Abstract

The main aim of this research is to investigate the possibilities and challenges involved in the electric arc welding of solid-state-recycled EN AW 6082 aluminum alloy. Lately, solid-state recycling has gained increased attention as a more sustainable and efficient aluminum recycling method, whereby only about 30% of the energy of conventional recycling is used. This method is based on the deformation of small-sized metal waste into solid recycled specimens without a remelting step. For the welding of solid-state-recycled specimens, both metal inert gas welding and tungsten inert gas welding methods are used. To evaluate the weldability of solid-state-recycled material, welded specimens are compared with welded, commercially produced EN AW 6082 aluminum alloy sheets. The welding is performed using the same processes, parameters, and conditions. To evaluate the welding potential of solid-state-recycled alloy, tensile tests, microhardness tests, optical metallography, and scanning electron microscopy, accompanied by energy-dispersive spectroscopy analysis, are performed.

1. Introduction

Aluminum recycling is increasingly essential due to its environmental, economic, and industrial benefits. With the demand for aluminum expected to continue growing, recycling plays a crucial role in meeting this demand sustainably and efficiently. Here are several reasons why aluminum recycling is vital now and will remain so in the future: Recycling aluminum saves up to 95% of the energy required to produce it from raw bauxite ore. The primary aluminum production process is a high-energy consumption process that uses about 160 GJ per ton. However, secondary aluminum production processes use only about 10–15 GJ per ton, depending on the waste type [1]. Demand for aluminum is increasing, especially in the automotive, electronics, aerospace, and packaging industries, which are also seeking to enhance their sustainability. Because of the increased demand for aluminum alloys, as well as the overall concern due to climate change, there is increased interest in and necessity of innovative and more efficient aluminum recycling methods. One method that is gaining attention is solid-state recycling (SSR) [2,3,4,5,6,7]. This approach typically involves the mechanical processing and consolidation of metal scrap, whereby small-sized aluminum waste is compacted by deformation, usually at elevated temperatures, without completely melting the material, which has significant environmental and economic advantages. The conventional recycling of aluminum alloy machining waste is problematic due to the fact that aluminum is a highly reactive material, and it tends to form aluminum oxide on its surface. This is even more pronounced for lightweight aluminum scrap due to its high surface-to-mass ratio. During the remelting process, this oxide floats on the melting surface mixed with dross. Therefore, aluminum lightweight scrap (chips, foils, and sheet skeletons) is problematic when conventional recycling technology is used, because up to 20% of the aluminum can be lost by the mixing with dross and burning [8]. Therefore, during the conventional recycling process by melting, there is a significant loss of material due to the oxidation of melted metal, but there are also losses due to the inclusion of slags, as well as during the casting and material processing, where the final material yield can be as low as 60% [9,10,11]. According to previous research papers concerned with the SSR process, it is possible for the material yield to be over 90% when this type of recycling is employed, while energy consumption can be up to three times less compared to the conventional recycling process, mostly because the remelting phase is completely avoided [12,13,14,15,16]. Aluminum production accounts for up to 1.5% of global processes and energy-related CO2 emissions. It is proposed that between 0.13% and 0.22% (51 Mt CO2) of global CO2 emissions could be saved by reusing aluminum machining chips through the mitigation of recycling-associated emissions [5]. Less energy use means a smaller reliance on fossil fuels, reducing the overall carbon footprint, while the absence of melting in solid-state recycling minimizes emissions of greenhouse gases and other pollutants associated with high-temperature processes. It is well understood that the presence of stable oxide films on the faying (i.e., contacting) surfaces of many materials can prevent the achievement of high-quality bonds via diffusion methods. Given the lower ductility of most oxide films, they can rupture when the parent materials are subject to a large amount of plastic deformation [5]. To perform solid-state recycling, severe deformation processes are commonly used, such as hot extrusion, equal channel angular pressing, friction stir extrusion, and spark plasma sintering [15,17,18,19,20]. Güley et al. [19] showed that critical shear stress should be achieved, whereby the encasing oxide layers break down and enable metal-to-metal contact, which consequently should secure good chip bonding. Also, a critical path length is defined, which is understood as the minimum length of contact by the chip surfaces during the process that is necessary to allow for sufficient welding. Only if both conditions are sufficiently met can a successful chip bonding process be achieved during the extrusion process. The parameter of critical shear stress is directly influenced by the extrusion ratio [21]. Thus, with a larger extrusion ratio, the effective shear stress increases [18,22]. Carvalho et al. showed that there is a promising possibility to produce deposition rods for tungsten inert gas welding utilizing friction stir extrusion of EN AW 6082 machining chips [23]. The main aim of this research is to investigate the possibilities and challenges during the welding of solid-state-recycled EN AW 6082 aluminum alloy. The authors of this paper did not find any research articles dealing with the joining of solid-state-recycled materials. Therefore, there is a significant research gap in this area. To perform semisolid recycling in this research, EN AW 6082 aluminum alloy machining chips were cold compacted and directly hot extruded to create solid samples. To obtain EN AW 6082 aluminum alloy sheets for welding, the hot rolling process was utilized afterward. It has already been shown that hot rolling can have a beneficial effect on solid-state-recycled specimens [24,25,26]. The welding of SSR specimens can be a challenging task due to the increased oxide particle content. It is known that because of the specific solid-state recycling procedure, specimens have a somewhat increased level of aluminum oxide, and for the 6xxx aluminum alloy series a magnesium oxide particle content as well [27]. Laurent-Brocq et al. showed that the overall oxygen content increased at every step of the recycling process for AA 6060 aluminum alloy. Furthermore, according to the authors, the initial thin Al2O3 layer on the chips are covered by a MgO layer during pre-annealing and hot extrusion. Thus, alloying elements, such as Mg, are also involved in oxidation. This results in a ten-fold increase in the oxygen content in the extrudate accompanied by a complex network of oxides with an average thickness of 290 nm and a low density [7]. In aluminum, welding aluminum oxide presents several challenges in welding because it has properties that interfere with the quality and integrity of the weld. Aluminum oxide has a much higher melting point (about 2000 °C) compared to pure aluminum (about 660 °C). This means that when you try to weld aluminum, the oxide layer does not melt as easily as the aluminum beneath it, making it difficult to achieve a clean, consistent weld. If not removed, the aluminum oxide layer can create a barrier between the molten aluminum and the welding material. This barrier leads to poor fusion, weak bonds, and potential porosity, compromising the weld’s strength and quality. Aluminum oxide can trap impurities and moisture from the environment. During welding, these impurities can lead to defects, contamination, and reduced weld quality. To overcome these challenges, welders typically employ mechanical cleaning, chemical cleaning, and AC (alternating current) in tungsten inert gas (TIG) welding, where the positive half-cycle helps to remove the oxide and, of course, using inert shielding gas to minimize oxidation during welding [28,29,30]. For the welding of the specimens in this research, both metal inert gas welding (MIG) and TIG methods were used to ensure a wider range of the process parameters and heat input, which is known to exert great influence during aluminum welding. TIG was also performed on one side and on two sides for the same reasons as stated above. Welding processes were conducted for solid-state-recycled specimens but also for conventionally produced specimens, which resulted in a total of six welding procedures being performed and analyzed. The weldability of the obtained solid-state-recycled specimens was determined utilizing optical microscopy and scanning electron microscopy accompanied by energy-dispersive X-ray spectroscopy, which served to determine the intermetallic distribution and size, as well as possible welding errors due to the increased heat input and metal melting. The mentioned analysis was also performed on welded, conventionally produced EN AW 6082 alloy specimens to compare microstructural characteristics. Furthermore, to investigate the mechanical properties of welded recycled specimens and to compare them with welded conventional specimens, tensile tests and microhardness measurements were carried out.

2. Materials and Methods

The main aim of this research was to determine the welding possibilities of solid-state-recycled EN AW 6082 aluminum alloy. This alloy was selected because it is an aluminum alloy in the 6xxx series (Al-Mg-Si), which is well-known for its strength, good weldability, and corrosion resistance. It has a high strength-to-weight ratio which makes it advantageous in applications where weight reduction is critical, such as shipbuilding. The alloy has good corrosion resistance making it suitable for structural applications in marine environments. It is suitable for welding, especially with MIG and TIG methods, which are commonly used in shipbuilding and other structural welding. Table 1 provides the chemical composition of the batch of selected aluminum alloy material.

Table 1.

Chemical composition of the EN AW 6082 aluminum alloy batch (%wt.).

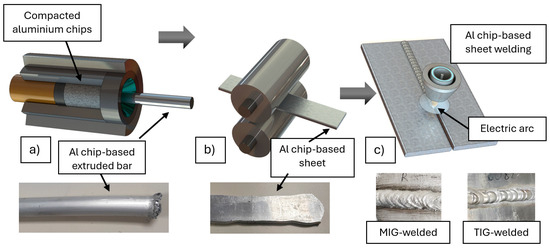

The alloy was machined on the Spinner VC 560 vertical machining center using a depth of cut, cutting speed, and feed rate of ap = 1 mm, vc = 120 m/min, and f = 0.1 mm/tooth, respectively. To avoid contamination with cooling and lubrication fluids, a dry-face milling process was performed. The used tool was composed of the WALTER (Walter AG, Tübingen, Germany) tool holder with the designation M4132-032-W32-02-09 and the SDHT09T304-G88 WK10 cutting insert. The obtained aluminum chips were weighed to a mass of 150 g and compacted in a cylindrical steel tool that was 38 mm in diameter. Compaction was performed on a 1 MN universal hydraulic press with a compaction force of 450 kN. The force was measured using the HBM load cell C6A 1MN sensor (HBM, Darmstadt, Germany). After the compaction step, a direct hot extrusion process was utilized. Chip-based billets were preheated for 20 min at 450 °C, placed in an extrusion cylinder with a diameter of 40 mm and directly hot extruded at 400 °C with a 7.1 extrusion ratio. A flat die with an orifice diameter of 15 mm was used in the extrusion process, and 15 mm diameter chip-based solid bars were produced. A schematic representation of the utilized direct hot extrusion process is presented in Figure 1a. The beginning part of the extruded profile was discarded because of insufficient pressure and visible individual chips. The hydraulic press punch speed was 1 mm/s. The temperature was controlled using the Omron E5CC temperature regulator (Omron Corporation, Kyoto, Japan) and a G3PE-225B DC12-24 relay (Omron Corporation, Kyoto, Japan). The extrusion pressure was measured with an HBM P15RVA1/500B pressure gauge transducer (HBM, Darmstadt, Germany). To increase the solid-state-recycled specimen’s quality and to obtain a 4 mm thick aluminum sheet for welding processes, a hot rolling process was performed (Figure 1b). Before rolling, the extruded bars were preheated to 400 °C. After the aluminum sheets were obtained, semi-automatized metal inert gas and hand tungsten inert gas welding were performed (Figure 1c). The same welding procedure with commercial aluminum alloy sheets was also performed. The commercial alloy was obtained in a 15 mm diameter bar in an extruded state in the T6 condition. Following the same production procedure to enable a fair comparison, the obtained bars were annealed at 400 °C for 20 min and then hot rolled at 400 °C to obtain the same sheets as made for the solid-state-recycled sheets.

Figure 1.

Schematic solid-state recycling and welding process overview: (a) direct hot extrusion; (b) rolling; (c) arc welding (MIG and TIG).

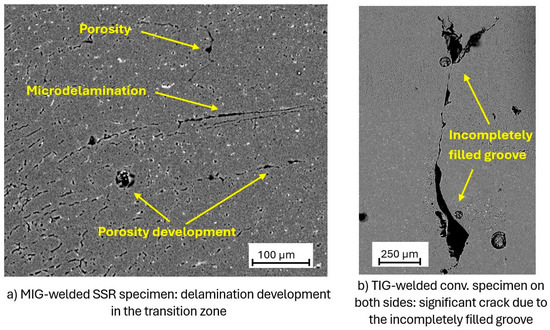

To perform MIG welding with precision and better parameter control, a semi-automatized process was performed with the linear moving device in the weld direction and a fixed welding speed set at 8.93 mm/s. The device used for the MIG welding was a Daihen Varstroj WB-P500L (Lendava, Slovenija). The specimens were welded in the flat position, and a butt weld was used as the type of weld joint. The welding torch angle for the TIG process was 15°, while for the MIG process the welding torch was perpendicular to the base material because of the automated linear displacement. The welding procedure was performed at room temperature, in a room environment. All specimens were brushed and cleaned with acetone prior to welding. After a few preliminary welding tests, with the proposed heat input according to the literature, some excess heat problems occurred. It was evident that porosity developed if too much heat was used (Figure 2). Also, as shown in Figure 2, some instances of delamination were visible on the aluminum machining chips, which indicates that the bonding of the machining chips could also be improved (Figure 2). Excessive porosity visibly developed at the end of the delamination lines. Therefore, the welding parameters, in this case, are strongly connected with the quality of the SSR specimens or the level of chip bonding during the solid-state recycling process.

Figure 2.

Excessive heat input’s influence on an SSR specimen welded with the MIG process: appearance of porosity and delamination.

This was the main motivation for employing TIG with a controlled and minimized heat input, to reduce possible delamination and porosity development to a minimum. The used device for TIG welding was the Daihen AVP-300 (Osaka, Japan). Because of the 4 mm aluminum sheet thickness, one-sided TIG was performed with the aim of further reducing the heat input. To simulate different welding conditions, two-sided TIG welding was also performed. Considering an arc efficiency of 80% for the MIG process, the heat input was calculated to be 3.528 kJ/cm. For the one-sided TIG welding procedure and an arc efficiency of 60%, the heat input was 2.7 kJ/cm, and for the two-sided TIG welding procedure it was 1.62 kJ/cm for each side. The formula for this calculation is as follows: heat input = (current × voltage × efficiency factor × 60)/(travel speed (cm/min) × 1000). For the welding process, AlMg5, or 5356, filler metal was selected. It is the most widely used welding alloy and can be classified as a general-purpose type of filler alloy. The chemical composition of the filler metal is as follows: Si, max. 0.25; Fe, max. 0.4; Cu, max. 0.1; Mn, 0.05–0.2; Mg, 4.5–5.5; Cr, 0.05–0.20; Zn, max. 0.1; Ti, 0.06–0.2; Be, max. 0.0003; Al, bal. It is recommended for EN AW 6082 aluminum alloy welding because using filler metal with a higher Mg content can significantly reduce the sensitivity to solidification cracking [31]. Table 2 summarizes all important parameters used in the welding process.

Table 2.

Parameters for welding the 4 mm thick EN AW 6082 aluminum alloy sheets.

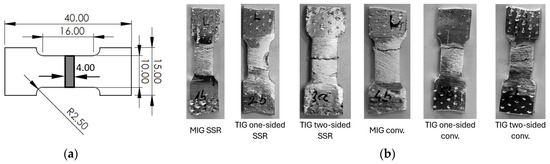

After welding, metallography, microhardness, and tensile test specimens were cut from each welded sheet. The macrostructure was characterized using an Olympus SZ61 optical stereomicroscope. The samples were etched with a reagent that consisted of 0.5 mL of 40% HF (hydrofluoric acid) dissolved in 100 mL of water for a duration of 40 s at room temperature. Scanning electron microscopy, accompanied by energy-dispersive X-ray spectroscopy, was performed, which served to determine the intermetallic distribution and size, as well as possible welding errors due to the increased heat input and melting of the metal. An FE-SEM FEI Quanta FEG 250 (FEI Company, Eindhoven, The Netherlands) scanning electron microscope and an Oxford EDS PentaFET (Oxford Instruments PLC, Abingdon, UK) energy-dispersive X-ray spectroscopy (EDS) device were utilized for this purpose. Microhardness testing was performed according to the HRN EN ISO 6507-1:2018 standard [32] for microhardness testing of metal material. The used device was a Shimadzu HMV-2T (Shimadzu, Kyoto, Japan) universal machine with an integrated DynoLITE camera with DynoCapture 2.0 software for computer analysis. The microhardness was measured utilizing the Micro Vickers method with an applied force of 9.8 N for a duration of 10 s at room temperature. All six specimens were marked in the middle of the weld zone, as well as on the right and left sides every 2 mm, to measure the hardness of the weld material, heat-affected zone, and base material. A tensile test was performed on an ETM-250-S Raagen universal tensile test machine with a maximum force of 250 kN (Ankara, Turkey). Tensile specimens had a reduced section length of 16 mm, fillet radius of 2.50 mm, and gauge width of 10 mm (Figure 3). Quasi-static tensile testing was performed at room temperature. For each specimen, three tensile tests were performed, and the mean value was selected.

Figure 3.

Tensile test specimens: (a) dimensions; (b) welded conventional and SSR specimens after tensile testing.

3. Results and Discussion

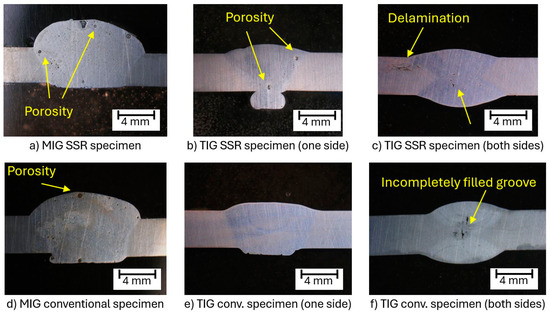

3.1. Macroscopy Analysis

Figure 4 shows the macrostructures for all six specimens obtained with different welding procedures. It seems that the appropriate selection of welding parameters was crucial to avoid significant delamination and porosity in the welded specimens. For both MIG-welded specimens (recycled and conventional), some microporosity is visible. Because of the round-shaped porosity, it is likely gas porosity (Figure 4a,d). This indicates that the specimen’s welding procedure can be further optimized; however, there is no significant difference in the appearances of the welded SSR and conventional specimens. This indicates that, despite the residual aluminum oxide concentrations in the SSR specimens from the surface of the machining chips, there is still the possibility of performing semi-automatized MIG welding without any significant errors. This is addressed and confirmed in this paper in the following investigation of the mechanical properties. For the specimens welded with the TIG process on one side, there was some porosity visible in the SSR specimen; however, in the conventional specimen there was no porosity (Figure 4b,e). However, the appearance of different fusion zones indicates that at this specific point the welding conditions were somewhat different, which is expected because it was hand-welded by a welder. Overall, both TIG-welded specimens had good overall appearances without any significant delamination or cracks, which indicates that the SSR and conventional specimens were similarly welded. For the two-sided TIG-welded specimens, a few interesting observations are noted in Figure 4c,f. Firstly, for the TIG SSR specimen, some delamination in the HAZ occurred (Figure 4c). This could be caused by overheating but is more likely due to the low extrusion ratio during the solid-state recycling; a low bonding chip area was revealed during etching.

Figure 4.

Macrophotography of the welded conventional and SSR specimens for the three different welding procedures: (a,d) MIG-welded; (b,e) TIG-welded on one side; (c,f) TIG-welded on both sides.

The macroscopy analysis results indicate that a higher extrusion ratio or rolling reduction should be used to prevent possible delamination during the welding of SSR specimens. Koch et al. [21] proved that, although micrographs of chip-based extruded profiles did not show delamination between individual chips, it was found that there was a critical diameter where the combination of the necessary properties of high strain and pressure was considered too low to lead to sufficient chip bonding, resulting in crack initiation and delamination during fatigue testing. The chip bonding quality, without a doubt, will interfere with the mechanical properties, as shown in previous research. Therefore, analogously, the chip bonding quality will have a significant impact on the solid-state-recycled specimens after processing (e.g., welding). According to Kolpak et al., the use of an extrusion ratio lower or equal to 17 will lead to delamination, and, therefore, a higher extrusion ratio should be applied for flat-face dies to prevent the aforementioned [15]. Another solution is to use a modified ECAP, or porthole die, to increase the deformation, which should lead to better chip bonding. Other research has shown that subsequent processing of extruded SSR specimens can improve the chip bonding quality [10,17]. In this research, the aim was to achieve successful chip bonding with the hot rolling process, but it seems that the extrusion ratio of 7.1 was still in the critical zone. Finally, for both specimens welded with TIG on two sides, an incompletely filled groove was visible in the middle of the specimens. This indicates that the welding procedure should be further optimized.

3.2. Mechanical Properties Analysis

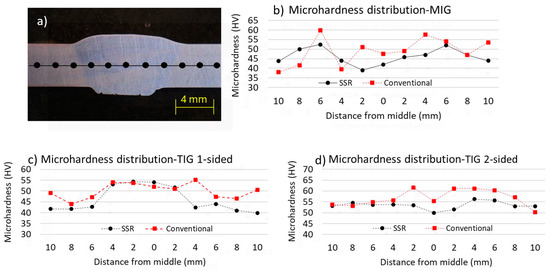

Figure 5 presents diagrams of the microhardness distribution along the welded specimens. Figure 5a shows the measuring positions on the welded specimens, and Figure 5b shows the microhardness distribution for both the SSR and conventional specimens after MIG welding. Because of the annealed characteristics of the specimens, the microhardness values were in a range from around 40 HV to 60 HV. The main aim of this research was to conduct a comparative analysis of the welded conventional and recycled specimens, and according to the measurements, quite similar behaviors were exhibited, with no significant drop in the hardness of the HAZs, fusion zones, or base materials. There was even an increase in the hardness near the HAZ and the transition zone between the base material and the fusion zone. Because of the high heat input during the welding and the annealed condition of the heat-treatable EN AW 6082 aluminum alloy, there is the possibility that some part of the material reached a solid solution temperature, which subsequently led to solid solution strengthening in that particular zone. According to Figure 5b, it is fair to claim that relatively similar microhardness distributions were achieved for both the SSR and conventional specimens. For other welding procedures, the same conclusion can be drawn; however, the microhardness measurement curves have different appearances (Figure 5). Figure 5c shows the microhardness distributions for both the SSR and conventional specimens after one-sided TIG welding. The microhardness distribution shows a somewhat increased microhardness in the fusion zone for both specimens. This is due to the annealed condition of the base material, which significantly reduced the alloy’s microhardness. According to Yang et al., because of the substantial addition of Mg from the 5087 filler metal into the molten pool, the solid solution strengthening in the weld pool zone (compared to the base metal) is enhanced, reducing the extent of softening compared to the heat-affected zone [33]. Therefore, similar to this research, the somewhat increased microhardness of the weld metal after the welding procedure is due to the AlMg5 filler metal’s increased Mg content. Similar microhardness distributions for all specimens welded with the TIG procedure indicates that, despite the hand-welding procedure, both specimens were welded with similar heat inputs. There were also similar microhardness distributions for both the SSR and conventional specimens after the two-sided TIG welding (Figure 5d). However, there was a drop in the microhardness only in the middle of the weld zone. This is due to the incompletely filled groove and, therefore, increased porosity. Despite this drop in the middle of the weld zone, the overall microhardness distribution was from 50 HV to 63 HV, which is higher than in other specimens welded with the procedure using a higher heat input. It is known that the microstructure of Al-Mg-Si alloys is highly temperature-sensitive [33]. The microhardness measurements in this research are similar to previous research in which 6061 aluminum alloy in a solid solution state was welded [34].

Figure 5.

Microhardness distribution for both the solid-state-recycled and conventional specimens with different welding procedures: (a) measurement positions; (b) MIG-welded; (c) TIG-welded on one side; (d) TIG-welded on both sides.

In Table 3 are presented the results of the tensile testing. Similar to the microhardness distribution comparison for both the conventional and SSR specimens (Figure 5), it can be concluded from the tensile testing results that both kinds of specimens, for all welding procedures, had similar mechanical properties (Table 3). Overall, the MIG-welded specimens had the highest ultimate tensile strength. For the welded solid-state-recycled specimens, the ultimate tensile strength was lower by 10 MPa compared to the welded conventional specimens; however, the elongation was about 7% higher. These results are comparable, or somewhat lower, compared to previous research that dealt with welding 6082 aluminum alloy [35,36,37]. The somewhat lower ultimate tensile strength results were expected because of the specific annealed thermal state of both the recycled and conventional base material sheets. For both MIG-welded specimens, fractures occurred in the heat-affected zone, which suggests that further softening of the material occurred (Figure 3). Furthermore, according to the results of the tensile tests of the specimens welded with TIG on the one side, there was a significant drop in the mechanical properties (Table 3). On the other hand, the microhardness measurements showed increased microhardness values compared with the MIG-welded specimens. This clearly indicates that the drop in the tensile testing results for the TIG-welded specimens was not due to the microstructural characteristics but to the incomplete fusion between the base materials and the filler material in the weld zone. The authors of this research attempted to obtain a visibly acceptable TIG weld with the lowest possible heat input to prevent delamination of the SSR specimens and development of porosity, as explained in Figure 2, but this led to a lack of interfusion, which is evident from the tensile testing results in Table 3. The lack of fusion and lack of penetration are the result of the low heat input from the low current applied [38,39,40]. For the specimens welded with TIG on two sides, despite a lower welding current and an incompletely filled groove, the tensile testing results for both ultimate tensile strength and elongation were twice as high compared with the TIG-welded specimens on one side (Table 3). This indicates and confirms that a better welding procedure and better fusion between the base material and filler material were necessary; however, the mechanical properties were still lower compared to the MIG-welded specimens due to the incompletely filled groove, as mentioned above. This is also why fracturing occurred in the middle of the weld material during the tensile tests of the two-sided TIG-welded specimens, while for the one-sided TIG-welded specimens, fracturing occurred near the fusion zone (Figure 3). This also confirms the abovementioned conclusions. Incomplete joint penetration in welds can occur due to factors such as insufficient heat, rapid travel speed, improper joint design, incorrect bevel angle, or poor arc control. This discontinuity is particularly problematic in groove welds under cyclic tension, as it can initiate cracks leading to catastrophic failure. In welds made from one side, incomplete penetration can cause bending at the root, resulting in failure with minimal deformation. For joints welded from both sides, when incomplete joint penetration is present at the neutral axis, the bending stresses are lower, but they are concentrated at the ends of the discontinuity [41]. Therefore, it is fair to claim that the TIG welding parameters should be changed with a higher heat input. This can be achieved using a regular DC current, without pulsed mode, and increasing the overall welding current or reducing the welding speed. Also, different joint preparations with applied bevel angles could be used for better penetration. Overall, for all TIG-welded specimens, a somewhat lower ultimate tensile strength and higher elongation were observed for the welded SSR specimens compared to the conventional ones. As the main objective of this research was a comparative analysis of the welding behaviors of both conventional and solid-state-recycled EN AW 6082 alloy, in general, it is fair to claim that under similar welding conditions, similar mechanical properties were achieved, but similar welding errors and imperfections were also present.

Table 3.

Tensile test results for the solid-state-recycled and conventional specimens after welding.

3.3. Scanning Electron Microscopy

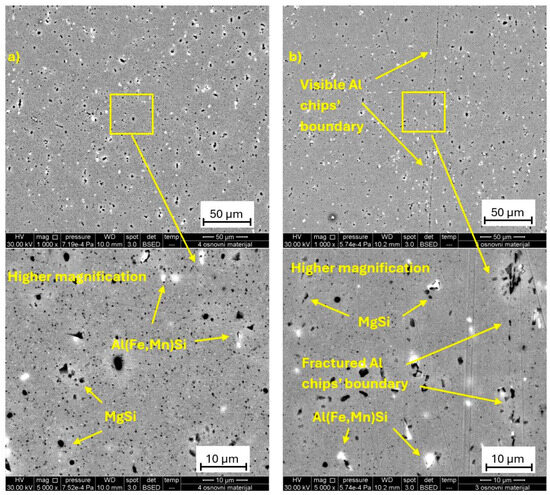

The main aim of the metallographic analysis was to evaluate the microstructures of the solid-state-recycled and conventional specimens welded with different procedures. The microstructure significantly affects the resistance to solidification cracking and mechanical properties of welds [34]. For the metallographic analysis, an FEI Quanta 250 FEG scanning electron microscope (SEM) and Oxford PentaFET energy-dispersive X-ray spectroscopy (EDX) were used. Samples were etched for 20 s at room temperature with a Keller reagent. Figure 6 shows the microstructures of the base material for the conventional and SSR specimens after the hot rolling process.

Figure 6.

Scanning electron microscope images of solid-state-recycled EN AW 6082 aluminum alloy in the hot-rolled condition: (a) conventional and (b) SSR specimens.

According to Figure 6, the microstructure of the SSR specimen was similar to the conventional one. The microstructure of the recycled sample was very homogeneous, and there were no visible cracks, voids, or porosity. However, a visible chip boundary was detected for the SSR specimen, which confirms the conclusion from the macrostructural and mechanical properties analysis. According to previous microstructural investigations of EN AW 6082 aluminum alloy, Al-Mg-Si phases (usually characterized as Al(FeMn)Si and MgSi) can usually be distinguished [17,42,43]. Since both samples in this investigation were in the annealed condition, the principal strengthening precipitates, Mg2Si phase particles, appeared in the form of coarse precipitates in black, while the bright spots were Al(FeMn)Si phase particles (Figure 7).

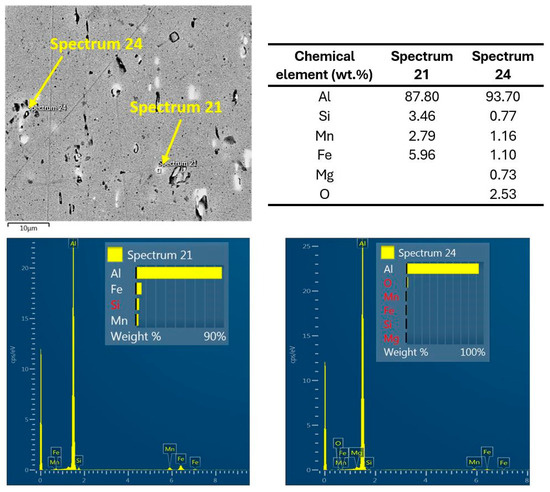

Figure 7.

EDS chemical element analysis of the SSR EN AW 6082 specimen welded with the MIG procedure for phase determination: spectrum 21 (Al(FeMn)Si) and spectrum 24 (Mg2Si).

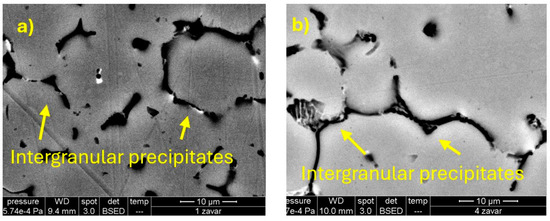

Visible similar-sized phase particles were homogeneously dispersed inside both samples, which confirms that the obtained conventional and solid-state-recycled sheets had similar microstructural states for the comparative welding analysis. In the weld zone, typical intergranular precipitates were observed, as shown in Figure 8, which, in previous research, were found to contain Fe, Mg, Mn, and Si elements [24]. The formation of α-Al15(Fe,Mn)3Si2 in alloys with added Mn and β-Al5FeSi has also been reported [29,30]. Therefore, the precipitates observed here probably consisted of Si, Mg2Si, and α-Al15(Fe,Mn)3Si2 and β-Al5FeSi phases.

Figure 8.

Appearance and distribution of intermetallics in the weld material of the specimens welded with the MIG procedure: (a) conventional and (b) SSR specimens.

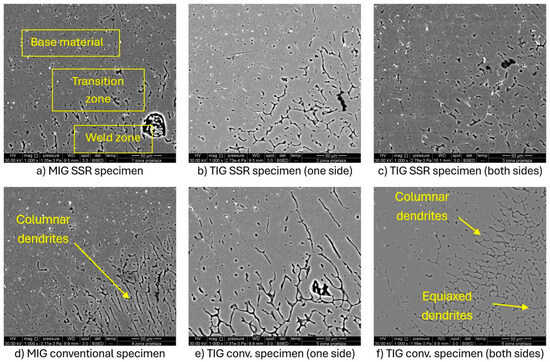

Figure 9 shows the transition zones between the base materials and weld zones. For all specimens, the transition zones were similar, with the base material containing finely distributed intermetallic phases. In the weld material, because of the filler metal’s different chemical composition and the metal solidification in the weld zone, characteristic larger intermetallic phases and aluminum dendrites were obtained. In the transition zone and beginning part of the weld zone, some columnar dendrites were visible, while farther from the transition zone, equiaxed dendrites formed. These columnar crystals grow perpendicular to the fusion line, along the direction of the heat flow [34].

Figure 9.

Scanning electron microscopy of the welded specimens in the transition zone from the base material to the HAZ and weld zone.

In order to additionally confirm the macroscopic images and above discussion of the behavior of the mechanical properties, Figure 10 was added to the manuscript. In Figure 10a, there is some visible development of microdelamination and, therefore, additional porosity, which were not present in the conventional specimens. These are responsible for the approximately 10 MPa lower mechanical property in the solid-state-recycled specimens, for all three welding processes in this research (Table 3). Furthermore, in Figure 10b there is a significant crack visible due to the incompletely filled groove, which is responsible for the significant decrements in the tensile strengths of the TIG-welded specimens on both sides (Table 3).

Figure 10.

(a) SEM image of microdelamination development in the weld transition zone of the MIG-welded SSR specimen; (b) crack in the TIG-welded conventional specimen due to the incompletely filled groove.

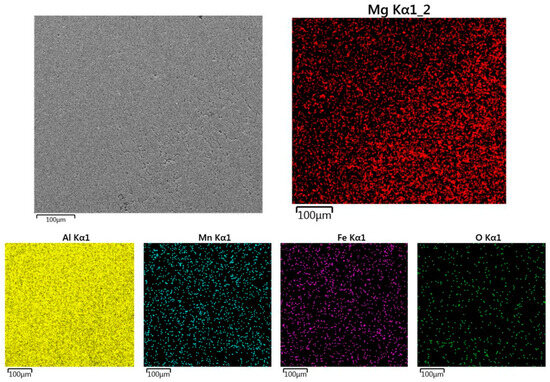

According to the chemical element mapping presented in Figure 11, neither increased oxide contamination nor the presence of oxide layers between aluminum chips were determined. An increase in the concentration of the alloying element Mg in the filler metal was visible from the element mapping, which confirms the abovementioned conclusion about the increment in the microhardness of the weld material. The homogeneous distribution of the other intermetallic phases was also confirmed.

Figure 11.

Chemical element mapping of the welding transition zone of the SSR specimen welded with the MIG procedure.

4. Conclusions

In this research, the main aim was to determine the possibility of using solid-state-recycled specimens in electric arc welding. After preliminary testing of the welding parameters, for both the TIG and MIG welding procedures, visually satisfying welds were achieved. All determined welding errors were similar for both the SSR and conventional specimens. According to the analysis of the welded specimens, the quality of SSR specimens is crucial to prevent delamination between insufficiently deformed and connected machining chips with excessive heat input and partial remelting during the welding process. This delamination can also cause significant porosity development. It seems that the aluminum oxide concentration inside the SSR specimens was not high enough to cause significant welding difficulties; however, it is necessary to achieve sufficient fragmentation of the oxide layer and machining chips to prevent possible delamination. Therefore, the welding potential of the SSR specimens seems to strongly depend on the SSR alloy’s manufacturing procedure, i.e., extrusion ratio, degree of deformation, and quality of machining chip bonding and oxide layer fragmentation.

Overall, this research demonstrates the possibility of welding solid-state-recycled specimens and their similar behavior to that of welded conventional specimens. Optimization of the welding parameters is important to obtain good mechanical and microstructural properties. Optimization of the welding process for SSR specimens should be performed to prevent delamination and the development of porosity, as well as to achieve the maximum mechanical properties. Furthermore, future research should determine the optimal SSR procedure to obtain a solid-state-recycled alloy with sufficient chip quality and weldability (e.g., the hot extrusion ratio or rolling reduction). The ability to join solid-state-recycled specimens by welding is an important step in the development of advanced and more sustainable aluminum recycling techniques.

Author Contributions

Conceptualization, J.K.; methodology, J.K. and N.Č.; software, J.K. and V.Š.; validation, J.K., M.B. and V.Š.; formal analysis, J.K., M.B. and V.Š.; investigation, J.K.; resources, J.K., M.B. and V.Š.; data curation, J.K. and M.B.; writing—original draft preparation, J.K. and N.Č.; writing—review and editing, J.K. and N.Č.; visualization, J.K., M.B. and V.Š.; supervision, J.K.; funding acquisition, J.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Croatian Science Foundation through the following project: Recycling of aluminum alloys in solid and semisolid states (IP-2020-02-8284).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the corresponding author on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Stacey, M. Aluminium Recyclability and Recycling; Cwningen Press: Carmarthen, UK, 2015; ISBN 9780993016219. [Google Scholar]

- Krolo, J.; Lela, B.; Grgić, K.; Jozić, S. Production of Closed-Cell Foams out of Aluminum Chip Waste: Mathematical Modeling and Optimization. Metals 2022, 12, 933. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Buonadonna, P.; Carta, M.; El Mohtadi, R.; Mele, A.; Morea, D. Sustainability Study of a New Solid-State Aluminum Chips Recycling Process: A Life Cycle Assessment Approach. Sustainability 2023, 15, 11434. [Google Scholar] [CrossRef]

- Feng, Z.; David, S.A.; Manchiraju, V.K.; Frederick, D.A.; Thomas, W. Friction Extrusion: Solid-State Metal Synthesis and Recycling in Sustainable Manufacturing. JOM 2023, 75, 2962–2973. [Google Scholar] [CrossRef]

- Murray, J.W.; Jin, X.; Cleaver, C.J.; Azevedo, J.M.C.; Liao, Z.; Zhou, W.; Cullen, J.M.; Allwood, J.M.; Clare, A.T. A Review of Principles and Options for the Re-Use of Machining Chips by Solid, Semi-Solid or Melt-Based Processing. J. Mater. Process. Technol. 2024, 331, 118514. [Google Scholar] [CrossRef]

- Altharan, Y.M.; Shamsudin, S.; Al-Alimi, S.; Saif, Y.; Zhou, W. A Review on Solid-State Recycling of Aluminum Machining Chips and Their Morphology Effect on Recycled Part Quality. Heliyon 2024, 10, e34433. [Google Scholar] [CrossRef] [PubMed]

- Laurent-Brocq, M.; Lilensten, L.; Pinot, C.; Schulze, A.; Duchaussoy, A.; Bourgon, J.; Leroy, E.; Tekkaya, A.E. Solid State Recycling of Aluminium Chips: Multi-Technique Characterization and Analysis of Oxidation. Materialia 2023, 31, 101864. [Google Scholar] [CrossRef]

- Paraskevas, D.; Kellens, K.; Dewulf, W.; Duflou, J.R. Resource Efficiency in Manufacturing: Identifying Low Impact Paths. In Proceedings of the 10th Global Conference on Sustainable Manufacturing (GCSM 2012), Istanbul, Turkey, 31 October–2 November 2012; pp. 271–276. [Google Scholar]

- Duflou, J.R.; Tekkaya, A.E.; Haase, M.; Welo, T.; Vanmeensel, K.; Kellens, K.; Dewulf, W.; Paraskevas, D. Environmental Assessment of Solid State Recycling Routes for Aluminium Alloys: Can Solid State Processes Significantly Reduce the Environmental Impact of Aluminium Recycling? CIRP Ann.-Manuf. Technol. 2015, 64, 37–40. [Google Scholar] [CrossRef]

- Krolo, J.; Gudić, S.; Vrsalović, L.; Lela, B.; Dadić, Z. Fatigue and Corrosion Behavior of Solid-State Recycled Aluminum Alloy EN AW 6082. J. Mater. Eng. Perform. 2020, 29, 4310–4321. [Google Scholar] [CrossRef]

- Kumar, N.; Bharti, A. Review on Powder Metallurgy: A Novel Technique for Recycling and Foaming of Aluminium-Based Materials. Powder Metall. Met. Ceram. 2021, 60, 52–59. [Google Scholar] [CrossRef]

- Tekkaya, A.E.; Schikorra, M.; Becker, D.; Biermann, D.; Hammer, N.; Pantke, K. Hot Profile Extrusion of AA-6060 Aluminum Chips. J. Mater. Process. Technol. 2009, 209, 3343–3350. [Google Scholar] [CrossRef]

- Allwood, J.M.; Cullen, J.M.; Cooper, D.R.; Milford, R.L.; Patel, A.C.H.; Carruth, M.A.; Mcbrien, M. Conserving Our Metal Energy; University of Cambridge: Cambridge, UK, 2010; pp. 1–20. [Google Scholar]

- Wan, B.; Chen, W.; Lu, T.; Liu, F.; Jiang, Z.; Mao, M. Review of Solid State Recycling of Aluminum Chips. Resour. Conserv. Recycl. 2017, 125, 37–47. [Google Scholar] [CrossRef]

- Kolpak, F.; Schulze, A.; Dahnke, C.; Tekkaya, A.E. Predicting Weld-Quality in Direct Hot Extrusion of Aluminium Chips. J. Mater. Process. Technol. 2019, 274, 116294. [Google Scholar] [CrossRef]

- Gronostajski, J.; Marciniak, H.; Matuszak, A. New Methods of Aluminium and Aluminium-Alloy Chips Recycling. J. Mater. Process. Technol. 2000, 106, 34–39. [Google Scholar] [CrossRef]

- Krolo, J.; Lela, B.; Dumanić, I.; Kozina, F. Statistical Analysis of the Combined ECAP and Heat Treatment for Recycling Aluminum Chips Without Remelting. Metals 2019, 9, 660. [Google Scholar] [CrossRef]

- Haase, M.; Ben Khalifa, N.; Tekkaya, A.E.; Misiolek, W.Z. Improving Mechanical Properties of Chip-Based Aluminum Extrudates by Integrated Extrusion and Equal Channel Angular Pressing (IECAP). Mater. Sci. Eng. A 2012, 539, 194–204. [Google Scholar] [CrossRef]

- Güley, V.; Güzel, A.; Jäger, A.; Ben Khalifa, N.; Tekkaya, A.E.; Misiolek, W.Z. Effect of Die Design on the Welding Quality during Solid State Recycling of AA6060 Chips by Hot Extrusion. Mater. Sci. Eng. A 2013, 574, 163–175. [Google Scholar] [CrossRef]

- Paraskevas, D.; Vanmeensel, K.; Vleugels, J.; Dewulf, W.; Deng, Y.; Duflou, J.R. Spark Plasma Sintering as a Solid-State Recycling Technique: The Case of Aluminum Alloy Scrap Consolidation. Materials 2014, 7, 5664–5687. [Google Scholar] [CrossRef]

- Koch, A.; Wittke, P.; Walther, F. Computed Tomography-Based Characterization of the Fatigue Behavior and Damage Development of Extruded Profiles Made from Recycled AW6060 Aluminum Chips. Materials 2019, 12, 2372. [Google Scholar] [CrossRef]

- Ab Rahim, S.N.; Lajis, M.A.; Ariffin, S. A Review on Recycling Aluminum Chips by Hot Extrusion Process. Procedia CIRP 2015, 26, 761–766. [Google Scholar] [CrossRef]

- Carvalho, G.H.S.F.L.; Campatelli, G.; Fratini, L. Feasibility Study of Using Friction Stir Extruded Recycled Aluminum Rods for Welding and Additive Manufacturing. Manuf. Lett. 2024, 42, 52–55. [Google Scholar] [CrossRef]

- Chiba, R.; Nakamura, T.; Kuroda, M. Solid-State Recycling of Aluminium Alloy Swarf through Cold Profile Extrusion and Cold Rolling. J. Mater. Process. Technol. 2011, 211, 1878–1887. [Google Scholar] [CrossRef]

- Kore, A.S.; Nayak, K.C.; Date, P.P. Formability of Aluminium Sheets Manufactured by Solid State Recycling. J. Phys. Conf. Ser. 2017, 896, 012007. [Google Scholar] [CrossRef]

- Chino, Y.; Mabuchi, M.; Iwasaki, H.; Yamamoto, A.; Tsubakino, H. Tensile Properties and Blow Forming of 5083 Aluminum Alloy Recycled by Solid-State Recycling. Mater. Trans. 2004, 45, 2509–2515. [Google Scholar] [CrossRef][Green Version]

- Zhang, Z.; Liang, J.; Xia, T.; Xie, Y.; Chan, S.L.I.; Wang, J.; Zhang, D. Effects of Oxide Fragments on Microstructure and Mechanical Properties of AA6061 Aluminum Alloy Tube Fabricated by Thermomechanical Consolidation of Machining Chips. Materials 2023, 16, 1384. [Google Scholar] [CrossRef] [PubMed]

- Brien, A.O. (Ed.) Welding Handbook—Welding Processes, Part 1; American Welding Society: Miami, FL, USA, 2004; Volume 2, ISBN 0-87171-729-89. [Google Scholar]

- O’Brien, A. (Ed.) Welding Handbook—MATERIALS AND APPLICATIONS, PART 2; American Welding Society: Miami, FL, USA, 2015; Volume 5, ISBN 978-0-87171-856-3. [Google Scholar]

- Mathers, G. The Welding of Aluminium and Its Alloys; CRC Press LLC: Boca Raton, FL, USA, 2002; ISBN 0-8493-1551-4. [Google Scholar]

- Kolarik, L.; Kovanda, K.; Valova, M.; Vondrous, P.; Dunovsky, J. Weldability Test of Precipitation Hardenable Aluminium Alloy En Aw 6082 T6. MM Sci. J. 2011, 2011, 243–247. [Google Scholar] [CrossRef]

- HRN EN ISO 6507-1:2018; Metallic Materials—Vickers Hardness Test—Part 1: Test Method (ISO 6507-1:2018; EN ISO 6507-1:2018); Croatia Standards Institute: Zagreb, Croatia, 2018. Available online: https://repozitorij.hzn.hr/norm/HRN+EN+ISO+6507-1%3A2018 (accessed on 20 January 2023).

- Yang, S.; Wang, Y.; Yang, X.; Lu, X.; Li, M.V.; Zhu, X. Effect of Softening of 6082-T6 Aluminum Alloy CMT Welded Joints on Mechanical Properties and Fracture Behavior. J. Manuf. Process. 2024, 124, 1567–1582. [Google Scholar] [CrossRef]

- Chu, Q.; Bai, R.; Jian, H.; Lei, Z.; Hu, N.; Yan, C. Microstructure, Texture and Mechanical Properties of 6061 Aluminum Laser Beam Welded Joints. Mater. Charact. 2018, 137, 269–276. [Google Scholar] [CrossRef]

- Yang, S.; Yang, X.; Lu, X.; Li, M.V.; Zuo, H.; Wang, Y. Strength Calculation and Microstructure Characterization of HAZ Softening Area in 6082-T6 Aluminum Alloy CMT Welded Joints. Mater. Today Commun. 2023, 37, 107077. [Google Scholar] [CrossRef]

- Han, X.; Yang, Z.; Ma, Y.; Shi, C.; Xin, Z. Porosity Distribution and Mechanical Response of Laser-MIG Hybrid Butt Welded 6082-T6 Aluminum Alloy Joint. Opt. Laser Technol. 2020, 132, 106511. [Google Scholar] [CrossRef]

- Arunakumara, P.C.; Sagar, H.N.; Gautam, B.; George, R.; Rajeesh, S. A Review Study on Fatigue Behavior of Aluminum 6061 T-6 and 6082 T-6 Alloys Welded by MIG and FS Welding Methods. Mater. Today Proc. 2023, 74, 293–301. [Google Scholar] [CrossRef]

- Samiuddin, M.; Li, J.-L.; Taimoor, M.; Siddiqui, M.N.; Siddiqui, S.U.; Xiong, J. tao Investigation on the Process Parameters of TIG-Welded Aluminum Alloy through Mechanical and Microstructural Characterization. Def. Technol. 2021, 17, 1234–1248. [Google Scholar] [CrossRef]

- Lee, H.K.; Chun, K.S.; Park, S.H.; Kang, C.Y. Control of Surface Defects on Plasma-MIG Hybrid Welds in Cryogenic Aluminum Alloys. Int. J. Nav. Archit. Ocean Eng. 2015, 7, 770–783. [Google Scholar] [CrossRef]

- Habba, M.I.A.; Alsaleh, N.A.; Badran, T.E.; El-Sayed Seleman, M.M.; Ataya, S.; El-Nikhaily, A.E.; Abdul-Latif, A.; Ahmed, M.M.Z. Comparative Study of FSW, MIG, and TIG Welding of AA5083-H111 Based on the Evaluation of Welded Joints and Economic Aspect. Materials 2023, 16, 5124. [Google Scholar] [CrossRef] [PubMed]

- Jenney, C.L.; O’Brien, A. (Eds.) Welding Handbook—Welding Science and Technology; American Welding Society: Miami, FL, USA, 2001; Volume 1, ISBN 0871716577. [Google Scholar]

- Tercelj, M.; Fazarinc, M.; Kugler, G.; Perus, I. Influence of the Chemical Composition and Process Parameters on the Mechanical Properties of an Extruded Aluminium Alloy for Highly Loaded Structural Parts. Constr. Build. Mater. 2013, 44, 781–791. [Google Scholar] [CrossRef]

- Krolo, J.; Lela, B.; Ljumović, P.; Bagavac, P. Enhanced Mechanical Properties of Aluminium Alloy EN AW 6082 Recycled without Remelting. Teh. Vjesn. 2019, 26, 1253–1259. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).