Abstract

Cashmere is widely acclaimed as one of the most luxurious textile fibers. Mongolia, a major player in cashmere production and processing, is key to this industry. Despite the rich history of cashmere, there is limited research on cashmere fiber properties, which are essential in producing high-quality garments. This study aims to improve our understanding of cashmere fibers’ physical and mechanical properties and to assess how genetic and non-genetic factors affect these characteristics. We analyzed key fiber characteristics, including scale morphology, and the physical and mechanical properties (such as fineness, length parameters, stress, and strain) in 11 samples from Mongolian goats of varying areas, breeds, ages, and genders. Through detailed statistical analysis, our experimental results revealed that both genetic and non-genetic factors significantly affect fiber fineness and the specific energy of rupture. Additionally, we observed that the influence of these factors can inform better classification systems for raw cashmere and enhance the determination of the fiber’s spinability limit.

1. Introduction

Cashmere is one of the most expensive and rare fibers, largely for its limited supply and the complex, costly technological processes required for its production. Cashmere accounts for about 0.5% of the world’s total fiber production. Despite the availability of synthetic fibers with similar or superior tactile and mechanical properties, global demand for cashmere continues to rise. This enduring popularity is due to cashmere’s exceptional qualities: lightness, softness, fineness, warmth, comfort, and luster [1,2,3]. These attributes ensure that cashmere remains highly sought after, despite its higher cost. Currently, global cashmere production is around 8000–9000 tons per year, with expectations of increasing production to meet rising demand.

Cashmere is a fine down fiber from the double-coated fleece of domestic goats, native to the mountainous regions of Central Asia (Figure 1). These goats, particularly native Mongolian breeds, are known for their ability to thrive in harsh continental climates, producing some of the highest quality cashmere in the world. Their fleece consists of a soft undercoat, which is highly valued for its fineness and warmth. Figure 1 shows typical Mongolian cashmere goats raised by local herders in traditional, pastoral systems, crucial for sustainable cashmere production. Mongolia produces about 20% of the global total of approximately 20,000 tons annually, while China accounts for about 70%, and the remaining 10% is produced by countries such as Iran, Pakistan, Afghanistan, Australia, Scotland, and Russia [4]. In Mongolia, the production and export of cashmere are vital to the livelihoods of herders, underpinning the rural textile industry and contributing significantly to the national economy.

Figure 1.

Cashmere goat.

The Mongolian goat, categorized as an Asian down or fleecy type, is exceptionally suited to the region’s traditional breeding methods, vast pasture lands, and harsh continental climate. Renowned for its superior fiber quality, native Mongolian goats constitute roughly 90% of the goat population [5,6]. Additionally, herders raise crossbred varieties such as “Mountain Brown” and “Gobi Gurvan Saikhan”, alongside distinct strains including “Shine Jinst”, “Buural”, “Bayandelger”, “Ulgin Ulaan”, and “Erchim”. Due to the unique breeding environment, these goats produce cashmere of high quality, which makes Mongolian cashmere highly competitive on the international market. Understanding the population dynamics, biological characteristics, and productivity metrics of these goats is essential for genetic enhancement efforts aimed at improving cashmere fiber quality. Enhanced cashmere quality increases the appeal and competitiveness of Mongolian cashmere products in the global market [7].

Despite the significance of Mongolian cashmere in the economic and industrial sectors, particularly due to its mechanical properties, these aspects have not been extensively studied. Furthermore, while previous studies have examined some zoological properties of cashmere, such as fineness and length, the mechanical properties that affect technological processes like spinning are less explored. Evaluating these properties is especially important as they significantly affect the fiber’s behavior in subsequent manufacturing steps, particularly in spinning.

Previous studies have provided some insights into the fiber properties of Mongolian goats. For instance, it has been noted that the fiber fineness of Asian cashmere fibers ranges from 14 to 16 microns, with those from Iran and Afghanistan being 1–3 microns coarser [6]. It has also been observed that the coefficient of variation (CV) of the diameter of well-dehaired cashmere is approximately 20% [8]. Experiments have shown that the length of cashmere fibers from different countries varies from 25 to 90 mm. Chinese standards indicate that the average length of haired cashmere varies between 24 and 36 mm depending on grade and color. Measurements of the length after carding (LAC), CV, and bundle tenacity of cashmere samples from various origins show that the LAC of two Mongolian samples was 20.2 and 26.9 mm, with a CV of 71%. Chinese samples have lengths of 14.6–29 mm, with CVs of 52.1–74%. Iranian and Afghan samples are generally longer. The “hauteur” of Mongolian cashmere tops range from 39.5 to 44.9 mm, with CVs from 36.8 to 51.6% [9].

However, while these studies provide useful zoological data, they fall short in offering a comprehensive technological perspective on fiber properties. The mean fiber diameter and length alone are insufficient for optimizing technological processes. Moreover, these studies lack detailed statistical assessments regarding the significance of variations in goat strain, breed, gender, age, and body part on these properties. Therefore, it is important to characterize Mongolian cashmere fibers from a technological perspective and to assess the influence of these factors using statistical methods.

In addition, the growing consumer demand for sustainable and ethically sourced materials has placed further pressure on cashmere producers to maintain high standards. Improving the mechanical properties of raw cashmere could help reduce waste during production and enhance the efficiency of textile manufacturing, aligning the industry with global sustainability trends [7,10].

This study aimed to address these gaps by providing a comprehensive analysis of the mechanical properties of Mongolian cashmere fibers. We examined the effects of various factors such as goat strain, breed, gender, age, and body part on fiber characteristics. Through statistical methods, we evaluated the significance of these variables and their impact on the technological processes involved in cashmere production. This study also explored how this deeper understanding can contribute to more efficient spinning techniques and overall product quality, ensuring that Mongolian cashmere remains a competitive and sustainable luxury fiber.

2. Materials and Methods

2.1. Sampling and Scouring of Samples

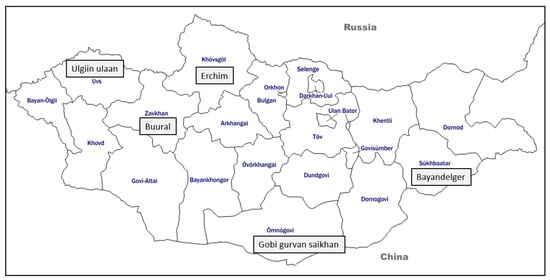

For this study, we selected four goat strains, “Buural”, “Bayandelger”, “Ulgiin Ulaan”, and “Erchim”, along with one crossbred variety, “Gobi Gurvan Saikhan”, based on climate, regional characteristics, the representativeness of the goat population, population density, and fiber quality (Figure 2).

Figure 2.

Breeding areas of selected goats.

In total, eleven cashmere samples were combed from female and male goats of different ages, breeds, and strains. Sample coding facilitated sample identification, as detailed in Table 1.

Table 1.

Coding of samples.

As no standard laboratory scouring process exists for raw cashmere, we conducted preliminary tests and established an optimal scouring method using Soxhlet solvent extraction to preserve fiber quality. Wax was removed through four successive extractions, followed by a 15 min rinse in water at 30 °C [11,12]. Drying was conducted at 85 °C until the sample weight stabilized; approximately 1 h was required to dry 3 g of sample at this temperature.

Tensile properties were assessed using an MTS M20 dynamometer (MTS Systems Corporation, Eden Prairie, MN, USA) in accordance with ISO 5079 [13]. An analysis of variance indicated no significant difference rupture energy distributions between scoured and raw samples, confirming that our scouring method preserved mechanical properties. Vegetative matter, animal dandruff, and coarse hairs were manually removed with care. Dehaired samples were conditioned for over 48 h at 20 ± 2 °C and 65 ± 2% relative humidity.

2.2. Methods

Fiber fineness was measured using a projection microscope following NF ISO 137 [14] guidelines. The number of measurements was determined, with the margin of error reduced to 1.1% based on nearly 1000 snippets. Diameter measurements of fibers finer than 30 microns were used to calculate the mean fiber diameter, standard deviation, and coefficient of variation (CV) across all samples.

Fiber length was determined using an Almeter Peyer texLab AL 100 (Siegfried Peyer AG, Zofingen, Switzerland) [15]. Each sample weighed between 100 and 150 g for each measurement. Three manual pulls were conducted on a black table, followed by a transfer to the preparatory machine “Peyer texLab FL 100” for initial fiber sheet preparation (Figure 3). This sheet was placed back on the carriage using manual clamps, ensuring that the tail of each sample was drawn first, effectively straightening the fibers.

Figure 3.

The Almeter Peyer texLab AL 100 device.

The resulting measurements yield essential characteristics related to fiber length and were expressed in two distinct forms: Hauteur (H), representing the mean length adjusted for the fiber cross-section (linear density), and Barbe (B), representing the mean length adjusted for the fiber weight.

The determination of Hauteur and Barbe values was carried out, respectively, according to Equations (1) and (2):

where, mi is the mass of the fiber bundles per class (mg); li, the length corresponding to the class center of fiber bundles (mm); and ti, the mass per unit length (tex).

Each sample underwent 4–6 measurements to calculate the mean (H) and (B) values along with their respective CVs.

The tensile properties of single fibers were measured using the MTS M20 dynamometer according to NF EN ISO 5079 [16]. Approximately fifty fibers were tested, with a gauge length of 10 mm set for sample 5b.1 due to its shorter length. The testing used a constant extension rate of 100% per minute. Tensile stress was calculated assuming a circular cross-section and constant area along each fiber length.

3. Results and Discussions

3.1. Fiber Characteristics

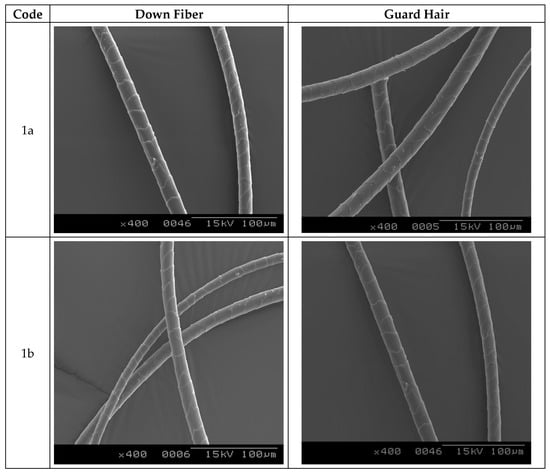

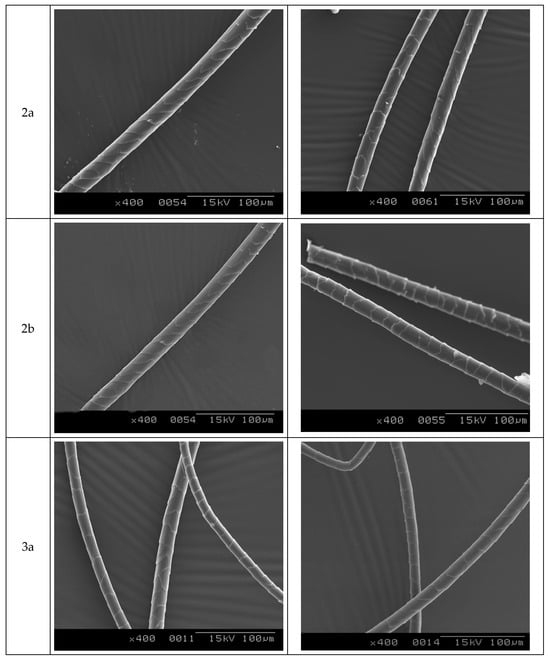

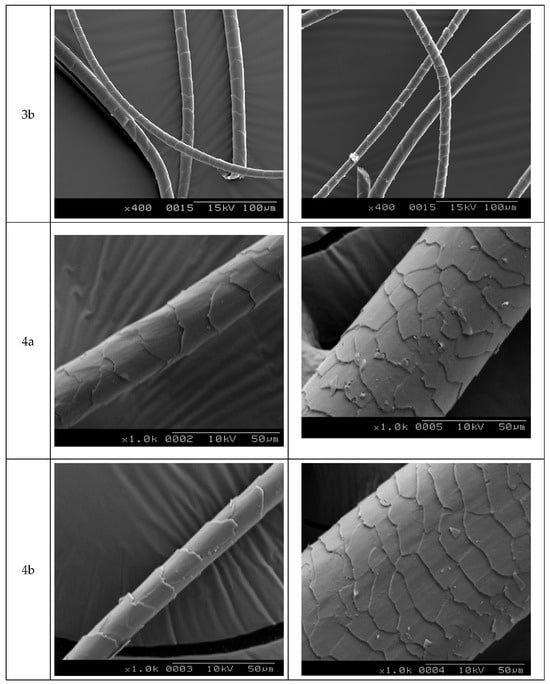

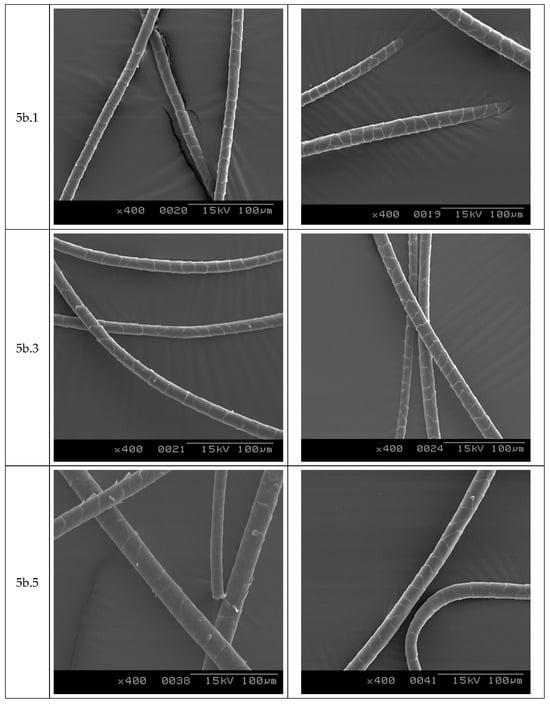

All samples were of different fibers: fine, short, flexible down fiber, and long and coarse guard hair (Figure 4). Down fibers have rectangular and regular-shaped scales. However, some fibers in sample 4 had short, arrowhead-shaped scales, and the scales’ edges were irregular or wavy.

Figure 4.

SEM images for down fiber and guard hair for all samples.

A detailed analysis of fiber characteristics, including a comparison between down fibers and guard hairs, underscored the significant variation in fiber properties among different samples. It comes from Figure 4 that the down fibers exhibit a regular scale pattern, contributing to their softness and flexibility. In contrast, the guard hairs have a more irregular scale pattern, reflecting their coarser texture. This morphological insight could be critical for tailoring processing techniques to optimize the quality of cashmere based on its source.

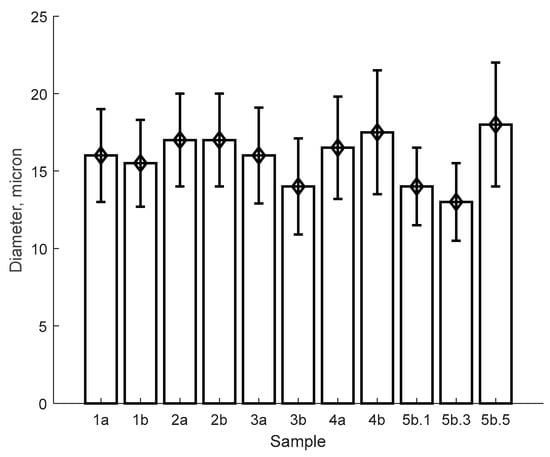

The mean fiber diameters and the standard deviations of the cashmere samples are shown in Figure 5. The mean fiber diameter of samples 1a, 1b, 2a, 2b, 3a, 36, 5b.1, and 5b.3 ranged from 13.2 to 16.7 microns. Its coefficient of variation was lower than 22%. The finest filers were combed from samples 3b, 5b.1, and 5b.3. The distinct difference in the fineness measurements of sample 5b.5 allowed us to note that the older the goat is, the more the fiber fineness and its CV increase.

Figure 5.

Mean fiber diameter and standard deviation of samples.

The observed relationship between fiber diameter and goat age provides valuable information for cashmere producers. The increase in fiber diameter with age could be attributed to the natural growth and maturation processes in goats. This finding is significant because it can inform selective breeding programs aimed at producing finer fibers by focusing on younger goats or specific age groups. Additionally, understanding how age affects fiber diameter can aid in predicting the quality of cashmere and optimizing harvesting strategies to achieve desired fiber characteristics.

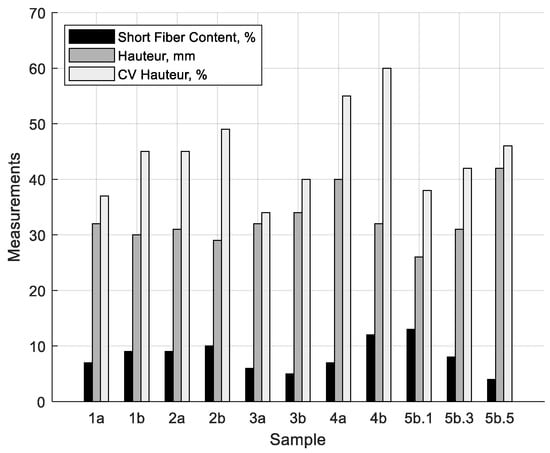

The down fibers of samples 4a and 4b are also coarser and more irregular (with CVs of 23–24%). Depending on goat breed, strain, age, and gender, the «Hauteur» of the samples varied from 25.5 mm to 43 mm (Figure 6).

Figure 6.

Short fiber content (%), mean fiber length Hauteur (mm), and CV% Hauteur.

The minimal and maximal values were obtained for samples 5b.1 and 5b.5. It is likely that the fiber length and its CV grow proportionally with the increase in the goat’s age. The fiber lengths of samples 4a and 4b as well as their CVs and short fiber content were higher than the others except sample 5b.5. It is obvious that the fibers are inclined to retract and curl up when they are transferred from a specimen holder due to the high crimp resistance and the elasticity of our samples.

The tensile properties of single fiber were measured on 40–60 fibers for each sample. The tensile stress of the samples was between 167 and 225 MPa. Its extension ranged from 40.7% to 46.1% (Table 2). The tensile stress of sample 2b was slightly different. The extension of sample 5b.1 was very high, as well as its stress. However, its energy at rupture was the lowest.

Table 2.

Tensile properties of the samples.

The observation that fibers tend to retract and curl due to high crimp resistance and elasticity, as noted in the analysis, highlights an important aspect of fiber behavior. High crimp resistance often leads to greater elasticity, which can affect the processing and final texture of the cashmere. This characteristic is crucial for manufacturers to consider, as it impacts spinning and weaving processes.

3.2. Statistical Analysis

To assess the main fiber properties across different breeds, strains, ages, and genders, statistical analysis was performed. Analysis of variance (ANOVA) was conducted on the energy at rupture and fiber diameter distributions to determine significant differences [17]. ANOVA is suitable for normally distributed experimental results with equal variances between distributions.

The aim was to compare the main fiber properties of the samples combed from the goats of different breeds, strains, age, and gender and to determine if there are any significant differences between them by means of statistical analysis. So, the analysis of variance on the energy at rupture and fiber diameter distributions was carried out. The technique of analysis of variance has to be used if the experimental results are normally distributed and the variances between distributions are the same.

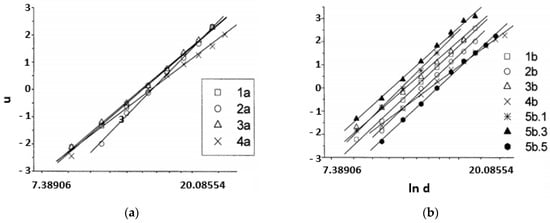

The Gibrat lines in Figure 7 show that the cashmere fiber diameters of all samples are log-normally distributed.

Figure 7.

Gibrat’s lines of diameter distributions (a) for samples 1a, 2a, 3a, and 4a; (b) for samples 1b, 2b, 3b, 4b, 5b.1, 5b.3, and 5b.5.

A variance comparison of the logarithm of the fiber diameters (log d) was performed to test their equality. The null hypothesis, stating that the variances ( and ) of two strains are equal, was tested using Gaussian distributions (Equations (3)–(6)).

The standard deviations, s1 and s2, of two samples follow Gaussian law, as illustrated in Equation (4).

Thus, the uc value calculating using Equation (5) has to follow normal law N(0,1):

where

Here, n1 and n2 are the numbers of the measurements of the two samples.

By rejecting the null hypothesis, we admitted the equality between «log d» variances for all compared samples except for samples 1 and 2. Since a direct relationship exists between fiber diameter and its «log d», the diameter variances were unequal. We presume that the fiber fineness of the tested samples was not the same because their diameter variances were different. Analysis of variance (ANOVA) was carried out on the «log d» values of samples 1 and 2. It showed that the influence exerted by the goat strain on the «log d» values is strong (Table 3).

Table 3.

ANOVA for fiber fineness measurements on samples from goats of different genders and ages.

Then, the equality of the «log d» variances of two samples, collected from male and female goats of the same strain using the same method, were tested. The test showed that the variances are equal for samples 2a, 2b, 3a, and 3b. This test indicated also that the «log d» variances of three samples coming from 1-, 3-. and 5-year-old goats are the same (Table 4).

Table 4.

Comparison of variances for fiber diameter and energy.

The ANOVA results reveal that fiber fineness in cashmere is significantly influenced by factors including goat strain, breed, age, and gender. The analysis of fiber diameters showed a range of mean diameter differences from 0.1 to 3.6 microns among different strains, with samples from strains 4b and 5b.5 exhibiting the highest fiber diameters. This variability in fiber diameter is indicative of the genetic and phenotypic diversity present within the goat population under study.

For energy at rupture, the assumption of normality was upheld for all samples except those from samples 4a and 4b. For these samples, the distribution of energy at rupture was confirmed to be log-normal, which implies that the data deviate from a normal distribution and are better described by a log transformation. This finding is crucial as it affects the interpretation of the variability and central tendencies of energy at rupture in these samples. The equality of energy at rupture variances between male and female goats was substantiated, suggesting that gender does not significantly influence this property when controlling for strain.

The influence of goat strain on energy at rupture was pronounced, with strain effects demonstrating a significant impact on the tensile strength of the fibers (Table 5). Analysis of variance indicated that while the energy at rupture is strongly influenced by the strain, gender differences within strains were statistically insignificant. This suggests that the genetic background of the goat, more so than gender, plays a critical role in determining the energy required to rupture the fibers.

Table 5.

Analysis of variance for energy at rupture on samples 1a, 1b, 2a, 2b, 3a, and 3b.

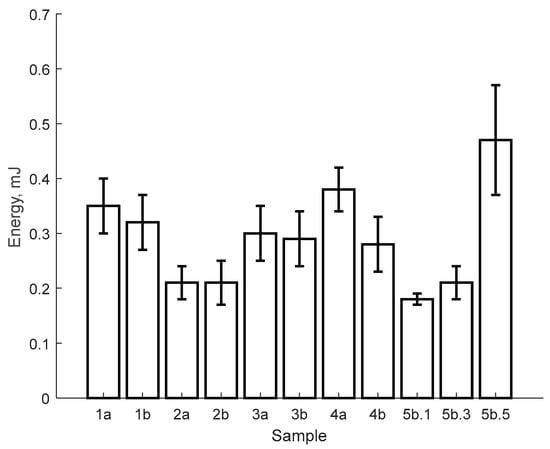

The effect of age on energy at rupture was also significant, with notable differences observed across different age groups. Specifically, the variance in energy at rupture among samples from different ages was significant, particularly with a 99% confidence level for the differences observed between sample 5b.5 and those from younger goats (5b.1 and 5b.3). This suggests a potential increase in the energy required to rupture fibers as goats age, likely reflecting changes in fiber structure or composition over time. The energy at rupture increased approximately 1.5–2 times with age, with the highest energy values recorded for samples 1a, 1b, and 4a, while the lowest values were noted in samples 2a and 2b, as shown in Figure 8.

Figure 8.

Mean energy and standard deviation of the samples.

The energy at rupture varied from 0.05 × 103 J to 0.09 × 103 J according to goat breed. It is necessary to note that the differences between breed or between ages within breed were negligible.

These results underscore the importance of considering genetic factors such as strain and breed, as well as physiological factors such as age and gender, when evaluating the quality and processing characteristics of cashmere fibers. The findings provide valuable insights into how these factors impact fiber properties, which is essential for optimizing cashmere production and processing.

3.3. Proposal of the Classification of Cashmere Raw Materials

The fiber composition and properties of down fibers from the crossbreed “Gobi Gurvan Saikhan” exhibit distinct characteristics when compared to those from other cashmere-producing goats. Specifically, the raw materials from this crossbreed show unique attributes in terms of fiber fineness and length, necessitating a separate classification and processing approach.

Our experimental results substantiate the need for distinct categorization based on the genetic background of the goats. The analysis reveals that cashmere from “Gobi Gurvan Saikhan” differs significantly from that of native Mongolian goats, both in fiber fineness and length. The observed variation in fiber fineness among samples from four different strains ranged from 0.5 to 3.6 microns, indicating substantial genetic variability. Additionally, within individual goats of different ages, fiber fineness varied between 0.9 and 5 microns, underscoring the influence of age on fiber quality.

The distribution of fiber length also varies significantly with age. Notably, fibers from goats aged 1 year exhibit different length distributions compared to those from 5-year-old goats. This variation suggests that age not only impacts fiber fineness but also affects the overall length of the cashmere, which can be crucial for processing and product quality.

Statistical analyses confirm that while goat strain, breed, and age have a significant impact on fiber fineness, the influence of gender on fiber diameter is minimal. This finding highlights that the primary determinants of fiber quality are genetic factors and physiological age rather than gender. Despite these variations in fiber fineness, the differences in tensile properties—such as the mean energy at rupture—across strains and age groups were relatively minor, indicating that the mechanical strength of the fibers remains consistent across different categories.

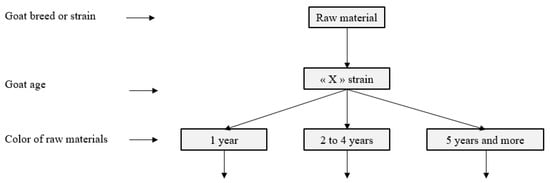

Given these insights, it is proposed that raw cashmere materials be classified based on goat strain, breed, and age (Figure 9).

Figure 9.

Classification of raw materials.

This classification system should account for the substantial variations in fiber fineness and length observed. Detailed classification will aid in optimizing processing techniques and ensuring the consistent quality of cashmere products.

To further refine this classification system, it is recommended to conduct similar studies on other cashmere-producing regions of Mongolia. This broader research would help in developing a comprehensive classification system that incorporates regional genetic variations and provides a standardized approach for cashmere grading and processing.

The proposed classification of cashmere raw materials based on strain, breed, and age is expected to enhance the accuracy and efficiency of cashmere processing. By recognizing and categorizing the inherent variability in cashmere fibers, processing industries can better align their methods to produce high-quality cashmere products that meet specific market demands.

4. Conclusions

This study elucidated the principal characteristics of Mongolian cashmere fibers and examined the effects of various factors, including goat breed, strain, gender, and age, on these fiber properties. Our analysis reveals significant variability in the fiber attributes across different goat strains and age groups.

The fleece of the four examined strains—“Buural”, “Bayandelger”, “Ulgin Ulaan”, and “Erchim”—consists of a mix of down fibers and coarse guard hairs. The mean fiber diameter across these strains ranges from 13.2 to 16.7 microns, reflecting the diversity in fiber fineness inherent to each strain. Additionally, the “Hauteur” or fiber length varies between 25.5 and 43 mm, further demonstrating the variability in fiber dimensions among different strains. Notably, fibers from the crossbreed “Gobi Gurvan Saikhan” exhibit coarser and longer characteristics compared to the native strains, with more irregularity in fiber structure.

The breaking extension of Mongolian cashmere fibers exceeds 40%, which is notably higher than the values reported in the existing literature. This elevated extension could potentially be a distinctive attribute of Mongolian cashmere, highlighting its unique mechanical properties. However, further comparative studies are warranted to assess the breaking extension of cashmere fibers from various origins under consistent testing conditions.

Statistical analysis indicates that cashmere fiber diameter follows a log-normal distribution, akin to wool. The energy at rupture for fibers from the four strains studied exhibits a normal distribution, while the crossbred “Gobi Gurvan Saikhan” fibers adhere to a log-normal distribution. This suggests distinct mechanical behavior in different cashmere types, influenced by genetic and environmental factors.

Our findings reveal that fiber fineness is significantly affected by goat breed, strain, age, and gender. Specifically, the breed and strain have a pronounced impact on fiber fineness and length. Although the gender of the goat does not significantly influence the energy values of cashmere fibers, with the exception of the “Gobi Gurvan Saikhan” strain, the effect of age is substantial. As goats age, their fibers become coarser, longer, and more irregular, underscoring the importance of age in fiber characterization.

In light of these findings, we recommend classifying raw cashmere primarily based on goat breed and strain due to the considerable influence that these factors have on fiber properties. Following this, classification should account for age and gender within each breed or strain. This hierarchical classification system will enhance the precision of cashmere grading and processing, ensuring that the raw materials are accurately represented and optimally utilized.

Further research across diverse breeding regions of Mongolia is suggested to validate and refine this classification system. Such studies would provide a comprehensive understanding of regional variations and contribute to the development of a standardized framework for cashmere quality assessment and processing.

Author Contributions

W.M.: methodology, software, formal analysis, investigation, writing—original draft, writing—review and editing, and visualization. S.U.: methodology, formal analysis, investigation, original draft, and visualization. J.-Y.D.: validation, resources, editing, and supervision. O.H.: methodology, validation, resources, writing—review and editing, supervision, and project administration. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Hunter, L.M. cashmere and other animal hair fibres. In Handbook of Natural Fibres; Woodhead Publishing: Sutton, UK, 2020; pp. 279–383. [Google Scholar]

- McGregor, B.A. Physical, chemical, and tensile properties of cashmere, mohair, alpaca, and other rare animal fibers. In Handbook of Properties of Textile and Technical Fibres; Woodhead Publishing: Sutton, UK, 2018; pp. 105–136. [Google Scholar]

- Upton, C. Introduction: Focus on Mongolia. Cent. Asian Surv. 2010, 29, 243–249. [Google Scholar] [CrossRef]

- Zhou, H.M.; Allain, D.; Li, J.Q.; Zhang, W.G.; Yu, X.C. Genetic parameters of production traits of Inner Mongolia cashmere goats in China. J. Anim. Breed. Genet. 2002, 119, 385–390. [Google Scholar] [CrossRef]

- Wang, P.; Liu, H.; Li, J. Estimation of genetic parameters for fleece traits in yearling Inner Mongolia Cashmere goats. Small Rumin. Res. 2013, 109, 15–21. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.; Su, R.; Liu, Z.; Wang, R.; Zhang, Y.; Li, J. Relationships between cashmere production and other important economic traits of Inner Mongolia cashmere goats. Ital. J. Anim. Sci. 2019, 18, 1626776. [Google Scholar] [CrossRef]

- Yu, H.; Ko, S. Survey on Strategies for Developing the Mongolian Cashmere Industry. J. Korean Soc. Costume 2014, 64, 84–97. [Google Scholar] [CrossRef]

- Bergen, W.V.; Mauersberger, H.R. American Wool Handbook; Textile Book Publishers: New York, NY, USA, 1948. [Google Scholar]

- Wortmann, F.J.; Phan, K.H. Cuticle scale heights of wool and specialty fibers and their changes due to textile processing. Text. Res. J. 1999, 69, 139–144. [Google Scholar] [CrossRef]

- McGregor, B. Improving Production Efficiency, Quality and Value-Adding of Rare Natural Animal Fibres; Deakin University: Docklands, VIC, Australia, 2011. [Google Scholar]

- Logan, R.I.; Rivett, D.E.; Tucker, D.J.; Hudson, A.H. Analysis of the intercellular and membrane lipids of wool and other animal fibers. Text. Res. J. 1989, 59, 109–113. [Google Scholar] [CrossRef]

- Hillbrick, G.C.; Tucker, D.J.; Smith, G.C. The lipid composition of cashmere goat fleece. Aust. J. Agric. Res. 1995, 46, 1259–1271. [Google Scholar] [CrossRef]

- Morton, W.E.; Hearle, J.W. Physical Properties of Textile Fibres; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- NF EN ISO 137; Wool—Determination of Fibre Diameter—Projection Microscope Method. Standard in Force. International Standard: Geneva, Switzerland, 2016.

- ASTM D 1440-90; Standard Test Method of Length and Length Distribution of Cotton Fibers (Array Method), Section Seven, Textiles. ASTM: West Conshohocken, PA, USA, 1997.

- ISO 5079; Textile Fibres—Determination of Breaking Force and Elongation at Break of Individual Fibres. International Standard: Geneva, Switzerland, 2020.

- St, L.; Wold, S. Analysis of variance (ANOVA). Chemom. Intell. Lab. Syst. 1989, 6, 259–272. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).