Abstract

In an Enterprise Resource Planning (ERP) system, production planning is influenced by a variety of parameters. Previous investigations show that setting parameter values is highly relevant to a company’s target system. Parameter settings should be checked and adjusted, e.g., after a change in environmental factors, by material planners. In practice, updating the parameters is difficult due to several reasons. This paper presents a simulation-based decision support system, which helps material planners in all stages of decision-making processes. It will present the system prototype’s user interface and the results of applying the system to a case study.

1. Introduction

Production planning and scheduling is one of the most important components of an ERP system. These standardized algorithms can be adapted to the changing needs of companies by a variety of planning parameters. For example, lead time and lot sizing heuristic parameters influence the Material Requirements Planning (MRP) algorithm. The setting of the planning parameters has a key effect on the factors: lateness, capital commitment, and throughput. This has been shown with the help of simulation studies [1].

The following Section 1.1 explains when the planning parameters of an ERP system should be checked. In addition, this section describes the stages of the decision-making process, as the decision whether the parameters need to be updated follows this process. Section 1.2 explains why updating the planning parameter of an ERP system is very challenging for material planners. Section 1.3 describes existing approaches to support material planners as well as knowledge gaps, such as considering the costs of changing parameters during the decision-making process. Supporting the stage control of the decision-making process has also not been previously considered.

This paper presents a simulation-based decision support system, aiding material planners. The system can support all stages of decision processes and is called SAEPP. The acronym SAEPP stands for “Simulationsbasiertes Assistenzsystem zur Entscheidungsunterstützung bei der Pflege der Planungsparameter”. The user interface of the systems prototype as well as the results of applying the prototype to a case study from literature is presented in this paper. The research process follows the guidelines for design science, which are described in [2]. The following text mentions how the individual guidelines are implemented/followed.

1.1. Planning Parameters of an ERP System

In the context of setting planning parameters, a distinction is made between the initial setting and optimization during operations. In many companies the frequency of checking parameters is relatively low [3]. This is alarming as the parameters have a key effect on the target system of a company as previously mentioned.

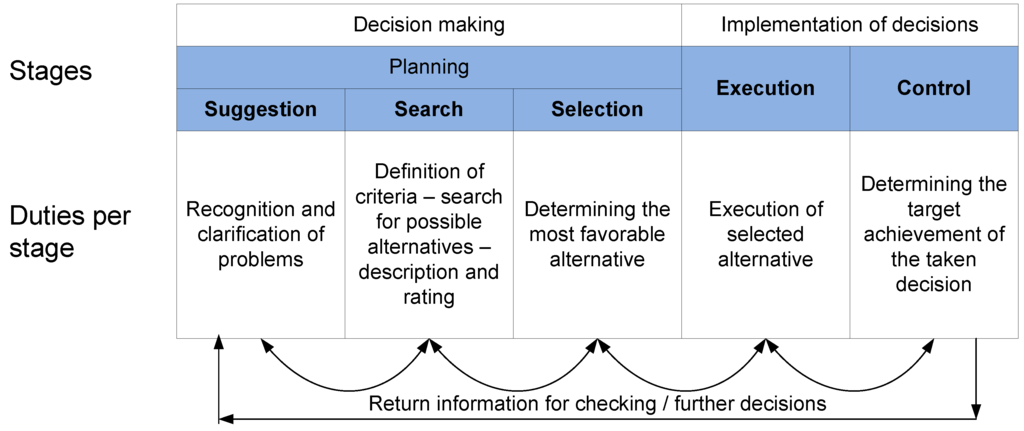

The parameters should be checked after substantial environment changes, adjustments in the production system, or at least once a year [4]. A material planner needs to decide if the parameters are still supporting the target system of an enterprise before each start of the MRP algorithm. If necessary, planners need to adjust the parameter settings. Making a decision is not a static act; it is a process that takes place over time and consists out of several stages [5]. These stages are suggestion, search, selection, execution, and control [6] (Figure 1).

Figure 1.

Stages of decision-making process (modified from [6]).

1.2. Challenges While Updating Planning Parameters of an ERP System

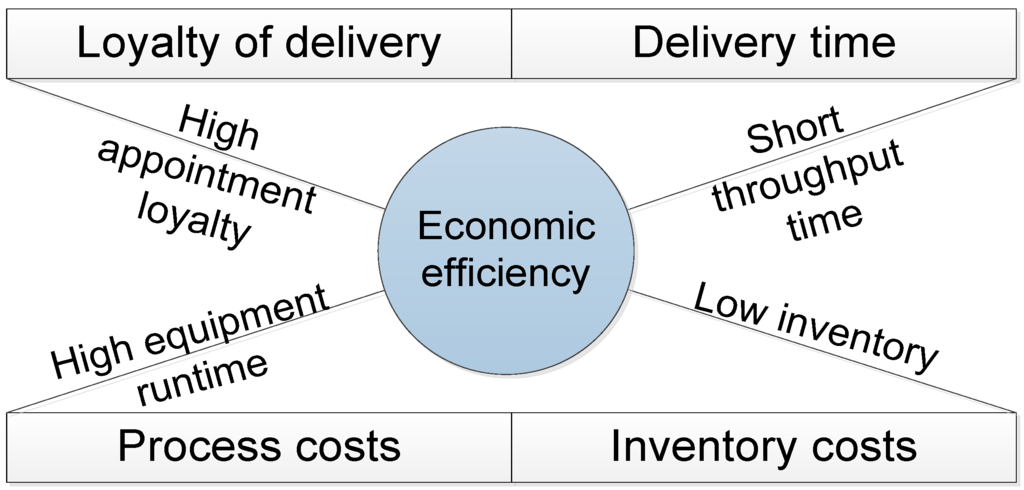

During operations it is difficult for a material planner to recognize if a substantial change of an environmental factor or a change of the production systems has occurred. If a planner determines that parameters should be adjusted, he needs to come up with an appropriate alternative. A value in the range 0–999,999 for example is possible for the parameter lead time. Furthermore, a material planner often has no or little evidence to indicate which values should be chosen for each parameter [1]. Another challenge results from the fact that a material planner is usually responsible for more than 500 products [7]. During the decision process, the future impact of each possible action must be described and rated. Once this is done, material planners must determine the action that is best in regards to the target system. Figure 2 shows the target system of Wiendahl for production planning and logistics.

Figure 2.

Target system production planning and logistic (modified from [8]).

1.3. Existing Approaches to Support Material Planners

In production planning and scheduling (PPS) systems and ERP systems no algorithms are included to support a material planner while updating the planning parameters [9]. Even the ERP system from the company SAP does not support parameter optimization. In this ERP system only rudimentary tools, such as the deposit analysis, are available [7]. Different authors in the literature already describe several algorithms and support systems.

A method that is event driven and based on knowledge has been presented in [10]. In [11] a PPS system that detects better parameter settings by using a genetic algorithm and a procalculation has been presented. A simulation environment that enables material planners to analyze the impact of parameters has been delineated in [12]. Another approach is to conceive the production planning and control as a closed loop control circuit [13]. Part of the existing literature are also manuals, which give an overview of how a project for optimizing planning parameters should be conducted.

Existing approaches do not adequately consider the costs of changing parameters during the decision-making process. In addition, the control stage of the decision-making process, which determines the target achievement of the decision taken, has not been previously considered. This paper presents a simulation-based decision support system, aiding material planners. This system can support all stages of the decision processes and is called SAEPP. It is an artifact and aims to solve an important business problem. (Section 1.1).

2. Experimental Section

Section 2.1 describes the concept of the SAEPP system, highlighting the components of the systems. Section 2.2 explains the case study. Worm gear units are produced in this example.

2.1. Concept of a Simulation-Based Support System

Finding an effective solution to a problem is a search process [2]. This is why it should be mentioned that an earlier version of the concept has been published [14].

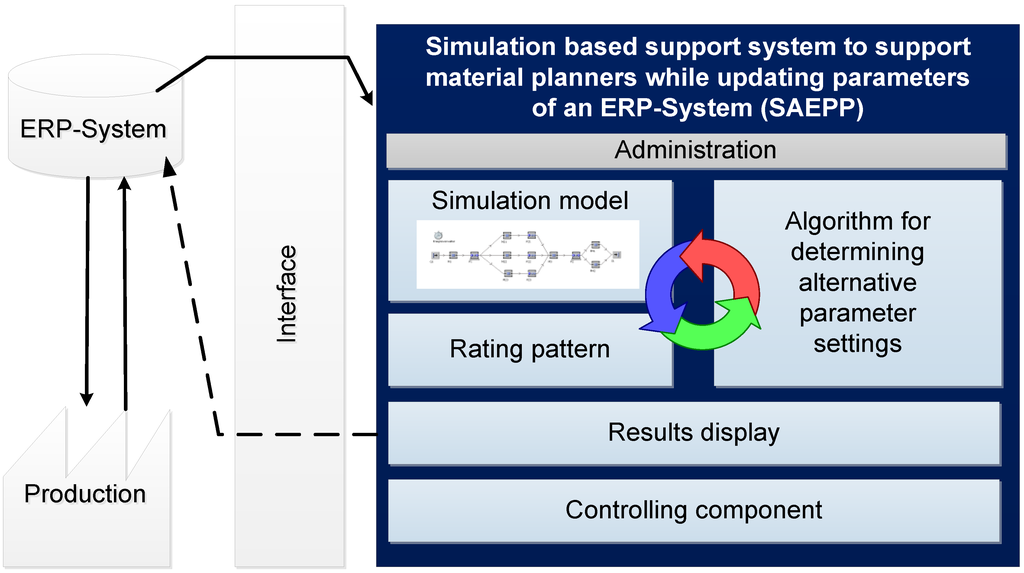

The production of an enterprise is steered through an ERP system. SAEPP will be attached to this system, as shown in Figure 3. The SAEPP system exists of the following components: administration, algorithm for determining alternative parameter settings, simulation model, rating pattern, results display, and controlling component. The main functions are described below. In addition, we also discuss which existing method (knowledge) is used in each component.

Figure 3.

Overview of the main elements of the SAEPP system.

A plausible simulation model needs to be available by the respective enterprise to integrate into the SAEPP system. Within the scope of the suggestion stage of the decision-making process, the simulation model takes into consideration the current business situation. Afterwards, a trial run, using the current parameter settings, is performed. This determines the future effects on each dimension of the target system.

Subsequently, the effects of the default alternative are rated in the so-called rating pattern. For the target dimensions, equipment runtime, and inventory, it is possible to value the monetary effects, assuming if suitable cost rates are given. Nevertheless, changing of the appointment loyalty in shortfall costs is very difficult [11]. Furthermore, the monetary assessment of throughput time is laborios. This is why the cost-effectiveness analysis is used within the scope of the rating pattern. With this method the utility-value analysis is applied only to criteria that are not quantifiable in monetary units. Criteria that can be valued monetarily come consistently into the assessment of this analysis. Cost and economic efficiency figures are, by division, put into relation by which the cost-effectiveness analysis indicator of the alternative arises [15].

Alternative parameter settings are generated in the stage search of the decision-making process, based on the actual parameter setting and provided by the so-called algorithm for determining alternative parameter settings of the SAEPP system. The algorithm consists of two parts. In the rule-based Part 1, a starting solution is generated for a parameter. In Part 2, the parameter setting proposal is further improved by using the heuristic simulated annealing. This approach was already introduced in [14]. Once an alternative setting combination is generated by the algorithm the future effects are determined with the help of simulation, again.

After carrying out the simulation run for each alternative, cost and economic efficiency figures, as well as the cost-effectiveness analysis indicator are determined within the rating pattern. The number of replications and the approach of calculating the individual number for each target during simulation are defined by the respective enterprise. To be able to carry out the utility-value analysis a scale is necessary for the assessment of each alternative. Within the scope of the SAEPP system the best alternative, up to now, for a non-monetary valuable target gets 10 points and the worst solution 1 point. For solutions in between the best and worst solution a proportionate point value is determined. Within the rating pattern it is also possible to consider unique costs, to avoid planning nervousness. Penal costs should, e.g., depend on the amount of time since the last change of the parameters.

The search stage of the decision-making process finishes once a termination condition of the algorithm for determining alternative parameter settings is fulfilled. The subsequent stage selection determines the alternative with the smallest cost-effectiveness analysis indicator. If the default alternative has the smallest indicator, there is no need for care of planning parameters at the current time. Otherwise, there is room for improvement and need for action is given. This is indicated by a traffic graphic display in the results display of the SAEPP system (Section 3.2).

Based on the information shown in the results display a material planner decides whether to transfer the suggested alternative to the ERP system. This is done in the execution stage by using the interface shown in Figure 3. For an assistance system, it is characteristic that a confirmation by a user is necessary, before a suggested alternative is automatically carried out [16].

The simulation-based assistance system SAEPP starts a defined period of time before each execution of the planning procedures in the ERP system.

After starting the target achievement, the decision made at the last execution is checked immediately. This is done by a target-actual comparison based on the validation method of predictions. The results are indicated in the so-called controlling component (Section 3.3).

We developed a prototype of the simulation-based assistance system SAEPP within the scope of this research project. This prototype builds up on the workshop simulation model of “Innovationszentrum für Produktionslogistik und Fabrikplanung” (IPF), of “Ostbayerische Technische Hochschule” (OTH) Regensburg. This model was realized with Plant Simulation by Siemens PLM software. However, the realization of administration, results display, and controlling component were not done in the workshop simulation model. It would have been too difficult and time-consuming in Plant Simulation to create an attractive user interface. In the prototype of the SAEPP system Microsoft Excel is used for administration, results display, and the controlling component. The binding of an Excel file to the workshop simulation model of the IPF is practical, because Plant Simulation supports Dynamic Data Exchange (DDE), which allows access to one program from another program [17].

2.2. Description of the Case Study

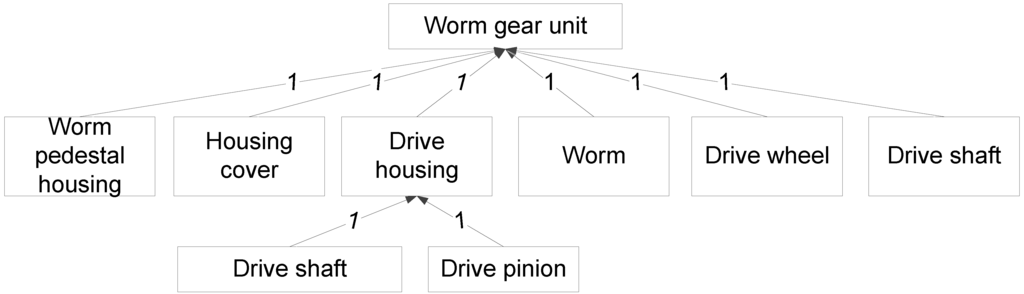

The case study used in this article is based on documentation [18], which again received data from the company G.U.N.T. Gerätebau GmbH, (Hamburg, Germany). In this example worm gear units are produced. Worm gear units are used, e.g., in traction drives of cranes, in wiper drives of automobiles, or in escalators. A worm gear unit encloses materials as shown in Figure 4. Only material produced in-house is considered in this example and in the SAEPP system.

Figure 4.

Part list (modified from [18]).

The manufacturing described in [18] is designed for a production of 33,000 to 35,000 worm gear units per year. In the initial situation customer orders are below the manufacturing capacity. At time t1 the increase in incoming customer orders is significant. This represents a change of environmental factors which should lead to the adjustment of the current parameter settings (Section 1.1). The SAEPP system supports the material planner by the decision if and how the parameters needs to be adapted at this moment of time.

3. Results and Discussion

The SAEPP system was applied to the case study worm gear units. Before we describe the results, we display the settings made in the administration. This is necessary to reconstruct the results and to check if the prototype is working correctly. Section 3.2 shows the result display of the SAEPP system and Section 3.3 details the controlling component. We present the user interface for the first time.

3.1. Administration

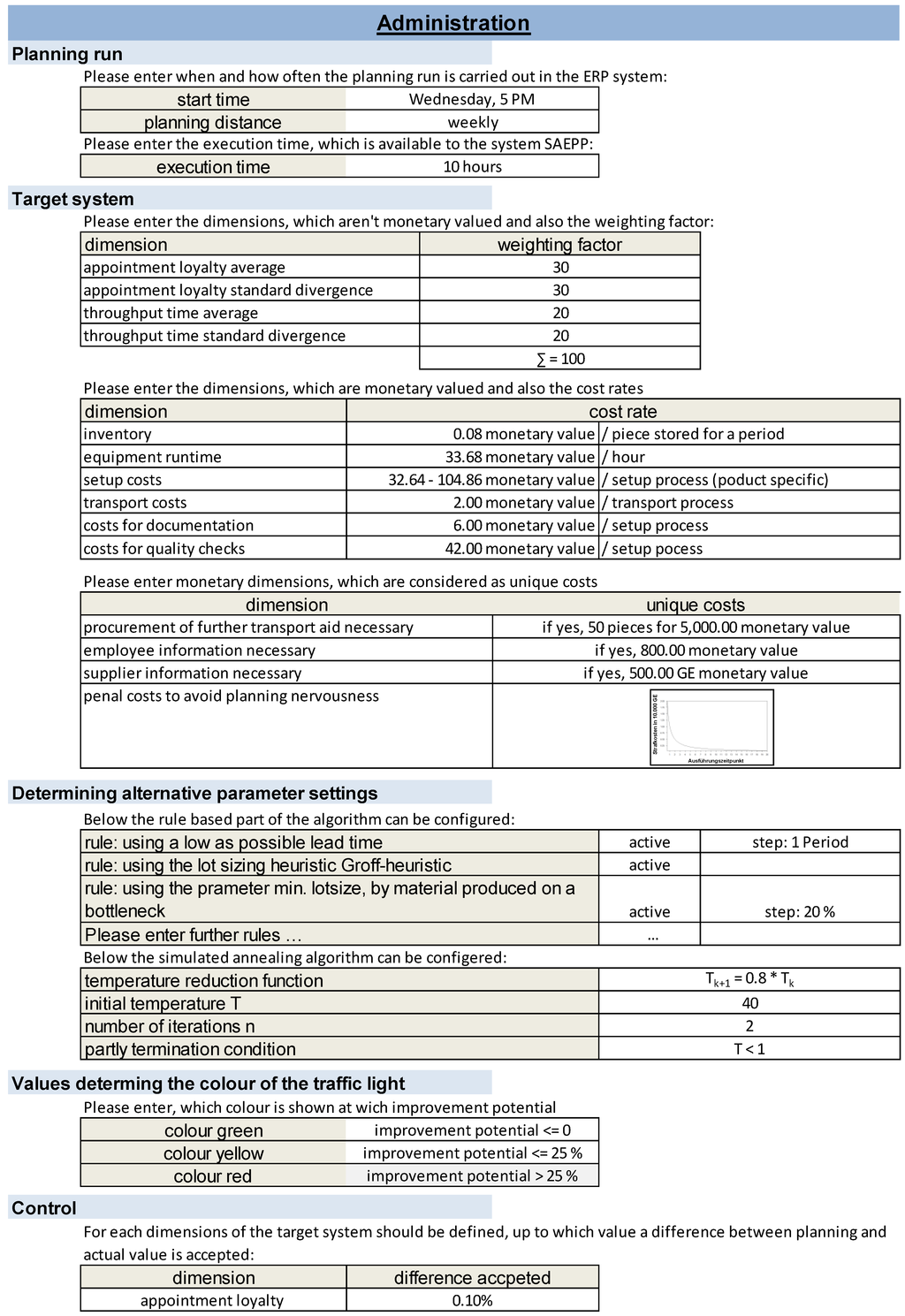

Before the first execution of the system SAEPP, different information needs to be deposited or checked in the administration (Figure 5).

Information about the time of the planning run of the ERP system in the respective enterprise shall be deposited in the segment planning run of the administration. In addition, which execution time is available to the SAEPP system must be defined.

In administration the target system of a company must be entered in the section target system before the first implementation of the system SAEPP. In doing so, a user has to differentiate between monetary dimensions and those not monetarily valued. The effects on the delay dimensions and throughput time are not monetarily valued, because of this problematic change (Section 2.1). For these dimensions the average and standard divergence is determined, as shown in Figure 5. In this case study it is supposed that a high appointment loyalty is more important to an enterprise than a low throughput time. This is considered in the utility-value analysis by different weighting factors.

Figure 5.

Administration of the SAEPP system.

In the rating pattern of SAEPP system the rating of monetary dimensions, e.g., inventory, equipment runtime, and setup costs are also taken into account (Section 2.1). The product-flow information obtained by the simulation is coupled with the deposited cost rates. This method is called post-stored cost-simulation analysis [19]. The cost rates shown in Figure 5 were taken from the documentation [18]. If no cost rates are available, appropriate assumptions have been made. It should be noted that these rates can be determined with the help of the equipment runtime calculation or activity-based costing. To avoid planning nervousness, penal costs can also be deposited in the administration (Section 2.1). In addition, in the case study it was defined, for example, that a significantly increased number of transport processes results in costs for the procurement of other transport aid. These unique costs are also considered in the cost-effectiveness analysis.

The initial configuration of the algorithm for determining alternative parameter settings should also be checked before the first start of the SAEPP system. In addition to that, the values until the traffic graphic display shows green, yellow, and red should also be checked. The traffic lights indicate if a need for updating the planning parameters is given (Section 2.1). In this case study, a red traffic light is indicated if an improvement potential of >25% is measured (Figure 5).

In the segment control of the administration a limited value can be defined for every dimension of the target system up to which a difference between a planning and actual value is accepted. Once a difference is larger, the simulation model is not credible. The result of the comparison is displayed in the controlling component by a traffic graphic display (Section 3.3). In the case study a credible simulation model is given when the actual value of the delay ranges between ±0.10% of the predicted value (Figure 5).

3.2. Results Display

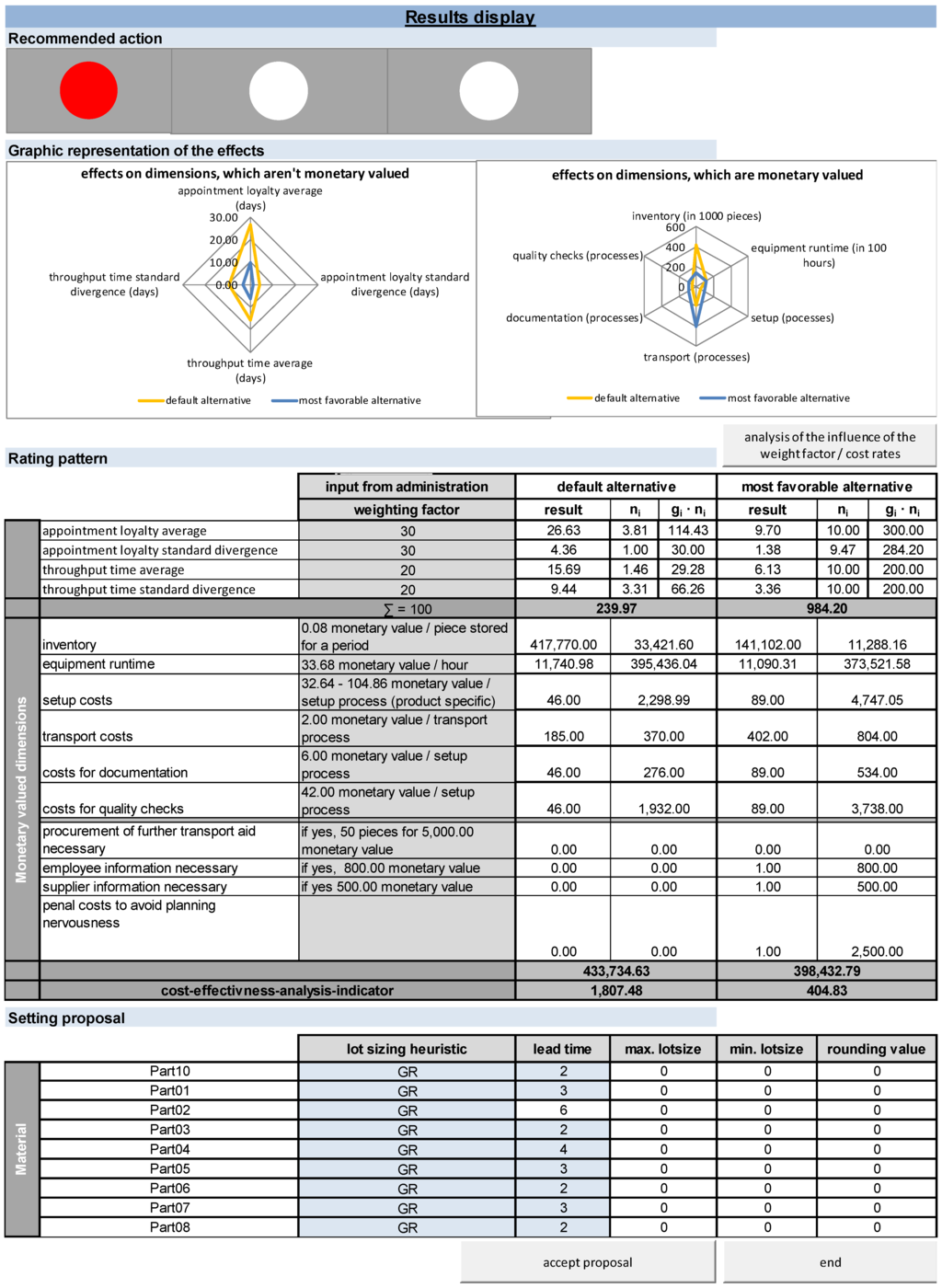

Once the stage suggestion and search have been carried out, as well as determining the most favorable alternative, the information obtained thus far will be presented in the results display of the SAEPP system. Figure 6 shows the results displayed to a material planner at time t1.

When the parameters are not adapted, the increase of customer orders at time t1 will lead in the prediction period to 26.63 days delay in average and a standard divergence of 4.36 days. In this example 107 alternatives were generated by the algorithm for determining alternative parameter settings. The most favorable alternative leads in the prediction period to 9.70 days delay, on average, with a standard divergence of 1.38 days (Figure 6).

The rating pattern as well as a graphic net diagram is visible in the results display of the SAEPP system (Figure 6). These elements show the amounts that have arisen in the prediction period for each dimension of the target system. The most favorable and the initial alternatives, in regard to the equipment runtime, are nearly equal. However, the inventory is significantly smaller in the prediction period when the most favorable alternative is used. This leads to much lower inventory costs and is due to the fact that, with this alternative, smaller lots are formed.

Since the most favorable alternative has a better utility and lower costs in the prediction period than the initial parameter settings, a smaller value arises for the cost-effectiveness analysis indicator. An indicator value of 404.83 arises for the most favorable alternative. This value is clearly lower than the initial alternative, which has a value of 1807.48. In this example the improvement potential amounts to 77.06% (Figure 6). A red traffic light is shown once the improvement potential is >25% (Figure 5). At time t1 a need for updating the planning parameter is given, which is indicated by the red light (Figure 6).

The setting proposal belonging to the most favorable alternative is also visualized in the results display of the SAEPP system. Compared with the initial alternative the setting of the lot sizing heuristic was changed. The use of the Groff heuristic is recommended for all products in the case study. Additionally, the setting of the lead time should be reduced of all products, with the exception of the product housing cover (Figure 6).

Figure 6.

Results display of the SAEPP system.

3.3. Controlling Component

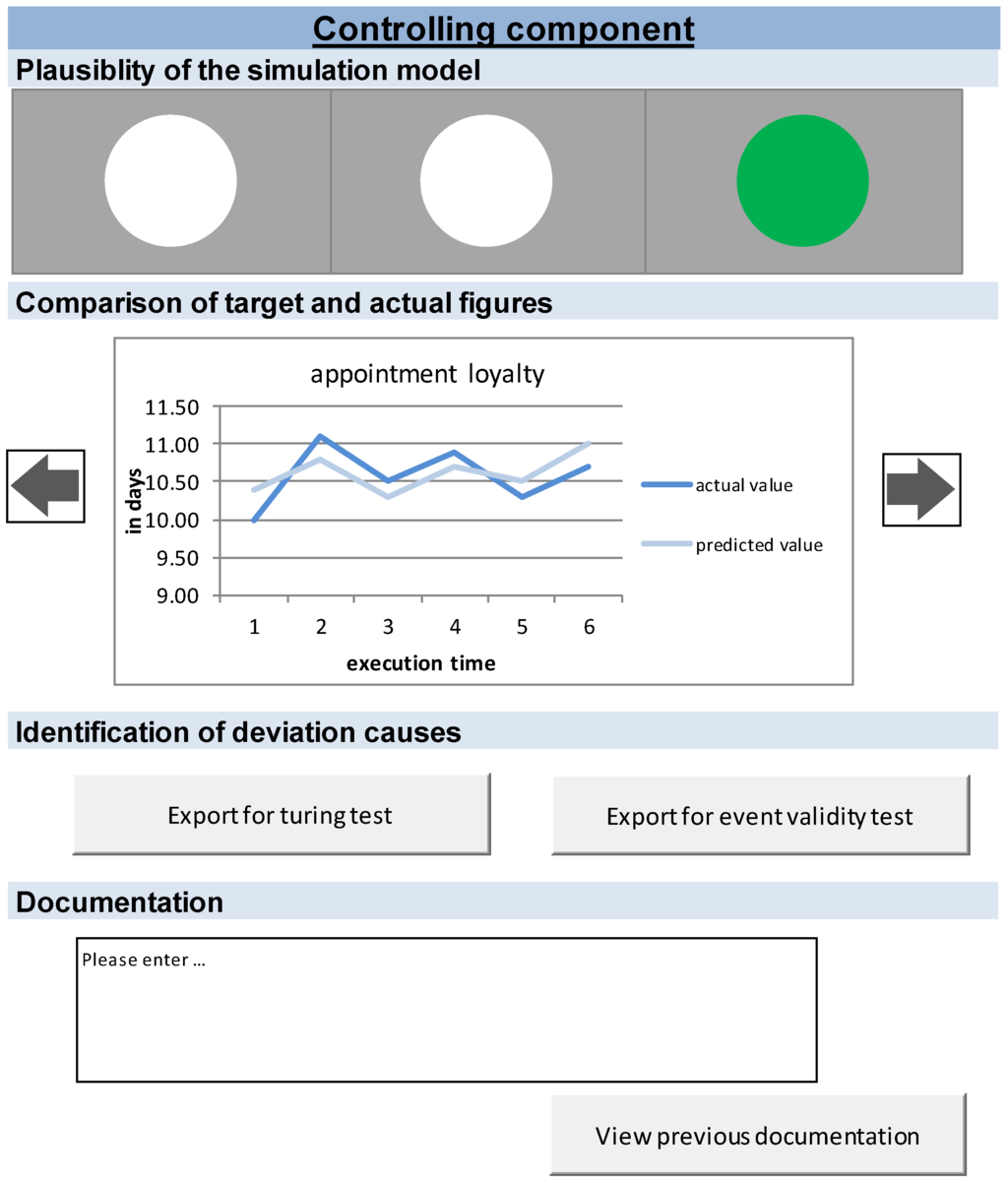

After starting the SAEPP system the material planner immediately sees the controlling component (Section 2.1). This displays how well the last provided prediction matches with the actual values. The following illustration (Figure 7) shows the controlling component of the system SAEPP.

Figure 7.

Controlling component of the SAEPP system.

When the limit values are crossed for several dimensions of the target system, the controlling component shows a red traffic light. The administration of the SAEPP system collects the limit values (Section 3.1). In case of a red light, the further execution of the SAEPP system stops and waits for a user action. In this case study, the limit values are kept as indicated by the green light (Figure 7). It should be noted that the illustrated values are assumptions. As the case study was taken from the literature, no actual values of the production exist.

With the help of the line diagram of the controlling component the courses of the single dimensions can be considered and analyzed by the user. If divergences or abnormalities are ascertained, the deviation causes must be identified. The turing test, as well as the event validity test, can test for such divergences by exporting necessary data from the SAEPP system (Figure 7).

Deviation causes, as well as the initiated measures, should be documented as part of the stage control of the decision-making process, in the illustrated text fields (Figure 7). Documentation provided at previous times can also be checked. This is useful for proofing measure effectiveness.

4. Conclusions

The prototype described in this article shows that it is possible to illustrate the concept of the SAEPP system in software. While developing the methods dimensional consistency test, desk checking, and submodel testing have been used to validate and verify the artifact. Additionally, the program flow was documented using the Unified Modeling Language (UML); these diagrams can be obtained from the author. This article also shows that the prototype is executable and delivers comprehensible results. This is one method that evaluates the utility and quality of the artifact. It will be further verified e.g., by performing another case study. One of the next research steps will be to use the SAEPP system in a live context and to update the planning parameter of an ERP system of a company in real-time. We plan further publications to communicate these research results.

For the first time the user interface of the system SAEPP is presented in this article. At this point of time no user feedback is available. The long-term goal is that all material planners can utilize the simulation-based support system SAEPP to support updating planning parameters. This research contributes to the support of material planners in all stages of the decision-making process. The advantages for a material planner when using SAEPP is that they do not need to recognize if a substantial change of an environmental factor or a change of the production systems had occurred. Furthermore, they do not need to specify an appropriate alternative. The SAEPP system shows a material planner, before every execution of the MRP algorithm, if, in regards to the target system, the parameters need updating. This alleviates many challenges facing a material planner, as outlined in Section 1.2. Based on the high economic relevance of the parameters of an ERP system the use of a support system, such as SAEPP, is effective.

Acknowledgments

Ulrike Stumvoll received the scholarship “Förderung der Chancengleichheit von Frauen in Forschung und Lehre” of “Landeskonferenz der Frauenbeauftragten der Bayerischen Fachhochschulen” between 2011 and 2013.

Author Contributions

The concept of the simulation-based assistance system SAEPP has been developed from Ulrike Stumvoll and Thorsten Claus. Ulrike Stumvoll conceived, performed and analyzed the experiments. Ulrike Stumvoll wrote the paper, with hints of Thorsten Claus.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dittrich, J.; Mertens, P.; Hau, M.; Hufgard, A. Dispositionsparameter in der Produktionsplanung Mit SAP; Vieweg + Teubner: Wiesbaden, Germany, 2009. [Google Scholar]

- Hevner, A.R.; March, S.T.; Park, J.; Ram, S. Design Science in Information Systems Research. MIS Q. 2004, 28, 75–105. [Google Scholar]

- Jonsson, P.; Mattsson, S.-A. A longitudinal study of material planning applications in manufacturing companies. Int. J. Op. Prod. Manag. 2006, 26, 971–995. [Google Scholar] [CrossRef]

- Jodlbauer, H. Produktionsoptimierung; Springer: Wien, Austria, 2008. [Google Scholar]

- Schiemenz, B.; Schönert, O. Entscheidung und Produktion; Oldenbourg: München/Wien, Austria, 2005. [Google Scholar]

- Heinen, E. Einführung in Die Betriebswirtschaftslehre; Gabler: Wiesbaden, Germany, 1985. [Google Scholar]

- Gulyássy, F.; Hoppe, M.; Isermann, M.; Köhler, O. Disposition mit SAP; Galileo Press: Boston, MA, USA, 2009. [Google Scholar]

- Wiendahl, H.-P. Betriebsorganisation Für Ingenieure; Hanser: München/Wien, Germany, 2008. [Google Scholar]

- Kemmner, G.-A.; Capellmann, A. Disposition im Zeitalter von Industrie 4.0. ZWF-Zeitschrift Für Wirtschaftlichen Fabrikbetrieb 2014, 109, 973–975. (In German) [Google Scholar]

- Hartinger, M. Die Pflege Der Parameter Von Standard Software; Dt. Univ.-Verl.: Wiesbaden, Germany, 1995. [Google Scholar]

- Kernler, H. Programme werden selbstständig. Logist. Heute 1994, 10, 101–102. (In German) [Google Scholar]

- Dittrich, J. Simulationsgestützte Analyse und Konfiguration von PPS-Stellgrößen am Beispiel ausgewählter Dispositionsparameter des Systems SAP R/3-PP; Dissertation: Nürnberg, Germany, 1997. [Google Scholar]

- Wiendahl, H.-P. Simulationsmodelle in der Produktionsplanung und -steuerung. ZWF-Zeitschrift für Wirtschaftlichen Fabrikbetrieb 1990, 85, 137–141. (In German) [Google Scholar]

- Stumvoll, U.; Nehls, U.; Claus, T. Ein Simulationsbasiertes Assistenzsystem zur Pflege von Dispositionsparametern Eines ERP-Systems im Laufenden Betrieb. In Simulation in Produktion und Logistik; Heinz-Nixdorf-Inst. Univ. Paderborn: Paderborn, Germany, 2013; pp. 569–578. [Google Scholar]

- Schulte-Zurhausen, M. Organisation; Vahlen: München, Germany, 2014. [Google Scholar]

- Hauß, Y.; Timpe, K.-P. Automatisierung und Unterstützung im Mensch-Maschine-System. In Mensch-Maschine-Systemtechnik; Symposion: Düsseldorf, Germany, 2002; pp. 41–62. [Google Scholar]

- Bangsow, S. Fertigungssimulationen mit Plant Simulation und SimTalk; Hanser: München, Germany, 2008. [Google Scholar]

- Prêt, U. Teilefertigungs- und Montageprojekt Schneckengetriebeproduktion. Available online: www.uwe-pret.de/fabrikplanung/skripte/stapel3/getriebe.pdf (accessed on 7 March 2015).

- VDI Norm 3633 Blatt 7. Simulation von Logistik-, Materialfluss und Produktionssystemen, Kostensimulation, Verein Deutscher Ingenieure: Düsseldorf, Germany, 2001.

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).