relative to A/N = 0.85, the optimized NH3 concentrations are slightly higher during some periods; however, they remain well-controlled without leading to significant ammonia accumulation, suggesting a balanced reductant dosing.

Figure 10.

Time-series comparison of NH3 (top) and NOx (bottom) emissions under fixed A/N ratios (0.85, 1.15, 1.45) and optimized SCR NH3 control. The legend colors are blue for A/N = 0.85, cyan for A/N = 1.15, yellow for A/N = 1.45, and magenta for the optimized control strategy. Note: All time series correspond to a single simulated WHTC cycle.

For NOx emissions, the optimized strategy achieves a substantial reduction compared to the A/N = 0.85 case, which exhibits frequent and intense NOx peaks throughout the cycle due to insufficient reductant supply. In comparison with the A/N = 1.15 condition, the optimized NOx concentrations remain lower for most of the operating period, particularly between 600 s and 1300 s, indicating improved conversion efficiency. However, when compared to the A/N = 1.45 case, the optimized profile shows slightly higher NOx concentrations during the majority of the cycle. Despite this, the optimized trajectory demonstrates noticeably reduced fluctuations and a more stable trend, reflecting enhanced robustness and consistency under transient conditions. These results suggest that although the absolute NOx levels under the optimized strategy may not always outperform those at A/N = 1.45, the overall emission stability and dynamic control characteristics are significantly improved. Overall, the optimization approach effectively reduces both NH3 leakage and NOx emissions relative to fixed-coefficient methods, achieving a more balanced and coordinated emission control.

These results demonstrate the capability of the constrained dynamic optimization framework in adapting to transient operating conditions and improving overall emission reduction performance. However, several practical considerations merit further discussion. For example, during the cold-start phase (0–570 s), exhaust temperature remained below 200 °C, preventing urea dosing and thus limiting the effectiveness of emission optimization; this phase resulted in high NOx emissions that are not actively controlled by the current framework. Under high-load conditions, transient peaks in exhaust flow can lead to rapid NH3 breakthrough, but our optimization approach was able to dynamically suppress such spikes, as observed between 1400 and 1800 s in the cycle. In addition, sensor latency or signal delays (e.g., from NOx or NH3 sensors) were not explicitly considered in this study; these factors may degrade real-world control responsiveness, and future implementations should incorporate predictive filtering or observer-based compensation to address such effects. It should also be noted that this study does not include direct comparisons with advanced control strategies such as model predictive control (MPC), reinforcement learning (RL), or adaptive observers. Although these approaches have demonstrated promise in recent literature, they often require more complex state estimation or large volumes of labeled training data. In this work, we focused on benchmarking the proposed method against the widely adopted industrial baseline of static A/N ratio control. Nevertheless, future research will implement and systematically compare our optimization framework with MPC and RL-based controllers to provide a more comprehensive assessment under dynamic driving scenarios.

The quantitative evaluation results summarized in Table 2 further substantiate these observations. Positive values in the reduction metrics indicate improvements in emission reduction, while negative values represent deteriorations relative to the baseline. Relative to the A/N = 1.15 baseline, the optimization approach achieves a 34.40% reduction in NH3 emissions and an 11.15% reduction in NOx emissions, resulting in a comprehensive evaluation improvement of 22.77%. These findings validate the high predictive accuracy and robustness of the LSTM-Attention model and highlight the effectiveness and potential of the dynamic constrained optimization framework for achieving simultaneous reductions in multiple pollutants under complex operating conditions. It should be emphasized that, to fully meet international emission standards, this approach should be combined with established aftertreatment measures. Ammonia slip catalysts (ASC) are commonly applied downstream of the SCR catalyst to remove excess NH3, particularly under cold-start or transient conditions. For NOx, technologies such as multi-stage SCR or lean NOx traps (LNT) are effective for further emission reduction during engine warm-up and low-temperature operation. We also acknowledge that practical aspects such as computational latency and hardware integration are important for real-world deployment. Although these factors were not specifically evaluated in this study, they will be considered in future work to further bridge the gap between simulation and application. It should also be noted that all evaluation results reported here are based on a single simulated WHTC cycle, and no statistical uncertainty or inter-cycle variability was assessed. Further validation across multiple cycles and experimental datasets will be conducted in future studies.

Table 2.

Reduction metrics compared to A/N 1.15.

Recent studies have shown that Model Predictive Control (MPC) applied to industrial or power plant SCR systems can reduce ammonia reagent consumption by approximately 25% and decrease outlet NOx fluctuations by up to two-thirds [31]. Reinforcement Learning-enhanced MPC (RL-MPC), such as SARSA-based approaches, has further improved NOx tracking and reduced NH3 slip in some industrial deployments [32]. In our study, the LSTM-attention model with dynamic constrained optimization achieved roughly 30–35% reduction in NH3 slip and 10–15% reduction in NOx emissions over the transient WHTC simulation. Compared to MPC or RL-MPC, our method is model-free, does not require explicit physical modeling or extensive policy training, and offers a practical and computationally efficient path toward real-time SCR emission control.

4. Conclusions

This study presents an integrated framework combining physics-based simulation, deep learning prediction, and dynamic optimization to enhance emission control in diesel engine selective catalytic reduction systems under transient operating conditions. Although the framework is currently validated within the GT-Power simulation environment using experimentally derived transient inputs, real-time testing on hardware-in-the-loop or engine bench platforms is not yet implemented. This represents a limitation of the present study. However, the simulation framework and predictive model are structured to support real-time deployment, and we plan to extend validation to embedded platforms and real-time controllers in future work to fully confirm the strategy’s practical viability. Furthermore, we acknowledge that real-world deployment may encounter additional challenges not fully captured in the simulation environment. These include measurement noise and drift in sensor signals, gradual deterioration of catalyst activity due to aging, and fluctuations in reagent quality or dosing system responsiveness. Such factors can impact both the accuracy of model predictions and the effectiveness of closed-loop optimization. Addressing these limitations will require future work focused on robust sensor data processing, adaptive calibration methods, and continuous online model updating to ensure long-term stability and reliability of the emission control strategy under realistic operating conditions.

1. The GT-Power-based one-dimensional SCR model was constructed and used to perform a series of simulations under the World Harmonized Transient Cycle (WHTC), using experimentally measured engine input data. By varying the fixed ammonia-to-NOx (A/N) ratios from 0.85 to 1.45, a comprehensive emission dataset was obtained, reflecting the system’s dynamic response to different urea dosing intensities.

2. A hybrid deep learning model integrating Long Short-Term Memory (LSTM) networks with multi-head attention mechanisms was constructed to predict SCR outlet NH3 leakage and NOx emissions under dynamic conditions. Compared to conventional LSTM models, the attention-augmented architecture improved prediction performance, achieving R2 values exceeding 0.977 and lower RMSE across training, validation, and test sets.

3. A constrained dynamic multi-objective optimization framework was developed. This framework adaptively adjusted the NH3 injection in real time to achieve simultaneous control of NH3 and NOx emissions. Compared to conventional fixed-ratio dosing strategies, the optimized control achieved a 34.40% reduction in NH3 emissions and an 11.15% reduction in NOx emissions, confirming the effectiveness of integrating machine learning prediction with physics-based optimization for advanced emission control.

Looking ahead, the developed integrated modeling and optimization framework has strong potential for practical deployment in advanced urea-SCR aftertreatment systems for both heavy-duty and light-duty diesel engines. With further validation, it may also be extended to real-time adaptive emission control in other automotive and industrial catalyst-based systems, supporting future regulatory compliance and cleaner engine technologies.

Author Contributions

Conceptualization, W.L. and J.W.; methodology, W.L. and J.W.; software, W.L. and J.W.; validation, W.L.; formal analysis, D.Y.; investigation, W.L. and F.W.; resources, L.W.; data curation, H.L.; writing—original draft preparation, W.L.; writing—review and editing, W.L. and H.H.; visualization, W.L. and J.W.; supervision, H.H.; project administration, W.L. and J.W.; funding acquisition, H.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by the Young Innovative Talent Program (Grant No. 2022A 135-G); the Ningbo Major Research and Development Plan Project (Grant No. 2021Z036&2022Z151) and the National Key R&D Program of China (Grant No. 2022YFE0209000).

Data Availability Statement

All relevant data are within the paper.

Conflicts of Interest

Author Weiqi Li, Jie Wu, Lei Wang, Hua Lou and Haibin He were employed by the company Ningbo C.S.I. Power & Machinery Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Cunanan, C.; Tran, M.-K.; Lee, Y.; Kwok, S.; Leung, V.; Fowler, M. A review of heavy-duty vehicle powertrain technologies: Diesel engine vehicles, battery electric vehicles, and hydrogen fuel cell electric vehicles. Clean Technol. 2021, 3, 474–489. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, Z.; Liu, H.; Wang, H.; Zheng, Z.; Wang, C.; Sun, X.; Xu, L.; Yao, M. Machine learning-based design of target property-oriented fuels using explainable artificial intelligence. Energy 2024, 300, 131583. [Google Scholar] [CrossRef]

- Li, W.; Dong, Z.; Miao, L.; Wu, G.; Deng, Z.; Zhao, J.; Huang, W. On-road evaluation and regulatory recommendations for NOx and particle number emissions of China VI heavy-duty diesel trucks: A case study in Shenzhen. Sci. Total Environ. 2024, 928, 172427. [Google Scholar] [CrossRef] [PubMed]

- Andrych-Zalewska, M. Analysis of exhaust emission processes during the Real Driving Emissions test. Arch. Transp. 2023, 66, 123–148. [Google Scholar] [CrossRef]

- Guan, B.; Zhan, R.; Lin, H.; Huang, Z. Review of state of the art technologies of selective catalytic reduction of NOx from diesel engine exhaust. Appl. Therm. Eng. 2014, 66, 395–414. [Google Scholar] [CrossRef]

- Ning, J. Active Disturbance Estimation and Compensation for Improving Diesel Aftertreatment Performance. Doctoral Dissertation, McMaster University, Hamilton, ON, Canada, 2017. [Google Scholar]

- Wang, T.; Huang, Z.; Luo, X.; Hu, J.; Wang, Z.; Cheng, Y. Model-based NH 3 Adaptation Method for SCR Control. Int. J. Automot. Technol. 2022, 23, 1621–1637. [Google Scholar] [CrossRef]

- Holmer, O.; Eriksson, L. Selective Catalytic Reduction Catalyst Modeling for Control Purposes. Energies 2022, 15, 8182. [Google Scholar] [CrossRef]

- Colombo, M.; Nova, I.; Tronconi, E. Detailed kinetic modeling of the NH3–NO/NO2 SCR reactions over a commercial Cu-zeolite catalyst for Diesel exhausts after treatment. Catal. Today 2012, 197, 243–255. [Google Scholar] [CrossRef]

- Gao, Z.; Pihl, J.; LaClair, T.; Fricke, B. Global kinetic modeling of NH3-SCR with two sites of NH3 storage on Cu-SSZ-13. Chem. Eng. J. 2021, 406, 127120. [Google Scholar] [CrossRef]

- Bozbağ, S.E.; Şanlı, D.; Özener, B.; Hisar, G.; Erkey, C. Development of a model based strategy for catalyst screening to control NOx and N2O emissions in NH3-SCR process towards Eu7 readiness. J. Environ. Chem. Eng. 2023, 11, 110232. [Google Scholar] [CrossRef]

- Dorscheidt, F.; Düzgün, M.; Claßen, J.; Krysmon, S.; Pischinger, S.; Görgen, M.; Dönitz, C.; Nijs, M. Hardware-in-the-Loop Based Virtual Emission Calibration for a Gasoline Engine. SAE Technical Paper. 6 April 2021.

- Shiyu, L.; Boyuan, W.; Zexian, G.; Buyu, W.; Zhaohuan, Z.; Xiao, M.; Chen-Teng, C.; Peng, W.; Xin, H.; Xingyu, S. Experimental investigation of urea injection strategy for close-coupled SCR aftertreatment system to meet ultra-low NOx emission regulation. Appl. Therm. Eng. 2022, 205, 117994. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, G.; Yang, L.; Chen, G.; He, S. Intelligent optimization of diesel engine Selective catalytic reduction urea injection based on multi-model state estimation to reduce NH3 slip and NOx emission. Fuel 2024, 365, 131188. [Google Scholar] [CrossRef]

- Zhu, X.; Du, J.; Yu, Z.; Cheng, Y.-B.; Wang, Y. NOx emission and control in ammonia combustion: State-of-the-art review and future perspectives. Energy Fuels 2023, 38, 43–60. [Google Scholar] [CrossRef]

- Sarkar, B.; Gundlapally, S.R.; Koutsivitis, P.; Wahiduzzaman, S. Performance evaluation of neural networks in modeling exhaust gas aftertreatment reactors. Chem. Eng. J. 2022, 433, 134366. [Google Scholar] [CrossRef]

- Hu, B.; Liu, C.; Yang, Y.; Wang, B.; Cai, D.; Xu, W. Adaptive internal model control of SCR denitration system based on multi-objective optimization. IEEE Access 2022, 10, 24769–24785. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Liu, Y.; Xu, Z.; Qu, X. A review of machine learning approaches for electric vehicle energy consumption modelling in urban transportation. Renew. Energy 2024, 234, 121243. [Google Scholar] [CrossRef]

- Hu, B.; Zhang, S.; Liu, B. A hybrid algorithm combining data-driven and simulation-based reinforcement learning approaches to energy management of hybrid electric vehicles. IEEE Trans. Transp. Electrif. 2023, 10, 1257–1273. [Google Scholar] [CrossRef]

- Shen, Q.; Wang, G.; Wang, Y.; Zeng, B.; Yu, X.; He, S. Prediction model for transient NOx emission of diesel engine based on CNN-LSTM network. Energies 2023, 16, 5347. [Google Scholar] [CrossRef]

- Guo, Y.; Mao, Z. Long-term prediction model for NOx emission based on LSTM–Transformer. Electronics 2023, 12, 3929. [Google Scholar] [CrossRef]

- Sun, J.; Ren, H.; Duan, Y.; Yang, X.; Wang, D.; Tang, H. Fusion of multi-layer attention mechanisms and CNN-LSTM for fault prediction in marine diesel engines. J. Mar. Sci. Eng. 2024, 12, 990. [Google Scholar] [CrossRef]

- Åberg, A.; Widd, A.; Abildskov, J.; Huusom, J.K. Methodology for Analysing the NOx-NH3 Trade-off for the Heavy-duty Automotive SCR Catalyst. IFAC-Pap. 2017, 50, 5998–6003. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhong, W.; Mao, C.; Xu, Y.; Lu, K.; Ye, Y.; Guan, W.; Pan, M.; Tan, D. Multi-objective optimization of Fe-based SCR catalyst on the NOx conversion efficiency for a diesel engine based on FGRA-ANN/RF. Energy 2024, 294, 130899. [Google Scholar] [CrossRef]

- Shi, Y.; Li, Z.; Zhang, H.; Shan, J. Multi-objective optimization of an electrical injector in Urea-SCR system. Proc. Inst. Mech. Eng. Part D 2024. [Google Scholar] [CrossRef]

- Liu, B.; Yan, F.; Hu, J.; Turkson, R.F.; Lin, F. Modeling and multi-objective optimization of NOx conversion efficiency and NH3 slip for a diesel engine. Sustainability 2016, 8, 478. [Google Scholar] [CrossRef]

- Fan, L.; Shi, W.; Jing, J.; Dong, Z.; Yuan, J.; Qu, L. An Artificial Intelligence Strategy for multi-objective optimization of Urea-SCR for vehicle diesel engine by RSM-VIKOR. Energy 2025, 317, 134667. [Google Scholar] [CrossRef]

- Pant, A.; Schmieg, S.J. Kinetic model of NOx SCR using urea on commercial Cu-zeolite catalyst. Ind. Eng. Chem. Res. 2011, 50, 5490–5498. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Tao, C.; Gao, S.; Shang, M.; Wu, W.; Zhao, D.; Yan, R. Get The Point of My Utterance! Learning Towards Effective Responses with Multi-Head Attention Mechanism. In Proceedings of the 27th International Joint Conference on Artificial Intelligence and 23rd European Conference on Artificial Intelligence (IJCAI-ECAI 2018), Stockholm, Sweden, 13–19 July 2018; pp. 4418–4424. [Google Scholar]

- Zhang, K.; Zhao, J.; Zhu, Y. MPC case study on a selective catalytic reduction in a power plant. J. Process Control 2018, 62, 1–10. [Google Scholar] [CrossRef]

- Hedrick, E.; Hedrick, K.; Bhattacharyya, D.; Zitney, S.E.; Omell, B. Reinforcement learning for online adaptation of model predictive controllers: Application to a selective catalytic reduction unit. Comput. Chem. Eng. 2022, 160, 107727. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).