Controlled Synthesis of Tellurium Nanowires

Abstract

1. Introduction

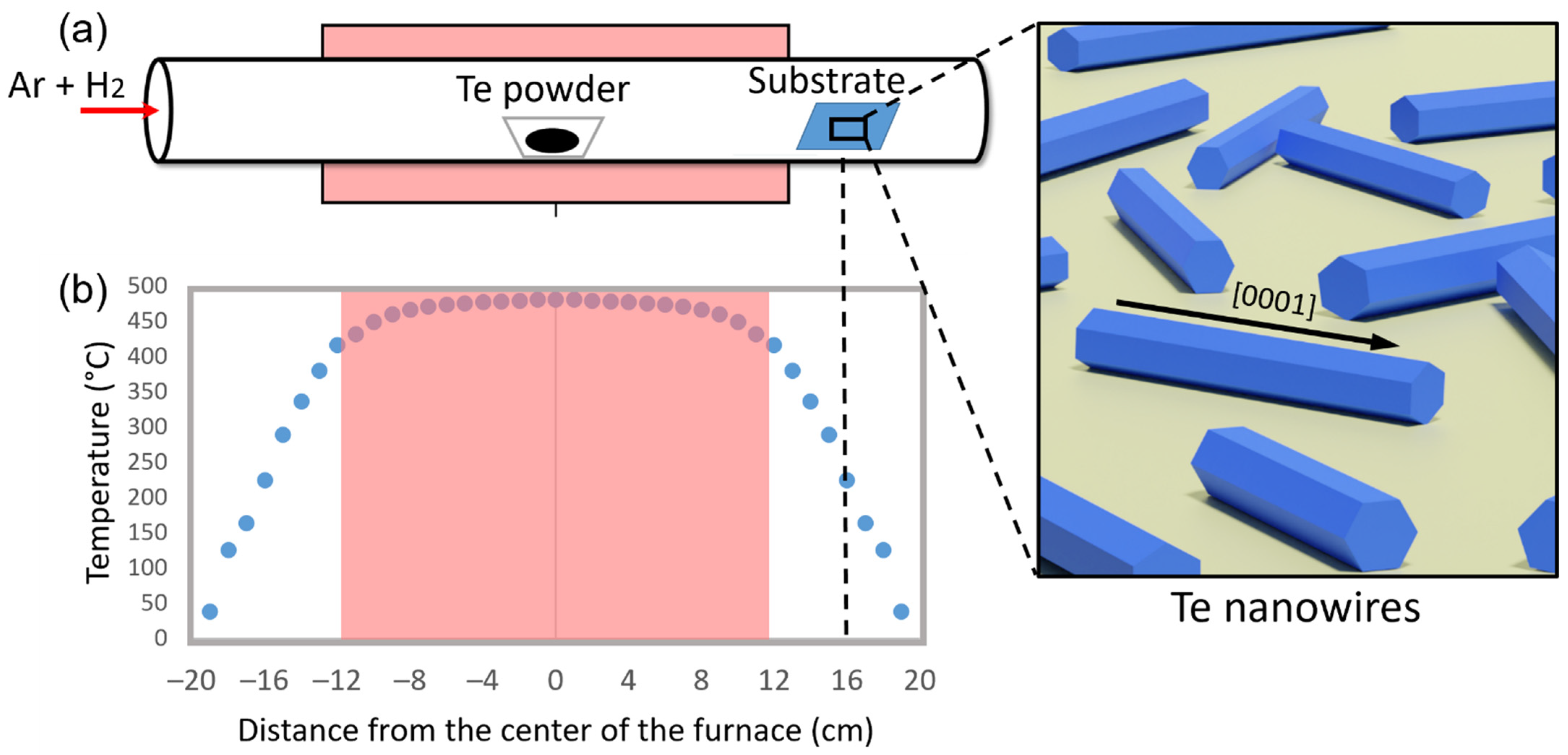

2. Experimental Details

3. Results and Discussion

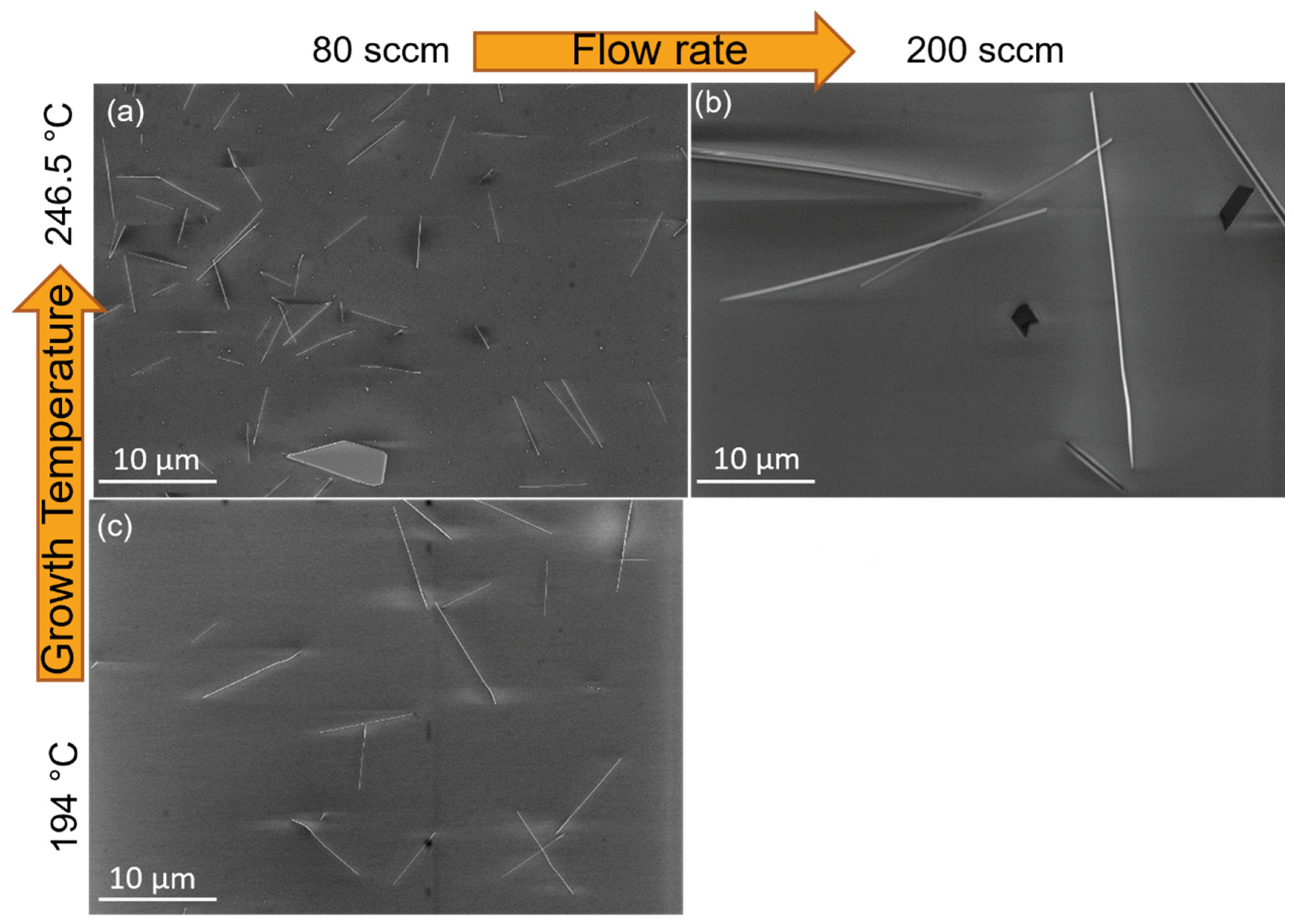

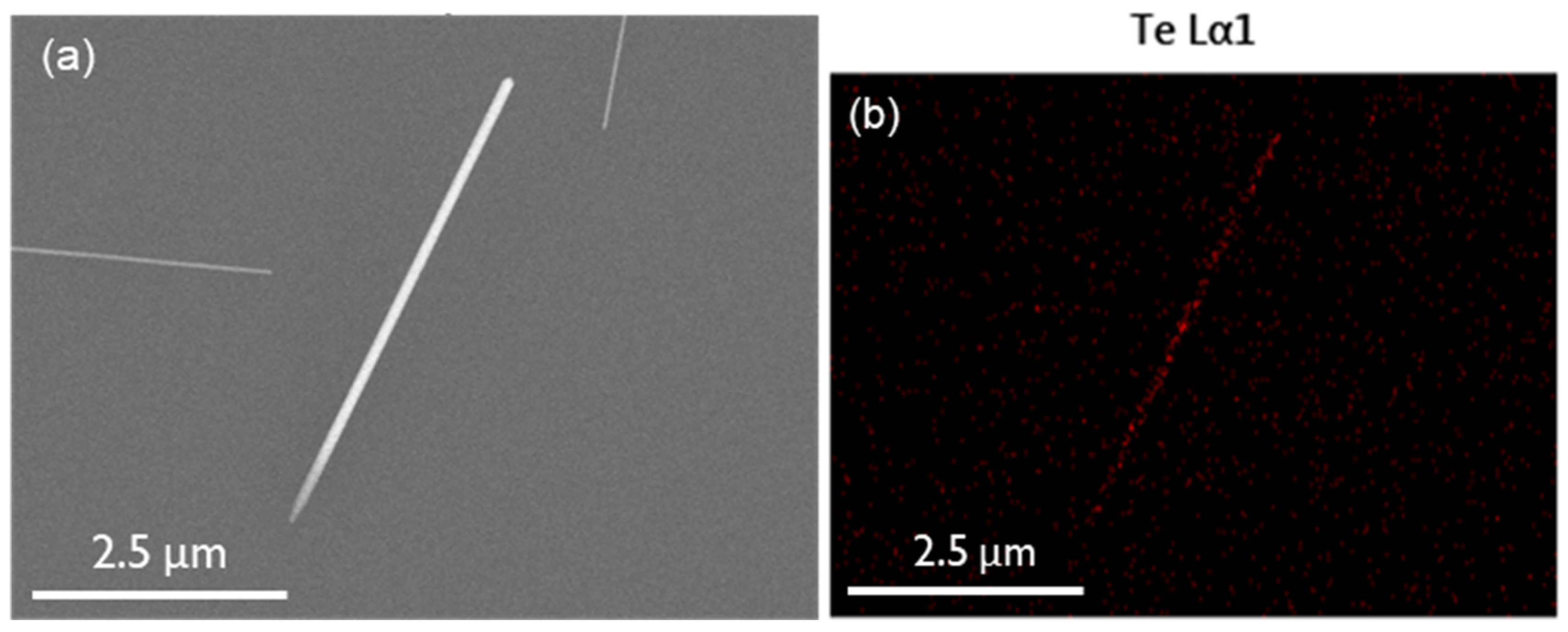

3.1. Effect of the Carrier Gas Flow Rate and System Temperature

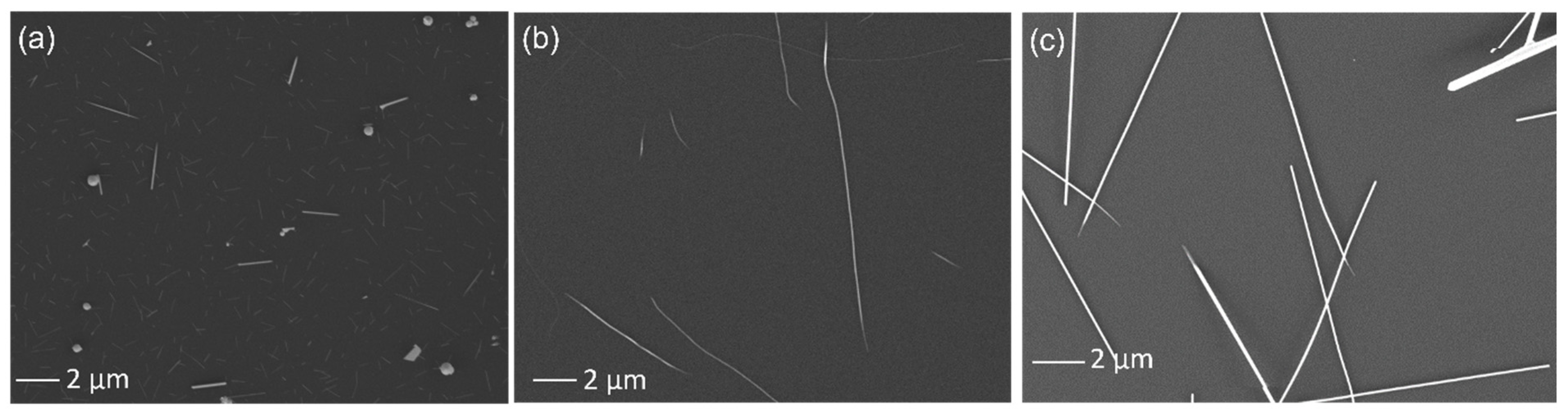

3.2. Effect of Growth Time and Heating Rate

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, Y.S.; Hwang, I.S.; Kim, S.J.; Lee, C.Y.; Lee, J.H. CuO nanowire gas sensors for air quality control in automotive cabin. Sens. Actuators B-Chem. 2008, 135, 298–303. [Google Scholar] [CrossRef]

- Tong, Z.Y.; Xie, T.; Ye, X.H.; Xia, H.; Li, J.Z.; Zhang, S.J.; Jiang, X.Y.; Chen, Z.Z.; Li, T.X. Research progress on semiconductor nanowires for high efficiency solar energy conversion. J. Infrared Millim. Waves 2019, 38, 508–519. [Google Scholar]

- Ngo, V.D.; Nguyen, T.D.; Nguyen, T.T.; Kim, E.T.; Nguyen, V.C.; Raj, M.; Lee, S.J. Field-Effect Transistor Behavior of Synthesized In2O3/InP (100) Nanowires via the Vapor-Liquid-Solid Method. J. Electron. Mater. 2021, 50, 59–64. [Google Scholar] [CrossRef]

- Tan, H.H.; Jiang, N.; Saxena, D.; Lee, Y.H.; Mokkapati, S.; Fu, L.; Gao, Q.; Joyce, H.J.; Jagadish, C. III-V Nanowires for Optoelectronic Applications; Semiconductors, Dielectrics, and Metals for Nanoelectronics 11. In Proceedings of the 2012 5th International Conference on Computers and Devices for Communication (CODEC), Kolkata, India, 17–19 December 2012; Electrochemical Society Inc.: Pennington, NJ, USA, 2013; Volume 58, pp. 93–98. [Google Scholar]

- Qiu, G.; Charnas, A.; Niu, C.; Wang, Y.X.; Wu, W.Z.; Ye, P.D.D. The resurrection of tellurium as an elemental two-dimensional semiconductor. Npj 2d Mater. Appl. 2022, 6, 17. [Google Scholar] [CrossRef]

- Hadar, I.; Hu, X.B.; Luo, Z.Z.; Dravid, V.P.; Kanatzidis, M.G. Nonlinear Band Gap Tunability in Selenium Tellurium Alloys and Its Utilization in Solar Cells. Acs Energy Lett. 2019, 4, 2137–2143. [Google Scholar] [CrossRef]

- Piacenza, E.; Presentato, A.; Zonaro, E.; Lampis, S.; Vallini, G.; Turner, R.J. Selenium and tellurium nanomaterials. Phys. Sci. Rev. 2018, 3, 20170100. [Google Scholar]

- Medina-Cruz, D.; Tien-Street, W.; Vernet-Crua, A.; Zhang, B.; Huang, X.; Murali, A.; Chen, J.; Liu, Y.; Garcia-Martin, J.M.; Cholula-Díaz, J.L.; et al. Tellurium, the Forgotten Element: A Review of the Properties, Processes, and Biomedical Applications of the Bulk and Nanoscale Metalloid. In Racing for the Surface: Antimicrobial and Interface Tissue Engineering; Li, B., Moriarty, T.F., Webster, T., Xing, M., Eds.; Springer International Publishing: Cham, Germany, 2020; pp. 723–783. [Google Scholar]

- Anzin, V.B.; Eremets, M.I.; Kosichkin, Y.V.; Nadezhdinskii, A.I.; Shirokov, A.M. Measurement of the energy gap in tellurium under pressure. Phys. Status Solidi A 1977, 42, 385–390. [Google Scholar] [CrossRef]

- Qian, H.S.; Yu, S.H.; Gong, J.Y.; Luo, L.B.; Fei, L.F. High-quality luminescent tellurium nanowires of several nanometers in diameter and high aspect ratio synthesized by a poly (vinyl pyrrolidone)-assisted hydrothermal process. Langmuir 2006, 22, 3830–3835. [Google Scholar] [CrossRef]

- He, Z.; Yang, Y.; Liu, J.W.; Yu, S.H. Emerging tellurium nanostructures: Controllable synthesis and their applications. Chem. Soc. Rev. 2017, 46, 2732–2753. [Google Scholar] [CrossRef]

- Ni, L.; Jacques, E.; Rogel, R.; Salaun, A.C.; Pichon, L.; Wenga, G. VLS silicon nanowires based resistors for chemical sensor applications. Procedia Eng. 2012, 47, 240–243. [Google Scholar] [CrossRef]

- Yin, H.; Yang, H.F.; Xu, S.; Pan, D.F.; Xu, J.; Chen, K.J.; Yu, L.W. High Performance Si Nanowire TFTs With Ultrahigh on/off Current Ratio and Steep Subthreshold Swing. IEEE Electron Device Lett. 2020, 41, 46–49. [Google Scholar] [CrossRef]

- Hanrath, T.; Korgel, B.A. Nucleation and growth of germanium nanowires seeded by organic monolayer-coated gold nanocrystals. J. Am. Chem. Soc. 2002, 124, 1424–1429. [Google Scholar] [CrossRef] [PubMed]

- Maliakkal, C.B.; Tornberg, M.; Jacobsson, D.; Lehmann, S.; Dick, K.A. Vapor-solid-solid growth dynamics in GaAs nanowires. Nanoscale Adv. 2021, 3, 5928–5940. [Google Scholar] [CrossRef] [PubMed]

- Ambrosini, S.; Fanetti, M.; Grillo, V.; Franciosi, A.; Rubini, S. Self-catalyzed GaAs nanowire growth on Si-treated GaAs(100) substrates. J. Appl. Phys. 2011, 109, 094306. [Google Scholar] [CrossRef]

- Zhou, G.; Addou, R.; Wang, Q.; Honari, S.; Cormier, C.R.; Cheng, L.; Yue, R.; Smyth, C.M.; Laturia, A.; Kim, J.; et al. High-Mobility Helical Tellurium Field-Effect Transistors Enabled by Transfer-Free, Low-Temperature Direct Growth. Adv. Mater. 2018, 30, 1803109. [Google Scholar] [CrossRef]

- Wang, Y.X.; Qiu, G.; Wang, R.X.; Huang, S.Y.; Wang, Q.X.; Liu, Y.Y.; Du, Y.C.; Goddard, W.A.; Kim, M.J.; Xu, X.F.; et al. Field-effect transistors made from solution-grown two-dimensional tellurene. Nat. Electron. 2018, 1, 228–236. [Google Scholar] [CrossRef]

- Kramer, A.; Van de Put, M.L.; Hinkle, C.L.; Vandenberghe, W.G. Tellurium as a successor of silicon for extremely scaled nanowires: A first-principles study. Npj 2d Mater. Appl. 2020, 4, 10. [Google Scholar] [CrossRef]

- Sen, S.; Bhatta, U.M.; Kumar, V.; Muthe, K.P.; Bhattacharya, S.; Gupta, S.K.; Yakhmi, J.V. Synthesis of tellurium nanostructures by physical vapor deposition and their growth mechanism. Cryst. Growth Des. 2008, 8, 238–242. [Google Scholar] [CrossRef]

- Hyung, J.H.; Kim, G.S.; Rai, A.K.; Jang, C.O.; Lee, C.Y.; Khurelbaatar, Z.; Acharya, S.K.; Lee, S.K. Dependence of the Morphology Evolution and Crystal Orientation of Tellurium (Te) Micro- and Nanostructures on the Growth Temperature. J. Korean Phys. Soc. 2012, 60, 47–50. [Google Scholar] [CrossRef]

- Safdar, M.; Zhan, X.; Niu, M.; Mirza, M.; Zhao, Q.; Wang, Z.; Zhang, J.; Sun, L.; He, J. Site-specific nucleation and controlled growth of a vertical tellurium nanowire array for high performance field emitters. Nanotechnology 2013, 24, 185705. [Google Scholar] [CrossRef]

- Metraux, C.; Grobety, B. Tellurium nanotubes and nanorods synthesized by physical vapor deposition. J. Mater. Res. 2004, 19, 2159–2164. [Google Scholar] [CrossRef]

- Hawley, C.J.; Beatty, B.R.; Chen, G.N.; Spanier, J.E. Shape-Controlled Vapor-Transport Growth of Tellurium Nanowires. Cryst. Growth Des. 2012, 12, 2789–2793. [Google Scholar] [CrossRef]

- Stoica, T.; Sutter, E.; Meijers, R.J.; Debnath, R.K.; Calarco, R.; Luth, H.; Grutzmacher, D. Interface and wetting layer effect on the catalyst-free nucleation and growth of GaN nanowires. Small 2008, 4, 751–754. [Google Scholar] [CrossRef]

- Li, X.; Ni, J.; Zhang, R. A Thermodynamic Model of Diameter- and Temperature-dependent Semiconductor Nanowire Growth. Sci. Rep. 2017, 7, 15029. [Google Scholar] [CrossRef] [PubMed]

- Mohanty, P.; Kang, T.; Kim, B.; Park, J. Synthesis of single crystalline tellurium nanotubes with triangular and hexagonal cross sections. J. Phys. Chem. B 2006, 110, 791–795. [Google Scholar] [CrossRef] [PubMed]

- Gudiksen, M.S.; Wang, J.F.; Lieiber, C.M. Synthetic control of the diameter and length of single crystal semiconductor nanowires. J. Phys. Chem. B 2001, 105, 4062–4064. [Google Scholar] [CrossRef]

- Baghchesara, M.A.; Yousefi, R.; Cheraghizade, M.; Jamali-Sheini, F.; Sa’aedi, A. Photocurrent application of Cd-doped ZnTe nanowires grown in a large scale by a CVD method. Vacuum 2016, 123, 131–135. [Google Scholar] [CrossRef]

- Jiang, T.C.; Wang, T.X.; Meng, X.Q. Synthesis and characterization of twin crystal CdTe nanowires. J. Cryst. Growth 2019, 526, 125202. [Google Scholar] [CrossRef]

- Li, Z.; Xu, E.; Losovyj, Y.; Li, N.; Chen, A.; Swartzentruber, B.; Sinitsyn, N.; Yoo, J.; Jia, Q.; Zhang, S. Surface oxidation and thermoelectric properties of indium-doped tin telluride nanowires. Nanoscale 2017, 9, 13014–13024. [Google Scholar] [CrossRef] [PubMed]

- Song, J.M.; Lin, Y.Z.; Zhan, Y.J.; Tian, Y.C.; Liu, G.; Yu, S.H. Superlong high-quality tellurium nanotubes: Synthesis, characterization, and optical property. Cryst. Growth Des. 2008, 8, 1902–1908. [Google Scholar] [CrossRef]

- Wu, B.Z.; Liu, X.H.; Yin, J.R.; Lee, H. Bulk beta-Te to few layered beta-tellurenes: Indirect to direct band-Gap transitions showing semiconducting property. Mater. Res. Express 2017, 4, 095902. [Google Scholar] [CrossRef]

| Sample | System Temperature (°C) | Growth Temperature (°C) | Time (h) | Gas Flow (sccm) | Initial/Final Heating Rate (°C/min) | Diameter (nm) | Length (μm) | Aspect Ratio |

|---|---|---|---|---|---|---|---|---|

| Te-A1 | 500 | 246.5 ± 18.4 | 1 | 50 | 30/30 | - | - | - |

| Te-A2 | 500 | 246.5 ± 18.4 | 1 | 80 | 30/30 | 77.3 ± 28.4 | 5.0 ± 1.7 | 65 |

| Te-A3 | 500 | 246.5 ± 18.4 | 1 | 200 | 30/30 | 200.8 ± 30.2 | 22.4 ± 9.4 | 112 |

| Te-A4 | 450 | 194.0 ± 15.4 | 1 | 80 | 30/30 | 53.4 ± 14.1 | 6.4 ± 1.4 | 120 |

| Te-A5 | 450 | 194.0 ± 15.4 | 1 | 50 | 30/30 | - | - | - |

| Te-C1 | 450 | 194.0 ± 15.4 | 2 | 80 | 30/6 | 18.3 ± 3.7 | 0.9 ± 0.4 | 49 |

| Te-C2 | 450 | 194.0 ± 15.4 | 3 | 80 | 30/6 | 26.0 ± 15.9 | 8.5 ± 2.5 | 327 |

| Te-C3 | 450 | 194.0 ± 15.4 | 3 | 80 | 30/3 | 54.6 ± 18.5 | 8.6 ± 0.9 | 157 |

| Bi-Te-C3 | 450 | 194.0 ± 15.4 | 3 | 80 | 30/3 | 49.1 ± 16.2 | 3.4 ± 0.7 | 69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miranda La Hera, V.; Wu, X.; Mena, J.; Barzegar, H.R.; Ashok, A.; Koroidov, S.; Wågberg, T.; Gracia-Espino, E. Controlled Synthesis of Tellurium Nanowires. Nanomaterials 2022, 12, 4137. https://doi.org/10.3390/nano12234137

Miranda La Hera V, Wu X, Mena J, Barzegar HR, Ashok A, Koroidov S, Wågberg T, Gracia-Espino E. Controlled Synthesis of Tellurium Nanowires. Nanomaterials. 2022; 12(23):4137. https://doi.org/10.3390/nano12234137

Chicago/Turabian StyleMiranda La Hera, Vladimir, Xiuyu Wu, Josué Mena, Hamid Reza Barzegar, Anumol Ashok, Sergey Koroidov, Thomas Wågberg, and Eduardo Gracia-Espino. 2022. "Controlled Synthesis of Tellurium Nanowires" Nanomaterials 12, no. 23: 4137. https://doi.org/10.3390/nano12234137

APA StyleMiranda La Hera, V., Wu, X., Mena, J., Barzegar, H. R., Ashok, A., Koroidov, S., Wågberg, T., & Gracia-Espino, E. (2022). Controlled Synthesis of Tellurium Nanowires. Nanomaterials, 12(23), 4137. https://doi.org/10.3390/nano12234137