Kinematics and Stiffness Analysis of a Novel 5-DOF Parallel Mechanism

Abstract

1. Introduction

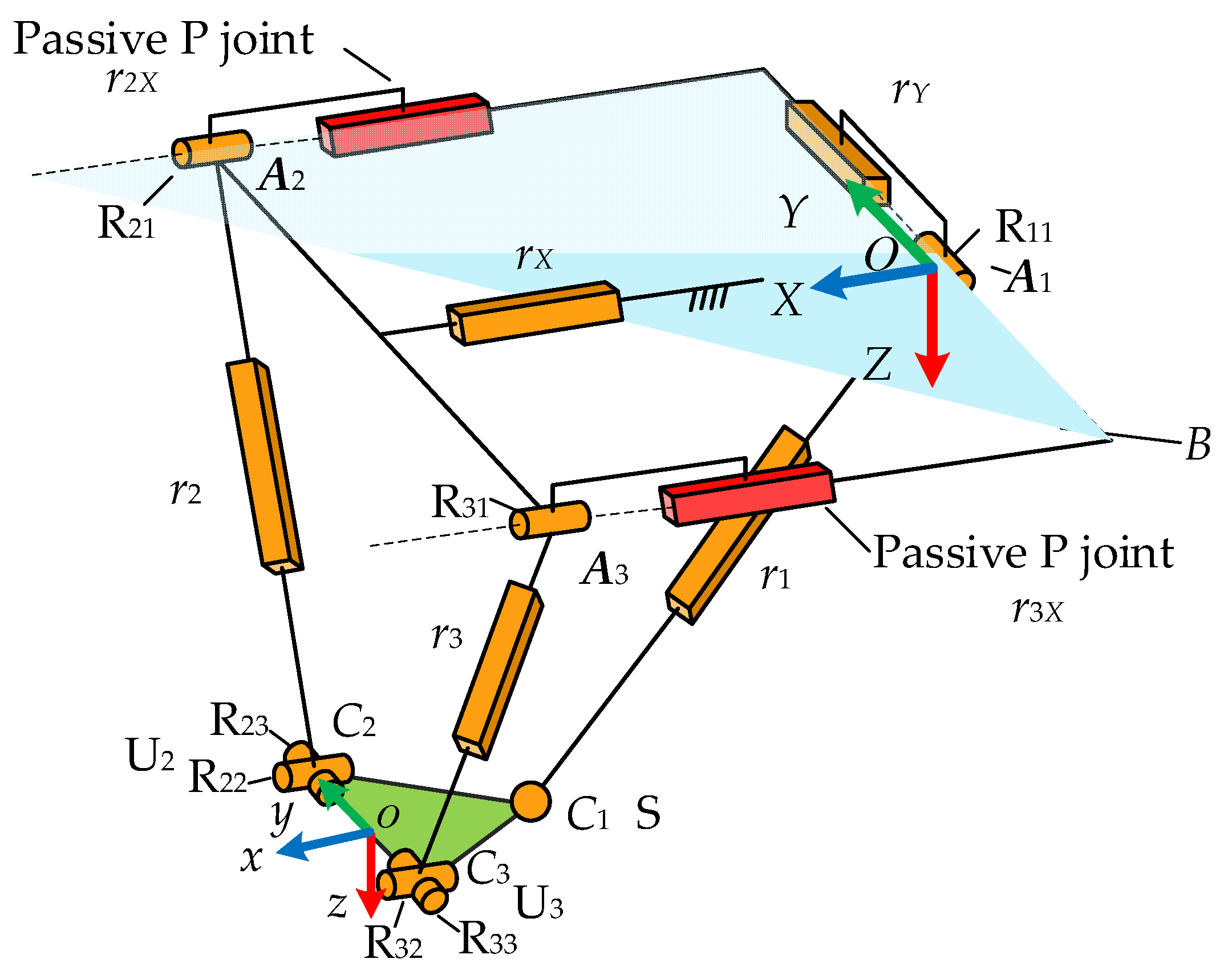

2. Description and Mobility Analysis

2.1. Configuration Description

2.2. Mobility Analysis

3. Kinematics Analysis

3.1. Kinematic Modeling

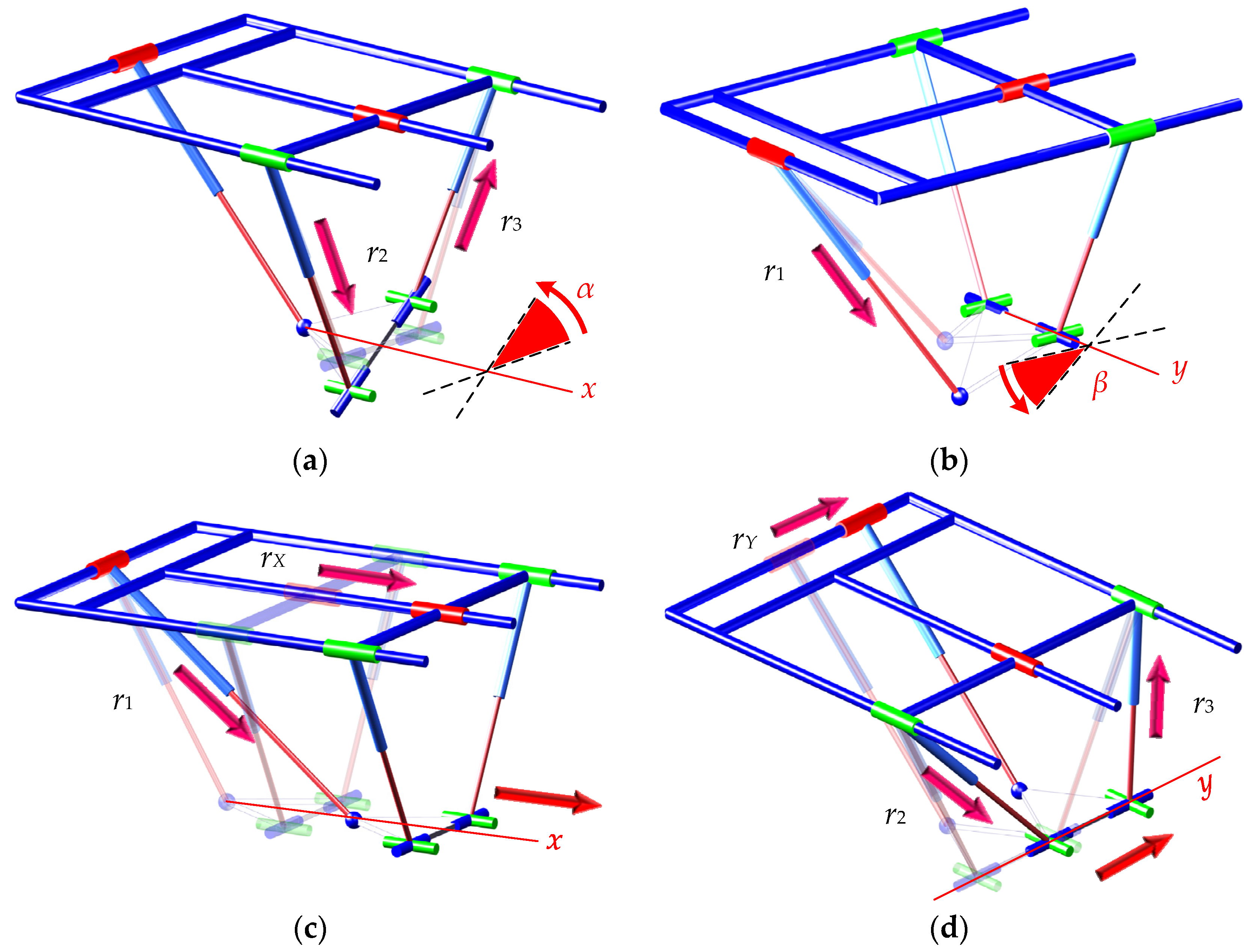

3.2. Kinematic Performance Analysis

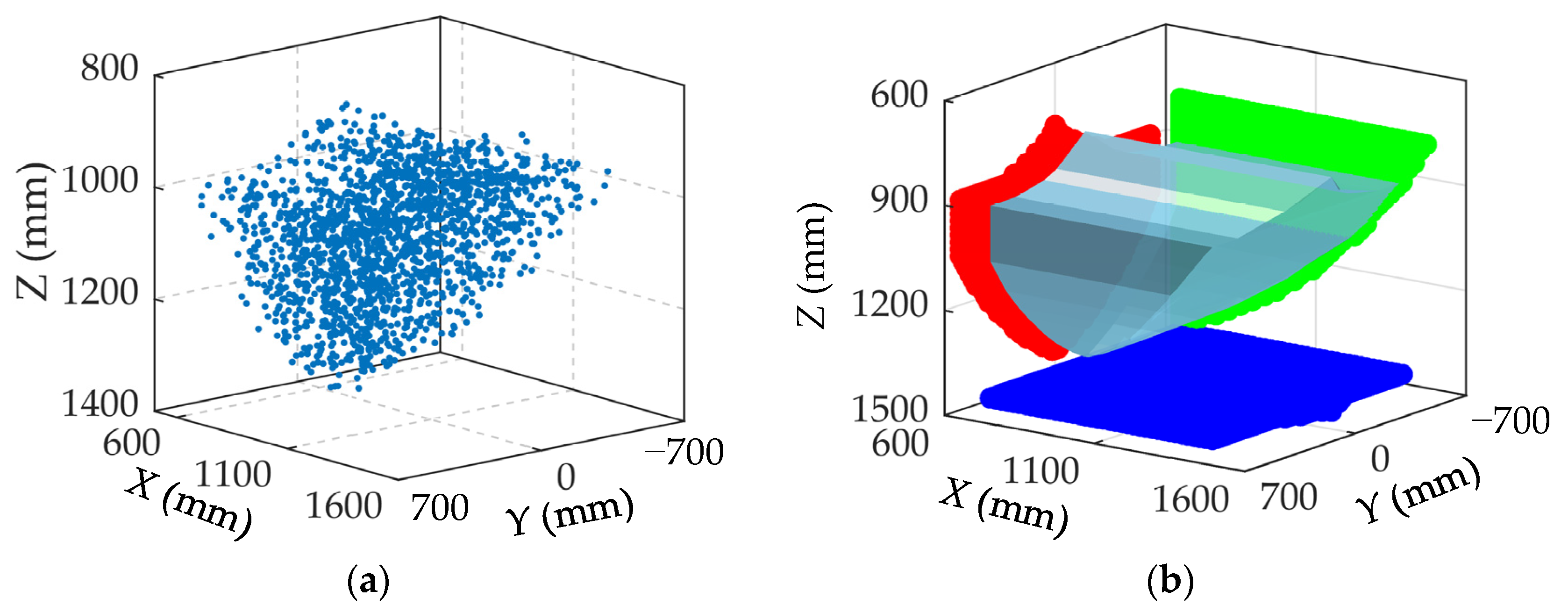

3.2.1. Workspace Analysis

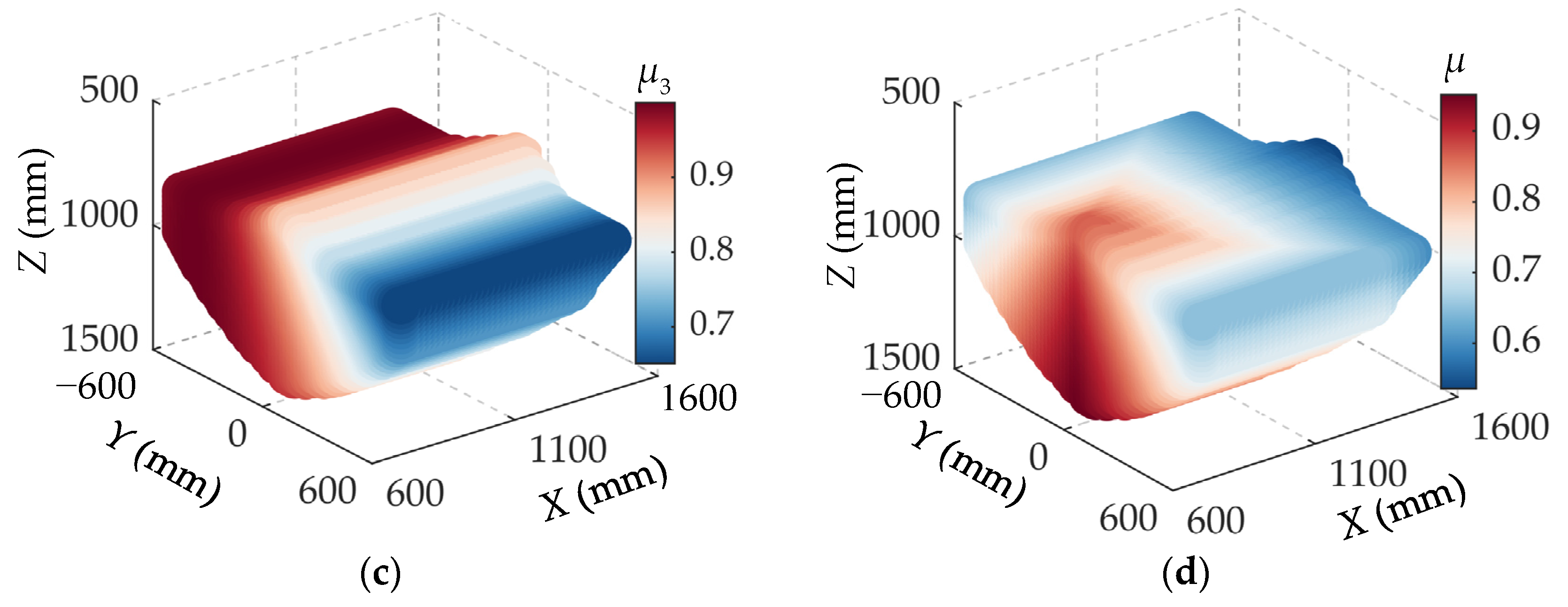

3.2.2. The Analysis of Transmission Performance

4. Stiffness Analysis

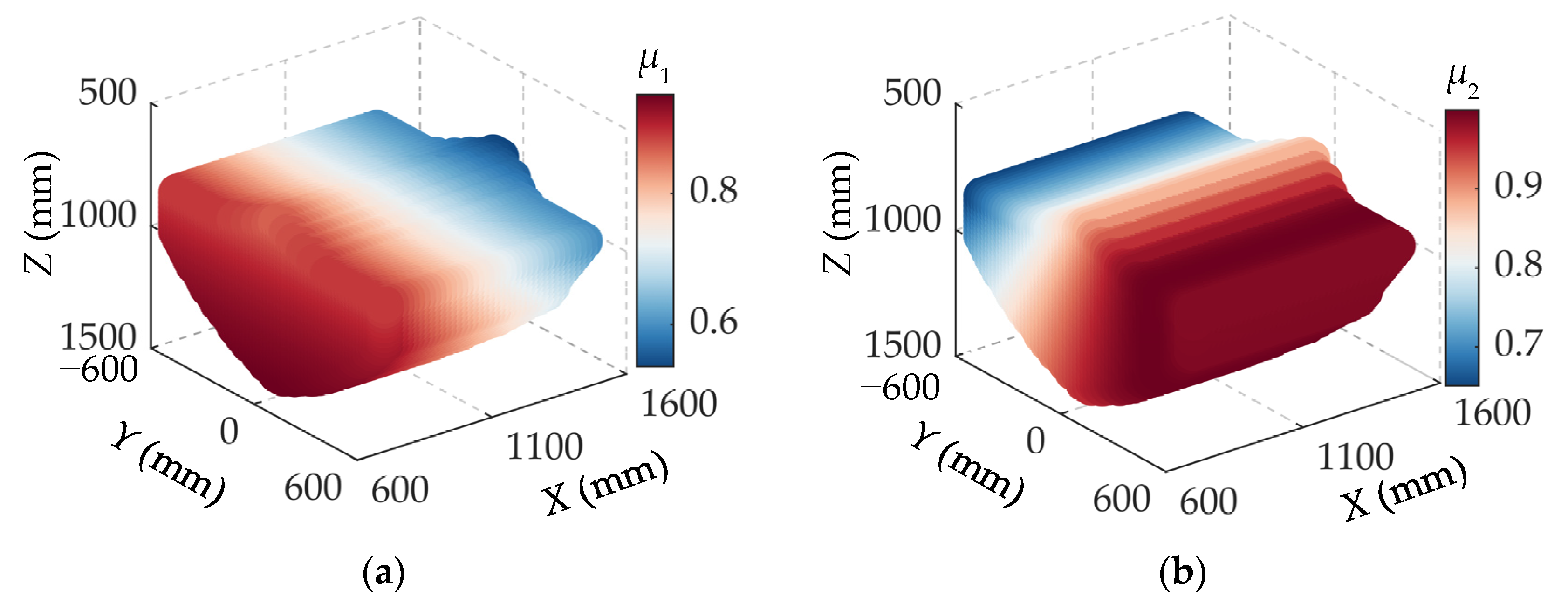

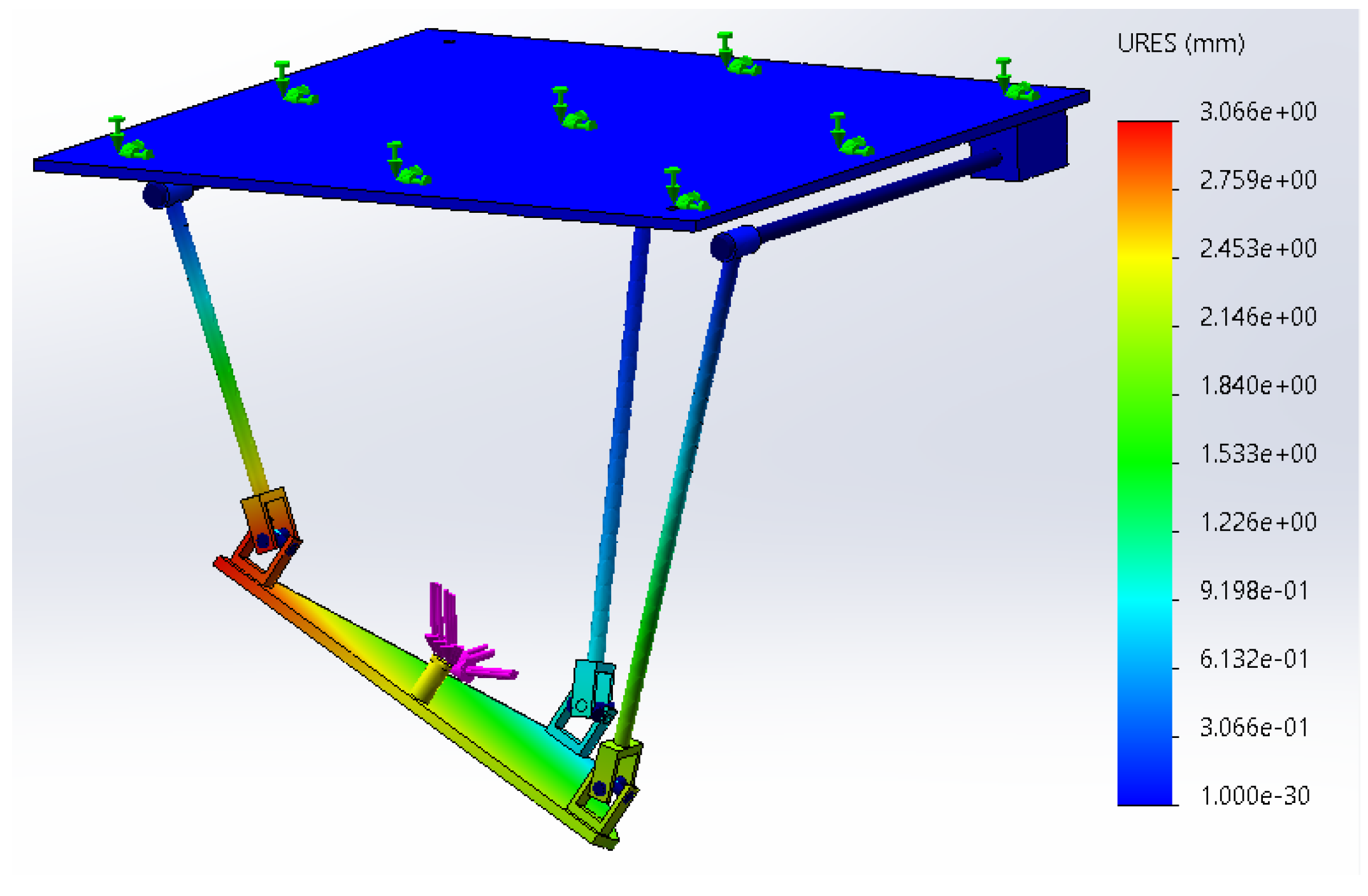

4.1. Stiffness Modeling

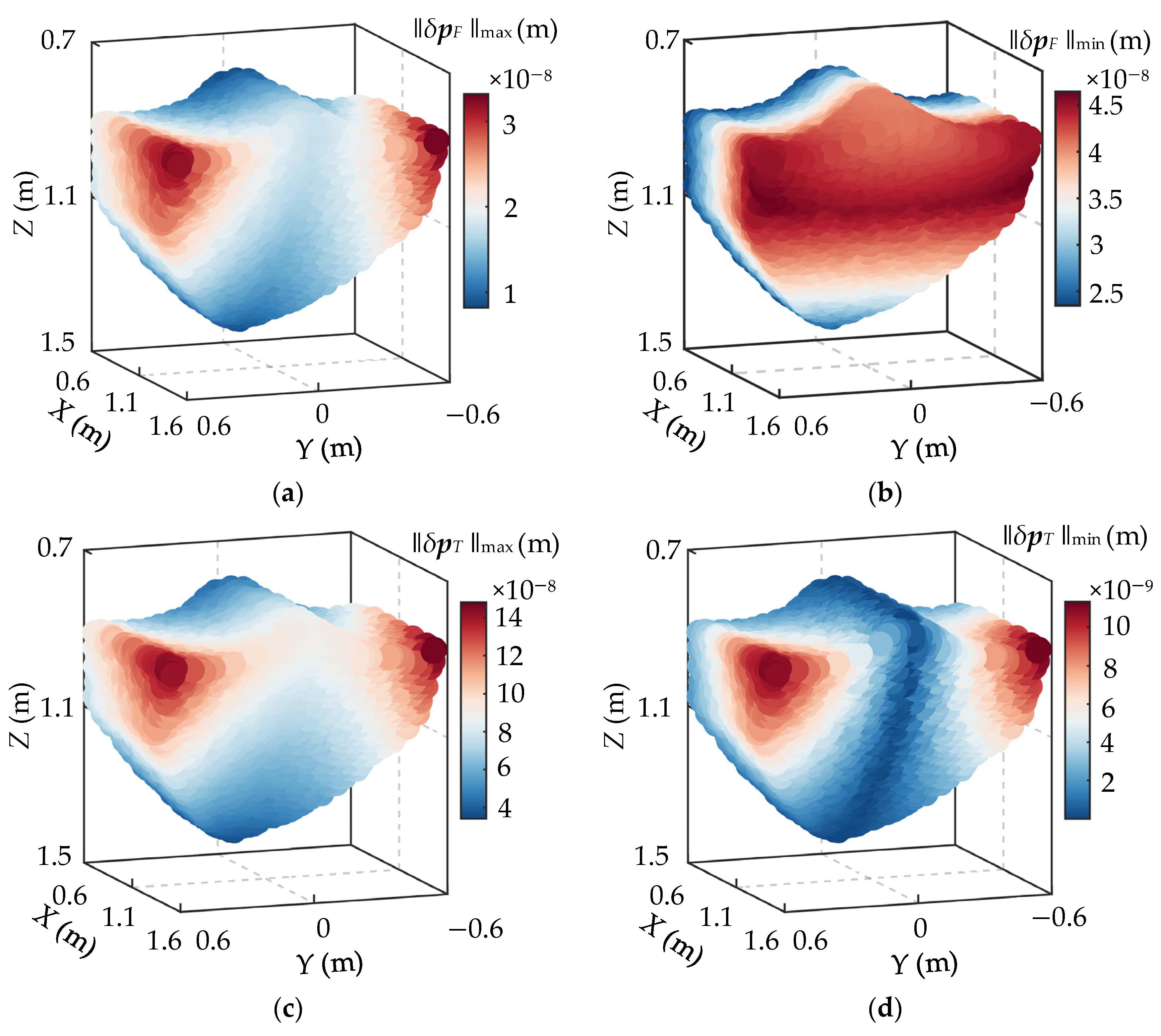

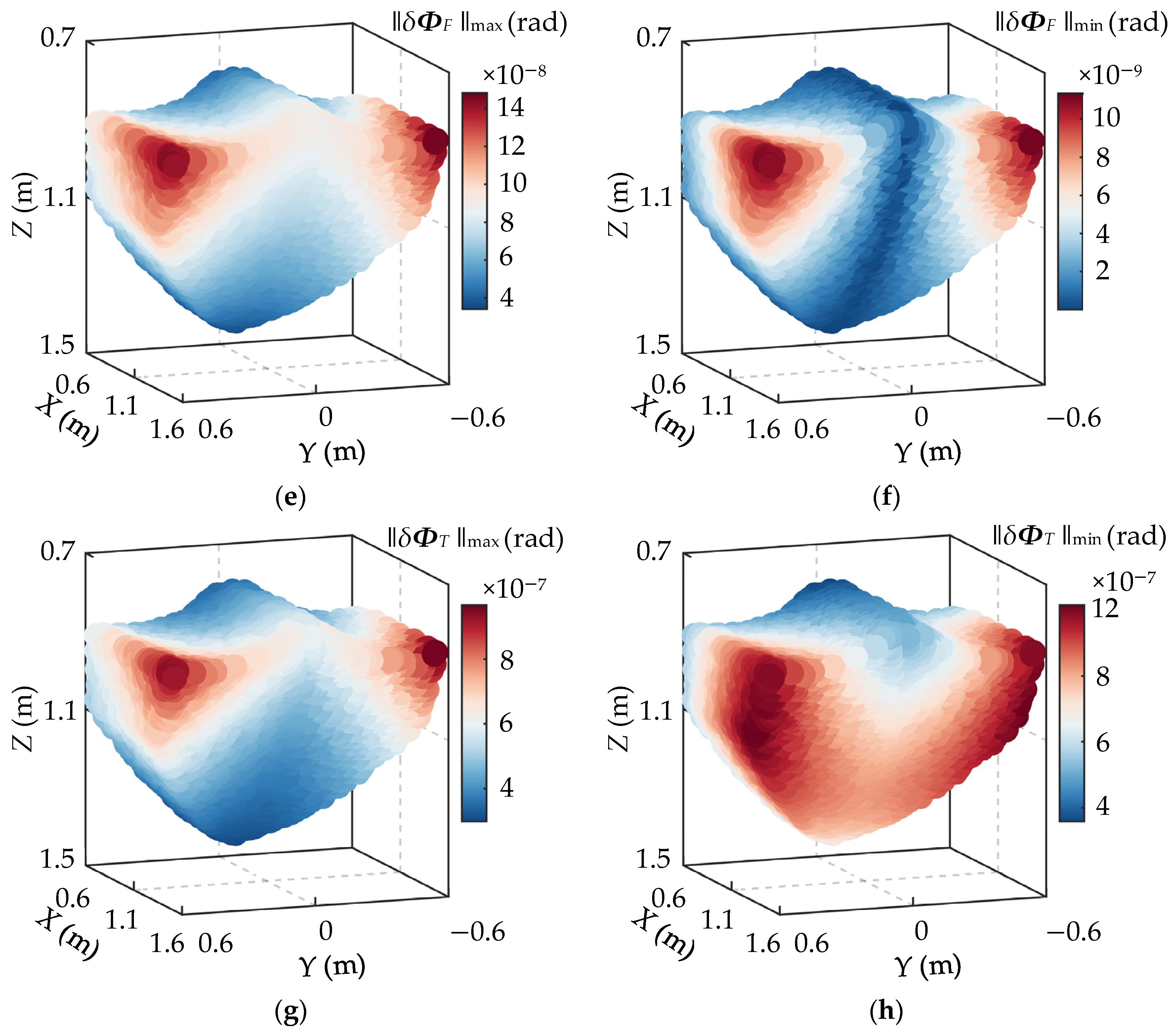

4.2. Stiffness Characteristics Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PM | parallel mechanism |

| DOF | degree of freedom |

References

- Wang, R.Y.; Niu, Z.L.; Chen, K.X.; Sun, T. Kinematic optimization design and performance simulation of novel 5-DOF parallel machining robots with spatial layout. Machines 2022, 10, 1187. [Google Scholar] [CrossRef]

- Dasgupta, B.; Mruthyunjaya, T.S. The Stewart platform manipulator: A review. Mech. Mach. Theory 2000, 35, 15–40. [Google Scholar] [CrossRef]

- Wu, J.; Wang, L.P.; Guan, L.W. A study on the effect of structure parameters on the dynamic characteristics of a PRRRP parallel manipulator. Nonlinear Dyn. 2013, 74, 227–235. [Google Scholar] [CrossRef]

- Dong, C.L.; Liu, H.T.; Huang, T.; Chetwynd, D.G. A screw theory-based semi-analytical approach for elastodynamics of the tricept robot. ASME. J. Mech. Robot. 2019, 11, 031005. [Google Scholar] [CrossRef]

- Hu, B. Kinematically identical manipulators for the Exechon parallel manipulator and their comparison study. Mech. Mach. Theory 2016, 103, 117–137. [Google Scholar] [CrossRef]

- Wang, Z.L.; Zhang, N.B.; Chai, X.X.; Li, Q.C. Kinematic/dynamic analysis and optimization of a 2-URR-RRU parallel manipulator. Nonlinear Dyn. 2017, 88, 503–519. [Google Scholar] [CrossRef]

- Ye, W.; Fang, Y.F.; Guo, S.; Qu, H.B. Type synthesis of 2R2T parallel mechanisms based on motion equivalent chain method. Proc. Inst. Mech. Eng. Part C 2014, 228, 3209–3217. [Google Scholar] [CrossRef]

- Ye, W.; He, L.Y.; Li, Q.C. A new family of symmetrical 2T2R parallel mechanisms without parasitic motion. ASME. J. Mech. Robot. 2018, 10, 011006. [Google Scholar] [CrossRef]

- Xie, F.G.; Liu, X.J.; Luo, X.; Wabner, M. Mobility, singularity, and kinematics analyses of a novel spatial parallel mechanism. ASME. J. Mech. Robot. 2016, 8, 061022. [Google Scholar] [CrossRef]

- Xie, Z.H.; Xie, F.G.; Liu, X.J.; Wang, J.S.; Mei, B. Tracking error prediction informed motion control of a parallel machine tool for high-performance machining. Int. J. Mach. Tools Manuf. 2021, 164, 103714. [Google Scholar] [CrossRef]

- Tunc, L.T.; Shaw, J. Experimental study on investigation of dynamics of hexapod robot for mobile machining. Int. J. Adv. Manuf. Technol. 2016, 84, 817–830. [Google Scholar] [CrossRef]

- Chen, K.X.; Wang, M.; Huo, X.M.; Wang, P.F.; Sun, T. Topology and dimension synchronous optimization design of 5-DoF parallel robots for in-situ machining of large-scale steel components. Mech. Mach. Theory 2023, 179, 105105. [Google Scholar] [CrossRef]

- Zhang, X.C.; Rong, Y.; Wang, H.B.; Zhang, S.J. Kinematics and Dynamics Analysis of a New 5-Degrees of Freedom Parallel Mechanism with Two Double-Driven Chains. Machines 2025, 13, 419. [Google Scholar] [CrossRef]

- Li, L.Q.; Fang, Y.F.; Guo, S.; Qu, H.B.; Wang, L. Type synthesis of a class of novel 3-DOF single-loop parallel leg mechanisms for walking robots. Mech. Mach. Theory 2020, 145, 103695. [Google Scholar] [CrossRef]

- Li, W.; Angeles, J. The design of a 3-CPS parallel robot for maximum dexterity. Mech. Mach. Theory 2018, 122, 279–291. [Google Scholar] [CrossRef]

- Wu, M.L.; Li, D.Z.; Cao, Y.R.; Wang, X.H.; Jia, L.D. Dynamic analysis and impedance control of a novel double-driven parallel mechanism. J. Intell. Robot. Syst. 2023, 108, 45. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, P.; Zhao, S.H.; Hu, B.; Han, J.D.; Sui, C.P. Kinematics and statics analysis of a novel 5-DoF parallel manipulator with two composite rotational/linear active legs. Robot. Comput. Integr. Manuf. 2014, 30, 25–33. [Google Scholar] [CrossRef]

- Rong, Y.; Zhang, X.C.; Dou, T.C.; Wang, H. Type synthesis of non-overconstrained and overconstrained two rotation and three translation (2R3T) parallel mechanisms with three branched chains. Mech. Sci. 2023, 14, 567–577. [Google Scholar] [CrossRef]

- Ye, N.J.; Hu, B. Kinematic and Stiffness Modeling of a Novel 3-DOF RPU+UPU+SPU Parallel Manipulator. IEEE Access 2021, 10, 6304–6318. [Google Scholar] [CrossRef]

- Ma, X.J.; Xu, Z.H.; Xu, Y.D.; Wang, Y.; Yao, J.T.; Zhao, Y.S. Evaluation on configuration stiffness of overconstrained 2R1T parallel mechanisms. Chin. J. Mech. Eng. 2024, 37, 62. [Google Scholar] [CrossRef]

- Ye, N.J.; Hu, B. Stiffness modeling of some 4-DOF over-constrained parallel manipulators with various constrained wrench forms. Mech. Mach. Theory 2022, 172, 104821. [Google Scholar] [CrossRef]

- Xue, Y.; Qu, H.B.; Li, X.; Guo, S. Stiffness performance analysis of a 3-PRPS kinematically redundant parallel mechanism. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 589–602. [Google Scholar] [CrossRef]

- Raoofian, A.; Taghvaeipour, A.; Kamali, A. On the stiffness analysis of robotic manipulators and calculation of stiffness indices. Mech. Mach. Theory 2018, 130, 382–402. [Google Scholar] [CrossRef]

- Li, Y.M.; Xu, Q.S. Stiffness analysis for a 3-PUU parallel kinematic machine. Mech. Mach. Theory 2008, 43, 186–200. [Google Scholar] [CrossRef]

| Material Property | Numeric Value |

|---|---|

| Elastic modulus | 211 GPa |

| Poisson’s ratio | 0.28 |

| Density | 7800 kg/m3 |

| Yield strength | 220 MPa |

| Ultimate tensile strength | 400 MPa |

| Elastic Deformation of m | δx (m) | δy (m) | δz (m) |

|---|---|---|---|

| FE model results | 0.5989 × 10−3 | 2.3500 × 10−3 | 0.1673 × 10−3 |

| Analytics results | 0.5920 × 10−3 | 2.4537 × 10−3 | 0.1568 × 10−3 |

| Error | 1.2% | 4.4% | 6.3% |

| Advantages | Disadvantages |

|---|---|

| The dual-drive configuration makes the structure compact | The theoretical analysis is complex |

| Good stiffness performance | The workspace is not entirely symmetrical |

| Good transmission performance | Complex control |

| The inertia coupling is relatively small | High manufacturing cost |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, X.; Zhang, X. Kinematics and Stiffness Analysis of a Novel 5-DOF Parallel Mechanism. Electronics 2025, 14, 3400. https://doi.org/10.3390/electronics14173400

Ren X, Zhang X. Kinematics and Stiffness Analysis of a Novel 5-DOF Parallel Mechanism. Electronics. 2025; 14(17):3400. https://doi.org/10.3390/electronics14173400

Chicago/Turabian StyleRen, Xiaoguang, and Xingchao Zhang. 2025. "Kinematics and Stiffness Analysis of a Novel 5-DOF Parallel Mechanism" Electronics 14, no. 17: 3400. https://doi.org/10.3390/electronics14173400

APA StyleRen, X., & Zhang, X. (2025). Kinematics and Stiffness Analysis of a Novel 5-DOF Parallel Mechanism. Electronics, 14(17), 3400. https://doi.org/10.3390/electronics14173400