Abstract

The surface of machine elements is changed to improve their mechanical properties. Ceramic-metal composite coatings are mainly used to increase the durability of machine parts. Therefore, new materials are constantly searched for application in the future development of metal and ceramic composites. The nickel and iron elements are usually used as a base and Al2O3 as tough particles. The welding technology for applying alloy and composite coatings is widely used. The common technology used to apply composite coatings is thermal spraying. It is a simple technology and very useful for the production or regeneration of machines. The surface layer is very rough and porous after applying the coating by thermal spraying. In order to obtain the proper surface quality of alloy and composite coatings, after-machining should be used. Many parts of machines strive to achieve an accurate surface. Therefore, a certain roughness is often required. The arithmetic mean of the ordinates of the surface roughness profile was (Ra = 0.16–1.25 μm). The article presents the influence of finishing on the roughness of the surface layer of the coating. After plastic working and machining, the roughness of the surface layer of the coating was reduced. However, it can be seen that, after plastic working, there is a strengthening of the surface layer of the coating and most of the pores were closed.

1. Introduction

The engineering materials such as metals, polymers, ceramics and composites are constantly used in the production and regeneration of machine parts. Composite materials are of great interest in mechanical engineering. One of the widely used groups of composites are those based on metals and ceramics. Composites are used in the energy, electronics, petrochemical, military, automotive, aviation, shipbuilding and other industries. Coatings can also be distinguished among composites. The composite coatings obtained by thermal spraying have a large surface roughness. Therefore, these coatings must be subjected to finishing. The most commonly used machining types are finishing, turning and grinding. Flame spray coatings are applied taking into account the allowance for finishing. After-machining should ensure not only adequate coating thickness associated with the nominal size of an object but also to obtain the required surface roughness and waviness. Surface texture is very important where it has a direct influence on the quality of the elements’ machine parts. Therefore, it has to be defined as precisely as possible with the help of standardized surface texture parameters. The best tool contour and angles and shape and grade inserts should be selected to obtain a minimum surface roughness.

The coatings are applied and often reflect the shape of the actual surface of the substrate. The structure of thermal sprayed coatings is characterized by, among other things, high porosity and considerable roughness. Thermal spraying is a technology that does not allow for precise control of the thickness of the coatings. Due to these considerations, coatings obtained by thermal spraying require the use of an after-machining. The coatings can be used, among other things, for the regeneration of drive shafts of centrifugal pumps. Traditional methods of the after-machining of the geometrical structure of the surface of the coatings are plastic working (rolling, burnishing) and machining (turning, grinding). Nowadays, machines and devices operate under increasingly greater operational loads. This forces the development of innovative construction materials or surface treatment technologies that would ensure high reliability and durability of machine parts [1,2,3,4,5,6,7,8]. In cases where durability is determined only by the surface properties of the material (resistance to abrasive wear, corrosion resistance, contact fatigue), it is not advisable to use expensive materials for the production of entire elements. Coatings are used for protection and for regeneration. Flame spraying is one of the most economical coating application technologies. One of the coating materials increasing the durability of machine parts is nickel and its alloys as well as a composite based on a nickel and ceramic phase [9,10]. Nickel matrix alloy and composite coatings obtained by thermal spraying achieve high surface roughness values. Therefore, these coatings must be subjected to finishing. The most common are turning and grinding [11,12,13]. It is also important that the coatings are applied with small thicknesses. This is related to the reduction of material costs, and thus environmental protection. The technology of plastic working is environmentally friendly (no chips, no scorching of the top layer of the coating). There have been and are ongoing tests of burnishing and rolling of alloy and composite coatings obtained by flame spraying, which was taken from the literature [14,15,16]. Therefore, it also seems reasonable to use, and perhaps, above all, plastic working for composite coatings after spraying. The technologies of manufacturing and regenerating products with a composite coating with a metal matrix are very interesting. Technologists and mechanical engineers widely use coatings for machine elements: due to the possibility of increasing the functional properties of the surface layer (fatigue strength, tribological and corrosion resistance, and decorative aspect). Composite with a metal matrix, metals–ceramics are characterized by high resistance to tribological and corrosive wear [17,18,19]. Based on the literature review [20,21,22,23,24,25], composite coatings based on nickel or aluminum were selected for testing.

The article presents the possibilities of using finishing to obtain the required roughness of the surface layer of the composite coating. The paper presents the results of research on the possibility of using plastic working (rolling, pressing, burnishing) to obtain selected properties of flame sprayed composite coatings. The nickel alloy coatings had a single-phase structure, while the volume fraction of the Al2O3 ceramic material in composite coatings was 15% and 30%. Ni-Al alloy and Ni-Al-Al2O3 composite coatings were experimental research.

2. Materials and Methods

The composite coatings are characterized by oxide inclusions, porosities, and the presence of a strongly developed surface after being flame sprayed. The finishing coats should be used in order to obtain the appropriate surface texture. For this purpose, burnishing, rolling, turning or grinding can be applied. Ni-Al alloy and Ni-Al-Al2O3 composite coatings, obtained by flame spraying, were investigated. The samples with shafts shape of steel C45 (ArcelorMittal, Dąbrowa Górnicza, Poland) (C—0.45%, Cr—0.4%, Mo—0.1%, Mn—0.7%, Si—0.3%, Ni—0.4%, P—0.045%, S—0.045%) [26] and spraying coatings were researched. The flame sprayed coatings were characterized by appreciable value of surface roughness. The surface roughness obtained by flame spraying was not satisfactory with respect to the service qualities because large values were reached. The tests were carried out on nickel alloy and nickel composite coatings on a C45 steel matrix using the subsonic flame spray method. The coatings were prepared with such materials as powder ProXon 21021 (Ni—94%, Al—5%, B—1%) and its combination with powder MetaCeram 28020 (Al2O3—97.7%, TiO2—2.2%, SiO2—0.1%), the powders were produced by Castolin Eutectic (Kriftel, Germany) [27,28,29]. Strengthening of the coatings based on ProXon 21021 may take place as a result of introducing a reinforcing phase into its structure in the form of dispersion ceramic particles. The material used as reinforcement was MetaCeram 28020, consisting of almost 100% Al2O3 particles with an average particle diameter of 60 μm. A few percent admixture of titanium oxide increases the impact strength of the material. Aluminum oxide is resistant to corrosion, tribological wear and has a low coefficient of friction. The evaluated materials of the composite coatings contained 15% and 30% of the volume fraction of the MetaCeram 28020 powder. The structure of the coatings (porosity and the proportion of oxides) was assessed by quantitative metallography based on graphical models of thermally sprayed coatings. The porosity of the sprayed coatings based on Ni-Al and Ni-Al-Al2O3, depending on the proportion of the ceramic phase (the so-called reinforcement) and the technology used, was in a wide range from 5% to 30%. The porosity depends on the composition of the sprayed coating material. With the proportion of the reinforcing phase to the value of 30%, the porosity of the coatings increases even threefold. Concentrations of non-metallic compound Al2O3 in the obtained coatings: 15% and 30%.

The coatings were sprayed with the following parameters:

- Oxygen pressure: 4 bar;

- Acetylene pressure: 0.7 bar;

- Spindle speed: n ≈ 150 rpm;

- Torch feed: p ≈ 5 mm/rev;

- Distance between the torch nozzle and the shaft surface: l = 150 mm;

- Number of layers applied: 6;

- Obtained coating thicknesses: hp = 0.6 mm.

Research methodology of finishing coatings by machining and plastic working was made.

Machining parameters of alloy and composite nickel coatings on the steel substrate obtained by flame spraying, through preliminary study, were developed for high-precision turning. Turning has been realized with cutting speed (vc = 45–214 m/min), feed rate (f = 0.06–0.20 mm/rev) and depth of cut (ap = 0.05–0.30 mm). To research appropriate holder and edge of tungsten, carbide and cubic boron nitride were chosen (Table 1).

Table 1.

The shape, type and grade of inserts to turning for nickel matrix composite coatings.

Plastic working tests have also been performed. Burnishing was performed by means of an NK-01 (Department of Marine Maintenance, Gdynia, Poland). Regarding burnishing, the following parameters were useful: feed (fn = 0.1–0.5 mm/rev); burnisher pass depth an = 0.5 mm; burnishing force F = 1.5 kN; burnishing speed vn = 70 m/min. The compressing force of the NK-01 burner was measured using a static method using the FT-5304M/A/16 strain gauge force sensor (Mecmesin, Slinfold, UK). The specimens were pressed in the cold process for the Maqstock MX-340G universal hydraulic press (Maqstock NARGESA, Girona, Spain), at real draft εh = 12% and unit pressure 900 MPa. Cold rolling was performed at room temperature using the mill with the cylinder diameter φ 200 mm and length 250 mm, at draft εh = 12%.

The microhardness test was carried with a Vickers Hardness Tester FM-800 (Gnehm Härteprüfer AG, Thalwil, Switzerland) according to PN-EN ISO 6507-1: 2018. The load of 0.49 N for 10 s at room temperature was applied. In accordance with the principle, five measurements were made for each measuring point.

The surface roughness was measured with the Hommel Tester T1000 profilometer (The Sempre Group Ltd., Gloucester, UK), with the assumed measuring section lengths of 4.8 mm and the sampling section of 0.8 mm. The roughness measurements were made worthy in accordance with the principles contained in standards EN ISO 4287:1997. The mean arithmetic deviation of the roughness profile was determined.

Visual assessment of the coating structure was performed with the use of optical microscope Axiovert 25 (ZEISS, Oberkochen, Germany) at 100× 200× magnification. Adhesion of the alloy and composite coatings was assessed accordingly using the following two qualitative methods: scratch and temperature change methods. Evaluation was made by observing the surface with an SZX16 stereoscopic microscope (Olympus, Tokyo, Japan) at 5× magnification. Coating adhesion was considered good if bubbles or exfoliation and amination were not observed.

The corrosion resistance of the coatings was performed by an electrochemical test in a three-electrode system. The surface area of 0.75 cm2 was degreased with acetone and then placed in a vessel containing 500 cm3 of 0.01 M H2SO4 at the ambient temperature together with a polarising electrode made of platinum coated titanium and the saturated calomel electrode. Electrochemical polarization testing is a classic corrosion method that is relatively well known and widely used. Measurements of potential and corrosion current were made using the direct current (polarization curves) and alternating current method [30]. The specimens had been exposed to an electrolyte for one hour to enable stabilisation of corrosion potential. The duration of the experiments and polarisation curves i = f(E) were recorded in the range ±150 mV from the corrosion potential. During the entire time that the measurement lasted, the electrolyte was constantly stirred. The first curve of cathodic was recorded and then an anodic one. In all cases, the potential change rate was 10 mV/min. Tests for electrochemicals by ATLAS 0931 device (ATLAS-SOLLICH, Banino, Poland) were performed.

3. Finishing Results of the Surface Layer of Composite Coatings

The results are presented in a graphic form. The technologies of plastic working and machining were compared with each other. A new feature is the addition of burnishing.

3.1. Results of Research for Machining Nickel Matrix Composite Coatings

The research allowed for resolution, that there is a relation between the surface of alloy and composite coatings and the type of grade used and the shape of the inserts. Trigon insert WNMG 080 408 S01030A and round insert N123J1-0600-RE 7015 of cubic boron nitride (CBN), were characterized by a smaller flank wear as compared to a square insert with SNGA 120 408 S01030A 7015 of CBN (presented in Table 1).

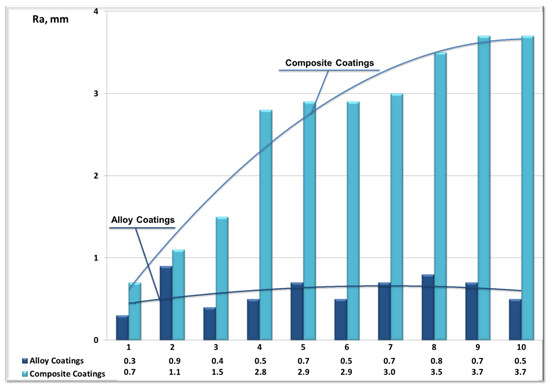

The surface roughness of turned alloy coatings insert round (Ra = 0.3 μm) and insert trigon (Ra = 0.4 μm) is nearly three times smaller than the roughness of the coatings for a square insert (Ra = 0.9 μm).

The trigon insert made of tungsten carbide, which determined that the minimum surface roughness of alloy coatings is obtained for grade GC3215 (Ra = 0.5 μm), was used.

The turning of composite coatings with square insert SNGA120408S01030A 7015 specifies that the arithmetical mean deviation of the assessed profile reached a lower value of Ra = 1.1 μm in comparison to the roughness of the surface with the trigon insert made of the same grades CB7015 and also with the trigon of tungsten carbide (about the grades: GC2015, GC3205, GC3210, GC3215) and tungsten carbide for triangular inserts (for grades: GC4015, H10F).

Lowest surface roughness Ra = 0.7 μm is achieved for composite coating turned insert round N123J1-0600-RE 7015. Round insert after turning composite coatings is characterized by the lowest flank wear related to the square, trigon and triangular.

Figure 1 shows the roughness parameter Ra of the assessed profile for alloy and composite coatings after turning for type inserts.

Figure 1.

The roughness parameter Ra for alloy coatings and for composite coatings for surface after turning samples’ inserts according to the study program (Table 1).

The parameter Rpk of the reduced peak height, which should be the lowest, is characteristic for the upper surface layer that quickly undergoes abrasion after the start of i.e., engine running. Reduced depth of roughness profile valley is described by Rvk parameter, which should be the highest. It is a measure of the working surface ability to keep the lubricant in the valleys created mechanically. The parameter Rk defines the core roughness depth, which should be the lowest in Table 2, and it was presented in Table 3. After turning the cylindrical steel samples with coating of alloys and composites, it was determined that there were relationships between surface texture and the type of material used and the shape of the tool inserts. Based on the analysis of test results, it was determined, due to the smaller surface roughness of the alloy coatings, that it was desirable to use trigon inserts made of GC3215 grade tungsten carbide and trigon inserts made of GC3215 grade tungsten carbide, cubic boron nitride grade CB7015 and round inserts CB7015.

Table 2.

The roughness parameters for alloy coatings for surface after turning samples inserts according to the study program.

Table 3.

The roughness parameters for composite coatings for surface after turning samples’ inserts according to the study program.

The roughness of the surface nickel coating subjected to turning by trigon insert with CBN is three times smaller than the roughness of the nickel coatings by a square insert. Therefore, it is advisable not use square inserts for machining alloy coatings. Based on analysis of experimental results after finishing composite coatings, it can be determined that the roughness profile parameters and parameter values of the bearing area curve reached the lowest values for samples.

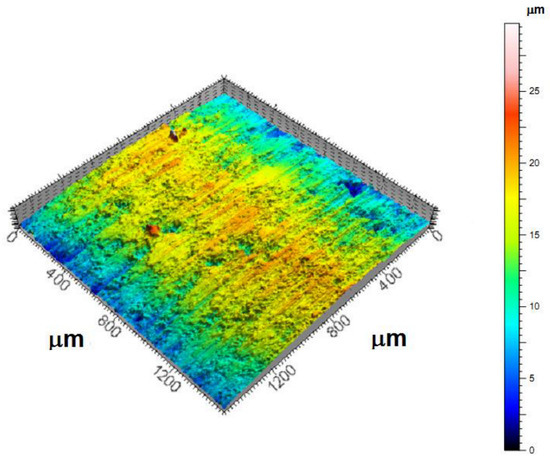

Figure 2 shows an example of the surface topography of the composite coatings for inserts with WNMG 080408 S01030A CB7015.

Figure 2.

The example of the surface topography of the composite coatings with volume fraction ceramic dispersed phase Vcdp = 15%Al2O3 for inserts with WNMG 080408 S01030A CB7015, after turning.

3.2. Results of Experiments by Plastic Working

The introduction of the ceramic dispersed phase itself increases hardness of the coatings base. Hence, plastic working as the strengthening finishing is advisable mainly for alloy coatings. After pressing, an increase in alloy coating hardness even up to 80% is observed, whereas, for composite coatings with 15% content of Al2O3, the coating base hardness rises by 50%. In the case of cold rolling, even greater hardening ratios for both alloy and composite coatings (93% for Ni-Al coating and 66% for coating Ni-Al-Al2O3) are attainable.

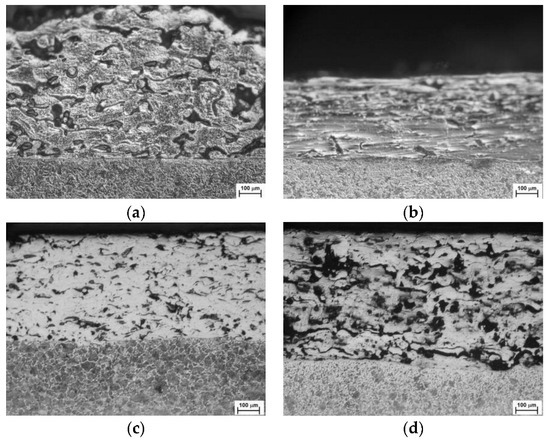

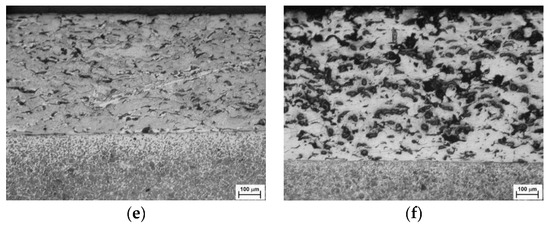

Draft and unit pressure applied in plastic working of the steel specimens with alloy and composite coatings caused only plastic strain of the coating material. In the base steel, no structure change testifying to its plastic strain was observed. The metallographic study showed reduction in the porousness of the alloy and composite coatings subjected to plastic working (Figure 3). Application of plastic working for thermal sprayed coatings results in a significant improvement of the surface quality. After plastic working, the average arithmetic roughness profile is twenty times smaller than the average arithmetic roughness profile of the coating before plastic working. As a result of rolling, parameter Ra reaches much lower values compared to the roughness profile deviation after pressing. Flame-sprayed alloy coatings were characterised by a greatly developed real surface. The average arithmetic roughness Ra = 13.0 μm. The applied methods of plastic working allowed a significant reduction of the value of the parameter considered. The minimum value of Ra = 0.3 µm for εh = 12% was achieved for cold rolled coatings, whereas the pressing process allowed for obtaining the surface roughness of the order of Ra = 1.2 μm. Loads applied within plastic working of the steel specimens with alloy and composite coatings caused only plastic strain of the coating material.

Figure 3.

The microstructure for: (a) alloy coatings after being flame sprayed and (b) alloy coatings after burnishing; (c) alloy and (d) composite coatings after rolling; (e) alloy and (f) composite coatings after pressing.

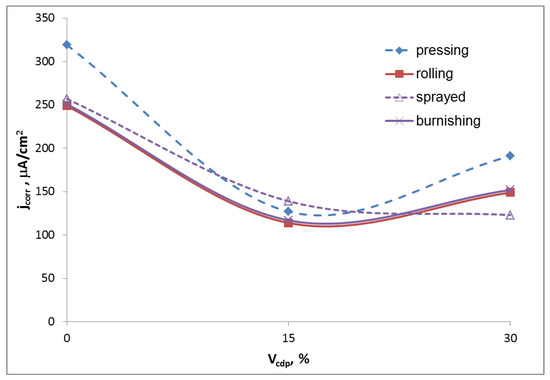

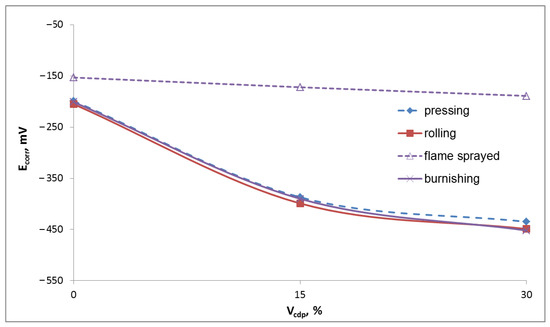

Figure 4 shows the influence of the ceramic dispersion in the nickel matrix composite coatings on corrosion current density after being flame sprayed and after plastic working. Corrosion current density for the composite coatings after plastic working is twice as low compared to the alloy coatings. This may prove that a lower rate of electrochemical corrosion (Figure 5) shows the influence of the ceramic dispersion in the composite coatings on corrosion potential after spraying and plastic working. The corrosion potential for composite coatings that has been treated with plastic working is three times smaller than for the alloy and composite coatings after spraying. An increase of ceramic dispersion reduces the corrosion potential and therefore increases the capacity of electrochemical corrosion. Electrochemical corrosion tests proved that the proposed finishing methods aimed at reducing the roughness of flame sprayed coatings resulted in the corrosion potential value shift towards the anodic values.

Figure 4.

The influence of the volume fraction ceramic dispersed phase in the composite coatings on corrosion current density after pressing, rolling, burnishing and flame spraying.

Figure 5.

The influence of the volume fraction ceramic dispersed phase in the composite coatings on corrosion potential after pressing, rolling, burnishing and flame spraying.

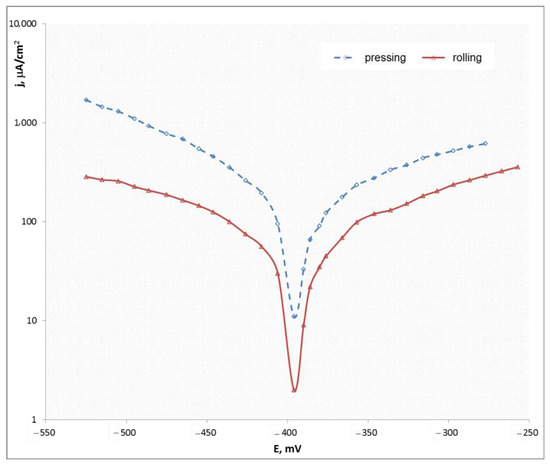

The purpose of the polarization test in a corrosive environment is to record the current-potential relationships in a specific range of potential or current. Figure 6 shows potentiostatic polarization curves on the nickel matrix composite coatings for Vcdp = 15%Al2O3 ceramic dispersion after plastic working. The powder manufacturer recommends using it for the regeneration of machine parts operating in tribological nodes. The alloy of nickel and aluminum may be operated in conditions which may lead to chemical and electrochemical corrosion. Aluminum oxide is resistant to corrosion, tribological wear and has a low coefficient of friction. The presence of the Al2O3 phase improves the protective properties of the thermal sprayed coatings.

Figure 6.

The curves’ potentiostatic polarization for composite coatings with volume fraction ceramic dispersed phase Vcdp = 15%Al2O3 after plastic working for pressing and rolling.

The application of pressing increased the coating corrosion rate jcorr and potential corrosion Ecorr compared to that before plastic working. A lower value of corrosion current density can provide a lower rate of electrochemical corrosion in the case of plastic working treated alloy and composite coatings. A lower value of the corrosion potential may be characterized by a greater ability to act electrochemical corrosion. Corrosion investigation made in 0.01 M H2SO4 showed that, in most cases of plastic working operations, there was an increase in the corrosive current density accompanied by the drop in the corrosion potential. In an acid environment, the corrosion rate of composite coatings is very much limited by the presence of the dispersion phase, and the porosity is reduced by rolling, pressing and burnishing. The burnishing process for the analyzed material increases the corrosion resistance of the coatings. Due to the reduction in surface roughness and waviness, a reduction in the actual surface area after burnishing is achieved compared to machining.

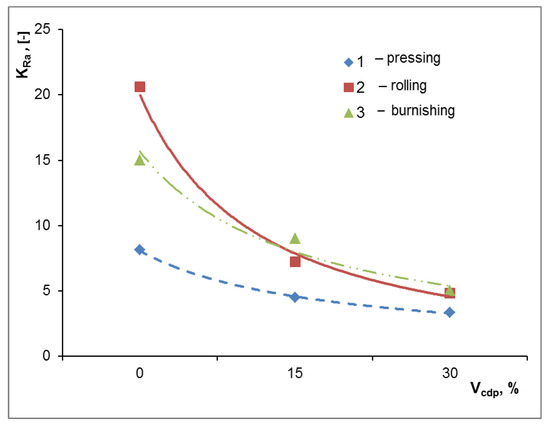

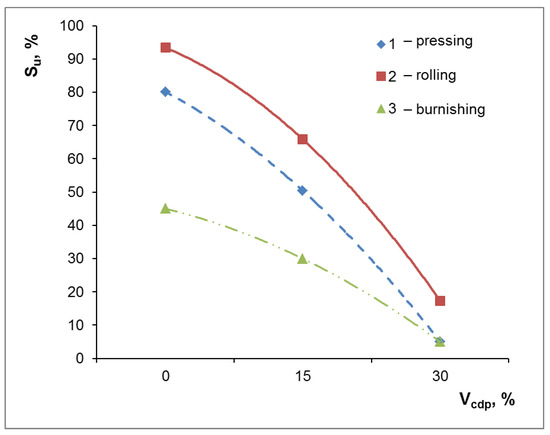

Figure 7 indicates that, the greater content of dispersion phase in composite coatings, the greater roughness is achieved. In addition, the surface roughness reduction ratio reaches its greatest values for alloy coatings. The lowest values of the roughness reduction ratio occur for composite coatings with 30% content of Al2O3.

Figure 7.

The impact of volume fraction ceramic dispersed phase Vcdp in obtained composite coatings on surface roughness reduction ratio after plastic working, 1—pressing, 2—rolling, 3—burnishing.

The experiments allowed for determination—based on the measurements of microhardness and roughness profile after flame spraying and after plastic working—that the dispersion phase content in the composite coating has a significant effect on strengthening and smoothness of the coating surface. The dependency of the ratio of relative strengthening of the composite coating on the nickel base, on the volume content of non-metallic material Al2O3, is shown in Figure 8. It shows that an increase in the percentage content of alumina is accompanied by a decrease in the coating strengthening ratio after plastic working. Another important thing is that after rolling, and also after pressing, the specimens with alloy coatings gain much greater microhardness compared to the specimens with composite coating. Therefore, the lower content of dispersion phase results in greater strengthening of the coating base.

Figure 8.

The influence of volume fraction ceramic dispersed phase Vcdp in achieved composite coatings on relative strengthening ratio after plastic working, 1—pressing, 2—rolling, 3—burnishing.

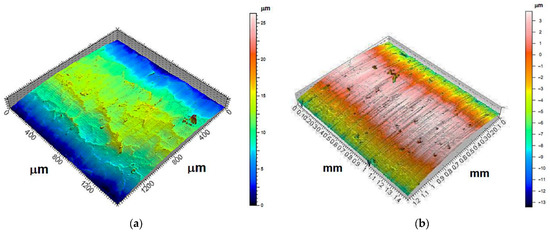

Introduction of the dispersion phase itself increases hardness of the coatings base. Hence, plastic working as the strengthening is advisable mainly for Ni-Al alloy coatings. In the case of cold rolling, even greater hardening ratios for both alloy and composite coatings (Su = 93% for Ni-Al coating and Su = 66% for coating Ni-Al-Al2O3) are attainable. The obtained results of hardness measurements showed that all the proposed methods of plastic working caused strengthening of the investigated coatings. The greatest ratio of coating strengthening occurred in the cold rolled and cold pressed specimens, whereas, in hot rolled specimens, the strengthening ratio was the least. The flame sprayed alloy coatings were characterized by a greatly developed actual surface. The applied methods of plastic working allowed for significant reduction of the value of the parameter in question. The minimum value of Ra = 0.3 μm was achieved for hot rolled coatings at actual draft εh = 12%, whereas the pressing process allowed for obtaining the surface roughness of the order of Ra = 1.2 μm. Figure 9 shows an example of the surface roughness topography, the amplitude distribution of the surface roughness profile and the material share of Ni-Al alloy coatings and Ni-Al-Al2O3 thermal sprayed composite coatings.

Figure 9.

The example of the surface topography of the composite coatings with volume fraction ceramic dispersed phase (a) Vcdp = 0%Al2O3, (b) Vcdp = 15%Al2O3, after burnishing.

The production and regeneration of products with applied coating are recognized among engineers. Composite coatings increased the performance characteristics of the surface layer (strength, tribological and corrosion resistance). These composite coatings are used in such as: aerospace, electronics, energy, industry, defense, automotive, aviation, shipbuilding and more. Based on a review, in the study, composite coatings based on nickel or aluminium were proposed.

4. Summary and Conclusions

The article presents the problems that can arise when producing coatings by thermal projection. It is important to obtain a low roughness. It can be seen that machining is most often performed and then material is lost.

An innovative approach to the problem is the proposition of plastic working (without material loss) as after-machining.

(1) After turning of alloy and composite coatings, it was determined that, due to obtaining the smallest surface roughness, with the least wear on the insert flank face and tool face, for a constant length of spiral cutting, round inserts with borazon were targeted to be used.

(2) It can be argued that, due to the surface quality coatings and durability of the turning inserts, for turning, shafts of centrifugal pumps with a coating alloy would need to be round and trigon inserts with borazon and trigon with tungsten carbide; for turning shafts of centrifugal pumps with composite coatings, round inserts with borazon should be applied.

(3) Based on experimental data, the ceramic dispersion content in the composite coating has a significant effect on strengthening and quality of the coating subjected to plastic working.

(4) Application of plastic working as a strengthening method of finishing is advisable mainly for alloy coatings, where significant strengthening occurs, and the ratios of coating strengthening are 45%—after burnishing, 80%—after pressing, and 93%—after rolling.

(5) Application of plastic working as a strengthening finish method is also advisable for composite coatings with 15% content of Al2O3 where hardness of the coating base increases by 30%—after burnishing, 50%—after pressing and by 66%—after rolling; minimum values of the surface roughness are obtained after rolling.

(6) The coating subjected to plastic working gained a more homogeneous structure as most of the pores, which had occurred after flame spraying, were closed.

(7) The lower value of corrosion potential in the coating plastic working composite shows that the increase of ceramic dispersion Al2O3 can affect the ability to increase the occurrence of electrochemical corrosion in the composite coatings.

(8) The smaller value of corrosion current density can provide a lower rate of electrochemical corrosion in the case of composite coatings after plastic working; the lowest corrosion current density occurs in the composite coatings containing 15%Al2O3 ceramic dispersion after rolling, burnishing and pressing.

(9) After the analysis of the results of plastic working and machining of alloy and composite coatings, it can be concluded that the technologies presented in the article may be recommended for surface chip-less forming of coatings.

Author Contributions

Conceptualization, R.S. and T.D.; methodology, R.S. and T.D.; software, R.S. and T.D.; validation, R.S. and T.D.; formal analysis, R.S. and T.D.; investigation, R.S. and T.D.; resources, R.S. and T.D.; data curation, R.S. and T.D.; writing—original draft preparation, T.D.; writing—review and editing, T.D.; visualization, T.D.; supervision, R.S. and T.D.; project administration, R.S. and T.D.; funding acquisition, T.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Starosta, R.; Charchalis, A.; Dyl, T. The Choice of Thermal Spray Technology and Burnishing in Terms of Improving the Exploitation Properties of Centrifugal Pump Shafts; The Report of the Research Project N504 303537; Gdynia, Poland, 2012; pp. 1–306. (In Polish) [Google Scholar]

- Dyl, T.; Starosta, R. Finishing of nickel matrix composite coatings. Preprints 2019, 2019110374. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Withers, P.J.; Axinte, D.; Preuss, M.; Andrews, P. Residual stresses in face finish turning of high strength nickel-base d superalloy. J. Mater. Process. Technol. 2009, 209, 4896–4902. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Gutiérrez, A.; Lamikiz, A.; Fernandes, M.H.; Sánchez, J.A. Turning of thick thermal spray coatings. J. Therm. Spray Technol. 2001, 10, 249–254. [Google Scholar] [CrossRef]

- Tan, A.W.-Y.; Tham, N.Y.S.; Chua, Y.S.; Wu, K.; Sun, W.; Liu, E.; Tan, S.C.; Zhou, W. Cold spray of nickel-based alloy coating on cast iron for restoration and surface enhancement. Coatings 2022, 12, 765. [Google Scholar] [CrossRef]

- Wrona, A.; Lis, M.; Pęcak, K.; Kalemba-Rec, I.; Dymek, S.; Wróbel, M.; Bilewska, K.; Kustra, K.; Węglowski, M.S.; Śliwiński, P. Ni–Cr powders modified with rhenium as a novel coating material—physical properties, microstructure, and behavior in plasma plume. Materials 2022, 15, 3844. [Google Scholar] [CrossRef] [PubMed]

- Morel, S. Thermally Sprayed Coatings; Czestochowa University of Technology: Czestochowa, Poland, 1997. (In Polish) [Google Scholar]

- Nadasi, E. Modern Spray Metallization Methods; WNT: Warszawa, Poland, 1975. (In Polish) [Google Scholar]

- Wang, P.; Xu, Z.; Liu, X.; Wang, H.; Qin, B.; Lin, J.; Cao, J.; Qi, J.; Feng, J. Regulating the interfacial reaction of Sc2W3O12/AgCuTi composite filler by introducing a carbon barrier layer. Carbon 2022, 191, 290–300. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Y.; Huang, J.; Ye, Z.; Yang, J.; Chen, S.; Zhao, X. Reaction-composite diffusion brazing of C-SiC composite and Ni-based superalloy using mixed (Cu-Ti)+C powder as an interlayer. J. Mate. Process. Technol. 2022, 300, 117419. [Google Scholar] [CrossRef]

- Tools for Metal Cutting, Turning Tools, Turning Inserts and Grades for Stainless Steel; Sandvik Coromant. 2021. Available online: http://www.sandvik.coromant.com/en-us/products/pages/tools.aspx (accessed on 6 June 2021).

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Study on the machinability during high speed turning. Mater. Des. 2009, 30, 1718–1725. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Higuchi, M.; Shimada, S.; Kaneeda, T. Tool life monitoring during the diamond turning of electroless Ni–P. Precis. Eng. 2007, 31, 196–201. [Google Scholar] [CrossRef]

- Khanna, N.; Airao, J.; Gupta, M.K.; Song, Q.; Liu, Z.; Mia, M.; Maruda, R.; Krolczyk, G. Optimization of power consumption associated with surface roughness in ultrasonic assisted turning of nimonic-90 using hybrid particle swarm-simplex method. Materials 2019, 12, 3418. [Google Scholar] [CrossRef] [Green Version]

- Kannan, S.; Kishawy, H. Surface characteristics of machined aluminium metal matrix composites. Int. J. Mach. Tools Manuf. 2006, 46, 2017–2025. [Google Scholar] [CrossRef]

- Caggiano, A. Machining of fibre reinforced plastic composite materials. Materials 2018, 11, 442. [Google Scholar] [CrossRef] [Green Version]

- Campo, M.; Carboneras, M.; López, M.; Torres, B.; Rodrigo, P.; Otero, E.; Rams, J. Corrosion resistance of thermally sprayed Al and Al/SiC coatings on Mg. Surf. Coat. Technol. 2009, 203, 3224–3230. [Google Scholar] [CrossRef]

- Wang, H.-T.; Chen, X.; Bai, X.-B.; Ji, G.-C.; Dong, Z.-X.; Yi, D.-L. Microstructure and properties of cold sprayed multimodal WC–17Co deposits. Int. J. Refract. Met. Hard Mater. 2014, 45, 196–203. [Google Scholar] [CrossRef]

- Galvanetto, E.; Borgioli, F.; Galliano, F.; Bacci, T. Improvement of wear and corrosion resistance of RPS Ti–TiN coatings by means of thermal oxidation. Surf. Coat. Technol. 2006, 200, 3650–3655. [Google Scholar] [CrossRef]

- Garcia, J.R.; Cuetos, J.M.; Ferna’ndez, E.; Higuera, V. Laser surface melting Cr–Ni coatings, in the erosive-corrosive atmosphere of boilers. Tribol. Lett. 2007, 28, 99–108. [Google Scholar] [CrossRef]

- Yang, J.; Chen, J.; Zhao, W.; Zhang, P.; Yu, Z.; Li, Y.; Zeng, Z.; Zhou, N. Diode laser welding/brazing of aluminum alloy to steel using a nickel coating. Appl. Sci. 2018, 8, 922. [Google Scholar] [CrossRef] [Green Version]

- Sierra, C.; Vázquez, A. NiAl coating on carbon steel with an intermediate Ni gradient layer. Surf. Coat. Technol. 2006, 200, 4383–4388. [Google Scholar] [CrossRef]

- St-Georges, L. Development and characterization of composite Ni–Cr+WC laser cladding. Wear 2007, 263, 562–566. [Google Scholar] [CrossRef]

- Wang, Y.; Normand, B.; Suo, X.; Planche, M.-P.; Liao, H.; Tang, J. Cold-sprayed AZ91D coating and SiC/AZ91D composite coatings. Coatings 2018, 8, 122. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Wang, Y.; Liu, X.; Liang, Z.; Jin, H. Electrodeposition kinetics of Ni/nano-Y2O3 composite coatings. Metals 2018, 8, 669. [Google Scholar] [CrossRef] [Green Version]

- Dyl, T.; Starosta, R.; Rydz, D.; Koczurkiewicz, B.; Kuśmierska-Matyszczak, W. The experimental and numerical research for plastic working of nickel matrix composite coatings. Materials 2020, 13, 3177. [Google Scholar] [CrossRef] [PubMed]

- Specification of Application and Processing Technology of Powder Coatings ProXon 21021, Castolin—Eutectic. 2021. Available online: https://www.castolin.com/pl-PL/product/proxon-21021 (accessed on 6 June 2021).

- Specification of Application and Processing Technology of Powder Coatings MetaCeram 28020, Castolin—Eutectic. 2021. Available online: https://www.castolin.com/de-DE/product/metaceram-28020 (accessed on 16 June 2021).

- Technologies, Our Technologies to Best Serve You, Maintaining Global Leadership in Surface Protection Technologies, Castolin—Eutectic. 2021. Available online: https://www.castolin.com/technologies (accessed on 26 June 2021).

- Yan, Y.; Lin, J.; Liu, T.; Liu, B.; Wang, B.; Qiao, L.; Tu, J.; Cao, J.; Qi, J. Corrosion behavior of stainless steel-tungsten carbide joints brazed with AgCuX (X = In, Ti) alloys. Corros. Sci. 2022, 200, 110231. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).