Reducing Plastic in Consumer Goods: Opportunities for Coarser Wool

Abstract

1. Introduction

1.1. Background

1.2. Previous Research

1.3. Properties of Wool and Plastics

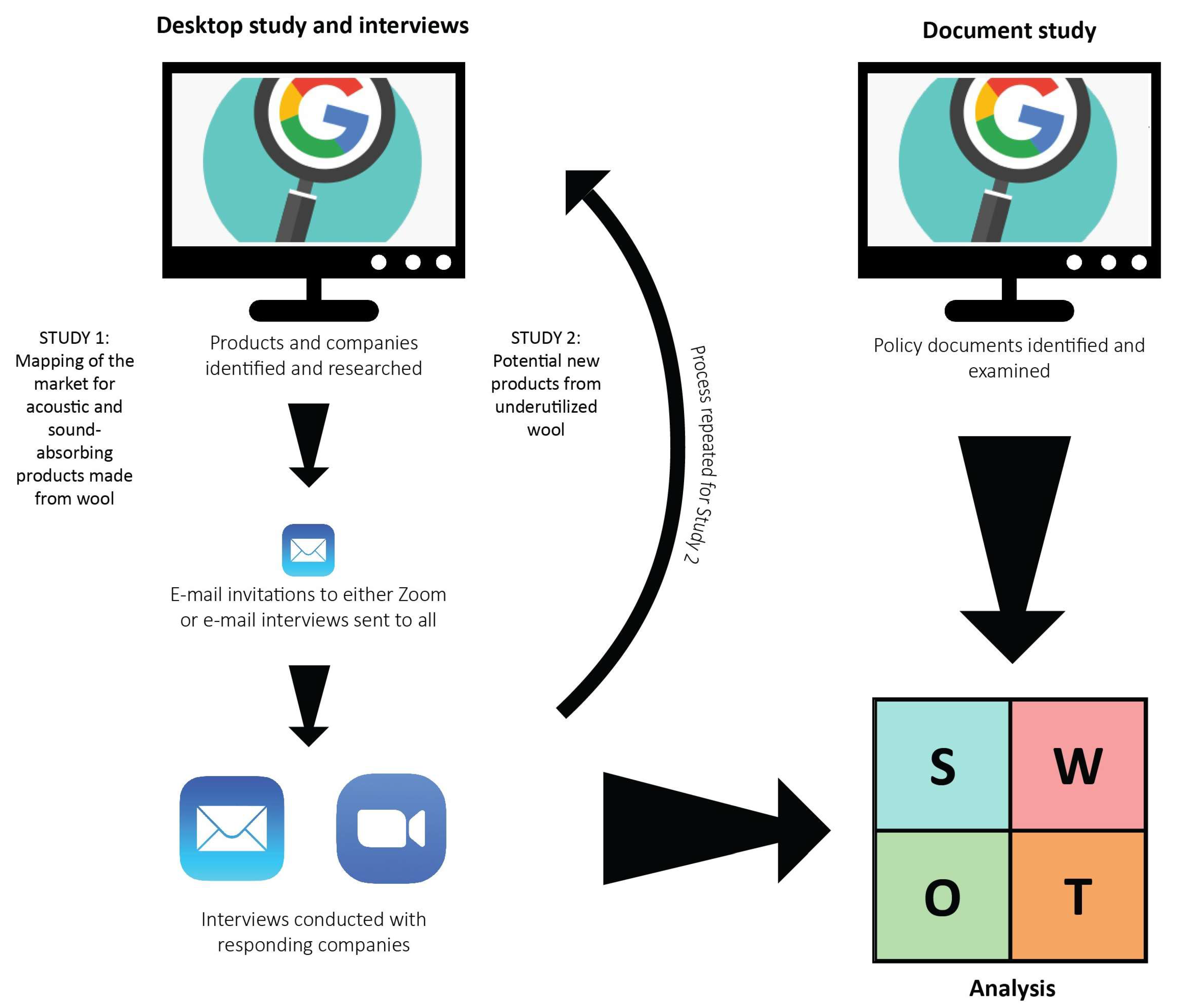

2. Materials and Methods

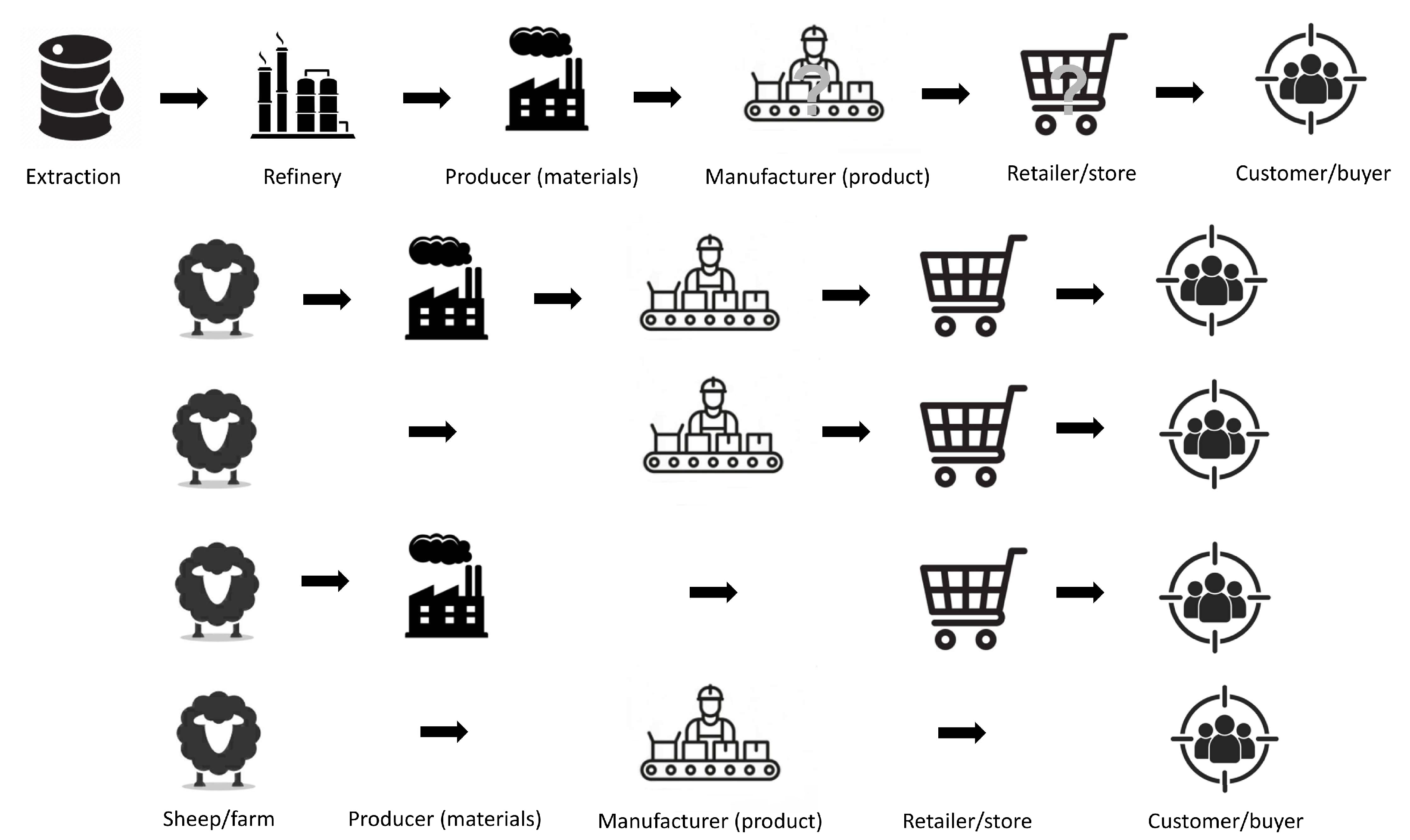

2.1. Desktop Studies and Interviews

- Business setup and product offering;

- Type and origin of wool;

- How the wool was purchased;

- Wool supply and value chain;

- The market for the product(s);

- The customers for the product(s);

- Advantages and challenges of using sheep wool;

- The potential for using coarser wool if using Merino wool.

2.2. Document Analysis

- International Resource Panel report: “Resource Efficiency: Potential and Economic Implications” [82];

- EU Waste Framework Directive [83];

- Regulation (EC) No 1069/2009 health rules as regards animal by-products and derived products not intended for human consumption [84];

- EU Directive on single-use plastic [85];

- EU Circular economy action plan [86];

- EU Strategy for Sustainable and Circular Textiles [87];

- EC: Microplastic pollution from textile consumption in Europe [88].

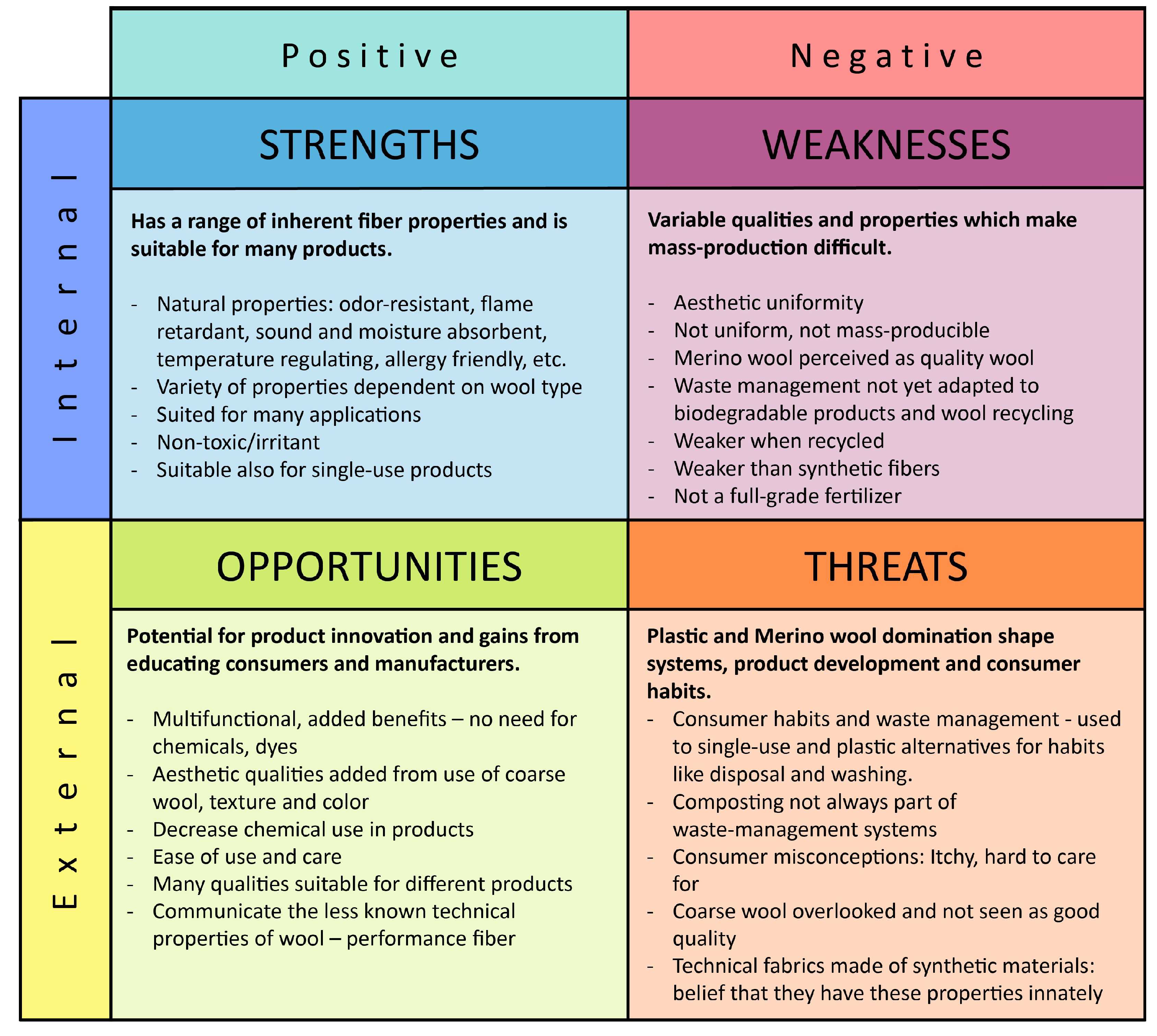

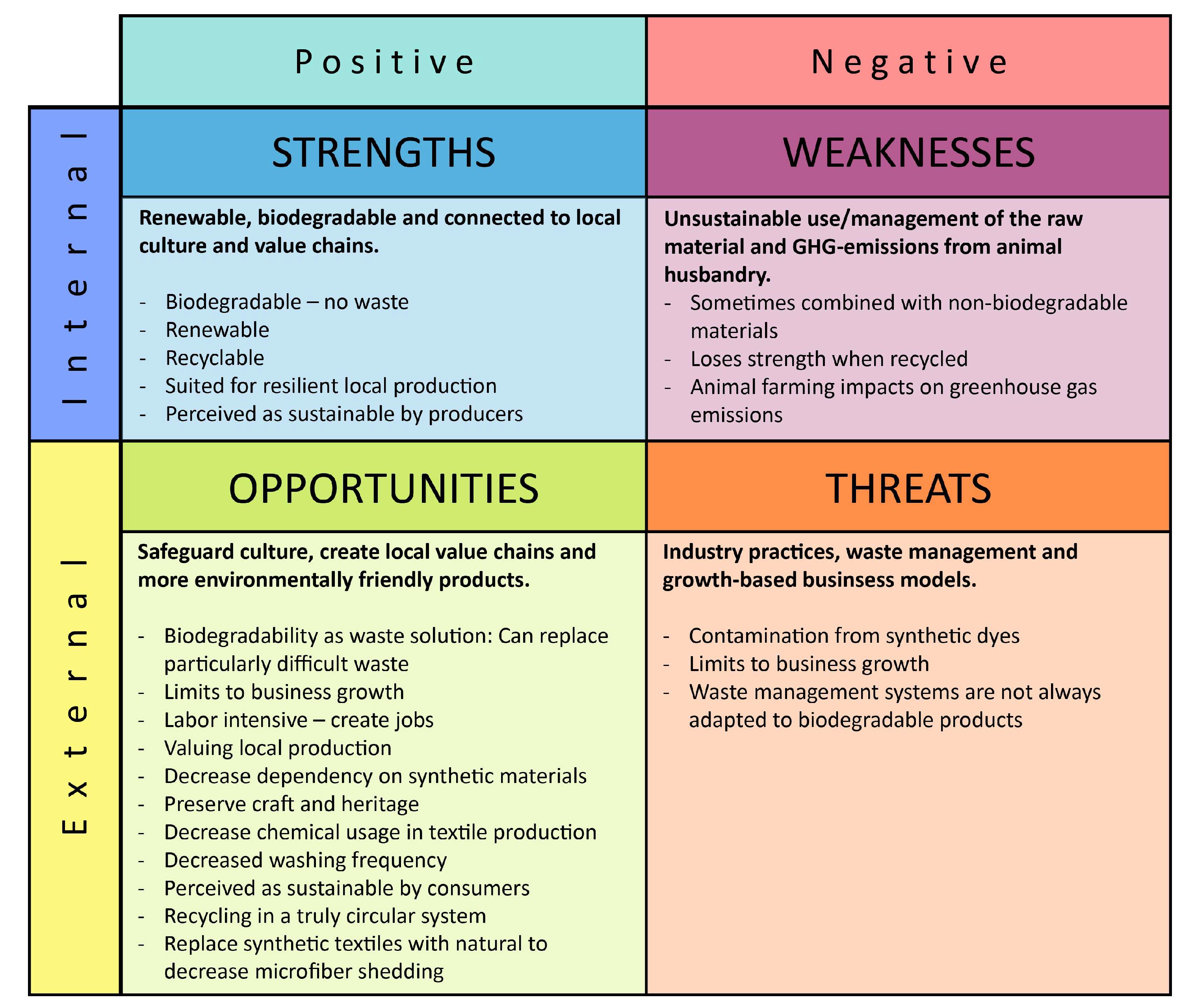

2.3. SWOT Analysis

2.4. Limitations

3. Results

3.1. Properties and Product Performance

3.2. Price and Availability

3.3. Sustainability

3.4. Regulation and Policy

4. Discussion

4.1. (Mis-)Conceptions

4.2. Price vs. Scale

- Small-scale, niche products with short and more localized value chains;

- Products with multiple positive properties or that are aesthetically more attractive;

- Marketing toward customers that are willing to pay more to avoid plastic.

4.3. Environmental, Social, Economic—And Cultural

4.4. Resource Utilization in Policy

4.5. A Systemic View

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salachna, A.; Kobiela-Mendrek, K.; Kohut, M.; Rom, M.; Broda, J. The Pastoralism in the Silesian Beskids (South Poland): In the Past and Today. In Sheep Farming—Herds Husbandry, Management System, Reproduction and Improvement of Animal Health; Ronquillo, M.G., Riocerezo, C.P., Eds.; IntechOpen: London, UK, 2021; pp. 51–68. [Google Scholar]

- Haugrønning, V.; Broda, J.; Espelien, I.S.; Klepp, I.G.; Kobiela-Mendrek, K.; Rom, M.; Sigaard, A.S.; Tobiasson, T.S. Upping the WOOLUME: Waste Prevention Based on Optimal Use of Materials. In Local, Slow and Sustainable Fashion: Wool as a Fabric for Change; Klepp, I.G., Tobiasson, T., Eds.; Palgrave Macmillan: London, UK, 2022; pp. 61–82. [Google Scholar]

- Sigaard, A.S.; Haugrønning, V. WOOLUME: Mapping the Market for Acoustic and Sound Absorbing Products Made of Wool; SIFO Report No. 9-2021; OsloMet: Oslo, Norway, 2021. [Google Scholar]

- Sigaard, A.S.; Løvbak Berg, L.; Klepp, I.G. WOOLUME: Potential New Products from Vacant Wool; SIFO Report No. 18-2021; OsloMet: Oslo, Norway, 2022. [Google Scholar]

- Parker, L. The World’s Plastic Pollution Crisis Explained; National Geographic: Washington, DC, USA, 2022. [Google Scholar]

- Conti, I.; Simioni, C.; Varano, G.; Brenna, C.; Costanzi, E.; Neri, L.M. Legislation to limit the environmental plastic and microplastic pollution and their influence on human exposure. Environ. Pollut. 2021, 288, 117708. [Google Scholar] [CrossRef] [PubMed]

- Changing Markets Foundation. Fossil Fashion: The Hidden Reliance on Fossil Fuels; Changing Markets Foundation: Utrecht, The Netherlands, 2021; p. 45. [Google Scholar]

- Klepp, I.G.; Løvbak Berg, L.; Sigaard, A.S.; Tobiasson, T.S.; Hvass, K.K.; Gleisberg, L. The Plastic Elephant: Overproduction and Synthetic Fibres in Sustainable Textiles Strategies; SIFO: Oslo, Norway, 2023. [Google Scholar]

- Henry, B.; Laitala, K.; Klepp, I.G. Microplastic Pollution from Textiles: A Literature Review; SIFO Project Report No. 1-2018; OsloMet: Oslo, Norway, 2018. [Google Scholar]

- Henry, B.; Laitala, K.; Klepp, I.G. Microfibres from apparel and home textiles: Prospects for including microplastics in environmental sustainability assessment. Sci. Total. Environ. 2018, 652, 483–494. [Google Scholar] [CrossRef] [PubMed]

- Klepp, I.G.; Laitala, K. Halver ditt utslipp av mikroplast fra klær. Aftenposten Vitenskap, 15 January 2018. [Google Scholar]

- Klepp, I.G.; Tobiasson, T.S. Debattinnlegg: Klærne våre Dreper liv i Havet. Forskning, 6 February 2017. [Google Scholar]

- Browne, M.A.; Crump, P.; Niven, S.J.; Teuten, E.; Tonkin, A.; Galloway, T.; Thompson, R. Accumulation of Microplastic on Shorelines Woldwide: Sources and Sinks. Environ. Sci. Technol. 2011, 45, 9175–9179. [Google Scholar] [CrossRef] [PubMed]

- Ragusa, A.; Svelato, A.; Santacroce, C.; Catalano, P.; Notarstefano, V.; Carnevali, O.; Papa, F.; Rongioletti, M.C.A.; Baiocco, F.; Draghi, S.; et al. Plasticenta: First evidence of microplastics in human placenta. Environ. Int. 2020, 146, 106274. [Google Scholar] [CrossRef] [PubMed]

- Jenner, L.C.; Rotchell, J.M.; Bennett, R.T.; Cowen, M.; Tentzeris, V.; Sadofsky, L.R. Detection of microplastics in human lung tissue using μFTIR spectroscopy. Sci. Total. Environ. 2022, 831, 154907. [Google Scholar] [CrossRef] [PubMed]

- Horvatits, T.; Tamminga, M.; Liu, B.; Sebode, M.; Carambia, A.; Fischer, L.; Püschel, K.; Huber, S.; Fischer, E.K. Microplastics detected in cirrhotic liver tissue. Ebiomedicine 2022, 82, 104147. [Google Scholar] [CrossRef]

- WHO. Dietary and Inhalation Exposure to Nano- and Microplastic Particles and Potential Implications for Human Health; WHO: Geneva, Switzerland, 2022. [Google Scholar]

- Merkl, A.; Charles, D. The Price of Plastic Pollution: Social Costs and Corporate Liabilities; Minderoo Foundation: Nedlands, Australia, 2022. [Google Scholar]

- Textile Exchange. Preferred Fiber & Materials Market Report 2021; Textile Exchange: Lamesa, TX, USA, 2021. [Google Scholar]

- Textile Exchange. Preferred Fiber & Materials Market Report: October 2022; Textile Exchange: Lamesa, TX, USA, 2022. [Google Scholar]

- IWTO. Market Information: Statistics for the Global Wool Production and Textile Industry; International Wool Trade Organisation: Brussels, Belgium, 2021. [Google Scholar]

- Petek, B.; Logar, R.M. Management of waste sheep wool as valuable organic substrate in European Union countries. J. Mater. Cycles Waste Manag. 2020, 23, 44–54. [Google Scholar] [CrossRef]

- Zoccola, M.; Montarsolo, A.; Mossotti, R.; Patrucco, A.; Tonin, C. Green Hydrolysis as an Emerging Technology to Turn Wool Waste into Organic Nitrogen Fertilizer. Waste Biomass Valorizat. 2015, 6, 891–897. [Google Scholar] [CrossRef]

- EC. CW—Circular Wool. Available online: https://single-market-economy.ec.europa.eu/sectors/fashion/eliit/learn/partnerships/cw-circular-wool_en (accessed on 13 January 2023).

- Dey, A.; Dhumal, C.V.; Sengupta, P.; Kumar, A.; Pramanik, N.K.; Alam, T. Challenges and possible solutions to mitigate the problems of single-use plastics used for packaging food items: A review. J. Food Sci. Technol. 2020, 58, 3251–3269. [Google Scholar] [CrossRef]

- Zhang, C.; Xia, L.; Zhang, J.; Liu, X.; Xu, W. Utilization of waste wool fibers for fabrication of wool powders and keratin: A review. J. Leather Sci. Eng. 2020, 2, 15. [Google Scholar] [CrossRef]

- Sun, Y.; Li, B.; Zhang, Y.; Dou, H.; Fan, W.; Wang, S. The progress and prospect for sustainable development of waste wool resources. Text. Res. J. 2022, 93, 468–485. [Google Scholar] [CrossRef]

- Haque, A.N.M.A.; Naebe, M. Waste Wool Powder for Promoting Plant Growth by Moisture Retention. Sustainability 2022, 14, 12267. [Google Scholar] [CrossRef]

- Lebedytė, M.; Sun, D. A review: Can waste wool keratin be regenerated as a novel textile fibre via the reduction method? J. Text. Inst. 2021, 113, 1750–1766. [Google Scholar] [CrossRef]

- Parlato, M.C.M.; Porto, S.M.C.; Valenti, F. Assessment of sheep wool waste as new resource for green building elements. Build. Environ. 2022, 225, 109596. [Google Scholar] [CrossRef]

- Parlato, M.C.M.; Porto, S.M.C. Organized Framework of Main Possible Applications of Sheep Wool Fibers in Building Components. Sustainability 2020, 12, 761. [Google Scholar] [CrossRef]

- Podjava, A.; Zarins, A.; Avotina, L.; Shvirksts, K.; Baumane, L.; Rasmane, D.A.; Grube, M.; Kizane, G. Latvian Sheep Wool Fiber as a Cheap Natural Adsorbent for the Removal of Congo Red Dye from Wastewater. Water Air Soil Pollut. 2022, 233, 451. [Google Scholar] [CrossRef]

- Aluigi, A.; Corbellini, A.; Rombaldoni, F.; Mazzuchetti, G. Wool-derived keratin nanofiber membranes for dynamic adsorption of heavy-metal ions from aqueous solutions. Text. Res. J. 2012, 83, 1574–1586. [Google Scholar] [CrossRef]

- Guna, V.; Ilangovan, M.; Vighnesh, H.R.; Sreehari, B.R.; Abhijith, S.; Sachin, H.E.; Mohan, C.B.; Reddy, N. Engineering Sustainable Waste Wool Biocomposites with High Flame Resistance and Noise Insulation for Green Building and Automotive Applications. J. Nat. Fibers 2019, 18, 1871–1881. [Google Scholar] [CrossRef]

- Khan, F.M.; Shah, A.H.; Wang, S.; Mehmood, S.; Wang, J.; Liu, W.; Xu, X. A Comprehensive Review on Epoxy Biocomposites Based on Natural Fibers and Bio-fillers: Challenges, Recent Developments and Applications. Adv. Fiber Mater. 2022, 4, 683–704. [Google Scholar] [CrossRef]

- Bhavsar, P.; Balan, T.; Fontana, G.D.; Zoccola, M.; Patrucco, A.; Tonin, C. Sustainably Processed Waste Wool Fiber-Reinforced Biocomposites for Agriculture and Packaging Applications. Fibers 2021, 9, 55. [Google Scholar] [CrossRef]

- Memon, H.; Wang, H.; Langat, E.K. Determination and Characterization of the Wool Fiber Yield of Kenyan Sheep Breeds: An Economically Sustainable Practical Approach for Kenya. Fibers 2018, 6, 55. [Google Scholar] [CrossRef]

- Ghermezgoli, Z.M.; Moezzi, M.; Yekrang, J.; Rafat, S.A.; Soltani, P.; Barez, F. Sound absorption and thermal insulation characteristics of fabrics made of pure and crossbred sheep waste wool. J. Build. Eng. 2020, 35, 102060. [Google Scholar] [CrossRef]

- Klepp, I.G.; Tobiasson, T.; Haugrønning, V.; Vittersø, G.; Grøva, L.; Kvingedal, T.; Espelien, I.; Kubberød, E. KRUS Final Report: Enhancing Local Value Chains in Norway; SIFO Report No. 8-2019; 8270634948; OsloMet: Oslo, Norway, 2019. [Google Scholar]

- OsloMet. WOOLUME: Polish Sheep Wool for Improved Resource Utilisation and Value Creation. Available online: https://www.oslomet.no/en/research/research-projects/woolume (accessed on 30 December 2022).

- Sousa, A.F.; Patrício, R.; Terzopoulou, Z.; Bikiaris, D.N.; Stern, T.; Wenger, J.; Loos, K.; Lotti, N.; Siracusa, V.; Szymczyk, A.; et al. Recommendations for replacing PET on packaging, fiber, and film materials with biobased counterparts. Green Chem. 2021, 23, 8795–8820. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, L.; McClements, D.J.; Yang, T.; Zhang, Z.; Ren, F.; Miao, M.; Tian, Y.; Jin, Z. Starch-based biodegradable packaging materials: A review of their preparation, characterization and diverse applications in the food industry. Trends Food Sci. Technol. 2021, 114, 70–82. [Google Scholar] [CrossRef]

- Semple, K.E.; Zhou, C.; Rojas, O.J.; Nkeuwa, W.N.; Dai, C. Moulded pulp fibers for disposable food packaging: A state-of-the-art review. Food Packag. Shelf Life 2022, 33, 100908. [Google Scholar] [CrossRef]

- Oliaei, E.; Lindström, T.; Berglund, L.A. Sustainable Development of Hot-Pressed All-Lignocellulose Composites—Comparing Wood Fibers and Nanofibers. Polymers 2021, 13, 2747. [Google Scholar] [CrossRef]

- Kathuria, A.; Zhang, S. Sustainable and Repulpable Barrier Coatings for Fiber-Based Materials for Food Packaging: A Review. Front. Mater. 2022, 9, 21. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, C.; Bokka, S.K.; He, Z.; Ni, Y. Molded fiber and pulp products as green and sustainable alternatives to plastics: A mini review. J. Bioresour. Bioprod. 2022, 7, 14–25. [Google Scholar] [CrossRef]

- Schmidtchen, L.; Roleda, M.Y.; Majschak, J.-P.; Mayser, M. Processing technologies for solid and flexible packaging materials from macroalgae. Algal Res. 2021, 61, 102300. [Google Scholar] [CrossRef]

- Santos, A.S.; Ferreira, P.J.T.; Maloney, T. Bio-based materials for nonwovens. Cellulose 2021, 28, 8939–8969. [Google Scholar] [CrossRef]

- Jason Mills LLC. Technical Textiles: Industrial Applications & Types of Fabric. Available online: https://www.jasonmills.com/technical-textiles/ (accessed on 2 November 2022).

- Devold. Natures Super Fiber. Available online: https://www.devold.com/en-nz/our-choices/natural-choices/natural-choices/ (accessed on 2 November 2022).

- Icebreaker. Merino: Nature’s Performance Fibre. Available online: https://www.icebreaker.com/en-au/our-story/natures-performance-fiber.html (accessed on 2 November 2022).

- NatureWorks LLC. Fiber and Fabric Properties; Technical Bulletin 180904; NatureWorks LLC.: Plymouth, MN, USA, 2005. [Google Scholar]

- Dénes, O.; Florea, I.; Manea, D.L. Utilization of Sheep Wool as a Building Material. Procedia Manuf. 2019, 32, 236–241. [Google Scholar] [CrossRef]

- Li, Y.; Luo, Z.X. Physical Mechanisms of Moisture Diffusion into Hygroscopic Fabrics during Humidity Transients. J. Text. Inst. 2000, 91, 302–316. [Google Scholar] [CrossRef]

- Tepe, E.S.; Hoover, E.E.; Poppe, S. The Wool Mulch System of Producing Strawberries: A Manual for Commercial Growers in Minnesota; University of Minnesota: Minneapolis, MN, USA, 2008. [Google Scholar]

- Røsvik, B.L. Utforming av Skillevegg i Ull; NTNU: Trondheim, Norway, 2012. [Google Scholar]

- Cai, Z.; Faruque, M.A.; Kiziltas, A.; Mielewski, D.; Naebe, M. Sustainable Lightweight Insulation Materials from Textile-Based Waste for the Automobile Industry. Materials 2021, 14, 1241. [Google Scholar] [CrossRef]

- Arnesen, K. Naturlig ull Som Lydabsorbentmateriale. Master’s Thesis, NTNU, Trondheim, Norway, October 2015. [Google Scholar]

- Ballagh, K.O. Acoustical properties of wool. Appl. Acoust. 1996, 48, 101–120. [Google Scholar] [CrossRef]

- del Rey, R.; Uris, A.; Alba, J.; Candelas, P. Characterization of Sheep Wool as a Sustainable Material for Acoustic Applications. Materials 2017, 10, 1277. [Google Scholar] [CrossRef]

- Allafi, F.; Hossain, M.S.; Lalung, J.; Shaah, M.; Salehabadi, A.; Ahmad, M.I.; Shadi, A. Advancements in Applications of Natural Wool Fiber: Review. J. Nat. Fibers 2020, 19, 497–512. [Google Scholar] [CrossRef]

- Kobiela-Mendrek, K.; Bączek, M.; Broda, J.; Rom, M.; Espelien, I.; Klepp, I. Acoustic Performance of Sound Absorbing Materials Produced from Wool of Local Mountain Sheep. Materials 2022, 15, 3139. [Google Scholar] [CrossRef]

- Kuffner, H.; Popescu, C. 8—Wool fibres. In Handbook of Natural Fibres; Kozłowski, R.M., Ed.; Woodhead Publishing: Cambridge, UK, 2012; Volume 1, pp. 171–195. [Google Scholar]

- Mansour, E.; Curling, S.; Stéphan, A.; Ormondroyd, G. Absorption of volatile organic compounds by different wool types. Green Mater. 2016, 4, 1–7. [Google Scholar] [CrossRef]

- Park, C.J.; Barakat, R.; Ulanov, A.; Li, Z.; Lin, P.-C.; Chiu, K.; Zhou, S.; Perez, P.; Lee, J.; Flaws, J.; et al. Sanitary pads and diapers contain higher phthalate contents than those in common commercial plastic products. Reprod. Toxicol. 2019, 84, 114–121. [Google Scholar] [CrossRef]

- Zallmann, M.; Smith, P.K.; Tang, M.L.; Spelman, L.J.; Cahill, J.L.; Wortmann, G.; Katelaris, C.H.; Allen, K.J.; Su, J.C. Debunking the Myth of Wool Allergy: Reviewing the Evidence for Immune and Non-immune Cutaneous Reactions. Acta Derm. Venereol. 2017, 97, 906–915. [Google Scholar] [CrossRef]

- McQueen, R.H.; Vaezafshar, S. Odor in textiles: A review of evaluation methods, fabric characteristics, and odor control technologies. Text. Res. J. 2019, 90, 1157–1173. [Google Scholar] [CrossRef]

- Kjeldsberg, M.; Eilertsen, K.; Buck, M.; Klepp, I.G. Lukten av Svette: Luktutvikling i Ulike Tekstiler [Smell of Sweat: Development of Odour in Different Textiles]; SIFO: Oslo, Norway, 2012. [Google Scholar]

- Broda, J.; Mitka, A.; Gawłowski, A. Greening of road slope reinforced with wool fibres. Mater. Today Proc. 2020, 31, S280–S285. [Google Scholar] [CrossRef]

- Broda, J.; Gawlowski, A. Influence of Sheep Wool on Slope Greening. J. Nat. Fibers 2018, 17, 820–832. [Google Scholar] [CrossRef]

- Ordiales, E.; Gutiérrez, J.I.; Zajara, L.; Gil, J.; Lanzke, M. Assessment of utilization of sheep wool pellets as organic fertilizer and soil amendment in processing tomato and broccoli. Mod. Agric. Sci. Technol. 2016, 2, 20–35. [Google Scholar]

- Parker, L. A Whopping 91 Percent of Plastic Isn’t Recycled. Natl. Geogr. 2022. Available online: http://aipack.com.au/a-whopping-91-of-plastic-isnt-recycled/ (accessed on 13 January 2023).

- Gorecki, R.S.; Gorecki, M.T. Utilization of Waste Wool as Substrate Amendment in Pot Cultivation of Tomato, Sweet Pepper, and Eggplant. Pol. J. Environ. Stud. 2010, 19, 1083–1087. [Google Scholar]

- McKinnon, K. Bruk av Restull i Jord-og Hagebruk En Delrapport i Prosjektet Ny giv for Pigmentert ull; Norsøk: Tingvoll, Norway, 2019. [Google Scholar]

- Zheljazkov, V.D. Assessment of Wool Waste and Hair Waste as Soil Amendment and Nutrient Source. J. Environ. Qual. 2005, 34, 2310–2317. [Google Scholar] [CrossRef] [PubMed]

- Hoover, E.E. Bio-Based Weed Control in Strawberries Using Sheep Wool Mulch, Canola Mulch, and Canola Green Manure; Minnesota Department of Agriculture: St Paul, MN, USA, 2020; p. 4. [Google Scholar]

- Cardno, C. Policy Document Analysis: A Practical Educational Leadership Tool and a Qualitative Research Method. Kuram Ve Uygul. Eğitim Yönetimi/Educ. Adm. Theory Pract. 2019, 24, 623–640. [Google Scholar] [CrossRef]

- Atkinson, P.; Coffey, A. Analysing documentary realities. In Qualitative Research: Theory, Method and Practice; Silverman, D., Ed.; Sage: London, UK, 2004; Volume 2, pp. 56–75. [Google Scholar]

- Thwaites, T.; Davis, L.; Mules, W. Introducing Cultural and Media Studies: A Semiotic Approach, 2nd ed.; Palgrave Macmillan: Basingstoke, UK, 2002. [Google Scholar]

- Taylor, S. Critical Policy Analysis: Exploring contexts, texts and consequences. Discourse Stud. Cult. Politi. Educ. 1997, 18, 23–35. [Google Scholar] [CrossRef]

- Bowen, G.A. Document Analysis as a Qualitative Research Method. Qual. Res. J. 2009, 9, 27–40. [Google Scholar] [CrossRef]

- UNEP. Resource Efficiency: Potential and Economic Implications; International Resource Panel: Nairobi, Kenya, 2017. [Google Scholar]

- European Commission (EC). Waste Framework Directive. Available online: https://ec.europa.eu/environment/topics/waste-and-recycling/waste-framework-directive_en#ecl-inpage-631 (accessed on 7 December 2022).

- European Commission (EC). Regulation (EC) No 1069/2009: Health Rules as Regards Animal By-Products and Derived Products Not Intended for Human Consumption, 2009; European Union: Brussels, Belgium, 2009. [Google Scholar]

- European Commission (EC). Single-Use Plastics. Available online: https://ec.europa.eu/environment/topics/plastics/single-use-plastics_en (accessed on 13 September 2021).

- European Commission (EC). Circular Economy Action Plan for a Cleaner and More Competitive Europe; European Union: Brussels, Belgium, 2020. [Google Scholar]

- European Commission (EC). EU Strategy for Sustainable and Circular Textiles; European Union: Brussels, Belgium, 2022. [Google Scholar]

- Manshoven, S.; Smeets, A.; Malarciuc, C.; Tenhunen, A.; Mortensen, L.F. Microplastic Pollution from Textile Consumption in Europe; European Topic Centre Circular Economy and Resource Use: Mol, Belgium, 2022. [Google Scholar]

- Sarsby, A. SWOT Analysis; Leadership Library: Oakland, UK, 2016. [Google Scholar]

- Speth, C.; Probert, C. The SWOT Analysis; Lemaitre Publishing: Namur, Belgium, 2015. [Google Scholar]

- McKinnon, K. VerdifULL: How Can We Boost the Value of Lower-Grade Wool and Increase the Share of First-Class Wool? Available online: https://www.norsok.no/en/projects/2021/verdifull-how-can-we-boost-the-value-of-lower-grade-wool-and-increase-the-share-of-first-class-wool (accessed on 9 January 2023).

- Siebers, R.W.; Crane, J. Does bedding affect the airway and allergy? Int. J. Occup. Environ. Med. 2011, 2, 65–75. [Google Scholar]

- Rosen, J. Farmers Are Facing a Phosphorus Crisis. The Solution Starts with Soil; National Geographic: Washington, DC, USA, 2020. [Google Scholar]

- Broda, J.; Przybyło, S.; Kobiela-Mendrek, K.; Biniaś, D.; Rom, M.; Grzybowska-Pietras, J.; Laszczak, R. Biodegradation of sheep wool geotextiles. Int. Biodeterior. Biodegrad. 2016, 115, 31–38. [Google Scholar] [CrossRef]

- Shahbandeh, M. Total Number of Sheep and Lambs in the United States from 2001 to 2022; Statista: Hamburg, Germany, 2022. [Google Scholar]

- Uldal, S.H. Norsk Ullstandard/Norwegian Wool Standard. Available online: https://www.animalia.no/no/Dyr/ull-og-ullklassifisering/norsk-ullstandard/ (accessed on 30 December 2022).

- British Wool. British Wool Grading System. Available online: https://www.britishwool.org.uk/grading (accessed on 30 December 2022).

- Sigaard, A.S.; Laitala, K. Natural and Sustainable? Consumers’ Textile Fiber Preferences. Fibers 2023, 11, 12. [Google Scholar] [CrossRef]

- Kerr, J.; Landry, J. Pulse of the Fashion Industry; Global Fashion Agenda & The Boston Consulting Group: Copenhagen, Denmark, 2017. [Google Scholar]

- European commission (EC). Animal By-Products. Available online: https://ec.europa.eu/food/safety/animal-products_en (accessed on 16 March 2022).

- SheMakes. Wool Mondays: Rethinking Wool Together in May Wool Ecosystems; TCBL: Le Mans, France, 2022. [Google Scholar]

- OECD. Update on Recent Progress in Reform of Inefficient Fossil-Fuel Subsidies that Encourages Wasteful Consumption 2021; OECD: Naples, Italy, 2021. [Google Scholar]

- WRAP. European Plastics Pact: Roadmap; WRAP: London, UK, 2020. [Google Scholar]

- Klepp, I.G.; Laitala, K.; Tobiasson, T.S. Woolbed—Sweet Dreams in Merino; Project report No. 2-2016; SIFO: Oslo, Norway, 2016. [Google Scholar]

- Laitala, K.; Klepp, I.G.; Haugrønning, V. Textile Cleaning and Odour Removal. In Odour in Textiles: Generation and Control, 1st ed.; Thilagavathi, G., Rathinamoorthy, R., Eds.; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Laitala, K.; Klepp, I.G. Environmental and ethical perceptions related to clothing labels among Norwegian consumers. Res. J. Text. Appar. 2013, 17, 50–58. [Google Scholar] [CrossRef]

- Heidenstrøm, N.; Haugsrud, 1.; Hebrok, M.; Throne-Holst, H. “Hvorfor kan Ikke bare alle Produkter være Bærekraftige?” Hvordan 905 Forbrukere Oppfatter og Påvirkes av Markedsføring med Bærekraftpåstander; SIFO Report 16-2021; OsloMet: Oslo, Norway, 2021. [Google Scholar]

- Smith, T.; Ehrnström-Fuentes, M.; Hagolani-Albov, S.E.; Klepp, I.G.; Tobiasson, T.S. Rethinking the (Wool) Economy. In Local, Slow and Sustainable Fashion Fibres: Wool as a Fabric for Change; Klepp, I.G., Tobiasson, T.S., Eds.; Palgrave MacMillan: London, UK, 2022; pp. 133–170. [Google Scholar]

- Miller, L.; Isaksen, K.; Burgess, R.; Klepp, I.G.; Tobiasson, T.S. Slow and Indigenous Approaches to Textiles Arts. In Local, Slow and Sustainable Fashion: Wool as a Fabric for Change; Klepp, I.G., Tobiasson, T., Eds.; Palgrave MacMillan: London, UK, 2022; pp. 83–131. [Google Scholar]

- Wennberg, M.V.; Östlund, Å. The Outlook Report 2011–2019: Mistra Future Fashion Final Program Report; Mistra Future Fashion: Stockholm, Sweden, 2019. [Google Scholar]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; De Vries, W.; De Wit, C.A.; et al. Planetary boundaries: Guiding human development on a changing planet. Science 2015, 347, 1259855. [Google Scholar] [CrossRef]

- Laitala, K.; Klepp, I.G.; Kettlewell, R.; Wiedemann, S. Laundry Care Regimes: Do the Practices of Keeping Clothes Clean Have Different Environmental Impacts Based on the Fibre Content? Sustainability 2020, 12, 7537. [Google Scholar] [CrossRef]

- Heidenstrøm, N.; Strandbakken, P.; Haugrønning, V.; Laitala, K. Product Lifetime in European and Norwegian Policies; SIFO Report No. 11-2021; OsloMet: Oslo, Norway, 2021. [Google Scholar]

- IPCC. Climate Change 2022: Mitigation of Climate Change; IPCC: Geneva, Switzerland, 2022; p. 2913. [Google Scholar]

- Klepp, I.G.; Laitala, K.; Haugrønning, V.; Sigaard, A.S.; Tobiasson, T.S. The Fate of Natural Fibres in Environmental Evaluations: A Question of Volume. In Local, Slow and Sustainable Fashion Fibres: Wool as a Fabric for Change; Klepp, I.G., Tobiasson, T., Eds.; Palgrave Macmillan: London, UK, 2022. [Google Scholar]

- Make the Label Count. Delivering EU Environmental Policy through Fair Comparisons of Natural and Synthetic Fibre Textiles in PEF; IWTO: Brussels, Belgium, 2022. [Google Scholar]

- Landbruksdirektoratet (Norwegian Directorate of Agriculture). Pristilskudd for ull og Skinn [Price Subsidies for Wool and Leather]; Landbruksdirektoratet: Oslo, Norway, 2021. [Google Scholar]

- Allwood, J.M.; Dunant, C.F.; Lupton, R.C.; Cleaver, C.J.; Serrenho, A.C.H.; Azevedo, J.M.C.; Horton, P.M.; Clare, C.; Low, H.; Horrocks, I.; et al. Absolute Zero: Delivering the UK’s Climate Change Commitment with Incremental Changes to Today’s Technologies; University of Cambridge: Cambridge, MA, USA, 2019. [Google Scholar]

- Salachna, A.; Marcol, K.; Broda, J.; Chmura, D. The Contribution of Environmental and Cultural Aspects of Pastoralism in the Provision of Ecosystem Services: The Case of the Silesian Beskid Mts (Southern Poland). Sustainability 2022, 14, 10020. [Google Scholar] [CrossRef]

- Sørensen, M.V.; Graae, B.J.; Hagen, D.; Enquist, B.J.; Nystuen, K.O.; Strimbeck, R. Experimental herbivore exclusion, shrub introduction, and carbon sequestration in alpine plant communities. BMC Ecol. 2018, 18, 29. [Google Scholar] [CrossRef]

- Whitehead, D. Management of Grazed Landscapes to Increase Soil Carbon Stocks in Temperate, Dryland Grasslands. Front. Sustain. Food Syst. 2020, 1–7. [Google Scholar] [CrossRef]

- Lazcano, C.; Gonzalez-Maldonado, N.; Yao, E.H.; Wong, C.T.; Merrilees, J.J.; Falcone, M.; Peterson, J.D.; Casassa, L.F.; Decock, C. Sheep grazing as a strategy to manage cover crops in Mediterranean vineyards: Short-term effects on soil C, N and greenhouse gas (N2O, CH4, CO2) emissions. Agric. Ecosyst. Environ. 2022, 327, 107825. [Google Scholar] [CrossRef]

| Property | Sheep Wool | Synthetic |

|---|---|---|

| Tenacity | Abrasion strength—medium Tenacity: 1.6 cN/tex [52] | Abrasion strength—high Tenacity: Polyamide (PA): 3.5–5.6 cN/tex; polyester (PET): 2.4–7.0 cN/tex [52] |

| Moisture absorption | Hydrophilic: Moisture regain: 14–18% [52] Hygroscopic: Absorbs up to 35% of its weight in moisture from the air [53] | Hydrophobic: Moisture regain: PA: 4–5%. PET: 0.2–0.4% [52] Polypropylene (PPE): Low hygroscopicity (0.4 ± 0.1%) [54] |

| Endothermic properties | Produces heat during absorption [54]. High heat production (+77 °C) and stays warm [54] Mulch greatly reduces variability in soil temperature and helps the soil retain moisture [55] | PPE: Low heat production (+0.5 °C) and cools quickly [54]. Synthetic mulch has little effect on soil moisture and temperature. |

| Thermal properties | Does not melt. | Thermoplastic: Melting temperature: PA 215 °C; PET 255 °C [52] |

| Flammability | Burns slowly; self-extinguishing Ignition temperature: ≈600 °C [56] | Melts. burns, high smoke. Ignition temperature: PA 530 °C; PET 440 °C [52] |

| Heat of combustion: 21 MJ/kg [52] | Heat of combustion: PA—3.1 MJ/kg; PET 25–30 MJ/kg [52] | |

| Limited oxygen index (LOI): 24–25% [52] | LOI: PA 20–24%; PET 20–22% [52] | |

| Thermal insulation | Comparable to currently used commercial synthetics [57] | Thermal resistance: PET 0.51 °C m2/W; Cotton (CO)/PET 0.49 °C m2/W [57] |

| Sound absorption | Similar or better acoustic properties than synthetic alternatives [58,59,60,61] Polish coarse wool: acoustic properties as Merino [62] | Fiberglass and polyurethane (PU) foam are less absorbent than wool [58,59,60,61]. |

| Sound isolation | Increases transmission loss of stud walls by up to 6 dB [59] Extremely good [57] | Similar to wool [57] |

| Antistatic ability | Residual voltage of ~42 from 90 starting voltage [63] | Residual voltage of ~88 from 90 starting voltage [63] |

| VOC-absorption | Absorbs volatile organic compounds (VOCs) and darkly pigmented fibers absorb more [64]. | Leaks VOCs [65] |

| Hypoallergenic properties | Lanoline in wool can cause allergies. Wool is hypoallergenic after scouring. Coarse wool fibers (≥30–32 μm) can cause cutaneous irritation (itching) [66]. | PET is used as an allergy-friendly alternative to, e.g., down in bedding. |

| Odor-prevention | The least odor retaining and lowest odor build-up of textile materials [67]. Airing has a good effect on the smell of sweat in wool [68] | PET and CO are the most odor-intensive textile fibers [67]. Airing does not affect the smell of sweat on synthetic materials [68]. |

| Biodegradability | Biodegradable; decomposes in 1–3 seasons depending on the type of soil [69,70,71] | Non-biodegradable; become microplastics in approx. 400 years [72] |

| Fertilizing capacity | Contains 10–12% nitrogen and 3–4% potassium, nitrogen compounds are released into soil during biodegradation; promotes growth of grass and other crops [69,70,71,73,74,75] | Fibers are not biodegradable and do not release nutrients promoting plant development |

| Herbicidal effect | Mulch decreases weeds in the fields [76] | Decreases weeds as a cover/blanket |

| Category | Product Type | Wool Type | Location * | Competition |

|---|---|---|---|---|

| Acoustic and sound-absorbing products | Wool felt Wool screens and panels Wool rugs and carpets | Merino wool, some coarser wool | AU, CH, DE, DK, ES, IE, IS, NL, NO, SE, UK | Screen dividers made from polyester felt or polyurethane acoustic foam. Rugs and carpets from polyester or other synthetic yarns. |

| Garden and cultivation | Wool garden felt | Unspecified | UK | Polypropylene textiles geotextiles for, e.g., erosion control during road construction and for garden felt to prevent weeds from growing. Burlap. |

| Wool garden felt | Unspecified RS wool | RS | ||

| Wool plant blanket | Unspecified AU/EU wool | AU | ||

| Wool fertilizer pellets | Surplus US coarse wool | US | Synthetic fertilizers from by-products of the petroleum industry or manure. | |

| Wool plant pots | US faulty wool hats | US | Plastic plant pots. | |

| Wool slug-repellent pellets | Unspecified wool waste | UK | Toxic slug repellents containing iron(III) phosphate, metaldehyde or methiocarb. | |

| Insulation | Batt or loose-fill insulation | Unspecified NZ wool | US | Stone or glass wool insulation for cars and housing. Polyester insulation for housing. |

| Wool roll insulation | Unspecified UK wool | UK | ||

| Insulating packaging for transport | Unspecified | UK | Plastic cooling elements and insulation. | |

| Bubble wool | Unspecified EE wool | EE | Plastic bubble wrap. | |

| Wool duvets | DK Shropshire wool | DK | Polyester or down duvets. | |

| Sanitary products | Technical wool materials for sanitary products | NZ strong wool | NZ | Polypropylene fabrics, polypropylene/polyester/cellulose fiber mix with chemical treatments. |

| Sanitary, makeup pads and diapers | Merino wool | CA | Single-use diapers and sanitary pads, mainly of plastic. | |

| Hygiene products (pads etc.) | Organic NZ wool | NZ | Single-use cotton pads and disposable wipes made of polyester or polypropylene mixed with cellulosic fibers. | |

| Other new products | Wool coffins | Merino wool | UK | Wood or plastic coffins: oil-based varnishes, synthetic fabric interiors. |

| Felted wool urns | Merino and DK wool | DK | Non-biodegradable urns, made of metal, ceramics, or polymer resin. | |

| Bio-resin “fiber wool” chair | UK Herdwick sheep wool | UK | Products made of conventional fiberglass using synthetic resin. | |

| “Fiber wool” boat | NZ strong wool | NZ | ||

| “Fiber wool” surfboard | NZ strong wool | USA/NZ |

| Products/Size | Micro (<10) | Small (<50) | Medium (<250) | Large (>250) | |

|---|---|---|---|---|---|

| Acoustic and sound-absorbing products | Felt | 1 * | 1 | ||

| Screens and panels | 6 * | 3 * | 3 | 2 | |

| Rugs and carpets | 2 | 1 | 2 | 2 | |

| Garden and cultivation | 2 * | 2 | 1 | ||

| Insulation | 4 | 1 * | |||

| Sanitary products | 3 * | ||||

| Other new products | 4 * | 1 * | 1 | ||

| Product | Wool | Polyester | PUR Acoustic Foam |

|---|---|---|---|

| Felt (m2) | 20–97 EUR | 6–7 EUR | 65–80 EUR |

| Space dividers | 2800–8000 EUR | 300–600 EUR | * |

| Obstacles | Opportunities |

|---|---|

| Standardization Large-scale production Focus on quantity and price Policy and regulations Missing local infrastructure and production facilities Consumer habits, perceptions, and knowledge | Product performance and innovation Local production Local job creation Focus on quality Preserving culture and heritage Sustainability Resilience Good resource utilization |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Løvbak Berg, L.; Klepp, I.G.; Sigaard, A.S.; Broda, J.; Rom, M.; Kobiela-Mendrek, K. Reducing Plastic in Consumer Goods: Opportunities for Coarser Wool. Fibers 2023, 11, 15. https://doi.org/10.3390/fib11020015

Løvbak Berg L, Klepp IG, Sigaard AS, Broda J, Rom M, Kobiela-Mendrek K. Reducing Plastic in Consumer Goods: Opportunities for Coarser Wool. Fibers. 2023; 11(2):15. https://doi.org/10.3390/fib11020015

Chicago/Turabian StyleLøvbak Berg, Lisbeth, Ingun Grimstad Klepp, Anna Schytte Sigaard, Jan Broda, Monika Rom, and Katarzyna Kobiela-Mendrek. 2023. "Reducing Plastic in Consumer Goods: Opportunities for Coarser Wool" Fibers 11, no. 2: 15. https://doi.org/10.3390/fib11020015

APA StyleLøvbak Berg, L., Klepp, I. G., Sigaard, A. S., Broda, J., Rom, M., & Kobiela-Mendrek, K. (2023). Reducing Plastic in Consumer Goods: Opportunities for Coarser Wool. Fibers, 11(2), 15. https://doi.org/10.3390/fib11020015