Abstract

This study investigates the impact of cryogenic treatment duration on the mechanical properties and microstructural evolution of 6082 aluminum alloy subjected to subsequent artificial aging. Tensile tests were conducted using an electronic universal testing machine, and the microstructure was characterized by employing optical microscopy (OM), scanning electron microscopy (SEM), and transmission electron microscopy (TEM). The results indicate that both the tensile strength and elongation of the alloy first increase and then decrease with the extension of cryogenic treatment duration. The alloy treated with 12 h of cryogenic treatment followed by artificial aging at 180 °C for 8 h achieved a peak strength of 390 MPa. Meanwhile, the alloy treated with 8 h of cryogenic treatment and the same artificial aging process reached a maximum elongation of 13%. All specimens of 6082 aluminum alloy subjected to cryogenic and aging treatments exhibited ductile fracture under room temperature tensile conditions. The size of dimples at the fracture surface first increased and then decreased with increasing cryogenic treatment duration, indicating a transition from deeper to shallower dimples. The cryogenic treatment did not significantly affect the grain size of the alloy, which remained approximately 230 µm on average. Cryogenic treatment facilitated the precipitation of fine, densely distributed precipitates, enhancing the pinning effect of dislocations and thus improving the tensile strength. Additionally, cryogenic treatment increased the dislocation density and promoted the formation of subgrains, while the grain boundary precipitates transitioned from a continuous to a discontinuous distribution, all of which contribute to the enhancement of the plasticity.

1. Introduction

Aluminum alloys, renowned for their low density, moderate strength, and excellent thermal workability, are extensively utilized as structural materials in various sectors such as aviation, modern rail transit, and equipment manufacturing [1]. The 6000 series aluminum alloys, characterized by their adequate strength, favorable weldability, corrosion resistance, and oxidation resistance [2,3], are widely applied in the industrial production and daily life where components are required to possess certain strength and high corrosion resistance. For instance, they are employed in the fabrication of aviation fixtures, furniture, railway vehicles, ships, trams, and pipelines. The primary alloying elements of the 6000 series aluminum alloys are magnesium and silicon, classifying them as heat-treatable alloys [4,5]. The typical precipitation sequence for the 6000 series aluminum alloys is as follows: supersaturated solid solution (SSSS) → atomic clusters → GP zones (β″ precursors) → β″ → β′ → β [6]. The GP zones form during the initial stages of aging and can be simply described as the enrichment of solute atoms in the aluminum matrix. β″ is the main precipitate phase observed during the alloy’s peak aging strength, playing a crucial role in enhancing strength. β′ is a metastable precipitate phase formed during the aging process, with slightly weaker strengthening effects, and β represents the equilibrium phase (Mg2Si) with the least strengthening effect. Chen et al. [7] explored a novel solution and aging treatment process for an Al-Mg-Si aluminum alloy. The alloy achieves optimal strengthening effects when the MgSi phase’s solubility and the precipitation of β″ (Mg2Si phase) are maximized. After solution treatment at 565 °C for 30 min and aging treatment at 175 °C for 10 h, the yield strength reaches 437 MPa, and the tensile strength reaches 453 MPa. Kang et al. [8] studied a cast Al-Si-Mg alloy, obtaining a maximum yield strength of 239.5 MPa and a maximum tensile strength of 290.93 MPa after solution treatment at 520 °C for 90 min, followed by artificial aging at 180 °C for 180 min. Optimizing the heat treatment parameters can enhance the mechanical properties of the 6000 series aluminum alloys.

With the continuous development and advancement of the aviation industry, higher demands are placed on the comprehensive mechanical properties of alloy materials. Research has found that while the strength of an alloy is increased, its plasticity tends to decrease, which significantly impacts its applications [9]. Therefore, how to simultaneously enhance the strength and plasticity of the alloy has become an urgent issue that needs to be addressed. In recent years, some researchers have combined deep cryogenic treatment with the aluminum alloy solution and aging process, discovering that a reasonable deep cryogenic treatment process can alter the structure and properties of the aluminum alloy. Deep cryogenic treatment (DCT) is a method that uses liquid nitrogen as a refrigerant to treat materials at temperatures below −100 °C [10,11]. It is an innovation and extension of traditional heat treatment, placing the parts to be treated in a specific and controllable low-temperature environment, causing changes in the material’s microstructure, thereby improving its comprehensive performance. This includes residual stress, machinability, wear resistance and mechanical properties of Al-Mg-Si aluminum alloy [12,13,14,15].

Additionally, there are studies on the impact of deep cryogenic treatment on the mechanical properties of aluminum alloys and the underlying mechanisms [16,17]. Huang et al. [18] delve into the impact of deep cryogenic treatment (DCT) on the aging processes of an Al-Mg-Si alloy; the DCT not only refines the grain structure and elevates the dislocation density but controls the evolution of precipitate. The DCT results in an enhancement in hardness. Jovičević-Klug et al. [19] present a comprehensive investigation into the influence of deep cryogenic treatment (DCT) on the microstructural evolution and aging behavior of the Al-Mg-Si alloy EN AW 6026, revealing that DCT induces a formation and evolution of precipitates, which results in a denser and more aligned distribution of precipitates along the <100> axis of the aluminum matrix. The DCT can significantly influence the hardness evolution and mechanical properties of the alloy. Li et al. [20] explores the impact of deep cryogenic treatment on the microstructure and mechanical properties of automotive 6063 aluminum alloy, revealing significant enhancements in hardness, tensile strength, yield strength, and elongation after DCT. The lattice distortion and increased dislocation density within the alloy contribute to the formation of refined grains and a superior mechanical performance. Deep cryogenic treatment can accelerate the precipitation process, refine the precipitate phases, and enhance the uniformity of the precipitate phase distribution. In general, during the deep cryogenic treatment process, the decrease in temperature causes lattice distortion, leading to a reduction in the aluminum alloy’s lattice constants and an increase in the supersaturation of solute atoms, thereby increasing the driving force for solute atom precipitation. Moreover, at deep cryogenic temperatures, the equilibrium concentration of vacancies in the alloy is relatively low. Prolonged low-temperature holding not only further reduces the vacancy concentration but also promotes the precipitation of solute atoms. During the cooling and low-temperature holding processes of the aluminum alloy, lattice distortion promotes the accumulation of a large amount of elastic strain energy in the alloy’s microstructure, which can provide the driving force for the precipitation of precipitate phases during the heating process.

Nowadays, the 6000 series alloys are increasingly used in the manufacturing of pressure vessels and the aviation industry, demanding better service performance. In this process, it is necessary to enhance the performance of traditional aluminum alloys without sacrificing other properties. This provides opportunities for the application of deep cryogenic treatment for aluminum alloys. Sonia et al. [21] conducted deep cryogenic treatment at −183 °C on 6082 aluminum alloy and found that as the deep cryogenic soaking time increased, the tensile strength and hardness increased. The grain size of the alloy studied decreased with the extension of the soaking time. Mani et al. [22] explored the impact of different deep cryogenic treatments on the low-cycle fatigue behavior of 6063 aluminum alloy. They found that samples treated with deep cryogenic treatment for 6 h had the highest fatigue life, with the formation of Mg2Si leading to an increase in fatigue performance and hardness. Madhloom et al. [23] treated AA6061 alloy at −196 °C for 24 h, and the results showed a significant increase in the alloy’s tensile strength. The uniformly distributed Mg2Si precipitate phases were the main reason for the strengthening effect. Jovičević-Klug et al. [24] conducted deep cryogenic treatment on Al-Mg-Si alloy and found that the alloy’s wear resistance significantly improved after treatment, with no impact on other mechanical properties. Deep cryogenic treatment can adjust the morphology and distribution of precipitate phases, which are related to the mechanical properties exhibited by the material. Based on the literature analysis, deep cryogenic treatment affects the microstructure and mechanical behavior of the material. It optimizes the mechanical properties of the material by regulating the microstructure. Therefore, further in-depth research is needed to explore the mechanical response of aluminum alloys after deep cryogenic treatment and the underlying micromechanisms.

The 6000 series aluminum alloy is a heat-treatable aluminum alloy with strong deformability, widely used in industrial production and daily life. To enhance the service performance of aluminum alloy components and fully tap the application potential of the 6000 series aluminum alloy, it is worthwhile to explore the impact of deep cryogenic treatment and the following aging treatment on its microstructure and mechanical properties, as well as to analyze the strengthening and toughening mechanisms. Although some progress has been made in the research on deep cryogenic treatment and related aging treatments for the 6000 series aluminum alloy, further exploration of its strengthening and toughening mechanisms is still required. In this context, this paper conducts deep cryogenic treatment and aging treatment on the 6082 alloy, studies the impact of heat treatments on its microstructure and mechanical properties, and analyzes the mechanisms of strengthening and toughening.

2. Materials and Experimental Methods

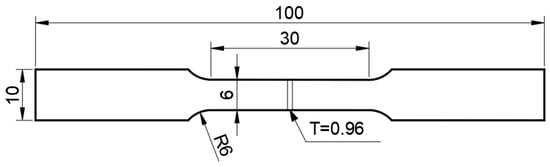

The material selected for this experiment is an industrially rolled 6082 aluminum alloy sheet with a thickness of 3 mm, and its chemical composition presented in Table 1 was acquired using a spark spectroscopy test. Tensile test specimens were machined from the transverse direction of the sheet using a wire cutting method. According to the requirement of ASTM standard [25], the shape and dimensions of the specimens are depicted in Figure 1. The length of each specimen is 100 mm, the width is 10 mm, and the thickness is 3 mm.

Table 1.

Chemical composition of the 6082 aluminum alloy sheet (mass fraction, %).

Figure 1.

The size of tensile specimen (mm).

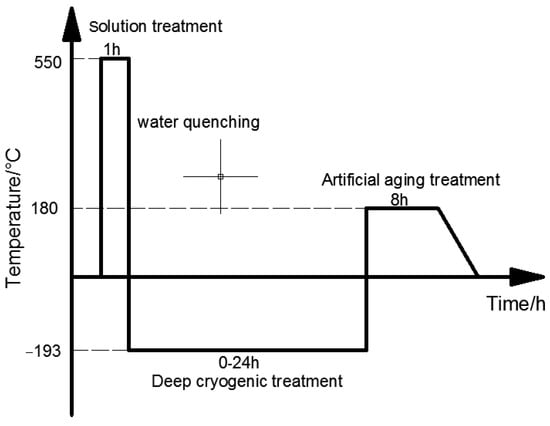

The tensile specimens were subjected to a deep cryogenic aging heat treatment process, the flowchart of which is illustrated in Figure 2. Initially, the specimens were placed into the furnace once solution temperature of 550 °C was obtained, and the duration was 1 h. Following the solution treatment, the specimens were rapidly quenched in water and then promptly immersed in liquid nitrogen for varying durations of deep cryogenic treatment. The durations of the deep cryogenic treatment were 4, 8, 12, 16, 20, and 24 h, respectively. Upon completion of the deep cryogenic treatment, the specimens were immediately subjected to an artificial aging treatment at a temperature of 180 °C for a period of 8 h; then, the specimens were air cooled to the ambient temperature. We have also prepared the specimens with only solution and artificial aging treatments to make a comparison. The solution and aging treatments were conducted using a box-type resistance furnace (Dt Industry, Guangzhou, China) and an oil bath aging furnace (HH-S, Changzhou, China), respectively, while the deep cryogenic treatment was performed within a dedicated liquid nitrogen container (Yizhong, Qingdao, China).

Figure 2.

Cryogenic treatment processes of the sample.

After the tensile specimens were polished using emery paper to achieve a uniform surface finish, tensile tests were conducted using an Instron universal testing machine at a strain rate of 0.001 s−1. In order to guarantee the accuracy of the experimental results, repetitive tensile tests were conducted for each condition. The stress–strain curves are the average results of five effective curves.

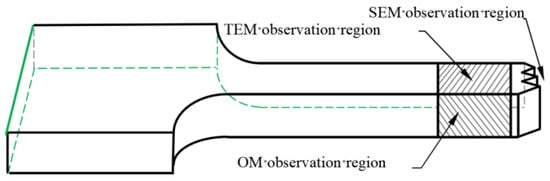

Figure 3 presents a schematic diagram of the sample characterization location. A small area near the fracture of the tensile specimen was sectioned for observation of the fracture structure. The samples were cleaned with alcohol and then observed using an EVO-18 scanning electron microscope (SEM). The metallographic (OM) observation surfaces were polished with emery papers of 600, 1000, and 2000 grit sizes, respectively. A scratch-free mirror-like finish was achieved through polishing, followed by anodic coating treatment using an electrolyte solution of 5% volume fraction hydrofluoric acid and boric acid, with an applied voltage of 20 V and an electrolysis time of 1–3 min. The microstructure observation and data acquisition were performed on an AX10 Zeiss (Jena, Germany) optical microscope.

Figure 3.

Characterization region of the sample.

For the thin foil samples taken near the fracture, mechanical thinning was conducted to a thickness of 0.07 mm. Subsequently, circular thin discs were punched out using a die with a diameter of 3 mm. These discs were then subjected to electrochemical dual-jet thinning and perforation on a MIP-1A magnetically driven dual-jet polisher. The electrochemical dual-jet thinning was performed using a solution with a volume ratio of 7:3 methanol to nitric acid, with the temperature controlled between −30 and −20 °C and an applied voltage of 20 V. Finally, the samples were characterized using a Tecnai G2 F20 (provided by FEI Company from the Hillsboro, OR, USA) transmission electron microscope (TEM) operated at a working voltage of 200 kV.

3. Results and Discussion

3.1. Mechanical Properties

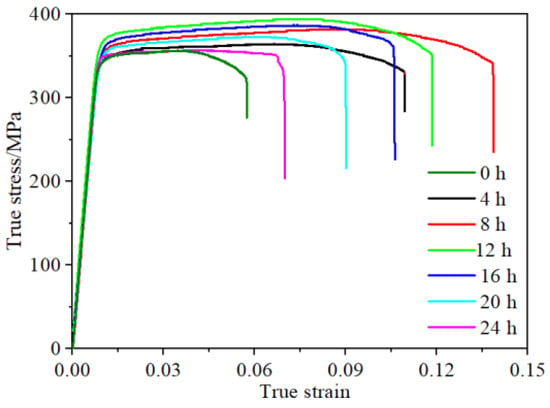

Figure 4 illustrates the true stress–true strain curves of the 6082 aluminum alloy sheets subjected to deep cryogenic aging treatment via various processes. As depicted in the figure, the overall trend of the tensile curves for the alloy in different heat treatment conditions is consistent. Initially, during the tensile process, the alloy undergoes elastic deformation, where the true stress is directly proportional to the true strain. Subsequently, the alloy transitions into the plastic deformation stage, with an increase in stress corresponding to an increase in strain. The formation of a multitude of dislocation tangles and dislocation cells within the alloy leads to an increase in dislocation density [26], and the deformation process is predominantly governed by work hardening. Upon reaching the ultimate tensile strength, the alloy enters a stage where the stress decreases with increasing strain, during which softening behavior becomes more pronounced. This is attributed to dynamic recovery that occurs during plastic deformation, facilitating the mutual annihilation of a significant number of dislocations within the alloy [27], resulting in a reduction in dislocation density and a decrease in the alloy’s slip resistance. Consequently, the material’s strength is diminished. In the final stage, the material undergoes fracture instability. Collectively, the room temperature true stress–true strain curve is the result of a continuous competition between work hardening and dynamic softening.

Figure 4.

True stress–strain curve of 6082 aluminum alloy under different cryogenic treatment.

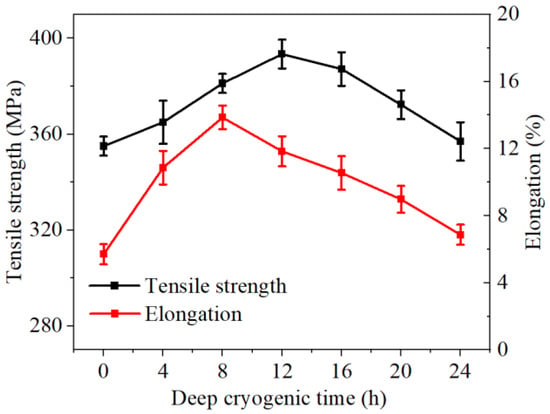

Figure 5 presents the mechanical properties of the 6082 aluminum alloy subjected to varying durations of deep cryogenic treatment. The error bars were established based on the effective values. The tensile strength of the 6082 aluminum alloy treated with deep cryogenic processing exhibits an initial increase followed by a decrease. Specifically, for the sample without cryogenic treatment, the tensile strength is 355 MPa, after a 4 h deep cryogenic treatment, the tensile strength of the alloy was 365 MPa, and it reached a peak value of 390 MPa after a 12 h treatment. This could be attributed to the volumetric contraction and grain rotation within the alloy caused by deep cryogenic treatment, as well as the shrinkage of vacancies and microvoids in the matrix, which enhances the material’s strength [28]. Additionally, deep cryogenic treatment can regulate the precipitation behavior during subsequent artificial aging, controlling the morphology and density of the precipitates, thereby increasing the material’s strength [29]. As the duration of deep cryogenic treatment is further extended, the tensile strength of the alloy tends to decrease, with a value of 360 MPa after a 24 h treatment. Moreover, the elongation rate of the alloy also shows a trend of initial increase followed by a decrease, for the sample without cryogenic treatment, the elongation is only 5.7%, the peaking elongation is 13% after an 8 h deep cryogenic treatment. According to the literature, on one hand, the micro-plastic deformation induced by deep cryogenic treatment promotes the proliferation of dislocations, increasing the dislocation density. An elevated dislocation density facilitates the recovery and recrystallization of the alloy, promoting the formation of subgrains [30]. On the other hand, deep cryogenic treatment transforms the originally continuous distribution of precipitates at the grain boundaries into a discontinuous distribution, and the size and spacing of the grain boundary precipitates increase with the extension of deep cryogenic time, thereby enhancing the alloy’s plasticity [20].

Figure 5.

Variations of tensile strength as a function of orientation under different heat treatment conditions.

3.2. Fracture Morphology

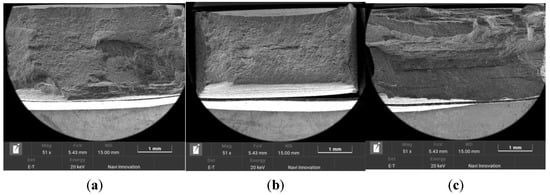

Figure 6 displays the macroscopic fracture surfaces of the 6082 aluminum alloy samples subjected to various deep cryogenic aging treatments. As can be observed from Figure 6a, under the condition of artificial aging following a 4 h deep cryogenic treatment, the fracture cross-sectional area is relatively large, indicating that the sample underwent significant plastic deformation. With an increase in the duration of deep cryogenic treatment, under the condition of a 12 h treatment as shown in Figure 6b, the fracture cross-sectional area decreases, the necking of the sample becomes more pronounced, and the alloy exhibits a higher elongation rate. When the deep cryogenic treatment duration is further increased, under the condition of a 24 h treatment, the fracture cross-sectional area increases, and the plasticity is reduced, indicating a decline in elongation rate. Deep cryogenic treatment influences the size, quantity, and distribution of precipitates during the subsequent artificial aging process, as well as the number, morphology, and distribution of dislocations, thereby affecting the tensile deformation behavior and the fracture process of the material.

Figure 6.

Macro morphology of tensile fracture surface of alloy after different heat treatments: (a) DC 4 h + AA; (b) DC 12 h + AA; (c) DC 24 h + AA.

Figure 7 presents the fracture morphologies of the alloy samples after tensile testing following different heat treatment processes. The fracture surfaces of the samples treated with three distinct processes all exhibit dimples of varying quantities, sizes, and depths, indicating a ductile fracture mode. As shown in Figure 7a, the sample treated with a 4 h deep cryogenic process displays a higher number of dimples that are deeper, suggesting better plasticity. With an increase in the deep cryogenic treatment duration, as illustrated in Figure 7b, the sample treated for 12 h exhibits a significant increase in the number of dimples, with larger sizes and deeper depths, which correlates with an enhancement in the alloy’s plasticity. When the deep cryogenic treatment duration is extended to 24 h, there is a reduction in the number, size, and depth of the dimples, indicating a continuous decrease in the alloy’s elongation rate.

Figure 7.

Fracture morphology of tensile surface of 6082 alloy after different heat treatments: (a) DC 4 h + AA; (b) DC 12 h + AA; (c) DC 24 h + AA.

The variation in dimple characteristics suggests that deep cryogenic treatment significantly influences the fracture behavior of the alloy. The increased plasticity observed with extended deep cryogenic treatment times can be attributed to the microstructural changes induced by the treatment, which may include the refinement of precipitates, alterations in dislocation structures, and the promotion of grain boundary sliding, all of which contribute to the alloy’s ability to undergo plastic deformation before fracture. However, excessive deep cryogenic treatment durations may lead to overaging effects, reducing the alloy’s plasticity and elongation capacity.

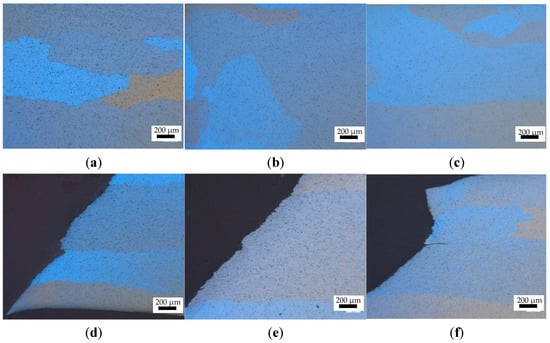

3.3. Microstructure

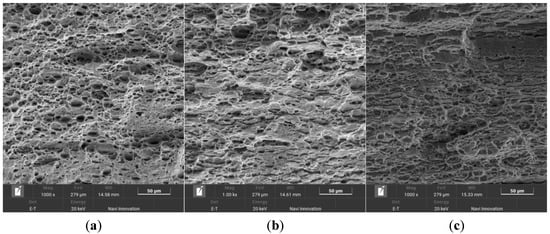

Figure 8 presents the OM images of the 6082 alloy before and after tensile fracture following various deep cryogenic aging treatments. As can be observed from Figure 8a–c, the morphology of the alloy’s grains does not undergo significant changes with the extension of the deep cryogenic treatment time, all the samples exhibiting a coarse grain structure. When the deep cryogenic treatment time is 4 h, the size of the grains is approximately 223 µm; at 12 h, the grain size is about 230 µm; and at 24 h, the grain size is around 220 µm. From Figure 8d–f, it can be seen that during the tensile process, the grains near the fracture area undergo shear deformation along the 45° direction. During tensile deformation, when the deformation reaches a certain level, microvoids nucleate and grow within the alloy, and the adjacent voids coalesce, ultimately leading to the fracture of the tensile specimen [31]. The microstructural observations suggest that while the deep cryogenic treatment does not significantly alter the grain size, it does influence the deformation behavior of the alloy. The shear deformation of grains and the nucleation and growth of microvoids are indicative of the alloy’s ductility and fracture mechanism. The relatively consistent grain size across different treatment durations implies that other microstructural features, such as the distribution and density of precipitates and dislocations, may play a more critical role in the observed changes in mechanical properties. Further analysis of the precipitate phases and dislocation structures would be necessary to fully understand the strengthening and toughening mechanisms induced by the deep cryogenic treatment.

Figure 8.

OM of 6082 alloy after different heat treatments: (a) DC 4 h + AA undeformed; (b) DC 12 h + AA undeformed; (c) DC 24 h + AA undeformed; (d) DC 4 h + AA deformed; (e) DC 12 h + AA deformed; and (f) DC 24 h + AA deformed.

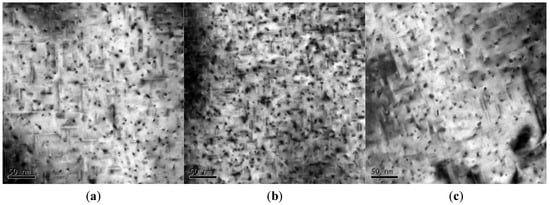

Deep cryogenic treatment following the solutionizing and quenching of the alloy can increase the supersaturation of the aluminum alloy matrix, thereby enhancing the driving force for subsequent precipitation. In the early stages of aging, a large number of GP zones form within the alloy, which then undergo a continuous precipitation transformation to form β″ [32]. Additionally, the low-temperature conditions during deep cryogenic treatment result in a lower atomic diffusion rate and shorter migration distances, which suppress the growth of the β′ and β phases. Consequently, the intragranular precipitates formed after deep cryogenic treatment are relatively fine in size. As shown in Figure 9a, the 6082 alloy with 4h deep cryogenic treatment contains a certain number of needle-like β″ precipitates dispersed within the matrix [33]. Figure 9b illustrate that, as the deep cryogenic treatment time increases, a large number of GP zones within the crystal precipitate first transform into β″ phase under the action of precipitation driving force, increasing in density, with the highest density of intragranular β″ phase observed at a deep cryogenic treatment time of 12 h. As the deep cryogenic treatment time continues to increase, the β″ precipitates further transform into β′ and β phases under the influence of precipitation driving force, and the density of β″ precipitates decreases, resulting in a significant reduction in the number of needle-like β″ precipitates after 24 h of deep cryogenic treatment.

Figure 9.

TEM of 6082 alloy after different heat treatments: (a) DC 4 h + AA; (b) DC 12 h + AA; (c) DC 24 h + AA.

When the size of the intragranular precipitates is small, that is, when the precipitates are primarily fine, GP zones and β″ phase, dislocations can more easily shear through the precipitates. This indicates that the dislocation movement mechanism is a shearing mechanism [34]. The strengthening effect can be expressed by Equation (1):

where λ is a constant, f is the volume fraction of the precipitates, and γ is the size of the precipitates.

In summary, deep cryogenic treatment leads to alterations in the morphology and quantity of the precipitates within the alloy matrix. The low-temperature conditions during deep cryogenic treatment inhibit the growth of precipitates, resulting in smaller precipitate sizes. This treatment also causes a volumetric contraction of the alloy, generating microstresses that induce plastic deformation in the material, which may contribute to the refinement and uniform distribution of the precipitates. The deep cryogenic treatment duration also impacts the distribution and size of the precipitates at the grain boundaries. After deep cryogenic treatment, the grain boundary precipitates transition from a continuous to a discontinuous distribution, with an increase in size and spacing as the duration of the deep cryogenic treatment is extended. This transition is beneficial for enhancing the plasticity of the alloy.

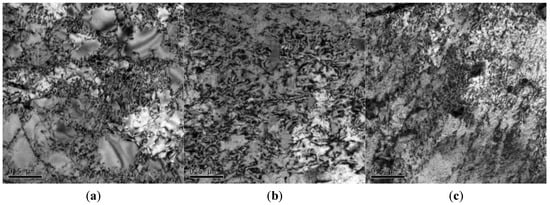

Figure 10 provides TEM micrographs illustrating the typical dislocation characteristics in the 6082 alloy after a different duration of deep cryogenic treatment. The images reveal that the dislocation density within the alloy is significantly increased following deep cryogenic treatment. With the extension of deep cryogenic treatment time, there is a progressive increase in the dislocation density around the grain boundaries; at a deep cryogenic treatment time of 4 h, dislocation walls were formed, and at 12 h, dislocation tangles were observed. Additionally, dislocations primarily proliferate in the vicinity of the precipitates. Although the size of the precipitates within the alloy matrix slightly decreases, their density markedly increases, which in turn enhances both the strength and plasticity of the alloy. When the deep cryogenic treatment time is extended to 24 h, there is a slight decrease in the dislocation density within the matrix. In conclusion, the deep cryogenic treatment significantly influences the microstructure of the 6082 aluminum alloy, leading to changes in dislocation density and the formation of dislocation structures. These microstructural changes contribute to the observed improvements in strength and plasticity, making deep cryogenic treatment a promising approach for enhancing the performance of aluminum alloys.

Figure 10.

TEM pictures of 6082 alloy after tension under different heat treatments: (a) DC 4 h + AA; (b) DC 12 h + AA; (c) DC 24 h + AA.

4. Conclusions

- The 6082 alloy subjected to deep cryogenic aging treatment exhibits a trend of initial increase followed by a decrease in both strength and elongation rate. Specifically, the yield strength reaches its peak value of 390 MPa after a 12 h deep cryogenic treatment followed by an artificial aging process at 180 °C/8 h. This could be attributed to the volumetric contraction and grain rotation within the alloy caused by deep cryogenic treatment, as well as the shrinkage of vacancies and microvoids in the matrix. Additionally, deep cryogenic treatment can regulate the precipitation behavior.

- The 6082 alloy that has undergone deep cryogenic aging treatment demonstrates characteristics of ductile fracture upon tensile failure. The cross-sectional area of the macroscopic fracture surface first decreases and then increases with varying durations of deep cryogenic treatment. The smallest cross-sectional area of the fracture surface is observed after a 12 h deep cryogenic treatment followed by an artificial aging process at 180 °C for 8 h, where the fracture exhibits the highest number of dimples, the largest dimple size, and the deepest dimples. The elongation rate achieves its maximum value of 13% after an 8h deep cryogenic treatment coupled with a 180 °C/8 h artificial aging process.

- The deep cryogenic aging treatment does not significantly affect the grain size of the 6082 alloy, with the average grain size remaining approximately 230 µm. Deep cryogenic treatment can increase the supersaturation of the aluminum alloy matrix, thereby enhancing the driving force for subsequent precipitation. A more refined and denser distribution of needle-like precipitates within the matrix of the 6082 alloy was observed, which contributed to a more pronounced pinning effect, resulting in a significant enhancement in the material’s strength. Additionally, the formation of subgrains was found after deep cryogenic treatment, and the grain boundary precipitates transitioned from a continuous to a discontinuous distribution. These microstructural changes are beneficial for improving the plasticity of the material.

Author Contributions

Conceptualization, T.Y. and S.Q.; Methodology, Y.W. and J.T.; Data curation, S.Q. and J.T.; Formal analysis, T.Y. and Y.T.; Funding acquisition, Y.W.; Investigation, E.X. and C.W.; Resources, Y.T. and C.W.; Writing—original draft, S.Q. and T.Y.; Validation, E.X. and J.T.; Visualization, C.W. and J.T.; Supervision Y.W.; Writing—review and editing, E.X. and S.Q. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully acknowledge financial support from the National Natural Science foundation of China [52201074, 52171115], Hunan Provincial Natural Science Foundation of China [2024JJ7114, 2024JJ7117].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Muzamil, M.; Iqbal, S.A.; Anwar, M.N.; Samiuddin, M.; Yang, J.; Raza, M.A. Wear Behavior assessment of new wire-arc additively manufactured surfaces on AA6061 and AA5086 alloys through multi-walled carbon nanotubes and Ni particles inducement. Coatings 2024, 14, 429. [Google Scholar] [CrossRef]

- Singh, P.; Ramacharyulu, D.A.; Kumar, N.; Saxena, K.K.; Eldin, S.M. Change in the structure and mechanical properties of Al-Mg-Si alloys caused by the addition of other elements: A comprehensive review. J. Mater. Res. Technol. 2023, 27, 1764–1796. [Google Scholar] [CrossRef]

- Khangholi, S.N.; Javidani, M.; Maltais, A.; Chen, X.G. Review on recent progress in Al-Mg-Si 6xxx conductor alloys. J. Mater. Res. 2022, 37, 670–691. [Google Scholar] [CrossRef]

- Baruah, M.; Borah, A. Processing and precipitation strengthening of 6xxx series aluminium alloys: A review. Int. J. Mater. Sci. 2020, 1, 40–48. [Google Scholar] [CrossRef]

- Bhat, K.U.; Panemangalore, D.B.; Kuruveri, S.B.; John, M.; Menezes, P.L. Surface modification of 6xxx Series aluminum alloys. Coatings 2022, 12, 180. [Google Scholar] [CrossRef]

- Hagen, A.B.; Wenner, S.; Bjørge, R.; Wan, D.; Marioara, C.D.; Holmestad, R.; Ringdalen, I.G. Local mechanical properties and precipitation inhomogeneity in large-grained Al–Mg–Si alloy. Mater. Sci. Eng. A 2023, 872, 144222. [Google Scholar] [CrossRef]

- Chen, Y.; Wei, W.; Zhao, Y.; Shi, W.; Zhou, X.; Rong, L.; Wen, S.; Wu, X.; Gao, K.; Huang, H.; et al. Effect of the solid solution and aging treatment on the mechanical properties and microstructure of a novel Al-Mg-Si alloy. Materials 2023, 16, 7036. [Google Scholar] [CrossRef]

- Kang, H.J.; Park, J.Y.; Choi, Y.S.; Cho, D.H. Influence of the solution and artificial aging treatments on the microstructure and mechanical properties of die-cast Al-Si-Mg alloys. Metals 2021, 12, 71. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, Y.; Liu, F. Microalloying-modulated strength-ductility trade-offs in as-cast Al-Mg-Si-Cu alloys. Mater. Sci. Eng. A 2022, 855, 143897. [Google Scholar] [CrossRef]

- Jovičević-Klug, P.; Tóth, L.; Podgornik, B. Comparison of K340 steel microstructure and mechanical properties using shallow and deep cryogenic treatment. Coatings 2022, 12, 1296. [Google Scholar] [CrossRef]

- Weng, Z.; Xu, X.; Yang, B.; Gu, K.; Chen, L.; Wang, J. Cryogenic thermal conductivity of 7050 aluminum alloy subjected to different heat treatments. Cryogenics 2021, 116, 103305. [Google Scholar] [CrossRef]

- Tang, P.; Yan, T.; Wu, Y.; Tang, H. Effect of Deep cryogenic aging treatment on microstructure and mechanical properties of selective laser-melted AlSi10Mg alloy. Metals 2024, 14, 493. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Y.; Liu, Y.; Huang, Y. Influence of substructures on precipitation behavior and mechanical properties of cryogenic rolled Al-Mg-Si alloys during aging treatment. J. Mater. Res. Technol. 2023, 25, 946–959. [Google Scholar] [CrossRef]

- Franco Steier, V.; Ashiuchi, E.S.; Reißig, L.; Araújo, J.A. Effect of a deep cryogenic treatment on wear and microstructure of a 6101 aluminum alloy. Adv. Mater. Sci. Eng. 2016, 2016, 1582490. [Google Scholar] [CrossRef]

- Gruber, B.; Grabner, F.; Fragner, W.; Schökel, A.; Spieckermann, F.; Uggowitzer, P.J.; Pogatscher, S. Ageing behaviour of Al-Mg-Si alloys after cryogenic and room temperature deformation. Materials 2020, 13, 554. [Google Scholar] [CrossRef] [PubMed]

- Park, D.H.; Choi, S.W.; Kim, J.H.; Lee, J.M. Cryogenic mechanical behavior of 5000-and 6000-series aluminum alloys: Issues on application to offshore plants. Cryogenics 2015, 68, 44–58. [Google Scholar] [CrossRef]

- Xia, E.; Ye, T.; Qiu, S.; Liu, J.; Luo, J.; Sun, L.; Wu, Y. Mechanical Properties and Microstructural evolution of 6082 aluminum alloy with different heat treatment methods. Coatings 2024, 14, 602. [Google Scholar] [CrossRef]

- Huang, Y.; Li, Y.; Ren, X.; Xiao, Z. Effect of deep cryogenic treatment on aging processes of Al-Mg-Si alloy. Phys. Met. Metallogr. 2019, 120, 914–918. [Google Scholar] [CrossRef]

- Jovičević-Klug, M.; Jovičević-Klug, P.; Podgornik, B. Influence of deep cryogenic treatment on natural and artificial aging of Al-Mg-Si alloy EN AW 6026. J. Alloy Compd. 2022, 899, 163323. [Google Scholar] [CrossRef]

- Li, G.; Cao, Z.; Wang, H.; Ye, Y.; Xiong, M.; Dong, K.; Guo, S.; Zhou, P. Effect of deep cryogenic treatment on microstructures and mechanical properties of automotive 6063Al alloy. J. Mater. Sci. 2024, 59, 5558–5575. [Google Scholar] [CrossRef]

- Sonia, P.; Verma, V.; Saxena, K.K.; Kishore, N.; Rana, R.S. Effect of cryogenic treatment on mechanical properties and microstructure of aluminium 6082 alloy. J. Mater. Today Proc. 2020, 26, 2248–2253. [Google Scholar] [CrossRef]

- Mani, S.; Subramanian, R.K. Experimental investigation on the low cycle fatigue performance and fractographic analysis of deep cryogenic treated 6063 aluminium alloy. Structures 2023, 58, 105588. [Google Scholar] [CrossRef]

- Madhloom, M.A.; Ataiwi, A.H.; Dawood, J.J. Influence of cryogenic treatment on hardness, tensile properties, and microstructure of aluminum alloy AA6061. J. Mater. Today Proc. 2022, 60, 2157–2161. [Google Scholar] [CrossRef]

- Jovičević-Klug, M.; Tegg, L.; Jovičević-Klug, P.; Dražić, G.; Almásy, L.; Lim, B.; Cairney, J.M.; Podgornik, B. Multiscale modification of aluminum alloys with deep cryogenic treatment for advanced properties. J. Mater. Res. Technol. 2022, 21, 3062–3073. [Google Scholar] [CrossRef]

- Briseno, J.; Casanova-Del-Angel, F. Fracture Mechanics on Aluminum Specimens. World J. Mech. 2021, 12, 11. [Google Scholar] [CrossRef]

- Qiu, S.; Xia, E.; Liu, L.; Ye, T.; Liu, J.; Tang, J.; Liu, W.; Wu, Y. Tensile Behavior and Microstructure Evolution of an Extruded 6082 Aluminum Alloy Sheet at High Temperatures. J. Metals. 2023, 14, 7. [Google Scholar] [CrossRef]

- Zhao, N.; Sun, Q.; Pang, Q.; Hu, Z. Comprehensive study of hot compression behaviors and microstructure evolution of solutionized 6082 aluminum alloy extruded bar. J. Alloy Compd. 2023, 931, 167541. [Google Scholar] [CrossRef]

- Yao, E.; Zhang, H.; Ma, K.; Ai, C.; Gao, Q.; Lin, X. Effect of deep cryogenic treatment on microstructures and performances of aluminum alloys: A review. J. Mater. Res. Technol. 2023, 26, 3661–3675. [Google Scholar] [CrossRef]

- Mavi, A.; Kaplan, Y.; Aksoz, S. Effects of aging and deep cryogenic treatment on wear behavior of Al7075 Alloy. J. Tribol. 2021, 143, 121702. [Google Scholar] [CrossRef]

- Chrominski, W.; Lewandowska, M. Influence of dislocation structures on precipitation phenomena in rolled Al–Mg–Si alloy. Mat. Sci. Eng. A 2020, 793, 139903. [Google Scholar] [CrossRef]

- Trink, B.; Weißensteiner, I.; Uggowitzer, P.J.; Strobel, K.; Hofer-Roblyek, A.; Pogatscher, S. Processing and microstructure–property relations of Al-Mg-Si-Fe crossover alloys. Acta Mater. 2023, 257, 119160. [Google Scholar] [CrossRef]

- Weng, Y.; Ding, L.; Zhang, Z.; Jia, Z.; Wen, B.; Liu, Y.; Muraishi, S.; Li, Y.; Liu, Q. Effect of Ag addition on the precipitation evolution and interfacial segregation for Al–Mg–Si alloy. J. Acta Mater. 2019, 180, 301–316. [Google Scholar] [CrossRef]

- Yang, M.; Chen, H.; Orekhov, A.; Lu, Q.; Lan, X.; Li, K.; Zhang, S.; Song, M.; Kong, Y.; Schryvers, D.; et al. Quantified contribution of β″ and β′ precipitates to the strengthening of an aged Al–Mg–Si alloy. J. Mat. Sci. Eng. A 2020, 774, 138776. [Google Scholar] [CrossRef]

- Yang, M.; Orekhov, A.; Hu, Z.Y.; Feng, M.; Jin, S.; Sha, G.; Li, K.; Samaee, V.; Song, M.; Du, Y.; et al. Shearing and rotation of β″ and βʹ precipitates in an Al-Mg-Si alloy under tensile deformation: In-situ and ex-situ studies. Acta Mater. 2021, 220, 117310. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).