Abstract

As an important industry of the national economy, the development of furniture manufacturing industry is very rapid. In particular, with the development of panel furniture industry, wood-based panels have become a necessary choice for furniture material for modern families in recent years. As a new particleboard material, in order to be more widely used in the furniture industry, it is not enough to have the characteristics of environmental protection. The material should also have excellent appearance and dimensional stability, so as to change people’s dependence on traditional wood-based panels. In this study, the rice straw particleboard (RSP) substrate was veneered by Betula sp. and Cyclobalanopsis glauca. In the process of veneering, different RSP specimens were treated by different sanding thicknesses and moisture contents of the RSP substrate, glue spread, species and thickness of veneer. The dimensional stability of different RSP specimens after veneering was analyzed. Based on the same variables, the change in the panel dimension and warp degree of the specimens of RSP which the sanding thickness was 0.2 mm were higher than the specimens with a sanding thickness of 0.6 mm. The dimensional stability of specimens of Cyclobalanopsis glauca veneer was better than that of Betula sp. veneer. A certain degree of change within the appropriate moisture content had a little effect on dimensional stability of veneered RSP. The greater of the amount of glue, the worse the dimensional stability of veneered RSP. The thinner the veneer, the worse was the dimensional stability of the veneered RSP.

1. Introduction

After the reform and opening to the outside world, the model of Chinese furniture manufacturing has gradually changed from traditional manual processing to modern industrial after more than 30 years of development and has become the world famous country in furniture manufacturing and exporting [1]. Wood has always been the main materials in the furniture industry, the rapid development of furniture manufacturing means the demand for wood materials will increase. However, China lacks forest resources; it is a country with the lowest forest area per capita of only 9.048 m3, ranking 119th in the world [2,3]. Wood-based panels have become the main material in furniture manufacturing. At present, the main types of wood-based panels in the furniture industry include particleboard, fiberboard, plywood. Wood-based panels have improved the utilization rate of wood waste to some extent. However, the use of wood materials has not been fundamentally reduced [4]. According to incomplete statistics, the annual output of wheat straw and rice straw in our country is as high as 400 million tons. The use of straw for the production of particleboard can not only solve the environmental pollution causing by the burning of straw, but also can replace wood as the main raw material of wood-based panels. It has solved the problem for agriculture and furniture industry in our country at the same time and achieved a win–win situation [5,6].

Rice board particleboard (RSP) is a new type of wood-based panel made of crop straw as raw material and glued with isocyanate. In the 20th century, the technology of making wood-based panels by crop straw originated in Europe. In 1921, the softboard was made by bagasse in the state of Louisiana in the United States. In the 1970s, wood-based panels made by corn stalk and cotton stalk as the raw materials began to appear. In the 1980s, the northern of United States and Canada began to make wood-based panels by wheat straw [7,8]. Compared with the traditional wood-based panel, adhesives are not used in the process of RSP production, and harmful substance such as formaldehyde is not released in the course of RSP using. Thus, the RSP belongs to renewability and environmental protection materials. However, the dimensional stability of RSP is worse than the traditional wood-based panel. Therefore, the problem of solving the dimensional stability of RSP is an important reason why it can be truly recognized [9].

At present, some research focuses on the RSP. Lu et al. found that the urea–formaldehyde resin Adhesive for traditional wood-based panels is not suitable for gluing the straw crushing in direct by researching the production process and performance of RSP. Yoko et al. found that the performance of RSP made of rice straw as raw material and hot pressed by urea–formaldehyde resin Adhesive will be affected by the surface structure, wax and silica of RSP. The study showed that the strength and water resistance of RSP surface can be improved greatly by sanding and extracting, and the defects and impurities of RSP surface would be removed. Dziurka et al. made particleboard by rape particle as the main materials and surfaced by beech veneer. The results had shown that the properties of rape particleboard were better than wood-chip-based particleboard. At the same time, the density of rape particleboard (350–550 kg/m3) was lighter than the traditional wood-chip-based particleboard (650 kg/m3). Nicolas et al. found that the urea–formaldehyde—or a resin based on epoxidized oil—had a negative effect on internal bond strength, flexural modulus and thickness swelling of straw particleboard. However, the organic content and properties of straw particleboard made by triglycerides and polycarbonic acid anhydrides was obviously improved. Xiong et al. used the infiltration height method to evaluate the surface activity of RSP which was treated by corona treatment and alkali treatment, the study showed that the higher the pH value of the alkaline solution, the stronger the surface activity of RSP, and there was a little effect on the RSP with a higher density by corona treatment [10,11,12,13,14].

At present, some research focuses on the dimensional stability of panel. Yan et al. studied the effects of hot pressing time, temperature, the density of panel and the amount of adhesive on physical properties of RSP, the results showed that with the increase of variables, the performance of RSP is better, and the dimension is more stable. Shen et al. used the veneer, edge banding and surface decoration of panel as variables to study the dimensional stability of straw particleboard, the study showed that there was a positive effect of veneering, edge banding and surface finishing on straw particleboard dimensional stability. Ma et al. added waterproofing agent and adhesive with a higher water resistance and heat treatment to the fiberboard in the process of making panel, the results showed that the dimensional stability of fiberboard can be greatly improved. Xu et al. used different glue consumption for RSP with different densities and studied the influence factors of RSP dimensional stability by using the immersion method. The results showed that density and glue consumption are important factors to dimensional stability of RSP. After summary, it is not difficult to find that the study related to RSP is mainly focused on the production technology and physical and chemical of RSP, and the study related to dimensional stability is mainly focused on wood materials instead of RSP. There are few studies on influencing factors of dimensional stability of RSP [15,16,17,18].

Based on this, two kinds of veneer of Betula sp. and Cyclobalanopsis glauca were used to veneer RSP with two different moisture content. The amounts of glue, sanding, the thickness of veneer, etc. were changed in the process of production. The panel dimension and warp degree of RSP specimens were measured and recorded, and the influence factors of dimensional stability of veneered RSP were analyzed. It provides a certain theoretical basis for panel industry to optimize the performance of RSP.

2. Materials and Methods

2.1. Materials

The RSP specimens used in the experiment were made according to the standard production of wood particleboard. The RSP was made of crop straw (rice straw) as the main raw material and isocyanate as the adhesive. The performance indexes of RSP specimens were different. The first density is 0.72 g/cm3, the moisture content is 10.2%, a total of fifteen specimens. The second density is 0.72 g/cm3,the moisture content is 8.5%, a total of three specimens. The size of RSP specimens with two different moisture content were 21 × 21 × 18 mm3.

Veneers were taken from Guangdong Yihua Wood Industry Co., Ltd., (Shantou, China). The thickness of the veneers of the two different tree species were different. The thicknesses of Betula sp. were 0.8 mm and 0.28 mm. The thickness of Cyclobalanopsis glauca was 0.8 mm.

Polyvinyl acetate emulsion was purchased from Nanjing Fashion Decoration Co., Ltd., (Nanjing, China).

2.2. Experimental Instruments

Related preparation equipment of veneered RSP specimens was as follows. The hot press was purchased from Qingdao Mingyu Machinery Technology Co., Ltd., (Qingdao, China). The type was XBL, the pressure was 5.0 MPa. Dry box was purchased from Suzhou Jiangdong Precision Instrument Co., Ltd., (Suzhou, China). The type was DGG-9140A, the accuracy was 0.1 °C. Climate chamber was purchased from Chongqing Yinhe Test Instrument Co., Ltd., (Chongqing, China). The type was BD/DHS-100, the temperature range was 0–150 °C, the temperature accuracy was 0.1 °C, and the humidity range was 30%–98%, the humidity accuracy was 1%.

Measuring instrument of RSP specimens. Vernier caliper was purchased from Guilin Guanglu Digital Measurement and Control Co., Ltd., (Guilin, China). The measurement range was 0–200 mm, the measurement accuracy was 0.01 mm.

3. Experiment Method

3.1. Preparation of Specimens

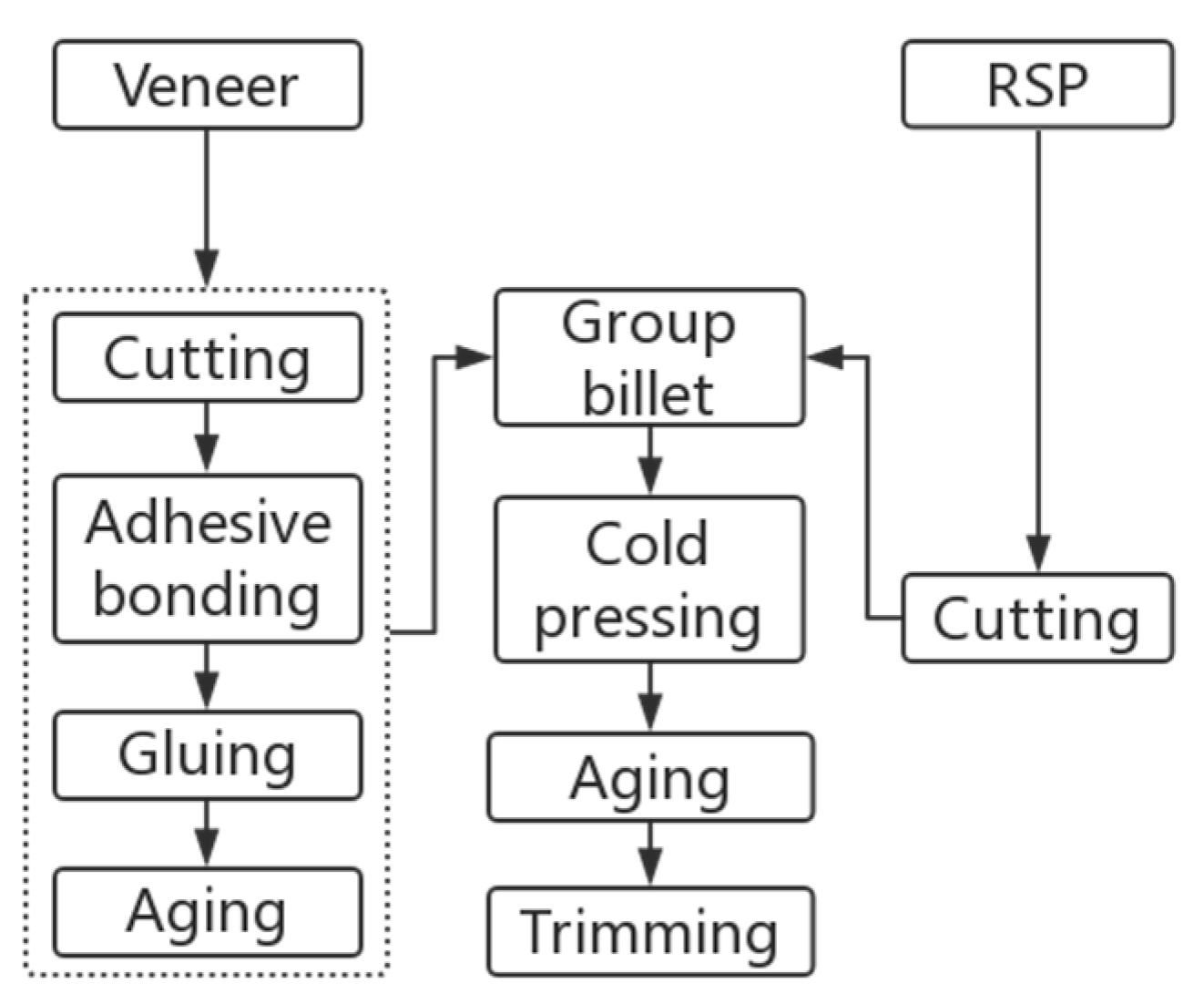

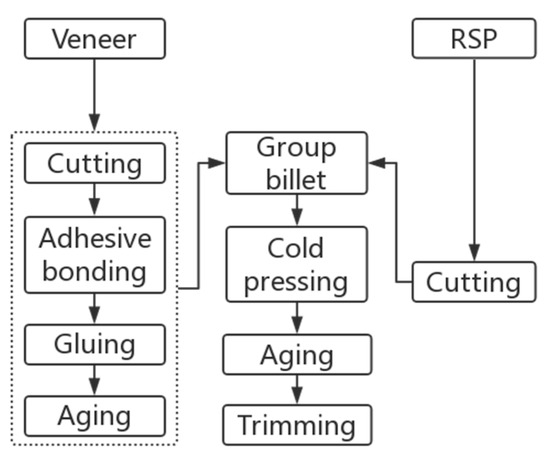

The main purpose of this experiment was to produce veneered RSP with six types performance indexes by changing the sanding thickness and moisture content of RSP, amount of glue, species and thickness of veneer. The process diagram was shown in Figure 1. The first step: sanding the surface of RSP with a belt sander, and the grit size of sandpaper is 600 #. Coating the surface of RSP uniformly with polyvinyl acetate emulsion and aging for 2–3 min. The second step: cutting and gluing the veneer. The third step: assembling the finished RSP and spliced veneer and ensuring the smooth and no defect of specimens in the process of assembly. The fourth step: the assembled veneered RSP was put into the hot press at 80 °C for 90 s. The fifth step: aging the pressed veneered RSP for 8–24 h. The final step: the veneered RSP was trimmed to ensure the edge of the trimmed veneered RSP specimens were smooth. The relevant parameters of the veneering process were shown in Table 1.

Figure 1.

Manufacturing of veneered rice straw particleboard (RSP).

Table 1.

Parameters in the process of veneering.

3.2. Grouping of Specimens

The prepared veneered RSP specimens were selected and divided into six groups, as shown in Table 2. The performance index of the veneered RSP numbered A1 is below. The RSP with 10.2% moisture content was sanded by 600 # sandpaper; the thickness of sanding was 0.2 mm. Veneering of the RSP was completed with 80 g/m2 glue amount and 0.8 mm Betula sp. The other five groups were numbered as A2–A6. Under the same other variables, the performance indices were based on the A1. The only indicator that was different, was the sanding thickness of RSP of A2, which was 0.6 mm. The veneer of A3 was 0.8 mm for Cyclobalanopsis glauca; the moisture content of RSP of A4 was 8.5%; the glue amount of A5 was 150 g/m2; the veneer of A6 was 0.28 mm for Betula sp. and three pieces were numbered from each specimen.

Table 2.

Group number and treatment of specimens.

3.3. Determination Method

The evaluation standard for dimensional stability of RSP included panel dimension and warp degree. Concerning the measurement method of dimensional stability in GB/T 15104-2006 [19], first, the RSP specimens needed to be balanced in moisture content before the measurement. We placed the specimens in a constant temperature and constant humidity box, and kept the RSP specimens in air with relative humidity (65% ± 5%) and temperature (20 ± 2 °C). Measurements were conducted when the mass of RSP specimens reached a constant state [20]. During measurement, the concave surface of the RSP specimens was placed upward, and the diagonal of specimens was connected and tightened with wires. The panel dimensional deviation of RSP specimens of two lengths, widths and diagonal were measured and recorded with a vernier caliper as the panel dimension. The maximum string height between the length, width, diagonal and the surface of RSP specimens was measured and recorded, the warp degree of specimens was calculated according to Equation (1) using the recorded panel dimension, exactly to 1%.

4. Results and Discussion

4.1. Experimental Results

As per the above experimental method, the panel dimensional deviation of six groups of veneered RSP specimens in lengths, widths and diagonals were measured and recorded. The average values of the size changes in lengths, widths and diagonals of each specimen were taken as the final measurement results, as shown in Table 3.

Table 3.

Panel dimensional deviation of veneered RSP with different performance.

As per the above experimental method, the size of two lengths, widths, diagonals of six groups veneered RSP specimens and their respective maximum string height were measured and recorded. The warp degree of different directions were calculated according to Equation (1), and average value of the warp degree changes in lengths, widths and diagonals of each specimens were taken as the final measurement results, as shown in Table 4.

Table 4.

Warp degree of veneered RSP with different performance.

4.2. Discussion

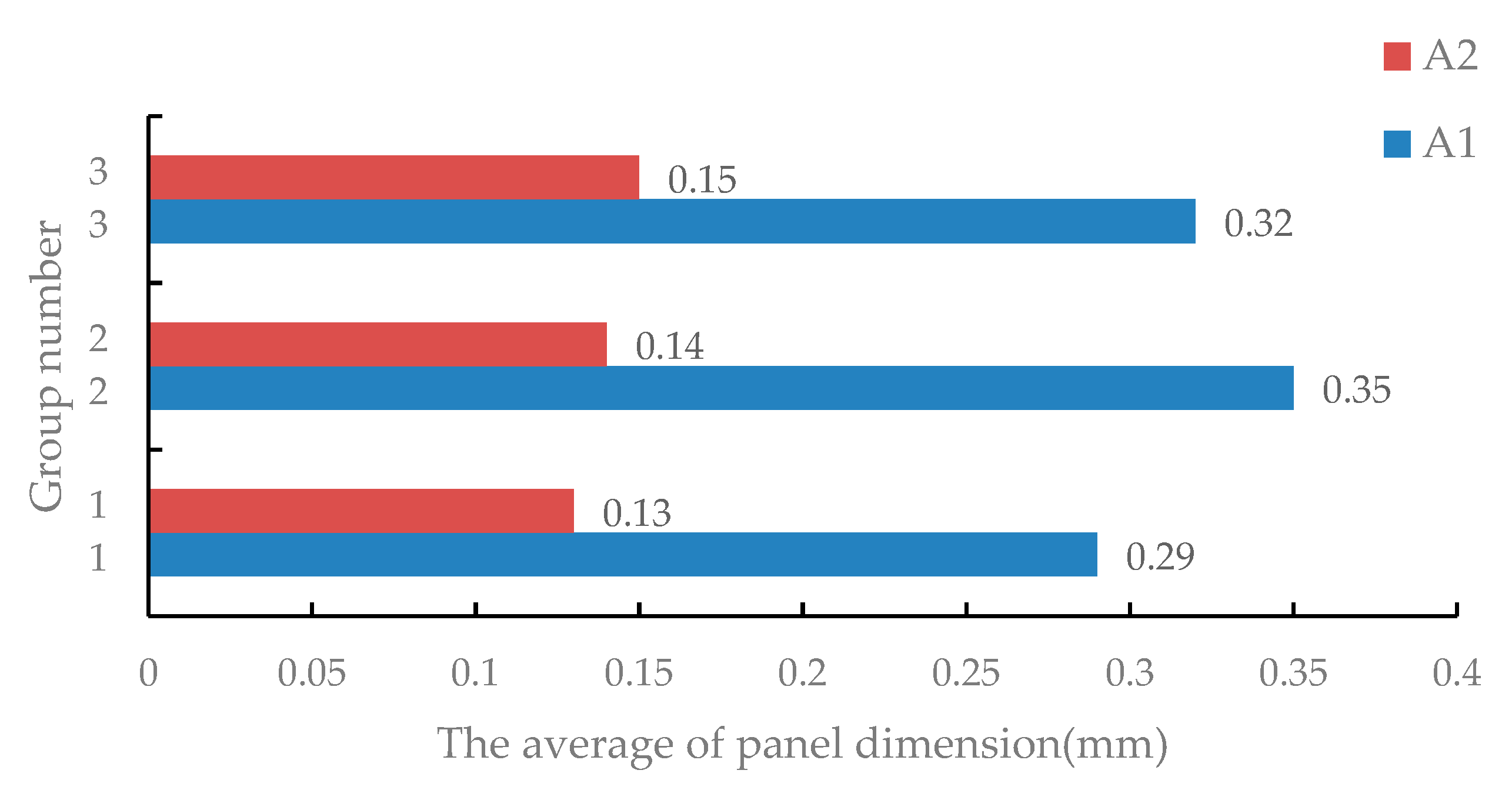

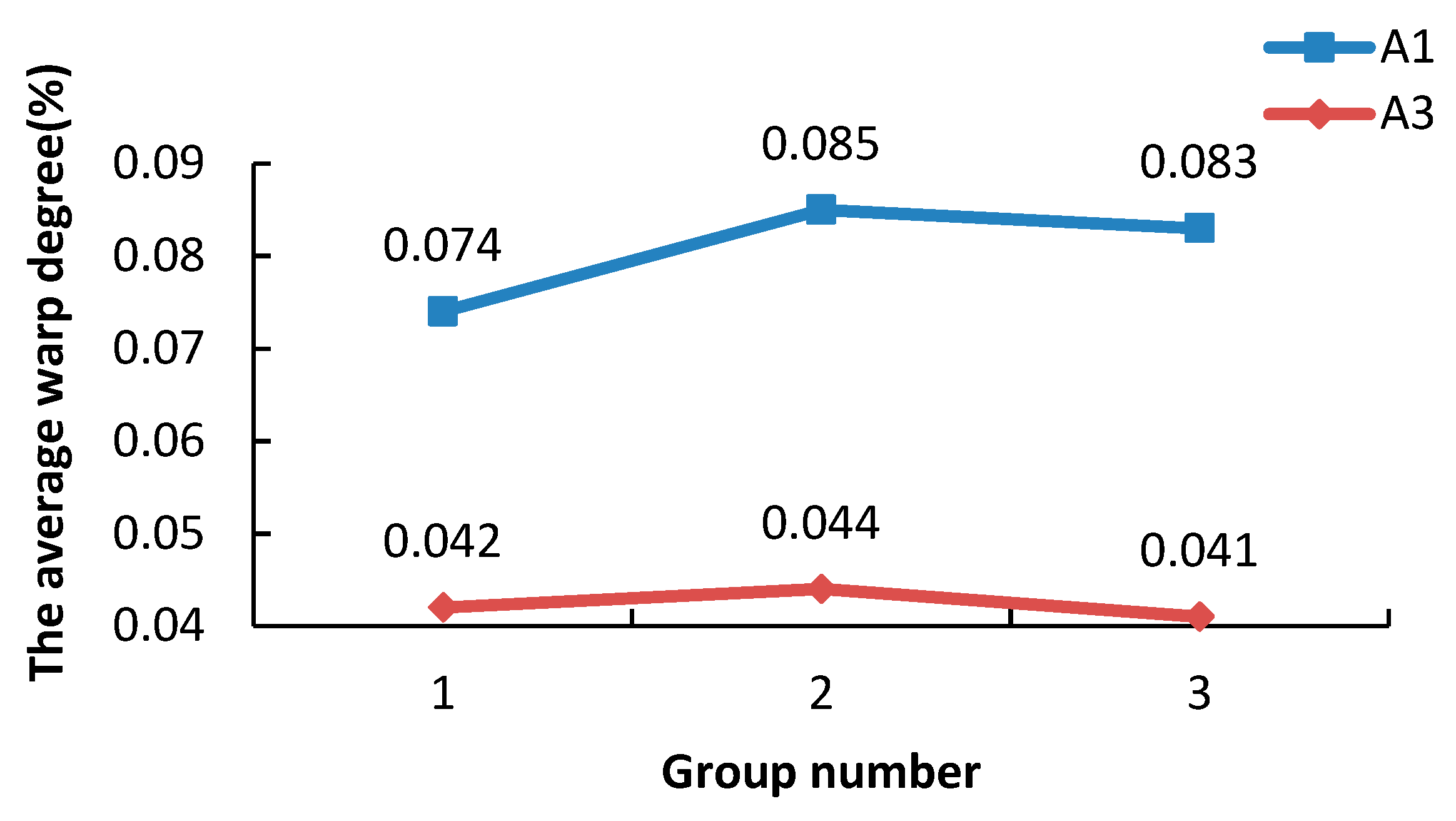

4.2.1. Effect of the Sanding Thickness of RSP on Dimensional Stability of Veneered RSP

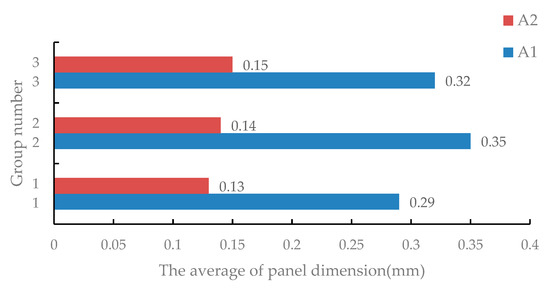

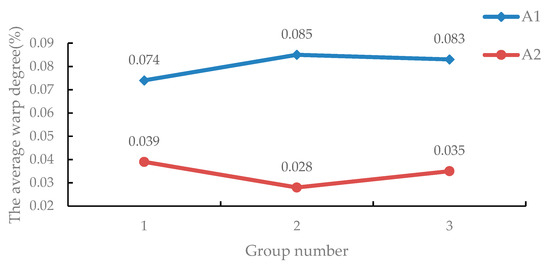

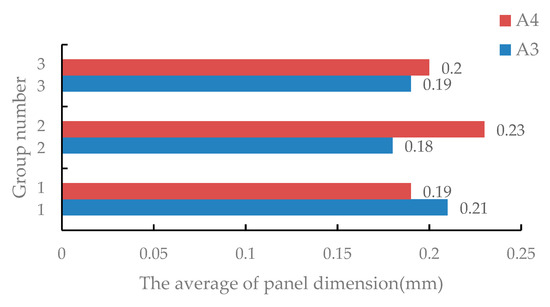

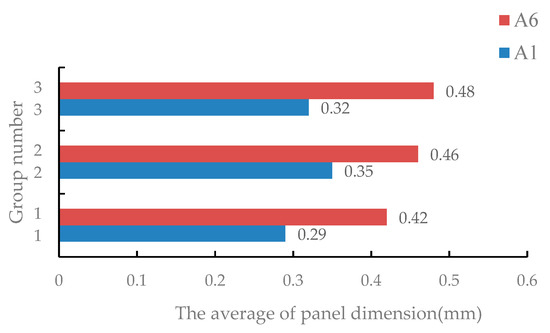

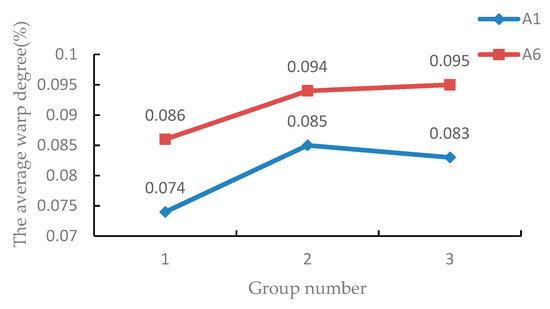

It can be seen from Table 3 and Table 4, the experimental results of panel dimension and warp degree of two groups RSP specimens of A1 and A2 could be used to analyze the effect of sanding thickness of RSP on dimensional stability of veneered RSP. As shown in Table 3, the effect of sanding thickness of RSP on panel dimension of veneered RSP was shown in Figure 2. As shown in Table 4, the effect of sanding thickness of RSP on warp degree of veneered RSP was shown in Figure 3.

Figure 2.

Effect of sanding thickness of RSP on panel dimension.

Figure 3.

Effect of sanding thickness of RSP on warp degree.

As can be seen from Figure 2, sanding the RSP in front of veneer with a different sanding thickness can significantly affect the dimensional stability of veneered RSP. The average varying value of panel dimension of RSP specimens with 0.2 mm sanding thickness obviously higher than the RSP specimens with 0.6 mm sanding thickness. It can be seen from Figure 3, the trend between warp degree and sanding thickness showed an opposite tendency. In other words, the smaller the sanding thickness, the bigger the warp degree of veneered RSP. The mainly reason was that a pre cured layer would be formed on the surface of RSP during the hot pressing process. The pre cured layer was not completely eliminated when the sanding thickness was relatively small, and the stress was not uniform in the process of post-sequence pressing which eventually leaded the defects such as surface warping of RSP. By consulting the literature, it can be seen that Xiong et al. drew a same conclusion by studying the influencing factors of dimensional stability of RSP veneered by Betula sp. With the increase of sanding thickness of surface of RSP, the warp degree of RSP specimens after the Betula sp. veneer gradually decreased. The deformation rate of RSP specimens was less than 1% after sanding, and the optimum sanding thickness of RSP was 0.8 mm [21].

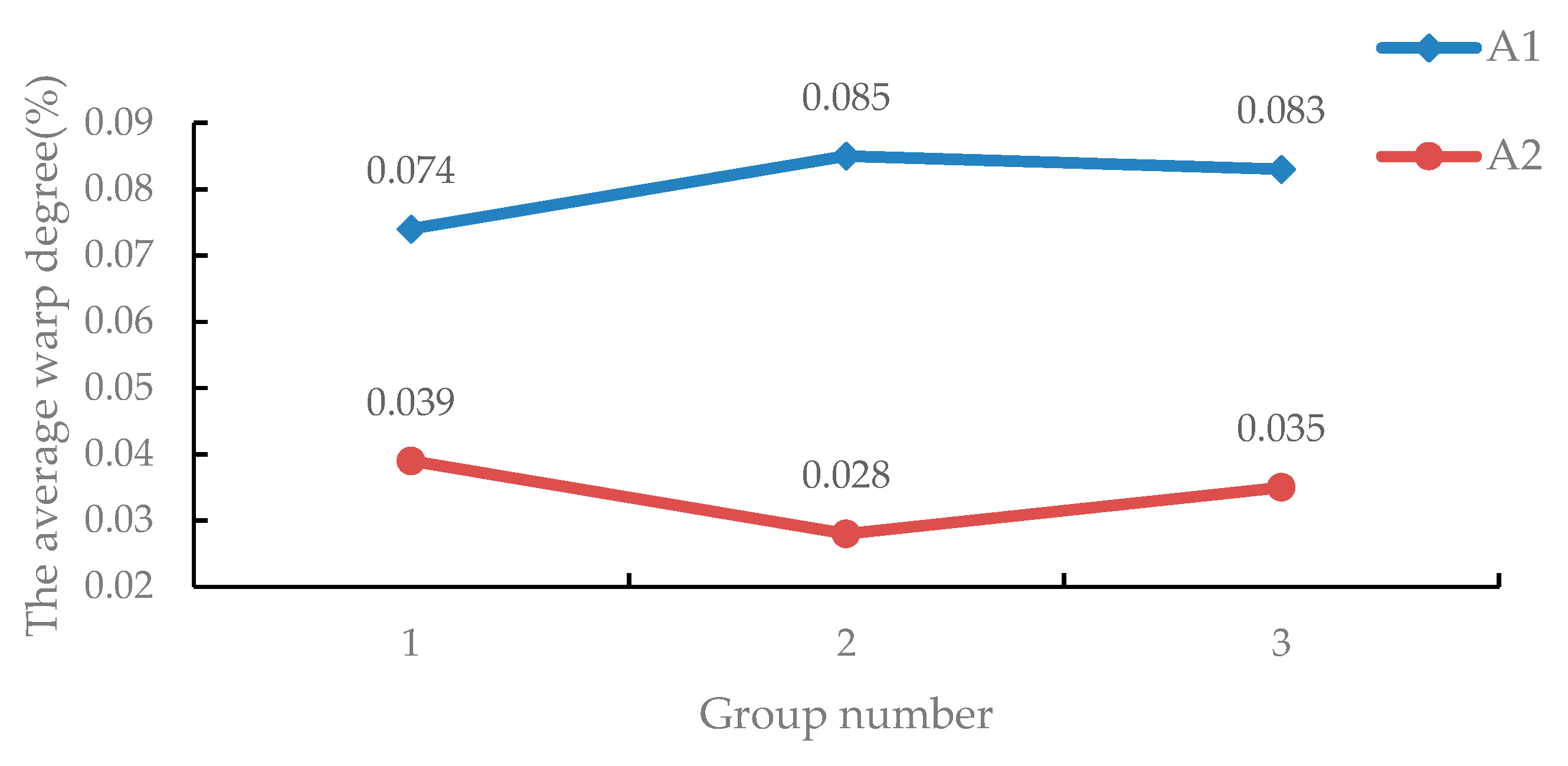

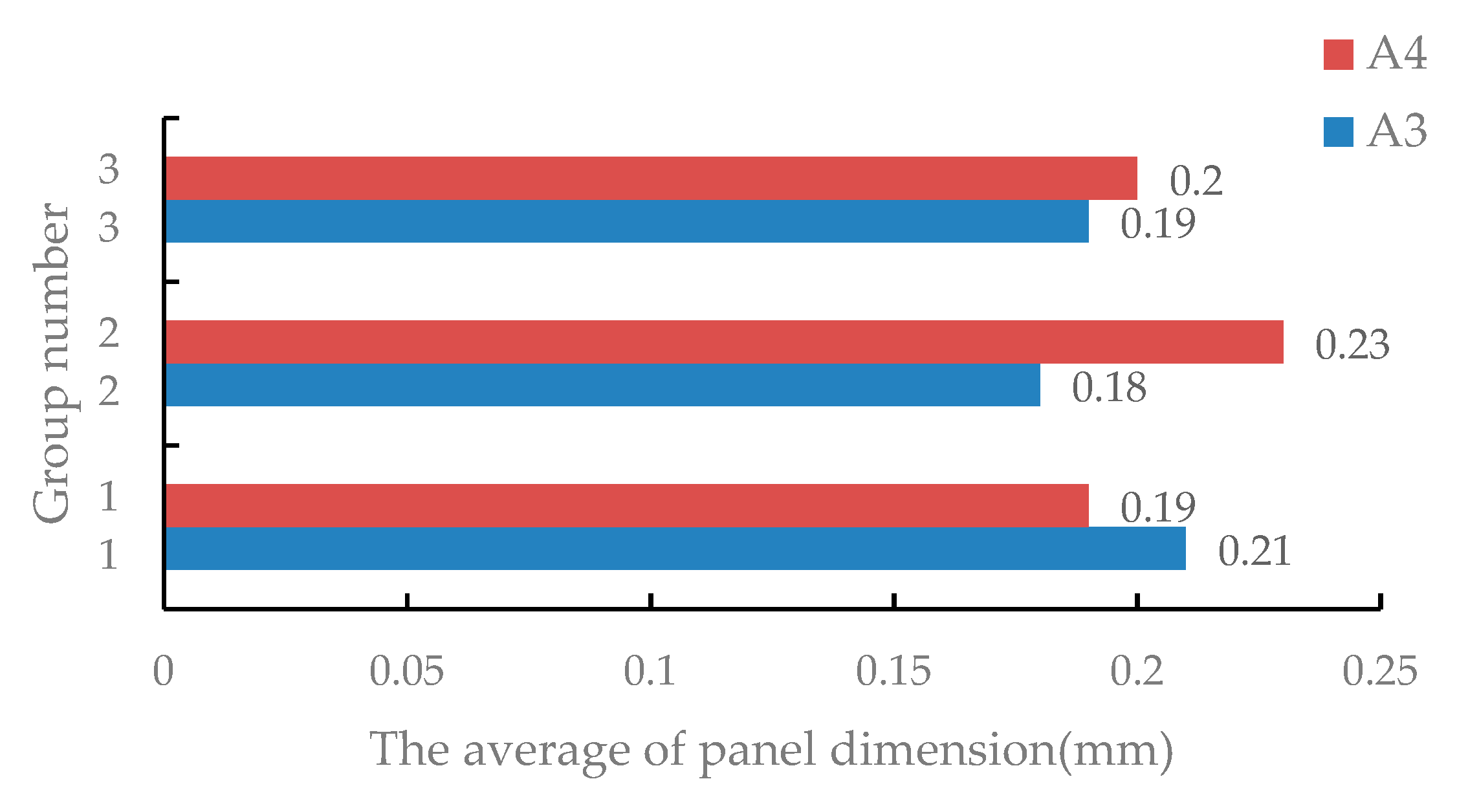

4.2.2. Effect of the Veneer Species on Dimensional Stability of Veneered RSP

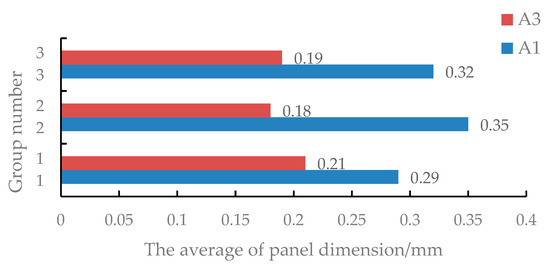

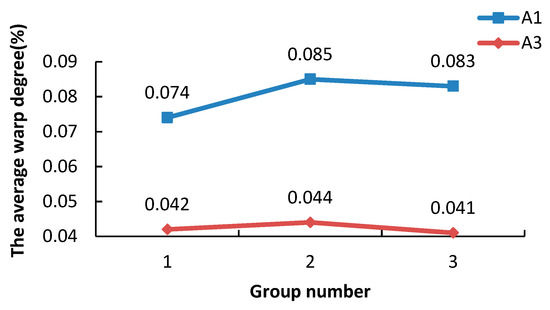

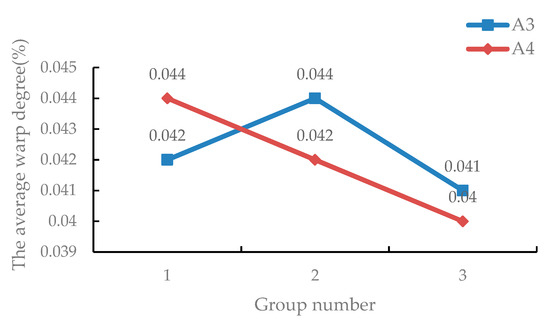

As can be seen from Table 3 and Table 4, the experimental results of panel dimension and warp degree of two groups RSP specimens of A1 and A3 could be used to analyze the effect of veneer species on dimensional stability of veneered RSP. As shown in Table 3, the effect of different veneer species on panel dimension of veneered RSP was shown in Figure 4. As shown in Table 4, the effect of different veneer species on warp degree of veneered RSP was shown in Figure 5.

Figure 4.

Effect of veneer species on panel dimension.

Figure 5.

Effect of veneer species on warp degree.

It can be seen from Figure 4 and Figure 5, the dimensional stability of RSP specimens with different veneer was obviously different. The average changes of panel dimension and warp degree of RSP specimens with Betula sp. veneer was significantly higher than the RSP specimens with Cyclobalanopsis glauca. The reason could be analyzed from the structural characteristics of species and the characteristics of wood. Compared with Cyclobalanopsis glauca, Betula sp. belongs to diffuse-porous wood, straight and rough grain, more pores. As a result, the water from adhesive would be more permeated to the RSP and relatively less radiated outward when veneering. Shrinkage and bulking was the characteristic of wood, the more the water in wood, the poorer the dimensional stability and the more serious the deformation.

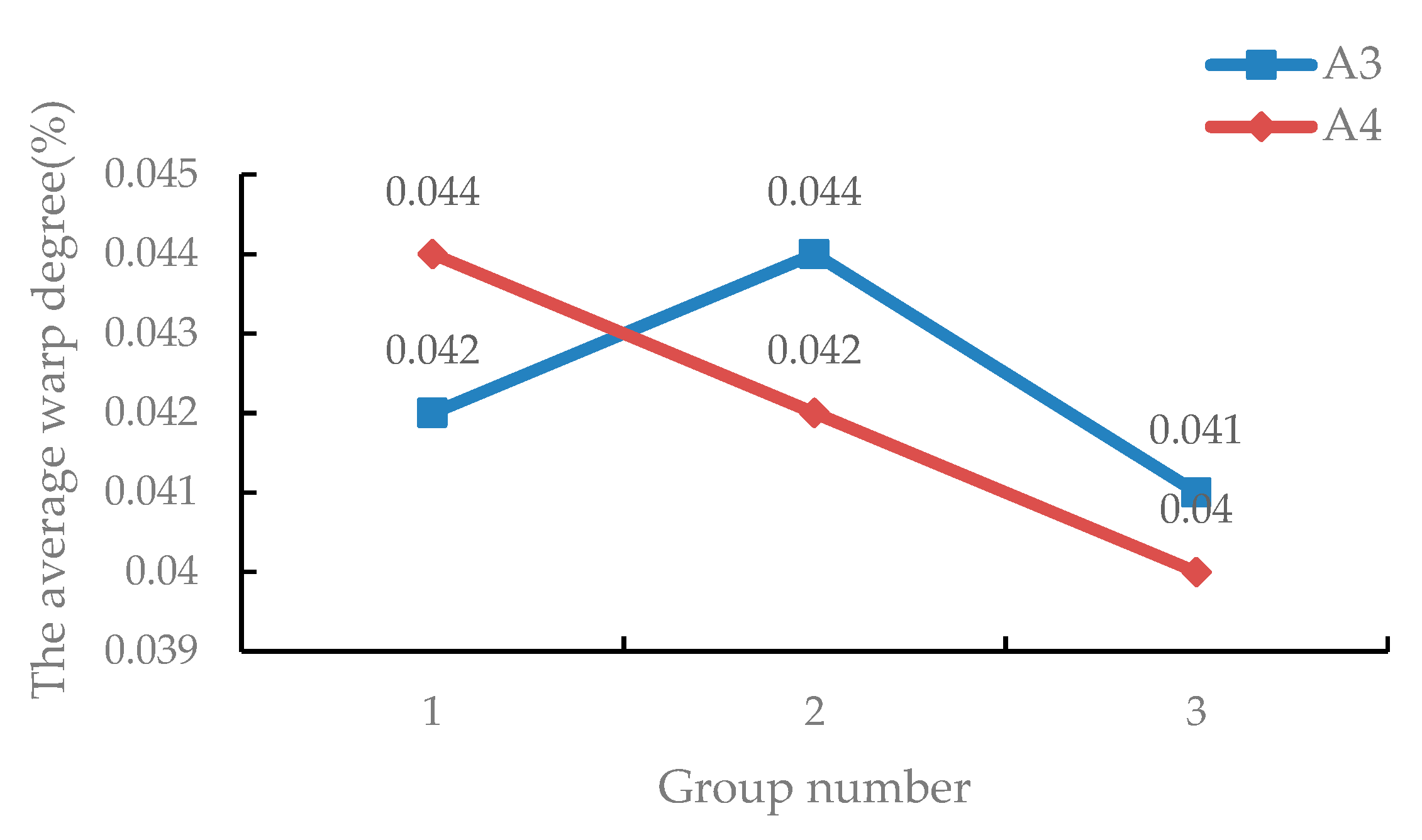

4.2.3. Effect of the Moisture Content of RSP on Dimensional Stability of Veneered RSP

It can be seen from Table 3 and Table 4, the experimental results of panel dimension and warp degree of two groups RSP specimens of A4 and A3 could be used to analyze the effect of moisture content of RSP on dimensional stability of veneered RSP. As shown in Table 3, the effect of moisture content of RSP on panel dimension of veneered RSP was shown in Figure 6. As shown in Table 4, the effect of moisture content of RSP on warp degree of veneered RSP was shown in Figure 7.

Figure 6.

Effect of moisture content of RSP on panel dimension.

Figure 7.

Effect of moisture content of RSP on warp degree.

It can be seen from Figure 6 and Figure 7, with the increase of moisture content of RSP, the panel dimension and warp degree of veneered RSP did not change significantly. The mainly reason was the moisture content of RSP specimens in this experiment was within a suitable range, and the change of the dimensional stability within this range would not been significantly affected. As shown in literature data, we can see that the effect of moisture content on dimensional stability showed a same trend. Yu et al. comprehensive summarized the influence factors of dimensional stability of wood-based panel. The results showed that the hot pressing, time, moisture content of panel, species and adhesive had a certain degree influence on wood-based panels [22]. Among them, there was a close connection between the moisture content of panel internal and aging time, the more uniform the moisture content of panel, the better the dimensional stability of wood-based panel.

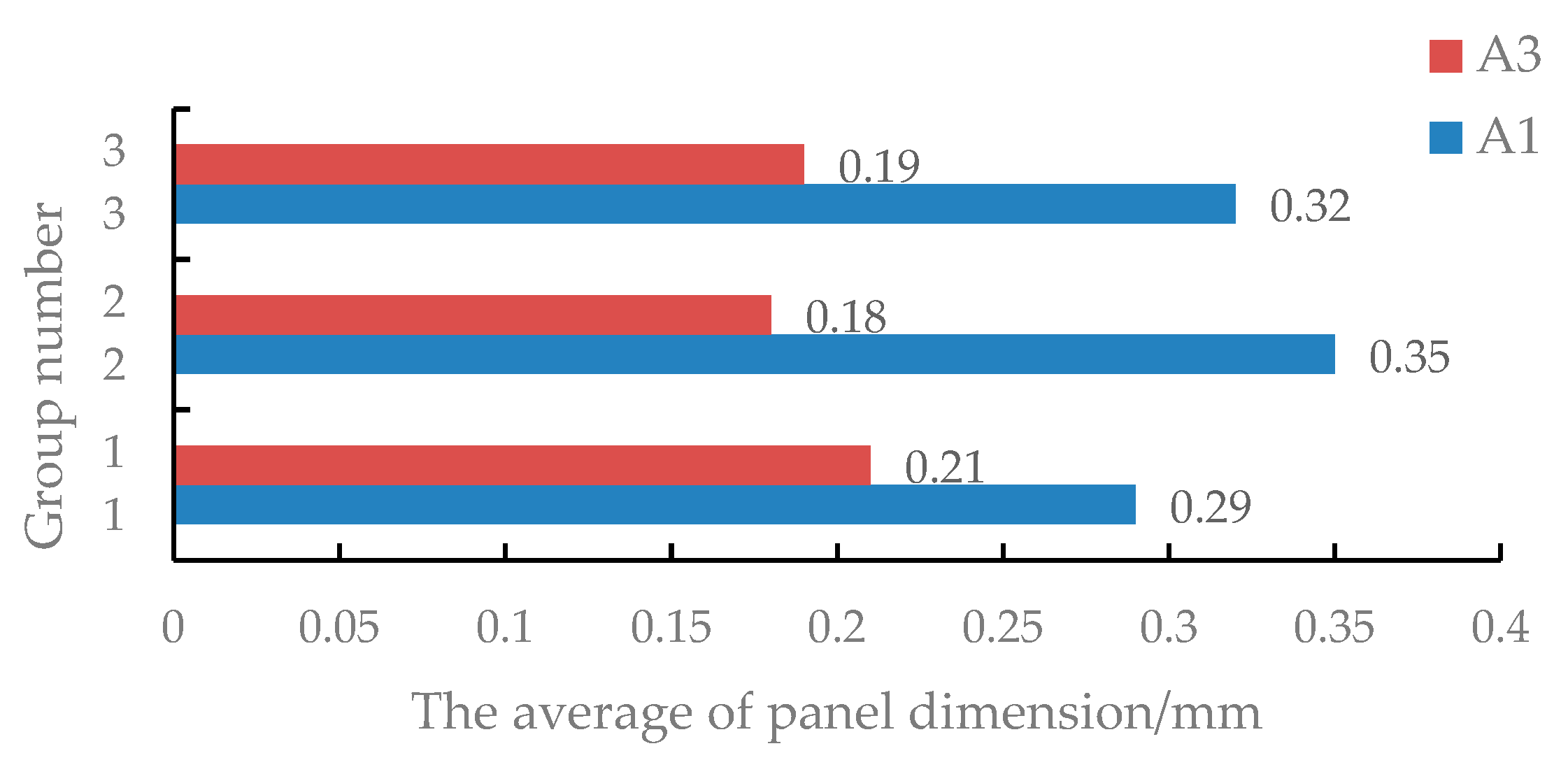

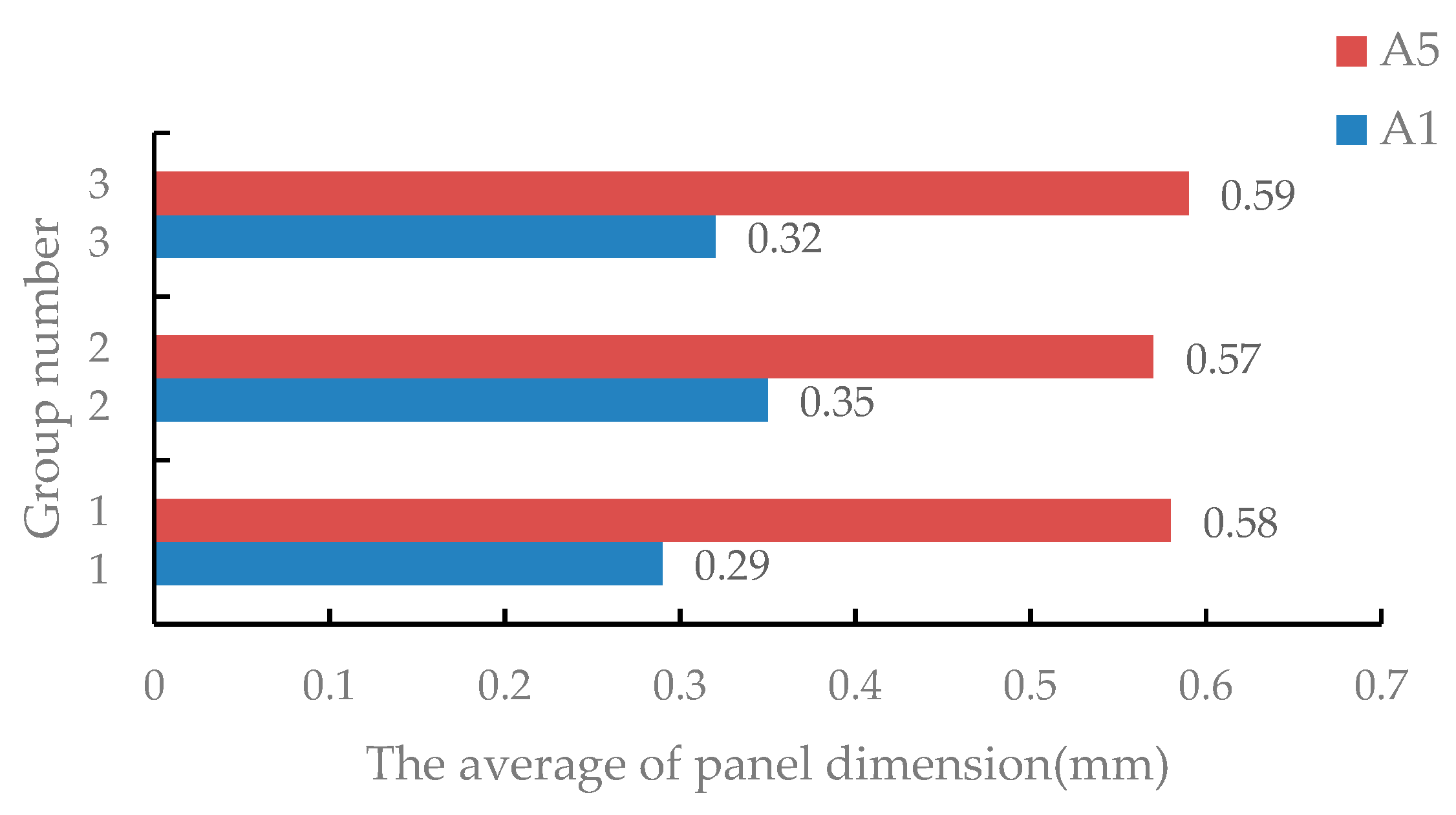

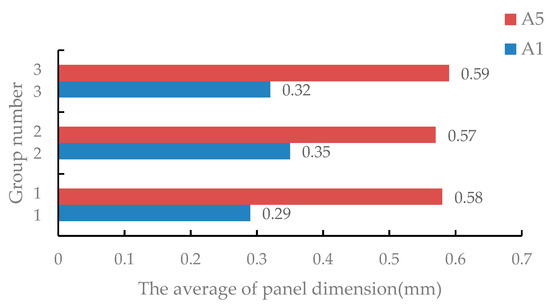

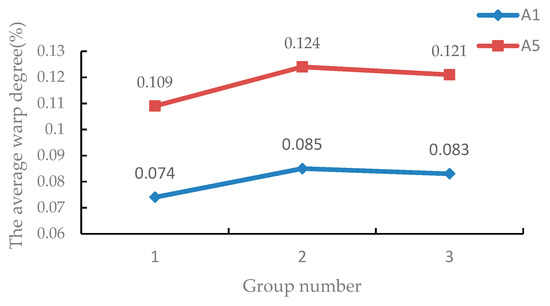

4.2.4. Effect of the Glue Spread on Dimensional Stability of Veneered RSP

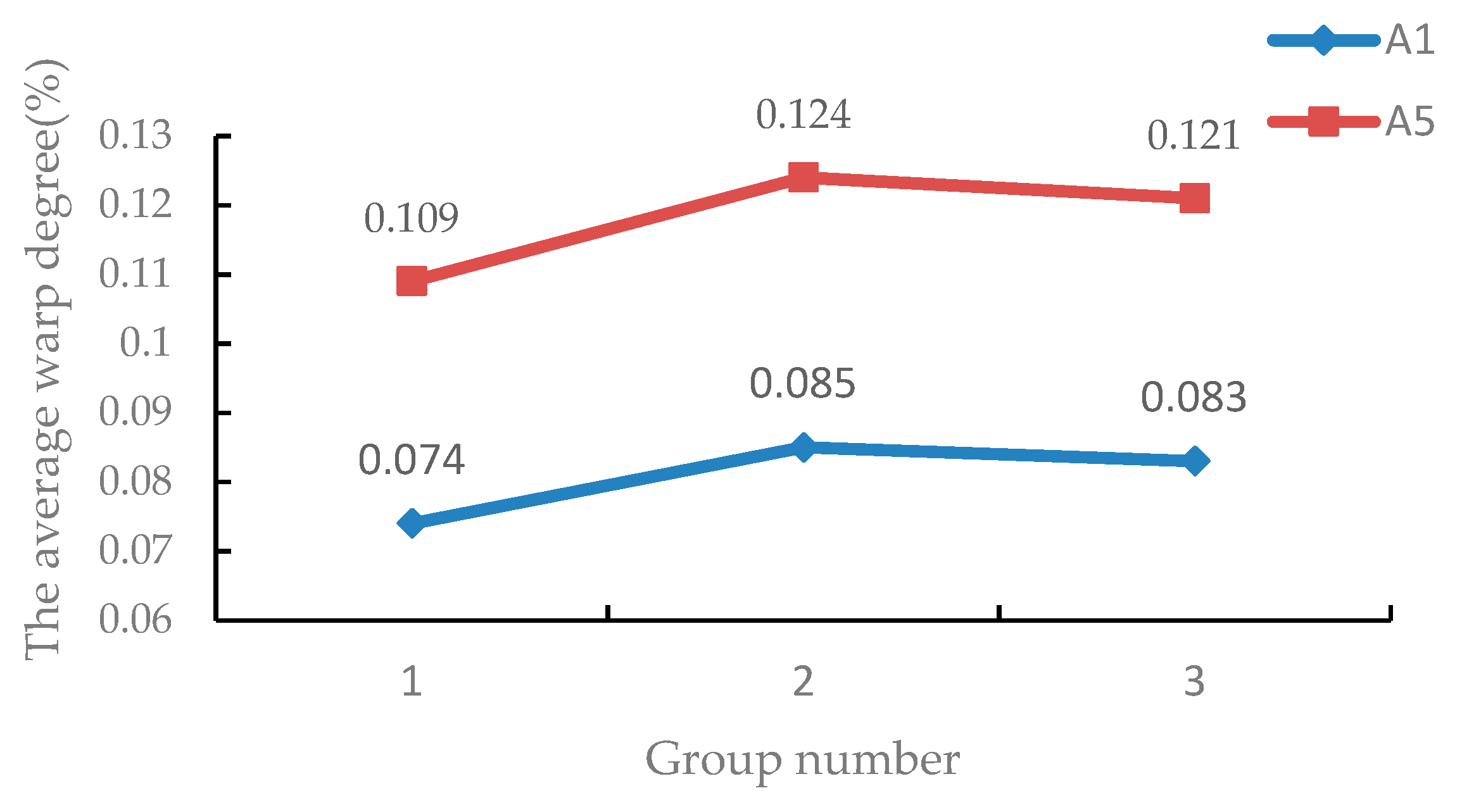

As we can see from Table 3 and Table 4, the experimental results of panel dimension and warp degree of two groups RSP specimens of A1 and A5 could be used to analyze the effect of the glue spread on dimensional stability of veneered RSP. As shown in Table 3, the effect of the glue spread on panel dimension of veneered RSP was shown in Figure 8. As shown in Table 4, the effect of the glue spread on warp degree of veneered RSP was shown in Figure 9.

Figure 8.

Effect of the glue spread on panel dimension.

Figure 9.

Effect of the glue spread on warp degree.

As shown in Figure 8, the effect of glue spread on panel dimension of veneered RSP was significant. The panel dimension changes of veneered RSP specimens with 150 g/m2 glue spread was obviously higher than the specimens with 80 g/m2 glue spread. It can be seen from Figure 9, the effect of glue spread on warp degree of veneered RSP showed the same trend as the panel dimension. That is to say, the more the glue spread, the greater the warp degree of veneered RSP, and the worse the dimensional stability. The main reason was the physical properties of Shrinkage and bulking of wood materials itself. The water which permeate into the RSP increased because of the water of adhesive when the glue spread increased. The greater the possibility of deformation.

4.2.5. Effect of the Veneer Thickness on Dimensional Stability of Veneered RSP

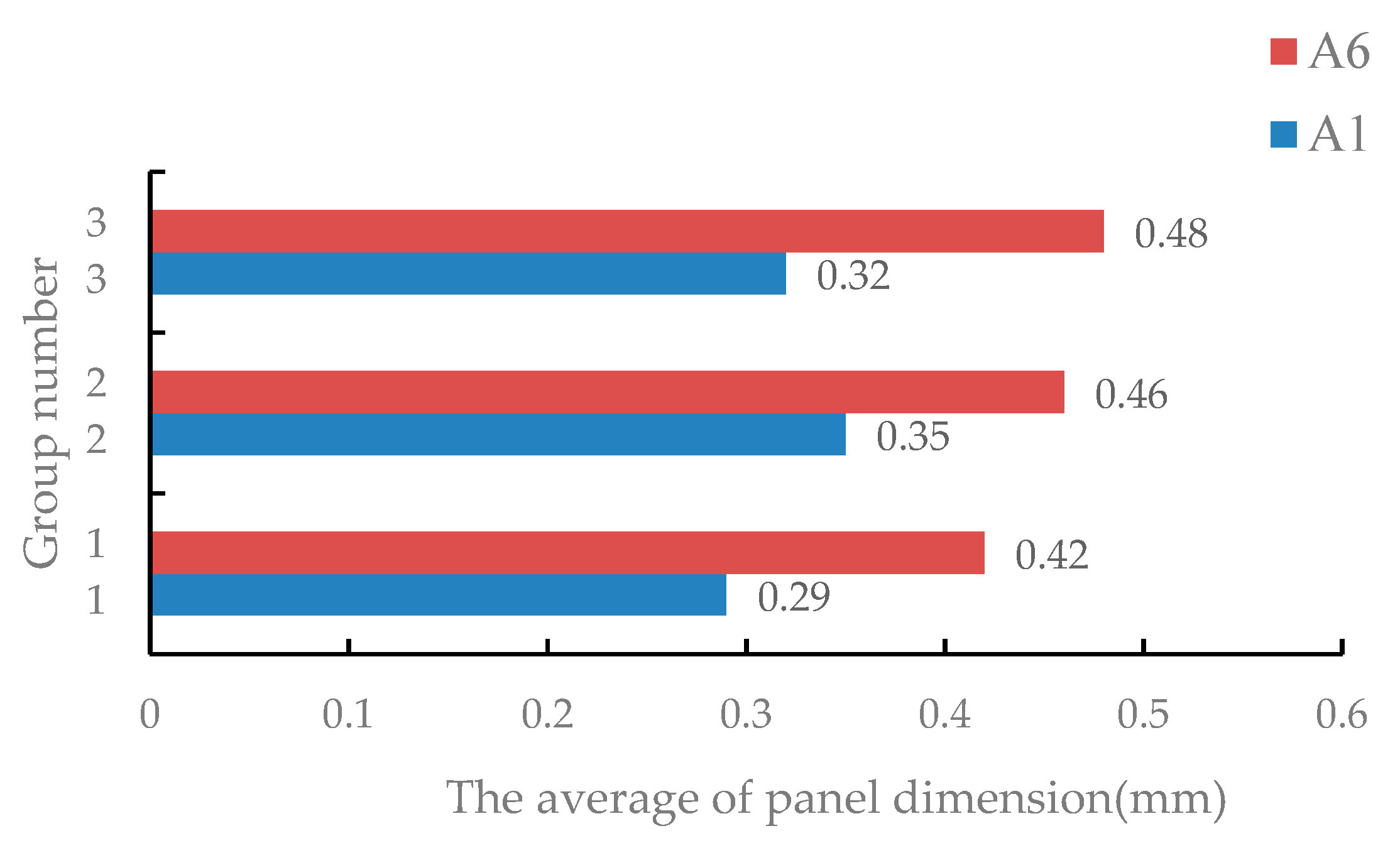

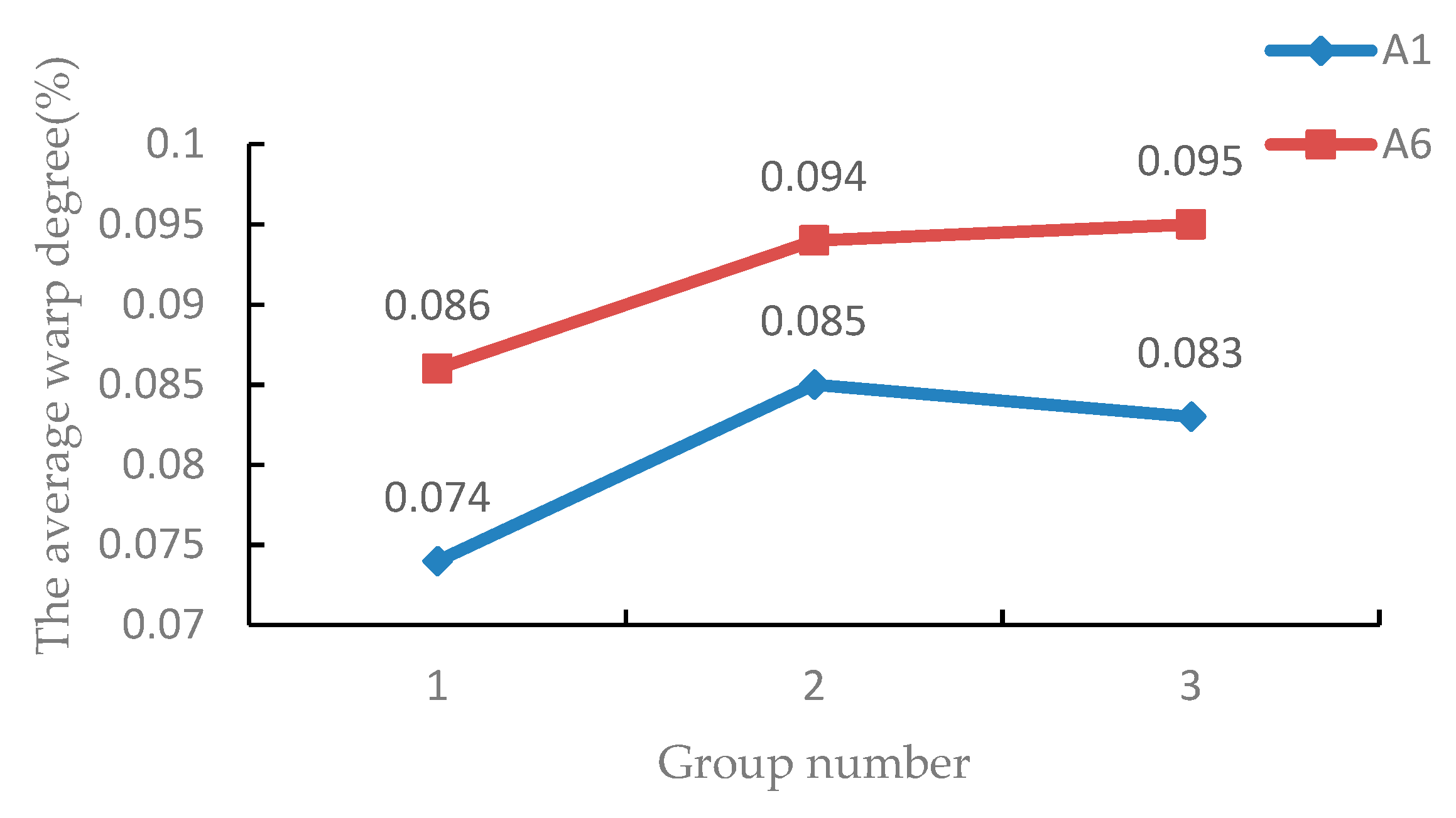

As we can see from Table 3 and Table 4, the experimental results of panel dimension and warp degree of two groups RSP specimens of A1 and A6 could be used to analyze the effect of veneer thickness on dimensional stability of veneered RSP. As shown in Table 3, the effect of veneer thickness on panel dimension of veneered RSP was shown in Figure 10. As shown in Table 4, the effect of veneer thickness on warp degree of veneered RSP was shown in Figure 11.

Figure 10.

Effect of veneer thickness on panel dimension.

Figure 11.

Effect of veneer thickness on warp degree.

It can be seen from Figure 10 and Figure 11 that the dimensional stability represented by panel dimension and warp degree of veneered RSP enhanced with the increase of veneer thickness, but the effect was not obvious. The mainly reason was that the environment more easily affected the super-veneer. The change of environmental humidity clearly caused problems such as hygroscopic expansion, water-loss shrinking deformation and the defects such as rough surface and bubbling. In general, the solution was to add a layer of veneer with a thickness of 0.6–1.5 mm as the medium panel before the super-veneer. The purpose was to increase the strength and ensure the leveling of the panel.

5. Conclusions

- According to the analysis of the experimental data, it can be concluded that there were many factors that influence veneered RSP in terms of dimensional stability. Among them, the effect of glue spread was the most significant. The more the glue spread, the worse the dimensional stability of veneered RSP. There was almost no effect of moisture content on dimensional stability of veneered RSP;

- The physical characteristic of shrinkage and bulking of the RSP itself was the essential point of the deformation of veneered RSP;

- By analyzing the reasons for the deformation of the appearance of the RSP specimens, it could be seen that the effect of moisture content on dimensional stability of veneered RSP was the main factor. However, within a reasonable range, an appreciable change of moisture content of RSP would cause a neglectable change in the dimensional stability of veneered RSP.

Author Contributions

Conceptualization, X.X.; methodology, X.X. and Y.N.; validation, X.X. and Y.Y.; data curation, X.X. and Y.N.; writing—original draft preparation, Y.N. and L.Z.; All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), Postgraduate Research &Practice Innovation Program of Jiangsu Province and Natural Science Foundation of Jiangsu Province (No. BK20150881).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wu, Z.H. Manufacturing model of furniture industry in industry 4.0. China For. Prod. Ind. 2016, 43, 6–10. [Google Scholar]

- Xiong, X.Q.; Yuan, Y.Y.; Niu, Y.T.; Zhang, L.T. Research on the Effects of Roughness on the Tactile Properties of Rice Straw Particleboard Surface. Sci. Adv. Mater. 2020, 12, 795–801. [Google Scholar] [CrossRef]

- Chang, L.; Wu, Z.H. Promoting the Competitiveness of China’s Furniture Industry. China Wood Based Panels 2011, 10, 46–48. [Google Scholar]

- Li, P.; Zuo, Y.F.; Wu, Y.Q.; Zhao, X.; Wang, J. Research process on the manufacture and application of straw-based panel. Mater. Rep. 2019, 33, 2624–2630. [Google Scholar]

- Zhang, W.Z. Research production and application of straw board. Guangdong Build. Mater. 2005, 2, 25–27. [Google Scholar]

- Hu, G.B. Review of rice straw based panel development and existent problems in China. China For. Prod. Ind. 2004, 31, 7–10. [Google Scholar]

- Ding, B.Y. Development of straw-based panels industry. China Wood Based Panels 2016, 23, 1–9. [Google Scholar]

- Zheng, F.S.; He, L. Review and discussion on development of the wheat/rice straw board industry in China. China Wood Ind. 2006, 20, 30–32. [Google Scholar]

- Zhang, D.X.; Zhao, T. A study into the cause of warpage in medium density strawboard. China Wood Based Panels 2010, 17, 13–15. [Google Scholar]

- Sun, S.J.; Zhao, Z.Y.; Shen, J. Effects of the Manufacturing Conditions on the VOCs Emissions of Particleboard. Bioresources 2019, 15, 1074–1084. [Google Scholar]

- Kurokochi, Y.; Sato, M. Effect of surface structure, wax and silica on the properties of binderless board made from rice straw. Ind. Crops Prod. 2015, 77, 949–953. [Google Scholar] [CrossRef]

- Dziurka, D.; Radosław, M. Lightweight boards from wood and rape straw particles. Drewno 2013, 56, 19–31. [Google Scholar]

- Boquillon, N.; Elbez, G.; Schönfeld, U. Properties of wheat straw particleboards bonded with different types of resin. J. Wood Sci. 2004, 50, 230–235. [Google Scholar] [CrossRef]

- Xiong, X.Q.; Yuan, Y.Y.; Niu, Y.T.; Zhang, L.T.; Wu, Z.H. Effects of Different Treatments on Surface Activity of Rice Straw Particleboard. Sci. Adv. Mater. 2020, 12, 289–295. [Google Scholar] [CrossRef]

- Yan, Y.L.; Li, X.G.; Liu, X.R. Study on hot-pressing process of straw particle board. J. Cent. South Univ. For. Technol. 2012, 32, 126–129. [Google Scholar]

- Shen, L.; Rao, X.; Yang, J. Effects of Surface Treatments on Dimensional stability of Straw Board. China Wood Based Panels 2008, 15, 12–14. [Google Scholar]

- Ma, X.W.; Cao, Q.; Lei, D.D.; Zhou, X.Z.; Zhang, S.B. Research on Dimensional stability of Fiberboard Product(I)-Present Situation of Research on Dimensional stability of Fiberboard Product at Home. Wood Based Panels 2004, 11, 4–7. [Google Scholar]

- Xu, X.W.; Wu, Q.L.; Zhou, D.G.; Zhou, X.Y. Fundamental hygroscopic characteristics of rice straw-based particleboard with modified mdi resin. China For. Prod. Ind. 2003, 30, 18–21. [Google Scholar]

- Decorative Veneered Wood-Based Panel; GB/T 15104-2006; State General Administration of the People’s Republic of China for Quality Supervision and Inspection and Quarantine: Beijing, China, 2006.

- Zhou, X.Y. The research on dimensional stability of structural panel products in foreign country. China For. Prod. Ind. 2000, 27, 6–10. [Google Scholar]

- Qian, W.T.; Fang, L.; Wu, Z.H. Producing process for veneer decorative straw particleboards. Wood Res. 2016, 61, 465–474. [Google Scholar]

- Yu, H.X.; Wan, Y.; Zheng, H.L.; Fang, C.R.; Yu, L.Q. Standards for wood-based panel dimensional stability testing. China For. Prod. Ind. 2011, 38, 37–41. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).