Abstract

The global need for energy has grown in tandem with mankind’s development and spread. This has resulted in an increase in the use of fossil energy sources, a decline in these sources and an increase in pollution, necessitating the search for renewable energy sources. One of the important ways to reduce pollution resulting from the increasing consumption of fossil energy is to enhance the sources of solar energy, of which photovoltaic cells (PV) are one of its most important tools. Therefore, it was necessary to pay attention to improving its efficiency for it to become a promising source of clean energy. PVs turn solar energy into electricity; however, the amount of electricity generated decreases as the temperature of the cells rises in response to the sun’s heat. Cooling of the optical surfaces is one of the most important elements to consider while running solar PV systems to obtain maximum efficiency. The electrical efficiency of PVs is enhanced when suitable cooling technology is used, and the rate of cell breakdown is reduced over time, extending the life of the PV panels. There are many materials used to remove unwanted heat in PV cells, and in recent years, the focus has been on integrating nanomaterials in specific proportions with traditional cooling materials such as water to improve their thermal properties. As a bio-material that is environmentally friendly, renewable, sustainable, inexpensive and has high mechanical properties, cellulose nanocrystals (CNCs) are one of the most promising materials for improving the properties of cooling materials for cooling PV cells and improving their performance.

1. Introduction

Fossil fuels produce more than 80% of the world’s energy. Combustion residues of these fuels negatively affect the environment by producing acid rain and causing global warming, which increases rapidly with development and increases in the world population because of the increasing demand for energy [1,2,3], so it was necessary to search for renewable energy sources [4]. Solar energy is one of the most significant renewable energy sources since it can readily be turned into thermal and electrical energy, in addition to being sustainable, available and clean energy [5].

This paper summarizes a set of research related to enhancing the efficiency of photovoltaic cells by controlling their temperature by cooling them using different ways and materials, which strengthens their position as a clean and environmentally friendly energy source.

2. The Review

PV panels convert solar energy into electricity. However, if the temperature of the cells rises owing to the sun’s temperature, the output of electricity falls. Therefore, different cooling techniques were used for solar cells to control their temperature, as shown in Table 1. Many of the research papers published in the literature on improving solar energy conversion and using it more efficiently have been reviewed and classified, and some of these papers are represented in Table 2. The thermal control of photovoltaic panels is emphasized in order to improve solar energy conversion to electricity through the development of cooling methods and cooling materials.

Table 1.

Photovoltaic cooling techniques.

Table 2.

Cooling technique methods.

In this work, we divide reviews of previous studies according to the reasons that prompted researchers to work on developing the performance of photovoltaic panels as a promising source of energy and a suitable alternative to fossil energy. This review is divided into three areas:

- 2.1

- Improving the generation of clean energy by cooling techniques to reduce environmental effects.

- 2.2

- Improving solar cell’s low efficiency.

- 2.3

- The use of cellulose nano-crystal (CNC) nanofluids as a cooling material.

It is clear from the total research reviewed in this paper that the percentage of research interested in using nanocellulose in thermal applications, which is shown in Table 3, is low, indicating that more attention should be paid to the use of this bio-sustainable, friendly environmental material.

Table 3.

Nanocellulose in thermal applications.

2.1. Improving the Generation of Clean Energy by Cooling Techniques to Reduce Environmental Effects

Because of the increasing demand for energy and the excessive use of traditional energy sources, this has led to an increase in environmental pollution due to emissions from burning fuels. Cooling solar cells increases their potential to create clean energy and use it as an alternative to traditional polluting energy sources.

Researchers provided an in-depth analysis of the design components of a concentrated photovoltaic thermal, heat transfer medium and new application sectors in this paper. The findings show that CPVT systems are a promising system for producing high amounts of clean electrical and thermal energy that are in line with the seven sustainable development goals by using this energy in a variety of thermal applications such as space heating and cooling, desalination, electrical energy generation, greenhouses and so on [71,72,73]. Other researchers compared the performance of a water-based photovoltaic system (thermal), a PV/T system with PCM, an air-based PV/T system and a conventional PV panel in different studies.

In comparison to alternative kinds of cooling, it was found that the efficiency of the systems in producing energy depends on the type of material used, and all the arrangements proved to be more important solutions for delivering superior thermal and electrical efficiency systems (compared with the conventional system), thus serving as a promising source as an alternative to fossil energy that gives rise to air pollution and an increased earth temperature [48,74,75]. Some researchers focused on the increasing consumption of fossil energy and the accompanying emissions and pollution as a result of urban transformation and expansion of the construction and service sectors in developing countries in particular. Accordingly, the researchers’ efforts focused on improving the performance of photovoltaic cells, whose efficiency is affected by atmospheric conditions, to make them a suitable substitute for the production of clean energy [76,77,78,79,80].

Researchers [3,81,82] looked at the energy-increasing and environmental impacts of using nanofluids (NFs) in PVTS by measuring their physical and thermal properties. The researchers discovered that dispersion of nanoparticles in the base fluid increases the PVTS’ thermal and electrical performance, which improves the systems’ environmental characteristics. In fact, a nano-fluid-based solar system may avoid the release of greenhouse gases emissions, particularly carbon dioxide (CO2), into the environment more effectively than pure heat pumps by producing more energy. The performance of the integration of the Kalina cycle with CPVT for a multi-generation and hydrogen production system was investigated utilizing air and water as a cooling medium and three distinct mass flow rates. According to the findings of these studies, electricity, hydrogen and hot air production were increased. These kinds of systems would be used to minimize pollution in the environment because the emissions will decrease significantly [83,84].

The steady increase in population numbers and the need to address the problem of food insecurity in some countries made some researchers search for quick, effective and environmentally friendly ways to dry food, as the drying process consumes energy intensively, and the use of fossil energy in the drying process increases pollution. In these cases, the focus was on improving the performance of solar energy systems to provide the appropriate energy [85,86,87]. On the other hand, water is also a paramount necessity for human life, and the need to provide for drinking water in water-poor countries requires desalination since desalination consumes a large amount of energy. Some researchers have developed ways to use solar energy when desalinating water as well as storing energy for use when needed. This reduces the consumption of fossil energy and the emission of gases [88,89].

2.2. Improving Solar Cells’ Low Efficiency

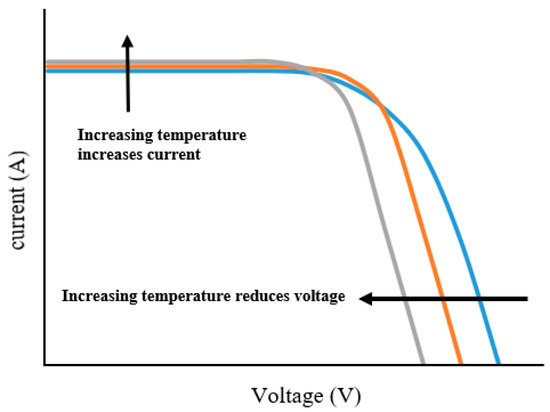

More than 50% of the solar radiation falling on PV cells turns into thermal energy rather than electricity [90]. This may cause a harmful consequence, such as a significant reduction in the efficiency of PV cells by approximately 0.45% per °C [34,91,92], and structural damage to the unit if heat stress persists for a long time [93]. In order to obtain high efficiency for PV cells, it is necessary to maintain a low temperature as much as possible, especially when using solar concentrators, which increase the temperature of cells very much [94]. When the temperature of solar cells rises, the maximum power output decreases (some photovoltaic cells, such as amorphous silicon and thin film cells, are exempt from this requirement); see Figure 1 [95].

Figure 1.

Effect of temperature on the I–V characteristic.

Several ways for cooling the PV module, such as the PV/T air-heating manifold and water-cooled PV/T, have been introduced and used. The heat transfer process from PV modules should be improved; the operating temperature must be reduced to improve the system’s efficiency. A hybrid PV/T solar system is one method for cooling the PV panels. It consists of a cooling system connected to a solar PV panel, so the hybrid model can be considered as two different mechanisms, one providing electrical energy and the other producing heat (thermal energy), which is used to warm the cooling medium [96]. It was found that cooling PV panels with water increases the solar cell’s output power by approximately 50% approximately and keeps the surface temperature of the cell at an acceptable level [97].

There is a lot of research that has studied the possibility of cooling photovoltaic cells using different materials such as phase change materials (PCM), salts, oils, nanomaterials and metallic materials with different thermal conductivities. In the same line, many researchers have also focused on improving the performance of PV cells by cooling them via traditional methods using air and water.

Because air is a less efficient coolant medium than water, water cooling functions at higher temperatures. It allows for more efficient waste heat recovery by utilizing it for household water heating or air conditioning. A coolant is a liquid or gas that is used to lower and regulate the system’s temperature. A good coolant has a high thermal capacity and a low viscosity that is inexpensive, chemically inert, non-toxic and does not corrode the cooling system. In order to benefit from the thermal energy absorbed from the PV panels, they are cooled and heat is extracted from them, which is reflected on their overall efficiency and increases their electrical efficiency, which is negatively affected by heat.

Researchers worked to address the effect of the efficiency of photovoltaic cells on temperature by working on cooling them in different ways. Cooling by air was one of the first and simplest methods used, which a group of researchers used in different ways and conditions. The results indicated a modest perspective because thermal air capacity is low, but there are advantages to the use of air, as it is used directly in buildings without heat exchange; the problems of fluid leakage are also not as critical when using air, and the problems of corrosion and freezing do not exist [48,98,99]. Air’s thermal properties make it less efficient as a coolant medium, so water cooling operates at higher temperature levels and allows waste heat recovery to be more efficient because of its high thermal capacity, which encouraged a large number of researchers to use water in innovative and multiple ways to cool photovoltaic cells. As a consequence, the final findings imply that installing water-cooled PV panels is an appealing and realistic alternative for improving short- and long-term efficiency, with a significant influence on the PVs’ power growth and durability [41,46,100,101,102]. The development of using traditional materials (air and water) as cooling materials in different ways and forms, and the possibility of obtaining different amounts of energy according to the amount of coolant flow, led to an expansion in the use of the resulting thermal energy according to the need for thermal applications [31,44].

As seen in Table 4 from the following research, the researchers add different nanomaterials to a base fluid in different quantities to determine the best concentration of nanoparticles for their application. The results showed that nanofluids have higher conductivity when the fluid density and viscosity increase slightly compared to the base fluid, and the higher the nanomaterials’ percentage in the base liquid, the more thermal the conductivity becomes.

Table 4.

Using nanomaterials in thermal applications.

So, examination of the performance of photovoltaic cells cooled with nanofluid improves the heat transfer coefficient, PV power and PV efficiency and therefore improves the overall efficiency of the system [34,42,47,90,113]. Other researchers have used the base and nanofluids materials as spectral beam splitting cells by installing a layer of coolant on the surface of the photovoltaic panel so that it cools it by absorbing excess heat and filters solar radiation by allowing only visible radiation to reach the photovoltaic cell and convert to electricity. They noticed that nanofluids were a good filter and water also has the best qualities, and it is easily available to compare with glass filters; in addition, the results demonstrated a considerable increase in the amount of energy generated by this suggested system as well as an increase in overall efficiency [114,115,116].

Some researchers successfully developed tools to increase the performance of solar cells by using concentrated solar energy to obtain the largest amount of solar radiation that can be received from these cells. The increase in solar radiation is accompanied by an increase in temperature, and thus cooling the cells is very important in these cases to avoid damage and a sharp decline in their efficiency. Multi-junction solar cells are also chosen for high concentration ratios due to their good performance at high operating temperatures. The results showed that high sun radiation and the volume flow rate of the cooling fluid have a significant influence on PVT performance, according to the research [43,117,118,119].

2.3. The Use of Cellulose Nano-Crystal (CNC) Nanofluids as Cooling Materials

Nanofluids are the most recent advancement in modern technology for enhancing the performance of engineering equipment and machinery [120]. The nanomaterial is dispersed with the basal fluid to prepare the nanofluids [121]. In general, chemical and physical synthesis techniques are used to produce nanoparticles [122]. Unfortunately, scientists have noted that the use of nanomaterials poses severe issues regarding toxicity and safety, particularly because the most-well-studied quantum dots (QDs) include hazardous components including CdSe, CdTe and CdS [123]. So, nano cellulose has received increased attention in recent years as a result of some of its significant qualities, including its biodegradability, excellent mechanical capabilities, decreased density, abundance, and most importantly, an eco-friendly aspect [124]. Nano cellulose can be considered an excellent material for the development of high-performance nanocomposites.

CNCs have attracted the attention of business and academia due to their unique qualities, which include their cheap cost, renewable resource extraction, minimal toxicity and high mechanical properties. This made some researchers conduct studies to find out the possibility of improving the thermophysical properties of cooling fluids by adding crystal nano cellulose at various concentrations and temperatures to them and using these materials in different applications. The results experimentally and theoretically indicate that thermal conductivity increases as the CNC volume concentration and temperature increase, so CNC is a promising material in industrial, electronic, and thermal applications [60,63,64]. Some researchers used experimental and one-dimensional modelling software to forecast the performance characteristics and efficacy of cellulose nanoparticles integrated with Ethylene Glycol as a coolant with varying percentages and compared it to pure water. The results revealed that using nano cellulose with Ethylene Glycol for automobile radiator applications had a higher thermal absorption effectiveness than using distilled water and that the heat transfer coefficient of cellulose nanofluids increased as the radiator size grew, so employing cellulose nanoparticles in conjunction with ethylene glycol as a coolant in automotive radiators is acceptable and enhances the heat transfer efficiency [61,62].

Furthermore, nano cellulose and aluminum oxide hybrid nanofluids as a novel coolant for car radiators was examined experimentally by Naiman et al. (2019). The thermal conductivity of the resultant fluid improved significantly, and the thermal conductivity of Al2O3/CNC composite nanofluids enhancement improved with the temperature and volume concentration, according to the researchers [35].

Other researchers have been interested in incorporating nanocellulose with other compounds to form nanocomposites and have studied their properties and investigated their performance as a superior heat transfer nanofluid than base fluid coolant at various concentrations and temperatures as depicted in Table 5. The incorporation of nano cellulose has generally improved nanocomposites’ thermal and thermomechanical properties. The hybrid nanofluids may be used to replace standard heat transfer fluids, resulting in more efficient thermal structures. They also have good aqueous solubility in the base liquid. [65,66,67]. Farhana et al. (2021) studied the addition of nanoparticles (Al2O3 and CNC) to the basic fluid of a solar collector and compared their effects on its thermal performance. They came to the conclusion that flat plate solar collectors’ energy gains and thermal efficiency had increased. For (0.5 percent) Al2O3, the greatest efficiency was approximately (2.48 percent), while for (0.5 percent) CNC nanofluids, it was around (8.46%) [58].

Table 5.

Nanocellulose in combination with other substances.

3. Summary and Evaluation

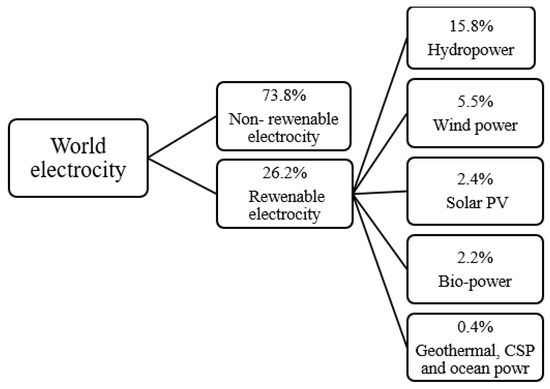

From the previous studies, it is clear that the use of PV cells has become one of the best ways to produce clean electric power in recent years and to increase the production of electricity while reducing the cost of solar systems and reducing the area on which the PV panels are installed. Even though interest in renewable energy sources has grown in recent decades, solar energy’s proportion of worldwide energy (power) output remains below 2.5 percent [125], as shown in Figure 2.

Figure 2.

Renewable energy shares of global electricity production.

The temperature of the PV cell rises when the radiation intensity is high, lowering its efficiency and increasing the risk of damage. Therefore, it is necessary to cool these cells by exposing them to a coolant medium (coolant system).

After a thorough examination of the subject of PV cells and their evolution over the previous decades, as well as previous studies that looked into different ways to improve the efficiency of PV systems and different methods and materials to cool them so that their temperature does not exceed the required limit, water is one of the best materials used for cooling because of its availability, easy storage, cheapness and the fact that it can be used in relatively high pressures and temperatures and has a high thermal capacity.

However, it is possible to work on improving water’s mechanical and thermal properties by adding nanomaterials to it, which will positively affect its performance. This also applies to other cooling materials so that their properties can be improved by adding certain materials to them or merging them with each other.

There are many tools and materials used to get rid of unwanted heat in PV cells, and in recent years, the focus has been on integrating nanomaterials in certain proportions with traditional cooling materials such as water to improve their thermal properties. The use of nanomaterials in cooling depends on their availability, price and environmental friendliness. Its efficiency by improving the properties of cooling liquids depends on the size of its components, the volume ratio and its stability in the liquid, in addition to the temperature.

Cellulose nanocrystal (CNCs) are one of the promising materials in improving the properties of cooling materials that can be used in PV cells’ cooling, and this is reflected in the performance of it, as this material is considered a bio-material that is environmentally friendly, renewable, sustainable, inexpensive and has high mechanical properties.

Author Contributions

Conceptualization, S.S.H.H. and A.A.K.A.A.; methodology, S.S.H.H.; sata curation, A.A.K.A.A.; formal analysis, A.A.K.A.A.; investigation, A.A.K.A.A.; software, A.A.K.A.A.; visualization, A.A.K.A.A.; writing—original draft preparation, A.A.K.A.A.; writing—review and editing, A.A.K.A.A., S.S.H.H., M.T.H.S., F.S.S. and A.U.M.S.; supervision, S.S.H.H.; project administration, S.S.H.H., M.T.H.S., F.S.S. and A.U.M.S.; resources, S.S.H.H.; validation, S.S.H.H.; funding acquisition, S.S.H.H. and M.T.H.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the BOLD Refresh Fund, UNITEN, Project ID: J510050002-2021097). The APC was funded by the Ministry of Higher Education, Malaysia, through the Fundamental Research Grant Scheme FGRS/1/2019/STG07/UPM/02/2, grant number 5540320.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the Innovation & Research Management Centre (IRMC), the Institute of Informatics and Computing in Energy (IICE), and the BOLD research Fund, UNITEN, for their continued support of this work. The authors would also like to thank the Department of Aerospace Engineering, Faculty of Engineering, Universiti Putra Malaysia and the Laboratory of Biocomposite Technology, Institute of Tropical Forestry and Forest Product (INTROP), Universiti Putra Malaysia (HICOE) for their continued support of this work and the activities that led to its development.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, M. World Energy 2017–2050: Annual Report; Department of Economics, University of Utah: Salt Lake City, UT, USA, 2017. [Google Scholar]

- Hassani, S.; Saidur, R.; Mekhilef, S.; Taylor, R.A. Environmental and exergy benefit of nanofluid-based hybrid PV/T systems. Energy Convers. Manag. 2016, 123, 431–444. [Google Scholar] [CrossRef]

- Salari, A.; Taheri, A.; Farzanehnia, A.; Passandideh-Fard, M.; Sardarabadi, M. An updated review of the performance of nanofluid-based photovoltaic thermal systems from energy, exergy, economic, and environmental (4E) approaches. J. Clean. Prod. 2021, 282, 124318. [Google Scholar] [CrossRef]

- Esfe, M.H.; Kamyab, M.H.; Valadkhani, M. Application of nanofluids and fluids in photovoltaic thermal system: An updated review. Sol. Energy 2020, 199, 796–818. [Google Scholar] [CrossRef]

- Aldossary, A.; Mahmoud, S.; Al-Dadah, R. Technical feasibility study of passive and active cooling for concentrator PV in harsh environment. Appl. Therm. Eng. 2016, 100, 490–500. [Google Scholar] [CrossRef]

- He, W.; Chow, T.-T.; Ji, J.; Lu, J.; Pei, G.; Chan, L.S.A. Hybrid photovoltaic and thermal solar-collector designed for natural circulation of water. Appl. Energy 2006, 83, 199–210. [Google Scholar] [CrossRef]

- Kim, J.H.; Ahn, J.G.; Kim, J.T. Demonstration of the performance of an air-type photovoltaic thermal (PVT) system coupled with a heat-recovery ventilator. Energies 2016, 9, 728. [Google Scholar] [CrossRef] [Green Version]

- Shahsavar, A.; Ameri, M. Experimental investigation and modeling of a direct-coupled PV/T air collector. Sol. Energy 2010, 84, 1938–1958. [Google Scholar] [CrossRef]

- Cuce, E.; Bali, T.; Sekucoglu, S.A. Effects of passive cooling on performance of silicon photovoltaic cells. Int. J. Low-Carbon Technol. 2011, 6, 299–308. [Google Scholar] [CrossRef] [Green Version]

- Dixit, K.K.; Yadav, I.; Gupta, G.K.; Maurya, S.K. A review on cooling techniques used for photovoltaic panels. In Proceedings of the 2020 International Conference on Power Electronics & IoT Applications in Renewable Energy and Its Control (PARC), Mathura, India, 28–29 February 2020; pp. 360–364. [Google Scholar]

- Indugowda, C.S.; Ranjith, P.K. Cooling Methods for Increasing Efficiency of PV Panel. In Research Scholar (M-Tech Thermal Engineering); Assistant Professor, Department of Mechanical Engineering Global Academy of Technology; International Journal of Scientific Development and Research (IJSDR): Gujaratm, India, 2016. [Google Scholar]

- Odeh, S.; Behnia, M. Improving Photovoltaic Module Efficiency Using Water Cooling. Heat Transf. Eng. 2009, 30, 499–505. [Google Scholar] [CrossRef]

- Wu, S.-Y.; Chen, C.; Xiao, L. Heat transfer characteristics and performance evaluation of water-cooled PV/T system with cooling channel above PV panel. Renew. Energy 2018, 125, 936–946. [Google Scholar] [CrossRef]

- Lupu, A.G.; Homutescu, V.M.; Balanescu, D.T.; Popescu, E.A. A review of solar photovoltaic systems cooling technologies. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 444, p. 082016. [Google Scholar]

- Dubey, S.; Tiwari, G. Thermal modeling of a combined system of photovoltaic thermal (PV/T) solar water heater. Sol. Energy 2008, 82, 602–612. [Google Scholar] [CrossRef]

- Bahaidarah, H.M. Experimental performance evaluation and modeling of jet impingement cooling for thermal management of photovoltaics. Sol. Energy 2016, 135, 605–617. [Google Scholar] [CrossRef]

- Hasan, H.A.; Sopian, K.; Jaaz, A.H.; Al-Shamani, A.N. Experimental investigation of jet array nanofluids impingement in photovoltaic/thermal collector. Sol. Energy 2017, 144, 321–334. [Google Scholar] [CrossRef]

- Nadda, R.; Kumar, A.; Maithani, R. Efficiency improvement of solar photovoltaic/solar air collectors by using impingement jets: A review. Renew. Sustain. Energy Rev. 2018, 93, 331–353. [Google Scholar] [CrossRef]

- Mehrotra, S.; Rawat, P.; Debbarma, M.; Sudhakar, K. Performance of a solar panel with water immersion cooling technique. Int. J. Sci. Environ. Technol. 2014, 3, 1161–1172. [Google Scholar]

- Zhu, L.; Boehm, R.F.; Wang, Y.; Halford, C.; Sun, Y. Water immersion cooling of PV cells in a high concentration system. Sol. Energy Mater. Sol. Cells 2011, 95, 538–545. [Google Scholar] [CrossRef]

- Rosa-Clot, M.; Tina, G.M.; Scandura, P. Submerged photovoltaic solar panel: SP2. Renew. Energy 2010, 35, 1862–1865. [Google Scholar] [CrossRef]

- Maiti, S.; Banerjee, S.; Vyas, K.; Patel, P.; Ghosh, P.K. Self regulation of photovoltaic module temperature in V-trough using a metal–wax composite phase change matrix. Sol. Energy 2011, 85, 1805–1816. [Google Scholar] [CrossRef]

- Hachem, F.; Abdulhay, B.; Ramadan, M.; El Hage, H.; El Rab, M.G.; Khaled, M. Improving the performance of photovoltaic cells using pure and combined phase change materials—Experiments and transient energy balance. Renew. Energy 2017, 107, 567–575. [Google Scholar] [CrossRef]

- Anderson, W.G.; Dussinger, P.M.; Sarraf, D.B.; Tamanna, S. Heat pipe cooling of concentrating photovoltaic cells. In Proceedings of the 2008 33rd IEEE Photovoltaic Specialists Conference, San Diego, CA, USA, 11–16 May 2008; pp. 1–6. [Google Scholar]

- Gang, P.; Huide, F.; Tao, Z.; Jie, J. A numerical and experimental study on a heat pipe PV/T system. Sol. Energy 2011, 85, 911–921. [Google Scholar] [CrossRef]

- Hou, L.; Quan, Z.; Zhao, Y.; Wang, L.; Wang, G. An experimental and simulative study on a novel photovoltaic-thermal collector with micro heat pipe array (MHPA-PV/T). Energy Build. 2016, 124, 60–69. [Google Scholar] [CrossRef]

- Jouhara, H.; Szulgowska-Zgrzywa, M.; Sayegh, M.; Milko, J.; Danielewicz, J.; Nannou, T.; Lester, S. The performance of a heat pipe based solar PV/T roof collector and its potential contribution in district heating applications. Energy 2017, 136, 117–125. [Google Scholar] [CrossRef] [Green Version]

- Popovici, C.G.; Hudişteanu, S.V.; Mateescu, T.D.; Cherecheş, N.C. Efficiency improvement of photovoltaic panels by using air cooled heat sinks. Energy Procedia 2016, 85, 425–432. [Google Scholar] [CrossRef] [Green Version]

- Radwan, A.; Ahmed, M. The influence of microchannel heat sink configurations on the performance of low concentrator photovoltaic systems. Appl. Energy 2017, 206, 594–611. [Google Scholar] [CrossRef]

- Gilmore, N.; Timchenko, V.; Menictas, C. Microchannel cooling of concentrator photovoltaics: A review. Renew. Sustain. Energy Rev. 2018, 90, 1041–1059. [Google Scholar] [CrossRef]

- Elqady, H.I.; Abo-Zahhad, E.M.; Radwan, A.; El-Shazly, A.; Elkady, M. Thermal and electrical performances of actively cooled concentrator photovoltaic system. Appl. Therm. Eng. 2021, 196, 117295. [Google Scholar] [CrossRef]

- Teo, H.; Lee, P.; Hawlader, M. An active cooling system for photovoltaic modules. Appl. Energy 2012, 90, 309–315. [Google Scholar] [CrossRef]

- Minea, A.A.; El-Maghlany, W.M. Influence of hybrid nanofluids on the performance of parabolic trough collectors in solar thermal systems: Recent findings and numerical comparison. Renew. Energy 2018, 120, 350–364. [Google Scholar] [CrossRef]

- Karaaslan, I.; Menlik, T. Numerical study of a photovoltaic thermal (PV/T) system using mono and hybrid nanofluid. Sol. Energy 2021, 224, 1260–1270. [Google Scholar] [CrossRef]

- Naiman, I.; Ramasamy, D.; Kadirgama, K. Experimental and one dimensional investigation on nanocellulose and aluminium oxide hybrid nanofluid as a new coolant for radiator. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 469, p. 01209. [Google Scholar]

- Alwaeli, A.H.A.; Chaichan, M.T.; Kazem, H.A.; Sopian, K. Comparative study to use nano-(Al2O3, CuO, and SiC) with water to enhance photovoltaic thermal PV/T collectors. Energy Convers. Manag. 2017, 148, 963–973. [Google Scholar] [CrossRef]

- Sami, S. Analysis of Nanofluids Behavior in a PV-Thermal-Driven Organic Rankine Cycle with Cooling Capability. Appl. Syst. Innov. 2020, 3, 12. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Jing, D. Investigation of the performance of photovoltaic/thermal system by a coupled TRNSYS and CFD simulation. Sol. Energy 2017, 143, 100–112. [Google Scholar] [CrossRef]

- Mojiri, A.; Taylor, R.; Thomsen, E.; Rosengarten, G. Spectral beam splitting for efficient conversion of solar energy—A review. Renew. Sustain. Energy Rev. 2013, 28, 654–663. [Google Scholar] [CrossRef]

- Joshi, S.S.; Dhoble, A.S. Experimental investigation of solar photovoltaic thermal system using water, coconut oil and silicone oil as spectrum filters. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3227–3236. [Google Scholar] [CrossRef]

- Aste, N.; Del Pero, C.; Leonforte, F. Water PVT Collectors Performance Comparison. Energy Procedia 2017, 105, 961–966. [Google Scholar] [CrossRef]

- Abbas, N.; Awan, M.B.; Amer, M.; Ammar, S.M.; Sajjad, U.; Ali, H.M.; Zahra, N.; Hussain, M.; Badshah, M.A.; Jafry, A.T. Applications of nanofluids in photovoltaic thermal systems: A review of recent advances. Phys. A: Stat. Mech. Its Appl. 2019, 536, 122513. [Google Scholar] [CrossRef]

- Alzahrani, M.; Shanks, K.; Mallick, T.K. Advances and limitations of increasing solar irradiance for concentrating photovoltaics thermal system. Renew. Sustain. Energy Rev. 2020, 138, 110517. [Google Scholar] [CrossRef]

- Lamnatou, C.; Vaillon, R.; Parola, S.; Chemisana, D. Photovoltaic/thermal systems based on concentrating and non-concentrating technologies: Working fluids at low, medium and high temperatures. Renew. Sustain. Energy Rev. 2020, 137, 110625. [Google Scholar] [CrossRef]

- Ji, J.; Guo, C.; Sun, W.; He, W.; Wang, Y.; Li, G. Experimental investigation of tri-functional photovoltaic/thermal solar collector. Energy Convers. Manag. 2014, 88, 650–656. [Google Scholar] [CrossRef]

- Nasrin, R.; Hasanuzzaman, M.; Rahim, N.A. Effect of high irradiation and cooling on power, energy and performance of a PVT system. Renew. Energy 2018, 116, 552–569. [Google Scholar] [CrossRef]

- Jia, Y.; Ran, F.; Zhu, C.; Fang, G. Numerical analysis of photovoltaic-thermal collector using nanofluid as a coolant. Sol. Energy 2019, 196, 625–636. [Google Scholar] [CrossRef]

- Fudholi, A.; Zohri, M.; Rukman, N.S.B.; Nazri, N.S.; Mustapha, M.; Yen, C.H.; Sopian, K. Exergy and sustainability index of photovoltaic thermal (PVT) air collector: A theoretical and experimental study. Renew. Sustain. Energy Rev. 2019, 100, 44–51. [Google Scholar] [CrossRef]

- Tan, W.C.; Chong, K.K.; Tan, M.H. Performance study of water-cooled multiple-channel heat sinks in the application of ultra-high concentrator photovoltaic system. Sol. Energy 2017, 147, 314–327. [Google Scholar] [CrossRef]

- Hu, M.; Zheng, R.; Pei, G.; Wang, Y.; Li, J.; Ji, J. Experimental study of the effect of inclination angle on the thermal performance of heat pipe photovoltaic/thermal (PV/T) systems with wickless heat pipe and wire-meshed heat pipe. Appl. Therm. Eng. 2016, 106, 651–660. [Google Scholar] [CrossRef] [Green Version]

- Hernandez-Perez, J.; Carrillo, J.; Bassam, A.; Flota-Banuelos, M.; Patino-Lopez, L. Thermal performance of a discontinuous finned heatsink profile for PV passive cooling. Appl. Therm. Eng. 2020, 184, 116238. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, J.; Zheng, W.; Zhang, Y.; Meng, Q. Comparative and sensitive analysis of the annual performance between the conventional and the heat pipe PV/T systems. Case Stud. Therm. Eng. 2021, 28, 101380. [Google Scholar] [CrossRef]

- Hadipour, A.; Zargarabadi, M.R.; Rashidi, S. An efficient pulsed-spray water cooling system for photovoltaic panels: Experimental study and cost analysis. Renew. Energy 2021, 164, 867–875. [Google Scholar] [CrossRef]

- Raju, M.; Sarma, R.N.; Suryan, A.; Nair, P.P.; Nižetić, S. Investigation of optimal water utilization for water spray cooled photovoltaic panel: A three-dimensional computational study. Sustain. Energy Technol. Assess. 2022, 51, 101975. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y.; Zhu, L.; Yin, B.; Xiang, H.; Huang, Q. Direct liquid-immersion cooling of concentrator silicon solar cells in a linear concentrating photovoltaic receiver. Energy 2014, 65, 264–271. [Google Scholar] [CrossRef]

- Chandel, S.; Agarwal, T. Review of cooling techniques using phase change materials for enhancing efficiency of photovoltaic power systems. Renew. Sustain. Energy Rev. 2017, 73, 1342–1351. [Google Scholar] [CrossRef]

- Amalu, E.H.; Fabunmi, O.A. Thermal control of crystalline silicon photovoltaic (c-Si PV) module using Docosane phase change material (PCM) for improved performance. Sol. Energy 2022, 234, 203–221. [Google Scholar] [CrossRef]

- Farhana, K.; Kadirgama, K.; Mohammed, H.A.; Ramasamy, D.; Samykano, M.; Saidur, R. Analysis of efficiency enhancement of flat plate solar collector using crystal nano-cellulose (CNC) nanofluids. Sustain. Energy Technol. Assess. 2021, 45, 101049. [Google Scholar] [CrossRef]

- Ramachandran, K.; Hussein, A.; Kadirgama, K.; Ramasamy, D.; Azmi, W.; Tarlochan, F. Thermophysical properties measurement of nano cellulose in ethylene glycol/water. Appl. Therm. Eng. 2017, 123, 1158–1165. [Google Scholar] [CrossRef]

- Samylingam, L.; Anamalai, K.; Kadirgama, K.; Samykano, M.; Ramasamy, D.; Noor, M.; Najafi, G.; Rahman, M.; Xian, H.W.; Sidik, N.A.C. Thermal analysis of cellulose nanocrystal-ethylene glycol nanofluid coolant. Int. J. Heat Mass Transf. 2018, 127, 173–181. [Google Scholar] [CrossRef]

- Benedict, F.; Kadirgama, K.; Ramasamy, D.; Noor, M.M.; Samykano, M.; Rahman, M.M.; Sagmesh, B. Nanocellulose as heat transfer liquid in heat exchanger. In Proceedings of the AIP Conference Proceedings, Kuantan, Malaysia, 11 January 2019; Volume 2059, p. 020044. [Google Scholar]

- Ibrahim, I.N.; Sazali, N.; Ramasamy, D.; Jamaludin, A.S.; Sharip, M.S.; Ibrahim, H. Effect of impregnate nanocellulose with ethylene glycol for car radiator application. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 58, 43–50. [Google Scholar]

- Razali, S.A.; Sidik, N.A.C.; Koten, H. Cellulose Nanocrystals: A Brief Review on Properties and General Applications. J. Adv. Res. Des. 2019, 60, 1–15. [Google Scholar]

- Ramachandran, K.; Kadirgama, K.; Ramasamy, D.; Azmi, W.H.; Tarlochan, F. Investigation on effective thermal conductivity and relative viscosity of cellulose nanocrystal as a nanofluidic thermal transport through a combined experimental–Statistical approach by using Response Surface Methodology. Appl. Therm. Eng. 2017, 122, 473–483. [Google Scholar] [CrossRef]

- Benedict, F.; Kumar, A.; Kadirgama, K.; Mohammed, H.A.; Ramasamy, D.; Samykano, M.; Saidur, R. Thermal Performance of Hybrid-Inspired Coolant for Radiator Application. Nanomaterials 2020, 10, 1100. [Google Scholar] [CrossRef]

- Gan, P.G.; Sam, S.T.; Bin Abdullah, M.F.; Omar, M.F. Thermal properties of nanocellulose-reinforced composites: A review. J. Appl. Polym. Sci. 2019, 137, 48544. [Google Scholar] [CrossRef] [Green Version]

- Sandhya, M.; Ramasamy, D.; Kadirgama, K.; Harun, W.S.W.; Saidur, R. Experimental study on properties of hybrid stable & surfactant-free nanofluids GNPs/CNCs (Graphene nanoplatelets/cellulose nanocrystal) in water/ethylene glycol mixture for heat transfer application. J. Mol. Liq. 2021, 348, 118019. [Google Scholar]

- Ramachandran, K.; Kadirgama, K.; Ramasamy, D.; Samykano, M.; Samylingam, L.; Tarlochan, F.; Najafi, G. Evaluation of specific heat capacity and density for cellulose nanocrystal-based nanofluid. J. Adv. Res. Fluid Mech. Therm. Sci. 2018, 51, 169–186. [Google Scholar]

- Anamalai, K.; Samylingam, L.; Kadirgama, K.; Samykano, M.; Najafi, G.; Ramasamy, D.; Rahman, M.M. Multi-objective optimization on the machining parameters for bio-inspired nanocoolant. J. Therm. Anal. 2018, 135, 1533–1544. [Google Scholar] [CrossRef]

- Kadirgama, K.; Anamalai, K.; Ramachandran, K.; Ramasamy, D.; Samykano, M.; Kottasamy, A.; Rahman, M.M. Thermal analysis of SUS 304 stainless steel using ethylene glycol/nanocellulose-based nanofluid coolant. Int. J. Adv. Manuf. Technol. 2018, 97, 2061–2076. [Google Scholar] [CrossRef]

- George, M.; Pandey, A.; Rahim, N.A.; Tyagi, V.; Shahabuddin, S.; Saidur, R. Concentrated photovoltaic thermal systems: A component-by-component view on the developments in the design, heat transfer medium and applications. Energy Convers. Manag. 2019, 186, 15–41. [Google Scholar] [CrossRef] [Green Version]

- Elminshawy, N.A.; El-Ghandour, M.; Elhenawy, Y.; Bassyouni, M.; El-Damhogi, D.; Addas, M.F. Experimental investigation of a V-trough PV concentrator integrated with a buried water heat exchanger cooling system. Sol. Energy 2019, 193, 706–714. [Google Scholar] [CrossRef]

- Khodadadi, M.; Farshad, S.A.; Ebrahimpour, Z.; Sheikholeslami, M. Thermal performance of Nanofluid with employing of NEPCM in a PVT-LFR system. Sustain. Energy Technol. Assess. 2021, 47, 101340. [Google Scholar] [CrossRef]

- Sharma, R.; Singh, S.; Mehra, K.S.; Kumar, R. Performance enhancement of solar photovoltaic system using different cooling techniques. Mater. Today Proc. 2021, 46, 11023–11028. [Google Scholar] [CrossRef]

- Tahmasbi, M.; Siavashi, M.; Norouzi, A.M.; Doranehgard, M.H. Thermal and electrical efficiencies enhancement of a solar photovoltaic-thermal/air system (PVT/air) using metal foams. J. Taiwan Inst. Chem. Eng. 2021, 124, 276–289. [Google Scholar] [CrossRef]

- Paul, S.J.; Kumar, U.; Jain, S. Photovoltaic cells cooling techniques for energy efficiency optimization. Mater. Today Proc. 2020, 46, 5458–5463. [Google Scholar] [CrossRef]

- Rao, V.T.; Sekhar, Y.R. Comparative analysis on embodied energy and CO2 emissions for stand-alone crystalline silicon photovoltaic thermal (PVT) systems for tropical climatic regions of India. Sustain. Cities Soc. 2021, 78, 103650. [Google Scholar]

- Yao, J.; Dou, P.; Zheng, S.; Zhao, Y.; Dai, Y.; Zhu, J.; Novakovic, V. Co-generation ability investigation of the novel structured PVT heat pump system and its effect on the “Carbon neutral” strategy of Shanghai. Energy 2021, 239, 121863. [Google Scholar] [CrossRef]

- Singh, H.P.; Arora, S.; Sahota, L.; Arora, M.K.; Jain, A.; Singh, A. Evaluation of the performance parameters of a PVT system: Case study of composite environmental conditions for different Indian cities. Mater. Today Proc. 2022, 57, 1975–1982. [Google Scholar] [CrossRef]

- Fu, Z.; Li, Y.; Liang, X.; Lou, S.; Qiu, Z.; Cheng, Z.; Zhu, Q. Experimental investigation on the enhanced performance of a solar PVT system using micro-encapsulated PCMs. Energy 2021, 228, 120509. [Google Scholar] [CrossRef]

- Muzaidi, N.A.S.; Fikri, M.A.; Wong, K.N.S.W.S.; Sofi, A.Z.M.; Mamat, R.; Adenam, N.M.; Adli, H.K. Heat absorption properties of CuO/TiO2/SiO2 trihybrid nanofluids and its potential future direction towards solar thermal applications. Arab. J. Chem. 2021, 14, 103059. [Google Scholar] [CrossRef]

- Hassani, S.; Taylor, R.A.; Mekhilef, S.; Saidur, R. A cascade nanofluid-based PV/T system with optimized optical and thermal properties. Energy 2016, 112, 963–975. [Google Scholar] [CrossRef]

- Raja, S.; Gangadevi, R.; Marimuthu, R.; Baskaran, M. Performance evaluation of water and air based PVT solar collector for hydrogen production application. Int. J. Hydrogen Energy 2020, 45, 7498–7507. [Google Scholar]

- Bamisile, O.; Huang, Q.; Dagbasi, M.; Adebayo, V.; Okonkwo, E.C.; Ayambire, P.; Ratlamwala, T.A. Thermo-environ study of a concentrated photovoltaic thermal system integrated with Kalina cycle for multi-generation and hydrogen production. Int. J. Hydrogen Energy 2020, 45, 26716–26732. [Google Scholar] [CrossRef]

- Tiwari, S.; Agrawal, S.; Tiwari, G. PVT air collector integrated greenhouse dryers. Renew. Sustain. Energy Rev. 2018, 90, 142–159. [Google Scholar] [CrossRef]

- Udomkun, P.; Romuli, S.; Schock, S.; Mahayothee, B.; Sartas, M.; Wossen, T.; Njukwe, E.; Vanlauwe, B.; Müller, J. Review of solar dryers for agricultural products in Asia and Africa: An innovation landscape approach. J. Environ. Manag. 2020, 268, 110730. [Google Scholar] [CrossRef]

- Çiftçi, E.; Khanlari, A.; Sözen, A.; Aytaç, I.; Tuncer, A.D. Energy and exergy analysis of a photovoltaic thermal (PVT) system used in solar dryer: A numerical and experimental investigation. Renew. Energy 2021, 180, 410–423. [Google Scholar] [CrossRef]

- Anand, B.; Shankar, R.; Murugavelh, S.; Rivera, W.; Prasad, K.M.; Nagarajan, R. A review on solar photovoltaic thermal integrated desalination technologies. Renew. Sustain. Energy Rev. 2021, 141, 110787. [Google Scholar] [CrossRef]

- Nieto-Maestre, J.; Muñoz-Sánchez, B.; Fernández, A.G.; Faik, A.; Grosu, Y.; García-Romero, A. Compatibility of container materials for Concentrated Solar Power with a solar salt and alumina based nanofluid: A study under dynamic conditions. Renew. Energy 2019, 146, 384–396. [Google Scholar] [CrossRef]

- Veeramanikandan, M.; Sathish, D.; Jeryrajkumar, L.; Boovendravarman, S. Effective study on developments in photovoltaic thermal (PV/T) water heating system. Mater. Today Proc. 2020, 42, 584–589. [Google Scholar] [CrossRef]

- Amelia, A.R.; Irwan, Y.M.; Leow, W.Z.; Irwanto, M.; Safwati, I.; Zhafarina, M. Investigation of the effect temperature on photovoltaic (PV) panel output performance. Int. J. Adv. Sci. Eng. Inf. Technol. 2016, 6, 682–688. [Google Scholar]

- Khan, S.A.; Bicer, Y.; Koç, M. Design and analysis of a multi-generation system with concentrating photovoltaic thermal (CPV/T) and hydrogen storage. Int. J. Hydrogen Energy 2020, 45, 3484–3498. [Google Scholar] [CrossRef]

- Chow, T.T. A Review on Photovoltaic/Thermal Hybrid Solar Technology. Appl. Energy 2010, 87, 365–379. [Google Scholar] [CrossRef]

- Chemisana, D. Building Integrated Concentrating Photovoltaics: A review. Renew. Sustain. Energy Rev. 2011, 15, 603–611. [Google Scholar] [CrossRef]

- Libra, M.; Petrík, T.; Poulek, V.; Tyukhov, I.I.; Kouřím, P. Changes in the Efficiency of Photovoltaic Energy Conversion in Temperature Range with Extreme Limits. IEEE J. Photovolt. 2021, 11, 1479–1484. [Google Scholar] [CrossRef]

- Good, C.; Chen, J.; Dai, Y.; Hestnes, A.G. Hybrid photovoltaic-thermal systems in buildings—A review. Energy Procedia 2015, 70, 683–690. [Google Scholar] [CrossRef] [Green Version]

- Bijjargi, Y.S.; Kale, S.S.; Shaikh, K.A. Cooling techniques for photovoltaic module for improving its conversion efficiency: A review. Int. J. Mech. Eng. Technol. (IJMET) 2016, 7, 22–38. [Google Scholar]

- Slimani, M.E.-A.; Amirat, M.; Kurucz, I.; Bahria, S.; Hamidat, A.; Chaouch, W.B. A detailed thermal-electrical model of three photovoltaic/thermal (PV/T) hybrid air collectors and photovoltaic (PV) module: Comparative study under Algiers climatic conditions. Energy Convers. Manag. 2017, 133, 458–476. [Google Scholar] [CrossRef]

- Nazri, N.S.; Fudholi, A.; Mustafa, W.; Yen, C.H.; Mohammad, M.; Ruslan, M.H.; Sopian, K. Exergy and improvement potential of hybrid photovoltaic thermal/thermoelectric (PVT/TE) air collector. Renew. Sustain. Energy Rev. 2019, 111, 132–144. [Google Scholar] [CrossRef]

- Herrando, M.; Markides, C. Hybrid PV and solar-thermal systems for domestic heat and power provision in the UK: Techno-economic considerations. Appl. Energy 2016, 161, 512–532. [Google Scholar] [CrossRef] [Green Version]

- Piotrowski, L.J.; Simões, M.G.; Farret, F.A. Feasibility of water-cooled photovoltaic panels under the efficiency and durability aspects. Sol. Energy 2020, 207, 103–109. [Google Scholar] [CrossRef]

- Singh, K.; Singh, S.; Kandpal, D.C.; Kumar, R. Experimental performance study of photovoltaic solar panel with and without water circulation. Mater. Today Proc. 2021, 46, 6822–6827. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, W.; Zhang, S.; Tian, D.; Tian, Z. Preparation and characterization of new nano-particle mixed as thermal storage material. Appl. Therm. Eng. 2019, 163, 114386. [Google Scholar] [CrossRef]

- Arat, A.A.K. Effect of Increasing The Concentration Of KAl (SO4)2·12H2O On Some Optical Properties of the Solutions Prepared. Adv. Phys. Theor. Appl. 2014, 30. [Google Scholar]

- Al-Bermany, A.K.J. Prepare and Study Some Mechanical and Electrical Properties of KAl(SO4)2·12H2O as Aqueous Solutions. Chem. Mater. Res. 2009, 3, 65–74. [Google Scholar]

- Sun, M.; Liu, L.; Ma, F.; Jing, M.; Cui, K.; Lin, L. Investigating the effect of graphene nanoplatelets on the thermal conductivity of KAl(SO4)2 12H2O. Mater. Res. Express 2018, 5, 045513. [Google Scholar] [CrossRef]

- Abdallah, S.R.; Elsemary, I.M.; Altohamy, A.A.; Abdelrahman, M.; Attia, A.A.; Abdellatif, O.E. Experimental investigation on the effect of using nano fluid (Al2O3-Water) on the performance of PV/T system. Therm. Sci. Eng. Prog. 2018, 7, 1–7. [Google Scholar] [CrossRef]

- Sardarabadi, M.; Hosseinzadeh, M.; Kazemian, A.; Passandideh-Fard, M. Experimental investigation of the effects of using metal-oxides/water nanofluids on a photovoltaic thermal system (PVT) from energy and exergy viewpoints. Energy 2017, 138, 682–695. [Google Scholar] [CrossRef]

- Hussein, H.A.; Numan, A.H.; Abdulrahman, R.A. Improving the hybrid photovoltaic/thermal system performance using water-cooling technique and Zn-H2O nanofluid. Int. J. Photoenergy 2017, 2017, 6919054. [Google Scholar] [CrossRef] [Green Version]

- Nasrin, R.; Rahim, N.A.; Fayaz, H.; Hasanuzzaman, M. Water/MWCNT nanofluid based cooling system of PVT: Experimental and numerical research. Renew. Energy 2018, 121, 286–300. [Google Scholar] [CrossRef]

- Hassan, A.; Wahab, A.; Qasim, M.A.; Janjua, M.M.; Ali, M.A.; Ali, H.M.; Jadoon, T.R.; Ali, E.; Raza, A.; Javaid, N. Thermal management and uniform temperature regulation of photovoltaic modules using hybrid phase change materials-nanofluids system. Renew. Energy 2019, 145, 282–293. [Google Scholar] [CrossRef]

- Karami, N.; Rahimi, M. Heat transfer enhancement in a PV cell using Boehmite nanofluid. Energy Convers. Manag. 2014, 86, 275–285. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.; Sopian, K.; Kazem, H.A.; Chaichan, M.T. Novel criteria for assessing PV/T solar energy production. Case Stud. Therm. Eng. 2019, 16, 100547. [Google Scholar] [CrossRef]

- Ramdani, H.; Ould-Lahoucine, C. Study on the overall energy and exergy performances of a novel water-based hybrid photovoltaic-thermal solar collector. Energy Convers. Manag. 2020, 222, 113238. [Google Scholar] [CrossRef]

- Wang, G.; Yao, Y.; Wang, B.; Hu, P. Design and thermodynamic analysis of an innovative hybrid solar PV-CT system with multi-segment PV panels. Sustain. Energy Technol. Assess. 2020, 37, 100631. [Google Scholar] [CrossRef]

- Kumar, S.; Thakur, R.; Singhy, A.; Tripathi, R.; Sethi, M. A review of heat removal mechanism in concentrated PVT systems using beam splitter. Mater. Today Proc. 2022, 50, 952–961. [Google Scholar] [CrossRef]

- Ustaoglu, A.; Ozbey, U.; Torlaklı, H. Numerical investigation of concentrating photovoltaic/thermal (CPV/T) system using compound hyperbolic–trumpet, V-trough and compound parabolic concentrators. Renew. Energy 2020, 152, 1192–1208. [Google Scholar] [CrossRef]

- Wang, G.; Wang, F.; Shen, F.; Chen, Z.; Hu, P. Novel design and thermodynamic analysis of a solar concentration PV and thermal combined system based on compact linear Fresnel reflector. Energy 2019, 180, 133–148. [Google Scholar] [CrossRef]

- Youssef, W.B.; Maatallah, T.; Menezo, C.; Nasrallah, S.B. Assessment viability of a concentrating photovoltaic/thermal-energy cogeneration system (CPV/T) with storage for a textile industry application. Sol. Energy 2018, 159, 841–851. [Google Scholar] [CrossRef]

- Bashirnezhad, K.; Ghavami, M.; Alrashed, A.A. Experimental investigations of nanofluids convective heat transfer in different flow regimes: A review. J. Mol. Liq. 2017, 244, 309–321. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H. A Review on Nanofluids: Preparation, Stability Mechanisms, and Applications. J. Nanomater. 2011, 2012, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Barot Vishalkumar, G.; Panchal, K.D. Nanofluid: A tool to increase the efficiency of solar collector. Int. J. Innov. Eng. Technol. 2015, 5, 350–355. [Google Scholar]

- Yang, L.; Luo, X.B.; Luo, S.L. Assessment on Toxicity of Nanomaterials. In Nanomaterials for the Removal of Pollutants and Resource Reutilization; Elsevier: Amsterda, The Netherlands, 2019; pp. 273–292. [Google Scholar]

- Ben Cheikh, S.; Ben Cheikh, R.; Cunha, E.; Lopes, P.E.; Paiva, M.C. Production of cellulose nanofibers from Alfa grass and application as reinforcement for polyvinyl alcohol. Plast. Rubber Compos. 2018, 47, 297–305. [Google Scholar] [CrossRef]

- Ranalder, L.; Busch, H.; Hansen, T.; Brommer, M.; Couture, T.; Gibb, D.; Sverrisson, F. Renewables in Cities 2021 Global Status Report; REN21 Secretariat: Paris, France, 2021. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).