Abstract

The search for a cost-effective, environmentally friendly and sustainable feedstock for biodiesel production has attracted attention among researchers. After frying, palm oil may become thermally degraded and unsuitable for consumption. In the current effort, neat palm oil (NPO), waste palm oil earlier utilized for frying fish and chips (WPOFC) and waste palm oil previously utilized to fry sausage and chips (WPOSC) were transesterified into waste palm oil methyl ester, namely, WPOMEFC and WPOMESC, respectively. The PO, WPOs and their ester derivatives were subjected to physicochemical properties, fatty acid (FA) compositions and 1H and 13C nuclear magnetic resonance (NMR) analyses. The thermal degradation, transesterification process and the foods the palm oil was used to fry affected the density, kinematic viscosity, acid value, pH, iodine value and FA profile of the samples. The outcome of the characterization reveals that the 1H and 13C NMR spectra of NPO, WPOFC and WPOSC show clear similarity, but NPO exhibits different intensities from that of the WPO samples. The absence of the peaks between δ 4.6 ppm and 5.0 ppm in the 1H NMR spectrum signifies the complete transformation of triglycerides in the WPO samples into biodiesel. The 13C NMR spectrum indicates the presence of ester carbonyl carbon (C=O) in WPOMEFC and WPOMESC, peculiar to ester, at a chemical shift ranging from 174.8 ppm to 174.9 ppm.

1. Introduction

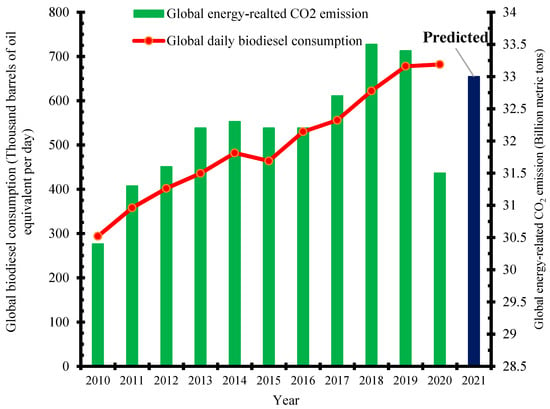

Increased population, modernization, industrialization and urbanization have resulted in higher energy demand over the past few decades. Globally, the carbon dioxide (CO2) emitted from energy-related activities increased from 30.4 billion metric tons (BMT) in 2010 to 31.5 BMT in 2020 (Figure 1) [1]. The reduction in CO2 emission in the year 2020 was due to the strict lockdown and disruption in industrial activities caused by the impact of COVID-19. With the global energy demand predicted to increase by 19% between 2020 to 2040 [2], there is a need for more investment in the renewable energy sector to safeguard our planet from the terrible effects of fossil fuel consumption. Global biodiesel consumption increased from 294 thousand barrels of oil equivalent per day (mboe/d) in 2010 to 682 mboe/d in 2020 (Figure 1) [3]. In addition, emissions from the consumption of fossil-based fuels increased from 16.5 gigatons of equivalent carbon dioxide (GtCO2e) in 2010 to 18.6 GtCO2e in 2018 [4]. To meet the increasing demand for biodiesel and reduce CO2 emissions from fossil fuel consumption, there is a need for more research into making biodiesel available and at a reduced pump price.

Figure 1.

Global biodiesel consumption (thousand barrels of oil equivalent per day) and global energy-related CO2 emission (billion metric tons). Adapted from [1, 3] by the authors.

The application of biodiesel, a form of biofuel, has been seen as a sustainable strategy for combating the challenges related to the deployment and utilization of petroleum-based diesel (PBD) fuel as a compression ignition (CI) engine fuel. Biodiesel is a renewable, sustainable and eco-friendly fuel containing mono-alkyl esters of long-chain fatty acids. Biodiesel is synthesized from a wide range of renewable and readily available feedstocks including neat vegetable oils, used vegetable oil, algal oils or animal fats [5]. The standard specifications, test methods and properties of biodiesel are as defined by ASTM D6751 and EN14214 [6]. Biodiesel is safer to handle, less flammable, eco-friendly, less harmful, biodegradable and offers visible advantages of higher cetane number, flash point, lubricating properties when compared with PBD fuel. CI engines fueled with biodiesel emit lower smoke, carbon monoxide, unburnt hydrocarbon, particulate matter emissions and improved thermal efficiency than CI engines powered with PBD fuel. Many governments are encouraging biodiesel as a sustainable alternative to PBD fuel to diminish crude oil and refined fuel imports and enhance energy security [7,8].

The application of second-generation feedstock, including used vegetable oil, retrieved oil from restaurants and recovered animal fats have gained acceptance in recent years. The attraction to the use of second-generation feedstock is due to its cost-effectiveness, availability, non-conflict with the food chain and environmental friendliness. The use of used frying oil as biodiesel feedstock also serves as an appropriate disposal channel. The inappropriate disposal of used frying oil blocks drains, weakens concrete and pollutes aquatic and terrestrial habitats. Worldwide, palm oil is reputed as a multipurpose and extensively used vegetable oil due to its pleasant frying properties, non-toxicity, low cost and accessibility when compared with cottonseed or sunflower oils [9]. With palm oil making up 33% of the total consumption of edible oils, waste palm oil (WPO), which is produced from frying processes, has become a favorable biodiesel feedstock [10]. However, during frying, palm oil is exposed to high temperature, moisture and contamination from the items which alter the physical, chemical and composition of the oil. When palm oil is heated to an elevated temperature, it becomes unstable due to the existence of active sites β- hydrogen in triacylglycerol structure [11], thereby limiting the application of palm oil as a lubricant. This drawback can, however, be surmounted by chemical alteration by the process of esterification with polyhydric alcohol such as neopentyl glycol, trimethylolpropane and pentaerythritol which substitutes glycerol as a mainstay of the palm oil structure [12]. Repeated consumption of WCO predisposes humans and animals alike to detrimental health challenges including diabetes, high blood pressure, vascular inflammation and other pathologies [13]. The conversion of WCO into biodiesel is, therefore, beneficial and desirable.

2. Previous Works on Characterization of NPO, WPO and WPOME

Non-destructive characterization techniques such as thermogravimetric analysis, Fourier transform infrared spectroscopy and nuclear magnetic resonance spectroscopy (NMR) have been applied to characterize WCO by various researchers [14,15]. NMR techniques are utilized for the determination of a compound’s unique structure through the identification of all active nuclei, including the carbon-hydrogen, fluorine, nitrogen, phosphorus, etc., structure of an organic compound. Proton or 1H and 13C are the most used magnetically active nuclei [16]. The 1HNMR and 13CNMR are non-invasive characterization methods that are fast, generate no chemical residues and offer comprehensive molecular information as soon as a spectrum is achieved with an adequately elevated signal-to-noise ratio and reasonable precision for the determination of the sample composition [17].

Various techniques are used to ascertain the physical, chemical, compositional, thermal and spectroscopic properties of compounds. There have been investigations on the properties, composition, thermal and spectroscopic characterization of some unused and used vegetable oils and their alkyl ester derivatives [13,14,18,19]. In addition, 1H and 13C NMR techniques, among others, have been used for the identification and characterization of spent vegetable oil [20,21] and biodiesel [22,23,24,25,26]. However, the application of 1H and 13C NMR for the characterization of neat palm oil (NPO), used palm oil and waste palm oil methyl ester (WPOME) have not been adequately exploited and reported. The motivation for this study is derived from the need to trace the trajectory of WPOME from NPO through the physicochemical properties, fatty acid (FA) composition and NMR characterization routes. This study, therefore, aims to interrogate the influence of thermal degradation and contamination caused by the food items the oil was employed to fry on the NPO, waste palm oil (WPO) and the resultant ester from two different samples. This present work is, however, limited to the determination of physicochemical properties, FA composition and characterization of NPO, WPO feedstocks and WPOME derived from the feedstocks by NMR technique.

3. Materials and Methods

3.1. Collection of Materials, NPO and WPO

The NPO and two WPO samples were retrieved from restaurants around the University of Johannesburg, Doornfontein Campus, South Africa. Methanol (analytical grade, 99.5%) was purchased from Merck, South Africa, while Magnesol (analytical grade, 60–100 mesh) was procured from Sigma-Aldrich, Germany, and used as an adsorbent. Magnesol is hygroscopic and, therefore, must be kept in an airtight glass jar and contact with eyes must be avoided. The NPO was collected from the stock used for frying and needs no pre-treatment, while the WPO was collected just at the point of disposal with food debris and light yellow. About one liter of NPO was collected while five liters of each WPO were collected and transported into the laboratory in a sealed glass container. This is to ensure enough WPO samples are available for testing and conversion to ester.

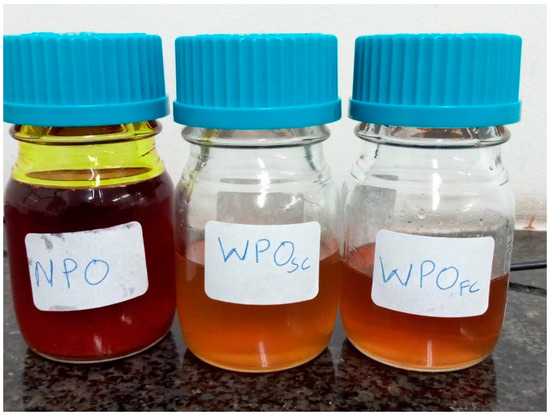

The information obtained about the WPO samples is displayed in Table 1, while Figure 2 is the picture of the collected samples. However, the cycle of usage and the frying temperature could not be accurately ascertained. The collected WPO samples were exposed to thermal treatment by pouring them into a clean stainless-steel container and heating it to about 50 °C using an electric stove amidst continuous stirring. The oil, now in liquid form, is subjected to physical treatments to get rid of solid food residues and other contaminants by filtration using a laboratory filter paper that allows the oils to pass. The filtered samples were dehydrated by heating the samples to 100 °C under a vacuum of 25 mmHg for 20 min to eliminate the water molecules contained in the samples. The treated WPO samples were subjected to acid value determination using the titration method to ascertain the appropriate conversion process to be employed [13].

Table 1.

Information on the collected WPO samples.

Figure 2.

Picture of NPO, WPOSC and WPOFC samples.

3.2. Production of WPOME

The total acid number of the WPO samples was found to be less than 2 mgKOH/g which makes one step transesterification reaction suitable for biodiesel production. Chicken eggshells collected from households and restaurants were cleaned, pulverized, sieved with a 75 µm mesh and calcinated to convert the calcium carbonate to CaO [27]. The use of chicken eggshells is to save cost, ensure appropriate disposal of the waste shells and convert waste to useful products [28]. The CaO derived from calcinated waste chicken eggshells was used as a heterogeneous catalyst. The clean WPO sample, methanol and CaO powder were poured into a round bottom flask, firmly corked and heated to a predetermined temperature of 60 °C for 90 min under continuous stirring of 1200 rpm maintained by a magnetic stirrer. The summary of the production parameters is shown in Table 2. The WPO was converted to WPOME by a single-stage transesterification process using the methanol to oil ratio of 6:1 and catalyst: oil ratio of 1% w/w [29]. A digital thermocouple was used for the verification of the temperature of the reacting solution during the experiments.

Table 2.

Summary of the WPOME production parameters.

At the end of the reaction, the mixture is filtered using laboratory filter paper in a vacuum filter set up to recover the catalyst. The solution is thereafter transferred into a separating funnel clamped on a tripod stand and left overnight. The glycerol and other impurities are coagulated at the base of the separating funnel where it is tapped and extracted. The crude biodiesel is subsequently decanted and purified using 1% w/w Magnesol:crude biodiesel at 60 °C for 30 min under agitation at 60 rpm by a magnetic stirrer. The mixture is filtered to remove the adsorbent and dehydrated by heating the biodiesel to 110 °C and 60 rpm stirring speed to remove the methanol and moisture in the biodiesel. Further polishing is done by using a 0.45 µm PTFE membrane syringe filter. The resulting clean WPOME was stored in well-labeled airtight bottles for characterization as shown in Figure 3.

Figure 3.

Picture of WPOMESC and WPOMEFC samples.

3.3. Determination of Physicochemical Properties of Samples

The density, kinematic viscosity, acid value and iodine value of the samples were determined according to the specified standard methods and equipment listed in Table 3. The pH of the neat and waste palm oil samples was measured using a pH meter [30]. Each test was conducted two times and the average results are recorded.

Table 3.

Standard methods and equipment for properties determination.

To determine the acid value, the titer value was first determined by titrating a solution of the sample in diethyl ether with a solution of potassium hydroxide. The titer value is determined when a faint pink color appears and persists for about 30 s. The acid value is calculated by Equation (1).

The iodine value is determined by titrating using 0.1 mol/L Na2S2O3 solutions as titrant to determine the iodine factor (IF). During this process, 0.2 g of liquid oil is added into a titration vessel to dissolve the oil. 10 mL cyclohexane, 0.5 mL mercuric acetate solution and 20 mL glacial acetic are added to determine the titer value. The IF and iodine value are calculated according to Equations (2) and (3).

3.4. Determination of Fatty Acid Profile of Samples

The fatty acid (FA) composition of NPO, WPOFC and WPOSC were determined by the pyrolysis gas chromatograph mass spectrometer (PyGCMS) (Shimadzu Corporation, Kyoto, Japan) using a Shimadzu Gas Chromatograph Mass Spectrometer (Shimadzu Corporation, Kyoto, Japan) using an ultra-alloy-5 capillary column and GCMS-QP2010 Plus software (Version 2.5, Shimadzu Corporation, Kyoto, Japan). On the other hand, gas chromatography-mass spectrometer (GCMS) with an ultra-alloy-5 capillary column and GCMS-QP2010 Plus software was used to determine the FA composition of WPOMEFC and WPOMESC. For both the PyGCMS and GCMS, the inlet temperature, carrier gas and the sample size used were 250 °C, helium and 2 μL, respectively. An Ultra alloy -5(MS/HT) column with 30 m, 0.25 mm internal diameter, 0.25 μm was used and a flow rate of 3 mL/min.

3.5. Characterization of Samples

The five samples, viz. NPO, WPOFC, WPOSC, WPOMEFC and WPOMESC were characterized by 1H and 13C NMR techniques using Bruker Avance III 600 MHz spectrometers (Karlsruhe, Germany). The chemical shifts are presented in parts per million (ppm), using the solvent proton signal as standard. The NMR tubes and caps were cleaned while all the solid particles in the samples were completely removed. This is to prevent distortion of the homogeneity of the magnetic field and ensure an accurate result. The NMR tube and the spinner are cleaned with Kimwipe to eliminate the fingerprints and the air in the magnet ejected before the injection of the samples and the start of the experiment. Denatured chloroform was used as solvent and tetramethylsilane as the internal standard. The sample 1H NMR (300 MHz) spectrum was noted with a cycle delay of 1.0 s and eight times scans with a pulse duration of 30°, (Table 3). A carbon 13C NMR (75 MHz) spectrum was recorded with a pulse duration of 30° and a cycle delay of 1.89 s, followed by scanning for 160 times. The data are analyzed and processed on the Topspin3.5 software on the computer.

4. Results and Discussions

The pretreated WPO samples were analyzed and the results were compared with ASTM and EN standards. At the end of the transesterification reaction, the WPO samples were converted into crude biodiesel. The biodiesel samples were separated in a separating funnel where the impurities were drained off. The crude biodiesel samples were purified to remove the excess moisture, catalyst and methanol trapped in the crude biodiesel. The clean FAME samples are kept in an airtight glass vial for analysis.

4.1. Physicochemical Properties of Samples

The results of the physicochemical analysis of the samples are shown in Table 4. The acidity and density of the WPO samples were lower than that of the NPO. However, the kinematic viscosity of the WPO samples was higher than that of the NPO. These outcomes are due to the impact of the thermal decomposition and contamination by the food items that occurred during frying [33]. The iodine value and kinematic viscosity of WPOFC were higher than that of WPOSC. On the other hand, the pH, congealing temperature, density and acid value of WPOSC were higher than that of WPOFC. This is attributed to the effect of the saturated and monounsaturated fats contained in the beef sausage that impacts the chemical properties. The effects of transesterification on the WPO samples were noticed by the lower values of density, kinematic viscosity and an acid value of the WPOME samples compared to the WPO samples [34,35]. The outcome of these tests showed the impact of frying on unused palm oil and that of transesterification on WPO samples. One of the advantages of converting WCO to biodiesel is the reduction of the iodine value [36].

Table 4.

Physicochemical properties of samples.

4.2. Fatty Acid Composition of Samples

The FA composition of the samples is presented in Table 5. Due to the impact of the food and thermal contamination during frying, the FA composition of NPO is remarkably different from that of the WPO samples. Similarly, the palmitic and oleic acids that were not present in the NPO became evident in the WPOFC and WPOSC samples. While the brassidic and capric acids that were noticed in NPO completely disappeared in the two WPO samples. The percentage of the saturated fatty acid (SFA) in the NPO was increased from 19.64% to 37.67% for WPOFC and 54.75% for WPOSC. This result agrees with the outcome of a similar investigation by Kadapure et al. [37]. The effect of the food items the oil was used to fry led to the WPOSC having predominantly more SFA of 54.75% and polyunsaturated fatty acid (PUFA) of 37.35%, while WPOFC shows more SFA of 37.67% and monounsaturated fatty acid (MUFA). These variations are a result of the contamination of the NPO arising from the addition of salt, sauce and moisture, repeated thermal contamination and cooling which causes the oil to deteriorate and consequently affected its degree of saturation [38].

Table 5.

FA composition of samples.

The effect of transesterification reaction became evident in the variations in the FA composition of WPO samples from WPOME samples. The concentration of SFA in WPOFC was reduced from 37.67% to 30.42% in WPOMEFC, while SFA in WPOSC reduced from 54.75% to 16.52% in WPOMESC. On the other hand, MUFA increased from 7.9% in WPOSC to 45.72% in WPOMESC. These variations can be attributed to the effect of the various chemical reaction that occurs during transesterification [38,39,40].

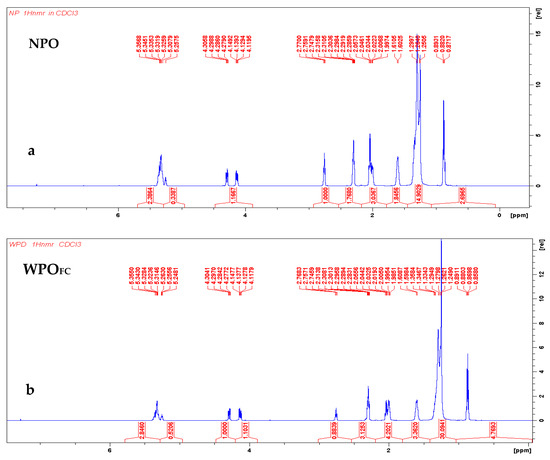

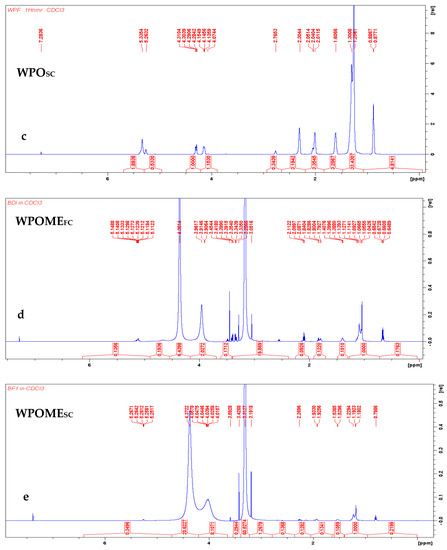

4.3. H and 13C NMR Characterization of Samples

The 1H and 13C NMR spectra of NPO, WPOFC, WPOSC, WPOMEFC and WPOMESC were investigated to analyze the effects of high temperature and food items contamination on the neat palm oil and waste palm oils feedstock and the biodiesel derived from each feedstock. The NMR spectrum of any oil sample must have at least nine signals of substantial intensity [19]. These signals are a result of the protons of the triglycerides, which is the main component in the oil samples. Neat palm oil contains a high content of beta-carotene which accounts for its red color. While NPO is usually consumed by human beings, the consumption of WPO has grave health implications. Toxic compounds are generated in the WPO during frying when fatty acids are oxidized, particularly to polyunsaturated fatty acids. This made the European Union, in 2002, ban the utilization of spent vegetable oil as an ingredient for animal feeds and raw materials for soap production was discouraged [41]. The line intensities (integrals) of the signals are believed to be proportional to the number of protons available in each functional group [42].

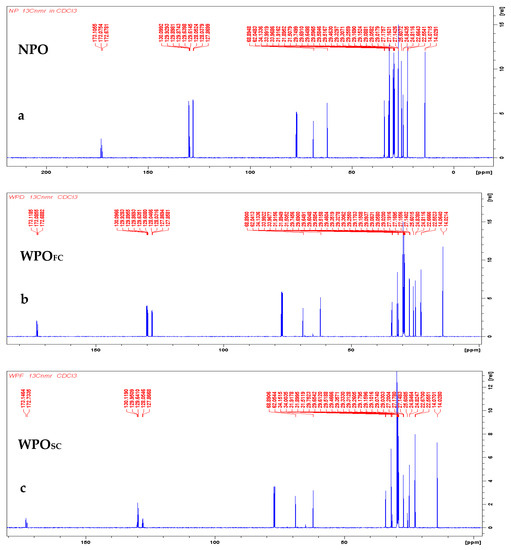

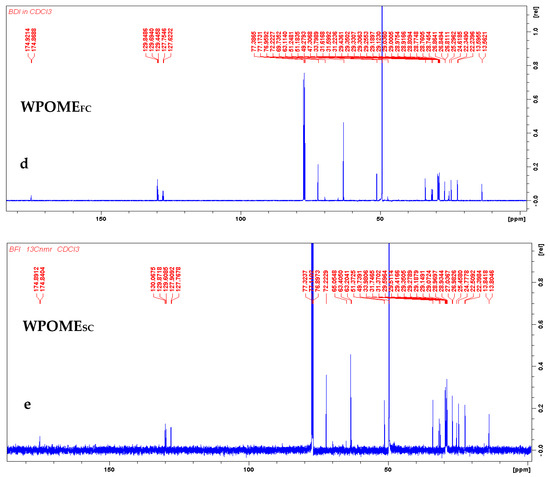

The 1H and 13C NMR spectra of NPO, WPOFC and WPOSC are displayed in Figure 4a–c and Figure 5a–c, respectively. The 1H and 13C NMR spectra for NPO, WPOFC and WPOSC have shown similar peaks, however, the integrations (intensity) of some of the NPO peaks are different from that of the WPO samples. The presence of the olefinic protons (-CH=CH-) at δ 5.25–5.38 ppm, the glyceryl protons at peaks δ 4.07–4.31 ppm and acyl proton peaks at δ 2.28–2.35 ppm suggested the presence of the triglyceride’s moiety. The presence of the bis-allylic proton peak (=HC-CH2-CH=) appeared at δ 2.75–2.77 ppm and the allylic proton peak (–CH2-CH=CH-) at δ 1.99–2.06 ppm suggested that triglyceride’s structure has some degree of unsaturation. The appearance of the acyl proton peaks (-OCO-CH2-CH2-) at δ 1.60–1.61 ppm, the aliphatic-methylene proton peaks –(CH2)n at δ 1.30–1.37 ppm and δ 1.25–1.29 ppm and the terminal methyl proton peaks (-CH3) at δ 0.77–0.98 ppm confirmed the presence of the saturated groups, which are categorized under the saturated, oleic and linoleic acyl group. Similarly, due to the effects of the high frying temperature, the NPO became oxidized. The NMR analysis of WPO samples revealed some oxidation products, including hydroxyperoxides, polymers, esters and aldehydes at peaks δ 1.5–2.04.

Figure 4.

1H NMR spectrum for NPO, WPO and WPOME samples.

Figure 5.

13C NMR spectra for NPO, WPO and WPOME samples.

WPOMEFC and WPOMESC, being a product of transesterification of WPOFC and WPOSC, respectively, using methanol as the alcohol, show typical proton peaks (1H NMR) corresponding to methoxyl hydrogen, OCH2 and olefinic hydrogen are clearly shown at δ 3.18–3.97 ppm. These are proton signals peculiar to biodiesel production and play a crucial role in influencing the outcome of the transesterification reaction [43]. As shown in Figure 4d,e, no signal was witnessed in the range between δ 4.6–5.0 ppm, indicating a complete conversion of triglycerides in the WPO samples into FAME. This fact is further demonstrated in the appearance of two major peaks in Figure 5d,e. In addition, a sharp signal was observed at δ 3.39 ppm in Figure 5e, revealing the formation of pure and quality FAME [44,45]. The same peak is observed in Figure 5d at 3.28 ppm The carbon spectra for WPOMEFC and WPOMESC showed distinct peaks downfield at chemical shift 174.8–174.9 ppm corresponding to the ester carbonyl carbons (C=O). These values confirm and agree with the chemical shift for carbon ester carbonyl (C=O) of 155–185 ppm as reported in the literature [12,46,47]. The presence of C-O for the WPOME samples at 51.37 ppm confirms the success of the transesterification reaction [48,49].

These results have demonstrated that transesterification has more impact on the oils than frying. This might be attributed to the effect of the methanol and several chemical processes involved in transesterification. Furthermore, the food items the oil was used to fry have insignificant effects on the ester formed from the WPO. The implication of this is that used vegetable oil from various sources can be collected and mixed for biodiesel production without taking cognizance of the fingerprint of the individual oils.

5. Conclusions

Waste palm oil is among the prominent feedstocks for biodiesel synthesis, owing to its availability, environmental friendliness and non-confrontation with the food chain. The application of NPO as feedstock will trigger a food vs fuel debate and increase the cost of feedstock and, consequently, the total cost of production. When NPO is used to fry different foods, the oil experiences thermal decomposition and contamination arising from the food substance the oil was deployed to fry. In the current effort, we have investigated the impacts of thermal degradation and food contamination on some physicochemical properties, 1HNMR and 13CNMR characterizations of unused palm oil, palm oil used to fry some foods (WPO) and the esters synthesized from the used palm oil. The physicochemical properties and spectroscopic behavior of palm oil are distorted by high-temperature frying and the transesterification process. The outcome of this research can be summarized as follows:

- The density, congealing temperature, acid value, pH, iodine value and kinematic viscosity are altered by the frying and contamination during usage. While frying reduces the density and the pH of the palm oil, the congealing temperature and kinematic temperature of WPO are higher than that of the NPO. The density, kinematic viscosity and acid value of FAME are lower than that of their feedstocks.

- The 1H and 13C NMR spectrum of investigated samples were observed to occur in nine signals of significant intensity, as mentioned in the literature.

- The proton spectra of 1H and 13C NMR for NPO, WPOFC and WPOSC are similar, the intensity of the NPO is, however, different from the proton spectra of the WPO samples.

- The 13C NMR spectrum exhibits the presence of ester carbonyl carbon (C=O) in WPOMEFC and WPOMESC, peculiar to ester, at chemical shift 174.8–174.9 ppm confirms the transesterification process carried out on the WPO samples.

- 1H and 13C NMR reinforce the suitability of WPO as feedstock for FAME synthesis.

Going forward, more research is required to determine the impacts of the salts and other condiments added to food items, the cycle of usage and frying temperatures of vegetable oil from various sources on the combustion, performance and emission characteristics of CI engines fueled with the FAME synthesized from such WCOs.

Author Contributions

Conceptualization: O.A., D.V.V.K., V.S.A.; methodology: O.A., D.V.V.K., V.S.A., V.M.; software: O.A., D.V.V.K., V.S.A., V.M.; investigation: O.A., D.V.V.K., V.S.A., V.M.; writing—original draft preparation: O.A.; writing—review and editing: D.V.V.K., V.S.A.; supervision: D.V.V.K., V.S.A.; funding acquisition: D.V.V.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors are grateful to the Faculty of Engineering and Built Environment, University of Johannesburg, South Africa and the School of Chemistry and Physics, University of KwaZulu-Natal, Westville campus, Durban, South Africa for their support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Energy-Related Carbon Dioxide Emissions Worldwide from 1975 to 2021 (in Billion Metric Tons). Available online: https://www.statista.com/statistics/526002/energy-related-carbon-dioxide-emissions-worldwide/ (accessed on 23 July 2021).

- Energy Consumption by the Numbers. Available online: https://www.capp.ca/energy/world-energy-needs/ (accessed on 23 July 2021).

- BStatistical Review of World Energy 2021 70th Edition. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2021-full-report.pdf (accessed on 23 July 2021).

- IEA. The Latest Trends in Energy and Emissions in 2018. In Global Energy & CO2 Status Report 2018. Available online: https://webstore.iea.org/global-energy-co2-status-report-2018 (accessed on 23 July 2021).

- Ndiaye, M.; Arhaliass, A.; Legrand, J.; Roelens, G.; Kerihuel, A. Reuse of waste animal fat in biodiesel: Biorefining heavily-degraded contaminant-rich waste animal fat and formulation as diesel fuel additive. Renew. Energy 2020, 145, 1073–1079. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Broch, A.; Robbins, C.; Ceniceros, E.; Natarajan, M. Review of biodiesel composition, properties, and specifications. Renew. Sustain. Energy Rev. 2012, 16, 143–169. [Google Scholar] [CrossRef]

- Chandran, D. Compatibility of diesel engine materials with biodiesel fuel. Renew. Energy 2020, 147, 89–99. [Google Scholar] [CrossRef]

- Yildiz, I.; Açıkkalp, E.; Caliskan, H.; Mori, K. Environmental pollution cost analyses of biodiesel and diesel fuels for a diesel engine. J. Environ. Manag. 2019, 243, 218–226. [Google Scholar] [CrossRef] [PubMed]

- Tullis, P. How the world got hooked on palm oil. In The Guardian; Guardian Media Group: London, UK, 2019; Available online: https://www.theguardian.com/news/2019/feb/19/palm-oil-ingredient-biscuits-shampoo-environmental (accessed on 23 July 2021).

- Thushari, I.; Babel, S.; Samart, C. Biodiesel production in an autoclave reactor using waste palm oil and coconut coir husk derived catalyst. Renew. Energy 2019, 134, 125–134. [Google Scholar] [CrossRef]

- Resul, M.F.M.G.; Ghazi, T.I.M.; Idris, A. Kinetic study of jatropha biolubricant from transesterification of jatropha curcas oil with trimethylolpropane: Effects of temperature. Ind. Crop. Prod. 2012, 38, 87–92. [Google Scholar] [CrossRef]

- Nor, N.M.; Derawi, D.; Salimon, J. Synthesis of palm oil fatty acid and trimethylolpropane based ester for biolubricant base stocks. AIP Conf. Proc. 2018, 1940, 020095. [Google Scholar] [CrossRef]

- Awogbemi, O.; Onuh, E.I.; Inambao, F.L. Comparative study of properties and fatty acid composition of some neat vegetable oils and waste cooking oils. Int. J. Low-Carbon Technol. 2019, 14, 417–425. [Google Scholar] [CrossRef]

- Atabani, A.E.; Shobana, S.; Mohammed, M.N.; Uğuz, G.; Kumar, G.; Arvindnarayan, S.; Aslam, M.; Al-Muhtaseb, A.H. Integrated valorization of waste cooking oil and spent coffee grounds for biodiesel production: Blending with higher alcohols, FT–IR, TGA, DSC and NMR characterizations. Fuel 2019, 244, 419–430. [Google Scholar] [CrossRef]

- Mohammed, M.; Atabani, A.; Uguz, G.; Lay, C.H.; Kumar, G.; Al-Samaraae, R. Characterization of hemp (Cannabis sativa L.) biodiesel blends with euro diesel, butanol and diethyl ether using FT-IR, UV–Vis, TGA and DSC techniques. Waste Biomass Valorization 2020, 11, 1097–1113. [Google Scholar] [CrossRef]

- García-Álvarez, L.; Busto, J.H.; Peregrina, J.M.; Avenoza, A.; Oteo, J.A. Applications of 1H Nuclear Magnetic Resonance Spectroscopy in Clinical Microbiology, Applications of Molecular Spectroscopy to Current Research. In Chemical and Biological Sciences; Stauffer, M.T., Ed.; IntechOpen: London, UK, 2016; pp. 28–291. [Google Scholar] [CrossRef]

- Dutra, E.D.; de Lima, T.A.; de Oliveira Souza, J.L.; Silva, J.G.V.; da Silva Aquino, K.A.; da Silva Aquino, F.; Ramos, C.S.; Menezes, R.S.C. Characterization of fat and biodiesel from mango seeds using 1 H NMR spectroscopy. Biomass Convers. Biorefin. 2018, 8, 135–141. [Google Scholar] [CrossRef]

- Awogbemi, O.; Onuh, E.I.; Komolafe, C.A. Thermal Degradation and Spectroscopic study of Neat Palm Oil, Waste Palm Oil, and Waste Palm Oil Methyl Ester. IOP Conf. Ser. Earth Environ. Sci. 2019, 331, 012032. [Google Scholar] [CrossRef]

- Ullah, Z.; Bustam, M.A.; Man, Z. Characterization of waste palm cooking oil for biodiesel production. Int. J. Chem. Eng. Appl. 2014, 5, 134–137. [Google Scholar] [CrossRef]

- Kara, K.; Ouanji, F.; Lotfi, E.M.; Mahi, M.E.; Kacimi, M.; Ziyad, M. Biodiesel production from waste fish oil with high free fatty acid content from Moroccan fish-processing industries. Egypt. J. Pet. 2018, 27, 249–255. [Google Scholar] [CrossRef]

- Santos, J.S.; Escher, G.B.; da Silva Pereira, J.M.; Marinho, M.T.; Prado-Silva, L.; Sant’Ana, A.S.; Dutra, L.M.; Barison, A.; Granato, D. 1H NMR combined with chemometrics tools for rapid characterization of edible oils and their biological properties. Ind. Crop. Prod. 2018, 116, 191–200. [Google Scholar] [CrossRef]

- Fernandez, J.; Hariram, V.; Seralathan, S.; Harikrishnan, S.; Premkumar, T.M. Biodiesel Production from Pongamia Pinnata and its Characterization using GC-MS, NMR and FT-IR Spectral Studies. Int. J. Veh. Struct. Syst. 2018, 10, 453–457. [Google Scholar] [CrossRef]

- Ng, M.H.; Yung, C.L. Nuclear magnetic resonance spectroscopic characterisation of palm biodiesel and its blends. Fuel 2019, 257, 116008. [Google Scholar] [CrossRef]

- Jeyalakshmi, P. Characterization of Simarouba glauca seed oil biodiesel. J. Therm. Anal. Calorim. 2019, 136, 267–280. [Google Scholar] [CrossRef]

- Chopra, A.; Tewari, A.; Vatsala, S.; Kumar, R.; Sarpal, A.; Basu, B. Determination of polyunsaturated fatty esters (PUFA) in biodiesel by GC/GC–MS and 1 H-NMR Techniques. J. Am. Oil Chem. Soc. 2011, 88, 1285–1296. [Google Scholar] [CrossRef]

- Fadhil, A.B.; Sedeeq, S.H.; Al-Layla, N.M. Transesterification of non-edible seed oil for biodiesel production: Characterization and analysis of biodiesel. Energy Sources A Recovery Util. Environ. Eff. 2019, 41, 892–901. [Google Scholar] [CrossRef]

- Awogbemi, O.; Inambao, F.L.; Onuh, E.I. Development and Characterization of Chicken Eggshell waste as Potential Catalyst for Biodiesel Production. Int. J. Mech. Eng. Technol. 2018, 9, 1329–1346. [Google Scholar]

- Awogbemi, O.; Kallon, D.V.V.; Aigbodion, V.S. Trends in the development and utilization of agricultural wastes as heterogeneous catalyst for biodiesel production. J. Energy Inst. 2021, 98, 244–258. [Google Scholar] [CrossRef]

- Awogbemi, O.; Inambao, F.; Onuh, E.I. Modelling and Optimization of Synthesis of Waste Sunflower Methyl Ester by Taguchi Approach. In Proceedings of the Lecture Notes in Engineering and Computer Science, World Congress on Engineering, London, UK, 3–5 July 2019; Ao, S.I., Gelman, L., Hukins, D.W.L., Hunter, A., Korsunsky, A.M., Eds.; pp. 137–143. [Google Scholar]

- Use of pH Meter. Available online: https://www.webserver.mbi.ufl.edu/~rowland/protocols/phmeter.pdf (accessed on 17 March 2021).

- BS EN 14214:2012+A2:2019 (2019) Liquid Petroleum Products. Fatty Acid Methyl Esters (FAME) for Use in Diesel Engines and Heating Applications. Requirements and Test Methods. Available online: https://shop.bsigroup.com/ProductDetail/?pid=000000000030217517 (accessed on 17 March 2021).

- Bockisch, M. Fats and Oils Handbook (Nahrungsfette und Öle), 1st ed.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 803–808. [Google Scholar]

- Meng, C.E.; Zakaria, A.; Bakar, S.A.; Kheng, E.S.; Norali, A.N.; Nasir, N.F.M.; Fhan, K.S.; Majid, M.S.A.; Yee, L.K.; Jamir, M.R.M. Dielectric and Colorimetric Analysis on Thermal Degradation of Cooking Oil. In Intelligent Manufacturing and Mechatronics. Lecture Notes in Mechanical Engineering; Bahari, M.S., Harun, A., Zainal, A.Z., Hamidon, R., Zakaria, S., Eds.; Springer: Singapore, 2021; pp. 747–759. [Google Scholar]

- Jindapon, W.; Ngamcharussrivichai, C. Heterogeneously catalyzed transesterification of palm oil with methanol to produce biodiesel over calcined dolomite: The role of magnesium oxide. Energy Convers. Manag. 2018, 171, 1311–1321. [Google Scholar] [CrossRef]

- Cárdenas, J.; Orjuela, A.; Sánchez, D.L.; Narváez, P.C.; Katryniok, B.; Clark, J. Pre-treatment of used cooking oils for the production of green chemicals: A review. J. Clean Prod. 2021, 289, 125129. [Google Scholar] [CrossRef]

- Hossain, M.N.; Siddik Bhuyan, M.S.; Alam, A.H.; Seo, Y.C. Biodiesel from Hydrolyzed Waste Cooking Oil Using a S-ZrO2/SBA-15 Super Acid Catalyst under Sub-Critical Conditions. Energies 2018, 11, 299. [Google Scholar] [CrossRef]

- Kadapure, S.A.; Kirti, P.; Singh, S.; Kokatnur, S.; Hiremath, N.; Variar, A.; Shaikh, S.; Chittaragi, R. Studies on process optimization of biodiesel production from waste cooking and palm oil. Int. J. Sustain. Eng. 2018, 11, 167–172. [Google Scholar] [CrossRef]

- Maneerung, T.; Kawi, S.; Dai, Y.; Wang, C.H. Sustainable biodiesel production via transesterification of waste cooking oil by using CaO catalysts prepared from chicken manure. Energy Convers. Manag. 2016, 123, 487–497. [Google Scholar] [CrossRef]

- Zein, Y.M.; Anal, A.K.; Prasetyoko, D.; Qoniah, I. Biodiesel Production from Waste Palm Oil Catalyzed by Hierarchical ZSM-5 Supported Calcium Oxide. Indones. J. Chem. 2016, 16, 98–104. [Google Scholar] [CrossRef][Green Version]

- Nguyen, V.P.; Nguyen, H.H.M.; Nguyen, D.T.; Nguyen, H.L.; Huynh, T.M. Optimization of biodiesel production from waste cooking oil using static mixer technology in Vietnam. Biofuels 2018, 9, 567–574. [Google Scholar] [CrossRef]

- Nanda, S.; Rana, R.; Hunter, H.N.; Fang, Z.; Dalai, A.K.; Kozinski, J.A. Hydrothermal catalytic processing of waste cooking oil for hydrogen-rich syngas production. Chem. Eng. Sci. 2019, 195, 935–945. [Google Scholar] [CrossRef]

- De Graaf, R.A. In Vivo NMR Spectroscopy: Principles and Techniques, 3rd ed.; John Wiley & Sons: West Sussex, UK, 2019; pp. 17–21. [Google Scholar]

- Nachid, N.; Ouanji, F.; Kacimi, M.; Liotta, L.F.; Ziyad, M. Biodiesel from moroccan waste frying oil: The optimization of transesterification parameters impact of biodiesel on the petrodiesel lubricity and combustion. Int. J. Green Energy 2015, 12, 865–872. [Google Scholar] [CrossRef]

- Sharma, Y.C.; Singh, B.; Madhu, D.; Liu, Y.; Yaakob, Z. Fast synthesis of high quality biodiesel from ‘waste fish oil’ by single step transesterification. Biofuel Res. J. 2014, 1, 78–80. [Google Scholar] [CrossRef]

- Shancita, I.; Masjuki, H.; Kalam, M.; Reham, S.; Shahir, S. Comparative analysis on property improvement using Fourier Transform Infrared Spectroscopy (FT-IR) and Nuclear Magnetic Resonance (NMR)(1H and 13C) spectra of various biodiesel blended fuels. Energy Fuels 2016, 30, 4790–4805. [Google Scholar] [CrossRef]

- Pavia, D.L.; Lampman, G.M.; Kriz, G.S.; Vyvyan, J.A. Introduction to Spectroscopy; Cengage Learning: Stamford, CT, USA, 2014; pp. 107–108. [Google Scholar]

- Kara, K.; Ouanji, F.; El Mahi, M.; Lotfi, E.M.; Kacimi, M.; Mahfoud, Z. Biodiesel synthesis from vegetable oil using eggshell waste as a heterogeneous catalyst. Biofuels 2019, 12, 1083–1089. [Google Scholar] [CrossRef]

- Ouanji, F.; Khachani, M.; Boualag, M.; Kacimi, M.; Ziyad, M. Large-scale biodiesel production from Moroccan used frying oil. Int. J. Hydrogen Energy 2016, 41, 21022–21029. [Google Scholar] [CrossRef]

- Tariq, M.; Ali, S.; Ahmad, F.; Ahmad, M.; Zafar, M.; Khalid, N.; Khan, M.A. Identification, FT-IR, NMR (1H and 13C) and GC/MS studies of fatty acid methyl esters in biodiesel from rocket seed oil. Fuel Process. Technol. 2011, 92, 336–341. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).