Content and Stability of Hydroxycinnamic Acids during the Production of French Fries Obtained from Potatoes of Varieties with Light-Yellow, Red and Purple Flesh

Abstract

1. Introduction

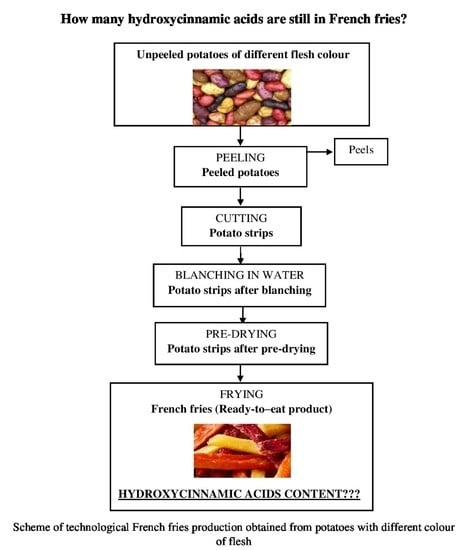

2. Materials and Methods

2.1. Raw Material

2.2. Samples Preparation from Potatoes

2.3. Chemicals

2.4. Extraction of Phenolic Acids from Potato Samples

2.5. HPLC Analysis of Phenolic Acids

2.6. Determination of Total Phenolic Content (TPC) and Antioxidants Activity (ABTS and DPPH) in Extracts

2.7. Statistical Analysis

3. Results and Discussion

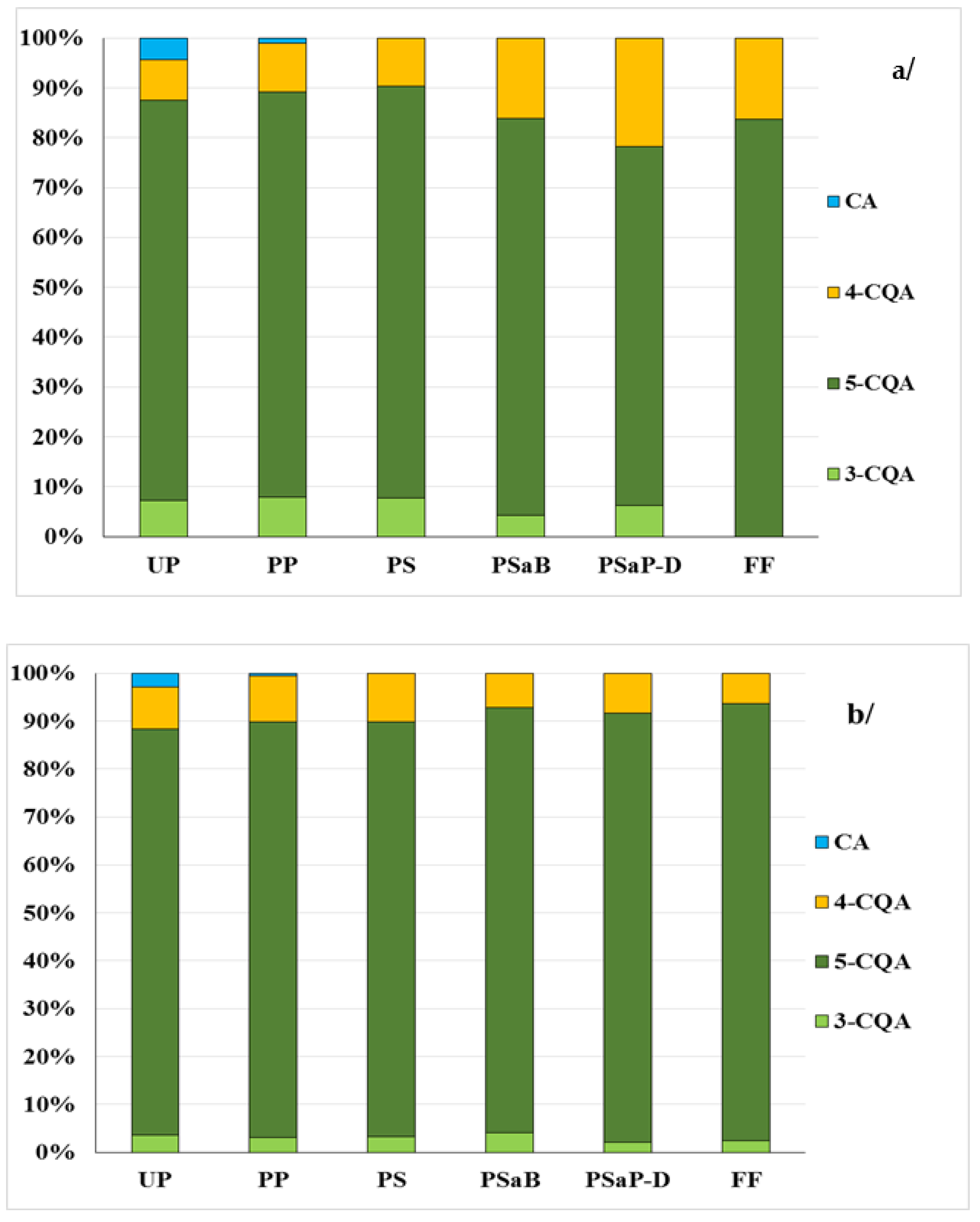

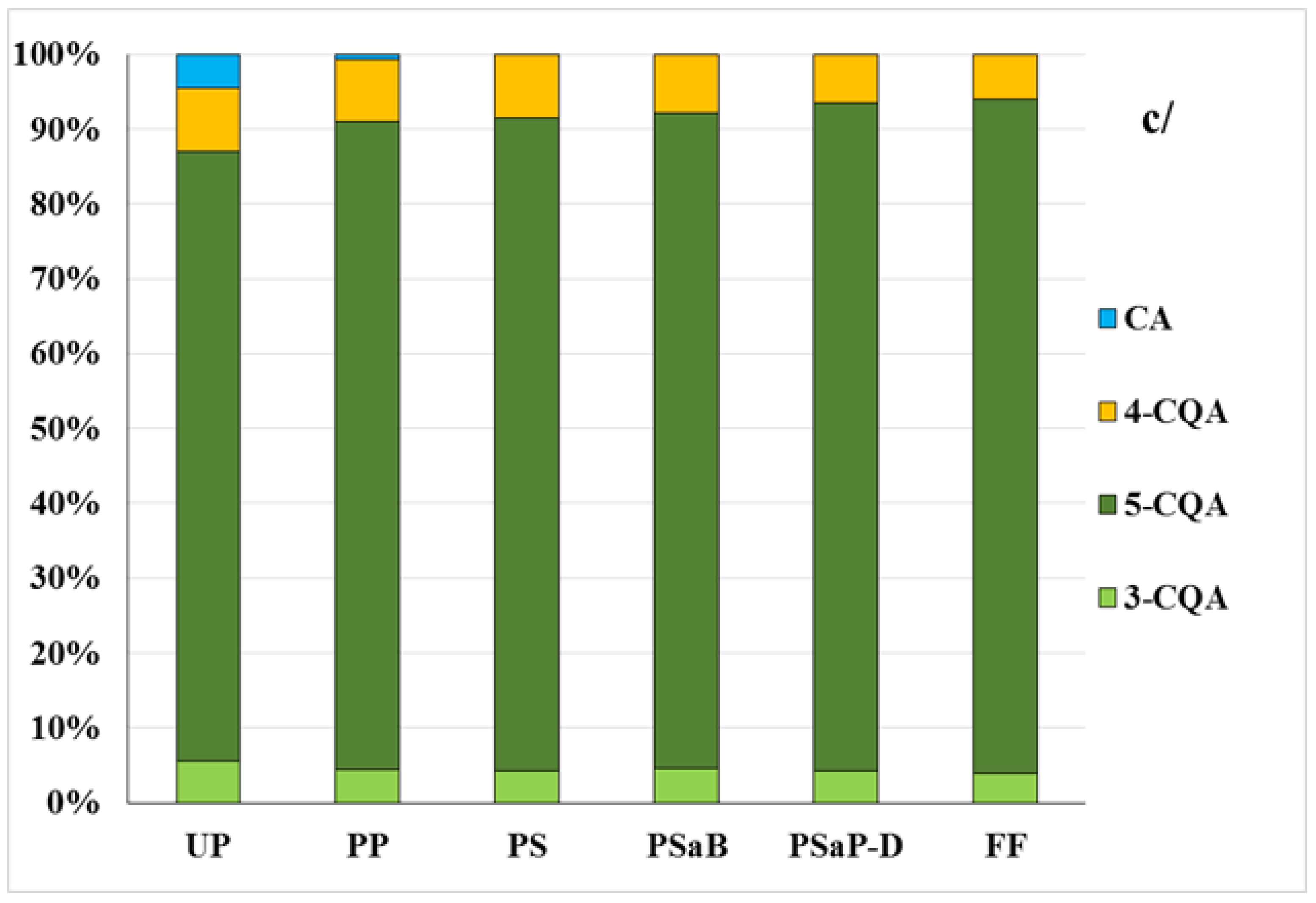

3.1. Identification of Hydroxycinnamic Acids in Potatoes and Ready-to-Eat Products

3.2. Hydroxycinnamic Acids Content in Potatoes with Different Flesh Colours

3.3. Technological Process of French Fries Production

3.3.1. The Influence of Peeling Process on Hydroxycinnamic Acids Content in Potato Flesh

3.3.2. The Influence of the Cutting Process on the Content of Hydroxycinnamic Acids in Potato Strips

3.3.3. The Influence of the Blanching Process on the Content of Hydroxycinnamic Acids in Potato Strips

3.3.4. The Influence of the Pre-Drying Process on the Content of Hydroxycinnamic Acids in Potato Strips

3.3.5. The Influence of the Frying Process on the Content of Hydroxycinnamic Acids in French Fries

3.4. Total Phenolic Content and ABTS and DPPH Activity in Potatoes with Different Flesh Colours

3.5. Total Phenolic Content and Antioxidant Activity of ABTS and DPPH during the Production of French Fries

3.5.1. Peeling

3.5.2. Cutting

3.5.3. Blanching

3.5.4. Pre-Drying

3.5.5. Frying

3.6. Correlation between Individual Phenolic Acid Content and TPC and Antioxidant Activity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Andre, C.M.; Legay, S.; Iammarino, C.; Ziebel, J.; Guignard, C.; Larondelle, Y.; Hausman, J.-F.; Evers, D.; Miranda, L.M. The Potato in the Human Diet: A Complex Matrix with Potential Health Benefits. Potato Res. 2014, 57, 201–214. [Google Scholar] [CrossRef]

- Gutiérrez-Quequezana, L.; Vuorinen, A.L.; Kallio, H.; Yang, B. Impact of cultivar, growth temperature and developmental stage on phenolic compounds and ascorbic acid in purple and yellow potato tubers. Food Chem. 2020, 326, 126966. [Google Scholar] [CrossRef] [PubMed]

- Camire, M.E.; Kubow, S.; Donnelly, D.J. Potatoes and Human Health. Crit. Rev. Food Sci. Nutr. 2009, 49, 823–840. [Google Scholar] [CrossRef] [PubMed]

- Lisińska, G.; Tajner-Czopek, A.; Kalum, L. The effects of enzymes on fat content and texture of French fries. Food Chem. 2007, 102, 1055–1060. [Google Scholar] [CrossRef]

- Kita, A.; Kołodziejczyk, M.; Michalska-Ciechanowska, A.; Brzezowska, J.; Wicha-Komsta, K.; Turski, W. The Effect of Thermal Treatment on Selected Properties and Content of Biologically Active Compounds in Potato Crisps. Appl. Sci. 2022, 12, 555. [Google Scholar] [CrossRef]

- Tajner-Czopek, A.; Figiel, A.; Carbonell-Barrachina, A.A. Effects of potato strip size and pre-drying method on french fries quality. Eur. Food Res. Technol. 2008, 227, 757–766. [Google Scholar] [CrossRef]

- Kalita, D.; Jayanty, S.S. Comparison of Polyphenol Content and Antioxidant Capacity of Colored Potato Tubers, Pomegranate and Blueberries. J. Food Process. Technol. 2014, 5, 358. [Google Scholar] [CrossRef]

- Rytel, E.; Tajner-Czopek, A.; Kita, A.; Kucharska, A.Z.; Sokół-Łętowska, A.; Hamouz, K. Content of anthocyanins and glycoalkaloids in blue-fleshed potatoes and changes in the content of α-solanine and α-chaconine during manufacture of fried and dried products. Int. J. Food Sci. Technol. 2017, 53, 719–727. [Google Scholar] [CrossRef]

- Ru, W.; Pang, Y.; Gan, Y.; Liu, Q.; Bao, J. Phenolic Compounds and Antioxidant Activities of Potato Cultivars with White, Yellow, Red and Purple Flesh. Antioxidants 2019, 8, 419. [Google Scholar] [CrossRef]

- Furrer, A.N.; Chegeni, M.; Ferruzzi, M.G. Impact of potato processing on nutrients, phytochemicals, and human health. Crit. Rev. Food Sci. Nutr. 2018, 58, 146–168. [Google Scholar] [CrossRef]

- Lachman, J.; Hamouz, K.; Musilová, J.; Hejtmánková, K.; Kotíková, Z.; Pazderů, K.; Domkářová, J.; Pivec, V.; Cimr, J. Effect of peeling and three cooking methods on the content of selected phytochemicals in potato tubers with various colour of flesh. Food Chem. 2013, 138, 1189–1197. [Google Scholar] [CrossRef] [PubMed]

- Rytel, E.; Tajner-Czopek, A.; Kita, A.; Aniołowska, M.; Kucharska, A.; Sokół-Łętowska, A.; Hamouz, K. Content of polyphenols in coloured and yellow fleshed potatoes during dices processing. Food Chem. 2014, 161, 224–229. [Google Scholar] [CrossRef] [PubMed]

- Vaitkevičienė, N.; Jarienė, E.; Kulaitienė, J.; Levickienė, D. The Physico-Chemical and Sensory Characteristics of Coloured-Flesh Potato Chips: Influence of Cultivar, Slice Thickness and Frying Temperature. Appl. Sci. 2022, 12, 1211. [Google Scholar] [CrossRef]

- Ezekiel, R.; Singh, N.; Sharma, S.; Kaur, A. Beneficial phytochemicals in potato—a review. Food Res. Int. 2013, 50, 487–496. [Google Scholar] [CrossRef]

- Rasheed, H.; Ahmad, D.; Bao, J. Genetic Diversity and Health Properties of Polyphenols in Potato. Antioxidants 2022, 11, 603. [Google Scholar] [CrossRef]

- Bao, L.; Li, J.; Zha, D.; Zhang, L.; Gao, P.; Yao, T.; Wu, X. Chlorogenic acid prevents diabetic nephropathy by inhibiting oxidative stress and inflammation through modulation of the Nrf2/HO-1 and NF-ĸB pathways. Int. Immunopharmacol. 2018, 54, 245–253. [Google Scholar] [CrossRef] [PubMed]

- Agunloye, O.M.; Oboh, G.; Ademiluyi, A.O.; Ademosun, A.O.; Akindahunsi, A.A.; Oyagbemi, A.A.; Omobowale, T.O.; Ajibade, T.O.; Adedapo, A.A. Cardio-protective and antioxidant properties of caffeic acid and chlorogenic acid: Mechanistic role of angiotensin converting enzyme, cholinesterase and arginase activities in cyclosporine induced hypertensive rats. Biomed. Pharmacother. 2019, 109, 450–458. [Google Scholar] [CrossRef]

- Tsao, R.; Deng, Z. Separation procedures for naturally occurring antioxidant phytochemicals. J. Chromatogr. B 2004, 812, 85–99. [Google Scholar] [CrossRef]

- Khoddami, A.; Wilkes, M.A.; Roberts, T.H. Techniques for Analysis of Plant Phenolic Compounds. Molecules 2013, 18, 2328–2375. [Google Scholar] [CrossRef]

- Narváez-Cuenca, C.-E.; Vincken, J.-P.; Gruppen, H. Identification and quantification of (dihydro) hydroxycinnamic acids and their conjugates in potato by UHPLC–DAD–ESI-MSn. Food Chem. 2012, 130, 730–738. [Google Scholar] [CrossRef]

- Kumar, N.; Goel, N. Phenolic acids: Natural versatile molecules with promising therapeutic applications. Biotechnol. Rep. 2019, 24, e00370. [Google Scholar] [CrossRef]

- Craig, A.P.; Fields, C.; Liang, N.; Kitts, D.; Erickson, A. Performance review of a fast HPLC-UV method for the quantification of chlorogenic acids in green coffee bean extracts. Talanta 2016, 154, 481–485. [Google Scholar] [CrossRef] [PubMed]

- Piñeros-Niño, C.; Narváez-Cuenca, C.-E.; Kushalappa, A.C.; Mosquera, T. Hydroxycinnamic acids in cooked potato tubers from Solanum tuberosum group Phureja. Food Sci. Nutr. 2017, 5, 380–389. [Google Scholar] [CrossRef] [PubMed]

- Lachman, J.; Hamouz, K.; Orsák, M. Coloured potatoes. In Advances in Potato Chemistry and Technology, 2nd ed.; Singh, J., Kaur, L., Eds.; Academic Press: London, UK, 2016; Chapter 9, pp. 249–281. [Google Scholar]

- Suo, H.; Peng, Z.; Guo, Z.; Wu, C.; Liu, J.; Wang, L.; Xiao, J.; Li, X. Deep eutectic solvent-based ultrasonic-assisted extraction of phenolic compounds from different potato genotypes: Comparison of free and bound phenolic profiles and antioxidant activity. Food Chem. 2022, 388, 133058. [Google Scholar] [CrossRef] [PubMed]

- Friedman, M. Chemistry, Biochemistry, and Dietary Role of Potato Polyphenols. A Review. J. Agric. Food Chem. 1997, 45, 1523–1540. [Google Scholar] [CrossRef]

- Silveira, A.C.; Falagán, N.; Aguayo, E.; Vilaró, F.; Escalona, V.H. Compositional changes on colored and light-yellow-fleshed potatoes subjected to two cooking processes. CyTA J. Food 2017, 15, 241–248. [Google Scholar] [CrossRef]

- Bellumori, M.; Innocenti, M.; Michelozzi, M.; Cerretani, L.; Mulinacci, N. Coloured-fleshed potatoes after boiling: Promising sources of known antioxidant compounds. J. Food Compos. Anal. 2017, 59, 1–7. [Google Scholar] [CrossRef]

- Külen, O.; Stushnoff, C.; Holm, D.G. Effect of cold storage on total phenolics content, antioxidant activity and vitamin C level of selected potato clones. J. Sci. Food Agric. 2013, 93, 2437–2444. [Google Scholar] [CrossRef]

- Ieri, F.; Innocenti, M.; Andrenelli, L.; Vecchio, V.; Mulinacci, N. Rapid HPLC/DAD/MS method to determine phenolic acids, glycoalkaloids and anthocyanins in pigmented potatoes (Solanum tuberosum L.) and correlations with variety and geographical origin. Food Chem. 2011, 125, 750–759. [Google Scholar] [CrossRef]

- Valcarcel, J.; Reilly, K.; Gaffney, M.; O’Brien, N.M. Levels of potential bioactive compounds including carotenoids, vitamin C and phenolic compounds, and expression of their cognate biosynthetic genes vary significantly in different varieties of potato (Solanum tuberosum L.) grown under uniform cultural conditions. J. Sci. Food Agric. 2016, 96, 1018–1026. [Google Scholar] [CrossRef]

- Tian, J.; Chen, J.; Lv, F.; Chen, S.; Chen, J.; Liu, D.; Ye, X. Domestic cooking methods affect the phytochemical composition and antioxidant activity of purple-fleshed potatoes. Food Chem. 2016, 197, 1264–1270. [Google Scholar] [CrossRef]

- Cuéllar-Cepeda, F.-A.; Parra-Galindo, M.-A.; Urquijo, J.; Restrepo-Sánchez, L.-P.; Mosquera-Vásquez, T.; Narváez-Cuenca, C.-E. Influence of genotype, agro-climatic conditions, cooking method, and their interactions on individual carotenoids and hydroxycinnamic acids contents in tubers of diploid potatoes. Food Chem. 2019, 288, 127–138. [Google Scholar] [CrossRef] [PubMed]

- Tajner-Czopek, A.; Kita, A.; Rytel, E. Characteristics of French Fries and Potato Chips in Aspect of Acrylamide Content—Methods of Reducing the Toxic Compound Content in Ready Potato Snacks. Appl. Sci. 2021, 11, 3943. [Google Scholar] [CrossRef]

- Tajner-Czopek, A.; Rytel, E.; Kita, A.; Pęksa, A.; Hamouz, K. The influence of thermal process of coloured potatoes on the content of glycoalkaloids in the potato products. Food Chem. 2012, 133, 1117–1122. [Google Scholar] [CrossRef]

- Rytel, E.; Tajner-Czopek, A.; Kita, A.; Tkaczyńska, A.; Kucharska, A.Z.; Sokół-Łętowska, A. The Influence of the Production Process on the Anthocyanin Content and Composition in Dried Potato Cubes, Chips, and French Fries Made from Red-Fleshed Potatoes. Appl. Sci. 2021, 11, 1104. [Google Scholar] [CrossRef]

- Tajner-Czopek, A.; Rytel, E.; Aniołowska, M.; Hamouz, K. The influence of French fries processing on the glycoalkaloid content in coloured-fleshed potatoes. Eur. Food Res. Technol. 2014, 238, 895–904. [Google Scholar] [CrossRef]

- Tajner-Czopek, A.; Gertchen, M.; Rytel, E.; Kita, A.; Kucharska, A.Z.; Sokół-Łętowska, A. Study of Antioxidant Activity of Some Medicinal Plants Having High Content of Caffeic Acid Derivatives. Antioxidants 2020, 9, 412. [Google Scholar] [CrossRef]

- Gao, X.; Björk, L.; Trajkovski, V.; Uggla, M. Evaluation of antioxidant activities of rosehip ethanol extracts in different test systems. J. Sci. Food Agric. 2000, 80, 2021–2027. [Google Scholar] [CrossRef]

- Nemś, A.; Pęksa, A.; Kucharska, A.Z.; Sokół-Łętowska, A.; Kita, A.; Drożdż, W.; Hamouz, K. Anthocyanin and antioxidant activity of snacks with coloured potato. Food Chem. 2015, 172, 175–182. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Yen, G.-C.; Chen, H.-Y. Antioxidant Activity of Various Tea Extracts in Relation to Their Antimutagenicity. J. Agric. Food Chem. 1995, 43, 27–32. [Google Scholar] [CrossRef]

- StatSoft, Inc. Electronic Statistics Textbook; StatSoft: Tulsa, OK, USA, 2013. [Google Scholar]

- Friedman, M.; Kozukue, N.; Kim, H.-J.; Choi, S.-H.; Mizuno, M. Glycoalkaloid, phenolic, and flavonoid content and antioxidative activities of conventional nonorganic and organic potato peel powders from commercial gold, red, and Russet potatoes. J. Food Compos. Anal. 2017, 62, 69–75. [Google Scholar] [CrossRef]

- Mulinacci, N.; Ieri, F.; Giaccherini, C.; Innocenti, M.; Andrenelli, L.; Canova, G.; Saracchi, M.; Casiraghi, M.C. Effect of Cooking on the Anthocyanins, Phenolic Acids, Glycoalkaloids, and Resistant Starch Content in Two Pigmented Cultivars of Solanum tuberosum L. J. Agric. Food Chem. 2008, 56, 11830–11837. [Google Scholar] [CrossRef]

- Navarre, D.A.; Pillai, S.S.; Shakya, R.; Holden, M.J. HPLC profiling of phenolics in diverse potato genotypes. Food Chem. 2011, 127, 34–41. [Google Scholar] [CrossRef]

- Finotti, E.; Bertone, A.; Vivanti, V. Balance between nutrients and anti-nutrients in nine Italian potato cultivars. Food Chem. 2006, 99, 698–701. [Google Scholar] [CrossRef]

- Payyavula, R.S.; Singh, R.K.; Navarre, D.A. Transcription factors, sucrose, and sucrose metabolic genes interact to regulate potato phenylpropanoid metabolism. J. Exp. Bot. 2013, 64, 5115–5131. [Google Scholar] [CrossRef]

- Yang, Y.; Achaerandio, I.; Pujolà, M. Effect of the intensity of cooking methods on the nutritional and physical properties of potato tubers. Food Chem. 2016, 197, 1301–1310. [Google Scholar] [CrossRef]

- Albishi, T.; John, J.A.; Al-Khalifa, A.S.; Shahidi, F. Phenolic content and antioxidant activities of selected potato varieties and their processing by-products. J. Funct. Foods 2013, 5, 590–600. [Google Scholar] [CrossRef]

- Giusti, M.M.; Wrolstad, R.E. Acylated anthocyanins from edible sources and their applications in food systems. Biochem. Eng. J. 2003, 14, 217–225. [Google Scholar] [CrossRef]

- Furia, E.; Beneduci, A.; Malacaria, L.; Fazio, A.; La Torre, C.; Plastina, P. Modeling the Solubility of Phenolic Acids in Aqueous Media at 37 °C. Molecules 2021, 26, 6500. [Google Scholar] [CrossRef]

- Lisińska, G.; Leszczyński, W. Potato Science and Technology; Elsevier Applied Science Publishers Ltd.: London, UK; New York, NY, USA, 1989; pp. 1–391. [Google Scholar]

- van Boekel, M.; Fogliano, V.; Pellegrini, N.; Stanton, C.; Scholz, G.; Lalljie, S.; Somoza, V.; Knorr, D.; Jasti, P.R.; Eisenbrand, G. A review on the beneficial aspects of food processing. Mol. Nutr. Food Res. 2010, 54, 1215–1247. [Google Scholar] [CrossRef]

- Nemś, A.; Kita, A.; Sokół-Łętowska, A.; Kucharska, A. Influence of blanching medium on the quality of crisps from red- and purple-fleshed potatoes. J. Food Process. Preserv. 2020, 44, e14937. [Google Scholar] [CrossRef]

- Blessington, T.; Nzaramba, M.N.; Scheuring, D.C.; Hale, A.L.; Reddivari, L.; Miller, J.C. Cooking Methods and Storage Treatments of Potato: Effects on Carotenoids, Antioxidant Activity, and Phenolics. Am. J. Potato Res. 2010, 87, 479–491. [Google Scholar] [CrossRef]

- Im, H.W.; Suh, B.-S.; Lee, S.-U.; Kozukue, N.; Ohnisi-Kameyama, M.; Levin, C.E.; Friedman, M. Analysis of Phenolic Compounds by High-Performance Liquid Chromatography and Liquid Chromatography/Mass Spectrometry in Potato Plant Flowers, Leaves, Stems, and Tubers and in Home-Processed Potatoes. J. Agric. Food Chem. 2008, 56, 3341–3349. [Google Scholar] [CrossRef]

- Chamorro, S.; Cueva-Mestanza, R.; de Pascual-Teresa, S. Effect of spray drying on the polyphenolic compounds present in purple sweet potato roots: Identification of new cinnamoylquinic acids. Food Chem. 2021, 345, 128679. [Google Scholar] [CrossRef]

- Ercoli, S.; Parada, J.; Bustamante, L.; Hermosín-Gutiérrez, I.; Contreras, B.; Cornejo, P.; Ruiz, A. Noticeable Quantities of Functional Compounds and Antioxidant Activities Remain after Cooking of Colored Fleshed Potatoes Native from Southern Chile. Molecules 2021, 26, 314. [Google Scholar] [CrossRef]

- Ruiz, A.; Aguilera, A.; Ercoli, S.; Parada, J.; Winterhalter, P.; Contreras, B.; Cornejo, P. Effect of the frying process on the composition of hydroxycinnamic acid derivatives and antioxidant activity in flesh colored potatoes. Food Chem. 2018, 268, 577–584. [Google Scholar] [CrossRef]

- Jarienė, E.; Vaitkevičienė, N.; Danilčenko, H.; Tajner-Czopek, A.; Rytel, E.; Kucharska, A.; Sokół-Łętowska, A.; Gertchen, M.; Jeznach, M. Effect of biodynamic preparations on the phenolic antioxidants in potatoes with coloured-flesh. Biol. Agric. Hortic. 2017, 33, 172–182. [Google Scholar] [CrossRef]

- Deußer, H.; Guignard, C.; Hoffmann, L.; Evers, D. Polyphenol and glycoalkaloid contents in potato cultivars grown in Luxembourg. Food Chem. 2012, 135, 2814–2824. [Google Scholar] [CrossRef]

- Starowicz, M.; Zieliński, H. How Maillard Reaction Influences Sensorial Properties (Color, Flavor and Texture) of Food Products? Food Rev. Int. 2019, 35, 707–725. [Google Scholar] [CrossRef]

- Pan, M.; Liu, K.; Yang, J.; Hong, L.; Xie, X.; Wang, S. Review of Research into the Determination of Acrylamide in Foods. Foods 2020, 9, 524. [Google Scholar] [CrossRef]

| Potato | Hydroxycinnamic | French Fries Processing | |||||

|---|---|---|---|---|---|---|---|

| Variety | Acids (HA) | (UP) | (PP) | (PS) | (PSaB) | (PSaP-D) | (FF) |

| (LA) | 3-CQA | 8.73 d ± 0.22 | 2.09 c ± 0.13 | 1.74 b ± 0.10 | 0.26 a ± 0.03 | 0.17 a ± 0.02 | n.d. |

| Light-yellow | 5-CQA | 97.11 f ± 1.28 | 21.36 e ± 0.23 | 18.45 d ± 0.12 | 4.85 c ± 0.12 | 1.94 b ± 0.11 | 0.97 a ± 0.02 |

| flesh potatoes | 4-CQA | 9.89 d ± 0.24 | 2.57 c ± 0.11 | 2.17 c ± 0.09 | 0.98 b ± 0.05 | 0.59 ab ± 0.02 | 0.19 a ± 0.01 |

| CA | 5.24 b ± 0.18 | 0.26 a ± 0.08 | n.d. | n.d. | n.d. | n.d. | |

| Total | 120.97 e | 26.28 d | 22.36 d | 6.09 c | 2.70 b | 1.16 a | |

| (MB) | 3-CQA | 11.97 d ± 0.33 | 5.38 c ± 0.08 | 5.02 c ± 0.08 | 2.39 b ± 0.01 | 0.59 a ± 0.01 | 0.23 a ± 0.02 |

| Red flesh | 5-CQA | 286.44 f ± 10.02 | 149.35 e ± 9.18 | 134.62 d ± 9.25 | 51.55 c ± 1.38 | 25.77 b ± 0.23 | 8.59 a ± 0.12 |

| potatoes | 4-CQA | 30.01 d ± 0.28 | 16.50 c ± 0.12 | 15.60 c ± 1.08 | 4.20 b ± 0.02 | 2.4 ab ± 0.12 | 0.60 a ± 0.05 |

| CA | 9.63 c ± 0.13 | 1.06 b ± 0.04 | 0.17 a ± 0.01 | n.d. | n.d. | n.d. | |

| Total | 338.05 e | 172.29 d | 155.41 d | 58.14 c | 28.76 b | 9.42 a | |

| (VQ) | 3-CQA | 21.37 e ± 0.25 | 11.11 d ± 0.81 | 10.04 d ± 0.12 | 3.20 c ± 0.06 | 1.70 b ± 0.16 | 0.64 a ± 0.13 |

| Purple | 5-CQA | 309.55 e ± 11.22 | 216.68 d ± 11.74 | 204.3 d ± 10.3 | 61.91 c ± 0.67 | 38.95 b ± 1.14 | 14.38 a ± 0.22 |

| flesh potatoes | 4-CQA | 32.47 e ± 1.63 | 20.78 d ± 1.13 | 19.48 d ± 1.07 | 5.51 c ± 0.08 | 2.59 b ± 0.08 | 0.97 a ± 0.09 |

| CA | 17.10 c ± 0.98 | 1.88 b ± 0.12 | 0.28 a ± 0.02 | nd. | nd. | nd. | |

| Total | 380.49 e | 250.45 d | 234.1 d | 70.79 c | 43.24 b | 15.99 a | |

| Indicators of Analysis | French Fries Processing | ||||||

|---|---|---|---|---|---|---|---|

| Potato Variety | Spectrophotometric Measurement | (UP) | (PP) | (PS) | (PSaB) | (PSaP-D) | (FF) |

| (LA) | TPC | 1.01 d ± 0.06 | 0.55 c ± 0.03 | 0.53 c ± 0.09 | 0.27 b ± 0.05 | 0.21 a ± 0.01 | 0.21 a ± 0.02 |

| Light-yellow | ABTS | 2.90 d ± 0.05 | 1.71 c ± 0.04 | 1.25 c ± 0.09 | 0.58 b ± 0.02 | 0.44 a ± 0.01 | 0.45 a ± 0.03 |

| flesh potatoes | DPPH | 3.19 d ± 0.04 | 1.86 c ± 0.11 | 1.34 c ± 0.02 | 0.66 b ± 0.04 | 0.45 a ± 0.03 | 0.46 a ± 0.01 |

| (MB) | TPC | 3.56 d ± 0.06 | 2.93 c ± 0.08 | 2.78 c ± 0.04 | 1.38 b ± 0.08 | 0.65 a ± 0.03 | 0.68 ab ± 0.04 |

| Red flesh | ABTS | 7.45 d ± 0.03 | 5.64 c ± 0.12 | 3.77 b ± 0.05 | 2.16 b ± 0.02 | 1.45 a ± 0.04 | 1.50 a ± 0.01 |

| potatoes | DPPH | 9.23 e ± 0.34 | 6.23 d ± 0.06 | 4.91 c ± 0.09 | 2.15 b ± 0.02 | 1.53 a ± 0.10 | 1.60 a ± 0.12 |

| (VQ) | TPC | 4.02 f ± 0.10 | 3.87 e ± 0.22 | 3.54 d ± 0.04 | 1.81 c ± 0.09 | 0.78 a ± 0.04 | 0.84 b ± 0.02 |

| Purple | ABTS | 8.12 f ± 1.03 | 6.11 e ± 0.30 | 5.04 d ± 0.02 | 2.58 c ± 0.02 | 2.14 a ± 0.09 | 2.32 b ± 0.11 |

| flesh potatoes | DPPH | 10.71 f ± 1.14 | 7.95 e ± 0.24 | 6.12 d ± 0.09 | 3.07 c ± 0.10 | 2.51 a ± 0.07 | 2.68 b ± 0.12 |

| Potato Variety | Dry Matter (g 100 g−1) | Starch (g 100 g−1) | Reducing Sugar (g 100 g−1) |

|---|---|---|---|

| (LA) Light-yellow flesh potatoes | 22.85 ± 0.11 | 16.97 ± 0.16 | 0.10 ± 0.09 |

| (MB) Red flesh potatoes | 21.61 ± 0.20 | 16.40 ± 0.11 | 0.13 ± 0.10 |

| (VQ) Purple flesh potatoes | 21.17 ± 0.14 | 15.67 ± 0.13 | 0.15 ± 0.12 |

| Hydroxycinnamic | (LA) Light-Yellow Flesh Potatoes | (MB) Red Flesh Potatoes | (VQ) Purple Flesh Potatoes | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Acids (HA) | TPC | ABTS | DPPH | TPC | ABTS | DPPH | TPC | ABTS | DPPH |

| Unpeeled potatoes | |||||||||

| 3-CQA | 0.600 * | n.s. | 0.601 * | 0.614 ** | 0.559 * | 0.622 ** | 0.613 ** | 0.576 * | 0.615 ** |

| 5-CQA | 0.701 ** | 0.673 ** | 0.688 ** | 0.894 ** | 0.792 ** | 0.844 ** | 0.981 ** | 0.912 ** | 0.927 ** |

| 4-CQA | 0.623 ** | 0.615 ** | 0.676 ** | 0.715 ** | 0.692 ** | 0.729 ** | 0.790 ** | 0.747 ** | 0.800 ** |

| CA | 0.510 * | n.s. | 0.509 * | n.s. | n.s. | n.s. | 0.524 * | n.s. | 0.501 * |

| French fries | |||||||||

| 3-CQA | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. |

| 5-CQA | 0.693 ** | 0.662 ** | 0.595 ** | 0.909 ** | 0.902 ** | 0.855 ** | 0.925 ** | 0.930 ** | 0.911 ** |

| 4-CQA | n.s. | n.s. | n.s. | 0.544 * | 0.523 * | n.s. | 0.632 ** | 0.628 ** | 0.613 ** |

| CA | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tajner-Czopek, A.; Rytel, E.; Kita, A.; Sokół-Łętowska, A.; Kucharska, A.Z. Content and Stability of Hydroxycinnamic Acids during the Production of French Fries Obtained from Potatoes of Varieties with Light-Yellow, Red and Purple Flesh. Antioxidants 2023, 12, 311. https://doi.org/10.3390/antiox12020311

Tajner-Czopek A, Rytel E, Kita A, Sokół-Łętowska A, Kucharska AZ. Content and Stability of Hydroxycinnamic Acids during the Production of French Fries Obtained from Potatoes of Varieties with Light-Yellow, Red and Purple Flesh. Antioxidants. 2023; 12(2):311. https://doi.org/10.3390/antiox12020311

Chicago/Turabian StyleTajner-Czopek, Agnieszka, Elżbieta Rytel, Agnieszka Kita, Anna Sokół-Łętowska, and Alicja Z. Kucharska. 2023. "Content and Stability of Hydroxycinnamic Acids during the Production of French Fries Obtained from Potatoes of Varieties with Light-Yellow, Red and Purple Flesh" Antioxidants 12, no. 2: 311. https://doi.org/10.3390/antiox12020311

APA StyleTajner-Czopek, A., Rytel, E., Kita, A., Sokół-Łętowska, A., & Kucharska, A. Z. (2023). Content and Stability of Hydroxycinnamic Acids during the Production of French Fries Obtained from Potatoes of Varieties with Light-Yellow, Red and Purple Flesh. Antioxidants, 12(2), 311. https://doi.org/10.3390/antiox12020311