Abstract

A frequent problem in geotechnics is soils with inadequate physical–mechanical properties to withstand construction work, incurring cost overruns caused by their engineering improvement. The need to improve the engineering properties of soils is not recent. The most common current alternatives are binders such as cement and lime. The climate change observed in recent decades and the uncontrolled emission of greenhouse gases have motivated geotechnical and geoenvironmental researchers to seek mechanisms for soil reinforcement from a more sustainable and environmentally friendly approach by proposing the use of recycled and waste materials. An alternative is natural fibers, which can be obtained as waste from many agro-industrial processes, due to their high availability and low cost. Sawdust, as a by-product of wood processing, has a rough texture that can generate high friction between the fiber and the matrix of the soils, leading to a significant increase in its shearing strength and bearing capacity. This concept of improving the properties of soils using natural fibers distributed randomly is inspired by the natural phenomenon of grass and/or plants that, when growing on a slope, can effectively stabilize the said slope.

1. Introduction

Soil is one of the most important and most complex building materials that civil engineers commonly work with [1,2]. It is the result of complex geological processes of physical or chemical weathering of rocks and disintegration of organic matter [3,4,5]. Based on the size of particles, there are four types of soils: gravels, sands, silts, and clays [6]. Clays present the worst physical and mechanical properties due to their moisture content [7,8,9], during changes in weather conditions [10].

Civil engineers frequently face two different problems in their work: (1) soils with a low capacity to adequately resist the stress to which are exposed [11] and (2) clays with high plastic properties [12] due to their mineral composition of montmorillonite type, expandable illite, and vermiculite [8,13].

Soil stabilization is a technique used to improve mechanical properties of soils to increase their strength [14]. Fortunately, this improvement can be performed on a variety of terrains [15].

On the other hand, expansive soils present change in volume by variations in their moisture content [10,16,17], resulting in serious damage and distortions to the structures founded on them, particularly in buildings and light pavements [18,19], so one method to control their volumetric change is to stabilize them with additives that reduce their volumetric instability [20,21,22].

These characteristically have a high moisture absorption capacity resulting in an excessive volume change and undesirable qualities when soil is used in building foundations and road construction [23]. Although engineers try to avoid them, conditions of work have made this inevitable [19]. Globally, expansive soils have been identified as one of the main causes of faults for many buildings built on them [19,24]. For example, in the United States of America, annually, the cost of damages due to swelling problems exceeds USD 100 billion, while in the United Kingdom, the cost exceeds GBP 150 million [16,25].

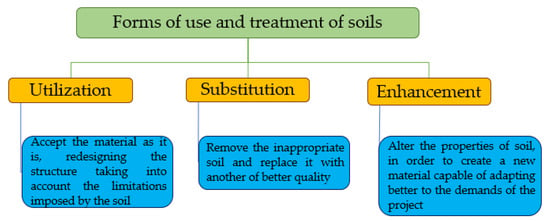

It is why there is a need to implement various alternatives for the improvement of soil’s physical and mechanical properties, related to strength and volume behavior of expansive soils [26,27]. According to Afrin [15], soil stabilization is a method of improving soil properties by blending and mixing other materials to improve the shearing strength parameters of soil, increasing the soil’s bearing capacity. Soil stabilization reduces the permeability and compressibility of the soil and increases its shear strength. Thus, most of the stabilization techniques are applied to improve the physical and mechanical properties of soils to guarantee structural stability of buildings [19,28,29,30,31], Figure 1 shows a scheme of the different alternatives related to the use of soil as a building material.

Figure 1.

Alternatives for use of the soils with deficient characteristics.

Currently, cement and lime are identified as the most used material for stabilizing expansive soils [32]. There have been several types of research that have been carried out on the stabilization of expansive soils with the use of these binding materials [9,20,33,34,35,36]. However, this type of treatment sometimes makes soils fragile, which is unfavorable in some dynamic load conditions, including traffic loads on pavement systems. Additionally, its production and use involve large amounts of energy and carbon dioxide emissions into the atmosphere [37].

In some cases, the improvements reached by these techniques are not required, i.e., in subgrade road projects [38,39], leading to the identification of cheaper materials as alternatives [15].

In recent decades, researchers and engineers have proposed numerous methods for the improvement of the mechanical properties of soils through mechanisms that are more environmentally friendly [40,41,42,43], i.e., the use of polypropylene [44], tire strips [45], and crushed tires [46], as well as the addition of artificial and natural fibers, such as fiberglass [7], coconut shell [47,48], water hyacinth [49], palm fibers [50], jute [51], kernel palm shells [5], and rice husk ash [52]. Similarly, some research has been observed on the use of electronic waste (e-waste) in activities to improve the engineering properties of soils [53,54].

All these studies are based on the concept of soil reinforcement using discrete fibers distributed randomly based on the natural phenomenon in which roots of grass and plants growing on a slope can effectively stabilize the terrain [55,56].

Innovative approaches are needed, by geotechnical and geoenvironmental engineers, towards sustainable soil stabilization and integrating the circular economy principles. In the best case, the circular economy contemplates the use of any waste produced (whether of domestic, municipal, or industrial origin) turning it into new and valuable materials that can be used in the economy as secondary raw materials [57,58,59,60].

According to Garg et al. [41], in developing countries, using natural fibers to improve the engineering properties of soils is promising, given that this type of material is easily obtained from the remains of fruits and plants used in the industry. Examples include the use of bamboo fibers [2], sisal fibers [61], coconut fibers [62], palm fibers [63], cane fibers [16], and jute fibers [64].

One of the most widespread economic activities in these developing countries is using and processing wood, which produces sawdust as waste [65,66]; according to Mwango et al. [67], many wood-producing countries annually generate more than 2 million m3 of this waste. This type of material is often disposed of in open dumps or through open-air burning, posing enormous environmental challenges related to climate change and destruction of ecosystems [68,69].

According to Sun et al. [18], there is limited research carried out on the stabilization of expansive soils using sawdust; and some research can be found on the use of this natural fiber in the elaboration of structural elements such as adobes [70,71], making evident the social, economic and environmental sustainability of building materials and soils improved with agricultural waste and by-products [72].

This work presents a review of the recent research on the use of natural sawdust fibers as an alternative for the improvement of soil properties, showing its potential use in construction because that waste from wood processing constitutes an abundant and low-cost material, easy to use, low density and similar mechanical properties of synthetic fibers, i.e., high strength-to-weight ratio [63]. Additionally, it tends towards an approach to an essential principle of sustainable development, since it is a low-cost technique, less polluting than those currently used, and therefore more environmentally friendly. The main motivation was to show information about the use of sawdust fibers as an alternative contemplated in the new trends in Geotechnical Engineering on the stabilization and/or reinforcement of soft soils using natural materials.

Figure 2 shows an outline of the types of products that can be obtained from wood waste, which constitute the main focus of the research papers reviewed and their possible use in improving the engineering properties of soils.

Figure 2.

Classification of the different types of wood waste.

This review is structured into a materials and methods section which describes the criteria for searching, classification and selection of articles, followed by a framework to introduce soils as a subject, their classification, and characteristics. This is followed by the description of soil stabilization as a technique to improve the properties of expansive soils with sawdust fiber and the concept of mercerization of natural fibers as the most widely used technique for the chemical treatment of fibers before their use. Subsequently, a description of the contributions of various authors in the stabilization of soils with sawdust fibers is made. Then, an analysis of results contained in articles is shown, indicating trends to that should be addressed, and a conclusions section established by the author.

2. Materials and Methods

2.1. Article Selection Criteria

For review process, papers published in English with the primary focus on the use of raw sawdust fibers for soil reinforcement worldwide were considered, excluding documents published in languages other than English. The review also considered papers published between 2015 and 2022. Articles to be considered should have been published in journals addressing the issue of improving mechanical properties of expansive soils by the addition of sawdust. Three different possible forms of sawdust were considered: chip, dust, or ash. Table 1 shows the selection criteria for the articles included in this review.

Table 1.

The inclusion and exclusion criteria.

2.2. Search Result

A total of 315 documents were retrieved from databases through Google Scholar (175), Science Direct (95), and Springer (45) that were used as search engines on the subject under investigation, with academic peer review which guarantees the quality of the information collected. Of the total papers collected, 60 were duplicates, and 125 were excluded based on their titles and/or abstracts, with no compatibility based on inclusion criteria. The final review included 43 articles on using natural sawdust fibers to improve soil engineering properties. In addition, 87 articles related to Geotechnical Engineering concepts and soil stabilization were included. To search for information, keywords were used at a first level such as: “soil reinforcement”, “soil stabilization”, “expansive soil reinforcement”, and “expansive soil treatment”; and in a second level with more specific phrases such as “soil reinforcement natural fibers”, “soil reinforcement sawdust fibers”, “soil improvement sawdust fibers”.

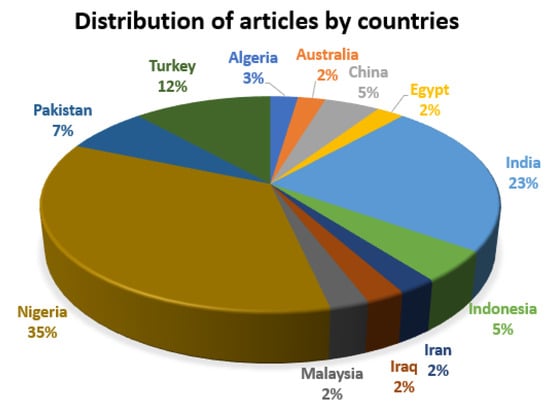

Figure 3 shows the worldwide distribution of the selected papers about fibers’ applications in expansive soils. It is important to note that research is carried out in countries from Asia, Africa, and Oceania mainly. This information allows visualizing, worldwide, the distribution and importance given in recent years towards the research of a more sustainable alternative for the improvement of physical and mechanical properties of soils. This work shows research published during the last seven years. While it is possible to have unanalyzed research, their motivations are likely similar.

Figure 3.

Distribution of articles in the world.

2.3. Information Analysis

The analysis of the information was based on the data extracted from the papers reviewed, considering the information on the type of sawdust fiber used and its characteristics, the laboratory tests carried out, country of origin, year of publication, the optimal dosage values, and organizing them in tables.

3. Soil Stabilization with Fibers

Soil reinforcement by adding fibers was used first in antiquity, around 5000 years ago, using straw and hay to reinforce mud blocks [73]. In modern history, French engineer Vidal was the first to stablish the soil reinforcement concept [74]. He showed that the addition of elements into a mass of soil improves the strength of the medium [75]. Consequently, after these results, there has been an increase in the use of fibrous materials for the improvement of expansive soils properties, as an imitation of the past [73].

Overall, 2000 types of plant fibers are available worldwide, e.g., wheat straw, coconut fiber, palm, kenaf, sugarcane bagasse, cotton, bamboo, wool, flax, maize, hemp, hay, jute, henequen, ramie, sisal, banana, and pineapple leaf [43], which could be used for soil reinforcement.

In general, the mixed fiber–soil combination behaves as a composite where fibers are embedded in a soil matrix [73]. Shear stresses on the ground are mobilized against tensile strength in the fibers, giving greater soil strength.

As proposed by Gowthaman et al. [75], soil reinforcement using natural fibers has gained momentum as a beneficial technique for improving properties of soils in geotechnical engineering due to its respect for the environment, the great possibility and abundance of resources, minimum energy consumption [76], cost-effectiveness, and high potential over other previously used materials. In addition, when these natural stabilizing materials are used to produce building materials, the resulting materials become more sustainable [77].

By carrying out a more rigorous analysis, the addition of natural fibers is more beneficial in terms of costs, energy efficiency, and health since these types of natural materials have less embodied energy and toxicity than previously used artificial materials [77].

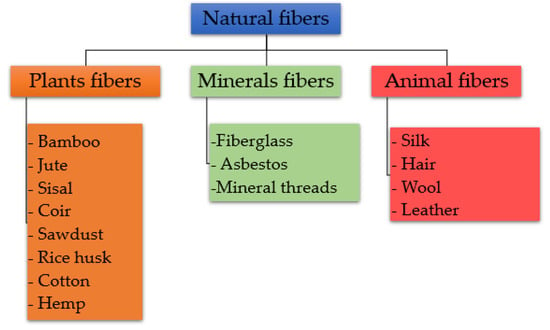

By consideration of their origin, natural fibers can be classified into three large groups: (1) vegetable fibers, (2) parts of animals containing proteins, and (3) minerals. Based on availability and applicability, geotechnical intentions refers to plant fibers in terms of natural fibers [75].

In Figure 4 we can see a scheme of the classification of natural fibers.

Figure 4.

Classification of natural fibers.

Plant fibers used for soil reinforcement can be classified into three categories of species: (1) cultivated, (2) uncultivated, and (3) invasive [75].

Table 2 shows some of the recent research carried out on improving soil characteristics with the use of natural fibers.

Table 2.

Summary of various natural fibers for soil reinforcement [78].

3.1. Mercerization of Natural Fibers

Some researchers claim that several drawbacks limit the potential of vegetable fiber to be used as an alternative to synthetic fibers [82,83], the main one is its hydrophilic nature [80] promoting a high absorption of water, which induces a low resistance to moisture and poor mechanical properties and dimensional stability of the compounds reinforced with them.

Currently, mercerization is one of the chemical treatments (alkaline treatment) of natural fibers most used in different applications to mitigate this limitation [84,85,86,87,88,89], which reduces the content of lignin, hemicellulose, waxes, and oils coating the surface of fibers [90,91], also increases the fibers surface roughness [82,84]. Among the substances used for the natural fibers treatment and coating to reduce their biodegradability, Boric Acid, Borax, Carbon Chloride (carbon tetrachloride), and Sodium Hydroxide (Sosa Caustic) are the most commonly used [75].

Equation (1) shows overall reaction mechanism of natural fiber with the alkaline agent sodium hydroxide (NaOH) [88].

In this method, the molecular structure of cellulose in natural fibers is modified by increasing the rate of fragmentation and disaggregation of fibers. In this process, amorphous regions are created where cellulose micromolecules are separated, leading to water filling the new spaces created [92]. Several studies on alkaline treatment report that mercerization increases the amount of amorphous cellulose by modification of crystalline cellulose [84].

The alkalizing OH groups break down and move out of the fiber structure, and an O-Na cell group of the fiber is created between the molecular cellulose chains of remaining molecules. Therefore, it reduces the amount of OH groups, the resistance of the fiber to moisture increases, and a certain amount of fiber components are extracted, such as hemicelluloses, lignin, pectin, wax, and oil. In this sense, the fibers surface become cleaner and more uniform, improving the ability to transfer stresses between cells [92].

John Mercer in 1851 described a method for changing the properties of cotton fibers by treating them with a concentrated alkaline solution. After removing the alkali, by rinsing with water and neutralizing it with acid, it was observed that the effects of the treatment on the properties of the cotton fibers were permanent for the subsequent wet finish [93].

In the implementation of this method, four possible options can be observed, namely (1) a constant concentration of NaOH for a constant period, (2) the use of different concentrations of NaOH for a constant period, (3) the maintenance of a constant concentration of NaOH for different periods, and (4) the use of different concentrations of NaOH for different periods [94], and the selection of one option is dependent on the type, chemical composition, and structure of natural fibers.

3.2. Sawdust

Sawdust is a lignocellulosic material, byproduct, or residue from a variety of woodworking-related processes, including sawing, routing, drilling, sanding operations, and furniture manufacturing. This type of waste can vary in shape and size depending on the wood’s sawing mechanism, including small chips, staple fibers, fine particles of wood, or calcined material (ash) [67,68,95].

Currently, the disposal of sawdust produced is in the open air at landfills or sometimes by open burning [26,36,37,68,96,97]. The sawdust disposal in landfills increases their load, and their burning contributes to greenhouse gas emissions, increasing the environmental impact produced [98].

The amount of sawdust produced from sawing depends on the efficiency of the sawmill, measured by the quality and quantity of sawn planks compared to the resulting wood waste. This wood residue is a combination of bark, sawdust, trimming, split wood, planer shavings, and sander powder [67]. According to Khan [61], about 10–13% of the total volume of wood logs is transformed into sawdust.

3.2.1. Soil Stabilization with Sawdust

Considering their great abundance and low cost, for some decades researchers have been given the task of studying their possible use as additives for soil reinforcement as an alternative proposal for the engineering improvement of their properties in geotechnical applications.

The experimental data available in the literature for soil reinforcement with sawdust are relatively limited. It has been observed that sawdust by itself is a non-cementitious material, but in the presence of moisture, lignin and cellulose present in sawdust serve as a surface active in the interaction of the soil–water–fiber system, generating a gel of high strength that can contribute to improving strength and compressibility of treated soils [18]. So, based on Karteek’s opinion [13], sawdust would give excellent results when used as a stabilizing material. Additionally, when sawdust is mixed with other materials that have binding properties such as lime, its use can produce better results [38,99].

Other options that have received significant recent attention include the study of modifications in the engineering properties of clay soils with the addition of sawdust in the form of ash (SDA) and ash sawdust with lime (SDAL) [99,100].

3.2.2. Sawdust-Based Biocomposites

In recent years there has been a sustainable approach to the use of sawdust in the elaboration of composites with applications in different fields of construction such as sawdust concrete, formwork, concrete blocks, and bricks [67,70], as well as the improvement of some engineering properties of soils [44,66] giving rise to the so-called biocomposites or sustainable composites [101], which can be a substitute for manufactured products such as steel and concrete, reducing potentially the fossil fuel consumption and greenhouse gas emissions [67,92,94].

Regarding soil stabilization, the union of sawdust with the soil matrix behaves as a composite material. It is well known that fibers improve the strength of the soil [44], and it is possible to increase even more their effect through chemical and physical treatments [90].

According to Gholampour, A. and Ozbakkaloglu [92], biocomposites can be classified into two large groups: (1) green compounds made up of bio-based resins and natural fibers and (2) partially green compounds made up of petrochemical resins and natural fibers.

4. Results

This section describes the research work carried out to study the improvement in the engineering properties of the soils with the use of sawdust fibers in the different disponible types such as sawdust chips, fine sawdust, and calcined sawdust, emphasizing the year of publication, the information on the materials used, the tests carried out, and their authors.

4.1. Sawdust Shavings

Sawdust shaving is the waste obtained when the wood is shaped or planed using carpentry tools or machines like planers and milling machines, varying the size and shape of the final waste.

Regarding research on its use in soil reinforcement, two articles were found, shown in Table 3.

Table 3.

Data of investigations with sawdust shaving fibers.

Related to research of addition of sawdust shavings on soil properties improvement, Mouissa et al. [102] studied the effects of percentages of sawdust (0.5, 1, 1.5, 2, and 2.5%) treated chemically with solutions of NaOH and KMnO4 on the thermal and mechanical properties of clay soil. Additionally, Jangid et al. [103] analyzed the improvement of mechanical properties of black cotton soil using sludge from Kota stone (15%) and certain percentages of sawdust (2.5, 5.0, 7.5, 10.0, and 12.5%).

4.2. Sawdust Powder

The sawdust powder is a waste byproduct of sawing, sanding, planning, and routing operations. It consists mainly of small particles of wood. Regarding research on its use in soil reinforcement, 19 articles were found, which are shown in Table 4.

Table 4.

Data of investigations with sawdust powder fiber.

In recent years, several studies have been carried out to witness the effect of sawdust powder on the mechanical properties of a variety of soil from different locations. In India the soil studied is black cotton, applying percentages of sawdust powder between 2 and 10% and marble dust between 2 and 10%, resulting in a maximum dry density (MDD) decreased with sawdust and increased with marble dust while the UCS value increased with the addition of marble powder. Additionally, the CBR value is greatly improved with the addition of sawdust [105]. Other research in India focused on the application of a combined sawdust powder with complementary stabilizers. A combination of sawdust and lime to improve mechanical properties of a marine clay soil from Kakinada region showed a decrease in the plasticity index and an increase in the value of the CBR and the optimal moisture content (OMC) for the value of fiber and binder used were observed [106]. Additionally the combination of sawdust powder with coir pith to apply in Palakkad soil increases OMC and decreases MDD, expansion pressure, and UCS [107]. In Turkey, research carried out on the application of pine sawdust powder passing the No. 4 sieve in Erzurum region soil showed a decrease in the MDD and an increase in the OMC and strength of unconfined compression with the increase in the percentage of sawdust added [1,108,109]; additionally, research carried out adding 1 to 5% of sawdust powder passing No. 20 sieve in Istanbul fine soil showed the strength to unconfined compression increased with an increase in the percentage of sawdust added, showing optima of 3% and 2% respectively. Permeability also increased with an increase in the percentage of sawdust added, while the PI, MDD, and OMC decreased. Research conducted in Nigeria is focused to improve the properties of lateritic residual soil with sawdust powder with a size smaller than sieve No. 40. Adding percentages between 2.5 and 15%, it was observed that plasticity and MDD decreased while OMC, CBR, and unconfined compressive strength increased due to the addition of sawdust [65]. Other research focused on the influence of sawdust powder on the geotechnical properties of tropical clay and bentonite from Covenant University, observing that the specific gravities, the Atterberg limits, the plasticity, the maximum dry unit weight, and the strength to unconfined compression decreased with an increasing percentage of sawdust in the soil, unlike the optimal moisture content and permeability that increased with an increase of the added sawdust [19]. In China, in a study using bamboo sawdust (BS) as a substitute for a new bio-based cementitious material, cement was replaced by BS treated with alkali in various percentages from 1 to 7% by mass in the mortar mixture, concluding that recycled BS can be a sustainable component to produce a lightweight and structural bio-based cementitious material, according to the minimum strength required in the Chinese specifications for the masonry mortar [113]. Other research analyzed the effect of the addition of various percentages of sawdust from 2.5 to 12.5% on the improvement of the expansive properties of clay soil (Illita) taken from the campus of the Nanjing Institute of Technology, observing a decrease in expansion potential and an increase in cohesion and internal friction angle as the percentage of sawdust added increased. Additionally, it was observed that the expansion potential decreases with an increase in vertical effort for all specimens and under the same vertical effort, the potential for expansion decreases with an increase in the amount of sawdust [18]. Research conducted in Indonesia examined the geotechnical properties of the expansive soil stabilized with the addition of percentages between 3 and 7% of Keruing sawdust, showing improved soil geotechnical properties by reducing plasticity index, but increasing unconfined compressive strength, and CBR, being an economical additive for expansive terrains [12]; other research analyzed the variation in the values of the shear strength of an expansive soil at the subgrade level during different curing periods when they are stabilized with different percentages of sawdust from 3 to 7% and lime, resulting in a significant reduction in the free expansion rate, plasticity index, and maximum dry density for a mixture of 3% sawdust and 3% lime. Moreover, an increase in optimal moisture content was observed. It was observed that the values of the strength to unconfined compression of soils treated with lime and sawdust are higher than soils treated only with sawdust [38]. In Australia, the effect of the addition of sawdust powder on the cohesion of yellow sand was analyzed, varying percentages from 3 to 10% produced a decrease in MDD and angle of friction while OMC and cohesion value increased with increasing of sawdust added [104]. Other research carried out in Egypt studied the effects of adding sawdust on the compressibility and shear strength characteristics of an organic clay from the city of Kafr Elsheikh where 5% cement was mixed with variable percentages of sawdust from 10 to 20%. It showed that the best results in the shear strength tests were obtained for a combination of 5% cement with 15% sawdust. While the combination of cement and sawdust gives better consolidation, the results are 5% cement with 10% sawdust [39]. Another study conducted in Pakistan analyzed the effect of the addition of variable percentages of the mixture of rice husk (0 to 21%) and sawdust (0 to 7%) applied to clay soil, mitigating their erosive potential and improving their parameters of shearing strength for the use on earthen embankments, observing that 5% sawdust and 15% rice husk are established as the optimal content for effective stabilization, and soil erosion control studied [112]. In Malaysia, the research analyzed the variation in the engineering properties of a peat-like soil with the addition of some percentages of sawdust varying from 2 to 5% and rice husk ash (RHA) with lime as an additive, as a result, it was observed a decrease in the value of the Atterberg limits, OMC, UCS, and MDD with the increase in the percentage of sawdust and rice husk ash added [24]. Other research developed in Iran, was focused on advancing a study of the improvement of the geotechnical properties of sandy soil with the addition of several percentages of zeolite and sawdust, resulting in the increase in OMC and a decrease in MDD with the use of sawdust, on the other hand, the increase in the percentage of sawdust (more than 4%) has reduced the strength of free compression of the soil [114].

4.3. Sawdust Ash

Sawdust ash (SDA) is the material resulting from the burning process of wood industry waste. Concerning research on its use in soil reinforcement, 22 articles were found, which are shown in Table 5.

Table 5.

Data of investigations with sawdust ash.

Sawdust ash is one of the most widely used alternatives for improving the mechanical properties of soils, due to the high content of silica-based components in its structure; research in different regions has evaluated the addition of sawdust ash to improve soil properties. In the last ten years, most research has been carried out in Nigeria using sawdust ash, analyzing the effect on mechanical properties on black cotton soil obtained at Adamawa State Polytechnic, showing that OMC decreased with an increase in the percentages of sawdust; complementary research carried out was focused on analyzing sawdust’s effect at different particle sizes; Ogundipe et al. [120] used sawdust ash passing through a No. 30 sieve, evaluating the effects of different compaction stresses on the strength of two lateritic soil samples (Ado-Ekiti and Ado-Iworoko road). It was observed that the MDD and plasticity index of natural and stabilized soils increases with increasing compaction efforts, while the optimal moisture content is reduced; in the research work conducted by Ilori and Udo [124], sawdust ash passing a No. 40 sieve was applied in lateritic soil in the city of Ile Ife. It was observed that 12% of SDA by weight of the soil investigated results in an optimal result of the geotechnical properties of the soil that allows the modified soil to be used efficiently and effectively; additionally, in research using sawdust ash passing a No. 70 sieve [119,122] applied in lateritic soil, an increase in the OMC and a decrease in the MDD and plasticity index were observed with the addition of the SDA mixture. Additionally, the UCS values were increased to a peak SDA value at a percentage of 6%; finest sawdust ash passing a No. 200 sieve [115,118,121,123] applied to lateritic soil and black cotton soil have evidenced that the addition of sawdust ash causes a decrease in the plasticity index (PI) and MDD, while OMC and CBR increases for maximum values obtained with a 4% addition of sawdust ash; additionally, complementary materials have been combined with sawdust ash to improve soil properties, like eggshell ash [116], lime [117], natural fibers of sisal table [66], and kernel palm shell ash [125], exhibiting considerable improvement of mechanical properties of soils, increasing MDD and decreasing OMC in the case of eggshell ash, while lime increased the durability index and natural fibers decreased the MDD while the OMC and UCS increased. Another region with abundant research on the use of sawdust ash is India, where studies carried out varying percentages of sawdust ash addition, ranging from 2% and up to 25%, showed that CBR and OMC increased while MDD decreased for a clay soil from Rajouri region [93] and the expansive soil from Sitarganj region [126], but increasing percentage addition of sawdust ash applied to black cotton soil from Kadapa region increased the MDD value and the permeability coefficient decreased [128]; other research shows that the addition of sawdust and coconut fiber on a kaolinitic clay from Kerala region caused the OMC and strength of the clay to increase, while a decrease in its MDD was observed. Additionally, the effect of adding some percentages of the mixture of sawdust ash and lime (SDAL) in an expansive black cotton soil [127] was analyzed. To improve compressive strength and swelling characteristics and increase its suitability use in construction, it was observed that MDD and UCS have a peak of 2% SDAL content and then decrease while the OMC decreases with an SDAL content of 1%, increases to a content of 2%, and then decreases with an increase in SDAL. Furthermore, CBR value increases up to 2% of SDAL and thereafter decreases; complementary research carried out adding sawdust ash and fly ash on a lateritic soil from Soraba Taluk region [129] showed that the expansion rate and plasticity index decreased and CBR increased with the percentage of addition, while the MDD increased for an addition of 10% and then decreased, showing similar behavior to OMC that increased to an addition of 20% and then decreased. Research carried out on Tarnab soil, in Pakistan, with the addition of sawdust ash [61] and expansive clay soil of the city of Istanbul adding SDAL [99], in Turkey, although research is carried out in Pakistan, showed that the liquid limit and the plastic limit decreased as the content SDAL increased; in contrast, this caused an increase in shearing strength. Additionally, it was observed that the permeability coefficient of the samples stabilized with SDAL in Istanbul soil was relatively higher than that of the non-stabilized samples [99] while in Tarnab, soil permeability was reduced with the increase of sawdust ash. Another project focused on studying the stabilization of the clay soil from the Al-Maymunah region, Iraq, with the addition of different percentages of sawdust ash [130], showed a reduction in specific gravity and MDD, as well as a reduction in compression coefficients (Cc and Cr) with an increase in SDA content additionally, an increase in OMC and shearing strength was observed with the increase in the SDA content.

5. Discussion

Next, we will analyze the information obtained from the 43 scientific articles reviewed on the use of sawdust in soil engineering improvement. This analysis was carried out concerning the type of wood waste used, the year and country of origin of the publications, the characteristics of the fiber such as the form of distribution of the fibers, the percentage of fibers added according to the weight of dry soil, the surface treatment alternatives for the fibers, the binder types added to the soil/fiber mixture, and the response variables corresponding to the characteristics of the soil such as its behavior before compaction, the parameters of resistance to cutting, and its bearing capacity.

5.1. Types of Waste from Sawdust Fibers

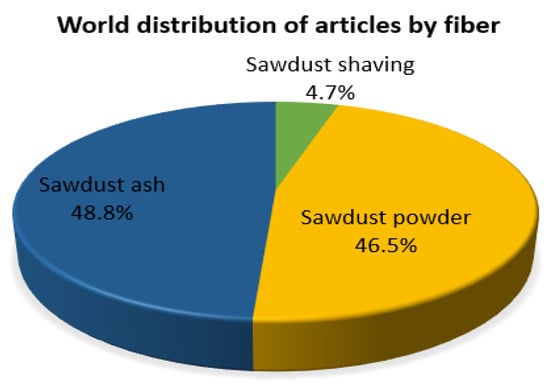

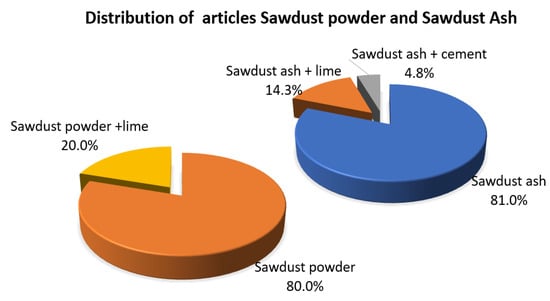

Figure 5 shows the distribution of the articles studied, based on the type of waste used from the waste of the wood industry. There is a general trend toward the use of sawdust in the form of calcined waste (22 articles) and dust (19 articles) in the total sample analyzed (43 articles).

Figure 5.

Distribution of articles by type of sawdust fiber.

This is mainly due to the high specific surface area of the material in the aforementioned states, which contributes notoriously to its better interaction with the matrix of the treated soil. In turn, the preference of many researchers for the use of sawdust ash is based mainly on its high silica content and the cementitious properties caused by pozzolanic reactions between it and the water of soils [9], which significantly impact the results obtained from improving the engineering properties of treated soils. However, its use has several drawbacks that reduce its sustainability, requiring its prior calcination, with the consequent consumption of energy, the emission of greenhouse gases, and the dispersion of flying particles in the environment.

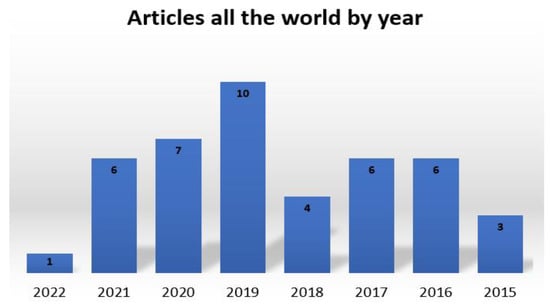

5.2. Year and Country of Publication

Figure 6 presents the distribution of the articles of research reviews by their year of publication. It shows that, although the current production is not very high, there is a nascent interest in geotechnical research with a sustainable approach, by giving added value to waste biomaterials and reincorporating them into the production chain, proposing their use in the reinforcement of clay soils, considering the large production of this type of waste, its inadequate final disposal and the environmental pollution produced.

Figure 6.

Distribution of research papers by year.

Additionally, Figure 7 shows the distribution by country of the analyzed articles. This information allows us to visualize the global trend of research focused on the use of natural fibers, as an ecological material in the reinforcement of expansive soils. It is observed that, of the research projects carried out with sawdust powder, 79% (15 out of 19) were conducted on the Asian continent, while 59% of the research conducted with sawdust ash (13 out of 22) was conducted on the African continent.

Figure 7.

Distribution of articles by country in the world.

Additionally, it is observed that more than a third of these (35%) correspond to material produced in the Federal Republic of Nigeria (Africa), with second place for the Republic of India (Asia) with 23%, so that over half of the works analyzed (58%) correspond to research carried out in the most populous country in Africa and second most populous country in Asia (trending to first place). Countries with high agricultural production and waste generation, with poor disposal practices, generate an environmental problem. This opens the opportunity to study sustainable alternatives to take advantage of this industrial waste in the reinforcement and improvement of physical and mechanical properties of soils.

5.3. Types of Soils Treated

The soils used by most researchers to analyze the incidence of the addition of variable percentages of sawdust fibers correspond to clay soils that have high plasticity and expansiveness, among which black cotton, marine clays, peat, lateritic soils, and in some cases materials corresponding to clay sands or silty sands of medium plasticity were used. This is mainly due to clays being the soils with the worst engineering characteristics and great abundance on the planet.

5.4. Fiber Orientation

One of the variables that affect the behavior of fiber-reinforced soil is the orientation of these within the soil matrix [83,90]. This arrangement can be made using oriented fiber distribution (OFD) and random fiber distribution (RDF). But it is only through the second method that the homogeneity of the obtained mixture can be guaranteed. Of the research analyzed, 95% used sawdust powder and sawdust ash, and although neither explicitly reported the type of distribution of their fibers, it is understood that for these materials a random distribution of the fibers in the soil was used. Additionally, of the two investigations that used sawdust shavings, only Mouissa et al. [102] reported the random distribution of the fibers.

5.5. Fiber Length and Size

In the investigations analyzed, the size of the fibers added to the soils is variable. Concerning the studies that used sawdust ash, although it has particle sizes similar to cement (less than 75 μm), it is observed that in some investigations the material was used as it was after calcination [9,31,79,80,117,125,128,129], while in others the material was selected and screened through sieves of openings between 600 mm and 75 μm (sieve No. 30 and sieve No. 200). Regarding the investigations that used powder sawdust [1,8,36,48,72,78,108,109,110], it was observed that these were screened with sieves of openings between 4.75 mm and 0.42 mm (Sieve No. 4 and Sieve No. 40). As far as the investigations using sawdust shavings [102,103] are concerned, none of them report the size of the fibers used.

5.6. Added Percentage of Fibers

Considering the variety of wood species that could be used in the different investigations, which depend fundamentally on the availability in each country and that affect the physical and chemical characteristics of the fibers, the variation in the type of sawdust fiber used leads to the percentages of addition of these to the soils were variable. Addition ranges of 0.5 to 12.5% of the dry weight of the soil are common when sawdust shaving is used, while addition from 0.5 to 20% is used in sawdust powder research carried out, and finally, addition between 1 to 30% is reported for research related to sawdust ash. This leads to establishing the effect of the variety of wood species and the type of soil in considering the percentage of fibers added to reach the optimal content to improve the mechanical properties of clay soils.

5.7. Component Mixing Method

Although the texts of the articles analyzed do not report the mixing method, it is considered that a manual mixing of the soil with different fibers facilitates achieving homogeneity of the mixtures at the level of laboratory tests. This is because, in the laboratory, the volume of soil and fiber used is small.

5.8. Fiber Surface Treatment

In the two investigations in which the use of sawdust in the form of shavings was chosen it was observed that, for one of them, a previous surface treatment of the same kind was used to improve their properties and the interaction with the treated soil [102], choosing sodium hydroxide (NaOH) and potassium permanganate (KMnO4), as an activating agent. In this sense, mercerization, or alkaline treatment, is the method used for the surface modification of the fibers and improving their adhesion with the soil matrix, compared to other available methods.

5.9. Additives to the Soil/Fiber Mixture

Another aspect of great importance studied corresponds to the use of a binder additive. Figure 8 shows that a significant percentage (approximately 20%) of the investigations carried out with sawdust fibers in the state of ash or dust used as an additive a binder such as lime or cement. This is based on the search to improve the results in the engineering improvement of soils. It should be noted that 80% of the research in the African continent where the addition of binders to soil and fiber mixtures was chosen corresponds to the country of Nigeria [117,119,122,123], while 67% of the investigations in the Asian continent with the use of binders to the mixtures of soil and fiber correspond to the country of India [106,127].

Figure 8.

Distribution of articles of sawdust powder and sawdust ash.

5.10. Results of Improvement of Soil Properties

According to Vettorelo and Clariá [83], some variables affect the behavior of soils with the addition of sawdust fibers, some of them attributable to fiber and others to the soil, namely: (1) Characteristics of the fiber (type of fiber, length, shape, aspect ratio (length–diameter), roughness). (2) Soil characteristics (particle size, shape, and roughness; moisture content; among others).

In general, properties analyzed in most research carried out were optimal moisture content plasticity properties that reduced their value during the addition of fiber, while properties like maximum dry density and unconfined compression strength increased their value.

Based on this, it is possible to observe a wide variability of the optimal percentages of the added fibers reported, which produce the maximum improvement in the engineering properties of the treated soils. This can be attributed mainly to the chemical composition of the fiber used, particle size, shape, and aspect ratio. Additionally, there is a deterioration of soil properties for percentages of addition above optimal values.

6. Conclusions

Although the technique of reinforcing soils with natural fibers dates back to time immemorial, in recent decades the interest in this study for applications in geotechnical engineering has grown, seeking to contribute to solving major environmental problems produced by the large volume generated in some agro-industrial processes and their inadequate final disposal, from a sustainable approach to the circular economy, seeking reuse, and giving added value to this type of waste that can have high availability in certain areas of the planet and its mechanical characteristics comparable with commonly used materials.

It is important to note that, in Latin America, research work on the use of sawdust fibers as soil reinforcement is scarce, predominating mainly in Asia and Africa. This opens an area of interest to work on the use of this type of highly available waste in the developing countries of America, for its identification and use as alternative material for the reinforcement of expansive clay soils, and thus also minimize the amount of industrial waste that is deposited in the environment and causes environmental pollution.

The main objective of the literature review is to better understand the scope and results obtained in some of the research developed for the analysis of variations in the engineering properties of soils when reinforcing them with the addition of sawdust fibers as an alternative in the field of sustainable geotechnics.

The study of the existing literature reveals that there is currently limited research carried out regarding the reinforcement of soils with expansive characteristics using sawdust fibers compared to other traditional materials that have been used commercially like cement or lime.

Sawdust, in the form of powder and chips, can be used to manufacture construction compounds with a high modulus of elasticity, water absorption, and strength characteristics that can meet international specifications in the field of civil and geotechnical engineering.

Sawdust powder by itself has little cementing value, but in the presence of moisture from the medium, it can react chemically and form certain cementitious compounds, to which the improvement of the strength and compressibility properties of soils can be attributed. In addition, it is estimated that, due to the rough texture of its surface, this type of fiber can produce high friction that affects the improvement of the resistance of the soil.

The creation of a value chain from this type of waste would contribute significantly to the creation of new jobs and additional income for the personnel who work with them. In the same way, it would generate a decrease in the environmental impact produced by its inadequate disposition and disposal and finally would lead to a reduction in the costs of construction projects. It is important to note that the materials that can be used as fibers are very low cost, making this type of reinforcement highly competitive against the alternatives widely used today.

Soil reinforcement with the use of natural fibers can be performed through the use of conventional construction equipment. Compaction of fiber-reinforced soil can be carried out with traditional compaction methods without the risk of damaging induced improvements in the soil.

This type of technique to improve the engineering properties of soils is not affected by climatic conditions, unlike other methods of reinforcement and/or stabilization, such as the addition of cement or lime.

It is important to consider the possibility of using a primary binder (cement) in combination with a secondary binder (sawdust ash) in the stabilization of clay soil for use as an effective road construction material.

New cementitious materials based on alkali-activated binders have recently become a promising sustainable alternative to conventional bonding materials. Alkali-activated bonding materials are a binder of the future for the following reasons: no high temperature is needed, there is no CO2 emission from reactions, and primary materials can be obtained from waste.

The cellulose content present within sawdust cells is primarily responsible for providing strength to the fiber. Lignin works by minimizing biodegradation caused by microorganisms. Hemicellulose is primarily responsible for moisture absorption and biodegradation. Therefore, exploring the use of sawdust fiber will not only help improve soil reinforcement but can also help mitigate the environmental impact produced by the poor final disposal of this waste.

In summary, the various advantages of sawdust fibers are low density, low cost, low energy consumption, comparable mechanical properties, and also better elasticity than polymeric compounds reinforced with natural fibers, so the opportunity to conduct similar studies in other parts of the world is opened. Where sawdust fibers are easily available as a waste material of the wood industry, that allows expanding the knowledge about this new technique to improve the engineering properties of the soils.

Other Research Priorities

According to the literature review carried out, the authors consider that the objectives for future research on the use of waste lignocellulosic materials in the improvement of the engineering properties of soils should include the following aspects, but are not limited to them:

- –

- Encourage the use of materials of natural origin more respectful of the environment, which contribute to the reduction of greenhouse gas emissions produced, in many cases, by the techniques currently used in soil reinforcement.

- –

- Analysis of the different sources of supply and procurement of sawdust fibers as one of the residues of the wood industry. Based on the underestimation of the actual volume of sawdust produced by an appreciable number of sawmills not officially registered.

- –

- Study of the biodegradability of sawdust as a drawback for its use and analysis of the efficiency of the different chemical treatment alternatives before its addition to soils.

- –

- The validation and standardization of the experimental results obtained for the mechanical properties of sawdust fibers after alkaline treatment are necessary to optimize the pretreatment processes and the methodology of application of the fiber in the soil reinforcement.

- –

- More detailed analysis of the effects of curing time on the parameters of mechanical strength of soils reinforced with sawdust fibers previously subjected to alkaline treatments.

- –

- More thorough analysis of factors that may affect the strength of sawdust-reinforced soils, for example, fiber length, the ratio of fiber percentage to soil mass, and coefficient of friction between fiber and soil,

- –

- More detailed study of variables such as age, type of wood species, soil moisture, the climate in the chemical composition (cellulose, lignin, and hemicellulose content), and mechanical properties of sawdust fibers, and their impact on the engineering improvement of soils.

Soil stabilization using natural fibers is a relatively new technique for the improvement of the engineering properties of soils, so there is not much information available in this regard or for the implementation of this type of technique. Further research is required in fields related to the incidences of factors such as the conditions of mixing of the fibers with the soil (manually or with mixer machine), optimal compaction energy, thicknesses of the layers to be compacted affect the results, as well as the durability of composites due to possible biodegradation of the fibers used. Considering the latter, there is not much information about how to evaluate the durability of the addition of fibers in the engineering properties of soils, however, some researchers have been analyzing the incidence of curing time (Butt [97], Niyomukiza [38], Yarbasi [1], Sani [66], Yousefi [114], and Obeta [117]) in the values obtained from the properties of soils that have been modified with the addition of this type of materials, to identify the time in which it is possible to achieve the best performance. In the same way, it is important to continue with the investigations to measure the effects of time (durability) on the values of soil parameters with the addition of this type of biomaterials.

Author Contributions

C.J.M.-M., L.C.S.H., S.A.Z.-C., R.V.-O., D.R.-G. wrote, coordinated, reviewed, and contributed to the scientific aspects of the article. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Request the corresponding author of this article.

Acknowledgments

C.J.M.-M. thanks, CONACYT for assigning the scholarship to study a doctorate in engineering sciences at the Instituto Tecnologico Superior de Misantla (ITSM) whose support facilitated the publication of this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yarbaşı, N.; Kalkan, E. Stabilization of Clayey Soils by Using the Organic Waste-Material. Int. J. Sci. Eng. Appl. 2020, 9, 129–132. [Google Scholar] [CrossRef]

- Brahmachary, T.K. Rokonuzzaman Investigation of random inclusion of bamboo fiber on ordinary soil and its effect CBR value. Int. J. Geo-Eng. 2018, 9, 10. [Google Scholar] [CrossRef]

- Duque Escobar, G.; Escobar Potes, C.E. Geomecánica. In Ingeniería Civil; Universidad Nacional de Colombia: Bogotá, Colombia, 2016. [Google Scholar]

- Khan, A.N.; Ansari, Y.; Mahvi, S.; Junaid, M.; Iqbal, K. Different Soil Stabilization Techniques. Int. J. Adv. Sci. Technol. 2020, 29, 7778–7791. Available online: https://www.researchgate.net/publication/350630921 (accessed on 26 August 2022).

- Ale, T.O. Effect of drying temperature on the engineering properties of stabilised and natural soils for road construction. Eng. Herit. J. 2020, 6, 19–26. [Google Scholar] [CrossRef]

- Das, B.M.; Sivakugan, N. Fundamentals of Geotechnical Engineering; Cengage Learning: Boston, MA, USA, 2020. [Google Scholar]

- Garg, R.; Biswas, T.; Alam, D.; Kumar, A.; Siddharth, A.; Singh, D.R. Stabilization of expansive soil by using industrial waste. J. Phys. Conf. Ser. 2021, 2070, 012238. [Google Scholar] [CrossRef]

- Amakye, S.Y.; Abbey, S.J. Understanding the performance of expansive subgrade materials treated with non-traditional stabilisers: A review. Clean. Eng. Technol. 2021, 4, 100159. [Google Scholar] [CrossRef]

- Dayioglu, M.; Cetin, B.; Nam, S. Stabilization of expansive Belle Fourche shale clay with different chemical additives. Appl. Clay Sci. 2017, 146, 56–69. [Google Scholar] [CrossRef]

- Al-Kalili, A.; Ali, A.S.; Al-Taie, A.J. A Review on Expansive Soils Stabilized with Different Pozzolanic Materials. J. Eng. 2022, 28, 1–18. [Google Scholar] [CrossRef]

- Wani, I.Y.; Khurshid, M.T.; Sharma, N. Analysis of Geotechnical Properties of an Expansive Soil Mixed with Polypropylene, Saw Dust Ash and Egg Shell Powder. Int. J. Eng. Appl. Sci. Technol. 2019, 4, 376–381. [Google Scholar] [CrossRef]

- Niyomukiza, J.B.; Wardani, S.P.R.; Setiadji, B.H. The influence of Keruing Sawdust on the geotechnical properties of expansive Soils. IOP Conf. Ser. Earth Environ. Sci. 2020, 448, 012040. [Google Scholar] [CrossRef]

- Asuri, S.; Keshavamurthy, P. Expansive Soil Characterisation: An Appraisal. INAE Lett. 2016, 1, 29–33. [Google Scholar] [CrossRef]

- Mahima, D.; Sini, T. Effect of Sawdust Ash and Coir Fibre on the Strength Characteristics of Kaolinite Clay. Int. J. Eng. Res. Technol. 2019, 8, 1269–1272. [Google Scholar]

- Afrin, H. A Review on Different Types Soil Stabilization Techniques. Int. J. Transp. Eng. Technol. 2017, 3, 19. [Google Scholar] [CrossRef]

- Dang, L.C. Enhancing the Engineering Properties of Expansive Soil Using Bagasse Ash and Hydrated Lime. GEOMATE J. 2016, 11, 2447–2454. [Google Scholar] [CrossRef]

- Charis, G.; Danha, G.; Muzenda, E. A review of timber waste utilization: Challenges and opportunities in Zimbabwe. Procedia Manuf. 2019, 35, 419–429. [Google Scholar] [CrossRef]

- Sun, S.; Liu, B.; Wang, T. Improvement of Expansive Soil Properties Using Sawdust. J. Solid Waste Technol. Manag. 2018, 44, 78–85. [Google Scholar] [CrossRef]

- Akinwumi, I.I.; Ojuri, O.O.; Ogbiye, S.A.; Booth, C.A. Engineering properties of tropical clay and bentonite modified with sawdust. Acta Geotech. Slov. 2017, 14, 47–56. [Google Scholar]

- Puppala, A.J.; Pedarla, A. Innovative ground improvement techniques for expansive soils. Innov. Infrastruct. Solut. 2017, 2, 24. [Google Scholar] [CrossRef]

- James, J. Sugarcane press mud modification of expansive soil stabilized at optimum lime content: Strength, mineralogy and microstructural investigation. J. Rock Mech. Geotech. Eng. 2020, 12, 395–402. [Google Scholar] [CrossRef]

- Gomes Correia, A.; Winter, M.G.; Puppala, A.J. A review of sustainable approaches in transport infrastructure geotechnics. Transp. Geotech. 2016, 7, 21–28. [Google Scholar] [CrossRef]

- Ikeagwuani, C.C.; Agunwamba, J.C.; Nwankwo, C.M.; Eneh, M. Additives optimization for expansive soil subgrade modification based on Taguchi grey relational analysis. Int. J. Pavement Res. Technol. 2021, 14, 138–152. [Google Scholar] [CrossRef]

- Hamzah, N.; Yusof, N.M.; Rahimi, M.I.H.M. Assessment of compressive strength of peat soil with sawdust and Rice Husk Ash (RHA) with hydrated lime as additive. MATEC Web Conf. 2019, 258, 01014. [Google Scholar] [CrossRef]

- Faezehossadat, K.; Jeff, B. Expansive Soil: Causes and Treatments. I-Manager’s J. Civ. Eng. 2016, 6, 1–13. [Google Scholar] [CrossRef]

- Ikeagwuani, C.C.; Nwonu, D.C. Emerging trends in expansive soil stabilisation: A review. J. Rock Mech. Geotech. Eng. 2019, 11, 423–440. [Google Scholar] [CrossRef]

- Oluremi, J.R.; Elsaigh, W.A.; Ikotun, B.D.; Osuolale, O.M.; Adedokun, S.I.; Oyelakin, S.E.; Ayodele, O.P. Strength enhancement in high silica wood ash stabilized lateritic soil using sodium tetraoxosulphate VI (Na2SO4) as activator. Int. J. Pavement Res. Technol. 2020, 14, 410–420. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, B. Strength and Deformation Behavior of Fiber-Reinforced Cohesive Soil Under Varying Moisture and Compaction States. Geotech. Geol. Eng. 2017, 35, 1767–1781. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Guney Olgun, C.; Firoozi, A.A.; Baghini, M.S. Fundamentals of soil stabilization. Int. J. Geo Eng. 2017, 8, 26. [Google Scholar] [CrossRef]

- Selvakumar, S.; Soundara, B. Swelling behaviour of expansive soils with recycled geofoam granules column inclusion. Geotext. Geomembr. 2019, 47, 1–11. [Google Scholar] [CrossRef]

- Bordoloi, S.; Yamsani, S.; Garg, A.; Sreedeep, S.; Borah, S. Study on the efficacy of harmful weed species Eicchornia crassipes for soil reinforcement. Ecol. Eng. 2015, 85, 218–222. [Google Scholar] [CrossRef]

- Owamah, H.; Atikpo, E.; Oluwatuyi, O.; Oluwatomisin, A. Geotechnical properties of clayey soil stabilized with cement-sawdust ash for highway construction. J. Appl. Sci. Environ. Manag. 2017, 21, 1378. [Google Scholar] [CrossRef]

- Chittoori, B.; Neupane, S. Evaluating the Application of Microbial Induced Calcite Precipitation Technique to Stabilize Expansive Soils. In Proceedings of the Tunneling in Soft Ground, Ground Conditioning and Modification Techniques: Proceedings of the 5th GeoChina International Conference 2018–Civil Infrastructures Confronting Severe Weathers and Climate Changes: From Failure to Sustainability, Hangzhou, China, 23–25 July 2018; pp. 10–19. [Google Scholar] [CrossRef]

- Kang, X.; Kang, G.-C.; Chang, K.-T.; Ge, L. Chemically Stabilized Soft Clays for Road-Base Construction. J. Mater. Civ. Eng. 2015, 27, 04014199. [Google Scholar] [CrossRef]

- Mahedi, M.; Cetin, B.; White, D.J. Performance Evaluation of Cement and Slag Stabilized Expansive Soils. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 164–173. [Google Scholar] [CrossRef]

- Miao, S.; Shen, Z.; Wang, X.; Luo, F.; Huang, X.; Wei, C. Stabilization of Highly Expansive Black Cotton Soils by Means of Geopolymerization. J. Mater. Civ. Eng. 2017, 29, 04017170. [Google Scholar] [CrossRef]

- Adedokun, S.I.; Oluremi, J.R. A review of the stabilization of lateritic soils with some agricultural waste products. Int. J. Eng. 2019, 17, 63–74. [Google Scholar]

- Niyomukiza, J.B.; Wardani, S.P.R.; Setiadji, B.H. The Effect of Curing Time on the Engineering Properties of Sawdust and Lime Stabilized Expansive Soils. In Proceedings of the 2nd International Symposium on Transportation Studies in Developing Countries (ISTSDC 2019), Kendari, Indonesia, 1–3 November 2019; pp. 157–161. [Google Scholar] [CrossRef]

- Agaiby, S.; Hassan, A.W.; Dakhli, A.H.; Elhakim, A. Sawdust Effect on Compressibility and Shear Strength Characteristics of Highly Organic Clay. ERJ. Eng. Res. J. 2022, 45, 379–387. [Google Scholar] [CrossRef]

- Afolayan, O.D.; Olofinade, O.M.; Akinwumi, I.I. Use of some agricultural wastes to modify the engineering properties of subgrade soils: A review. J. Phys. Conf. Ser. 2019, 1378, 022050. [Google Scholar] [CrossRef]

- Garg, A.; Bordoloi, S.; Mondal, S.; Ni, J.-J.; Sreedeep, S. Investigation of mechanical factor of soil reinforced with four types of fibers: An integrated experimental and extreme learning machine approach. J. Nat. Fibers 2018, 17, 650–664. [Google Scholar] [CrossRef]

- Dauda, D.; Dominic, M. Effectiveness of agricultural wastes in soil stabilization. Sustain. Agric. Food Environ. Res. 2022, 10, 14. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Ahmad, A. A Comprehensive Review of Types, Properties, Treatment Methods and Application of Plant Fibers in Construction and Building Materials. Materials 2022, 15, 4362. [Google Scholar] [CrossRef]

- Darvishi, A.; Vosoughifar, H.; Saeidijam, S.; Torabi, M.; Rahmani, A. An experimental and prediction study on the compaction and swell–expansion behavior of bentonite clay containing various percentages of two different synthetic fibers. Innov. Infrastruct. Solut. 2020, 5, 31. [Google Scholar] [CrossRef]

- Irani, N.; Ghasemi, M. Effect of scrap tyre on strength properties of untreated and lime-treated clayey sand. Eur. J. Environ. Civ. Eng. 2019, 25, 1609–1626. [Google Scholar] [CrossRef]

- Saberian, M.; Khotbehsara, M.M.; Jahandari, S.; Vali, R.; Li, J. Experimental and phenomenological study of the effects of adding shredded tire chips on geotechnical properties of peat. Int. J. Geotech. Eng. 2018, 12, 347–356. [Google Scholar] [CrossRef]

- Danso, H.; Martinson, B.; Ali, M.; Williams, J. Physical, mechanical and durability properties of soil building blocks reinforced with natural fibres. Constr. Build. Mater. 2015, 101, 797–809. [Google Scholar] [CrossRef]

- Jayasree, P.K.; Balan, K.; Peter, L.; Nisha, K.K. Volume Change Behavior of Expansive Soil Stabilized with Coir Waste. J. Mater. Civ. Eng. 2015, 27, 04014195. [Google Scholar] [CrossRef]

- Vardhan, H.; Bordoloi, S.; Garg, A.; Garg, A. Compressive strength analysis of soil reinforced with fiber extracted from water hyacinth. Eng. Comput. 2017, 34, 330–342. [Google Scholar] [CrossRef]

- Irani, N.; Ghasemi, M. Effects of the inclusion of industrial and agricultural wastes on the compaction and compression properties of untreated and lime-treated clayey sand. SN Appl. Sci. 2020, 2, 1660. [Google Scholar] [CrossRef]

- Wei, L.; Chai, S.X.; Zhang, H.Y.; Shi, Q. Mechanical properties of soil reinforced with both lime and four kinds of fiber. Constr. Build. Mater. 2018, 172, 300–308. [Google Scholar] [CrossRef]

- Bastasaa, J.D.; Roxasa, A.J.B.; Sagayapa, K.D.; Salurioa, R.R.L.; Sampayana, J.O.; Taniñasa, H.L.; Amatosa, T.A., Jr. Swell Classification Analysis for Re-engineering Expansive Soil using Agricultural Waste Materials. Int. J. Appl. Eng. Res. 2019, 14, 2399–2404. Available online: https://www.researchgate.net/publication/333770206 (accessed on 18 August 2022).

- Kumar, J.K.; Kumar, V.P. Experimental analysis of soil stabilization using e-waste. Mater. Today Proc. 2019, 22, 456–459. [Google Scholar] [CrossRef]

- Chaugule, M.; Deore, S.; Gawade, K.; Tijare, A.; Banne, S. Improvement of Black Cotton Soil Properties Using E-waste. IOSR J. Mech. Civ. Eng. 2017, 14, 76–81. [Google Scholar] [CrossRef]

- Veylon, G.; Ghestem, M.; Stokes, A.; Bernard, A. Quantification of mechanical and hydric components of soil reinforcement by plant roots. Can. Geotech. J. 2015, 52, 1839–1849. [Google Scholar] [CrossRef]

- Wang, F.; Han, J.; Khatri, D.K.; Parsons, R.L.; Brennan, J.J.; Guo, J. Field Installation Effect on Steel-Reinforced High-Density Polyethylene Pipes. J. Pipeline Syst. Eng. Pract. 2016, 7, 04015013. [Google Scholar] [CrossRef]

- European Commission. Environment, Green Growth, Raw Materials. Available online: https://ec.europa.eu/environment/green-growth/raw-materials/index_en.htm (accessed on 25 August 2022).

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Pehme, K.-M.; Kriipsalu, M. Full-scale project–From landfill to recreational area. Detritus 2018, 1, 174–179. [Google Scholar] [CrossRef]

- Urbinati, A.; Chiaroni, D.; Chiesa, V. Towards a new taxonomy of circular economy business models. J. Clean. Prod. 2017, 168, 487–498. [Google Scholar] [CrossRef]

- Khan, S.; Khan, H. Improvement of Mechanical Properties by Waste Sawdust Ash Addition into Soil. Jordan J. Civ. Eng. 2016, 10, 18–28. [Google Scholar] [CrossRef]

- Upadhyay, P.; Singh, Y. Soil Stabilization Using Natural Fiber Coir. Int. Res. J. Eng. Technol. 2017, 4, 1808–1812. [Google Scholar]

- Qu, J.; Zhao, D. Stabilising the cohesive soil with palm fibre sheath strip. Road Mater. Pavement Des. 2016, 17, 87–103. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, P.; Dai, F.; Li, X.; Zhao, Y.; Liu, Y. Behavior and Modeling of Fiber-Reinforced Clay under Triaxial Compression by Combining the Superposition Method with the Energy-Based Homogenization Technique. Int. J. Geomech. 2018, 18, 04018172. [Google Scholar] [CrossRef]

- Owoyemi, O.O. Effect of Sawdust on the Geotechnical Properties of a Lateritic Soil. J. Min. Geol. 2021, 57, 127–139. Available online: https://www.researchgate.net/publication/351094727 (accessed on 28 August 2022).

- Sani, J.E.; Afolayan, J.O.; Chukwujama, I.A.; Yohanna, P. Effects of wood saw dust ash admixed with treated sisal fibre on the geotechnical properties of lateritic soil. Leonardo Electron. J. Pract. Technol. 2017, 31, 59–76. [Google Scholar]

- Mwango, A.; Kambole, C. Engineering Characteristics and Potential Increased Utilisation of Sawdust Composites in Construction—A Review. J. Build. Constr. Plan. Res. 2019, 7, 59–88. [Google Scholar] [CrossRef]

- Assiamah, S.; Agyeman, S.; Adinkrah-Appiah, K.; Danso, H. Utilization of sawdust ash as cement replacement for landcrete interlocking blocks production and mortarless construction. Case Stud. Constr. Mater. 2022, 16, e00945. [Google Scholar] [CrossRef]

- Niyomukiza, J.B.; Wardani, S.P.R.; Setiadji, B.H. Recent advances in the stabilization of expansive soils using waste materials: A review. IOP Conf. Ser. Earth Environ. Sci. 2021, 623, 012099. [Google Scholar] [CrossRef]

- De Castrillo, M.C.; Ioannou, I.; Philokyprou, M. Reproduction of traditional adobes using varying percentage contents of straw and sawdust. Constr. Build. Mater. 2021, 294, 123516. [Google Scholar] [CrossRef]

- Khtou, O.; Aalil, I.; Aboussaleh, M.; EL Wardi, F.Z. Mechanical Analysis of Fiber Reinforced Adobe. Civ. Eng. Arch. 2021, 9, 2160–2168. [Google Scholar] [CrossRef]

- Jannat, N.; Al-Mufti, R.L.; Hussien, A.; Abdullah, B.; Cotgrave, A. Influence of Sawdust Particle Sizes on the Physico-Mechanical Properties of Unfired Clay Blocks. Designs 2021, 5, 57. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Vidal, H. The principle of reinforced earth. Highw. Res. Rec. 1969, 282, 1–16. Available online: http://onlinepubs.trb.org/Onlinepubs/hrr/1969/282/282-001.pdf (accessed on 25 August 2022).

- Gowthaman, S.; Nakashima, K.; Kawasaki, S. A State-of-the-Art Review on Soil Reinforcement Technology Using Natural Plant Fiber Materials: Past Findings, Present Trends and Future Directions. Materials 2018, 11, 553. [Google Scholar] [CrossRef]

- Kielė, A.; Vaičiukynienė, D.; Tamošaitis, G.; Pupeikis, D.; Bistrickaitė, R. Wood shavings and alkali-activated slag bio-composite. Eur. J. Wood Wood Prod. 2020, 78, 513–522. [Google Scholar] [CrossRef]

- Sharma, V.; Vinayak, H.K.; Marwaha, B.M. Enhancing compressive strength of soil using natural fibers. Constr. Build. Mater. 2015, 93, 943–949. [Google Scholar] [CrossRef]

- Medina-Martinez, C.J.; Sandoval-Herazo, L.C.; Zamora-Castro, S.A.; Vivar-Ocampo, R.; Reyes-Gonzalez, D. Natural Fibers: An Alternative for the Reinforcement of Expansive Soils. Sustainability 2022, 14, 9275. [Google Scholar] [CrossRef]

- Jairaj, C.; Kumar, M.T.P.; Raghunandan, M.E. Compaction characteristics and strength of BC soil reinforced with untreated and treated coir fibers. Innov. Infrastruct. Solut. 2018, 3, 21. [Google Scholar] [CrossRef]

- Qu, J.; Zhu, H. Function of Palm Fiber in Stabilization of Alluvial Clayey Soil in Yangtze River Estuary. J. Renew. Mater. 2021, 9, 767–787. [Google Scholar] [CrossRef]

- Oderah, V.; Kalumba, D. Laboratory Investigation of Sugarcane Bagasse as Soil Reinforcement Material. In Proceedings of the Fourth Geochina International Conference, Shandong, China, 25–27 July 2016; pp. 61–68. [Google Scholar] [CrossRef]

- Hashim, M.Y.; Amin, A.M.; Marwah, O.M.F.; Othman, M.H.; Yunus, M.R.M.; Huat, N.C. The effect of alkali treatment under various conditions on physical properties of kenaf fiber. J. Phys. Conf. Ser. 2017, 914, 012030. [Google Scholar] [CrossRef]

- Vettorelo, P.V.; Clariá, J.J. Suelos Reforzados con Fibras: Estado del Arte y Aplicaciones. Rev. Fac. Cienc. Exactas FÍSicas Nat. 2014, 1, 27–34. [Google Scholar]

- Hassan, M.M.; Wagner, M.H. Surface Modification of Natural Fibers for Reinforced Polymer Composites: A Critical Review. Rev. Adhes. Adhes. 2016, 4, 1–46. [Google Scholar] [CrossRef]

- Deshmukh, G.; Singh, I. A Review on Effect of Pretreatment of Fibers on Physical and Mechanical Properties of Natural Fiber Reinforced Polymer Composites. Int. J. Eng. Res. Curr. Trends 2020, 2, 34–40. [Google Scholar]

- Matykiewicz, D.; Barczewski, M.; Mysiukiewicz, O.; Skórczewska, K. Comparison of Various Chemical Treatments Efficiency in Relation to the Properties of Flax, Hemp Fibers and Cotton trichomes. J. Nat. Fibers 2021, 18, 735–751. [Google Scholar] [CrossRef]

- Adams, R.H.; Cerecedo-López, R.A.; Alejandro-Álvarez, L.A.; Domínguez-Rodríguez, V.I.; Nieber, J.L. Treatment of water-repellent petroleum-contaminated soil from Bemidji, Minnesota, by alkaline desorption. Int. J. Environ. Sci. Technol. 2016, 13, 2249–2260. [Google Scholar] [CrossRef]

- Koohestani, B.; Darban, A.K.; Mokhtari, P.; Yilmaz, E.; Darezereshki, E. Comparison of different natural fiber treatments: A literature review. Int. J. Environ. Sci. Technol. 2019, 16, 629–642. [Google Scholar] [CrossRef]

- Jaramillo-Quiceno, N.; Vélez, R.J.M.; Cadena Ch, E.M.; Restrepo-Osorio, A.; Santa, J.F. Improvement of Mechanical Properties of Pineapple Leaf Fibers by Mercerization Process. Fibers Polym. 2018, 19, 2604–2611. [Google Scholar] [CrossRef]

- Girijappa, Y.G.T.; Rangappa, S.M.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Cruz, J.; Fangueiro, R. Surface Modification of Natural Fibers: A Review. Procedia Eng. 2016, 155, 285–288. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2019, 55, 829–892. [Google Scholar] [CrossRef]

- Rippon, J.A.; Evans, D.J. Improving the properties of natural fibres by chemical treatments. Handb. Nat. Fibres 2020, 2, 245–321. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar] [CrossRef]

- Mallakpour, S.; Sirous, F.; Hussain, C.M. Sawdust, a versatile, inexpensive, readily available bio-waste: From mother earth to valuable materials for sustainable remediation technologies. Adv. Colloid Interface Sci. 2021, 295, 102492. [Google Scholar] [CrossRef]

- Fregoso-Madueño, J.N.; Goche-Télles, J.R.; Rutiaga-Quiñones, J.G.; González-Laredo, R.F.; Bocanegra-Salazar, M.; Chávez-Simental, J.A. Alternative uses of sawmill industry waste. Rev. Chapingo Ser. Cienc. For. Ambiente 2017, 23, 243–260, ISSN 2007-3828. Available online: https://www.redalyc.org/articulo.oa?id=62950747001 (accessed on 26 August 2022).

- Butt, W.A.; Gupta, K.; Jha, J.N. Strength behavior of clayey soil stabilized with saw dust ash. Int. J. Geo Eng. 2016, 7, 18. [Google Scholar] [CrossRef]

- Okedere, O.; Fakinle, B.; Sonibare, J.; Elehinafe, F.; Adesina, O. Particulate matter pollution from open burning of sawdust in Southwestern Nigeria. Cogent Environ. Sci. 2017, 3, 1367112. [Google Scholar] [CrossRef]

- Khan, A.; Jasim, O.H.; Umar, D. Effect of Sawdust-Lime and Sawdust Ash-Lime on the Geotechnical the Geotechnical Properties of an Expansive. 2020. Available online: https://www.researchgate.net/publication/343600730 (accessed on 6 January 2023).

- Ikeagwuani, C.; Obeta, I.; Agunwamba, J. Stabilization of black cotton soil subgrade using sawdust ash and lime. Soils Found. 2019, 59, 162–175. [Google Scholar] [CrossRef]

- Singh, P.; Singh, B. Assessment of Mechanical Properties of Biocomposite Material by using Sawdust and Rice Husk. INCAS Bull. 2019, 11, 147–156. [Google Scholar] [CrossRef]

- Mouissa, F.; Benyahia, A.; Djehiche, M.; Belmokre, K.; Deghfel, N.; Redjem, A.; Rahmouni, Z.E.A. The effect of chemical treatment on the mechanical and thermal properties of composite materials based on clay reinforced with sawdust. Matériaux Tech. 2021, 109, 101. [Google Scholar] [CrossRef]

- Jangid, A.K.; Khatti, J.; Bindlish, A. Stabilization of black cotton soil by 15% Kota stone slurry with wooden saw dust. Int. J. Adv. Res. Sci. Eng. 2018, 7, 108–114. [Google Scholar]

- Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H. Effect of sawdust on Cohesion of Sand-Sawdust mixture. Int. J. Eng. Appl. Sci. Technol. 2020, 4, 14–16. [Google Scholar] [CrossRef]

- Sharma, S.; Verma, K.; Sharma, J.K. Experimental Study of Stabilization of Expansive Soil Mixed with Sawdust and Marble Dust. In Proceedings of the Indian Geotechnical Conference 2019: IGC-2019; Springer: Singapore, 2021; Volume III, pp. 535–547. [Google Scholar] [CrossRef]

- Karteek, G.S. An Investigation on the Influence of Lime on Marine Clay Treated with Sawdust for Flexible Pavement Subgrade. Int. J. Recent Innov. Trend Technol. 2018, 4, 7–21. [Google Scholar]

- Johnson, S.; Gopinath, B. A Study on the Swell Behaviour of Expansive Clays Reinforced with Saw Dust, Coir Pith Marble Dust. Int. J. Eng. Res. 2016, 5, 565–570. [Google Scholar] [CrossRef]

- Yarbaşı, N.; Kalkan, E. Investigation of Wet-Dry Cycle Effect on Swelling Behavior of Stabilized Expansive Soils. Int. J. Sci. Eng. Appl. 2020, 9, 153–157. [Google Scholar]

- Kalkan, E.; Yarba, N. The Effects of Pine Tree Sawdust on the Volume Compressibility of Expansive Soils. Int. J. Sci. Eng. Appl. 2020, 10, 29–33. [Google Scholar] [CrossRef]

- Jasim, O.H.; Çetin, D. Effect of the Time on the Undrained Shear Strength and Permeability of Clay-Wooden Sawdust Mixtures Used to Improve Landfills Liner. Key Eng. Mater. 2020, 857, 311–318. [Google Scholar] [CrossRef]

- Jasim, O.H.; Çetin, D. Effect of sawdust usage on the shear strength behavior of clayey silt soil. Sigma J. Eng. Nat. Sci. 2016, 34, 31–41. Available online: https://www.researchgate.net/publication/299285436 (accessed on 6 January 2023).

- Farooq, M.U.; Mujtaba, H.; Farooq, K.; Sivakugan, N.; Das, B.M. Evaluation of Stability and Erosion Characteristics of Soil Embankment Slope Reinforced with Different Natural Additives. Iran. J. Sci. Technol. Trans. Civ. Eng. 2020, 44, 515–524. [Google Scholar] [CrossRef]

- Tong, Y.; Seibou, A.-O.; Li, M.; Kaci, A.; Ye, J. Bamboo Sawdust as a Partial Replacement of Cement for the Production of Sustainable Cementitious Materials. Crystals 2021, 11, 1593. [Google Scholar] [CrossRef]

- Yousefi, R.; Amooei, A.A.; Amel Sakhi, M.; Karimi, A. Experimental Study on Influence of Using Urease Enzyme on Stabilized Sandy Soil’s Engineering Property by Zeolite and Sawdust. Int. J. Marit. Technol. 2021, 15, 17–27. [Google Scholar]

- Oriaje, A.T.; Adeyemo, K.; Ojo, O. Stabilization of Lateritic Soil with Mahogany (Hardwood) Sawdust Ash. J. Eng. Environ. Sci. 2021, 3, 8–11. [Google Scholar] [CrossRef]

- Ayodele, A.; Oketope, O.; Olatunde, O. Effect of sawdust ash and eggshell ash on selected engineering properties of lateralized bricks for low cost housing. Niger. J. Technol. 2019, 38, 278. [Google Scholar] [CrossRef]

- Obeta, I.; Ikeagwuani, C.; Attama, C.; Okafor, J. Stability and durability of sawdust ash-lime stabilised black cotton soil. Niger. J. Technol. 2019, 38, 75. [Google Scholar] [CrossRef]

- Kolo, S.S.; Jimoh, Y.A.; Yusuf, I.; Adeleke, O.O.; Balarebe, F.; Shehu, M. Sawdust ash stabilization of weak lateritic soil. In Proceedings of the 3rd International Engineering Conference (IEC 2019), Minna, Nigeria, 24–26 September 2019. [Google Scholar]