Abstract

Given the decline in fossil energy reserves and the need for less pollution, achieving carbon zero is challenging in major industrial sectors. However, the emergence of large-scale hydrogen production systems powered by renewable energy sources offers an achievable option for carbon neutrality in specific applications. When combined with energy storage systems, static power converters are crucial in these production systems. This paper offers a comprehensive review of various power converter topologies, focusing on AC– and DC–bus architectures that interface battery storage units, electrolyzers, and fuel cells. The evaluation of DC/AC, AC/DC, and DC/DC converter topologies, considering cost, energy efficiency, control complexity, power level suitability, and power quality, represents a significant advancement in the field. Furthermore, the subsequent exploration of battery aging behavioral modeling, characterization methods, and real-time parameter estimation of the battery’s equivalent electrical circuit model enhances our understanding of these systems. Large-scale hydrogen production systems most often use an AC–bus architecture. However, DC–bus configuration offers advantages over AC–bus architecture, including high efficiency, simpler energy management, and lower system costs. In addition, MVDC or HVDC DC/DC converters, including isolated and non-isolated designs based on multiple cascaded DABs and MMC-type topologies, have also been studied to adapt the DC–bus to loads. Finally, this work summarizes several battery energy storage projects in the European Union, specifically supporting the large-scale integration of renewable energy sources. It also provides recommendations, discussion results, and future research perspectives from this study.

1. Introduction

The emergence of low-pollution renewable energy sources is becoming a global economic issue due to rising energy demands, the stakeholders’ knowledge of climate change issues, and the depletion of fossil fuel reserves [1]. Globally, several nations have established initiatives aimed at achieving net-zero carbon emissions. The United Nations Agenda and the Sustainable Development Goals (SDGs), adopted in 2015 and consisting of 17 goals, notably include Goal 7, which aims to promote the use of clean, environmentally friendly, and accessible energy sources, to achieve carbon neutrality [2,3]. At the European Union (EU) level, the establishment of the “European Green Deal” in 2019 aligns with the objective of carbon neutrality by 2050 [4]. Hydrogen as an energy carrier [5,6], produced by renewable energy sources (such as solar and marine renewable sources) through water electrolysis, is a key solution to specific pollution issues (in industrial sectors, transportation, etc.) and energy supply challenges (hydrogen storage). Large-scale green hydrogen production is essential, made possible by using high-power electrolyzers. However, the intermittent nature of energy delivered by renewable sources and the operating conditions are likely to degrade the components of the hybrid storage unit (electrolyzers, fuel cells (FCs), and batteries), thus accelerating their aging processes, as partially studied in the literature [7]. A system control through a practical energy management approach, considering real operating constraints, will enhance system reliability and achieve a better balance between hydrogen demand and production [8,9,10].

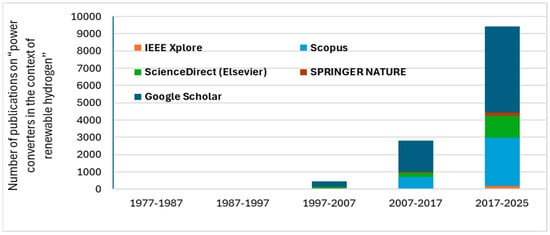

Since power electronic converters are at the center of multiple supply mechanisms, ensuring the energy flow between the different sources of the system (electrolyzer, batteries, fuel cells, wind farms, tidal farms, and AC power grids), they play a crucial role in the effective management of energy through the integration of the operating dynamics of each component. They thus contribute significantly to the reliability, efficiency, and sustainability of the components they interface with. Ultimately, depending on the adopted architecture, they guarantee both the stability of the DC–bus or AC–bus and optimal energy management [11]. Research on “power converters in the context of renewable hydrogen” has expanded rapidly during the last 50 years, as shown in Figure 1.

Figure 1.

Publications on the topic of “power converters in the context of renewable hydrogen production” before 2025; data from IEE Xplore, Scopus, ScienceDirect (Elsevier), Springer Nature, and Google Scholar.

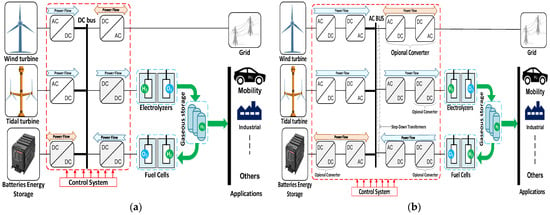

This study aims to provide a thorough and comprehensive analysis of static power converters interfacing the hybrid storage system in the context of large-scale hydrogen production from marine renewable energy sources (MREs), as seen in Figure 2. It demonstrates the critical importance of batteries in maintaining system efficiency and energy stability in a world increasingly focused on renewable energy sources. It also critically analyzes the main behavioral aging models of LFP batteries. Additionally, it presents an updated overview of technological advancements in materials used in manufacturing power semiconductors and batteries, along with a series of projects integrating batteries for large-scale energy storage. Finally, key recommendations are proposed to guide future development in large-scale hydrogen production, encouraging researchers and industry professionals to engage in this essential pathway for more environmentally friendly and sustainable energy production.

Figure 2.

Green hydrogen production system using MREs: (a) Architecture based on DC–bus; (b) Architecture based on AC–bus.

This paper is divided into six sections. After introducing the central role of power electronic converters in hydrogen production systems and clarifying the research objectives, Section 2 provides an overview of the static power electronics converters that interface the hybrid storage unit (electrolyzers, fuel cells (FCs), and batteries) and the fundamental criteria for designing an efficient converter. Section 3 presents an overview of battery energy storage technologies, followed by a review of behavioral aging models for LFP batteries, aimed at improving control over their degradation. It also includes an overview of large-scale battery energy storage projects in Europe, whether they are under construction, announced, or operational. Section 4 discusses the technological advancements of power electronics and battery energy storage and some prospects for batteries. Finally, Section 5 and Section 6 are devoted, respectively, to in-depth discussions and the review’s conclusions.

2. Power Electronic Converters in Hydrogen Production Systems

Figure 2 demonstrates the role of power electronic converters in interfacing with various energy sources. This paper focuses on converters that serve batteries, fuel cells, and electrolyzers. Their primary function is to ensure minimal current ripples at low and high frequencies, thereby extending the lifespan of these energy sources. They also enable the regulation of each converter’s input/output characteristics, a key factor in maximizing system energy management. This, in turn, ensures service continuity in the event of an electrical power switch failure and contributes to achieving high efficiency, among other functions.

2.1. Overview of AC/DC Converters Supplying Electrolyzers

Different types of converters can be chosen for the electrolyzer power supply. However, the selection of the rectifier topology depends on the power level required by the electrolyzer, i.e., the voltage and current rating needed for its operation. The following section summarizes the current state of AC/DC converter topologies for the energy supply to industrial electrolyzers.

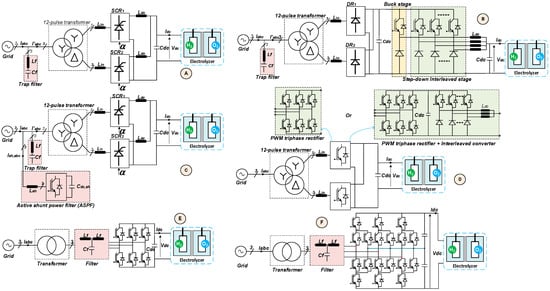

B. Yodwong et al. [12] evaluated AC/DC converters for electrolyzer power supply in electrical grids and wind energy systems, focusing on thyristor-based rectifier bridges and chopper rectifiers. The rectifier–chopper configuration is especially suitable for wind energy systems [13]. Commonly used converters include six-pulse diode rectifiers paired with different chopper topologies, such as conventional buck, interleaved buck, and three-level interleaved buck. Traditional topologies face limitations with current switching capacity, which is problematic for high-power (MW-scale) electrolyzers. Using interleaved buck converters improves fault tolerance, ensuring continuous power even if a switch fails, and reduces current ripple, though with a limited voltage step-down ratio and high voltage stress. Three-level interleaved converters address these issues, lowering voltage stress and current ripple, thus enhancing reliability and efficiency for electrolyzer applications. P. Azer and A. Emadi [14] generalize the average state model (GSSAM) of interleaved converters (Buck, Boost, and Buck–Boost types). The number of phases in the interleaved converter remains proportional to the output power to achieve maximum efficiency over the operating range. M. Chen et al. [15] reviewed high-current, high-power AC/DC converters for power-to-hydrogen (PtH) applications in MW-scale electrolyzer systems. Thyristor-based converters are commonly used, capable of delivering 1.5–10 kA DC at 1 kV, with power levels of up to 10 MW per unit. However, these systems require filters to mitigate harmonics fed into the grid and reactive power compensators for power factor correction, increasing overall costs. Several other converter topologies, such as the 12-Pulse Thyristor Rectifier (12-TR), 12-Pulse Diode Rectifier with Multi-Phase Chopper (12-DRMC), 12-Pulse Thyristor Rectifier with Active Shunt Power Filter (12-TRASPF), and Active Front End (AFE) Rectifier, were examined, whose main characteristics are summarized in Table 1. Additionally, the authors proposed a transformer-free modular converter topology, combining AFE AC/DC conversion with galvanically isolated DC/DC stages, improving system flexibility and efficiency. The different architectures of the converters mentioned above are listed in [12,15,16], and Figure 3 illustrates some of them.

Table 1.

Comparison of topologies.

The diode rectifiers used in [12] for AC/DC conversion systems directly connected to wind turbines generate current and voltage harmonics, leading to low-frequency pulsations and possible resonance with the mechanical shaft of the wind turbine systems. Using PWM rectifiers to power large-scale electrolyzers will enable efficient control of system variables and reduce the filters required to mitigate current and voltage ripples.

Milad Bahrami et al. [17] present a review of power converters for water electrolysis within microgrids using excess energy. This study compares different AC/DC and DC/DC converter topologies regarding specific energy, efficiency, and economic performance. The findings reveal that combining a simple rectifier with a DC/DC converter (such as a buck or interleaved buck converter) generates fewer harmonics, which positively affects the efficiency and lifespan of the electrolyzer. M. Khedar et al. [18] aim to demonstrate that the integration of a three-phase thyristor rectifier combined with an interleaved buck converter improves power quality compared to the traditional three-phase thyristor rectifier used to power 20 MW PEM (Proton Exchange Membrane) electrolysis systems. This configuration was validated by simulation in Matlab/Simulink, supported by experimental data from a 20 MW industrial PEM electrolyzer at the Air Liquide Plant in Bécancour. The results show that the current THD is below 5% at full load, and the power factor exceeds 0.95. Under partial load, the current THD rises to 12%, thus enabling a reduction in filter size compared to the conventional six-pulse thyristor topology. M. Kumar et al. [18] comprehensively analyze high-power rectifier integration in hydrogen production plants, covering key aspects such as system architecture, efficiency, and the advantages and challenges of operating at a gigawatt-scale. According to the study, integrating a high-power rectifier with a common DC–bus for 1 GW hydrogen electrolyzer projects offers an innovative solution for large-scale green hydrogen production. However, the viability of this approach depends on the electrolyzer’s capacity to operate in series or parallel configurations. In order to ensure scalability and redundancy to satisfy the fast-growing hydrogen industry, this solution must also solve issues like DC voltage management, harmonic reduction, and strict safety requirements. The Y. Lin and L. Fu [16] study aims to solve the network structure problem and design a control strategy for a hydrogen production system in an island electric system. The hydrogen production system, composed of alkaline electrolyzers of 5 MW per unit, is interfaced by a DC/DC converter TPTL (three-phase, three levels) with PSPWM (Phase-shifted Pulse Width Modulation), which adapts to scenarios related to the structure of the MVDC network (Medium Voltage Direct Current).

Figure 3D–F are more suitable for coupling with renewable energy sources (wind or tidal turbines), allowing the transformer to be eliminated by directly connecting the sources to the AC/DC converters. The topologies in Figure 3A–C require two stages of conversion (AC/DC/AC).

Figure 3.

(A) 12-Pulse Thyristor Rectifier (12-TR), (B) 12-Pulse Diode Rectifier with Multi-Phase Chopper (12-DRMC), (C) 12-Pulse Thyristor Rectifier with Active Shunt Power Filter (12-TRASPF), (D) Active Front End (AFE) Rectifier [12,15,16], (E) Two-level Voltage source rectifier, and (F) Three-level active neutral point-clamped voltage source [19].

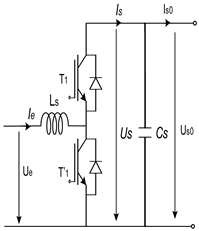

2.2. DC/DC Converters for Power Fuel Cell (FC) Power Supply

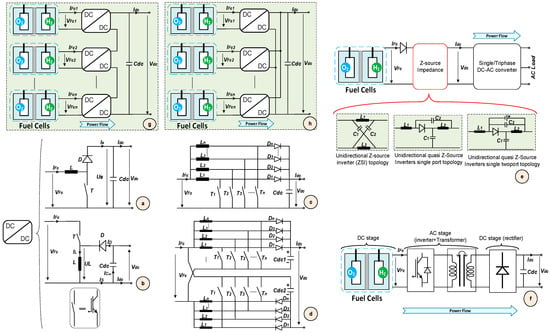

Different DC/DC converter architectures are studied in [20] for FC. They are classified according to their fields of application (automotive, railway, aeronautical, and stationary). Among them are the Boost converter, Buck–Boost converter, Interleaved-Boost converter, Floating-Interleaved Boost converter, Z-source inverter topology, and DC/AC/DC isolated converter (Figure 4). Interleaved-Boost and the Floating-Interleaved Boost converters are best suited for re-electrification in a hydrogen production system. They ensure low current ripple and reduce the voltage and current stresses on the power switches, thus reducing accelerated degradation of FC due to aging. An optimal 2 MW power supply with a DC voltage range between 400 V and 1500 V for testing equipment in the IEEE 1547 standard with a four-stage interleaved DC/DC converter is studied in [21]. The converter was implemented in the MATLAB/Simulink environment, and virtual simulations validated the results. Interleaved boost DC/DC converters offer high energy efficiency, fast set-up performance, no need for bulky passive storage components, and a compact, modular, reliable, and redundant architecture. This redundancy ensures service continuity in a switch failure (fault tolerance) [20,22]. However, if higher power is required in the FC system, four architectures can be employed: parallel configuration, series configuration, hybrid configuration, and modular configuration [23,24].

Figure 4.

(a) Boost converter, (b) Buck–Boost converter, (c) Generalized Interleaved-Boost converter, (d) Generalized Floating-Interleaved-Boost converter, (e) Z-source inverter topology, (f) DC/AC/DC isolated converter topology, and “FC—power converter’’ modules association in multi-stack architectures: (g) association in series, (h) association in parallel.

2.3. DC/DC Converters for Battery Power Supply

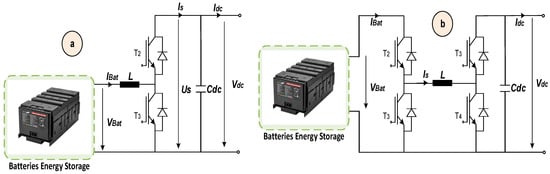

The fluctuating nature of the MREs necessitates the use of electrical energy storage devices (batteries) in the hydrogen production system to use to maintain a constant and continuous supply of energy to the DC–bus, storing and discharging the stored energy. To facilitate the energy exchange between the storage device and the DC–bus, a bidirectional current Buck–Boost DC/DC converter is indispensable, providing not only flexible control in all operating modes but reassurance of its adaptability and scalability. Two groups of bidirectional Buck–Boost DC/DC converters can be distinguished, depending on the application: non-isolated bidirectional Buck–Boost converters (NIBDC) and isolated bidirectional Buck–Boost converters (IBDC) [25]. NIBDC converters are characterized by their simple structure, which allows them to achieve high efficiency compared to IBDC converters. IBDC converters, on the other hand, are based on a DC/AC/High-Frequency Transformer/AC/DC architecture, where galvanic isolation provided by the transformer ensures personnel safety, reduces noise, and ensures proper system protection. However, to improve efficiency, size, weight, and cost, the NIBDC type is more attractive, especially in high-power applications and spacecraft power systems [25,26]. Variants of NIBDC and IBDC converters are studied in [25,27,28].

Figure 5 illustrates some topologies of current bidirectional DC/DC converters. The IBDC structures have a structure identical to that of Figure 4f, with the fuel cell replaced by batteries. Configurations can be made to increase the power on the DC–bus, as illustrated in Figure 4g,h.

Figure 5.

(a) Bidirectional Buck–Boost converter and (b) two back-to-back connected NIBDCs.

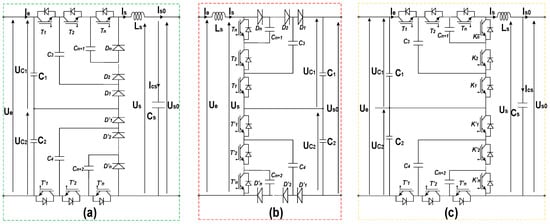

2.4. Other Multilevel DC/DC Converters for Supplying Electrolyzers, Fuel Cells, and Batteries in a Hydrogen Production System

A solution to traditional non-isolated DC/DC converters and interleaved converters is provided by non-isolated DC/DC multilevel converters. These converters, with their reduced voltage stress on power switches and decreased size and cost of filters (inductor and capacitor) in the system, now have practical applications in high- and medium-power systems [29,30]. However, these converters present specific issues related to balancing the voltages at the terminals of the capacitors in series, as well as across the terminals of the flying capacitors. The following work reviews various methods for balancing capacitor voltages.

Fan L. et al. [31,32] analyzed in detail the operating principle and the parameter design process of a three-level buck converter and developed a 200 V, 7200 A DC power supply for electrolysis. Experimental results demonstrate that this topology can fulfill the requirements for low-voltage and high-current outputs and reduce the output current ripple to within 4%. Costa LF et al. [33] introduced the general architecture of non-isolated DC/DC multilevel converters (Buck, Boost, and Buck–Boost (Figure 6)) dedicated to high-voltage and high-power applications. The detailed analysis of a non-isolated, five-level DC/DC converter operating in buck mode showed that it is possible, through a simple proportional controller, to regulate the voltages of the DC–bus capacitors and flying capacitors, given the integral nature of the system’s transfer functions. The results have been validated experimentally (capacitor voltage control) on a 10 kW prototype that was designed and built, demonstrating the feasibility of the proposed converter. Z. S. Du, P. Channegowda et al. [29] presented a synthesis of non-isolated DC/DC converters, highlighting their high-power density for transportation applications. Flying capacitor topologies and Buck–Boost multilevel DC/DC converters (operating in boost mode) offer high power density compared to other architectures, and only these two types of converters have been studied and simulated. Table 2 in [29] presenting the technological specifications of the two converter topologies studied was included, covering power ratings of 250 kW and 500 kW. H. Shi et al. [34] proposed a method for balancing capacitor voltage in a non-isolated bidirectional Buck–Boost three-level converter for energy storage in a battery. The results obtained through simulation and experimentation validated the capacitor voltage control method. M. Liu et al. [35] proposed a method for controlling capacitor terminal voltages in a five-level DC/DC converter. This control method is based on a single voltage sensor’s measurement to rebalance the capacitor voltage. The entire system was validated through virtual simulation using Matlab/Simulink software.

Figure 6.

Multilevel DC/DC converter. (a) Buck-type topology. (b) Boost-type topology. (c) Bidirectional topology [33].

Several other works dealing with non-isolated multi-level DC/DC converters, intended for high-power devices, operating at medium and high voltage (HVDC), have been explored by a community of researchers. For example, H. You and X. Cai [36] proposed a new Buck-TL-MDCC (Buck three-level modular DC/DC converter), and a comparative analysis with other converter topologies demonstrates that the Buck-TL-MDCC offers higher efficiency and requires lower capacitance. X. Zhao et al. [37], X. Zhao and Y. Zhang [38], S. Dusmez et al. [39], L. F. Costa et al. [40] developed theoretical analysis supported by experimental validation of a five-level DC/DC converter with bidirectional energy flow of 10 kW. P. Thounthong [41] used a three-level boost converter to supply a fuel cell for electric vehicle applications.

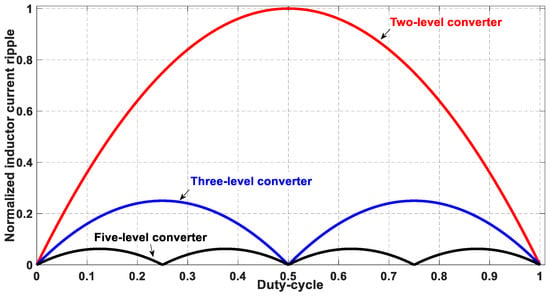

Figure 7 depicts the normalized variations of the current ripple in the inductor as a function of duty cycle for different DC/DC converter levels (conventional two-level DC/DC converter, three-level DC/DC converter, and five-level DC/DC converter). This figure illustrates that as the number of voltage levels in the DC/DC converter increases, the current ripple decreases, reaching as low as 1/16 for a five-level DC/DC converter compared to the conventional two-level DC/DC converter.

Figure 7.

Normalized inductor current ripple as a function of duty cycle for different-level DC/DC converters.

Table 2.

Bidirectional Buck–Boost DC/DC converter.

Table 2.

Bidirectional Buck–Boost DC/DC converter.

| Two-Level DC/DC Converter [26] | Three-Level DC/DC Converter [41] | Five-Level DC/DC Converter [38,39,40] |

|---|---|---|

|  |  |

represents the maximum current ripple in the inductance , is the switching frequency, and is the supply voltage of the converter.

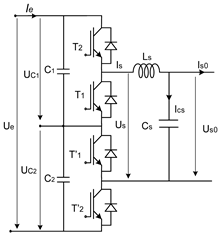

2.5. DC/AC Converter for FC or Battery Power Supply Based on AC Architecture

DC/AC converters that interface storage sources and fuel cells need to be bidirectional in current to enable battery charging and discharging and unidirectional in current for a non-reversible FC in a hydrogen production system. These converters can include conventional topologies such as AFE, as well as multilevel topologies such as three-level NPC, ANPC, three-level flying capacitor inverter, Cascaded H-Bridge (CHB), modular multilevel inverter, and other architectures. The advantages and disadvantages of multilevel converters are reviewed in [42,43]. On the other hand, there are also converter topologies based on multi-port architectures that allow numerous sources and/or loads to be interfaced within the same system. The advantages of these converters over other architectures include their compact design and centralized control that regulates the interactions between the various ports, enhancing energy flow coordination. Several studies have highlighted these multi-port converters in applications such as intelligent storage systems, electric vehicles, renewable energies, microgrid, and distributed networks [44,45,46,47,48].

2.6. Comparative Study of DC–Bus and AC–Bus Architectures of Hydrogen Production Systems

Table 3 compares the two hydrogen production system architectures that were studied based on factors including cost, energy efficiency, architecture-specific control complexity, power level suitable for the application, and energy quality.

Table 3.

Comparison of proposed hydrogen production system architectures.

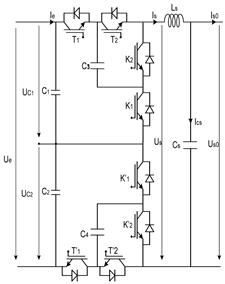

2.7. Key Considerations for Implementing Efficient Power Converters for Large-Scale Hydrogen Production System

Electrolyzers require a high level of Direct Current (DC) supply and a relatively low/medium voltage [49]. This requirement necessitates a diverse range of power semiconductors, each catering to specific applications. The power semiconductors used in this context must be capable of handling high current and withstanding the corresponding voltage without sustaining damage, making them a key factor in the design of power converters that supply high-power electrolyzers. Power semiconductors are grouped into several technological families to meet a wide range of applications. Figure 8 categorizes them into different groups [50].

Figure 8.

Key power semiconductor devices are available on the market, along with silicon carbide and gallium nitride power devices that have been developed and researched in recent years.

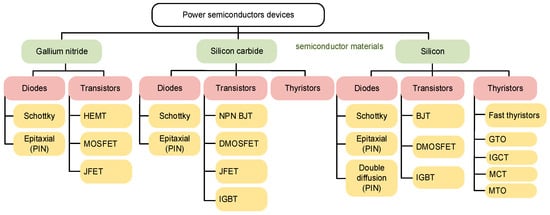

Figure 9 serves as a visual aid to classify high-power semiconductors based on voltage amplitude (kV) and switchable current (kA). These include silicon-controlled rectifier thyristor (SCR), gate turn-off thyristor (GTO), gate-controlled thyristor (GCT), integrated gate-commutated thyristor (IGCT), injection enhanced gate transistor (IEGT), insulated-gate bipolar transistor (IGBT), metal-oxide-semiconductor field-effect transistor (MOSFET), silicon carbide (SiC) IGBTs and MOSFET, and gallium nitride (GaN) power junction field-effect transistor (JFET) (also call enhanced-mode high-electron-mobility transistor (E-HEMT)) [50,51,52,53].

Figure 9.

Maximum volt-ampere capabilities of current Si (SCR, GTO/MCT, IGCT, IEGT, IGBT, and MOSFET), SiC (MOSFET and IGBT), and GaN (E-HEMT, H2C-HEMT, HEMT) high-power semiconductors.

Aside from power semiconductors, several other parameters are necessary for a power converter to achieve high efficiency, thereby contributing to the overall efficiency of a large-scale hydrogen production system. These include thermal management, power loss reduction, cost-effective energy management strategies, EMC (Electromagnetic Compatibility)/EMC (Electromagnetic Interference), switching frequency, power quality, fault tolerance, and other factors that must be considered during the design process [54,55].

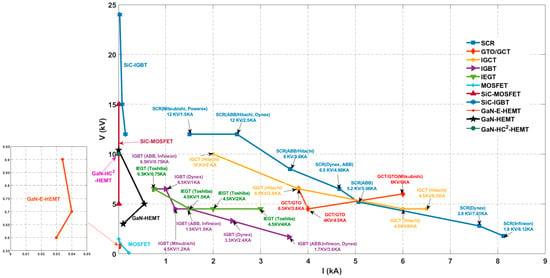

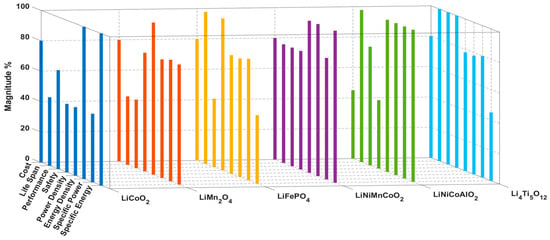

3. Electrical Energy Storage Systems for Stability and Reliability

In large-scale hydrogen production systems using RES, storing energy and regulating the intermittency of renewable generation is necessary. Generally, two storage systems are used, namely electrical storage systems (batteries) to filter power peaks in the event of RES overproduction and to support RES during underproduction and hydrogen storage systems already reviewed in [7]. Several comprehensive studies have been carried out on electrochemical storage units, including comparative studies on different battery technologies that can be used. These investigations have revealed that lithium-ion batteries offer the best advantages in high energy density, fast response time, and long cyclic life. They find applications in various domains, including all aspects of generation, transmission, distribution, and utilization, including renewable energy production stabilization and frequency regulation [56,57,58]. Depending on the nature of the cathode, several derivatives of lithium-ion batteries can be distinguished, such as ( , (LFP) and ), a comparison of which is illustrated in Figure 10 [59,60,61]. Battery performance also differs from one type to another, depending on the nature of the materials used. LCO batteries offer good performance but remain costly. Cobalt is a limited resource and has low capacity. The NCA and NMC batteries offer exceptional performance and high voltage but also come with a high cost. Nickel, like cobalt, is a limited resource. LMO technology has a low cost due to the availability of manganese, average safety, and excellent performance, but it has a limited lifespan and low capacity. LTO technology offers high efficiency and good cycling properties, but low voltage and capacity. LFP technology provides good safety, cycling life, thermal stability, and performance, with abundant iron, low cost, and low environmental toxicity. However, it has low capacity, voltage, and energy [58,60].

Figure 10.

Characteristics of lithium-ion battery technologies.

Table 4 and Table 5, respectively, present the most commonly used materials for cathodes and anodes in lithium-ion batteries, along with their key properties such as specific capacity, theoretical capacity, potential (V vs. Li/Li+), and gravimetric energy [62,63,64,65,66]. Furthermore, Figure 10 highlights the main comparison criteria used to evaluate the principal materials constituting the cathode of lithium-ion batteries.

Table 4.

Most common cathode materials used for lithium-ion batteries.

Table 5.

Most common anode materials used for lithium-ion batteries.

Graphite is currently the most widely used material in lithium-ion batteries due to its maturity, low cost, absolute abundance, non-toxicity, structural stability, and low average potential. However, its low theoretical capacity, volume changes during cycling, and side reactions at low voltages limit performance and safety. To overcome these drawbacks, alternative anodes with higher capacity, better stability, and improved safety have been developed. Based on their reaction mechanisms, LIB anode materials are generally classified into three types: intercalation (graphite, lithium titanate), conversion (transition metal oxides, sulfides), and alloying (silicon, tin, germanium, antimony) [66].

During battery operation, several internal aging mechanisms degrade their cells. This degradation is observed as a decrease in storage capacity, a significant increase in internal resistance, and safety consequences. This aging process is influenced by internal and external stress factors such as temperature, State of Charge (SoC), the number of charge/discharge cycles, power supply quality (DC ripple, frequency of DC ripple), Depth of Discharge (DoD), and more [67,68,69].

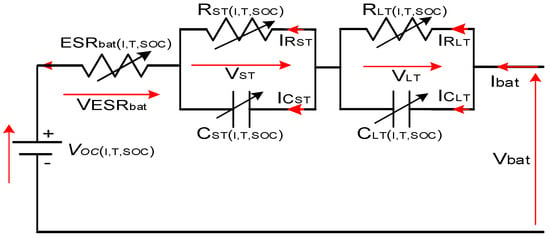

3.1. Behavioral Aging LFP Battery

Three types of models are distinguished for describing the dynamic behavior of lithium-ion batteries: electrochemical models, empirical/mathematical models, and Equivalent Circuit Models (ECMs). Combinations of these model types are also possible [70,71,72]. Different levels of accuracy and complexity characterize these models. Electric circuit-based models are the most suitable solutions for modeling Li-ion batteries when integrated into system-wide simulations due to their characteristics, such as high accuracy of 1 to 5% and medium computational complexity [73,74]. The ECM generally used is still called the Thevenin model and consists of an OCV (open circuit voltage) source, a series resistance corresponding to that of the connectors and electrolyte, and a parallel RC network for the charge transfer phenomenon described by the resistance (R) and the double-layer phenomenon described by the capacitance (C). The more parallel RC branches there are, the more accurate the system is [75].

Several studies on the behavioral aging of batteries have been published in the literature. A key step in this process is characterizing an individual cell that enables the establishment of a behavioral model for a battery pack within a system. This is achieved through parameter extraction methods (online or offline) after the electrical model characterization. These methods enable the plotting of characteristic curves for battery-related variables as a function of system operating conditions, providing valuable insights into the battery’s performance [76,77,78,79]. The following work summarizes the state of the art in LFP battery modeling. In this study, K. Bellache et al. [80] used a temporal characterization approach to characterize an LFP battery subjected to a dynamic current profile. The ECM, based on two parallel RC branches, was used, and an offline serial resistor extraction method was proposed. This resistance is influenced by the temperature and frequency of DC ripples during charging and discharging operations. The comparison results between the simulation and experimental models show an error of less than 1%. Hence, the proposed model is suitable for use in dynamic power applications but also has the potential to significantly improve battery accuracy. In [81], a behavioral aging model was introduced based on ECM with two parallel branches, one for charging operations and the other for discharging. The objective was to assess the combined effects of temperature and current ripple frequency on a set of cells’ storage capacity and series resistance. The battery was characterized by using the dynamic triangle current profile. This study shows that the frequency of current ripples during charging and discharging operations, and the temperature affects the energy capacity, the series and charge transfer resistances, and the double layer capacities. These factors influence the aging of the LFP battery. Y. Gao et al. [82] used an extended Kalman filter (EKF) to estimate the LFP battery’s State of Charge (SoC) in real time. Temperature, RMS current, and State of Charge were used to build real-time degradation models for energy capacity, series resistance, charge transfer resistance, and double-layer capacitance. These models are built around a semi-empirical approach and are estimated with characterization data using an Enhanced Multiple Hybrid Pulsed Power Characterization (EMHPP)-based current profile. The simulation and experimental models’ results agree in all dynamic verification tests, providing further evidence of the potential of the proposed model to improve SoC estimation and consequently the performance of battery technology.

D.-I. Stroe et al. [73] proposed a seven-stage characterization method for a 2.5 Ah Li-ion battery (LPF), in which the battery parameters (capacity, resistance, inductance, and constant-phase cells) are determined considering operating conditions (temperature, current, and State of Charge). The model is used to characterize and model battery performance behavior based on an ECM subjected to a dynamic current profile, including HPPC (Hybrid Power Pulse Characterization) and electrochemical impedance spectroscopy (EIS). The study demonstrated that the model developed can estimate battery voltage with high accuracy, independently of circuit operating conditions, since the error obtained is less than 5%. K. Saleem et al. [83] presented a new technique for estimating the parameters of the ECM of the Li-ion battery in real time by reducing the computational complexity of the parameters. The parameters are identified using the Trust Region Optimization-based Least Squares (TRO-LS) algorithm for a single-order ECM. This method can be extended to higher-order ECMs, but it would increase computational complexity. Under standard conduit profiles and laboratory tests, the technique has shown a reduction in processing time compared to others (KF, EKF) and a minimization of the error between simulated and actual battery output voltage. E. Mouncef et al. [84] proposed an optimization algorithm for extracting the ECM parameters of an LFP battery and estimating the output voltage in real time for application to the electric vehicle. The study demonstrated that the algorithm used to simulate the dynamic behavior of the LFP battery voltage could predict the output voltage with an error of ±0.03%. J. E. Bester et al. [74] in their study aimed to estimate the SoC of a 50 Ah LFP battery using an extended Kalman filter (EKF). The second-order ECM model of the battery with parameters dependent on operating conditions (SoC, current, and temperature) was characterized with a dynamic HPPC test profile for parameter identification and a constant discharge current profile for model validation. Battery data from the real-time simulator OPAL-RT were acquired using MATLAB/Simulink software and stored in a 3D Look-Up-Table (LUT) to extract resistance, capacitance, energy capacity, OCV, and other parameters. The results showed that SoC estimation using the EKF was highly accurate, with an average SoC error of less than 1%.

The State of Health (SoH) of a battery is the metric that indicates either a decrease in its energy storage capacity or a reduction in its power performance characteristics. Several studies have been conducted for SoH estimation based on machine learning; these methods combine experimental and model-based approaches. Among these machine learning methods, we have Support Vector Regression (SVR), fuzzy logic-based approaches, and neural networks, as outlined in [85,86]. Their advantages and disadvantages have also been summarized.

Several other studies in the literature have modeled lithium-ion batteries by proposing methods for characterization and parameter extraction related to a single cell [87,88,89,90]. Generally, storage units are characterized at the laboratory scale and then extrapolated to match the power requirements in real systems. To increase the power of battery storage units, series and parallel combinations are required to increase the voltage and current generated, respectively. In large-scale hydrogen production systems, behavioral battery aging models with real-time parameter extraction are more appropriate due to the intermittent nature of RES. These models enable performance optimization, efficient energy management, maintenance prediction, and improved battery safety. These benefits contribute to a more reliable, sustainable, and cost-effective use of batteries in these systems.

In this review, the battery’s State of Charge (SoC), a crucial parameter for battery energy management, is investigated using a variety of methodologies, including model-based, experimental, and machine learning (AI) approaches. However, despite the extensive work devoted to SoC estimation, the problem of accurately determining the battery SoC has not yet been effectively solved [91,92].

Figure 11 below illustrates the behavioral aging model of an LFP battery based on the ECM with two parallel RC branches which aims to enhance the model’s accuracy [82].

Figure 11.

Basic model of the LFP battery (charge mode).

According to Figure 11, the model results from the combination of a voltage source, representing the open circuit voltage VOC(I,T,SoC) of LFP battery, an ESRbat(I,T,SoC) resistor corresponding to that of the connectors and electrolyte, an RST(I,T,SoC) charge transfer resistor in parallel with the CST(I,T,SoC) double layer capacitor, and RLT(I,T,SoC)-CLT(I,T,SoC) branch to represent the diffusion phenomenon. The mathematical equations from Figure 11 are detailed below.

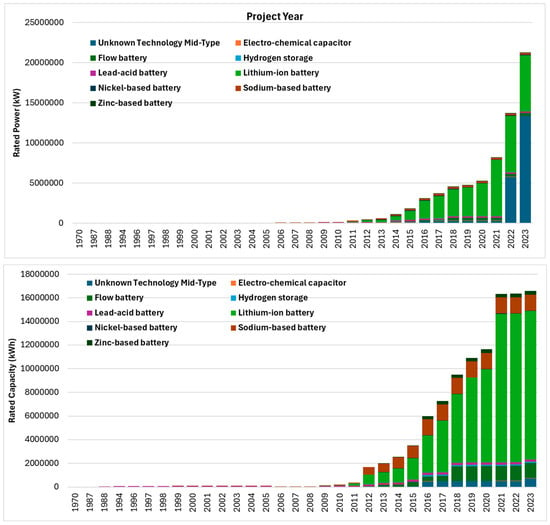

3.2. Various Projects on the Successful Integration of Energy Storage in Large-Scale Electrical System, Including Current Projects

Table 6 summarizes several large-scale electric energy storage projects in batteries across the European Union, particularly to support the large-scale integration of renewable energy sources (wind, solar, marine, etc.) into existing power systems. They achieve this by providing grid stabilization, frequency regulation, and smoothing renewable energy due to the dynamics of these sources. The table also provides detailed information on key factors such as the project name, implementation country, storage capacity, battery type (if applicable), service, application, and project status [93].

Table 6.

Large-scale electrical energy storage project in the European Union [94].

The Global Energy Storage Database is a comprehensive resource that provides detailed information on large-scale energy storage projects worldwide. Within the European Union, the European Association for Storage of Energy (EASE) database offers insights into energy storage projects across Europe. Other databases, such as those maintained by the International Renewable Energy Agency (IRENA), also provide information on renewable energy production and storage. Additionally, Bloomberg New Energy Finance (BNEF) delivers market reports and analyses on energy storage [94,95,96]. The graph in Figure 12 presents the cumulative sum of data on yearly energy storage installations globally [94].

Figure 12.

Cumulative sum of energy storage installations by year.

The work in [97,98,99,100,101,102] also provides information on projects already carried out on large-scale electrical energy storage in batteries in various applications and the battery technologies used.

4. Future Prospects and Technological Advancements in Power Electronics and Battery Energy Storage

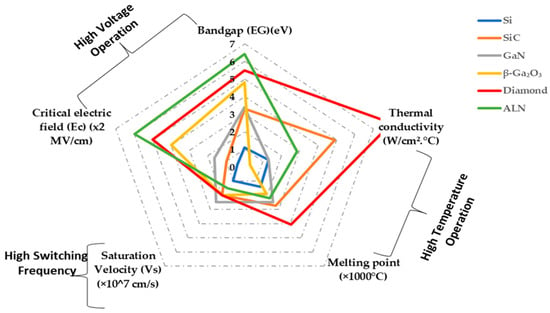

4.1. Exploration of Emerging Semiconductor Materials Technologies for Power Switch Converters

Over the past decades, the emergence of wide bandgap (WBG) semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN), has led to the development of technologies that offer significantly wider energy bandgaps and much higher performance levels compared to silicon (Si) semiconductors, which today have certain performance limitations in the field of high-power applications. SiC-based semiconductor technologies are becoming more and more popular because of their increased efficiency, weight reduction, compactness, and high-frequency operation [103]. As of recent, other semiconductor materials with an ultra-wide bandgap (UWBG), such as diamond, β-Ga2O3 (gallium oxide), and ALN (Aluminum Nitride), are under development for high-voltage (HV) applications that exceed the capabilities of gallium nitride (GaN) and silicon carbide (SiC) [103,104].

Figure 13 compares the different performances of the semiconductor materials such as Si, SiC, GaN, β-Ga2O3, and ALN [103,105,106]. Considering intrinsic material properties alone, diamond is the most promising candidate for extreme high-power applications due to its wide bandgap, exceptional thermal conductivity, and high electron and hole mobility.

Figure 13.

Comparison between semiconductor materials: Si, WBG (SiC and GaN), and UWBG (diamond, β-Ga2O3 and ALN).

4.2. Emerging Power Converter Topology for Supplying High-Power Electrolyzers from Renewable Energy Sources

Conventional converters, while effective, have limitations in supplying high-power capacity electrolyzers due to the high current and voltage requirements. Multiple converters are often connected in parallel or series to overcome these challenges, significantly increasing conversion system costs and components used. However, research has highlighted a new topology of modular multilevel converters (MMCs), which are increasingly used in high-power applications due to their scalability and efficiency. When integrated with renewable energy sources such as wind, tidal, or solar power [107], MMCs can be adapted to supply large-scale electrolyzers, enabling them to manage variable loads while maintaining grid stability [108,109]. This adaptability reassures of the versatility of MMCs in various applications. Their attractiveness is attributed to several factors: enhanced fault tolerance, ease of maintenance, and the capability to accommodate variable power levels, making them particularly suitable for dynamic hydrogen production processes.

Isolated DC/DC converters with their voltage ratio capability modularity and easy-to-build high-frequency transformers offer significant advantages. For electrolysis operation, several converter topologies can be utilized to interface electrolyzers with Marine Renewable energy over a DC–bus in high or medium voltage (DC–bus architecture based on MVDC/HVDC). These include the adaptable Dual Active Bridge (DAB), Half Bridge (HB), Full Bridge (FB) and Push–Pull (PP) [110,111]. The DAB offers several benefits over other topologies, including low current ripple, lower component stress, high power density, multi-level capability, modularity with series-parallel configuration capability (cascaded multi-DAB), smaller required filter sizes (capacitors and inductors), and soft-switching operations [112,113]. In [112], the authors present the concept of an adaptative modular converter to supply large-scale electrolyzer systems for green hydrogen production. The approach involves using a 100 kW DAB converter per module, with the module series and/or parallel connections on both high-voltage and low-voltage sides of the DC–bus. In [114], the authors review isolated and non-isolated DC/DC converters for a medium-voltage DC network. According to the application, power rate, and voltage ratio, some advantages and disadvantages of the studied converters are presented. They conclude that the optimal topologies for MVDC networks must combine the merits of modularity, bidirectional power flow, and galvanic isolation to meet the required voltage and improve overall efficiency. For offshore wind farms, the converters must be able to cope with high/low voltage gains and high power such as multimodule DAB or non-isolated DC-MMC converters for low/high voltage ratio. For photovoltaic (PV) systems, two-level or three-level DAB, MMC DAB-based, and cascade multi-DABs can achieve all PV requirements.

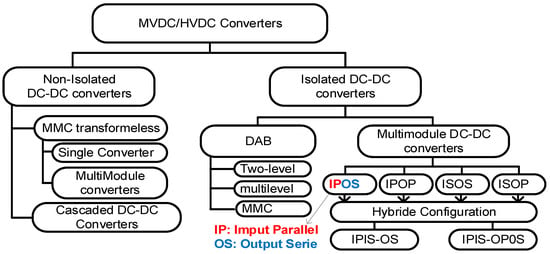

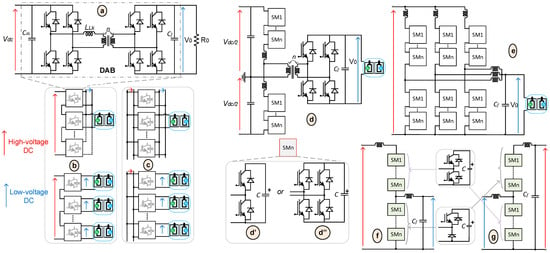

Figure 14 summarizes DC/DC converters for high-power applications in MVDC/HVDC systems [114,115,116]. Figure 15 illustrates various converter topologies for MVDC/HVDC connections designed to supply high-power electrolyzers, fuel cells (FCs), or batteries in large-scale hydrogen production systems based on a DC–bus architecture [111,112,114,117,118,119,120,121].

Figure 14.

MVDC/HVDC converters for high-power application classifications.

Figure 15.

High- and medium-voltage converters for high-power applications (e.g., large-scale electrolyzer systems) (a) DAB converter, (b) ISOP-DAB, (c) IPOP-DAB, (d) MMC-based DAB (submodules (SMs): (d′) unipolar submodule, and (d″) bipolar submodule), (e) MMC step-down converter, (f) unidirectional step-down DC/DC converter based on MMC for electrolyzer, and (g) unidirectional step-up DC/DC converter based on MMC for fuel cell.

4.3. Battery Perspectives for Large-Scale Stationary System

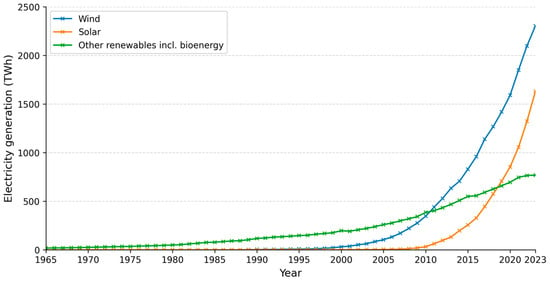

Global battery energy storage capacity has increased significantly, from less than 1 GW in 2012 to almost 21 GW in 2023 (Figure 12). Despite this growth, there is still a significant gap between the amount of renewable energy generated (4702.89 TWh in 2023 (Figure 16), excluding hydropower) and storage capacity [122,123]. Currently, Li-ion batteries are the most used in stationary applications due to their characteristics outlined in Section 3. However, their use increases system costs, primarily due to the need for replacement at the end of their life cycle. An emerging techno-economic solution is the reuse of aging batteries from the “second life” of electric vehicles [124,125]. The materials required to make lithium batteries present another major challenge due to their limited availability. To meet this challenge, there is a pressing need for developing or improving new battery technologies based on less rare and more cost-effective materials. Among these alternatives are aqueous batteries, which use a water-based electrolyte solution to transfer ions between the anode and cathode (zinc-ion batteries, sodium-ion batteries with aqueous electrolytes, redox flow batteries (vanadium), and aqueous nickel-iron or nickel-cadmium batteries) [124].

Figure 16.

Modern renewable energy generation by source worldwide.

5. Discussion

An investigation into a range of power converters, from conventional to multilevel topologies, has practical implications for the design and operation of hydrogen production systems, regardless of the architecture. We conducted a brief review of the literature on energy storage batteries, including behavioral aging models and different approaches to estimating their parameters.

In the context of AC–bus architecture for large-scale hydrogen production, thyristor bridges play a pivotal role as the most commonly used converters due to their capacity to switch high currents, a proven track record and simplicity. These converters depend on the pulsation index and the power required by the electrolyzer. Integrating a DC/DC converter between the thyristor bridge and the electrolyzer is intended to enhance the power quality delivered to the electrolyzer while minimizing the required size of the filters. In contrast, for DC–bus architecture, multilevel DC/DC converters based on the MMC topology (isolated or non-isolated), as well as isolated modular DC/DC converters based on the DAB principle, are essential for adapting voltage levels between the DC–bus and electrolyzers.

In recent literature, the integration of Artificial Intelligence (AI), Digital Twin (DT), and the Internet of Things (IoT) has been attracting growing interest in multi-source systems, particularly in renewable hydrogen production systems [126,127,128,129,130,131]. These technologies work complementary to enhancing these systems by facilitating intelligent energy management, optimizing the overall efficiency of the system, and providing advanced data analysis capabilities as well as the integration of machine learning models [130,132]. In [133], authors examine how AI can enhance battery management systems (BMSs), specifically in monitoring, SoH assessment, and cell balancing, with more accurate estimation of SoH and SoC-based variables like temperature, current waveforms, etc., as well as fault detection. In [134], the authors use a Digital Twin (DT) for the numerical modelling of a PEM electrolyzer for hydrogen storage. An Equivalent Circuit Model (ECM) is commonly employed to describe the static operation of PEM cells (resistance and reversible potential). Experimental values and internal resistance measurements are consistent with theoretical values, confirming the validity of the model.

Based on the literature reviewed in this paper, some recommendations for further study have been provided for researchers and industry professionals for future investigation of the design of high-power converters for large-scale electrolysis operations.

- Power switches using advanced technologies such as current silicon carbide (SiC) and gallium nitride (GaN) technologies offer significant advantages. These technologies can drastically reduce the size of converters due to their superior voltage and current characteristics. For instance, recent SiC MOSFETs and IGBTs have rated voltages exceeding 10 kV and current capabilities ranging from a few amperes to several kiloamperes. Moreover, these switches provide higher efficiency than silicon (Si)-based switches, making them a promising area for further scientific and technical investigations.

- There is a pressing need for the development of new converter topologies that are specifically adapted to the DC–bus architecture for high-power electrolyzer supply. These architectures, which are easier and simpler to implement, offer different energy management flexibility and are crucial for the future of large-scale electrolysis operations. Importantly, they require fewer converters connecting to other system components and marine renewable energy sources, making them a potential viable option for future systems.

- Efficient energy management within converters is a critical area for further scientific and technical investigations. To minimize the degradation of industrial-scale electrolyzers, fuel cells, and batteries, it is essential to develop efficient energy management techniques. This requires the development of new and accurate aging models for electrolyzers, fuel cells, and batteries that are adapted to specific operational conditions. More collaboration between researchers and industry professionals is also necessary to develop reliable and accurate models based on real operational data, integrating Artificial Intelligence (AI), Digital Twins (DTs), and Internet of Things (IoT) technologies.

6. Conclusions

This work provides a detailed review of power converters and the role of battery energy storage large-scale hydrogen production systems. Two main architectures are investigated: the DC–bus architecture and the AC–bus architecture.

Based on the literature review, several converter topologies, ranging from conventional to multilevel, are studied and summarized. The advantages and disadvantages of these topologies and architectures are presented, considering criteria such as cost, energy efficiency, control complexity, power range suitability for the application, and power quality. In the industrial context application, AC–bus architecture has some advantages, including the high step-down transformer to reduce the voltage level required to supply high-power converters, such as multi-pulse thyristor rectifiers, conventional, multilevel, or modular multilevel three-phase converters for large-scale electrolysis operation. However, these architectures present major drawbacks, including efficiency reduction, high costs due to multiple conversion stages, additional filter requirements to improve the power quality and power factor (particularly when a thyristor rectifier is used to supply the electrolyzer), and more control complexity. Regarding DC–bus-based architecture, MVDC and HVDC converters (particularly DAB and DC/DC MMC-based converters) are attractive options adapted to large-scale electrolysis operations. Their modularity, effectiveness, fault-tolerance capability, and most importantly reduced complexity in energy management at the architecture level make them highly suitable for this purpose.

At the battery storage level, we outline their role in a hydrogen production system utilizing MREs. Several studies have summarized behavioral aging models for LFP batteries, and methods for estimating the equivalent electrical circuit-based model parameters have been investigated and summarized. Integrating aging behavioral models into a hydrogen production system is necessary to propose energy management strategies considering the dynamics of the energy delivered by MREs. In addition to controlling the storage unit’s aging, this approach optimizes battery lifespan and provides real-time parameter evolution, particularly in estimating the storage unit’s remaining lifespan. Finally, a series of projects aimed at installing large-scale energy storage systems for stationary applications at the European level further demonstrates the feasibility of such a system.

Finally, several recommendations and perspectives regarding researchers and industrial professionals are proposed. As part of the future research, it consists of the implementation of step-down DC/DC converters based on DAB or MMC topology adapted to MVDC for electrolyzers, step-up DC/DC converters for fuel cells, and bidirectional Buck–Boost converters for battery supply, as well as the characterization and parameter estimation of the dynamic behavioral aging models of LFP batteries as a first step. Then, by combining electrolyzer and fuel cell aging models, the goal is to develop an intelligent energy management strategy that integrates the behavioral aging models of the hybrid storage system (electrolyzer, fuel cells, and batteries). This approach aims to enhance the system’s overall efficiency and extend the lifespan of its components.

Author Contributions

Methodology, J.D.N.E., M.B.C. and M.L.D.; formal analysis, J.D.N.E. formal analysis; writing—original draft preparation, J.D.N.E., M.B.C. and J.S.-M.; writing—review and editing, J.D.N.E., M.B.C., M.L.D., B.D. and J.S.-M.; supervision, M.B.C. and M.L.D.; project administration, M.B.C. and M.L.D. All authors have read and agreed to the published version of the manuscript.

Funding

This work is co-funded by the European Union through the European Regional Development Fund (ERDF), University of Le Havre Normandie (France), and Université du Québec à Trois-Rivières (Canada).

Data Availability Statement

No new data were created or analyzed in this study.

Acknowledgments

This work was performed at the GREAH Laboratory of the University of Le Havre Normandie and the GREI Laboratory, Université du Québec à Trois-Rivières, respectively by the research team of Renewable Energies and Storage Systems (MERS), and the research group on Industrial Electronics and Computer Science. The authors would like to thank the Normandy Region, University of Le Havre Normandie, and Université du Québec à Trois-Rivières for their financial support.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| DC | Direct Current |

| AC | Alternating Current |

| HVDC | High-Voltage Direct Current |

| MVDC | Medium-Voltage Direct Current |

| MMC | Modular Multilevel Converter |

| DAB | Dual Active Bridge |

| SDGs | Sustainable Development Goals |

| FCs | Fuel Cells |

| MREs | Marine Renewable Sources |

| LFP | Lithium Iron Phosphate |

| GSSAM | Generalized State Space Average Model |

| PtH | Power to Hydrogen |

| NIBDCs | Non-Isolated Bidirectional Converters |

| IBDCs | Isolated Bidirectional Converters |

| AFE | Active Front End |

| CHB | Cascaded H-Bridge |

| NPC | Neutral-Point-Clamped |

| ANPC | Active-Neutral-Point-Clamped |

| Lithium Cobalt Oxide | |

| Lithium Nickel Cobalt Aluminum Oxide | |

| Lithium Nickel Manganese Cobalt Oxide | |

| Lithium Manganese Oxide | |

| Lithium Titanate Oxide | |

| ECMs | Equivalent Circuit Models |

| SoC | State of Charge |

| DoD | Depth of Discharge |

| OCV | Open-Circuit Voltage |

| SoH | State of Health |

| EMHPP | Enhanced Multiple Hybrid Pulsed Power Characterization |

| KF | Kalman Filter |

| EKF | Extended Kalman Filter |

| SVM | Support Vector Regression |

| RESs | Renewable Energy Sources |

| ESRbat(I,T,SoC) | Variable Internal Resistance of LFP Batteries [Ω] |

| Variable Open-Circuit Voltage [V] | |

| Parallel resistance of the LFP battery model corresponding, respectively, to short-term and long-term phenomena [Ω] | |

| Parallel capacitances in the LFP battery model, associated with short-term and long-term dynamic phenomena [F] |

References

- Energy Institute. Statistical Review of World Energy. Available online: https://www.energyinst.org/statistical-review (accessed on 12 September 2024).

- Strelkovskii, N.; Komendantova, N. Integration of UN Sustainable Development Goals in National Hydrogen Strategies: A Text Analysis Approach. Int. J. Hydrogen Energy 2025, 102, 1282–1294. [Google Scholar] [CrossRef]

- Carlsen, L.; Bruggemann, R. The 17 United Nations’ Sustainable Development Goals: A Status by 2020. Int. J. Sustain. Dev. World Ecol. 2022, 29, 219–229. [Google Scholar] [CrossRef]

- Sikora, A. European Green Deal–Legal and Financial Challenges of the Climate Change. In Proceedings of the Era Forum, Brussels, Belgium, 17 September 2021; Springer: Berlin/Heidelberg, Germany, 2021; Volume 21, pp. 681–697. [Google Scholar]

- Mazloomi, K.; Gomes, C. Hydrogen as an Energy Carrier: Prospects and Challenges. Renew. Sustain. Energy Rev. 2012, 16, 3024–3033. [Google Scholar] [CrossRef]

- Rosen, M.A.; Koohi-Fayegh, S. The Prospects for Hydrogen as an Energy Carrier: An Overview of Hydrogen Energy and Hydrogen Energy Systems. Energy Ecol. Environ. 2016, 1, 10–29. [Google Scholar] [CrossRef]

- Ngando Ebba, J.D.; Camara, M.B.; Doumbia, M.L.; Dakyo, B.; Song-Manguelle, J. Large-Scale Hydrogen Production Systems Using Marine Renewable Energies: State-of-the-Art. Energies 2023, 17, 130. [Google Scholar] [CrossRef]

- Higuita Cano, M.; Agbossou, K.; Kelouwani, S.; Dubé, Y. Experimental Evaluation of a Power Management System for a Hybrid Renewable Energy System with Hydrogen Production. Renew. Energy 2017, 113, 1086–1098. [Google Scholar] [CrossRef]

- Chaoui, H.; Kandidayeni, M.; Boulon, L.; Kelouwani, S.; Gualous, H. Real-Time Parameter Estimation of a Fuel Cell for Remaining Useful Life Assessment. IEEE Trans. Power Electron. 2020, 36, 7470–7479. [Google Scholar] [CrossRef]

- Jouin, M.; Gouriveau, R.; Hissel, D.; Péra, M.-C.; Zerhouni, N. Joint Particle Filters Prognostics for Proton Exchange Membrane Fuel Cell Power Prediction at Constant Current Solicitation. IEEE Trans. Reliab. 2016, 65, 336–349. [Google Scholar] [CrossRef]

- Guilbert, D.; Yodwong, B.; Kaewmanee, W.; Phattanasak, M. Power Converters for Hybrid Renewable Energy Systems with Hydrogen Buffer Storage: A Short Review. In Proceedings of the 2018 International Conference on Smart Grid (icSmartGrid), Nagasaki, Japan, 4–6 December 2018; IEEE: New York, NY, USA, 2018; pp. 28–33. [Google Scholar]

- Yodwong, B.; Guilbert, D.; Phattanasak, M.; Kaewmanee, W.; Hinaje, M.; Vitale, G. AC-DC Converters for Electrolyzer Applications: State of the Art and Future Challenges. Electronics 2020, 9, 912. [Google Scholar] [CrossRef]

- Yodwong, B.; Guilbert, D.; Phattanasak, M.; Kaewmanee, W.; Hinaje, M.; Vitale, G. Proton Exchange Membrane Electrolyzer Modeling for Power Electronics Control: A Short Review. C 2020, 6, 29. [Google Scholar] [CrossRef]

- Azer, P.; Emadi, A. Generalized State Space Average Model for Multi-Phase Interleaved Buck, Boost and Buck-Boost DC-DC Converters: Transient, Steady-State and Switching Dynamics. IEEE Access 2020, 8, 77735–77745. [Google Scholar] [CrossRef]

- Chen, M.; Chou, S.-F.; Blaabjerg, F.; Davari, P. Overview of Power Electronic Converter Topologies Enabling Large-Scale Hydrogen Production via Water Electrolysis. Appl. Sci. 2022, 12, 1906. [Google Scholar] [CrossRef]

- Lin, Y.; Fu, L. A Study for a Hybrid Wind-Solar-Battery System for Hydrogen Production in an Islanded MVDC Network. IEEE Access 2022, 10, 85355–85367. [Google Scholar] [CrossRef]

- Bahrami, M.; Jamshidpour, E.; Bayati, N.; Pierfederici, S. Exploring Power Electronics Converters for Water Electrolysis in Microgrid Applications: A Comprehensive Overview. In Proceedings of the 2023 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Chiang Mai, Thailand, 28 November–1 December 2023; pp. 1–5. [Google Scholar]

- Keddar, M.; Zhang, Z.; Periasamy, C.; Doumbia, M.L. Power Quality Improvement for 20 MW PEM Water Electrolysis System. Int. J. Hydrogen Energy 2022, 47, 40184–40195. [Google Scholar] [CrossRef]

- Abdelhakim, A.; Viitanen, T.; Canales, F. State-of-the-Art Power Supplies for Electrolyzers. ABB Rev. 2022, 4, 60–63. [Google Scholar]

- Kolli, A.; Gaillard, A.; De Bernardinis, A.; Bethoux, O.; Hissel, D.; Khatir, Z. A Review on DC/DC Converter Architectures for Power Fuel Cell Applications. Energy Convers. Manag. 2015, 105, 716–730. [Google Scholar] [CrossRef]

- Liu, Y.; Farnell, C.; Balda, J.C.; Mantooth, H.A. Topology, Cost and Efficiency Comparisons of a 2 MW DC Supply Using Interleaved DC-DC Converter. In Proceedings of the 2014 IEEE 5th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Galway, Ireland, 24–27 June 2014; IEEE: New York, NY, USA, 2014; pp. 1–6. [Google Scholar]

- Guilbert, D.; Gaillard, A.; N’Diaye, A.; Djerdir, A. Fault-Tolerant Control for PEMFC and Its DC/DC Converter. In Proceedings of the 2015 5th International Youth Conference on Energy (IYCE), Pisa, Italy, 27–30 May 2015; IEEE: New York, NY, USA, 2015; pp. 1–6. [Google Scholar]

- Thounthong, P.; Mungporn, P.; Guilbert, D.; Takorabet, N.; Pierfederici, S.; Nahid-Mobarakeh, B.; Hu, Y.; Bizon, N.; Huangfu, Y.; Kumam, P. Design and Control of Multiphase Interleaved Boost Converters-Based on Differential Flatness Theory for PEM Fuel Cell Multi-Stack Applications. Int. J. Electr. Power Energy Syst. 2021, 124, 106346. [Google Scholar] [CrossRef]

- Yu, X.; Starke, M.R.; Tolbert, L.M.; Ozpineci, B. Fuel Cell Power Conditioning for Electric Power Applications: A Summary. IET Electr. Power Appl. 2007, 1, 643–656. [Google Scholar] [CrossRef]

- Karshenas, H.R.; Daneshpajooh, H.; Safaee, A.; Jain, P.; Bakhshai, A. Bidirectional Dc-Dc Converters for Energy Storage Systems. Energy Storage Emerg. Era Smart Grids 2011, 18, 161–168. [Google Scholar]

- Tytelmaier, K.; Husev, O.; Veligorskyi, O.; Yershov, R. A Review of Non-Isolated Bidirectional Dc-Dc Converters for Energy Storage Systems. In Proceedings of the 2016 II International Young Scientists Forum on Applied Physics and Engineering (YSF), Kharkiv, Ukraine, 10–14 October 2016; IEEE: New York, NY, USA, 2016; pp. 22–28. [Google Scholar]

- Eroǧlu, F.; Kurtoǧlu, M.; Vural, A.M. Bidirectional DC–DC Converter Based Multilevel Battery Storage Systems for Electric Vehicle and Large-scale Grid Applications: A Critical Review Considering Different Topologies, State-of-charge Balancing and Future Trends. IET Renew. Power Gener. 2021, 15, 915–938. [Google Scholar] [CrossRef]

- Mumtaz, F.; Yahaya, N.Z.; Meraj, S.T.; Singh, B.; Kannan, R.; Ibrahim, O. Review on Non-Isolated DC-DC Converters and Their Control Techniques for Renewable Energy Applications. Ain Shams Eng. J. 2021, 12, 3747–3763. [Google Scholar] [CrossRef]

- Du, Z.S.; Channegowda, P.; Kshirsagar, P.; Dwari, S. High Density High Power DC-DC Converter Architectures for Future Electric Transportation Applications. In Proceedings of the 2019 IEEE energy conversion congress and exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; IEEE: New York, NY, USA, 2019; pp. 5862–5869. [Google Scholar]

- Hu, H.; Ghosh, S.; Siwakoti, Y.; Long, T. Generalized Multilevel Converter in DC-DC Application. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; IEEE: New York, NY, USA, 2019; pp. 5137–5143. [Google Scholar]

- Lei, J.; Ma, H.; Qin, G.; Guo, Z.; Xia, P.; Hao, C. A Comprehensive Review on the Power Supply System of Hydrogen Production Electrolyzers for Future Integrated Energy Systems. Energies 2024, 17, 935. [Google Scholar] [CrossRef]

- Fan, L.; Luo, S.; Lai, Y.; Liu, H. Development of Three Level DC Power Supply for Hydrogen Production from Electrolytic Water. Power Electron. Power Electron. Technol. 2023, 57, 31–34. [Google Scholar]

- Costa, L.F.; Mussa, S.A.; Barbi, I. Multilevel Buck/Boost-Type DC–DC Converter for High-Power and High-Voltage Application. IEEE Trans. Ind. Appl. 2014, 50, 3931–3942. [Google Scholar] [CrossRef]

- Shi, H.; Wang, K.; Xiao, X.; Sun, K. Capacitor Voltage Balancing of a Three-Level Bi-Directional Buck-Boost Converter for Battery Energy Storage System. In Proceedings of the 2014 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; IEEE: New York, NY, USA, 2014; pp. 325–329. [Google Scholar]

- Liu, M.; Yao, Z.; He, X.; Jiang, L.; Chen, W. A Balancing Control Method with Single Voltage Sensor for Five-Level Buck/Boost Converter. In Proceedings of the 2022 IEEE 17th Conference on Industrial Electronics and Applications (ICIEA), Chengdu, China, 16–19 December 2022; IEEE: New York, NY, USA, 2022; pp. 690–695. [Google Scholar]

- You, H.; Cai, X. A Three-Level Modular DC/DC Converter Applied in High Voltage DC Grid. IEEE Access 2018, 6, 25448–25462. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Y.; Guan, Q. A Balancing Control Method for Flying Capacitors in Five-Level Buck/Boost Converter with Synchronous Phase Shifting Decoupling. In Proceedings of the 2021 IEEE 1st International Power Electronics and Application Symposium (PEAS), Shanghai, China, 12–15 November 2021; IEEE: New York, NY, USA, 2021; pp. 1–6. [Google Scholar]

- Zhao, X.; Zhang, Y. Start-up Control Method for Five-Level Buck/Boost Converter. In Proceedings of the 2022 IEEE International Power Electronics and Application Conference and Exposition (PEAC), Xiamen, China, 4–7 November 2022; IEEE: New York, NY, USA, 2022; pp. 1005–1010. [Google Scholar]

- Dusmez, S.; Hasanzadeh, A.; Khaligh, A. Comparative Analysis of Bidirectional Three-Level DC–DC Converter for Automotive Applications. IEEE Trans. Ind. Electron. 2014, 62, 3305–3315. [Google Scholar] [CrossRef]

- Costa, L.F.; Mussa, S.A.; Barbi, I. Steady-State Analysis of a 5-Level Bidirectional Buck+ Boost Dc-Dc Converter. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; IEEE: New York, NY, USA, 2013; pp. 1290–1295. [Google Scholar]

- Thounthong, P. Control of a Three-Level Boost Converter Based on a Differential Flatness Approach for Fuel Cell Vehicle Applications. IEEE Trans. Veh. Technol. 2012, 61, 1467–1472. [Google Scholar] [CrossRef]

- Pires, V.F.; Romero-Cadaval, E.; Vinnikov, D.; Roasto, I.; Martins, J.F. Power Converter Interfaces for Electrochemical Energy Storage Systems–A Review. Energy Convers. Manag. 2014, 86, 453–475. [Google Scholar] [CrossRef]

- Trintis, I.; Munk-Nielsen, S.; Teodorescu, R. A New Modular Multilevel Converter with Integrated Energy Storage. In Proceedings of the IECON 2011—37th Annual Conference of the IEEE Industrial Electronics Society, Melbourne, VIC, Australia, 7–10 November 2011; IEEE: New York, NY, USA, 2011; pp. 1075–1080. [Google Scholar]

- Foti, S.; Testa, A.; Scelba, G.; De Caro, S.; Tornello, L.D. A V2G Integrated Battery Charger Based on an Open End Winding Multilevel Configuration. IEEE Open J. Ind. Appl. 2020, 1, 216–226. [Google Scholar] [CrossRef]

- Dakanalis, M.; Koutroulis, E.; Kanellos, F.D. Single-Phase Standalone Multi-Port DC/AC Inverter for Multiple Energy Production and Storage Units. IEEE Trans. Circuits Syst. I Regul. Pap. 2024, 71, 3926–3936. [Google Scholar] [CrossRef]

- Wang, J.; Sun, K.; Xue, C.; Liu, T.; Li, Y. Multi-Port DC-AC Converter With Differential Power Processing DC-DC Converter and Flexible Power Control for Battery ESS Integrated PV Systems. IEEE Trans. Ind. Electron. 2022, 69, 4879–4889. [Google Scholar] [CrossRef]

- Ebrahimi, J.; Eren, S. A Multi-Source DC/AC Converter for Integrated Hybrid Energy Storage Systems. IEEE Trans. Energy Convers. 2022, 37, 2298–2309. [Google Scholar] [CrossRef]

- Roditis, I.; Dakanalis, M.; Koutroulis, E.; Kanellos, F.D. Three-Phase Multiport DC–AC Inverter for Interfacing Photovoltaic and Energy Storage Systems to the Electric Grid. IEEE J. Emerg. Sel. Top. Ind. Electron. 2023, 4, 982–994. [Google Scholar] [CrossRef]

- Tao, M.; Azzolini, J.A.; Stechel, E.B.; Ayers, K.E.; Valdez, T.I. Engineering Challenges in Green Hydrogen Production Systems. J. Electrochem. Soc. 2022, 169, 54503. [Google Scholar] [CrossRef]

- Rashid Muhammad, H. Power Electronics Handbook; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Kouro, S.; Rodriguez, J.; Wu, B.; Bernet, S.; Perez, M. Powering the Future of Industry: High-Power Adjustable Speed Drive Topologies. IEEE Ind. Appl. Mag. 2012, 18, 26–39. [Google Scholar] [CrossRef]

- Silva, J.F.; Redondo, L.; Canacsinh, H.; Dillard, W.C. Solid-State Pulsed Power Modulators and Capacitor Charging Applications. In Power Electronics Handbook; Elsevier: Amsterdam, The Netherlands, 2024; pp. 621–685. [Google Scholar]

- Yuan, X.; Laird, I.; Walder, S. Opportunities, Challenges, and Potential Solutions in the Application of Fast-Switching SiC Power Devices and Converters. IEEE Trans. Power Electron. 2020, 36, 3925–3945. [Google Scholar] [CrossRef]

- Laloya, E.; Lucía, Ó.; Sarnago, H.; Burdío, J.M. Heat Management in Power Converters: From State of the Art to Future Ultrahigh Efficiency Systems. IEEE Trans. Power Electron. 2016, 31, 7896–7908. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Z.; Ericsen, T.; Raju, R.; Burgos, R.; Boroyevich, D. Advances in Power Conversion and Drives for Shipboard Systems. Proc. IEEE 2015, 103, 2285–2311. [Google Scholar] [CrossRef]

- Farhadi, M.; Mohammed, O. Energy Storage Technologies for High-Power Applications. IEEE Trans. Ind. Appl. 2015, 52, 1953–1961. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, J.; Yang, Z.; Lemmon, J.P.; Imhoff, C.; Graff, G.L.; Li, L.; Hu, J.; Wang, C.; Xiao, J. Materials Science and Materials Chemistry for Large Scale Electrochemical Energy Storage: From Transportation to Electrical Grid. Adv. Funct. Mater. 2013, 23, 929–946. [Google Scholar] [CrossRef]

- Yao, L.; Yang, B.; Cui, H.; Zhuang, J.; Ye, J.; Xue, J. Challenges and Progresses of Energy Storage Technology and Its Application in Power Systems. J. Mod. Power Syst. Clean Energy 2016, 4, 519–528. [Google Scholar] [CrossRef]

- Diouf, B.; Pode, R. Potential of Lithium-Ion Batteries in Renewable Energy. Renew. Energy 2015, 76, 375–380. [Google Scholar] [CrossRef]

- Hannan, M.A.; Hoque, M.M.; Hussain, A.; Yusof, Y.; Ker, P.J. State-of-the-Art and Energy Management System of Lithium-Ion Batteries in Electric Vehicle Applications: Issues and Recommendations. IEEE Access 2018, 6, 19362–19378. [Google Scholar] [CrossRef]

- El Kharbachi, A.; Zavorotynska, O.; Latroche, M.; Cuevas, F.; Yartys, V.; Fichtner, M. Exploits, Advances and Challenges Benefiting beyond Li-Ion Battery Technologies. J. Alloys Compd. 2020, 817, 153261. [Google Scholar] [CrossRef]

- Feyzi, E.; MR, A.K.; Li, X.; Deng, S.; Nanda, J.; Zaghib, K. A Comprehensive Review of Silicon Anodes for High-Energy Lithium-Ion Batteries: Challenges, Latest Developments, and Perspectives. Next Energy 2024, 5, 100176. [Google Scholar] [CrossRef]

- Julien, C.M.; Mauger, A.; Zaghib, K.; Groult, H. Comparative Issues of Cathode Materials for Li-Ion Batteries. Inorganics 2014, 2, 132–154. [Google Scholar] [CrossRef]

- Liang, S.; Wang, X.; Cheng, Y.-J.; Xia, Y.; Müller-Buschbaum, P. Anatase Titanium Dioxide as Rechargeable Ion Battery Electrode-A Chronological Review. Energy Storage Mater. 2022, 45, 201–264. [Google Scholar] [CrossRef]

- Mahmood, N.; Tang, T.; Hou, Y. Nanostructured Anode Materials for Lithium Ion Batteries: Progress, Challenge and Perspective. Adv. Energy Mater. 2016, 6, 1600374. [Google Scholar] [CrossRef]

- Goriparti, S.; Miele, E.; De Angelis, F.; Di Fabrizio, E.; Zaccaria, R.P.; Capiglia, C. Review on Recent Progress of Nanostructured Anode Materials for Li-Ion Batteries. J. Power Sources 2014, 257, 421–443. [Google Scholar] [CrossRef]

- Prabhukhot Prachi, R.; Wagh Mahesh, M.; Gangal Aneesh, C. A Review on Solid State Hydrogen Storage Material. Adv. Energy Power 2016, 4, 11–22. [Google Scholar] [CrossRef]

- Usman, M.R. Hydrogen Storage Methods: Review and Current Status. Renew. Sustain. Energy Rev. 2022, 167, 112743. [Google Scholar] [CrossRef]

- Ratnakar, R.R.; Gupta, N.; Zhang, K.; van Doorne, C.; Fesmire, J.; Dindoruk, B.; Balakotaiah, V. Hydrogen Supply Chain and Challenges in Large-Scale LH2 Storage and Transportation. Int. J. Hydrogen Energy 2021, 46, 24149–24168. [Google Scholar] [CrossRef]

- Paya, J.; Linder, M.; Laurien, E.; Corberan, J.M. Dynamic Model and Experimental Results of a Thermally Driven Metal Hydride Cooling System. Int. J. Hydrogen Energy 2009, 34, 3173–3184. [Google Scholar] [CrossRef]

- Suarez, S.H.; Chabane, D.; N’Diaye, A.; Ait-Amirat, Y.; Djerdir, A. Static and Dynamic Characterization of Metal Hydride Tanks for Energy Management Applications. Renew. Energy 2022, 191, 59–70. [Google Scholar] [CrossRef]

- Abe, J.O.; Popoola, A.P.I.; Ajenifuja, E.; Popoola, O.M. Hydrogen Energy, Economy and Storage: Review and Recommendation. Int. J. Hydrogen Energy 2019, 44, 15072–15086. [Google Scholar] [CrossRef]

- Stroe, D.-I.; Swierczynski, M.; Stroe, A.-I.; Knudsen Kær, S. Generalized Characterization Methodology for Performance Modelling of Lithium-Ion Batteries. Batteries 2016, 2, 37. [Google Scholar] [CrossRef]

- Bester, J.E.; El Hajjaji, A.; Mabwe, A.M. Modelling of Lithium-Ion Battery and SOC Estimation Using Simple and Extended Discrete Kalman Filters for Aircraft Energy Management. In Proceedings of the IECON 2015—41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; IEEE: New York, NY, USA, 2015; pp. 2433–2438. [Google Scholar]

- Marin-Garcia, G.; Vazquez-Guzman, G.; Sosa, J.M.; Lopez, A.R.; Martinez-Rodriguez, P.R.; Langarica, D. Battery Types and Electrical Models: A Review. In Proceedings of the 2020 IEEE International Autumn Meeting on Power, Electronics and Computing (ROPEC), Ixtapa, Guerrero, Mexico, 4–6 November 2020; IEEE: New York, NY, USA, 2020; Volume 4, pp. 1–6. [Google Scholar]

- Tian, H.; Qin, P.; Li, K.; Zhao, Z. A Review of the State of Health for Lithium-Ion Batteries: Research Status and Suggestions. J. Clean. Prod. 2020, 261, 120813. [Google Scholar] [CrossRef]

- Lavety, S.; Keshri, R.K.; Chaudhari, M.A. A Dynamic Battery Model and Parameter Extraction for Discharge Behavior of a Valve Regulated Lead-Acid Battery. J. Energy Storage 2021, 33, 102031. [Google Scholar] [CrossRef]

- Park, S.W.; Lee, H.; Won, Y.S. A Novel Aging Parameter Method for Online Estimation of Lithium-Ion Battery States of Charge and Health. J. Energy Storage 2022, 48, 103987. [Google Scholar] [CrossRef]

- Jiang, S. A Parameter Identification Method for a Battery Equivalent Circuit Model; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Bellache, K.; Camara, M.B.; Dakyo, B. Characterization and Electric Behavior Modeling of Lithium-Battery Using Temporal Approach for Parameters Computing. In Proceedings of the 2018 7th International Conference on Renewable Energy Research and Applications (ICRERA), Paris, France, 14–17 October 2018; IEEE: New York, NY, USA, 2018; pp. 1330–1335. [Google Scholar]

- Bellache, K.; Camara, M.B.; Dakyo, B.; Ramasamy, S. Aging Characterization of Lithium Iron Phosphate Batteries Considering Temperature and Direct Current Undulations as Degrading Factors. IEEE Trans. Ind. Electron. 2020, 68, 9696–9706. [Google Scholar] [CrossRef]

- Gao, Y.; Huang, R.; Qin, D.; Wang, T.; Ma, S.; Qin, S. State-of-Charge Estimation of Lithium-Ion Battery Based on Capacity Degradation Model Considering the Dynamic Currents and Temperatures. Int. J. Electrochem. Sci. 2021, 16, 210424. [Google Scholar] [CrossRef]

- Saleem, K.; Mehran, K.; Ali, Z. Online Reduced Complexity Parameter Estimation Technique for Equivalent Circuit Model of Lithium-Ion Battery. Electr. Power Syst. Res. 2020, 185, 106356. [Google Scholar] [CrossRef]

- Mouncef, E.; Mostafa, B.; Naoufl, E. Online Parameter Estimation of a Lithium-Ion Battery Based on Sunflower Optimization Algorithm. In Proceedings of the 2020 2nd Global Power, Energy and Communication Conference (GPECOM), Ephesus, Izmir, Turkey, 20–23 October 2020; IEEE: New York, NY, USA, 2020; pp. 53–58. [Google Scholar]

- Noura, N.; Boulon, L.; Jemeï, S. A Review of Battery State of Health Estimation Methods: Hybrid Electric Vehicle Challenges. World Electr. Veh. J. 2020, 11, 66. [Google Scholar] [CrossRef]

- Di Fonso, R.; Teodorescu, R.; Bharadwaj, P. Aging-Aware Equivalent Circuit Model for SOH Estimation in Lithium-Ion Batteries. In Proceedings of the 2024 IEEE International Communications Energy Conference (INTELEC), Bengaluru, India, 4–7 August 2024; IEEE: New York, NY, USA, 2024; pp. 1–5. [Google Scholar]