Abstract

Textured coating technology is an effective method to improve the friction and wear performance of mold surfaces. The adhesion strength at the interface between the texture and the coating is crucial for its long-term serviceability. This paper studies the adhesion strength of micro-dimple’s topography textured coatings, aiming to reveal the influence mechanism of micro-dimples on the adhesion strength of textured coating interfaces. Different diameters or texture area ratios of micro-dimples were prepared on the sample surface using a picosecond laser, followed by PVD coating deposition. Scratching tests and indentation tests were then conducted on the textured coating surface. The adhesion strength and crack propagation behavior of the coating on the surface of different samples were studied under dynamic and static contact conditions. The results showed that under dynamic contact conditions, the critical load for coating failure of most textured samples was higher than that of non-textured samples. As the depth and diameter of the micro-dimple’s topography increased, the critical load first increased and then decreased, with the maximum critical load being 14.9% higher than that of the non-textured samples. Under static contact conditions, almost no coating spalling was observed around the indentation on the surface of the micro-dimple’s topography textured coating, while the spalling areas of non-textured samples were mainly at the edges and surrounding areas of the indentation. In contrast, the spalling regions of the textured samples were primarily concentrated at the edges of the texture. It can be seen that the dimpled texture hinders crack propagation and reduces the interlocking network of cracks, thereby reducing coating spalling. The research results provide important theoretical guidance for the design and optimization of textured coatings on mold surfaces.

1. Introduction

The friction and wear performance of mold surfaces is a critical factor affecting processing quality and mold life. Traditional surface treatment methods, such as surface carburizing/nitriding treatment [1], often lead to surface cracking and fail to meet the high demands of modern manufacturing. With the development of coating technology and the continuous reduction of manufacturing costs, hard, thin coatings have become widely used. Physical Vapor Deposition (PVD) coatings are commonly applied in harsh processing fields such as molds [2] and tools [3,4,5] due to their high wear resistance [6,7], low friction coefficient [8], and thermal stability [9]. However, due to issues like a thermal mismatch and chemical incompatibility, the adhesion strength between the coating and the substrate is relatively weak, leading to easy coating spalling and, consequently, component failure. Therefore, it is imperative to improve the adhesion strength between the coating and the substrate.

Physical bonding, surface stress, and chemical compatibility are important factors influencing coating adhesion strength [10]. To enhance the adhesion strength of the coating to the substrate, surface pretreatment is required. Compared to traditional processes such as sandblasting [11] and intermediate layer deposition [12], laser surface technology demonstrates higher efficiency, lower pollution, and controllable processing, showing better application value. Li et al. [13] used ultraviolet laser pretreatment on the surface of hard alloys and found that appropriate laser processing times can generate grainy surface morphology and produce tungsten carbide with better chemical compatibility with diamond coatings. This helps release residual stress in the coating and enhances mechanical interlocking and chemical bonding between the coating and the substrate. However, despite the controllability of processing times, the surface morphology formed after laser treatment remains uncontrollable, leading to unpredictable coating crack propagation on this disordered surface, which is not conducive to further quantifiable optimization of surface morphology design.

Laser surface texturing technology not only effectively improves surface friction performance [14,15,16] but also precisely controls surface morphology. In recent years, research on applying surface texturing to coating surface pretreatment has gradually emerged and has been proven to enhance coating adhesion strength significantly. Firstly, laser texturing increases the actual contact area between the coating and the substrate, providing more attachment space for the coating and producing a mechanical anchoring effect, thereby improving the adhesion strength of the coating [17,18]. Secondly, laser texturing alters the stress distribution on the substrate surface [19], and coating deposition helps release residual stress within the coating, thereby reducing defects caused by residual stress in the coating [20]. Lastly, some compounds with better chemical compatibility with the coating can be produced on the substrate surface after laser processing, enhancing the adhesion strength between the coating and the substrate [21].

Molds are often subjected to high temperatures and heavy load working environments, coupled with poor lubrication, leading to defects such as wear, cracking, and spalling, resulting in mold failure [22]. Micro-dimple’s topography textured coating is an effective way to improve the friction and wear performance of mold surfaces. The adhesion strength at the interface between the texture and the coating is crucial for its long-term serviceability. Therefore, different diameters or texture area ratios of micro-dimples were prepared on the sample surface using a picosecond laser, followed by PVD coating deposition. Scratching tests and indentation tests were then conducted on the textured coating surface. The adhesion strength and crack propagation behavior of the coating on the surface of different samples were studied under dynamic and static contact conditions. Ultimately, the influence mechanism of micro-dimple’s topography on the adhesion strength of textured coating interfaces was revealed, providing important theoretical guidance for the design and optimization of textured coatings on mold surfaces.

2. Experimental Details

2.1. Sample Preparation

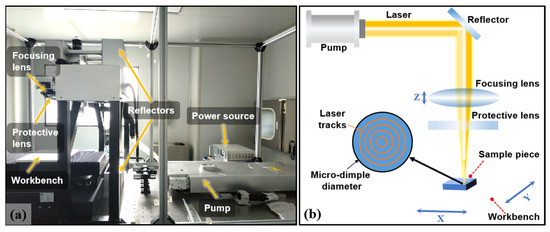

In this study, DC53 die steel was used as the substrate. Due to its high hardness, toughness, and tempering hardness, it is gradually becoming a mainstream cold work die steel, with a hardness of HRC56 ± 1. The composition of the substrate is shown in Table 1. Square specimens with dimensions of 30 × 8 × 8 mm were used, with a flatness error of 0.02 mm and a parallelism error of 2.5 μm. Initially, the specimens were polished with sandpaper ranging from 100 to 2000 grit, followed by polishing with a W0.5 diamond polishing paste on a polishing machine. Roughness was measured using a confocal microscope (Nano Focus, Oberhausen, Germany, μ-Surf expert) with a cutoff wavelength of 80 μm and a sampling length of 0.8 μm. Gaussian regression filtering was used. Five different samples were randomly selected, and then five different regions of each sample were measured to obtain an average roughness of Ra0.02. Subsequently, the micro-dimple’s topography was created using the picosecond laser with a scanning fill method. The laser processing system and processing schematic are shown in Figure 1, with a spacing of 10 μm between laser tracks. The parameters are detailed in Table 2. Post-laser processing, all samples were polished to remove surface splatter and recast material. Then, they were subjected to a 15 min ultrasonic cleaning in anhydrous ethanol to remove residual impurities and diamond particles as thoroughly as possible.

Table 1.

Chemical composition of DC53 die steel (mass fraction, %).

Figure 1.

(a) Photo of the laser processing system; (b) Schematic diagram of the processing process.

Table 2.

Laser parameters.

This study prepared a total of ten sets of specimens. One set was a control group without the micro-dimple’s topography as a blank control group. The other nine sets consisted of micro-dimple topography samples with varying depths and diameters: maintaining a depth of 10 μm with diameters ranging from 60 to 140 μm and maintaining a diameter of 100 μm with depths ranging from 3 to 17 μm. The morphological parameters and their corresponding laser parameters are detailed in Table 3. The texture area ratio is 10%, as shown in Formula (1).

where stands for the diameter of micro-dimples, and stands for the spacing between micro-dimples.

Table 3.

Micro-dimple morphology parameters and their processing parameters.

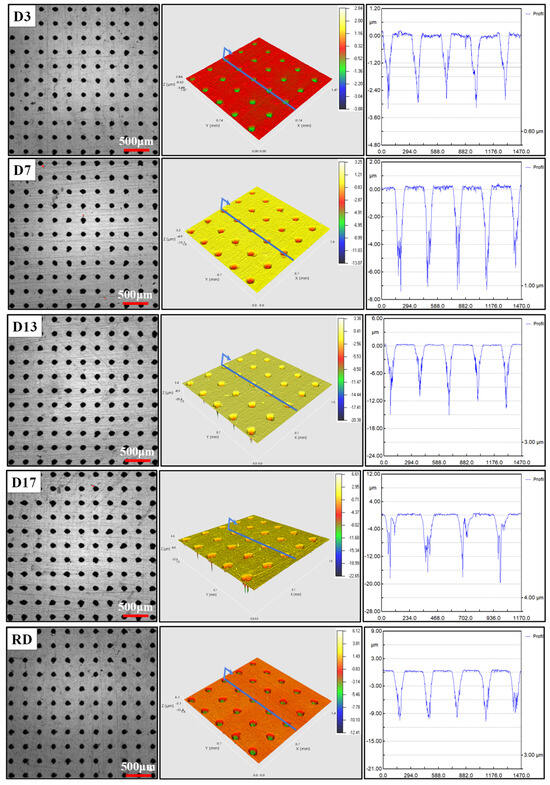

The three-dimensional morphology and local two-dimensional contour maps of each sample after laser processing are shown in Figure 2. In order to fully reflect the cross-sectional morphology and depth of the texture, a section is selected at the center position to obtain the complete two-dimensional contour.

Figure 2.

Surface morphology of each sample. Column 1: Electron microscopy image with a scale of 500 μ m. Column 2: Texture 3D morphology diagram, with blue arrows indicating the cross-sectional direction. Column 3: 2D contour map along the section direction.

Subsequently, the surfaces of each test specimen were treated using cathodic arc ion plating technology, and a 2.5 ± 0.5 μm thick AlCrN coating was prepared on a commercial coating machine (Superwei, Suzhou, China, CW1180). The chemical composition of the coating is detailed in Table 4, and its mechanical properties are outlined in Table 5. Due to its relatively low coefficient of friction (COF) and excellent wear resistance, this coating is widely used on mold surfaces. Deposition parameters are provided in Table 6.

Table 4.

Chemical composition of AlCrN coating (mass fraction, %).

Table 5.

Mechanical properties of AlCrN coating.

Table 6.

Deposition process parameters of AlCrN coating.

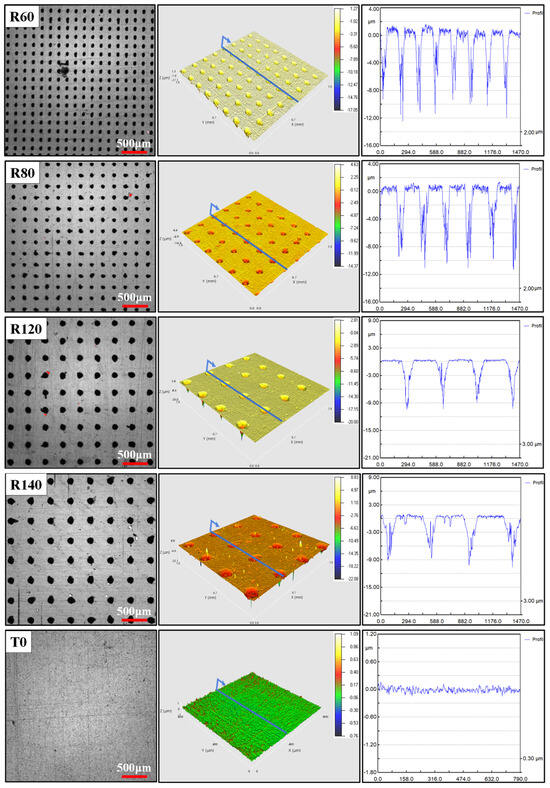

2.2. Scratch Test

During stamping, the rounded corners of the mold sidewalls experience significant relative movement with the sheet metal, primarily subjected to tangential shear forces and normal pressures. Therefore, scratching tests were conducted to analyze the coating’s adhesion strength and crack propagation behavior under dynamic contact conditions. The scratching experiments in this study were performed using a multifunctional test machine (Rtec, San Jose, CA, USA, MFT-5000), as illustrated in Figure 3a. A Rockwell hardness tester diamond head with a diameter of 200 μm and an angle of 120° was used. In the scratching tests, a linear load with a maximum value of 100 N was applied for 5 min, with a scratch length of 5 mm ± 0.3 mm. The coefficient of friction (COF) was sampled ten times per second. Five experiments were conducted at different positions on each sample surface. To minimize fluctuations in COF due to scratches passing over micro-textures and to determine failure locations accurately, each scratch position was adjusted multiple times to ensure that it passed through the textures. After the experiments, scratches were observed under a confocal microscope, and three-dimensional images were captured. Finally, combining the COF curve–load curve and observed scratches determined the critical load Lc at which continuous coating delamination began. Lc was averaged from five scratching experiments.

Figure 3.

(a) Schematic diagram of the scratch test. (b) Schematic diagram of the indentation test.

2.3. Indentation Test

During the stamping process, the bottom of the mold experiences relatively minor relative movement with the sheet metal, primarily subjected to normal pressures. Therefore, indentation tests were conducted to analyze the coating’s adhesion strength and crack propagation behavior under static contact conditions. The indentation experiments used the multifunctional test machine (Rtec, USA, MFT-5000) with the same indenter head used in the scratching tests. As shown in Figure 3b, the experimental process involved a linear loading sequence: initially ramping up linearly from 0 N to 1471 N over one minute, holding for 30 s, and then linearly unloading back to 0 N over one minute. Five experiments were conducted at different positions on each sample surface. After the experiments, crack propagation around the indentation and coating delamination were observed under SEM.

3. Results and Discussion

3.1. Coating Cross-Sectional Morphology

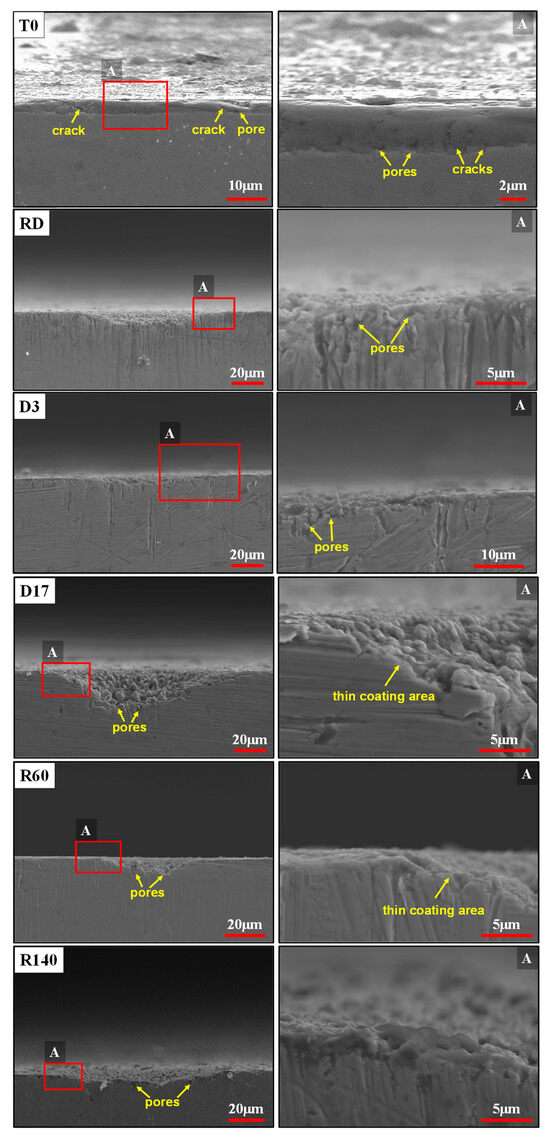

The cross-sectional morphology of six typical samples is shown in Figure 4. Within the coating of sample T0, numerous micro-cracks and micro-pores can be observed, likely caused by thermal mismatch between the coating and the substrate [20]. Due to the significant difference in thermal expansion coefficients between the coating and the substrate, strains differ during the deposition and cooling processes, forming micro-cracks and micro-pores. In contrast, the coating adheres well to the substrate for textured samples, with only a few micro-pores observed and almost no micro-cracks. In the micro-dimpled surface processed by the picosecond laser, there are many micro-protrusions. Due to the small gaps between some of these micro-protrusions, the coating cannot nucleate and grow in these gaps, resulting in micro-pores. However, these micro-protrusions may simultaneously act as micro-anchors for the coating, and micro-dimples’ presence facilitates stress relief [20], buffering substrate deformation. Therefore, it reduces the strain difference between the coating and the substrate during coating deposition and cooling, thereby reducing micro-cracks’ formation.

Figure 4.

SEM images of typical sample cross sections. The second column is a zoomed in view of the A area.

For different textured coating samples, it can be observed that samples D17 and R60 exhibit thinning of the coating at the edges of the micro-dimples. This is because the micro-dimples in the D17 and R60 samples have a larger depth-to-diameter ratio, resulting in a greater slope at their edges. This greater slope leads to stress concentration at the edges, causing a significant difference in deformation between the coating and the substrate in these areas. As a result, cracks are more likely to form, and even coating delamination can occur, causing the coating to thin. In contrast, the D3 and R140 samples exhibit gentler slopes at their edges, which reduces the stress concentration and results in a more uniform coating thickness in these regions, with no uncovered areas. Thus, as the depth-to-diameter ratio increases, the slope at the edges of the micro-dimples becomes steeper, leading to greater stress concentration, more cracks, thinner coatings, and potentially uncovered areas at the edges. This directly impacts the adhesion strength between the coating and the substrate at the edges.

3.2. Adhesion Strength of Coatings under Dynamic Contact Conditions

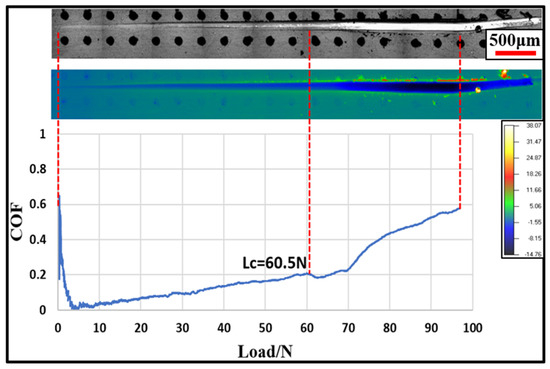

The critical load Lc at which continuous coating delamination begins was determined by combining changes in the coefficient of friction (COF) curve with two-dimensional optical micrographs and depth maps of the scratches. Typical COF curve and scratch morphology images are shown in Figure 5. From the grayscale image of the scratch; it can be observed that the silver-white substrate becomes visible when the coating begins to delaminate continuously at the critical load. It is essential to note in the figure that due to minor elastic deformation of the loading rod caused by significant horizontal force during horizontal movement in the experiment, upon lifting the loading rod after the experiment, accumulated elastic potential energy is released, causing the loading rod to continue sliding along the scratch for a distance, leaving a ‘tail’ at the end of the scratch. The deepest point of the scratch, indicating the actual endpoint of the scratch in the experiment, can be determined from the scratch’s two-dimensional depth map.

Figure 5.

Typical COF (Coefficient of Friction) curve and scratch morphology diagram (Sample RD). Three red vertical dotted lines represent the starting position, critical load position, and ending load position of the load, respectively.

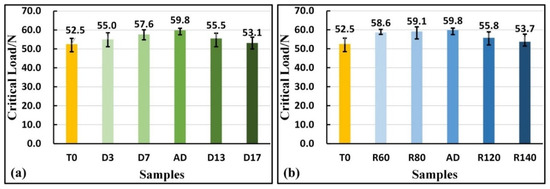

The critical load Lc for coating failure in the scratching tests of each sample is shown in Figure 6. It can be observed that the crucial load for all textured samples is higher than that for the non-textured sample, indicating stronger adhesion between the coating and the textured substrate surface. Additionally, Figure 6a shows that for textured samples with a constant micro-dimple diameter, the critical load initially increases and then decreases with increasing micro-dimple depth. The maximum critical load is 59.8 N for a depth of 10 μm (sample AD), whereas it reduces to a minimum of 53.1 N for a depth of 17 μm (sample D17). Figure 6b shows that with a constant micro-dimple depth, the critical load also initially increases and then decreases with increasing micro-dimple diameter. The maximum crucial load of 59.8 N is observed for a diameter of 100 μm (sample AD), while the minimum critical load of 53.1 N is observed for a diameter of 140 μm (sample R140). Furthermore, when the micro-dimple diameter is below 100 μm, the critical loads are relatively close. In contrast, they decrease more rapidly when the diameter exceeds 100 μm, indicating that 100 μm is a crucial threshold for maintaining good adhesion strength.

Figure 6.

The critical failure loads of each sample’s coatings: (a) Samples with the same diameter but different depths; (b) Samples with the same depth but different diameters.

The reasons for the enhanced adhesion strength of the coating under dynamic contact conditions with micro-dimple textures may be attributed to two factors: (1) Micro-dimple textures increase the actual contact area of the substrate surface. The larger actual contact area provides more attachment space for the coating, allowing the micro-dimples to create a mechanical interlocking effect. Additionally, the micro-protrusions inside the dimples can also produce a micro-interlocking effect. When the coating experiences horizontal shear forces, the micro-interlocking effect of the micro-dimples can counteract some of the shear forces, reducing the shear strain on the coating. This enables the coating to withstand higher loads before failure, enhancing adhesion strength. (2) Textured surfaces reduce internal defects in the coating. During coating deposition and cooling, micro-dimples help to release some stress, thereby reducing the deformation difference between the substrate and the coating. This reduction helps minimize the formation of internal micro-cracks and micro-pores in the coating.

For textured samples, assuming the micro-dimple shape approximates an inverted cone with smooth inner walls, the adhesion area for the textured substrate per unit projected area can be approximated as:

where represents the texture area ratio, and denotes the total inner wall area of micro-dimples within the unit projected area

Here, is the projected area of a single micro-dimple, and is the area of the inner wall of a single micro-dimple.

Here, is the diameter of the micro-dimple, and is the depth of the micro-dimple.

Substituting Equations (3)–(5) into Equation (2), we obtain:

From Equation (6), it can be seen that when the micro-texture area ratio is determined, the adhesion area of the textured surface is proportional to the depth-to-diameter ratio . When the diameter of the micro-dimple remains constant, an increase in depth increases the depth-to-diameter ratio, thereby increasing the adhesion area of the textured surface. This enhances the mechanical interlocking effect on the substrate surface, improving the adhesion strength between the coating and the substrate. However, at the same time, due to the concentration of internal stresses in the layer at the edges of the micro-dimples [19], as the depth-to-diameter ratio increases, the corners at the edges of the dimples become smaller, leading to increased stress concentration at the edges. This increases the likelihood of thinning or even delamination of the coating at the edges, thereby reducing the adhesion strength between the coating and the substrate. When the depth of the micro-dimple remains constant, an increase in diameter decreases the depth-to-diameter ratio, reducing the adhesion area and weakening the mechanical interlocking effect. However, lower edge stresses minimize the likelihood of edge thinning and delamination, strengthening the adhesion between the coating and the substrate. Therefore, an optimal depth-to-diameter ratio, which in this study is 0.1, corresponds to sample RD.

3.3. Coating Crack Propagation Behavior under Static Contact Conditions

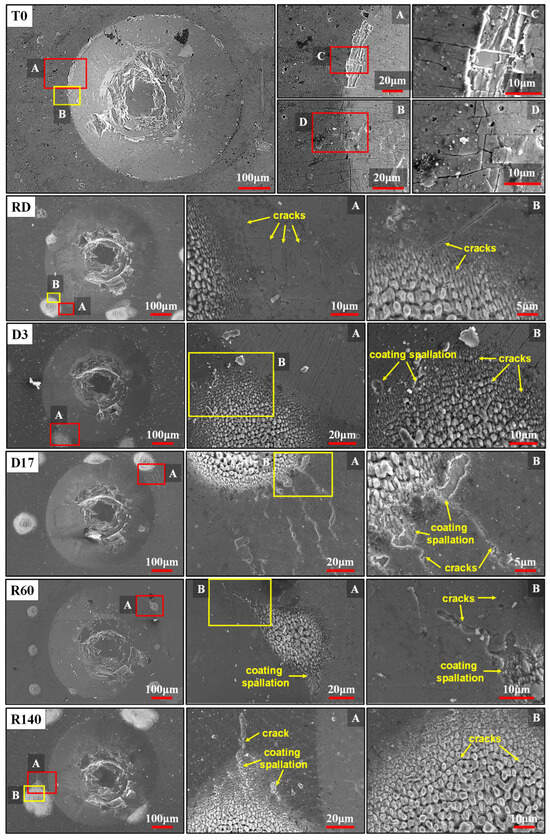

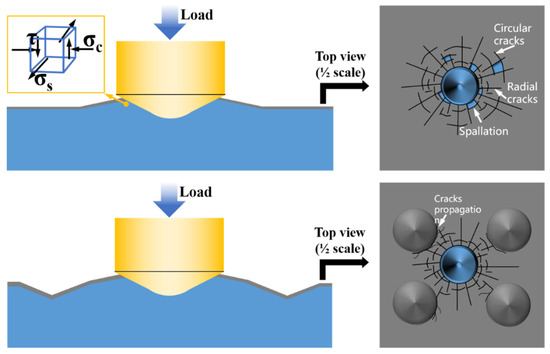

After the indentation tests, SEM images of the six typical samples’ indentation sites are shown in Figure 7. For the T0 sample, partial coating delamination appeared at the edge of the indentation, with larger coating delamination areas around the indentation. From the magnified images of the delamination areas, it can be seen that the shapes of the delaminated regions are mostly regular rectangles, with radial cracks (from now on referred to as “radial cracks”) and circumferential cracks (from now on referred to as “circumferential cracks”) distributed around the indentation (Figure 7, T0, C). This indicates that these delaminations are caused by the network of cracks formed by radial and circumferential cracks. This is more pronounced in an area where the coating is about to delaminate (Figure 7, T0, D). No coating delamination was observed around the indentation of the textured samples, with only a small amount of coating delamination observed around the micro-dimple areas of some samples, and the shapes were irregular. Among them, samples D17 and R60 had larger delamination areas, with larger cracks appearing around the delamination areas. No coating delamination was observed on sample RD. Around its micro-dimples, some cracks were observed extending along the edges of the micro-dimples, and a few cracks extended into the micro-dimples before stopping. On samples D3 and R140, some cracks extended into the interior of the micro-dimples, with a small amount of coating delamination appearing at the edges of the micro-dimples. Thus, it is evident that textured samples can effectively suppress crack formation, thereby reducing coating delamination and enhancing adhesion strength. As the texture diameter or depth increases, the ability of the texture to suppress cracks initially improves but then deteriorates. When the depth-to-diameter ratio is large, cracks tend to grow along the texture edges, while a smaller ratio causes cracks to propagate inward.

Figure 7.

SEM images of typical sample indentations. A–D are partial enlarged views.

After static contact is applied to the surface, the pressure around the indentation center shows a radial distribution, causing the material to deform in a bulging manner. As the load linearly increases, the bulge expands outward, increasing in diameter, thereby inducing circumferential tensile stress in the material. Radial cracks form when this tensile stress exceeds the material’s tensile limit. Simultaneously, as the indentation depth increases, more material is squeezed out, increasing bulge height. Differences in bulge height between the inner and outer rings of the indentation result in normal shear stress on the material. When this shear stress exceeds the material’s tensile limit, circumferential cracks form. The network of cracks formed by radial and circumferential cracks ultimately leads to coating delamination [23]. When the surface is textured, the extension of radial and circumferential cracks changes due to the obstruction of the texture, extending along the edges of the texture and increasing the energy required for crack propagation, thereby reducing the formation of crack networks and minimizing coating delamination. Figure 8 illustrates the formation of radial and circumferential cracks and the inhibitory effect of micro-dimple textures on crack propagation. However, when the depth-to-diameter ratio is small (samples D3, R140), this inhibitory effect is reduced, allowing some radial cracks to extend into the interior of the micro-dimples, forming a network of cracks inside and even causing a small amount of coating delamination. Conversely, when the depth-to-diameter ratio is large (samples D17, R60), radial cracks are more likely to extend along the edges of the micro-dimples due to coating thinning at the edges of the micro-dimples, intersecting with circumferential cracks to form a network of cracks, resulting in more coating delamination.

Figure 8.

Schematic diagram showing the formation of radial and circumferential cracks and the inhibitory effect of micro-dimple textures on crack propagation.

4. Conclusions

Firstly, combining femtosecond laser processing and PVD coating deposition technology, samples with micro-dimple textured AlCrN coatings of different depths and diameters were prepared on the surface of DC53 die steel. To study the bonding strength of textured coatings, scratch and indentation experiments were conducted on the surface of the sample. Afterward, the cross-sectional morphology of the non-textured coating samples and the micro-dimple textured coating samples with different depths and diameters were observed. The coatings’ adhesion strength and crack propagation behavior on different samples were compared under dynamic and static contact conditions. The main conclusions are as follows:

(1) The non-textured coating samples exhibit numerous internal defects, such as micro-pores and micro-cracks. In contrast, the textured coating samples show fewer internal defects. For the micro-dimple textured coating samples, due to the micro-protrusions inside the micro-dimples, there are micro-pores within the coating. Moreover, when the depth-to-diameter ratio of the micro-dimples is large (≥0.17), coating thinning or even delamination occurs at the edges of the texture.

(2) Under dynamic contact conditions, the critical failure load of most textured samples is higher than that of the non-textured samples. For the micro-dimple textured coating samples, with increasing depth and diameter, the critical load shows a trend of increasing and decreasing. The sample RD showed the highest critical load at 59.8 N, which increased by 14.9% compared to the essential load of 52.5 N in the nonwoven sample.

(3) Under static contact conditions, the delamination areas on the surfaces of most textured samples are fewer compared to those on non-textured samples. Delamination on non-textured samples mainly occurs at the edges and around the indentations, while on textured samples, delamination areas are primarily concentrated at the edges of the texture. Almost no delamination is observed around the indentations on the surfaces of micro-dimple textured coating samples.

(4) Texturing inhibits crack propagation by causing cracks to extend along the edges of the texture, consuming energy required for crack propagation and reducing the interlocking of cracks, thereby reducing coating delamination.

Author Contributions

Conceptualization, H.F. and M.M.; methodology, H.F.; software, X.Y.; validation, H.F. and M.M.; formal analysis, J.Y.; investigation, X.Y.; resources, M.M.; data curation, X.Y.; writing—original draft preparation, H.F.; writing—review and editing, M.M. and J.Y.; visualization, Y.Z.; supervision, J.J.; project administration, Y.F.; funding acquisition, H.F. and M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Basic Science Project of Colleges and Universities of Jiangsu Province (21KJB460012), Jiangsu Province Post-Doctoral Research Funding Scheme, grant No. 2019K233, Major Project of Basic Science (Natural Science) Research in Universities of Jiangsu Province [22KJA460007], and Special Science and Technology Innovation Project of Young scientific and Technological talents of Nantong [JC12022096] for providing research funds.

Institutional Review Board Statement

This study did not require ethical approval.

Informed Consent Statement

This study did not involve humans.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Aliofkhazraei, M. Modern Surface Engineering Treatments; BoD–Books on Demand: Norderstedt, Germany, 2013. [Google Scholar]

- Bobzin, K.; Brögelmann, T.; Brugnara, R.H.; Kruppe, N.C. CrN/AlN and CrN/AlN/Al2O3 coatings deposited by pulsed cathodic arc for aluminum die casting applications. Surf. Coat. Technol. 2015, 284, 222–229. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, W.; Li, B.; Wang, C.; Kuang, T.; Li, Y. Physical vapor deposition technology for coated cutting tools: A review. Ceram. Int. 2020, 46, 18373–18390. [Google Scholar] [CrossRef]

- Kumar CH, R.V.; Nair, P.K.; Ramamoorthy, B. Characterization of multilayer PVD nanocoatings deposited on tungsten carbide cutting tools. Int. J. Adv. Manuf. Technol. 2008, 38, 622–629. [Google Scholar] [CrossRef]

- Durairaj, S.; Guo, J.; Aramcharoen, A.; Castagne, S. An experimental study into the effect of micro-textures on the performance of cutting tool. Int. J. Adv. Manuf. Technol. 2018, 98, 1011–1030. [Google Scholar] [CrossRef]

- Boing, D.; De Oliveira, A.J.; Schroeter, R.B. Evaluation of wear mechanisms of PVD and CVD coatings deposited on cemented carbide substrates applied to hard turning. Int. J. Adv. Manuf. Technol. 2020, 106, 5441–5451. [Google Scholar] [CrossRef]

- He, Q.; Paiva, J.M.; Kohlscheen, J.; Beake, B.D.; Veldhuis, S.C. An integrative approach to coating/carbide substrate design of CVD and PVD coated cutting tools during the machining of austenitic stainless steel. Ceram. Int. 2020, 46, 5149–5158. [Google Scholar] [CrossRef]

- Lei, S.; Ji, X.; Tianen, Y. Friction and cutting performance of CVD/PVD coatings on the surfaces of metal ceramics and hard alloys. China Surf. Eng. 2019, 32, 45–55. [Google Scholar]

- Koyilada, B.; Gangopadhyay, S.; Thakur, A. Comparative evaluation of machinability characteristics of Nimonic C-263 using CVD and PVD coated tools. Measurement 2016, 85, 152–163. [Google Scholar] [CrossRef]

- Sam, Z. Thin Films and Coatings Toughening and Toughness Characterization; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Amada, S.; Hirose, T. Planar fractal characteristics of blasted surfaces and its relation with adhesion strength of coatings. Surf. Coat. Technol. 2000, 130, 158–163. [Google Scholar] [CrossRef]

- Xu, F.; Xu, J.H.; Yuen, M.F.; Zheng, L.; Lu, W.Z.; Zuo, D.W. Adhesion improvement of diamond coatings on cemented carbide with high cobalt content using PVD interlayer. Diam. Relat. Mater. 2013, 34, 70–75. [Google Scholar] [CrossRef]

- Li, T.; Lou, Q.; Dong, J.; Wei, Y.; Zhou, J.; Liu, J.; Zhang, Z.; Sun, F. Improved adhesion of diamond coating on cobalt-cemented tungsten carbide hardmetal by using pulsed-UV-laser substrate surface pretreatment. Appl. Surf. Sci. 2002, 193, 102–119. [Google Scholar]

- Xu, Y.; Peng, Y.; Dearn, K.D.; You, T.; Geng, J.; Hu, X. Fabrication and tribological characterization of laser textured boron cast iron surfaces. Surf. Coat. Technol. 2017, 313, 391–401. [Google Scholar] [CrossRef]

- Li, J.; Xiong, D.; Zhang, Y.; Zhu, H.; Qin, Y.; Kong, J. Friction and wear properties of MoS2-overcoated laser surface-textured silver-containing nickel-based alloy at elevated temperatures. Tribol. Lett. 2011, 43, 221–228. [Google Scholar] [CrossRef]

- Vlădescu, S.C.; Olver, A.V.; Pegg, I.G.; Reddyhoff, T. Combined friction and wear reduction in a reciprocating contact through laser surface texturing. Wear 2016, 358, 51–61. [Google Scholar] [CrossRef]

- Kromer, R.; Costil, S.; Cormier, J.; Courapied, D.; Berthe, L.; Peyre, P.; Boustie, M. Laser surface patterning to enhance adhesion of plasma sprayed coatings. Surf. Coat. Technol. 2015, 278, 171–182. [Google Scholar] [CrossRef]

- Neves, D.; Diniz, A.E.; Lima, M.S.F. Microstructural analyses and wear behavior of the cemented carbide tools after laser surface treatment and PVD coating. Appl. Surf. Sci. 2013, 282, 680–688. [Google Scholar] [CrossRef]

- Zhang, Z.; Lu, W.; Feng, W.; Du, X.; Zuo, D. Effect of substrate surface texture on adhesion performance of diamond coating. Int. J. Refract. Met. Hard Mater. 2021, 95, 105402. [Google Scholar] [CrossRef]

- Xu, C.; Xu, F.; Shi, L.; Gao, J.; Tu, L.; Zuo, D. Enhancement of substrate-coating adherence of boron-doped diamond electrodes by nanosecond laser surface texturing pretreatment. Surf. Coat. Technol. 2019, 360, 196–204. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, J.; Meng, R.; Lei, S.; Yu, X. Influence of laser substrate pretreatment on anti-adhesive wear properties of WC/Co-based TiAlN coatings against AISI 316 stainless steel. Int. J. Refract. Met. Hard Mater. 2016, 57, 101–114. [Google Scholar] [CrossRef]

- Jhavar, S.; Paul, C.P.; Jain, N.K. Causes of failure and repairing options for dies and molds: A review. Eng. Fail. Anal. 2013, 34, 519–535. [Google Scholar] [CrossRef]

- Diao, D.F.; Kato, K.; Hokkirigawa, K. Fracture mechanisms of ceramic coatings in indentation. J. Tribol. Oct. 1994, 116, 860–869. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).