Abstract

With an increase of environmental pressure on economic activities, reverse flow is increasingly important. It seeks to save resources, eliminate waste, and improve productivity. This paper investigates the optimization of the disassembly, remanufacturing and assembly system, taking into account assembly-disassembly system degradation. An analytical model is developed to consider disassembly, remanufacturing of used/end-of-life product and assembly of the finished product. The finished product is composed of remanufactured and new components. A maintenance policy is sequentially integrated to reduce the system unavailability. The aim of this study is to help decision-makers, under certain conditions, choose the most cost-effective process for them to satisfy the customer as well as to adapt to the potential risk that can perturb the disassembly-assembly system. A heuristic is developed to determine the optimal ordered date of the used end-of-life product as well as the optimum release dates of new external components. The results reveal that considering some remanufacturing and purchase components costs, the proposed model is more economical in comparison with a model without remanufactured parts. Numerical results are provided to illustrate the impact of the variation of the ordering cost and quality of the used end-of-life product on the system profitability. Finally, the risk due to system repair periods is discussed, which has an impact on managerial decision-making.

1. Introduction

Manufacturing companies aim to transform raw materials or components received from their suppliers and to assemble them into finished products to be delivered to their customers. As well as market volatility and the competitive context, the management of this concept differs from one company to another. Supply chain management draws the attention of several researchers in the field of industrial engineering. A growing body of recent books has been published whose researchers present supply chain management with different concepts and techniques in diverse entities related to the logistics chain [1,2,3]. Stadtler [2] also investigated the essence of supply chain management and advanced planning. He presented the latest research results for the resolution described in his paper. Management approaches in the field of industrial engineering are diverse. On the other side, with the rise of consumption, concepts of supply chain management are extended. Indeed, more and more of production waste, resources reduction, and even environmental degradation encourage us to develop new approaches that manage these problems. Several firms are consequently increasingly responsible for their post-consumer products owing to stricter regulations for managing industrial sustainability [4,5]. Accordingly, today, the supply chain is driven by sustainable supply chain management [6,7]. Sustainable supply chain management can be defined as the integration of environmental and financial approaches into the entire supply chain lifecycle. All supply chains can be optimized using sustainable approaches. To achieve profitability, supply chain sustainability approaches must deliver improved environmental performance within a financially viable operating construct. Thus, we consider the issue of planning management regarding assembly and disassembly systems in a supply chain under different uncertainties.

The production of durable goods has exploded, resulting in an increased flow of returns from customers to suppliers. This is called “reverse logistics”. Govindan et al. [8] proposed a review paper. They reviewed and analyzed recently published papers in reverse logistics and closed-loop supply chains to clarify and suggest future research opportunities. In fact, they mentioned that reverse logistics start from end users. The used products are collected from customers and then they attempt to manage them through different decisions (recycling, remanufacturing, repairing, and disposing of). In our study, we consider the remanufacturing process—in other words, the remanufacturing of components derived from good parts of used/end-of-life product disassembly in order to recover them in the assembly process and have a saleable product. The remanufacturing of used products is an area that is very much addressed in the literature on reverse logistics [9,10]. These remanufacturing processes are significantly more environmentally friendly than recycling or first-time manufacturing. In fact, these operations use fewer materials and less energy. Most of the concerned firms are specialized in the remanufacture of automobile, truck, and other vehicle components such as starters, alternators, transmissions, etc. [11]. Many researchers tried to find solutions within their countries by studying problems and roadblocks that prevent the start of the process of remanufacturing [12]. Therefore, compared to previous studies that deal with disassembly-assembly issues, this work considers the remanufacturing of used product with disassembly and assembly activities.

Disassembly operations are among the main process in remanufacturing process. The objective of these operations is to obtain the valuable components of used/end-of-life products while separating those which affect the environment. In the literature, many researchers were interested in the problems of the disassembly system such as disassembly planning and scheduling, disassembly shop scheduling and control, etc. Priyono et al. [13] presented a literature review paper where they analyzed what had been done the first time and what needs to be done the second time in the field of disassembly in remanufacturing. Therefore, Bentaha et al. [14] studied the problem of disassembly process planning considering the states or quality of the products to be disassembled. Meanwhile, the problem of disassembly process planning and the definition of the disassembly sequences have been studied in numerous works; we cite Yu et al. [15], Sanchez et al. [16], Ren et al. [17] and Peeters et al. [18]. In other studies [19,20], authors also considered the problem of disassembly scheduling under a single period of disassembly. In the same context, Ferrer et al. [11] treated the problem of determining the quantity and timing of disassembling each parent item for a given disassembly structure in order to satisfy the demand of leaf items over a planning horizon with discrete time periods. However, these above-mentioned studies have treated the disassembly process under different uncertainties independently of the manufacturing process. Indeed, in real-life systems, the disassembly operation depends on the demand for manufacturing of finished products.

Our paper is based on Material Requirements Planning (MRP) taking into account remanufacturing components. Within recent decades, MRP systems were among the most popular methods of production and inventory planning for companies, and of interest to many researchers [21,22,23,24,25]. However, MRP tends to be an assembly-oriented scheduling system [17]. Some studies noted that most MRP does not provide capabilities to plan disassembly [18]. Inderfurth and Jensen [26] proposed a mathematical analysis of remanufacturing within the MRP framework to develop control rules for undertaking production of new components, refurbishing returned cores, and disposing of excess cores. Their model is also limited to remanufacturing processes that maintain a finished good identity. In the work of Raupp et al. [27], they presented an MRP optimization model where they treated a particular production system. In addition to manufacturing a final product, its main assembling component can be recovered from parts of the returned product. Gotzel and Inderfurth [28] developed an extended MRP model for a hybrid single-stage multi-period production and remanufacturing system. Compared to those studies cited above, the MRP examined in our system considering not only finding release dates of new components, but also the order date of used product from the suppliers.

To solve this kind of problem, Taleb and Gupta [29] proposed an algorithm whose objective it is to determine the quantity and the disassembly schedule for the item to fulfill that demand on time. In another paper [30], they proposed two companion algorithms to obtain the quantity and disassembly operations schedule; they treated a more complex problem with the existence of multiple product structures and common parts and/or materials. In addition, Langella [19] dealt with the same problem and proposed a modified version of the algorithm of Taleb and Gupta [30]. Indeed, Kim et al. [20] proposed a cost objective function to minimize the sum of setup, inventory holding costs, and disassembly operation. They implemented a heuristic algorithm based on linear programming relaxation to solve the proposed cost function. Kim et al. [31] treated a production planning problem in disassembly systems with a branch and bound algorithm. Prakash et al. [32] presented a new form of constraint-based simulated annealing (CBSA) in his paper to determine the ordering and disassembly schedule, to minimize inventory level for products with general assembly product structure.

This paper aims to bridge the gap in research on the disassembly-assembly system by developing an optimal disassembly-assembly plan. Indeed, we consider stochastic lead-times of intermediate disassembled and assembled components. Moreover, we propose an integrated maintenance plan that considers deterioration of the system, which also depends on the disassembly-assembly activities. The integration of a maintenance plan aims to study the risk of disruption of the disassembly-assembly plan caused by machine breakdowns.

This paper is organized as follows: in Section 2, the global assembly-disassembly system is described as well as the different assumptions considered. An analytical model is presented in Section 3. A maintenance plan is implemented for the proposed assembly-disassembly system in Section 4. The last section is denoted by numerical examples as well as sensitivity studies of some parameters that influence the system.

2. MRP System with Disassembly and Remanufacturing Parts

In this section, we describe the problem and illustrate the different assumptions considered for our study.

We introduce the following parameters:

2.1. Notation

Parameters

| H | finite work horizon. |

| time period length. | |

| due date for the finished product. | |

| demand (known) for the finished product. | |

| number of components in each level 1. | |

| number of components in each level 2. | |

| component i at level 1 or component issued from the used end-of-life product disassembly . | |

| component j at level 2 or leaf item from disassembling . | |

| set of new components ordered from external resources necessary to assembly one component Ci,1. | |

| set of remanufactured components issued from the disassembly processes necessary to assembly one component | |

| random lead-time for the component . | |

| random lead-time for the new or remanufactured component . | |

| random lead-time for the disassembled part . | |

| period between two preventive maintenance actions. | |

| assembly period for the component . | |

| assembly period for the finished product. | |

| disassembly period for the component . | |

| disassembly period for the used/end-of-life product. | |

| level of machine solicitation at period k . | |

| Maximum level of machine solicitation. | |

| average number of failures over the finite horizon H. | |

| failure rate of the assembly machine at time t. | |

| nominal failure rate corresponding to the maximal level of machine solicitation. | |

| purchase cost of a used/end-of-life product. | |

| remanufacturing cost of leaf item . | |

| disposal cost of damaged leaf item . | |

| purchasing cost of new component . | |

| unit holding cost of one component . | |

| unit holding cost of one component . | |

| b | unit backlogging cost for the finished product. |

| r | unit storage cost of the finished product. |

| total maintenance cost. | |

| cost of each corrective maintenance action. | |

| cost of each preventive action . |

Decision variables:

| release date for component with | |

| order date for the used or end-of-life product. | |

| number of preventive maintenance actions over the finite horizon. |

2.2. Problem Definition

In this paper, we describe our proposed system. We consider a real-life system, a robotic arm manipulator that allows the making of different functions, such as disassembly and assembly processes. The proposed system responds to technological evolution and economic benefits. Among the advantages of such a system are optimization of workspace, maintenance actions, energy, and material consumption, etc. These systems are used widely in the industry.

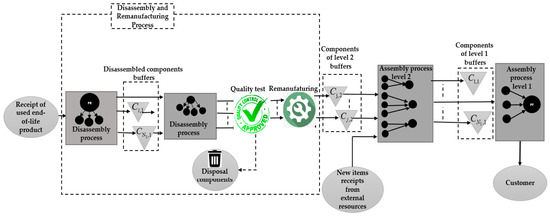

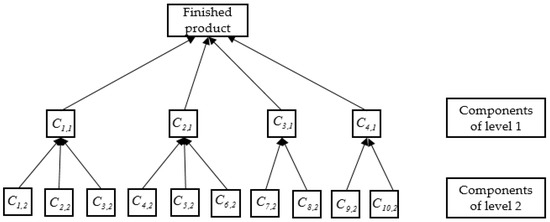

The system shown in Figure 1 describes the manufacturing process of the final product and its main assembling components, the proposed finished product is a two-level assembly product. New and remanufactured components of level 2 Cj,2 are assembled to give semi-finished products Ci,1. The latter are also assembled to give a finished product. The remanufactured parts are issued from the disassembly of a used end-of-life product, which is ordered as needed. It is assumed that a remanufactured component has the same quality as a new one.

Figure 1.

System Description.

In our system, the finished product is based initially on items recovered from the used/end-of-life product.

Remanufacturing converts returned products into an appropriate condition to be sold again like a new product. As shown in Figure 2, remanufacturing can be defined as a process that consists of disassembling used end-of-life products, sorting of the different disassembled items to decide which items can be remanufactured, and which ones should be disposed, testing its quality and finally repairing or replacing damaged parts to be considered like “new” components. Consequently, depending on the sort and type of components that can be remanufactured, the rest of the components needed to start the assembly process are ordered from external suppliers (see Figure 1).

Figure 2.

Different steps of having remanufacturing parts.

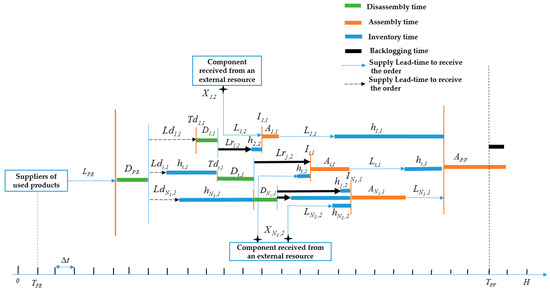

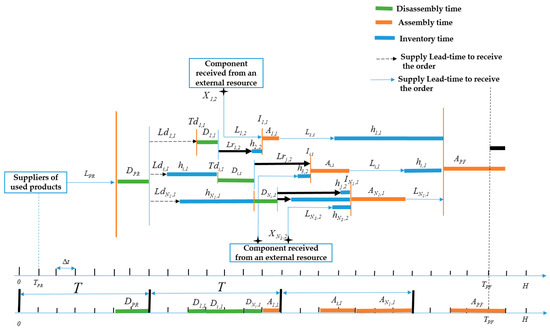

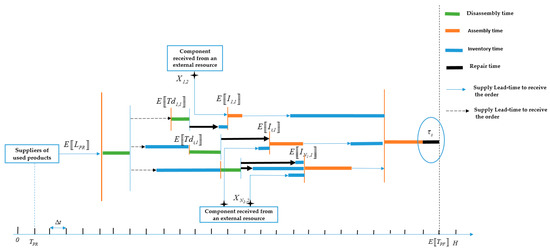

Therefore, this paper presents the optimization of a MRP model with remanufactured components. The objective is to find the optimal order date of used/end-of-life products as well as optimal release dates to purchase new components to satisfy customer demand on a given delivery date. Respecting these dates, disassembly and assembly plans are performed sequentially. We study a finished product with a two-level assembly structure. Figure 3 explains the system further by placing different parameters of periods and dates. The ordered used/end-of-life product arrives with a stochastic lead-time . Upon receipt, the disassembly process starts instantly, which takes periods. The returned product has the same structure as a finished product. The set of components issued from this operation are named components of level 1. These components do not start their assemblies immediately; a stochastic lead-time is affected for each component. This lead-time includes cleaning, preparation, and convoy steps. Likewise, for these components, disassembly operations occur sequentially under assumption 1 noted below. If a component is ready to be disassembled but the system is occupied by another operation, the component will be stored until the system is released. is the unit inventory cost of each component . Each component takes periods to be disassembled. We have the components that are derived from the components of level 1 that will be inspected. According to the quality of these items, the manufacturer distinguishes the components with good quality (remanufacturable components) from ones with bad quality (unremanufaturable components). The remanufacturable components will be remanufactured and are supposed as new ones. A unit remanufacturing cost for each component is added. However, the unremanufaturable components will be disposed of with a unit disposal cost . Following the inspection, the manufacturer decides which components should be ordered from an external supplier to start product manufacturing. Each new component costs . A stochastic remanufacturing lead-time is for components issued from disassembly and supply lead-time for new ordered components. The arrived components must be stored until the set of necessary components for the assembly component at level 1 arrives to begin the assembly process. Each component takes periods to be assembled. In addition, components at level 1 are stored until the arriving of all components for final assembly. When a component is ready, it is conducted within a lead-time to begin finished product assembly. The necessary period is designed to make an assembled finished product. We note that r is the unit inventory cost for the finished product if it is ready before the planned lead-time. Otherwise, when the finished product is ready after the planned lead-time, a unit backlogging cost denoted by b is considered for each period.

Figure 3.

Description of one manufacturing finished product planning.

The assumptions described above are taken into consideration in our study:

- A single system is assigned for all disassembly and assembly operations.

- Disassembly and assembly operations are done by level of nomenclature whatever the number of used/end-of-life products to be disassembled or of the customer demand, which mean, we disassemble or assemble the first level of all components and then we go to the other levels one by one, to reduce the time of setup of the machine. To simplify the complexity of the model, we order a single used/end-of-life product and we fix the demand D at one product, D = 1.

- Remanufacturing components are assumed to be as new.

- Inventory holding, remanufacturing, purchasing, disposal, and backlogging costs are deterministic.

- We assume a single period optimization model, and a horizon for a single demand with a deterministic delivery date.

- We assume that the used/end-of-life product is entirely disassembled.

- The quantity of remanufactured components is stochastic.

- According to the real-life case, we assume that the costs of purchase new items is greater in front of the unit cost of purchasing a used/end-of-life product and costs of remanufacturing and disposal of items issued from the disassembly process.

- Periods of corrective and preventive maintenance actions are negligible.

- We assume that each component of level 2 is used to assemble only one type of component at level 1.

In the next section, we propose mathematical models to optimize the disassembly and assembly plans as well as the maintenance plan.

3. Description of the MRP Mathematical Model with Remanufacturing Parts

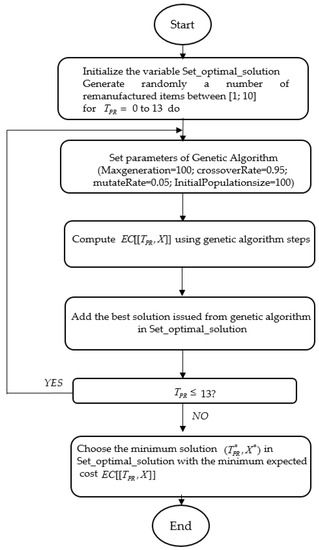

In this section, an optimization MRP model with remanufacturing parts is considered. First, a mathematical model is developed to determine the optimal ordered date for used/end-of-life product as well as the optimal vector of release dates for components at level 2 (or new raw materials) to satisfy customer demand over a finite horizon. In the second step, from the optimal dates founded, we built a disassembly-assembly plan for the system. The proposed system is disposed to random failures that lead to an unavailability of the system and therefore a delay in the delivery of the customer demand. To reduce breakdown frequency, a mathematical model is implemented to determine the optimal preventive maintenance plan (Figure 4).

Figure 4.

Description of one manufacturing finished product planning with a maintenance plan.

3.1. Disassembly-Assembly Plan

The mathematical model proposed below leads to minimize these costs: inventory holding costs of different components (disassembled components, leaf-items, new components ordered from external resources, assembled components at level 1, finished product), remanufacturing costs, disposal costs, purchasing costs of new components and of used/end-of-life product, and backlogging cost of finished product. This mathematical function optimizes the order date of used/end-of-life product as well as the release dates of new components at level 2 over a finite horizon.

The mathematical expressions mentioned below are used to clarify the analytical proposed model:

The disassembly date for each component is issued from the disassembly of the used/end-of-life product. This date represents the initiation of the disassembly process of . The disassembly process of each component begins after a random lead-time that includes the component transmission, component preparation, etc. If the component is ready to be disassembled and the system is occupied by another operation, the component is stocked until the system is released.

We note by the stock period of each component is which is calculated as follows:

We suppose that:

: If the machine is occupied in .

: If the machine is available in .

| 1: | |

| 2: | |

| 3: | |

| 4: | |

| 5: | |

| 6: | |

| 7: | |

| 8: |

The assembly date for each component is , which begins when all the necessary components required for its assembly are ready. The assembly of the component Ci,1 consists of a set of new components ordered from external resources and a set of remanufacturing components resulting from the disassembly process of used/end-of-life component. Components arriving early will be stored until all other components are received. At the assembly, if the system is busy, all the components must be stored until the system is released. The expression of the assembly date is as follows:

We note by the stock period of each component is which is calculated as follows:

Where in this expression, the stock is calculated as follow:

: If the machine is occupied in .

: If the machine is available in .

| 1: | |

| 2: | |

| 3: | |

| 4: | |

| 5: | |

| 6: | |

| 7: |

The assembly date for the finished product is : the assembly of the finished product is started when all components of level 1 are ready:

The maximum between the end of the finished product assembly and the planned delivery time is noted by :

The minimum between the end of the finished product assembly and the planned delivery time is noted by :

The objective function includes:

The inventory costs of disassembled components:

The inventory costs of components at level 2:

The inventory costs of components at level 1:

Backlogging costs for the finished product:

Inventory holding costs for the finished product:

Therefore, the total function cost denoted by which is composed of inventory holding costs of the different components (disassembled components issued from the disassembly of the used/end-of-life product, components at level 1 and 2, and the finished product), backlogging costs, purchasing costs (purchasing of the used/end-of-life product and ordered components of level 2 from external resources), remanufacturing, and disposal costs.

With , where , and .

The procurement lead times of used/end-of-life product , disassembled components issued from this latter and components of level 1 and 2 are random variables. The determination of the ordered dates ( and ) and the maintenance plan when minimizing the cost function is done sequentially. First, we determine the ordered dates; the cost function does not include maintenance costs. Following these dates, we determine the disassembly-assembly system plan. This plan will be used to determine the optimal preventive maintenance plan.

To have an optimal disassembly-assembly system plan, we need to resolve the expected total cost function , which is given by:

3.2. Maintenance Plan

According to optimal dates founded as and , we determine the optimal disassembly-assembly plan. This plan allows determination of the system’s solicitation rate, which has an influence on the effectiveness of the system; likewise, it leads to failures. The objective is to find the optimal number of preventive maintenance N*. We assume that, after each corrective maintenance, the system is in the state just before breakdown. In addition, preventive and corrective actions have negligible times. Between two preventive maintenance actions, the failure rate depends on the disassembly or assembly processes. Each disassembly or assembly process solicits the machine at a solicitation rate, which depends on the process type and relative to the highest level of system solicitation. We propose in this paper an example of solicitation levels u for disassembly types in Table 1 and assembly types in Table 2. We take the example of five types of components which can be assembled together or disassembled from each other; each disassembly or assembly operation of a specific type gives a machine solicitation rate. We assume that the maximum level of machine solicitation is U = 2.

Table 1.

Example of the different levels of machine solicitation related to the type of disassembly for the proposed system.

Table 2.

Example of the different levels of machine solicitation related to the type of assembly for the proposed system.

The following analytical expression of the total maintenance cost includes preventive and corrective maintenance actions:

where and which represents the expected function of failures number during the horizon depending on the disassembly-assembly plan. The failure rate is cumulative at the beginning of each interval k and is relative to the level of machine solicitation

is determined from the optimal disassembly-assembly plan. We give the failure rate in the interval k as follows:

with:

where is the failure rate for nominal conditions is equivalent to the failure rate of the maximum level of machine solicitation during all horizon .

Our work is based on Hajej et al. [33] where they established an optimal integrated maintenance-production policy under subcontractor constraint, considering the influence of the production rate variation on the manufacturing system degradation and consequently on the maintenance strategy adopted.

Based on the work of Hajej et al. [33], the average failure number expressed as follows:

We replace by its expression and T with :

4. Numerical Results

In this section, we try to prove the profitability and the effectiveness of the proposed MRP system when considering remanufacturing parts. At first, we test an MRP model without taking the recovery of used/end-of-life products into account, which means that all raw materials (components of level 2) are ordered and new. Second, we interpret the results given as compared with our proposed model. Based on the calculation of the expected cost in Ben-Ammar et al. [24], we calculate to minimize the expected total cost (details in the Appendix). Then, we determine the disassembly-assembly plan during the system’s work horizon. From this disassembly-assembly plan, we find the vector of the system solicitation levels for each period and type of disassembly or assembly process. We calculate the optimal preventive maintenance number

We consider a finished product with the two-level assembly structure described in Figure 5.

Figure 5.

Nomenclature of the proposed finished product.

The data noted below are used for the computation:

Table 3 and Table 4 illustrate the different values of the unit inventory holding costs for components and in monetary units.

Table 3.

The holding cost of components at level 2.

Table 4.

The Holding cost of components at level 1.

The other values of our example are:

- ,

- .

Table 5. The remanufacturing cost of components at level 2.

Table 5. The remanufacturing cost of components at level 2. Table 6. The purchasing cost of components at level 2.

Table 6. The purchasing cost of components at level 2.

The procurement time of the different components (used/end-of-life component, disassembled component, components at level 2 and assembled component at level 1) follow a uniform probability law.

For the calculation of the expected average number of failures, we adopt for a Weibull distribution with two parameters . This distribution is generally used to describe the system’s failure rate in industrial areas.

4.1. Optimal Ordered Date of Used/End-of-Life Product and Release Dates Plan of Components at Level 2

To calculate the optimal ordered date of used/end-of-life product and the vector of release dates for components at level 2, we implement a genetic algorithm with a simulation method. These components at level 2 must be ordered following the destruction of certain components after the disassembly process. The algorithm is implemented within JAVA language to resolve . Figure 6 illustrates the proposed algorithm. Indeed, the choice of the genetic algorithm is decided upon from its widespread use to solve discrete optimization problems, which proves that it is among the most used algorithms [34] considering that is a relevant, accurate and fast algorithm. The objective of using the classical simulation method is to evaluate all possible values of the decision variables one by one. Indeed, our search space for the decision variable is very reasonable, which helps us to calculate the total expected cost for each value, whereas the decision vector depends on and other deterministic and stochastic parameters of the system, which seems impossible to list all the possible combinations of the vector. This vector depends too on the number of components to be ordered. Therefore, as indicated in the flowchart of Figure 6, we initialize at first the set of optimal solutions founded for each value of . Then, we generate a random vector that represents the state of each component of the disassembled product. As mentioned above in Figure 5, the proposed product consists of 10 parts at level 2, so among its components, we have remanufacturable and unremanufacturable parts. Then, we apply the genetic algorithm steps (selection, crossing, mutation) to find the best vector The parameters of the genetic algorithms are noted in Figure 6. In the second step, to calculate the optimal number of preventive maintenance actions, we implement the mathematical function CM within the “Wolfram Mathematica” tool.

Figure 6.

Flowchart of the proposed algorithm.

The results found are shown in tables below (Table 7 and Table 8). In Table 7, the disassembly process is not considered; all components of level 2 are ordered from suppliers (external resources). On the other hand, Table 8 shows results of the proposed model. The number of remanufactured components is generated randomly. As shown, the vector of dates of new components ordered from external suppliers consists of five dates, which proves that the disassembly of the used/end-of-life product has given us five remanufacturable components. Indeed, the optimal ordered date of the used/end-of-life product founded with the proposed algorithm is given in the table. We also observe the difference between costs, which proves the advantage of integrating the disassembly and remanufacturing process.

Table 7.

Optimal release dates and cost in the case of assembly system (finished product is composed only of new complements).

Table 8.

Optimal release dates, optimal ordered date of used/end-of-life product and expected cost in the case of disassembly, remanufacturing, assembly system (finished product is composed of new and remanufactured complements).

4.2. Optimal Maintenance Plan

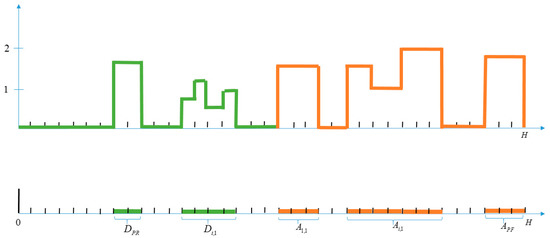

In this sub-section, we try to find the optimal preventive maintenance plan for the disassembly-assembly system. We adopt the sequential strategy whose objective is to integrate the system plan obtained from the optimal dates calculated above (Table 8). This preventive maintenance plan is determined by the disassembly-assembly plan. Based on dates founded in Table 8, we built the disassembly-assembly system plan as shown in Figure 7. According to the different levels of the system solicitation presented in Table 1 and Table 2 for different types, we suppose that our disassembly and assembly operations types vary between type 1 and type 5. In addition, depending on the different disassembly and assembly process and types of our example, Figure 7 present levels of system solicitation on a time scale with the disassembly-assembly schedule planning. We suppose that the used/end-of-life disassembly operation solicits the machine at and the solicitation rate of the finished product assembly at .

Figure 7.

Disassembly-assembly schedule planning with the representation of levels of machine solicitation on the time scale.

The mathematical function takes into consideration the influence of the variation of system solicitation on the disassembly-assembly system. These solicitation rates presented in Figure 7 represents the vector . This vector is used to calculate the average number of failures .

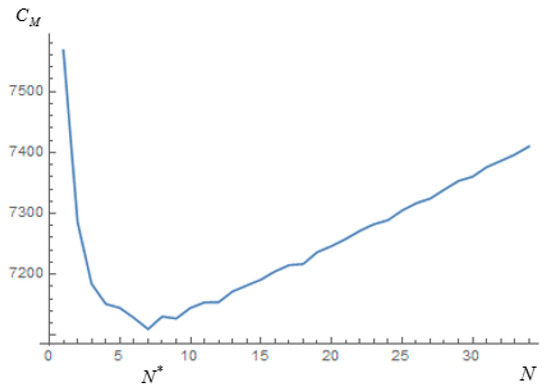

To find the optimal value of preventive maintenance number, we implement the maintenance cost function within the “Wolfram Mathematica” tool. We try to vary the variable N from 0 to H-1 and we calculate, at each value of N, the total maintenance cost using . As shown in Figure 8, the curve has a convex form. The value represents the number of preventive maintenance with minimum cost 7109.4 mu.

Figure 8.

Total cost maintenance in function of preventive maintenance actions N.

4.3. The Influence of Ordering Cost of the Used/End-of-Life Product on the System Profitability

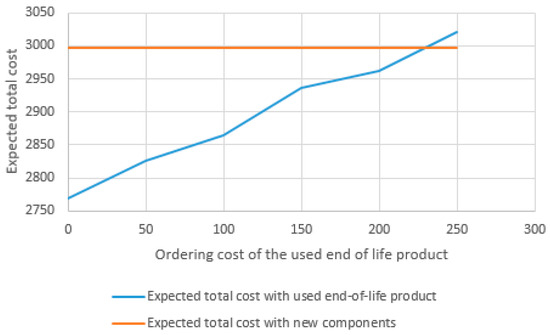

In this subsection, we discuss the impact of ordering cost of the used/end-of-life product on system profitability, at a time when we are talking about environmental management, ecological responsibility on the future of end-of-life manufactured products, environmental certification, and finally, when many companies are looking after techniques and processes for re-evaluating end-of-life products. Besides the interest on the environment, entrepreneurs are also interested in the profitability of these processes and techniques. In this subsection, we are looking for the profitability of disassembly and remanufacturing processes compared to manufacturing process from new items. In fact, generally, the purchase of used/end-of-life products are cheaper than a new product. We are looking for the influence of the purchase cost of the used/end-of-life product. Figure 9 shows a sensitivity study of the expected total cost as a function of the purchase cost of used/end-of-life product. The chosen values of costs reflect the real case study (Assumption 7). We tried to find the ordering cost threshold of the used/end-of-life product to avoid falling into the profit-loss risk.

Figure 9.

Sensitivity diagram of the unit purchase cost of used/end-of-life product.

As shown in Figure 9, using the values of the chosen example, we try to vary the ordering cost of the used/end-of-life product from 0 mu to 250 mu. If we exceed 230 mu, the expected total cost of our model exceeds the expected total cost without manufactured components of level 2.

In that case, the proposed system with remanufacturing parts becomes unprofitable. Consequently, by integrating the remanufacturing process, to have an effective cost, even as the cost of remanufacturing is very low compared to the purchase cost of the new products, it is inevitable to take into consideration the cost of used end-of-life product compared to total cost of new components.

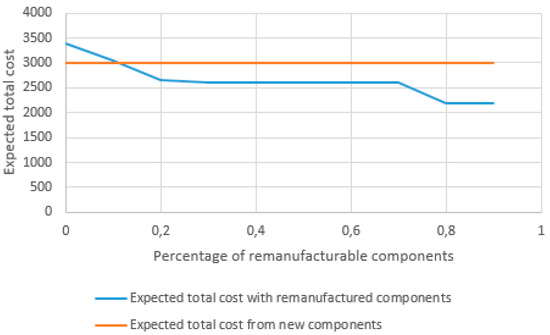

4.4. The Influence of the Used/end-of-life Quality on the System Profitability

In this sub-section, we study the influence of the used/end-of-life quality on system profitability; in other words, the influence of the percentage of remanufactured parts. The number of remanufactured items is usually uncertain, and it will not be known until the end of the disassembly process. In fact, we cannot detect the quality of disassembled items from the arrival of the returned product. This uncertainty may have caused profit-loss risk compared to the expected cost of manufacturing a product from new items. In Figure 10, a sensitivity study is illustrated by the expected total cost as a function of the percentage of remanufactured items. The percentage of remanufactured items is adjusted to see their influence on the total expected cost. To a percentage found, a profit-loss risk will be discussed.

Figure 10.

Sensitivity diagram of the percentage of remanufactured items.

As shown in Figure 10, increasing the percentage of remanufacturing items from 0 to 90% under 10% of remanufactured parts, the expected total cost exceeds the expected cost with new items. Therefore, the proposed system with remanufacturing parts becomes unprofitable compared to the manufactured system with the purchase of new items in level 2. As a result, it is crucial to put requirements and standards for the quality of the used end-of-life product. Indeed, the remanufacturing process requires us to add used purchase cost of an end-of-life product, remanufacturing cost of disassembled parts, cost of storage of disassembled components, system maintenance cost, etc. Therefore, it is the handling of the used/end-of-life product with poor quality that causes a very low percentage of remanufactured items. The integration of a remanufacturing process becomes unprofitable and can even engender profit losses.

4.5. The Influence of the Corrective Maintenance Periods on the Lead-Time of the Finished Product

Many uncertainties can disturb the manufacturing process. In the implementation of the maintenance plan realized above, repair periods are negligible. This has no influence on disassembly-assembly plan. In a real industrial case, some failures take important periods, which disturb the manufacturing process and cause a delay in the delivery. Thus, decision makers must consider this repair time in planning before starting the order processing. In our work, we discuss the period that can take corrective maintenance actions according to the optimal plan implemented by the manager.

We suppose a threshold period noted (Figure 11). This period represents the time that corrective maintenance actions can take it.

Figure 11.

Threshold period for repairing corrective maintenance actions.

As described above, we propose to study the system in a sequential way. From Figure 11, we first implement the plan of disassembly and assembly which is determined from the optimal ordered date of used/end-of-life product and the vector of release dates for components at level 2. However, this optimal plan does not take into consideration the system repair time that causes the machine breakdowns, therefore the delay in disassembly and assembly processes. In fact, according to the representation of the optimal disassembly-assembly plan (Figure 11), the product can be delivered to the customer at .

Using this plan, we calculated the average number of random failures during the working horizon.

In the example illustrated above, we found that the average number of failures . Therefore, if we consider the same plan already calculated, we can note that .

Therefore, if we can quantify each repair time, we can say that each failure should not exceed 1/6 of a period: .

Beyond this period, the decision makers must re-implement the finished product manufacturing plan. Otherwise, a profit-loss risk must be discussed.

5. Conclusions

In a volatile industrial market, decision-makers find it difficult to choose the right approach that suits them to satisfy customers on time with a good-quality product in a first instance and with the lowest cost ahead of their competitors in the second instance. In this context, an optimization of disassembly, remanufacturing and assembly planning system is considered. The proposed system is composed of a single machine for disassembly and assembly operations, inventory of the disassembled components issued from the disassembly process of used/end-of-life product, inventory of components at level 2 and 1 and inventory of the finished product. The disassembly-assembly system is subject to random failures during the working horizon, which leads us to integrate a maintenance policy to deal with the unavailability of the system.

A mathematical model is proposed to formulate the problem. An optimization algorithm based on genetic algorithm and simulation is developed to find the optimal ordered date of used/end-of-life product and the vector of release dates for components at level 2. Using the optimization algorithm, numerical results reveal that the proposed model is more cost effective, under certain costs, than a simple MRP with new items. The costs that can influence the system are the ordering cost of the used/end-of-life product, and purchase costs of new components and remanufacturing costs. For this reason, the influence of ordering cost of the used end-of-life product on system profitability as well as the influence of the quality of the used/end-of-life product are studied. Finally, the risk of considering periods of corrective maintenance is investigated. This evaluation shows that the repair periods influence the disassembly-assembly plan. Beyond a certain threshold time, corrective maintenance actions must be integrated into the manufacturing planning. Otherwise, the profit-loss risk due to delay caused by the repair periods must be evaluated.

This research can serve as a decision support to manage certain product manufacturers. This approach can be used in many examples of product manufacturing. In fact, diverse products consist of expensive components as well as limited natural resources. In that case, remanufactured components become more cost effective than buying new ones. A lot of companies in the automotive and aeronautic sectors are looking to improve their productivity by integrating recovery and remanufacturing concepts in their process. Indeed, incorporating such an approach helps a manager reduce costs if components are very expensive compared to buying and processing a used one. In addition, this proposed method helps decision makers to know when to order a used product to exploit its different remanufacturable parts and when ordering new components that are missing in order to begin customer request processing. This method has been proved by the experiments proposed in this paper to encourage concerned researchers to develop it.

For future research, we will consider a multi-level disassembly-assembly product and a new maintenance policy. We will look to take other uncertainties, which can disrupt the supply chain.

Author Contributions

Z.G., S.T., N.R. and A.D. are designed this work. Z.G. developed the mathematical model and simulation program. She also wrote the paper. S.T. supervised this work and contributed to revise this paper. N.R. and A.D. conducted this research, supervised, and revised this work.

Funding

This research received no external funding

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

In this appendix, we detail the different parts of the expected cost of Equation (11) which is:

We mention that:

To determine the total expected cost, we must calculate:

These variables are positive discrete random variables with a finite number of possible values that varies between , the values of and change for each variable as mentioned below:

•

with,

•

with,

•

with,

•

Let is a discrete random variable positive or zero. His mathematical expectation is equal to:

Moreover, has integer values, so the two sums of equality above can be switched as follows:

We also note by,

: distribution function of the variable of the assembled component with .

: distribution function of the variable of the component with .

Starting by calculating :

For , we have:

Moreover, and , random variables and are independent, so,

We note by , so:

Finally, we calculate and in order to determine after that

and are independent random variables, so:

Thus,

is known and higher than 0, so:

Knowing that,

, random variables are also independent:

The random variables and, for and , are independent:

For , we have:

We have:

We have and are independent, so:

Lead-time is known and higher than 0, so:

Consequently,

For , we note that, for any random variable A, we have . We deduce that:

Therefore, the total expected cost is written as follows:

with:

References

- Kahraman, C.; Oztaysi, B. Supply Chain Management under Fuzziness; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Stadtler, H. Supply chain management: An overview. In Supply Chain Management and Advanced Planning; Springer: Berlin/Heidelberg, Germany, 2015; pp. 3–28. [Google Scholar]

- Hugos, M.H. Essentials of Supply Chain Management; John Wiley & Sons: New York, NY, USA, 2018. [Google Scholar]

- Xie, M.; Wang, J.; Chen, K. Coordinated development analysis of the “resources-environment-ecology-economy-society” complex system in China. Sustainability 2016, 8, 582. [Google Scholar] [CrossRef]

- Barba-Sánchez, V.; Atienza-Sahuquillo, C. Environmental proactivity and environmental and economic performance: Evidence from the winery sector. Sustainability 2016, 8, 1014. [Google Scholar] [CrossRef]

- Galve, J.E.; Elduque, D.; Pina, C.; Javierre, C. Sustainable supply chain management: The influence of disposal scenarios on the environmental impact of a 2400 L waste container. Sustainability 2016, 8, 564. [Google Scholar] [CrossRef]

- Moon, I.; Jeong, Y.J.; Saha, S. Fuzzy Bi-Objective Production-Distribution Planning Problem under the Carbon Emission Constraint. Sustainability 2016, 8, 798. [Google Scholar] [CrossRef]

- Govindan, K.; Hamed, S.; Devika, K. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- Turki, S.; Didukh, S.; Sauvey, C.; Rezg, N. Optimization and Analysis of a Manufacturing–Remanufacturing–Transport–Warehousing System within a Closed-Loop Supply Chain. Sustainability 2017, 9, 561. [Google Scholar] [CrossRef]

- Turki, S.; Rezg, N. Unreliable manufacturing supply chain optimisation based on an infinitesimal perturbation analysis. Int. J. Syst. Sci. Oper. Logist. 2018, 5, 25–44. [Google Scholar] [CrossRef]

- Ferrer, G.; Whybark, D. Material planning for a remanufacturing facility. Prod. Oper. Manag. 2001, 10, 112–124. [Google Scholar] [CrossRef]

- Sharma, V.; Garg, S.K.; Sharma, P.B. Identification of major drivers and roadblocks for remanufacturing in India. J. Clean. Prod. 2016, 112, 1882–1892. [Google Scholar] [CrossRef]

- Priyono, A.; Ijomah, W.; Bititci, U. Disassembly for remanufacturing: A systematic literature review, new model development and future research needs. J. Ind. Eng. Manag. 2016, 9, 899. [Google Scholar] [CrossRef]

- Bentaha, M.L.; Voisin, A.; Marangé, P.; Battaïa, O.; Dolgui, A. Prise en compte de l’état des produits pour la planification de leur désassemblage. Revue D’intelligence Artificielle 2016, 1, 26. [Google Scholar] [CrossRef]

- Yu, B.; Wu, E.; Chen, C.; Yang, Y.; Yao, B.Z.; Lin, Q. A general approach to optimize disassembly sequence planning based on disassembly network: A case study from automotive industry. Adv. Prod. Eng. Manag. 2017, 12, 305–320. [Google Scholar] [CrossRef]

- Sanchez, B.; Haas, C. A novel selective disassembly sequence planning method for adaptive reuse of buildings. J. Clean. Prod. 2018, 183, 998–1010. [Google Scholar]

- Ren, Y.; Tian, G.; Zhao, F.; Yu, D.; Zhang, C. Selective cooperative disassembly planning based on multi-objective discrete artificial bee colony algorithm. Eng. Appl. Artif. Intell. 2017, 64, 415–431. [Google Scholar] [CrossRef]

- Peeters, J.R.; Vanegas, P.; Duflou, J.R.; Mizuno, T.; Fukushige, S.; Umeda, Y. Effects of boundary conditions on the end-of-life treatment of LCD TVs. CIRP Ann. Manuf. Technol. 2013, 62, 35–38. [Google Scholar] [CrossRef]

- Langella, I.M. Heuristics for demand-driven disassembly planning. Comput. Oper. Res. 2007, 34, 552–577. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, D.H.; Xirouchakis, P.; Züst, R. Disassembly scheduling with multiple product types. CIRP Ann. Manuf. Technol. 2003, 52, 403–406. [Google Scholar] [CrossRef]

- Dolgui, A.; Prodhon, C. Supply planning under uncertainties in MRP environments: A state of the art. Ann. Rev. Control 2007, 31, 269–279. [Google Scholar] [CrossRef]

- Hnaien, F.; Delorme, X.; Dolgui, A. Genetic algorithm for supply planning in two-level assembly systems with random lead times. Eng. Appl. Artif. Intell. 2009, 22, 906–915. [Google Scholar] [CrossRef]

- Ben-Ammar, O.; Dolgui, A.; Wu, D.D. Planned lead times optimization for multi-level assembly systems under uncertainties. Omega 2018, 78, 39–56. [Google Scholar] [CrossRef]

- Ben-Ammar, O.; Dolgui, A. Optimal order release dates for two-level assembly systems with stochastic lead times at each level. Int. J. Prod. Res. 2018, 56. [Google Scholar] [CrossRef]

- Guiras, Z.; Turki, S.; Rezg, N.; Dolgui, A. Optimal supply planning for two-levels assembly system with stochastic lead-times and maintenance actions. In Proceedings of the 2016 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bali, Indonesia, 4–7 December 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 551–556. [Google Scholar]

- Inderfurth, K.; Thomas, J. Analysis of MRP policies with recovery options. In Modeling and Decisions in Economics; Physica: Heidelberg, Germany, 1999; pp. 189–228. [Google Scholar]

- Raupp, F.M.; Angeli, K.D.; Alzamora, G.G.; Maculan, N. MRP optimization model for a production system with remanufacturing. Pesquisa Oper. 2015, 35, 311–328. [Google Scholar] [CrossRef]

- Gotzel, C.; Inderfurth, K. Performance of MRP in product recovery systems with demand, return and lead-time uncertainties. In Quantitative Approaches to Distribution Logistics and Supply Chain Management 2002; Springer: Berlin/Heidelberg, Germany, 2002; pp. 99–114. [Google Scholar]

- Gupta, S.M.; Taleb, K.N. Scheduling disassembly. Int. J. Prod. Res. 1994, 32, 1857–1866. [Google Scholar] [CrossRef]

- Taleb, K.N.; Gupta, S.M. Disassembly of multiple product structures. Comput. Ind. Eng. 1997, 32, 949–961. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, D.H.; Xirouchakis, P.; Kwon, O.K. A branch and bound algorithm for disassembly scheduling with assembly product structure. J. Oper. Res. Soc. 2009, 60, 419–430. [Google Scholar] [CrossRef]

- Prakash, P.K.; Ceglarek, D.; Tiwari, M.K. Constraint-based simulated annealing (CBSA) approach to solve the disassembly scheduling problem. Int. J. Adv. Manuf. Technol. 2012, 60, 1125–1137. [Google Scholar] [CrossRef]

- Zied, H.; Sofiene, D.; Nidhal, R. Optimal integrated maintenance/production policy for randomly failing systems with variable failure rate. Int. J. Prod. Res. 2011, 49, 5695–5712. [Google Scholar] [CrossRef]

- Stawowy, A. Evolutionary based heuristic for bin packing problem. Comput. Ind. Eng. 2008, 55, 465–474. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).