Abstract

In this work we have synthesized Ti3C2TX MXene powder and studied its structure. Composite electrochemical coatings (CECs) of Ni-Ti3C2TX MXene were obtained from a sulfate– chloride bath in the galvanostatic regime. The microstructure of CEC was researched using X-ray phase analysis and scanning electron microscopy methods. It has been established that a Ni–Ti3C2TX MXene CEC microhardness rises by about 1.80 times compared with electrolytic Ni without a dispersed phase. For corrosion research, different corrosive media is applied. The corrosion–electrochemical behavior of Ni–Ti3C2TX MXene CECs by the chronovoltamperometry method in 0.5 M H2SO4 solution has been investigated. Trials in 3.5% NaCl have shown that Ti3C2TX MXene inclusion into the matrix of the electrochemical Ni results in a decrease in the corrosion rate by 1.60–1.75 times. These effects are due to the addition of Ti3C2TX MXene into the nickel matrix and the formation of CECs with a strengthening fine-grained structure.

1. Introduction

The electrochemical deposition of nickel coatings is one of the most common methods for modifying the surface of metal products. Electrolytic nickel and the alloys based on it are superior to many metals in such properties as corrosion resistance, wear resistance, and hardness, which results in their wide application (gas and steam turbines, chemical and oil and gas equipment, medical instruments, etc.) [1,2]. By co-precipitating nickel with dispersed particles of various natures, it is possible to greatly improve its functional properties. Coatings obtained through the electrodeposition of metals together with the dispersed phase are called composite electrochemical coatings (CEC). In particular, nickel-based CECs are known for their excellent adhesion, good corrosion resistance, and abrasion resistance [2,3].

Compounds of various natures can be used as a dispersed phase in the deposition of nickel CECs. The modification of the nickel matrix with ceramic particles (SiC [4] TiO2 [5]), polymers [6], and carbon compounds (fullerenes [7,8], carbon nanotubes [9,10,11], nanodiamonds [12], graphene, and its derivatives [13,14,15]) is known.

Recently, two-dimensional materials called MXenes, discovered in 2011, have aroused great interest [16,17,18,19,20,21]. MXenes are a new class of two-dimensional nanomaterials based on early transition metal carbides and/or nitrides and can be represented by a general formula Mm+1XmTx (m = 1–4), where M is a transition metal (Sc, Ti, V, Cr, Nb, Ta, Nb, Zr, or Mo), X–C and/or N, Tx–surface terminations (such as -O, -OH, -F, -Cl) [22]. The methods for obtaining MXenes are based on a selective etching of the A layer from Mn+1AXn (MAX) structures, where A is usually an element such as Al, Si, Ga, etc. However, Ti3C2 MXene is the most popular compound among these, due to its availability and unique set of functional properties. Etching is usually carried out by treating MAX phase powders in hydrofluoric acid (HF) or mixtures of hydrochloric acid (HCl) and fluoride salts (LiF, KF, etc.) [23]. The great interest in this class of nanomaterials is associated primarily with their exceptional optical, mechanical, electrical, magnetic, and physicochemical properties [24,25]. In this regard, MXenes are promising for a wide range of different applications, such as water treatment, energy storage, catalysts, sensors, and more [26]. In addition, due to the mechanical, tribological, and anti-corrosion properties of MXenes, they can be used in coatings to improve their anti-friction and anti-corrosion properties and to increase their microhardness. For example, their application as lubricating additives makes it possible to reduce the friction coefficient and improve their wear protection due to the formation of a layer from MXene nanosheets which has unique properties [27,28]. In Ref. [29], a polypyrrole/Ti3C2Tx coating was applied to stainless steel by galvanostatic electrodeposition. It has been shown that MXene plays a key role in improving corrosion resistance, anode protection, and adhesion. Currently, few studies have been published on the use of MXene in metal composite coatings to improve their properties. The authors of [30] show that the addition of Ti3C2TX and Ti3C2TX/MoS2 particles into the composition of the Ni-P coating makes it possible to reduce the friction coefficient and increase the wear resistance, microhardness, etc. Similar results were obtained through the inclusion of Ti3C2Tx–Ce into the Ni–P matrix [31], where, besides an increase in microhardness, corrosion resistance was also improved due to the effective blocking of the diffusion of aggressive substances. Furthermore, 2D MXene, especially Ti3C2Tx, has been widely used in the realm of corrosion inhibition and protective coatings [32].

However, there are practically no works on the modification of nickel with a Ti3C2Tx MXene compound, so it is relevant to obtain composite nickel coatings containing Ti3C2 Tx MXene and to research the influence of this compound on the operating characteristics of electrolytic nickel.

The purpose of this study is to obtain Ni–Ti3C2Tx MXene composite coatings in a stationary mode of electrolysis and to examine their structure and their physical–mechanical and corrosion properties.

2. Materials and Methods

- (a)

- Ti3C2Tx MXene synthesis

The Ti3AlC2 MAX phase precursor powder was obtained using the molten salt-assisted synthesis method [33] from TiC elemental powders (Mark B, TU 87 48-42-6-84, 0.8–1.5 µm, Mreda, Beijing, China), Ti (PTM -1, TU 14-22-57-92, Polema, Tula, 88 Russia), and Al (PA 4, less 100 µm, Russian Standard 6058-73, Nizhny Novgorod, Russia). To do this, the corresponding powders with the stoichiometric molar ratio TiC:Ti:Al = 2:1:1 were mixed and pressed into cylindrical granules with a diameter and height of ≈12 mm, which were immersed into molten KCl-NaCl salt (molar ratio 1/1) and kept in the muffle furnace at 1300 °C for 3 h in an air atmosphere. The resulting powders were washed with deionized water until the salts were completely removed, filtered, and dried at 100 °C.

Hydrofluoric acid (HF, 49 wt.%, Russian Standard 10484-78, Russia) was used for the selective etching of aluminum layers from Ti3AlC2 MAX phase to create layered Ti3C2Tx MXene titanium carbides. For this, 100 mL of HF solution (25 wt%) was poured into a Teflon reactor, into which 5 g of the Ti3AlC2 MAX phase powder was then immersed in small portions. The reaction was carried out at 30 °C for 60 h with constant stirring. The resulting suspension was washed several times with HCl (6 M) and then with deionized water until neutral pH ≈ 6 was reached, and then it was dried in the vacuum oven at 60 °C for 24 h.

- (b) Electrodeposition of nickel–Ti3C2Tx composite coatings

Composite Ni–Ti3C2Tx MXene coatings were deposited on a steel substrate (steel 45) from a sulfate–chloride bath (Table 1).

Table 1.

Electrolyte composition and deposition parameters used for Ni–Ti3C2Tx MXene.

Ti3C2Tx MXene was added into the bath in the form of a powder. Electrochemical deposits of pure nickel were obtained from the above-mentioned solution without Ti3C2Tx. The thickness of all studied coatings was 20 μm. Pretreatment of the electrode surface consisted of mechanical cleaning by sandpaper from 200 to 2500 grit systematically, anodic etching in 48% H3PO4 with Pb counter electrode, and washing in distilled water.

- (c) Investigation of structure and properties

The phase composition was studied with the help of ARL X’TRA device (Thermo Scientific, Ecublens, Switzerland) applying Cu Kα radiation (λ = 0.15412 nm). Ti3C2Tx powders morphology and the surfaces of the nickel coatings were examined using an ASPEX Explorer scanning electron microscope (ASPEX, Framingham, MA, USA).

Electrochemical measurements were performed on a P-30J potentiostat (Elins, Russia). The potentials were set relative to a saturated silver chloride reference electrode and recalculated on the hydrogen scale.

Vickers microhardness (HV) was measured using a PMT-3 instrument (AO LOMO, Russia). A tetrahedral diamond pyramid was statically pressed into the Ni electrolytic deposits under a load of 100 g. The average penetration depth of the imprint was 3.06 μm. The distance between the imprints was no more than two diagonals. Based on the tests conducted, values of both diagonals of the imprint were determined. The calculation of HV was carried out according to the data of seven parallel measurements. The experiment error was 3%.

To assess the corrosion–electrochemical behavior of nickel coatings, anodic potentiodynamic plots were obtained in the 0.5 M H2SO4 solution (potential sweep rate Vp = 8 mV/s). Corrosion rate was studied in 3.5% NaCl solution.

3. Results and Discussion

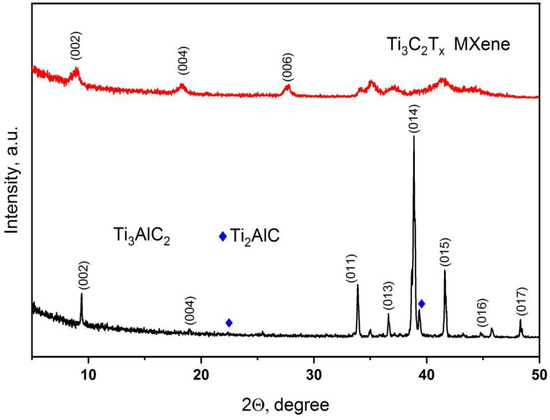

The properties of CECs significantly depend on the properties and structure of the dispersed particles. Figure 1 shows the X-ray diffraction patterns (XRD) of the Ti3AlC2 MAX phase powder obtained by sintering in the melt of salts and Ti3C2Tx MXene powder synthesized by the selective etching of Al from the MAX phase structure. The phase composition of the initial powder used for etching is represented by Ti3AlC2 (JCPDS 52-0875) as the main phase, and a small content of the secondary phase Ti2AlC. After the MAX phase powder treatment in the HF solution, significant changes are observed in the diffraction pattern. All the peaks corresponding to the Ti3AlC2 phase disappear and wide peaks appear at angles 2θ = 7.78o and 2θ = 15o, which confirm its transformation into a multilayer Ti3C2Tx MXene. In this case, the peak obtained upon reflection from the (002) plane shifted towards smaller angles from 2θ = 9.47° to 2θ = 8.91°. Thus, it is possible to draw the conclusion that the lattice parameter c increased due to the destruction of Ti-Al bonds and an etching of the Al layer from the Ti3AlC2 structure.

Figure 1.

XRD patterns of Ti3AlC2 MAX phase and Ti3C2Tx MXene.

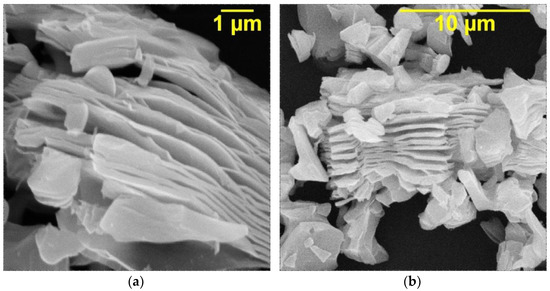

The study of Ti3AlC2 powders using scanning electron microscopy (SEM) after their treatment in hydrofluoric acid shows that their morphology is represented by layered accordion-like particles (Figure 2a,b). This indicates that the Al layers were successfully etched from the MAX phase with hydrofluoric acid, resulting in a layered 2D Ti3C2Tx MXene structure.

Figure 2.

SEM images of Ti3C2Tx MXene (a,b), pure Ni (c), and CEC Ni–Ti3C2Tx MXene (d) deposited at ic = 10 A/dm2.

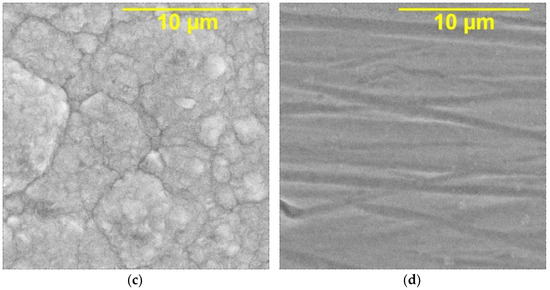

The study of the process of the joint electrodeposition of nickel with Ti3C2Tx MXene by taking potentiodynamic plots (PDP) shows that the inclusion of the Ti3C2Tx dispersed phase into the nickel-plating electrolyte affects the kinetics of electrode processes. A nickel deposit in the presence of dispersed particles is formed on the cathode at less negative electrode potentials. Electrodeposition currents of nickel–Ti3C2Tx MXene CECs increase compared with pure nickel (Figure 3), which indicates an increase in the rate of the cathodic process. During electrodeposition, Ni ions in the electrolyte with a positive charge are absorbed by Ti3C2Tx particles due to electrostatic forces. Nickel cations with adsorbed particles move towards the cathode and reduce on the electrode surface, forming a nickel deposit together with the dispersed phase. The Ti3C2Tx MXene compound (Figure 2a,b) has a developed multilayer structure with a large specific surface area, which provides more vacant places for nucleation. This increases the rate of nucleation and the deposition rate of the nickel matrix as a whole. The higher the nucleation rate, the more metal grains are formed on the surface, which must determine the fine grain size of the electrochemical deposits. The SEM study of the surface of nickel coatings shows that the dispersed phase of Ti3C2Tx MXene significantly changes the morphology of nickel deposits. The Ti3C2Tx layers prevent excessive nickel grain growth and promote the formation of a fine-grained, uniform deposit, which is consistent with the analysis of coating morphology using the SEM method (Figure 2c,d). Under the influence of Ti3C2Tx, there occurs a transition from an amorphous, coarse-grained, and disordered structure of pure nickel (Figure 2c) to a fine-grained, uniform, and dense structure of the composite coating (Figure 2d).

Figure 3.

Potentiodynamic plots of Ni electrodeposition process (1) and Ni– Ti3C2Tx MXene CEC (2) (potential sweep rate Vp = 10 mV/s).

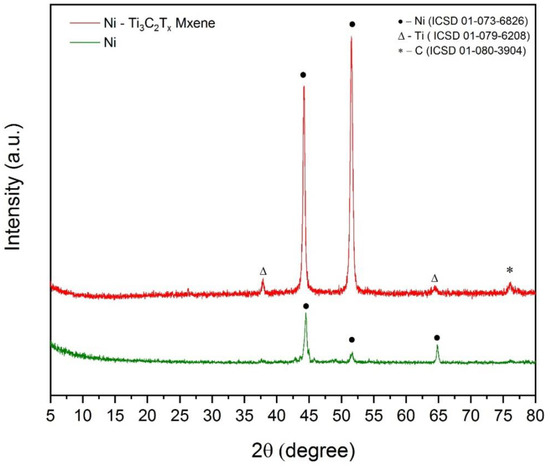

Nickel forms a face-centered cubic lattice, which corresponds to the peaks at 44º and 52º in the diffractogram (Figure 4). When nickel is modified with the Ti3C2Tx MXene compound, the intensities of the peaks at 44º and 52º, which correspond to the nickel (111) and (200) planes, increase significantly compared with pure nickel. This indicates a change in the crystal structure under the influence of the dispersed phase—the growth of a nickel crystal occurs simultaneously in two directions (111) and (200), and the peak corresponding to the crystal plane (200) is predominant for the nickel–Ti3C2Tx CEC, while for pure nickel, according to Figure 4, the preferred crystal growth orientation is the (111) plane. The appearance of the peaks corresponding to Ti and C in the nickel–Ti3C2Tx CEC diffraction pattern proves the inclusion of Ti3C2Tx into the metal matrix of the electrochemical coating. The peaks corresponding to Ni in the XRD pattern of the Ni coatings increase significantly. The intensity ratio of the composite coating changes because Ti3C2Tx has a layered structure. Nickel deposits and grows on the Mxene sheets, which leads to changes in the crystallite structure and, hence, to an increase in the peaks (the Mxene sheets affect the crystal growth).

Figure 4.

XRD patterns of Ni coating and CEC Ni–Ti3C2Tx MXene deposited at ic = 10 A/dm2.

The penetration of a dispersed phase into the structure of an electrochemical metal matrix leads to a shift, not only in their composition and structure, but also in their operational properties. Of significant practical interest are the physical and mechanical characteristics of metal surfaces, in particular their microhardness. With an increase in the cathode current density, the microhardness of the researched nickel coatings grows (Table 2). This is probably due to the inclusion of hydrogen and hydroxides in their structure, which leads to the distortion and compression of crystallites. On the transition from Ni coatings without a disperse phase to Ni–Ti3C2Tx CECs, there is a growth in microhardness of about 1.80 times in the investigated interval of current densities (Table 2). This effect is due to several reasons. First, this is due to the formation of a fine-grained structure and the dispersion strengthening of the nickel matrix in the presence of Ti3C2Tx. The embedded Ti3C2Tx sheets are located between the forming nickel grains, preventing their growth and, thus, ensuring the grinding of the grains of the composite coatings. The small grain size increases the length of the grain boundaries and prevents the movement of defects (primarily dislocations) along the crystal lattice. Secondly, the excellent physical–mechanical properties of the Ti3C2Tx particles also contribute to an increase in the hardness of the studied CECs. Moreover, the embedded particles are distributed along the grain boundaries and act as a barrier to the propagation of slip planes.

Table 2.

Microhardness HV0.10 values in MPa of Ni coatings *.

Another important property of electrochemical deposits is corrosion resistance. The following aspects are relevant to this problem: increasing the reliability of metal products to reduce material losses and prevent industrial accidents, as well as the preservation of the world’s metal resources. When metal comes into contact with an electrolyte solution, electrochemical corrosion occurs, which is a combination of two conjugate heterogeneous processes: the anodic oxidation of the metal and the cathodic reduction of the oxidizer. In the case of composite coatings, the nature of corrosion damage is conditioned by both the characteristics of the metal matrix and the dispersed phase.

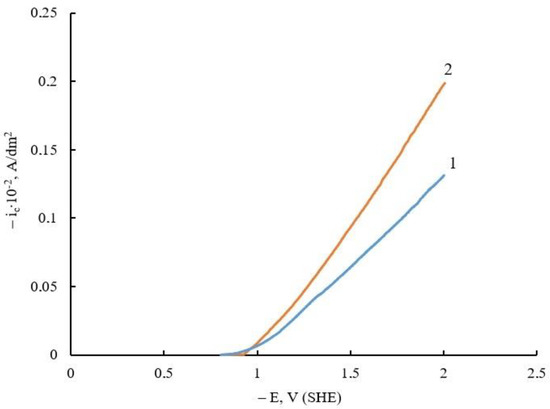

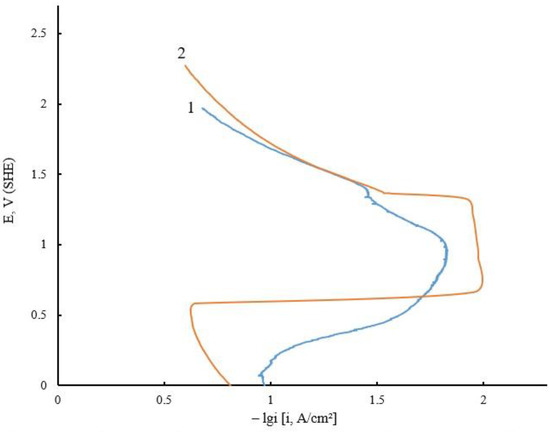

The corrosion–electrochemical behavior of the Ni deposits was investigated in 0.5 M H2SO4 solution using the chronovoltamperometry method. The anodic PDPs of Ni and the Ni–Ti3C2Tx MXene CEC (Figure 5) show that the particles of the disperse phase increase the potential and, accordingly, decrease the active anodic dissolution current of the studied coatings. The potential for the beginning of the passivation of pure Ni and CEC Ni–Ti3C2Tx are close. A characteristic feature of the anodic PDP of the Ni–Ti3C2Tx CEC is a wide, pronounced passive area, while for a Ni deposit not containing an MXene disperse phase, it is significantly smoothed. It should be noted that the rate of metal dissolution does not depend much on the potential value and can only decrease slightly when the potential shifts to the more positive values. Consequently, the broadening of the passive region for the composite coating is associated with the influence of the MXene dispersed phase. On the basis of chronovoltamperometry studies in 0.5 M H2SO4 solution, it was expected the corrosion rate of the Ni–Ti3C2Tx CECs to be less than that of the Ni deposits without a disperse phase.

Figure 5.

Potentiodynamic polarization plots of Ni (1) and Ni–Ti3C2Tx MXene (2) (deposited at ic = 10 A/dm2) in 0.5 M H2SO4.

The corrosion rate of the nickel-based electrolytic deposits was measured using the weight loss, when kept in 3.5% NaCl for 24 h (the templates were weighed before and after dipping), with the help of the next equation [34,35]:

where K is constant (8.76∙104), W is the mass loss in g, A is the exposed area of a coating template (1 cm2), T is the dipping time in hours, and D is the density of nickel (8.90 g/cm3).

Tests in 3.5% NaCl medium show that the corrosion rate of Ni–Ti3C2Tx deposits decreases by 1.60–1.75 times in comparison with that of electrolytic Ni without MXene (Table 3). It is difficult to single out only one reason for this effect. When analyzing the influence of Ti3C2Tx on the corrosion behavior of the studied Ni coatings, it is worth paying attention to several factors. The Ni–Ti3C2Tx coatings have a regular fine-grained structure, in contrast to Ni without an MXene phase (Figure 2c,d), which conditioned a uniform distribution of the corrosion current over the surface. Wetting the coating surface with a corrosive medium is important. A fine-grained metal surface is more difficult to wet, which results in a slower corrosion rate. It should be noted that corrosion is a spontaneous process with a Gibbs free energy negative value. The tendency of nickel to suffer corrosion damage depends on the crystallographic orientation, which conditions the surface free energy per unit area of the material. The ability of metal ions to penetrate through the cross-section of the dispersed particles in the coating affects the corrosion behavior. The high impermeability and stability of the Ti3C2Tx MXene phase contribute to the lengthening of the diffusion path for an aggressive environment and prevents the penetration of Ni2+ ions through the micro-particle cross section. The effect of the dispersed phase in the matrices of CECs is observed only if the particles form compounds that are more resistant to corrosion than the metal deposit at the phase boundaries or throughout the volume. Obviously, compounds like that are also formed in the volume of the studied composite coatings. All the above-mentioned reasons working in common determined a decrease in the corrosion rate of Ni–Ti3C2Tx CECs compared with electrolytic Ni without MXene.

Table 3.

Corrosion rates in mm/year of nickel coatings *.

4. Conclusions

In this work we synthesized Ti3C2TX MXene powder and studied its structure. The conducted electrochemical research allows us to conclude that in the galvanostatic electrolysis mode, CECs are formed from the sulfate–chloride nickel plating bath including Ti3C2TX MXene particles. The addition of Ti3C2TX MXene into the nickel matrix leads to a transformation in the microstructure and has a remarkable effect on the physicomechanical properties and corrosion rate of obtained CECs. The modification of electrolytic Ni by the Ti3C2TX MXene results in a growth in the microhardness of coatings by about 1.80 times, and their corrosion rate decreases by 1.60–1.75 times. These effects are due to the formation of a fine-grained structure and the strengthening of the nickel matrix by adding Ti3C2TX particles. The Ni–Ti3C2TX MXene CEC obtained at ic = 10 A/dm2 has better operating characteristics.

Author Contributions

Conceptualization, V.T.; data curation, D.T. and A.D.; formal analysis, A.T. (Alexey Tsyganov), N.G. and A.T. (Alena Tribis); investigation, V.T., A.T. (Alena Tribis), D.T., A.D., A.T. (Alexey Tsyganov) and N.G.; methodology, V.T., A.D., D.T., A.T. (Alexey Tsyganov) and N.G.; project administration, V.T.; supervision, V.T., A.D. and A.T. (Alexey Tsyganov); visualization, A.D., A.T. (Alena Tribis), D.T., A.T. (Alexey Tsyganov) and M.L.; writing—original draft, V.T., A.D. and A.T. (Alexey Tsyganov); writing—review and editing, V.T., A.D., A.T. (Alena Tribis), D.T., A.T. (Alexey Tsyganov), N.G. and M.L. All authors participated in the discussion of the results and the writing of the text of the article. All authors have read and agreed to the published version of the manuscript.

Funding

Funding: A.T. (Alexey Tsyganov) and N.G. thank for the synthesis, SEM and XRD of MXene the Russian Science Foundation, grant number 19-73-10133, https://rscf.ru/en/project/19-73-10133/ (accessed on 3 August 2022).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of financial or non-financial interest requiring disclosure in this article.

Abbreviations

| The list of acronyms: | |

| CEC | composite electrochemical coating |

| PDP | potentiodinamic plot |

| SEM | scanning electron microscopy |

| XRD | X-ray diffraction |

References

- Orinakova, R.; Turonova, A.; Kladekova, D.; Galova, M.; Smith, R.M. Recent developments in the electrodeposition of nickel and some nickel-based alloys. J. Appl. Electrochem. 2006, 36, 957–972. [Google Scholar] [CrossRef]

- Dordsheikh Torkamani, A.; Velashjerdi, M.; Abbas, A.; Bolourchi, M.; Maji, P. Electrodeposition of nickel matrix composite coatings via various boride particles: A review. J. Compos. Compd. 2021, 3, 106–113. [Google Scholar] [CrossRef]

- Tseluikin, V.N. Composite coatings modified with nanoparticles: Structure and properties. Nanotechnologies Russ. 2014, 9, 1–14. [Google Scholar] [CrossRef]

- Huang, P.C.; Hou, K.H.; Hong, J.J.; Lin, M.H.; Wang, G.L. Study of fabrication and wear properties of Ni–SiC composite coatings on A356 aluminum alloy. Wear 2021, 477, 203772. [Google Scholar] [CrossRef]

- Xiang, Y.; He, Y.; Tang, W.; Li, H.; Zhang, Y.; Song, R.; Liu, B.; He, Y.; Guo, X.; He, Z. Fabrication of robust Ni-based TiO2 composite@TTOS superhydrophobic coating for wear resistance and anti-corrosion. Colloids Surf. 2021, 629, 127394. [Google Scholar] [CrossRef]

- Iacovetta, D.; Tam, J.; Erb, U. Synthesis, structure, and properties of superhydrophobic nickel–PTFE nanocomposite coatings made by electrodeposition. Surf. Coat. Technol. 2015, 279, 134–141. [Google Scholar] [CrossRef]

- Tseluikin, V.N.; Chubenko, I.S.; Gun’kin, I.F.; Pankst’yanov, A.Y. Colloidal dispersion of fullerene C60 free of organic solvents. Russ. J. Appl. Chem. 2006, 79, 325–326. [Google Scholar] [CrossRef]

- Tseluikin, V.N.; Solov’ova, N.D.; Gun’kin, I.F. Electrodeposition of nickel-fullerene C60 composition coatings. Prot. Met. 2007, 43, 388–390. [Google Scholar] [CrossRef]

- Yang, P.; Wang, N.; Zhang, J.; Lei, Y.; Shu, B. Investigation of the microstructure and tribological properties of CNTs/Ni composites prepared by electrodeposition. Mater. Res. Express 2022, 9, 036404. [Google Scholar] [CrossRef]

- Tseluikin, V.N.; Koreshkova, A.A. Electrochemical deposition and properties of composite coatings consisting of zinc and carbon nanotubes. Russ. J. Appl. Chem. 2015, 88, 272–274. [Google Scholar] [CrossRef]

- Tseluikin, V.N.; Koreshkova, A.A. Pulsed electrodeposition of composite coatings based on zinc–nickel alloy. Prot. Met. Phys. Chem. Surf. 2018, 54, 453–456. [Google Scholar] [CrossRef]

- Hong, Q.; Wang, D.; Yin, S. The microstructure, wear and electrochemical properties of electrodeposited Ni-diamond composite coatings: Effect of diamond concentration. Mater. Today Commun. 2023, 34, 105476. [Google Scholar] [CrossRef]

- Yasin, G.; Arif, M.; Nizam, N.M.; Shakeel, M.; Khan, M.A.; Khan, W.Q.; Hassan, T.M.; Abbas, Z.; Farahbakhsh, I.; Zuo, Y. Effect of surfactant concentration in electrolyte on the fabrication and properties of nickel-graphene nanocomposite coating synthesized by electrochemical co-deposition. RSC Adv. 2018, 8, 20039–20047. [Google Scholar] [CrossRef]

- Jyotheender, K.S.; Srivastava, C. Ni-graphene oxide composite coatings: Optimum graphene oxide for enhanced corrosion resistance. Compos. Part B 2019, 175, 107145. [Google Scholar] [CrossRef]

- Lou, G.; Shen, L.; Qian, Y.; Chen, Y.; Bai, H.; Cheng, H.; Xu, J.; Yang, Y. Study on the antibacterial and anti-corrosion properties of Ni-GO/Ni-rGO composite coating on manganese steel. Surf. Coat. Technol. 2021, 424, 127681. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, M.; Xu, W.; Shen, X.; Gao, F.; Zhu, J.; Wan, X.; Lian, X.; Xu, J.; Tong, Y. Chemical Preparation of New Ti3C2MXene and the Performance and Mechanism of Memristor Based on MXene. Acta Phys. Chim. Sin. 2022, 38, 1907076. [Google Scholar]

- Huang, Y.; Wang, C.; Wang, R.; Zhang, Y.; Li, D.; Zhu, H.; Wang, G.; Zhang, X. Ethanol Solution Plasma Loads Carbon Dots onto 2D HNb3O8 for Enhanced Photocatalysis. ACS Appl. Mater. Interfaces 2023, 15, 1157–1166. [Google Scholar] [CrossRef]

- Cheng, S.; Xiong, Q.; Zhao, C.; Yang, X. Synergism of 1D CdS/2D Modified Ti3C2Tx MXene Heterojunctions for Boosted Photocatalytic Hydrogen Production. Chin. J. Struct. Chem. 2022, 41, 2208058–2208064. [Google Scholar]

- Chang, C.; Chen, W.; Chen, Y.; Chen, Y.; Chen, Y.; Feng, D.; Fan, C.; Fan, H.J.; Fan, Z.; Gong, C.; et al. Recent progress on Two-Dimensional Materials. Acta Phys. Chim. Sin. 2021, 37, 2108017. [Google Scholar] [CrossRef]

- Cao, X.; Hou, C.; Li, Y.; Li, K.; Zhang, Q.; Wang, H. MXenes-Based Functional Fibers and Their Applications in the Intelligent Wearable Field. Acta Phys. Chim. Sin. 2022, 38, 2204058. [Google Scholar] [CrossRef]

- Bu, F.; Zagho, M.M.; Ibrahim, Y.; Ma, B.; Elzatahry, A.; Zhao, D. Porous MXenes: Synthesis, structures, and applications. Nano Today 2020, 30, 100803. [Google Scholar] [CrossRef]

- Naguib, M.; Barsoum, M.W.; Gogotsi, Y. Ten Years of Progress in the Synthesis and Development of MXenes. Adv. Mater. 2021, 33, 2103393. [Google Scholar] [CrossRef] [PubMed]

- Salim, O.; Mahmoud, K.A.; Pant, K.K.; Joshi, R.K. Introduction to MXenes: Synthesis and characteristics. Mater. Today Chem. 2019, 14, 100191. [Google Scholar] [CrossRef]

- Ronchi, R.M.; Arantes, J.T.; Santos, S.F. Synthesis, structure, properties and applications of MXenes: Current status and perspectives. Ceram. Int. 2019, 45, 18167–18188. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Cao, Y.; Wang, G. Functional Mxene Materials: Progress of Their Applications. Chem. Asian J. 2018, 13, 2742. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Righi, M.C.; Sumant, A.V.; Anasori, B.; Mochalin, V.N. Perspectives of 2D MXene Tribology. Adv. Mater. 2023, 35, 2207757. [Google Scholar] [CrossRef]

- Miao, X.; Li, Z.; Liu, S.; Wang, J.; Yang, S. MXenes in tribology: Current status and perspectives. Adv. Powder Mater. 2023, 2, 100092. [Google Scholar] [CrossRef]

- Bian, H.; Du, Y.; Ren, Y.; Wu, H.; Ma, Y.; Yang, B.; Tang, S.; Bin, D.; Lu, H.; Meng, X. One-step electrodeposition of polypyrrole/Ti3C2Tx MXene composite coating for 304SS bipolar plates in PEMFC. Surf. Coat. Technol. 2023, 462, 129460. [Google Scholar] [CrossRef]

- Du, Y.; Wang, D.; Si, P.; Wei, L.; Wang, Y.; Yu, B.; Zhang, X.; Ye, S. Electrodeposition of a Ni-P-Ti3C2Tx/MoS2 coating incorporating MoS2 intercalated Ti3C2Tx particles. Surf. Coat. Technol. 2018, 354, 119–125. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, S.; Weng, Y.; Li, J.; Han, P.; Ye, S.; Zhang, X. Preparation of Ni-P-Ti3C2Tx-Ce composite coating with enhanced wear resistance and electrochemical corrosion behavior on the surface of low manganese steel. Surf. Coat. Technol. 2022, 441, 128508. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, B.; Xu, B.; Yang, B. Ambient-stable polyethyleneimine functionalized Ti3C2Tx nanohybrid corrosion inhibitor for copper in alkaline electrolyte. Mater. Lett. 2023, 337, 133979. [Google Scholar] [CrossRef]

- Galvin, T.; Hyatt, N.C.; Rainforth, W.M.; Reaney, I.M.; Shepherd, D. Molten salt synthesis of MAX phases in the Ti-Al-C system. J. Eur. Ceram. Soc. 2018, 38, 4585–4589. [Google Scholar] [CrossRef]

- Yang, F.; Kang, H.; Guo, E.; Li, R.; Chen, Z.; Zeng, Y. The role of nickel in mechanical perfopmance and corrosion behaviour of nickel-aluminium bronze in 3.5 wt.% NaCl solution. Corros. Sci. 2018, 139, 333–345. [Google Scholar] [CrossRef]

- Rekha, M.Y.; Srivastava, C. Microstructural evolution and corrosion behavior of Zn-Ni-graphene oxide composite coatings. Met. Mater. Trans. A 2019, 50, 5896–5913. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).