Abstract

Porous asphalt mixtures play a pivotal role in enhancing pavement drainage capacity and traffic safety, where the performance of asphalt binder constitutes a determining factor. This study introduces an innovative advancement through the development of a high-viscoelastic modifier and corresponding modified asphalt based on SBS-modified asphalt, coupled with optimized preparation protocols. The optimal composition and dosage of the modifier were systematically determined through standardized tests including penetration, ductility, softening point, and bending beam rheometer (BBR) analysis. A comprehensive evaluation of road performance was conducted on two porous asphalt mixtures, namely conventional SBS-modified asphalt versus the novel high-viscoelastic modified asphalt (designated as 10-A). Experimental protocols encompassed high-temperature rutting resistance tests, low-temperature beam bending tests, freeze–thaw splitting tests, two-point bending fatigue tests, accelerated abrasion tests, and dynamic friction tester (DFT) measurements. The results demonstrate that the 10-A-modified mixture exhibits superior high- and low-temperature performance. Notably, its fatigue resistance and skid resistance showed minimal divergence from conventional SBS-modified asphalt, attributable to physicochemical crosslinking interactions among antioxidants, resins, and stabilizers. This research elucidates the synergistic mechanism of components within the 10-A modifier system. The proposed high-viscoelastic asphalt formulation meets the technical requirements for functional drainage asphalt mixtures while providing material-level support for implementing sponge city initiatives.

1. Introduction

By the end of 2020, the total length of roads in China had reached 5.35 million kilometers [1]. However, the rapid increase in traffic volume, along with the higher frequency of axle overloading and extreme weather events, has introduced a series of new challenges for road construction and maintenance [2]. Inadequate skid resistance of road pavements has been identified as a significant contributing factor to road traffic accidents [3]. Therefore, improving the skid resistance of pavements is an urgent issue for the current road construction and maintenance industry [4].

Porous asphalt pavement is a widely used functional pavement. It can extend the service life of the pavement, improve its anti-skid performance, and ensure the safety and comfort of driving [5]. Under the repeated action of vehicle loads, water in the voids of the mixtures continuously flushes the interface between the asphalt and the aggregates. This reduces the bonding effect of the asphalt binder on the mineral materials, leading to pavement loosening, particle loss, and other issues. On the other hand, traditional modified asphalt cannot meet the application requirements of porous asphalt layers, which significantly affects the road surface function and endangers driving safety [6,7,8].

Recent advancements in polymer-modified asphalt technologies have focused on improving the mechanical properties of porous asphalt mixtures [9]. Among these, styrene-butadiene-styrene (SBS) modified asphalt has become a benchmark material due to its balanced viscoelasticity [10]. However, conventional SBS modifiers exhibit limitations in maintaining high-temperature stability under heavy traffic conditions, with viscosity reductions exceeding 35% at 60 °C. This degradation directly impacts the cohesion–aggregate interlock mechanism, leading to premature raveling and reduced service life [11]. High-viscosity modifiers (HVMs) have emerged as a potential solution, yet existing formulations often compromise low-temperature flexibility or require complex production processes [12]. High-viscoelastic modifier raw materials, including antioxidants, can improve the heat and oxygen aging resistance of modified asphalt. Stabilizers can prevent the decomposition and aging of modified asphalt and enhance its stability. Therefore, the content of antioxidants and stabilizers has a significant impact on the effectiveness of high-viscoelastic modifiers. The Ohio Department of Transportation designed an ultra-thin wear layer mix with two gradations, A and B. Both mixtures used high-viscosity modified asphalt as the binder. Type A mixtures, similar to asphalt sand, were suitable for roads with lower traffic volumes, while Type B mixtures were designed for roads with higher traffic volumes [13]. Molenaar et al. [14] investigated the relationship between the viscosity of high-viscosity asphalt and the water stability properties of porous asphalt mixtures. Their research indicated that increasing the asphalt dosage within a certain range positively affected the water damage resistance of porous asphalt mixtures. To reduce the cost of drainage asphalt pavement in China, further study is needed on high-viscosity modified asphalt and high-viscosity additives tailored to China’s heavy traffic conditions. The scientific novelty of this study lies in its development of a novel HVM through strategic molecular design. Unlike previous approaches that solely focus on viscosity enhancement, our modifier incorporates reactive elastomeric terpolymers that form covalent bonds with asphalt components. This chemical interaction not only increases zero-shear viscosity magnitude compared to conventional SBS-modified asphalt but also maintains penetration index values within the optimal range for thermal cracking resistance [15].

This study focuses on the technological development and engineering application of a novel high-viscosity modifier (HVM). Through systematic experimental investigations on asphalt binders and mixtures, three primary objectives are pursued. First, an innovative preparation process for HVM is proposed to overcome the technical limitations of conventional methods, including complex production procedures and poor compatibility. Second, the optimal dosage range of HVM in asphalt matrices is determined through comprehensive performance evaluations, incorporating penetration tests, ductility tests, softening point measurements, and 60 °C dynamic viscosity analyses. Finally, a gradation optimization framework is developed for PA-10 porous asphalt mixtures to address the critical challenge of balancing road performance with structural durability. The attenuation patterns of pavement skid resistance are systematically investigated to provide theoretical foundations for enhancing the long-term service performance of heavy-duty pavements.

2. Preparation and Performance Analysis of High-Viscoelastic Modified Asphalt

2.1. Raw Materials

High-viscoelastic modifiers primarily consist of thermoplastic materials, resins, antioxidants, stabilizers, co-solvents, and other materials. Thermoplastic materials and resins make up 70% of the total.

- (1)

- Thermoplastic materials

Styrene–butadiene–styrene block polymers (SBS) are among the most abundant, lowest-cost, and widely used thermoplastic materials globally. SBS is primarily used in four major fields, namely rubber products, resin modifiers, adhesives, and asphalt modifiers [16]. SBS exhibits excellent tensile strength, good low-temperature performance, excellent electrical properties, and good processing performance.

- (2)

- Resin

Hydrocarbon resin is one of the by-products of oil cracking. It is a resinous substance formed by the copolymerization of aldehydes, aromatic hydrocarbons, and terpenes [17]. Resin primarily acts as a binder, enhancing the viscoelasticity, acid resistance, and alkali resistance of the modified bitumen. Additionally, it can effectively reduce production costs.

- (3)

- Antioxidant

Antioxidants are alkylated monophenolic compounds that primarily function to enhance aging resistance and improve the high-temperature stability of polymers.

- (4)

- Stabilizer

Stabilizers are white, powdery organic substances. Their primary function is to prevent the decomposition and aging of polymer plastics, rubbers, and synthetic fibers. Stabilizers also improve the surface mechanical properties of modified bitumen.

- (5)

- Co-solvent

The co-solvent is a product of the catalytic cracking of petroleum. It promotes the dispersion and solubility of high-viscoelastic modifiers in asphalt. The co-solvent used in this research has a relative density of 1.05 g/cm3 and contains 0.1% mechanical impurities.

2.2. Preparation Process of High-Viscosity Modifier

The high-viscosity elastomeric modifier enhances asphalt performance through synergistic molecular interactions among its components. An interpenetrating network structure is formed between SBS and resin components, wherein the polystyrene blocks establish a three-dimensional elastic skeleton via π-π stacking interactions with aromatic rings, while the polybutadiene segments immobilize light asphalt fractions through physical entanglement, thereby improving elastic recovery properties [18,19]. Antioxidants and stabilizers collaboratively mitigate aging degradation: radical scavengers inhibit oxidative chain reactions by neutralizing free radicals, whereas sulfur-containing stabilizers modulate asphalt micelle stability through coordination bonds with asphaltene aggregates [20,21]. The co-solvent maintains dynamic equilibrium between polymer swelling and asphalt compatibility, critically governing the thermodynamic stability and processing characteristics of the modified system.

This article prepared high-viscoelastic modifiers A and B by controlling the content of the two materials. The specific ratios of the high-viscosity modifiers are shown in Table 1. The preparation of these modifiers involves the following steps: mixing, melting, extruding, cooling, and shearing [22,23,24]. The ‘mixing’ step involves high-speed shearing and high-temperature stirring of the various raw materials. The ‘melting’ step involves melting the mixed raw materials at a high temperature to achieve an optimal plasticized state. The ‘extruding, cooling, and shearing’ steps involve extruding the plasticized mixture through a die, cooling and shaping it, and finally shearing it into a suitable shape [25,26,27,28,29]. The method of preparing the high-viscoelastic modifiers is described below:

Table 1.

Raw material ratios of high-viscoelastic modifiers.

- (1)

- Shear all raw materials at high speed for 10 min, then transfer them to a high-temperature mixer and mix for 10 min.

- (2)

- Transfer the mixed materials to a twin-screw extruder for extrusion.

- (3)

- Place the molded material in 5 °C pure water to cool for 20 min.

- (4)

- Place the cooled material in a shearing device to shear it into granular high-viscoelastic modifiers A and B.

2.3. Preparation Process of High-Viscoelastic Modified Asphalt

In this article, high-viscoelastic modified asphalt was prepared using the high-speed shear + mixing method [30]. To investigate the optimal content of the high-viscoelastic modifier in asphalt, the study set the modifier content at 0%, 3%, 6%, 9%, and 12%. All high-viscoelastic modified asphalt samples were prepared using the same method to minimize errors introduced by test variables [26,31,32]. The specific preparation process was as follows:

- (1)

- Heat the SBS-modified bitumen in an oven at 175 °C until it melts.

- (2)

- Heat the asphalt to 170–180 °C, add the high-viscoelastic modifier and co-solvent separately, and activate the high-speed shear for dispersion. The shear time is 45 min at a rotational speed of 4000 rad/min.

- (3)

- After shearing, add the stabilizer and stir at 180 °C for 30 min to obtain the high-viscoelastic modified bitumen.

2.4. Determination of Optimum Content of High-Viscoelastic Modifier in Asphalt

This study selected 3%, 6%, 9%, and 12% modifier contents to investigate the compatibility of the modifier-bitumen system. At concentrations below 3%, the modifier is insufficient to form a continuous network structure (evidenced by abrupt changes in penetration and softening point, reflecting weakening of colloidal structure), leading to simultaneous deterioration in high-temperature deformation resistance and low-temperature crack resistance. Within the 3–12% concentration range, the dispersed modifier phase and continuous asphalt matrix achieve thermodynamic dynamic equilibrium, resulting in synergistic enhancement of high- and low-temperature performance to meet engineering mechanical requirements [33,34]. When the modifier content exceeds 12%, oversaturation induces phase separation, reducing cohesive strength and confirming irreversible performance degradation beyond the thermodynamic stability threshold; such concentrations were excluded from the research scope. Therefore, based on the mechanical performance and economic considerations of modified asphalt, this article prepared high viscoelastic modifiers and added them to the asphalt at proportions of 3%, 6%, 9%, and 12%. Five different contents of high-viscoelastic modified asphalt were tested for dynamic viscosity at 60 °C [35]. Based on the test results, the optimal content of high-viscoelastic modified asphalt in SBS-modified asphalt was determined.

2.4.1. Penetration Test and Analysis of Results

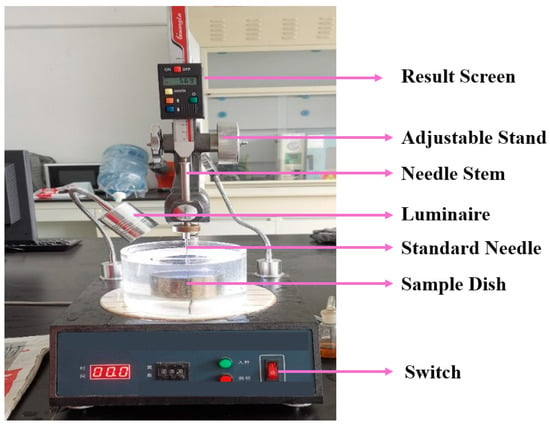

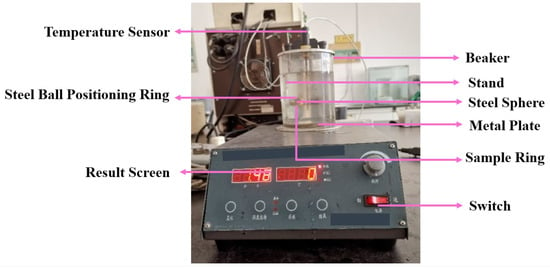

The penetration test is the most commonly used method to characterize the consistency and softness of asphalt. The test was conducted at a temperature of 25 °C with a 100 g load, and the penetration time was 5 s. The test results were accurate to 0.1 mm. The test procedure is illustrated in Figure 1, and the test results are presented in Figure 2.

Figure 1.

Penetration test.

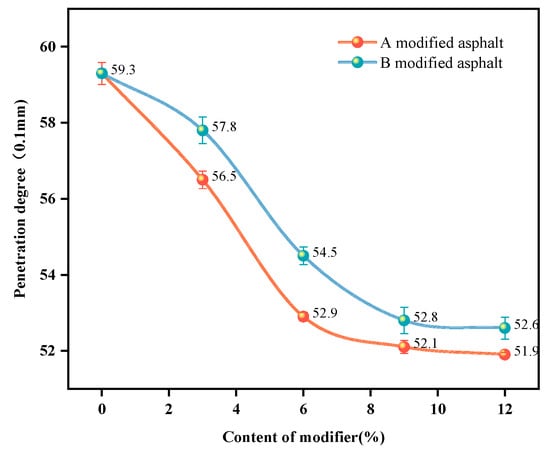

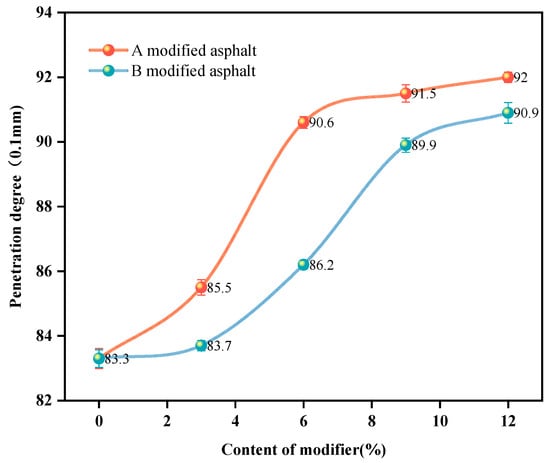

Figure 2.

Penetration test results.

From Figure 2, it was observed that the penetration of the two modified asphalts decreased with the increase in the content of the modifiers, indicating that both modifiers A and B improved the consistency of the asphalt. This improvement is attributed to the presence of a resin component in the modifiers, which increases the consistency of the asphalt and enhances its high-temperature performance. At the same modifier content, the penetration of the high-viscosity A-modified asphalt was lower than that of high-viscosity B-modified asphalt, suggesting that A-modified asphalt has greater hardness, higher consistency, and better resistance to deformation under external forces. The slopes of the penetration curves for both A- and B-modified asphalts were steepest in the content range of 0% to 9%, indicating a significant effect on asphalt consistency in this range. The slopes of the penetration curves for both modifiers gradually decreased from 9% to 12%, suggesting a limited effect on asphalt consistency in this range. Based on the penetration test data, both modifiers A and B performed well at a content of 9%.

2.4.2. Ductility Test and Result Analysis

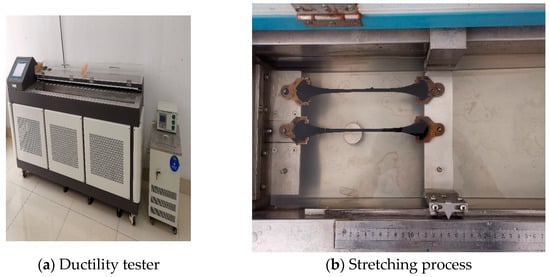

Ductility reflects the low-temperature ductility of asphalt [36]. The greater the ductility, the stronger the ability of asphalt to adapt to elastic-plastic deformation at low temperatures, and the better the pavement’s performance in resisting low-temperature cracking. In this study, the 5 °C ductility test was conducted with a tensile speed of 5 cm/min. The test procedure is illustrated in Figure 3, and the test results are presented in Figure 4.

Figure 3.

Ductility test.

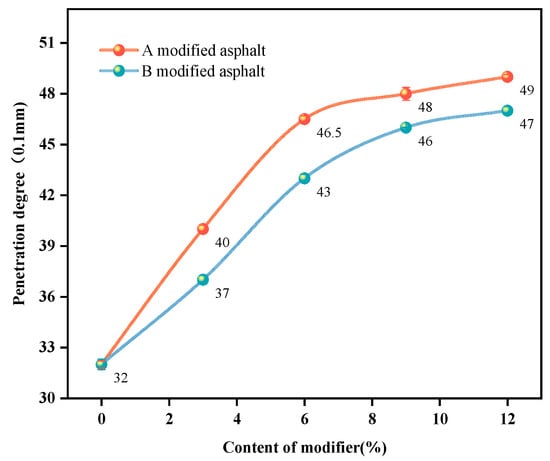

Figure 4.

Ductility test results.

As shown in the test results, the ductility of both modified asphalts increased with the increase in the dosage of high-viscosity modifiers A and B. This phenomenon is attributed to the presence of certain plasticizers and rubber components in modifier A, and a large amount of thermoplastic rubber in modifier B. Both components effectively improved the asphalt ductility. When the modifier content was the same, the ductility of A-modified asphalt was higher than that of B-modified asphalt, indicating that A-modified asphalt has better ductility and stronger low-temperature cracking resistance. When the content of modifiers A and B was between 0% and 9%, the slope of the ductility curve was steep, and the ductility increased rapidly. After 9%, the slope of the ductility curve flattened, and the rate of ductility increase slowed down. When the content of both modifiers was 9% of the asphalt mass, the low-temperature ductility of both modified asphalts reached 47 cm, indicating the best ductility performance at this dosage. Based on the 5 °C ductility test, the optimal content of modifiers A and B was determined to be 9%.

2.4.3. Softening Point Test and Analysis

The softening point characterizes the high-temperature performance of asphalt materials. The higher the softening point, the more resistant the asphalt is to distortion in high-temperature environments [37]. The test procedure is illustrated in Figure 5, and the test results are presented in Figure 6.

Figure 5.

Softening point test.

Figure 6.

Softening point test results.

From Figure 6, the softening point of both high-viscosity modified asphalts increased with the increase in modifier content. The softening point of both modified asphalts exceeded 80 °C as the modifier content increased. The high-temperature performance of the modified asphalt improved with increasing modifier content. At the same modifier content, the softening point of high-viscosity A-modified asphalt was higher than that of high-viscosity B-modified asphalt, indicating that A modifier improved the high-temperature performance of asphalt more significantly and was more effective in enhancing asphalt’s resistance to high-temperature deformation. When the content of modifier A was increased from 3% to 9%, the softening point of the modified asphalt increased by 7 °C. When the content of modifier B was increased from 3% to 9%, the softening point of the modified asphalt increased by 6 °C, indicating that both modifiers had a significant effect on the high-temperature performance of asphalt in this content range. At a modifier content of 9%, the softening points of both high-viscosity modified asphalts exceeded 90 °C, and A high-viscosity modified asphalt exhibited better high-temperature performance.

2.4.4. 60 °C Dynamic Viscosity

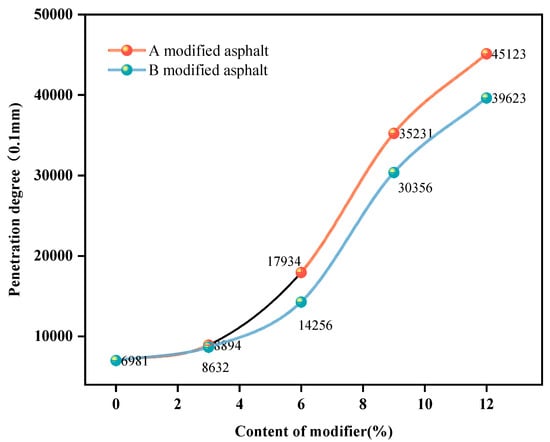

Viscosity reflects the rheological properties of asphalt, and temperature is an important factor affecting the viscosity index of asphalt. The 60 °C dynamic viscosity can also reflect the high-temperature deformation resistance of asphalt [38]. The test results are shown in Figure 7.

Figure 7.

60 °C dynamic viscosity test results.

From the data in Figure 7, the 60 °C dynamic viscosity of both modified asphalts increases with the increase in modifier content. Both modified asphalts had 60 °C dynamic viscosities less than 2 × 104 Pa·s when the modifier content was less than 9%. When the modifier content was higher than 3%, the slopes of the viscosity curves for both A- and B-modified high-viscosity asphalts increased significantly, indicating that the two modifiers enhance the rate of viscosity improvement. At a modifier content of 9%, the viscosity of the modified asphalts increased by more than five times compared to unmodified asphalt, indicating a significant enhancement in the cohesion of the modified asphalt.

In conclusion, based on the analysis of the test results, when the modifier content was 9% of the asphalt mass, the modifier had a significant improvement effect on the performance of the modified asphalt.

2.5. Research on the Optimum Type of High-Viscosity Modifier

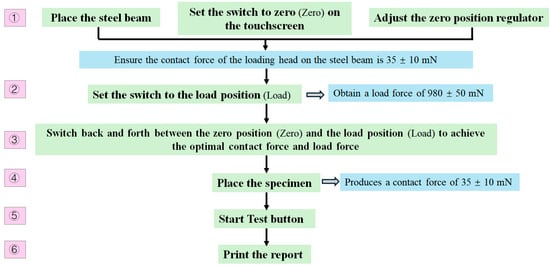

To determine whether both A and B high-viscosity modified asphalts meet the performance requirements for porous asphalt courses, this study investigated the rheological performance of two types of high-viscosity modified asphalt and normal SBS-modified asphalt using BBR. The test results were used to identify a high-viscosity modified asphalt suitable for actual project needs, aiding in engineering selection. BBR can measure the mechanical performance of asphalt materials at low temperatures. The test flowchart is shown in Figure 8.

Figure 8.

The operation flow chart of the bending beam rheometer.

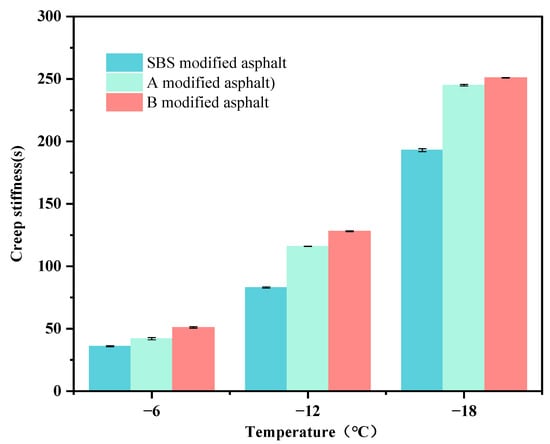

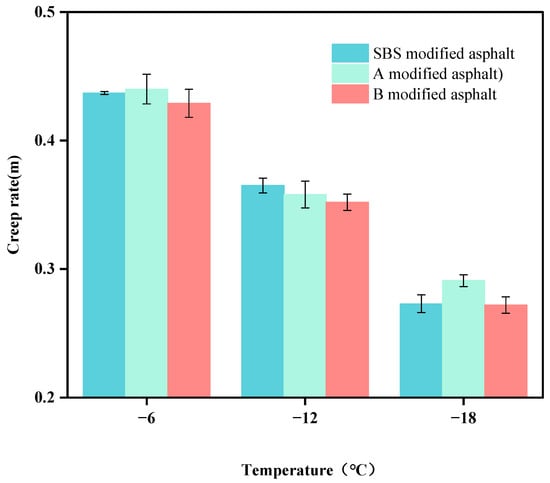

The asphalt was first subjected to RTFOT short-term aging, followed by PAV long-term aging. The aged asphalt was then placed into test molds with dimensions of 101.6 mm × 12.7 mm × 6.4 mm. After the asphalt was completely cooled, the creep strength (s) and creep rate (m) were measured at −6 °C, −12 °C, and −18 °C to characterize the low-temperature cracking resistance of the asphalt [39]. The test results are shown in Figure 9 and Figure 10.

Figure 9.

The change in creep strength S with temperature for high-viscosity modified asphalt.

Figure 10.

The change in creep rate m with temperature for high-viscosity modified asphalt.

From the test results in Figure 9 and Figure 10, the S values of the three asphalts showed an increasing trend, while the m values showed a decreasing trend as the temperature decreased. At temperatures ranging from −6 °C to −18 °C, the asphalt creep strength (S) and low-temperature fracture resistance were inversely proportional. At −6 °C and −12 °C, all three asphalt specimens had m ≥ 0.3, meeting the specifications. However, the creep rate of the three asphalt specimens was below 0.3 at −18 °C, indicating that the fracture-resistant properties of asphalt gradually weakened with decreasing temperature. When the test temperature was −12 °C, the S values were ordered as follows: A-modified asphalt < B-modified asphalt < SBS-modified asphalt. The m values were ordered as follows: SBS-modified asphalt > A-modified asphalt > B-modified asphalt. These results show that the incorporation of high-viscosity modifiers increased the strength of asphalt [40]. To provide a more intuitive analysis of the low-temperature performance of different asphalt materials, the creep rate and creep strength ratio (m/S) were introduced to evaluate the low-temperature performance of asphalt. A larger ratio indicates better low-temperature cracking performance [41]. At −12 °C, the m/S ratios were ordered as follows: A-modified asphalt > B-modified asphalt > SBS-modified asphalt. This indicates that the incorporation of the two high-viscosity modifiers enhanced the resistance of asphalt materials to temperature shrinkage cracking at low temperatures, with modifier A being more effective. Therefore, in this research, high-viscosity modifier A was used to prepare high-viscosity modified asphalt, and porous asphalt mixtures were designed using A-modified asphalt for mechanical performance research.

3. Research on Mechanical Performance of Porous Asphalt Mixture

The mechanical performance of porous asphalt mixtures is highly correlated with the mixture gradation design. Good gradation design can significantly improve the mechanical performance of the mixture and extend the service life of the pavement. This study focuses on the gradation design of porous asphalt mixtures using high viscosity modified asphalt A. The research evaluates the high-temperature stability, low-temperature crack resistance, water stability, and anti-fatigue performance of the porous asphalt mixtures to ensure they meet actual engineering requirements.

3.1. Raw Material and Mixture Design

3.1.1. Raw Material

- (1)

- Asphalt

For this study, the raw material for the high-viscosity modified asphalt was selected as SBS-modified asphalt (I-D). The technical specifications of the SBS-modified asphalt are provided in Table 2.

Table 2.

Technical index of SBS-modified asphalt.

- (2)

- Aggregate

The aggregate used in this study was selected as high-quality basalt crushed stone aggregate with the following specifications: 5–10 mm, 3–5 mm, and 0–3 mm. The specific indicators are provided in Table 3.

Table 3.

Properties of coarse aggregates.

- (3)

- Filler

The filler used in this study was mineral powder made from finely ground limestone. The specific indicators are provided in Table 4.

Table 4.

Properties of fillers.

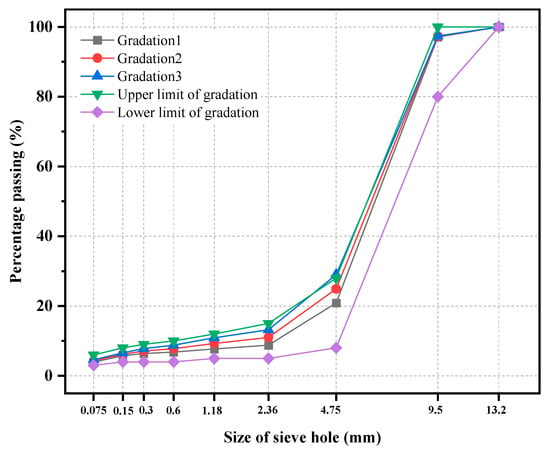

3.1.2. Porous Asphalt Mixture Design

The coarse and fine aggregates used in the test porous asphalt mixture were basalt, and the filler was finely ground mineral powder from limestone. The optimal asphalt content for the porous asphalt mixture was determined to be 5.06% using Marshall tests, raveling tests, and draindown tests. The grading curve of one of the porous asphalt mixtures is shown in Figure 11.

Figure 11.

Grading curve.

3.2. Research on Mechanical Performance of High-Viscosity Modified Asphalt Mixtures

This study used SBS-modified asphalt and high-viscosity modified asphalt to prepare two types of porous asphalt mixtures. The porous asphalt mixture prepared with high-viscosity modified asphalt was designated as 10-A, while the mixture prepared with SBS-modified asphalt was designated as 10-B. High-temperature rutting tests, low-temperature beam tests, freeze–thaw splitting tests, and two-point fatigue tests were conducted on both mixtures to verify whether the mechanical performance of the porous high-viscosity modified asphalt mixtures meets the engineering requirements.

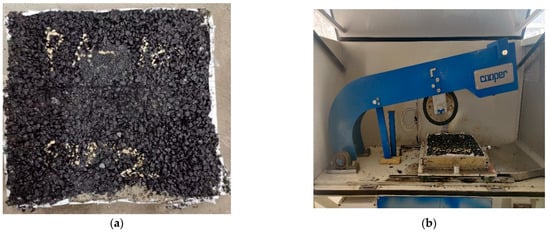

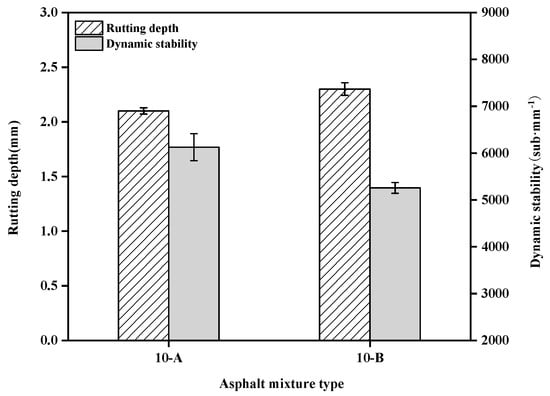

3.2.1. High Temperature Stability

According to the Chinese specification JTG E20-2011 (T0719), in a high-temperature environment, if the ability of the asphalt mixture to resist shear stress is lower than the shear stress generated by vehicle loads, the pavement will produce rutting deformation [42]. This study used a high-temperature rutting test to verify the high-temperature stability of porous asphalt mixtures. The high-temperature rutting test involves subjecting mixture specimens to repeated wheel rolling under specified temperature conditions and evaluating the high-temperature stability of the asphalt mixtures based on the depth of rutting and test time. The test procedure is shown in Figure 12, and the test results are shown in Figure 13. The specific test requirements are as follows:

Figure 12.

Porous asphalt mixture high temperature rutting test. (a) Porous asphalt mixture. (b) Rut tester.

Figure 13.

Porous asphalt mixture high temperature rutting test result.

- (1)

- Specimen Formation: The specimen size is 300 mm × 300 mm × 50 mm, prepared using an indoor rutting tester. The test begins 48 h after the specimen is formed and left to stand.

- (2)

- Test Process: Before starting the test, the specimen should be placed in a 60 °C heat preservation box for 6 h. Then, a small rutting test machine should be used to perform the rutting and crushing test. The test temperature is 60 °C, the rubber wheel crushing pressure is 0.7 MPa, the crushing speed is 42 times per minute, and the crushing time is 1 h.

- (3)

- Data Collection: The rut depth and dynamic stability indices are obtained from the deformation depth versus time curve at the end of the wheel rolling.

Excellent high-temperature rutting resistance is characterized by high dynamic stability and low rutting deformation depth. As shown in Figure 13, the dynamic stability of both 10-A and 10-B exceeded 5000 times/min, indicating that both mixes exhibit good high-temperature rutting resistance. Under the same mixture preparation process, 10-A demonstrated higher dynamic stability and lower rutting depth. This is because the modifier particles in 10-A melt and adhere to the aggregate surface at high temperatures, forming an adhesive film. This film enhances the adhesion between the aggregate and binder, thereby improving the deformation resistance of the mixture at high temperatures [43].

These findings suggest that the 10-A modifier particles may enhance rutting resistance via a high-temperature fusion mechanism, aligning with the results reported by Zhuang et al. (2017) [44,45]. However, unlike previous studies concluding that merely increasing the SBS content improves the high-temperature performance of asphalt mixtures, our research indicates that increasing the ratio of the modifier antioxidant to the resin could be a critical factor in achieving superior performance. Future investigations should aim to further validate this hypothesis and elucidate the underlying mechanisms.

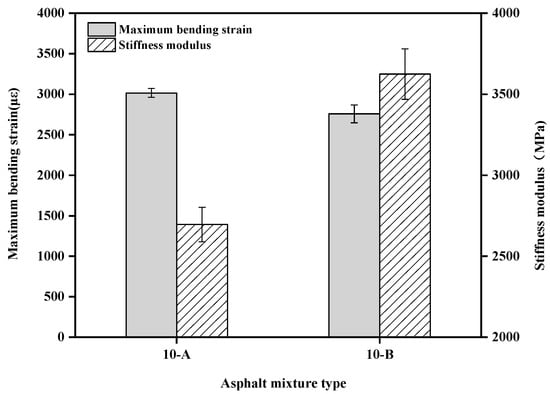

3.2.2. Low Temperature Cracking Resistance

According to the Chinese specification JTG E20-2011, in a low-temperature environment, when the temperature contraction stress in asphalt mixtures surpasses the resistance stress, the mixture is likely to experience low-temperature cracking damage [46]. This study employed a low-temperature beam bending test to evaluate the low-temperature performance of porous asphalt mixtures. Standard rutted plate specimens (300 mm × 300 mm × 50 mm) prepared through indoor rolling were cut into 250 mm × 35 mm × 30 mm standard beam specimens. The beam specimens were placed in a −10 °C thermostat for 5 h to ensure that the internal temperature of the specimens stabilized at the −10 °C test temperature. The bending test was conducted using a UTM-100 universal testing machine. A loading rate of 50 mm/min was applied at the mid-span position of the beam specimen until the specimen failed. The test procedure is illustrated in Figure 14, and the test results are presented in Figure 15.

Figure 14.

Porous asphalt mixture low temperature beam test.

Figure 15.

Porous asphalt mixture low temperature trabecular test results.

From Figure 15, the maximum bending and tensile strains of asphalt mixtures were found to be directly proportional to the low-temperature cracking resistance, while the stiffness modulus was inversely proportional to the low-temperature cracking resistance. The maximum bending and tensile strains of both mixtures exceeded 2500 με, indicating that both mixtures possessed good low-temperature cracking resistance. Mixture 10-A exhibited higher maximum bending and tensile strains and a lower stiffness modulus, suggesting that 10-A had a greater capacity to withstand deformation at low temperatures and demonstrated superior low-temperature performance. The results also indicated that the adhesion of high-viscosity modified asphalt to aggregate was superior to that of SBS-modified asphalt under low-temperature conditions and with the same mixture gradation. This finding is consistent with the study by Singhvi et al. (2019) [47], which indicated that the quantity of asphalt modifier can significantly influence the rheological properties of modified asphalt. However, our results also reveal that when the dosage of 10-A was increased to 15%, the high-temperature performance of the asphalt mixture was notably compromised, likely due to an increase in resin content leading to a reduction in the softening point of the asphalt material. This suggests that the optimal dosage of the modifier may depend on precise control according to service conditions. Furthermore, excessive use of modifiers may necessitate further investigation into their economic benefits and impacts on other road properties.

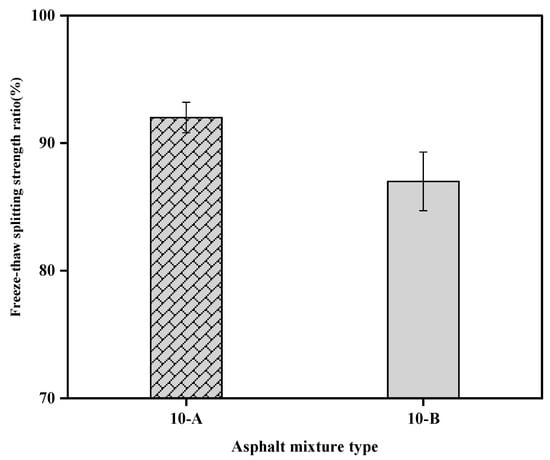

3.2.3. Water Stability

According to the Chinese specification JTG E20-2011, asphalt pavements with poor water stability are prone to water damage. This damage often takes the form of potholes and loose pavements. Therefore, improving the water stability of asphalt mixtures is particularly important [48]. In this study, the water stability of porous asphalt mixtures was evaluated using a freeze–thaw splitting test. The front and back sides were compacted 50 times each to form two groups of Marshall specimens. One group of specimens was placed in a refrigerator at −18 °C for 16 h after vacuum soaking. The other group was kept at room temperature as a control group. After freezing, the specimens from the frozen group were immersed in a 60 °C constant temperature water tank for 24 h. Subsequently, both groups of specimens were placed together in a 25 °C constant temperature water tank for 2 h. The tests were conducted using a loading rate of 50 mm/min. The test results are presented in Figure 16.

Figure 16.

Freeze–thaw splitting test results of porous asphalt mixture.

From Figure 16, the freeze–thaw splitting strength ratios of both 10-A and 10-B were higher than 85%. However, the freeze–thaw splitting strength ratio of 10-A was higher than that of 10-B, indicating that the water stability performance of 10-A was superior. Porous asphalt mixtures have a skeleton void structure. During freeze–thaw cycles, a larger void ratio can affect the internal mechanical behavior of the mixture. The incorporation of high-viscosity modifier A improves the adhesion between the binder and aggregate. Additionally, the addition of high-viscosity modifier A reduces the spalling effect on asphalt during freeze–thaw cycles, thereby enhancing water stability [49]. A high dosage of SBS and co-solvent in the modifier can adversely affect the high-temperature stability and water stability of asphalt mixtures, a trend observed in similar studies (Yu et al., 2017 [50]). This suggests that increasing the content of co-solvent may promote the exposure of hydrophobic groups within the modifier, particularly after experiencing high and low temperature cycles. The aforementioned phenomenon is notably evident. The underlying mechanism can be further corroborated by the research conducted by Guo et al. [51].

3.2.4. Fatigue Resistance

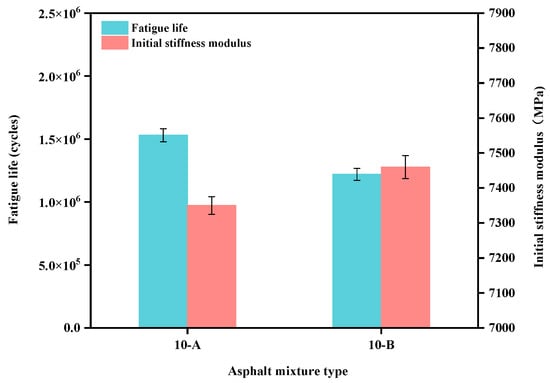

According to the Chinese specification JTG E20-2011, in the actual use of asphalt mixtures, repeated exposure to ambient temperature and vehicle loads can cause internal cracking within the mixture, leading to pavement fatigue cracking [52]. This study adopted a two-point fatigue test to investigate the fatigue performance of porous asphalt mixtures. The test results are presented in Figure 17.

Figure 17.

Two-point fatigue test results.

From Figure 17, the fatigue lifetimes of porous asphalt mixtures were 10-A > 10-B in a descending order. Because of the large void ratio of porous and the amount of asphalt used, excellent asphalt properties could reduce internal cracking in the mixtures. In addition, at the joints of aggregate particles, the high-viscosity modified bitumen could exert greater adhesion to bond the coarse aggregate as a single unit, resulting in the excellent fatigue resistance of 10-A [53]. Tafti et al. observed that the production of stabilizers and antioxidants in modifiers could be significantly influenced by their respective dosages [54]. This finding aligns with previous research by Pilati et al. [55], which indicated that a high dosage of stabilizers coupled with a low dosage of antioxidants might reduce asphalt fluidity, thereby increasing the risk of aging. However, this study did not clarify the causal relationship between antioxidant content and aging resistance, an issue that warrants further exploration through long-term longitudinal studies.

It is also important to note that the effect of stabilizer content in modifiers may depend on the type and concentration of the stabilizer used. Future investigations should take into account the diversity of stabilizers, including tin-based stabilizers, co-stabilizers, and heat stabilizers.

4. Research on Skid Resistance of Porous Asphalt Mixtures

Porous asphalt mixtures are often used as the top layer of roads. During actual use, they come into direct contact with vehicle tires and, therefore, the mixture should have good surface anti-skid properties [56]. In the actual use of porous asphalt mixtures, the cumulative effect of vehicle loads leads to continuous abrasion and impact between vehicle tires and the asphalt pavement. The asphalt film on the surface of the aggregate can peel off due to the repeated rolling action of the wheels. Under the repeated crushing action of the wheels, the asphalt film on the aggregate surface can shed and polish, leading to changes in the micro-texture and macro-structure of the asphalt pavement. These changes result in a decrease in skid resistance performance, thereby reducing traffic safety [57].

4.1. Anti-Skid Performance Test and Evaluation Method

- (1)

- Friction Coefficient Measurement Method

The British pendulum tester can measure the coefficient of friction of asphalt pavement under wet conditions. It is easy to operate and portable. The British pendulum tester is shown in Figure 18. First, the tester was placed on top of a large, rutted plate specimen molded in the chamber. The tester was then zeroed to ensure that the pointer returned to the zero point after the pendulum was released. Next, the sliding length was calibrated to ensure it was 126 mm. The coefficient of friction is obtained by spraying water at the measurement point and releasing the pendulum, which slides over the road surface.

Figure 18.

British pendulum tester.

- (2)

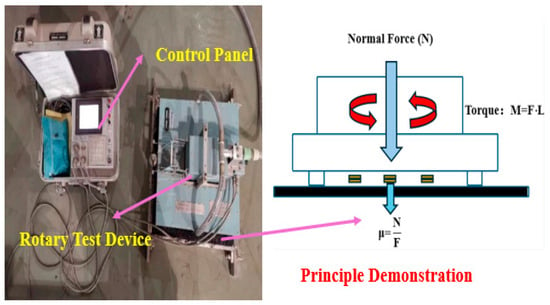

- Dynamic Friction Coefficient Measurement

The British pendulum tester can only determine the coefficient of friction of a road surface at low speeds of 20 km/h. To investigate the dynamic friction coefficient of porous asphalt mixtures at high speeds, this study adopted a dynamic friction coefficient tester (DFT) to measure the dynamic friction coefficient of porous asphalt mixtures over the speed range of 0–80 km/h [58]. The DFT is shown in Figure 19. The DFT consists of a freely rotating small disk positioned below the main rotating disk, with three rubber sliders mounted on the small disk. The disk rotates until the rubber sliders reach a linear speed of 80 km/h, at which point the disk is released onto the road surface. The disk continues to rotate until it comes to a stop due to the friction with the road surface. During this process, sensors record the friction between the rubber sliders and the road surface, and a curve of the coefficient of friction versus speed is generated.

Figure 19.

Dynamic friction tester.

- (3)

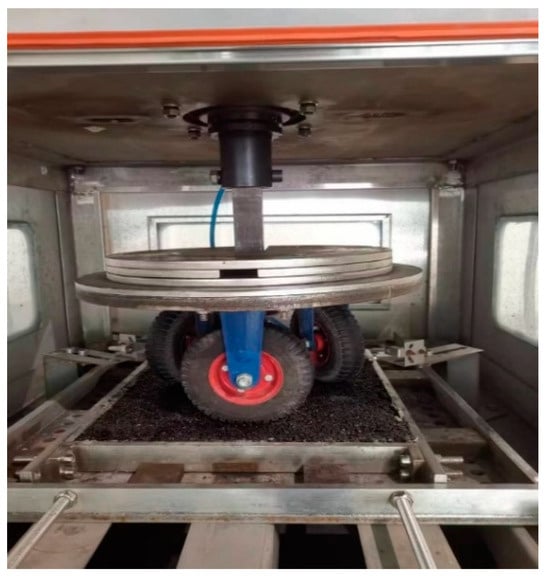

- Indoor accelerated wear test

The accelerated wear tester, designed based on the wheel-road friction principle, consists of the following modules: drive system, control system, and wheelset loading system. The specimens are 50 cm × 50 cm × 5 cm large, rutted plate specimens. Place the specimen under the abrasive wheels, ensuring that all three abrasive wheels are in contact with the surface of the specimen. Spray water on the surface of the specimen to maintain a moist condition. Activate the accelerated abrasion tester, setting the test abrasion speed to 100 r/min. The specimen is abraded for 8 h, and the changes in the friction coefficient and dynamic friction coefficient are measured at 1 h intervals. The accelerated abrasion tester is shown in Figure 20 and Figure 21.

Figure 20.

Accelerated wear tester.

Figure 21.

Accelerated wear test process.

4.2. Research on the Slip Degradation Law of High-Viscosity Porous Asphalt Mixture Based on Indoor Accelerated Wear Tests

4.2.1. Research on the Initial Value of Slip Resistance

- (1)

- Friction coefficient of pendulum value

The pendulum coefficient of friction was determined for both mixes 10 A and 10 B, and the test results are shown in Table 5.

Table 5.

Porous asphalt mixtures pendulum value test results.

- (2)

- Dynamic friction coefficient

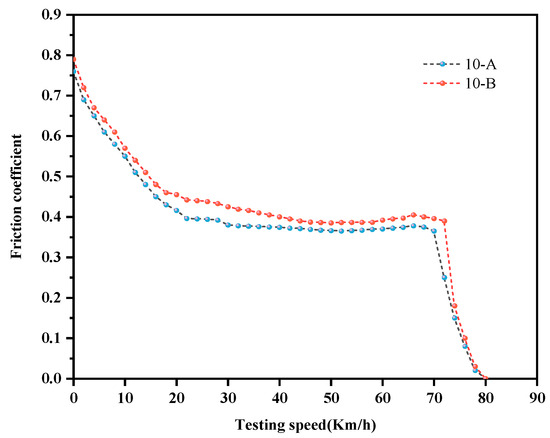

DFT tests were conducted on both mixtures, and the coefficient of friction versus velocity curves were obtained, as shown in Figure 22.

Figure 22.

Dynamic friction coefficient and speed variation curve.

From Figure 22, the friction coefficients of both mixes showed a decreasing trend with increasing test speed. The frictional resistance between the surface of the porous asphalt mixtures and the tires decreased as the driving speed increased. This is because when the vehicle is stationary, the tire deformation can fit into the road gaps, increasing the friction force between the tire and the road surface. As the speed increases, the effective contact area decreases, resulting in a reduction in friction force. Over the speed range of between 0 km/h and 80 km/h, the friction coefficient curve of 10-A remained above that of 10-B, indicating that 10-A had a higher coefficient of friction and better anti-slip performance. This is attributed to the greater surface roughness of 10-A, which provides higher surface friction resistance.

4.2.2. Research on Skidding Decay Pattern of Porous Asphalt Mixtures

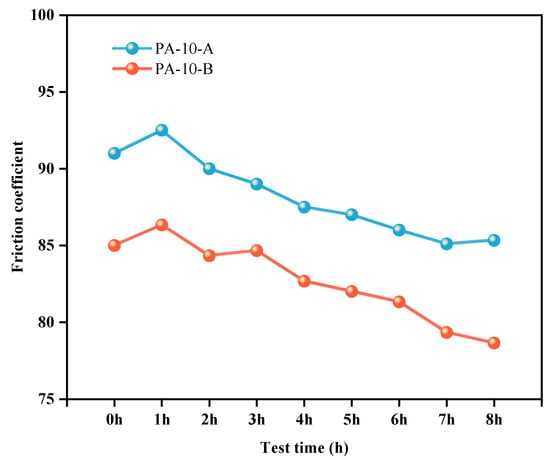

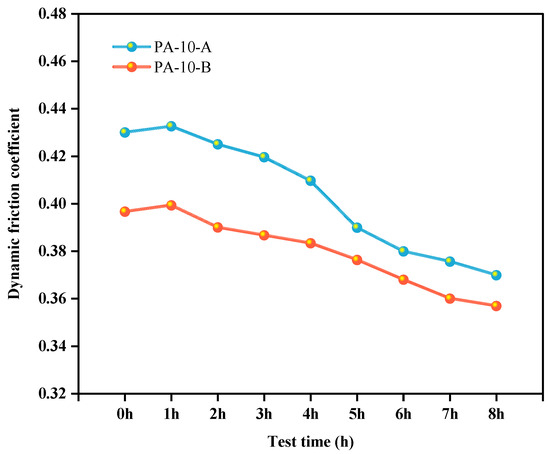

Accelerated wear tests were conducted on both mixtures, and the variations in the coefficient of friction and the dynamic coefficient of friction (DF60) at a speed of 60 km/h with respect to wear time were measured. The test results are shown in Figure 23 and Figure 24.

Figure 23.

Pendulum value friction coefficient with accelerated wear time.

Figure 24.

Dynamic friction coefficient with accelerated wear time.

As shown in Figure 23 and Figure 24, the coefficients of friction and dynamic friction coefficients of both mixtures exhibited an initial increase followed by a decrease as the test time increased. The friction coefficients and dynamic friction coefficients of 10-A and 10-B began to decrease after 1 h of wear (approximately 6000–10,000 wear cycles). During the wear process, the asphalt film on the surface of the mixture specimens deteriorates due to the cumulative load, exposing sharp stones and causing the surface structure to become rough, which initially increases the friction coefficient. As the number of wear cycles increases, the exposed aggregates on the surface are gradually abraded, leading to a gradual decrease in the friction coefficient [59]. Despite this, the pendulum friction coefficients of both mixtures remained above 75 after 8 h of wear, indicating that the skid resistance of both mixtures degraded minimally during short-term pavement service.

In this study, it was observed that reducing the SBS content resulted in decreased high-temperature stability and low-temperature ductility of the asphalt, which in turn affected the macrotexture stability of the pavement. This finding is consistent with Gong et al.’s (2021) observations in similar materials [60,61]. Pavement skid resistance is primarily generated by friction between tires and the pavement surface. As the SBS content decreases, the resin content increases, potentially allowing the asphalt coating on the aggregate surface to bond more firmly with both SBS and resin, thus exhibiting improved overall skid resistance. However, it is important to note that altering the gradation can lead to coarse aggregates embedding into a stable skeleton structure, with voids being filled by high-viscoelastic modified asphalt. The cutting effect of micro-protrusions on the aggregate surface may be limited under these conditions, potentially leading to changes in initial anti-skid properties. Therefore, future research should further investigate how different gradation types and the resin content in modifiers affect the anti-skid performance of asphalt pavements within their overall service environment.

5. Conclusions

This study developed a high-performance 10-A viscoelastic asphalt modifier through molecular engineering of conventional SBS-modified asphalt, establishing an optimized formulation with enhanced preparation parameters. Three key technological breakthroughs were systematically demonstrated:

- (1)

- The novel preparation protocol enables precise control over viscoelastic balance, with modifier content demonstrating a critical threshold effect. At 9% dosage, the modified asphalt achieves optimal engineering performance, showing 16.6% and 9.3% simultaneous improvement in high-/low-temperature indices compared to 10-B asphalt mixture.

- (2)

- The redesigned modifier architecture enhances rutting resistance and water stability through strategic antioxidant–resin ratio optimization. This breakthrough resolves the traditional trade-off between fatigue resistance and thermal stability.

- (3)

- Friction dynamics analysis reveals that the PA-10 mixture’s unique stabilizer-antioxidant synergy enables speed-adaptive friction characteristics, maintaining BPN > 85 even after 8 h abrasion cycles. This provides a theoretical foundation for smart pavement design in extreme climates.

This study’s limitations include unvalidated long-term aging performance beyond 5-year service and pending economic feasibility analysis. Future work should focus on life-cycle cost modeling and multi-scale performance prediction frameworks. Industrial-scale production trials are recommended to verify field applicability.

Author Contributions

W.C.: Writing—original draft, Z.Z. and W.C.: Data curation. W.W., C.G. and Z.Z.: Methodology. J.W., Y.S., W.W. and X.Z.: Project administration. J.W., Y.S. and X.Z.: Investigation. J.W.: Supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Shandong Provincial Transport Department—Research on Key Technologies for Testing and Evaluation of Accelerated Abrasion of Road Surface Functions [grant numbers 2020-MS1-047]; the Science and Technology Plan of Shandong Transportation Department [grant number 2020B28].

Institutional Review Board Statement

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to thank the Shandong Transportation Research Institute for their support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Chen, W.; Wei, K.S.; Wei, J.C.; Han, W.Y.; Zhang, X.M.; Hu, G.L.; Wei, S.S.; Niu, L.; Chen, K.; Fu, Z.; et al. Research on the Road Performance of Asphalt Mixtures Based on Infrared Thermography. Materials 2022, 15, 4309. [Google Scholar] [CrossRef]

- Liu, S.J.; You, Q.L. Mechanical Response of Asphalt Pavement under Overloading. Appl. Mech. Mater. 2013, 361–363, 1869–1872. [Google Scholar] [CrossRef]

- Qin, C.L.; Liu, C.Q. Analysis of Characters of Traffic Accidents Based on Road Factors. Technol. Econ. Areas Commun. 2010, 12, 14–17. [Google Scholar]

- Izuo, H.; Nabeshima, M.; Yasuhisa, K.; Kishira, R.; Ueno, A. Evaluation Method of Road Surface Texture Related to Skid Resistance of Concrete Pavement. J. Jpn. Soc. Civ. Eng. Ser. E1 (Pavement Eng.) 2021, 77, I_145–I_153. [Google Scholar] [CrossRef] [PubMed]

- Jun, L.; Ge, W.; Mingliang, L.; Yue, Z.; Shi, F.; Dingding, H. Mixture Performance Analysis and Engineering Application of High Strength and Toughness Wearing Course STC-8. In Proceedings of the 13th International Conference on Road and Airfield Pavement Technology (ICPT), Beijing, China, 6–8 July 2023; pp. 429–438. [Google Scholar]

- Li, W.B.; Zheng, M.L.; Ning, Z.; Zhang, W.W.; Ding, X.Y. The design and performance evaluation of low-noise rubber-fibre micro-surfacing pavement. Int. J. Pavement Eng. 2024, 25, 2414056. [Google Scholar] [CrossRef]

- Chang, J.; Li, J.; Yang, H.; Wang, Y.D.; Hu, H.W. Optimizing epoxy asphalt tack coat formulations for improved adhesion and working performance of ultrathin wearing course. J. Adhes. Sci. Technol. 2024, 1–26. [Google Scholar] [CrossRef]

- Ziaei-Rad, V.; Nouri, N.; Ziaei-Rad, S.; Abtahi, M. A numerical study on mechanical performance of asphalt mixture using a meso-scale finite element model. Finite Elem. Anal. Des. 2012, 57, 81–91. [Google Scholar] [CrossRef]

- Geng, J.G.; Chang, Q.; Yuan, J.A.; Dai, J.L. Study on SBS Modified Asphalt Crosslink Structure and Its Stabilization by GPC. J. Zhengzhou Univ. (Eng. Sci.) 2008, 29, 14–17. [Google Scholar]

- Shi, C.; Wu, Y.; Wang, T.; Yu, Y.; Wang, H.; Yang, J. Rheological properties and polymer phase structure characterization of SBS/CR composite modified asphalt (CMA) binders. Mater. Struct. 2023, 56, 33. [Google Scholar] [CrossRef]

- De Maio, U.; Gaetano, D.; Greco, F.; Luciano, R.; Pranno, A. Degradation analysis of dynamic properties for plain concrete structures under mixed-mode fracture conditions via an improved cohesive crack approach. Fract. Struct. Integr. 2024, 18, 422–439. [Google Scholar] [CrossRef]

- Yao, H.; Wang, T.; Wang, Q.; Cao, Y.; Zhou, X. Applicability of Standard Rheological Evaluation Methods for High Content SBS Polymer Modified Asphalts. Buildings 2023, 13, 1156. [Google Scholar] [CrossRef]

- Kandhal, P. New generation open-graded asphalt friction courses. Public Work 2001, 132, 18–21. [Google Scholar]

- Molenaar, J.M.M.; Hagos, E.T.; Ven De Ven, M.F.C. An Investigation into the Specification of Rheological Properties of Polymer Modified Bitumen. In Proceedings of the 3rd Eurasphalt and Eurobitume Congress, Vienna, Austria, 12–14 May 2004. [Google Scholar]

- Kmetz, M.; Timm, D.; Rodezno, C.; Tran, N.; Yin, F. Laboratory Characterization of Additive-Modified Asphalt Concrete Mixtures. Transp. Res. Rec. 2024, 2678, 1119–1130. [Google Scholar]

- Vinogradov, G.V.; Dreval, V.E.; Malkin, A.Y.; Yanovsky, Y.G.; Barancheeva, V.V.; Borisenkova, E.K.; Zabugina, M.P.; Plotnikova, E.P.; Sabsai, O.Y. Viscoelastic properties of butadiene-styrene block copolymers. Rheol. Acta 1978, 17, 258–263. [Google Scholar]

- Du, M.A.; Yu, Q.M.; Lu, Y.; Zheng, Q.A. Viscoelastic Relaxation of Styrene-Butadiene-Styrene Block Copolymers with Different Topological Structures. J. Appl. Polym. Sci. 2011, 120, 2962–2970. [Google Scholar] [CrossRef]

- Li, K.; Ma, H.; Xie, J.; Li, S.; Pan, Y.; Zhang, Z.; Guan, Y. Compatibility Assessment of High-viscosity Additive and SBS-modified Asphalt. J. Phys. Conf. Ser. 2024, 2920, 012004. [Google Scholar]

- Islam, S.S.; Singh, S.K.; Ransinchung R.N., G.D.; Ravindranath, S.S. Performance Degradation during Elevated Storage Temperature of SBS-Modified Binders and Asphalt Mixes: Impact of SBS Molecular Structure. J. Mater. Civ. Eng. 2023, 35, 04022457. [Google Scholar]

- Zhang, F.; Hu, C. The research for thermal behaviour, creep properties and morphology of SBS-modified asphalt. J. Therm. Anal. Calorim. 2015, 121, 651–661. [Google Scholar]

- Dong, F.; Lu, J.; Yu, X.; Yang, P.; Jin, Y.; Wan, L.; Ding, Y.; Chen, H. Insight into the diffusion behaviors of SBS-compatibilizer-coupled modified asphalt: Molecular dynamics simulation and experimental validation. J. Vinyl Addit. Technol. 2024, 30, 15. [Google Scholar]

- Xu, B.; Chen, J.; Li, M.; Cao, D.; Ping, S.; Zhang, Y.; Wang, W. Experimental investigation of preventive maintenance materials of porous asphalt mixture based on high viscosity modified bitumen. Constr. Build. Mater. 2016, 124, 681–689. [Google Scholar]

- Bulatovic, V.O.; Rek, V.; Markovic, K.J. Effect of polymer modifiers on the properties of bitumen. J. Elastomers Plast. 2014, 46, 448–469. [Google Scholar] [CrossRef]

- Zhong, K.; Cao, D.W.; Luo, S. Determination the Modifier Content in SBS Modified Asphalt Based on Infrared Spectroscopy Technique. Appl. Mech. Mater. 2010, 34–35, 1129–1134. [Google Scholar]

- Sukhanov, A.S.; Kolosov, A.D.; Kondrat’Ev, V.V.; Kononenko, R.V. Technology for the production of modifying additives for concrete and asphalt concrete. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1159, 012047. [Google Scholar]

- Baghaee Moghaddam, T.; Soltani, M.; Karim, M.R.; Baaj, H. Optimization of asphalt and modifier contents for polyethylene terephthalate modified asphalt mixtures using response surface methodology. Measurement 2015, 74, 159–169. [Google Scholar]

- Wang, Y.L.; Yi, H.Y.; Cui, Y.; Li, S.J.; Zhou, S.X.; Yan, C.Q. Research on the Preparation Process of SBS-Modified Asphalt Using Early Shearing Instead of High-Speed Shearing of Modifier. Appl. Sci. 2023, 13, 10335. [Google Scholar] [CrossRef]

- Izumoto, R. Asphalt Modifier, and Method of Producing Modified Asphalt and Paving Material. U.S. Patent Application No. 09/888,409, 15 August 2002. [Google Scholar]

- Zhi-Lin, S.; Xiao-Ming, H.; Rui, Z.; Yan, W. Study on Effect of Asphalt Modifier on Asphalt Mixtures Fatigue Performance. J. Highw. Transp. Res. Dev. 2008, 4, 33–36. [Google Scholar]

- Gorbaty, M.L.; Peiffer, D.G.; Mchugh, D.J. Polymer-Modified, Functionalized Asphalt Compositions and Methods of Preparation (C-2747). U.S. Patent 5,348,994, 5 March 2012. [Google Scholar]

- Weiyu, F.; Xue, X.; Ming, L.; Yan, Y.; Fuqiang, D.; Guozhi, N. Comparative study on the rheological properties and storage stability of modified bitumen prepared by different modifiers. Zhongguo Shiyou Daxue Xuebao (Ziran Kexue Ban)/J. China Univ. Pet. (Ed. Nat. Sci.) 2015, 39, 165–170. [Google Scholar]

- Zhao, P.; Song, X.; Dong, M.; Sun, H.; Wu, W.; Zhang, R.; Sun, M.; Zhao, X. Preparation and characterization of CQDs/SBS composites and its application performance as asphalt modifier. Constr. Build. Mater. 2022, 320, 126312. [Google Scholar]

- Ahmed, M.B.; Abed, A.H.; Al-Badran, Y.M.H. Enhancement of porous asphalt mixture for resisting environmental conditions using modified asphalt. IOP Conf. Ser. Mater. Sci. Eng. 2020, 737, 012118. [Google Scholar]

- Hao, P.W. Study on compatibility between SBS modifier and asphalt. Pet Process Petrochem 2001, 32, 54–56. [Google Scholar]

- Yu, X. Reasonable Dosage of Modifiers for Modified Asphalt Pavement of Ji-Mu Freeway. J. Northeast For. Univ. 2006, 34, 118–119. [Google Scholar]

- Sun, D.Q.; Lu, W.M. Evaluation of low temperature performances of polymer modified asphalts by force-ductility test. J. Build. Mater. 2007, 10, 37–42. [Google Scholar]

- Algurah, E.R.; Alghurabi, S.J.; Alhumeidawi, B.H. Laboratory evaluation of properties of modified asphalt binder with different types of additives. IOP Conf. Ser. Earth Environ. Sci. 2023, 1232, 012043. [Google Scholar] [CrossRef]

- Babagoli, R.; Jalali, F.; Khabooshani, M. Performance properties of WMA modified binders and asphalt mixtures containing PPA/SBR polymer blends. J. Thermoplast. Compos. Mater. 2023, 36, 274–306. [Google Scholar] [CrossRef]

- Bahia, H.U.; Anderson, D.A. The Development of the Bending Beam Rheometer; Basics and Critical Evaluation of the Rheometer. In Physical Properties of Asphalt Cement Binders; ASTM International: West Conshohocken, PA, USA, 1995. [Google Scholar]

- Guo, Y.; Ji, G.; Wang, X.; Tian, B.; Zhang, Y. Physico-chemical and mechanical properties of asphalt binders blended with waste bio-shell powder. Int. J. Pavement Eng. 2023, 24, 2211213. [Google Scholar] [CrossRef]

- Aurilio, M.; Tavassoti, P.; Elwardany, M. Characterization of styrene-butadiene-styrene (SBS)-modified asphalt binders using the bending beam rheometer and the asphalt binder cracking device. Can. J. Civ. Eng. 2023, 50, 681–687. [Google Scholar] [CrossRef]

- Syukri, M.; Juandana, H.; Kusdian, D.; Garnida, H.; Pratiwi, A.A.R. Analysis of Pavement Conditions and Handling of Road Damage at the Surface Layer. IOP Conf. Ser. Earth Environ. Sci. 2024, 1321, 012032. [Google Scholar] [CrossRef]

- Praveen, K.P.; Kiran, K.B.V.; Manjunatha, S.G.P.B. An Experimental Investigation on the Rutting Performance of the Polymer Modified Bituminous (PMB) Mixes. Civ. Eng. Archit. 2024, 12, 1260–1268. [Google Scholar]

- Wu, B.; Luo, C.; Pei, Z.; Xia, J.; Kang, A. Effect of Different Polymer Modifiers on the Long-Term Rutting and Cracking Resistance of Asphalt Mixtures. Materials 2021, 14, 3359. [Google Scholar] [CrossRef]

- Zhuang, C.; Li, N.; Zhao, W.; Cai, C. Effects of SBS Content on the Performance of Modified Asphalt. IOP Conf. Ser. Mater. Sci. Eng. 2017, 216, 012028. [Google Scholar] [CrossRef]

- Chen, H.X.; Zhang, H.L.; Jiang, Y.; Li, S. Low-temperature properties of aged asphalt mixtures. J. Chang. Univ. (Nat. Sci. Ed.) 2010, 30, 1–5. [Google Scholar]

- Singhvi, P.; Karakas, A.; Ozer, H.; Al-Qadi, I.L.; Hossain, K. Impact of Asphalt Modifier Dosage on Modified Binder Rheology and Chemistry with Long-Term Aging. In Proceedings of the International Airfield and Highway Pavements Conference 2019, Chicago, IL, USA, 21–24 July 2019. [Google Scholar]

- Sun, Z.H.; Yang, G.F.; Wang, T.B.; Wang, Z.S. Research on Evaluation Index of Water Stability for Asphalt Mixtures. Adv. Mater. Res. 2013, 634–638, 2724–2728. [Google Scholar]

- Manoj, K.G. System Identification Framework for Modeling of Static Creep and Dynamic Creep Behavior of Dense-Graded Asphalt Mixtures. Transp. Res. Rec. 2024, 2678, 776–789. [Google Scholar] [CrossRef]

- Ren, S.S.; Liu, X.Y.; Jing, R.X.; Gao, Y.M.; Lin, P.; Erkens, S. Investigating the rheological properties and compatibility behaviours of RET/PE and WR/CR/SBS compound-modified bitumen. Road Mater. Pavement Des. 2024, 25, 653–677. [Google Scholar] [CrossRef]

- Meng, G.; Yiqiu, T. Effects of Various Modifiers on Rheological Property of Asphalt. In Multi-Scale Modeling and Characterization of Infrastructure Materials: Proceedings of the International RILEM Symposium, Stockholm, Sweden, 10–12 June 2013; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Yazdipanah, F.; Ameri, M.; Shahri, M.; Hasheminejad, N.; Haghshenas, H. Laboratory investigation and statistical analysis of the rutting and fatigue resistance of asphalt mixtures containing crumb-rubber and wax-based warm mix asphalt additive. Constr. Build. Mater. 2021, 309, 125165. [Google Scholar]

- Nuñez, J.Y.M.; Leonel, E.D.; Faxina, A.L. Fatigue characteristics of modified asphalt binders using fracture mechanics. Eng. Fract. Mech. 2016, 154, 1–11. [Google Scholar]

- Tafti, M.F.; Aqda, S.A.H.; Motamedi, H. The impacts of type and proportion of five different asphalt modifiers on the low-temperature fracture toughness and fracture energy of modified HMA. Fract. Struct. Integr. 2019, 13, 169–185. [Google Scholar] [CrossRef]

- Pilati, F.; Furlan, A.P.; Faxina, A.; Fabbri, G.; Sória, M.; Gigante, A. Effects of Some Modifiers on Moisture Susceptibility of Dense Graded Asphalt Mixtures. In Proceedings of the Sixth International Conference on Maintenance and Rehabilitation of Pavements and Technological Control (MAIREPAV6), Turin, Italy, 8–10 July 2009. [Google Scholar]

- Xiao-Ming, H.; Bin-Shuang, Z.; Transportation, S.O.; University, S. Research Status and Progress for Skid Resistance Performance of Asphalt Pavements. China J. Highw. Transp. 2019, 4, 32–49. [Google Scholar]

- Croney, D.; Croney, P. The Design and Performance of Road Pavements; McGraw-Hill: New York, NY, USA, 1977. [Google Scholar]

- Schmitz, T.L.; Action, J.E.; Ziegert, J.C.; Sawyer, W.G. Dynamic Friction Coefficient Measurements: Device and Uncertainty Analysis. In Proceedings of the 18th American Society of Precision Engineers, Annual Meeting, Portland, OR, USA, 26–31 October 2003. [Google Scholar]

- Liu, J.; Guan, B.; Chen, H.; Liu, K.; Xiong, R.; Xie, C. Dynamic Model of Polished Stone Value Attenuation in Coarse Aggregate. Materials 2020, 13, 1875. [Google Scholar] [CrossRef]

- Gong, Y.; Pang, Y.; Li, F.; Ma, Y. Analysis of the Influence of SBS Content and Structure on the Performance of SBS/CR Composite Modified Asphalt. Adv. Mater. Sci. Eng. 2021, 2021, 5585891. [Google Scholar]

- Zhu, S.; Ji, X.; Zhang, Z.; Shao, D.; Li, H.; Yun, C. Evolution characteristics of the surface texture of the wearing course on asphalt pavement based on accelerated pavement polishing. Constr. Build. Mater. 2022, 333, 127266. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).