Abstract

This study proposes a stability index to quantitatively evaluate the psychological stability of drivers during truck platooning. Truck platooning is a technique in which a manually driven lead truck is followed by automated trucks using V2X communication and onboard sensors. While significant technical advances have been made in truck platooning, research on drivers’ psychological comfort remains limited. Due to the shorter intervehicle time gaps compared to conventional trucking, truck platooning raises concerns regarding drivers’ psychological stability. The proposed index quantifies this aspect and is validated using a driving simulator. Both the stability index calculations and the survey consistently indicate that when the time gap decreases to 0.6 s (approximately 15 m) or less, drivers’ psychological stability deteriorates. However, increasing the time gap beyond 0.6 s does not significantly improve it. Furthermore, this study investigates the effect of the see-through functionality, which provides real-time front-view footage of the preceding vehicle to the following driver. The results confirm that this functionality enhances psychological stability, even under a short time gap. The stability index should serve as a practical indicator for designing truck platooning systems that consider drivers’ psychological stability and may be extended to various advanced driving technologies, including general vehicle platooning.

1. Introduction

Although research on autonomous driving technology for passenger vehicles has been underway since the 1950s, studies on truck automation began only in the mid-1990s [1]. Among the various truck automation technologies, truck platooning is a technique in which multiple trucks form a convoy and drive together. The leading vehicle in a platoon is manually driven by a human driver, whereas the following vehicles use automated driving technology to follow the leader based on vehicle-to-everything (V2X) communication and onboard sensors.

According to previous studies, autonomous driving and platooning technologies for trucks are projected to offer several benefits, such as increased traffic capacity, improved fuel efficiency through reduced air resistance from shorter intervehicle gaps, reduced emissions, and enhanced driver convenience [2,3,4,5]. The effectiveness of truck platooning in terms of energy savings by reducing intervehicle distances has already been experimentally verified [1,6]. Despite these advantages, several potential drawbacks have also been identified. First, as the intervehicle distance decreases, the risk to driving safety increases. Additionally, the formation and dissolution of a platoon may cause disturbances in the surrounding traffic flow and hinder prompt responses to unexpected situations [7].

Despite various efforts to implement platooning for its benefits, most studies have focused solely on its technical aspects, with little consideration given to driver acceptance. Although drivers will be the primary users when platooning technology is commercialized, studies on their psychological stability during platooning are limited. If only technical aspects are considered, the platooning time gap will be minimized to meet the braking distance requirement, thereby maximizing the road capacity and fuel efficiency. However, compared with conventional human driving habits, a time gap may be perceived as excessively short. Therefore, if the time gap is determined solely based on technical considerations without considering human psychological stability, the following drivers may experience psychological discomfort due to the short distance to the preceding vehicle. Therefore, it is crucial to consider the psychological stability of the truck drivers in a platoon when determining the optimal intervehicle time gap.

The objective of this study is to develop and validate a quantitative evaluation index for assessing the psychological stability of following drivers in a truck platoon. Driving simulation experiments were conducted to reproduce actual road environments. Professional truck drivers participated in these experiments under various driving scenarios and selected an appropriate intervehicle time gap. The psychological stability was quantitatively evaluated using the proposed index. In addition, a qualitative questionnaire survey was conducted to validate the index.

Furthermore, this study examined the effect of the see-through functionality on enhancing the psychological stability of trailing drivers while reducing the intervehicle time gap by engaging them with real-time traffic conditions ahead of the leading vehicle within the platoon.

The quantitative evaluation index developed in this study should be applicable to not only truck platooning but also platooning systems for general vehicles.

2. Review of Related Works and Technological Trends

2.1. Review of Related Technologies

Unlike standalone autonomous driving, truck platooning refers to a synchronized driving mode in which the leading vehicle is manually driven while the following vehicles autonomously operate in a platoon based on driving information (e.g., speed, acceleration, and steering) obtained from the leading vehicle through V2X communication. In this context, the intervehicle distance within the platoon is defined in terms of the time gap, measured in s.

Truck platooning is generally performed in four stages: (1) general driving, where vehicles travel either before joining or after leaving the platoon; (2) platoon formation, in which the following vehicle requests to join the platoon, and upon approval from the leading vehicle, longitudinal control (pedal release) and lateral control (steering release) are automated sequentially; (3) platooning maintenance, where vehicles in the platoon continue to drive in a synchronized state; and (4) platoon dissolution, where the following vehicle requests to leave the platoon and, upon approval from the leading vehicle, returns to manual longitudinal (pedal operation) and lateral (steering operation) control. In addition to the platoon formation and dissolution phases, emergency response procedures are activated when general vehicles enter the platoon or when emergency braking is required. In such situations, the following vehicles automatically adjust their distances and perform synchronized braking when the leading vehicle suddenly applies brakes [8]. Most studies on platooning have been conducted using highways as the spatial background as their simpler road structure, traffic flow, signal systems, intersections, vehicle densities, and lane-changing frequencies make them more technically feasible than urban roads [9].

The see-through functionality enables the leading vehicle of the platoon to transmit real-time forward-facing traffic footage to the following vehicles. The leading vehicle captures the real-time traffic situation and transmits it to the following vehicles through V2X communication. The following vehicles display the footage through a human–machine interface (HMI), allowing drivers to recognize the traffic situation ahead of the platoon. This functionality could contribute to enhancing the psychological stability of following drivers under distressing conditions such as abrupt braking.

2.2. Trends in Truck Platooning Technology

Research on truck platooning began with Europe’s “CHAUFFEUR” project in 1996, which was part of the EU initiative called T-TAP. Subsequently, various European projects have promoted the development of truck platooning technology, such as Safe Road Trains for the Environment (SARTRE) [6], which aimed to operate truck platooning while preserving existing road infrastructure and traffic flow, and Enabling Safe Multi-brand Platooning for Europe (ENSEMBLE) [2], which aimed to develop a cloud-based embedded platooning system [10].

In the United States, attempts have been made to introduce platooning to increase highway capacity while minimizing infrastructure construction. The government-led Partners for Advanced Transit and Highways (PATH) project demonstrated the technical feasibility of platooning by maintaining a 3 m gap for two trucks and a 4 m gap for three trucks [6]. The Federal Highway Administration conducted the Exploratory Advanced Research project, where three trucks maintained a time gap of 0.6–1.5 s while traveling at 90 km/h using V2V communication based on Wireless Access in Vehicular Environment technology. In this experiment, the platooning vehicles were equipped with various perception sensors, such as cameras and radars, and were designed to automatically adjust the intervehicle distances in response to merging vehicles [3].

Japan conducted the Energy ITS project from 2008 to 2012 to reduce fuel consumption by suppressing unnecessary acceleration and deceleration during truck platooning and alleviating traffic congestion. In 2010, a real-road experiment successfully demonstrated truck platooning at a speed of 80 km/h with a 4 m intervehicle distance [11].

From 2018 to 2021, a national project led by the Ministry of Land, Infrastructure, and Transport in Korea developed truck platooning technology, safety systems, and operational services. This project confirmed that truck platooning contributed to improving fuel efficiency, road capacity, logistics competitiveness, and safety. In the final demonstration conducted in 2021, three trucks traveled an 80 km stretch at speeds of up to 90 km/h while maintaining a time gap of 0.5 s.

2.3. Review of Literature

2.3.1. Driver Behavior Analysis Using a Driving Simulator

The most effective and ideal approach to analyzing driver behavior characteristics is to conduct experiments in actual road environments. However, actual road experiments are limited by difficulties in control, accident risk, budget, and challenges in consistently reproducing various scenarios. Therefore, this study reviewed previous studies that used simulators, considering safety and cost-effectiveness.

Manawadu et al. [12] analyzed the differences in driver responses to conventional and autonomous vehicles using a driving simulator. The study recruited experienced and inexperienced drivers operating conventional and autonomous vehicles in various driving environments. The results showed that experienced drivers preferred manual vehicles for driving enjoyment and flexibility, whereas inexperienced drivers preferred autonomous vehicles for safety and convenience.

Su et al. [13] developed a methodology for recognizing driver intentions and behaviors using PanoSim and a Gaussian mixture model. The driving style of participants was classified into cautious, normal, and aggressive. Forward collision avoidance (FCA) strategies tailored to each style were designed. The proposed system improved driver comfort, acceptability, and safety compared to existing FCA systems that did not consider driving behavior.

Huang et al. [14] analyzed the effectiveness of diagrammatic guide signs (DGSs) at urban expressway interchanges using a driving simulator. Twelve scenarios were developed by combining four DGS configurations and three ramp types, and driver perceptions and reactions to these DGSs were quantified. The results showed that DGSs effectively reduced the lane-change frequency and driving speed.

Guo et al. [15] anticipated that the mixed operation of autonomous and manual vehicles in mixed traffic environments could cause safety issues within the traffic system. Therefore, they analyzed the lane-changing and gazing behaviors of manual vehicle drivers using a driving simulator. In a cut-in experiment with 11 drivers under different platooning headways (0.8, 1.1, and 1.4 s), drivers tended to delay lane change when the headway was 0.8 s, even though autonomous vehicles were expected to yield. This tendency diminished as the headway increased. The study emphasized that in initial mixed traffic scenarios, human drivers should avoid decision-making delays caused by underestimating the headways.

Tang et al. [16] argued that, in Level 3 autonomous driving, not only efficiency and safety but also driver acceptance must be considered, especially when drivers are required to take command of the vehicle upon system request. Accordingly, they proposed the Tsallis actor–critic (ATAC) algorithm for the longitudinal control of Level 3 autonomous vehicles. Using a next-generation simulation program, they established reward functions related to safety, efficiency, and comfort and trained car-following strategies using six reinforcement learning algorithms. The ATAC algorithm outperformed the other models by simultaneously improving driver comfort and road capacity compared to the conventional full velocity difference model.

Wang et al. [17] utilized a driving simulator to estimate the duration of reduced driver performance during the takeover process in autonomous driving. To this end, vehicle trajectory and driver behavior data were collected under both critical and non-critical takeover scenarios. The results revealed that the duration of reduced driver performance was 27.25 s in critical situations and 17.48 s in non-critical situations. This duration tended to increase when the lead vehicle’s speed was higher and when the preceding automated driving period was longer.

2.3.2. Studies on Platooning Using a Driving Simulator

Zheng et al. [18] used a driving simulator to evaluate the HMI system of truck platooning. Among the three types of HMI (numerical, graphical, and hybrid), the numerical and graphical types were preferred by 60% of the participants because of their ease of understanding platooning situations. The study also determined that a 10 m intervehicle distance significantly increased drivers’ psychological stress. The essential information displayed by the HMI included vehicle control status (graphical), speed, and current and target intervehicle distances, whereas acceleration and fuel efficiency information were regarded as less important. The participants emphasized the need to clearly display the driving speed and distance to the leading vehicle.

Zheng et al. [19] analyzed the psychological stress caused by short intervehicle distances during platooning. Participants engaged in experiments in manual and automated driving environments with intervehicle distances of 20–30 m for manual driving and 4–12 m for automated driving. The results showed that short intervehicle distances significantly increased driver stress, and abrupt deceleration by the leading vehicle was the main cause of increased stress in the following drivers.

Heikoop et al. [20] analyzed the stress changes associated with different types of tasks assigned to drivers. Three scenarios were considered: (1) No task, where drivers simply monitored the road; (2) Voluntary task, where drivers performed tasks of their choice; and (3) Detection task, where drivers were required to detect vehicle colors as instructed by experimenters. The results showed that the Detection task had a high detection rate (95%) but also resulted in higher stress levels. In contrast, the Voluntary task resulted in relatively lower stress. Additionally, the average heart rate tended to decrease with increasing scenario repetitions due to the time-on-task effect.

Gerrits et al. [21] evaluated a platooning partner-matching system using an agent-based simulation model. They applied two algorithms, the first-viable match and best match, considering real-time matching during vehicle stops and opportunistic matching during highway driving. An experiment, conducted at the Port of Rotterdam and nearby highways, confirmed that the main factors determining the economic viability of platooning were wage reduction and feasibility of platooning between trucks from different manufacturers.

2.4. Contributions and Distinctions of This Study

Most studies on truck platooning have focused on improving vehicle control performance or developing infrastructure to support platooning. Studies that considered the changes in driver stress or psychological conditions caused by the introduction of platooning have mostly remained at the level of simple monitoring and lacked a quantitative evaluation or analysis of drivers’ psychological discomfort. In summary, these studies have not systematically addressed drivers’ psychological stability during actual truck platooning experiences.

This study analyzes the psychological stability of drivers expected to be the most affected by changes in the driving environment when truck platooning is introduced. Beyond simply monitoring drivers’ conditions during truck platooning, this study develops a quantitative index to evaluate their psychological stability and uses it to derive an appropriate intervehicle time gap for each scenario. In addition, the effectiveness of the see-through functionality, which should enhance psychological stability, is quantitatively analyzed.

3. Development of a Quantitative Evaluation Index—‘Stability Index’ for Assessing Drivers’ Psychological Stability

In this section, a quantitative evaluation index is developed to assess the psychological stability of drivers within a truck platoon. A review of related studies confirmed that the physiological signals of the human body can be utilized to monitor its psychological states, such as stability and anxiety [22,23]. Physiological signals commonly used to analyze human psychological states are the heart rate (HR), respiratory interval (RI), and galvanic skin response (GSR). In this study, RI and GSR were selected as indicators for developing the evaluation index owing to their sensitivity to stability and anxiety. HR, on the other hand, was deemed inappropriate as an indicator for assessing psychological stability, as it varies significantly depending on emotional states such as happiness–sadness or compassion–anger, rather than directly reflecting stability or anxiety [24,25]. In general, the higher the psychological stability, the longer the RI and the lower the GSR [22].

The definitions of RI and GSR are as follows: The RI refers to the average respiratory interval over one minute and is used to assess the driver’s psychological anxiety level based on the respiratory cycle. Mathematically, RI is defined as the sum of inhalation time gaps per minute divided by the total number of inhalations, where represents the respiration peak time of the -th inhalation and denotes the total number of inhalations per minute:

where denotes the time divided into one-minute intervals during the experiment and denotes the starting time of the experiment. GSR quantifies changes in the driver’s psychological anxiety using the electrical signals of the skin, which varies with sweat gland activity. Mathematically, it is defined as the inverse of skin resistance (R), measured in Ω. To unify the units with RI, this study adopted the GA, which represents the average GSR value per minute, and is defined as follows:

However, because RI and GSR represent physiological signals at a specific point in time, they are insufficient for evaluating drivers’ psychological stability unless their variations under different conditions are analyzed. Therefore, this study defined two additional metrics: the respiration interval ratio (RIR) and the galvanic skin response average ratio (GAR).

First, the RIR expresses the percentage change in the current RI relative to the RI measured one minute prior to the start of the experiment. It is defined as follows:

The GAR, similar to the RIR, represents the percentage change in the current average GSR relative to the average GSR measured one minute prior to the start of the experiment. It is defined as follows:

In this study, the RIR and GAR were utilized to quantitatively analyze the driver’s psychological stability. The evaluation index was named the stability index as it represents the degree of psychological stability of drivers. Consequently, the stability index at time is defined as follows:

Stability Index(t) = RIR(t) − GAR(t).

As explained earlier, when the subject is psychologically stable, the RI and RIR tend to increase, whereas the GSR and GAR tend to decrease. Therefore, the stability index yields a higher value when the driver is more psychologically stable and a lower value when the driver is more anxious.

4. Experimental Environment for Truck Platooning

4.1. Selection of Truck-Platooning Experimental Methodology

The first step in constructing an experimental environment for truck platooning is to select an appropriate experimental methodology. This study considered the following criteria for methodology selection: (1) the experimental environment must enable the implementation of truck platooning technology and its see-through functionality; (2) the implemented technology must possess sufficient realism; (3) it should be able to accommodate various truck platooning scenarios to assess drivers’ psychological stability; and (4) it must allow the measurement of physiological signals reflecting drivers’ psychological stability.

To evaluate psychological stability during truck platooning, three experimental approaches were considered: real-vehicle experiments on a proving ground (PG), real-road experiments, and virtual environment experiments using a driving simulator. Although PGs allow for real-vehicle testing with high safety, they require long straight sections, making them impractical for truck platooning experiments. Real-road experiments offer the highest realism, but they are difficult to control, pose safety challenges, and increase accident risk. Although a driving simulator is slightly less realistic than real-road experiments, it is highly safe, easily controllable, and advantageous for applying and repeating various scenarios. After comparing the advantages and disadvantages of the three methods, this study determined that a driving simulator best met the objectives of the experiment. It not only prevents safety risks associated with testing the relatively novel truck platooning technology but also facilitates the repeated execution of diverse scenarios and enables the measurement and collection of drivers’ physiological indicators necessary for psychological stability assessment.

4.2. Selection of Driving Simulator and Construction of Experimental Environment

This study employed a high-performance driving simulator of the Korea Expressway Corporation (KEC) located at the Vehicle Driving Simulation Facility of the Road Traffic Research Institute. This simulator is utilized in various fields, including the new Electronic Toll Collection System (ETCS), traffic safety, Cooperative-Intelligent Transport Systems (C-ITS), and autonomous driving. It reproduces highly realistic driving experiences by enhancing vehicle dynamics during lane change and acceleration/deceleration through longitudinal and lateral rails and a six-degrees-of-freedom (DOF) actuator. The simulator consists of a real-time vehicle dynamics simulation module, three-dimensional (3D) video generation and display, audio generation and output, motion, capsule and control load systems, and integrated control and monitoring systems.

This study constructed a virtual road traffic environment and implemented truck platooning on the driving simulator. The construction of the virtual environment involved two stages: (1) the creation of a high-definition (HD) map-based video database, and (2) the development of truck platooning strategies. For the driving simulator experiment, a realistic virtual environment based on a video database of the target road section is essential. In the HD map-based video-database construction stage, the video database was generated as 4D videos derived from HD maps, reflecting road surface conditions (e.g., slipperiness, slope, and curvature) and vehicle movement characteristics. The 3D-Max program was used to implement the geometry of the target section in the simulator.

In the truck platooning strategy-development stage, realistic road environments and traffic conditions similar to actual platooning scenarios were reproduced. Because the objective of this study was to analyze drivers’ psychological stability during platooning situations, the traffic environment was configured to reflect real-world conditions while minimizing the psychological instability caused by non-platooning-related traffic congestion. To this end, a level of service (LOS) B traffic environment (10 vehicles per km per lane) was applied. In all scenarios, the number of surrounding vehicles, driving speeds, and driving patterns were kept constant to exclude any psychological anxiety factors unrelated to the purpose of the experiment. Finally, the experimental vehicle automatically formed a platoon upon entering the test section and was set to drive in the outer lane, in compliance with the Road Traffic Act.

Subsequently, truck platooning was implemented on the driving simulator. The simulator had an interchangeable cabin structure depending on the experimental conditions. The cabin is the space in which the participants ride and is driven by a motion platform, which simulates the form of a general vehicle. To replicate the actual truck driving conditions, a truck-shaped cabin was installed for the experiment. The motion platform was tuned, and the vehicle dynamics were adjusted to reproduce the detailed movements of the truck. In the final stage of constructing the experimental environment, the formation and dissolution characteristics of truck platooning were configured with reference to ISO/DIS 4272 and the KEC’s research on “V2X-based Truck Platooning Operation Technology Development”. The platoon formation and dissolution procedures from the perspective of the following vehicles are presented in Table 1, and the simulator and experimental environments used in the experiment are shown in Figure 1.

Table 1.

Process of truck platooning formation and dissolution.

Figure 1.

Driving simulator used in the experiment and the experimental environment.

4.3. Collection of Physiological Signals

This study involved human participants, during which physiological signals were collected through experimental procedures. As such, it may be subject to approval by an Institutional Review Board (IRB). However, under Korea National Institute for Bioethics Policy (KoNIBP) regulations, studies that do not collect or record personally identifiable information and involve only minimal physical contact through non-invasive measurement or observational devices—without inducing any physiological changes (e.g., drug administration)—are exempt from IRB approval. Therefore, IRB approval was not required for this study.

The AIM Gen2 device developed by CGX was used to collect the drivers’ physiological signals. The AIM Gen2 can measure and record various physiological responses in the human body, including HR, body temperature, respiration, GSR, and peripheral capillary oxygen saturation. The device was designed as a compact and lightweight system to minimize interference with participants during experiments and operates as a standalone system. The AIM Gen2 is capable of sampling at rates of up to 1000 Hz by default. In this study, respiratory and GSR sensors were employed to collect the RI and GSR data. The respiratory sensor was attached immediately below the clavicle to measure the participant’s inhalation/exhalation ratios, while the GSR sensor was attached to the palm or other areas with high resistance variabilities to detect resistance changes caused by subtle changes in skin moisture.

5. Driver Psychological Stability Evaluation Experiment Using Driving Simulator

In the driver psychological stability evaluation experiment, experimental scenarios were designed based on variations in the intervehicle time gap and the availability of the see-through functionality. Using the driving simulator, the drivers’ psychological stability under each scenario was evaluated by calculating the stability index. The see-through functionality was implemented in the HMI inside the driving simulator cabin, as shown in Figure 2. The participants could check the real-time traffic situation ahead of the platoon-leading vehicle by viewing the video provided by the see-through functionality on the in-vehicle display. All participants were thoroughly informed about the experimental procedures, methods, and the devices used in the experiment.

Figure 2.

Example of implementation of see-through functionality.

5.1. Experimental Procedure and Scenario Design

To ensure the consistency of the experimental results, this study standardized the spatial scope to a 30 km section of the Seoul–Sejong Expressway in Korea and designated a third truck in the platoon as the experimental subject. The intervehicle time gap in the platoon is expressed in s, and the actual distance (in m) between vehicles is calculated by multiplying the time gap by the vehicle speed (in m/s). For example, in a platoon traveling at 90 km/h, a time gap of 1.0 s corresponds to an actual intervehicle distance of 25.0 m, calculated as .

During all experiments, the participants wore sensors to collect physiological signals. As mentioned earlier, the measurement devices were designed to be compact and lightweight to minimize their influence on the experiment. Before the main experiment, the participants were given time to familiarize themselves with the driving simulator by driving without platooning. After this pre-drive session, the participants accelerated to 90 km/h, during which the baseline values of the RI and GSR, the evaluation indicators, were measured.

Following the baseline measurement, the official platooning procedure was initiated, and the participants performed the experiments according to each scenario. All participants were tested under two main scenarios, depending on how the time gap was adjusted. To ensure that the experimental conditions remained consistent, the platoon was controlled to maintain a speed of 80 km/h. This speed was selected in accordance with the Enforcement Decree and Rules of the Road Traffic Act in South Korea, which specify a maximum speed limit of 80 km/h for freight vehicles on expressways.

The first scenario involved the automatic adjustment of the time gap. In this scenario, experiments were conducted for five time gaps ranging from 0.2–1.0 s, in 0.2 s increments. To minimize bias, the order of the time intervals was randomly assigned.

The second scenario involved manual adjustment of the time gap by the participants, depending on the availability of the see-through functionality. In each condition, the experiment was initiated with a time gap of 0.6 s, and participants adjusted the time gap in 0.1 s increments within the range of 0.2–1.0 s, selecting what they perceived as the most appropriate time gap. A summary of the experimental procedure is presented in Table 2.

Table 2.

Entire experimental procedure.

5.2. Participant Recruitment

Participants were recruited to participate in the driving simulator experiment. To prevent distortion of the experimental results due to inexperienced driving, eligibility requirements were set, requiring participants to have at least two years of truck driving experience and possess a freight transport operator license. Twenty participants were recruited, and their demographic information is presented in Table 3.

Table 3.

Participant demographics.

5.3. Evaluation of Drivers’ Psychological Stability by Scenario

The results of deriving the stability index using the drivers’ physiological signals collected for each scenario are summarized in Table 4. The stability index was calculated by subtracting the GAR from the RIR, as expressed in Equation (5), where a higher value indicates a more psychologically stable state.

Table 4.

Stability index according to intervehicle time gap.

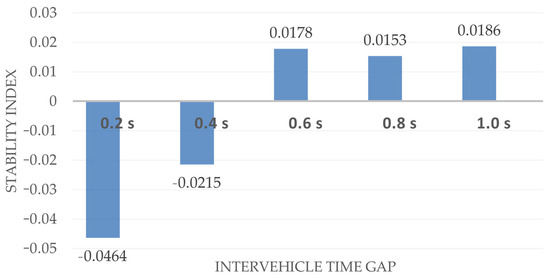

In the first scenario involving automatic time-gap adjustment, the stability index was analyzed for each time gap. The results showed that when the time gap was less than 0.6 s (15 m), the index significantly decreased. In contrast, when the time gap exceeded 0.6 s (15 m), it remained relatively unchanged. Therefore, the appropriate time gap derived using the proposed stability index was identified as 0.6 s.

Although the stability index slightly decreased when the time gap increased from 0.6 s (15 m) to 0.8 s (20 m), the variation was statistically insignificant. A graphical representation of the stability index according to different intervehicle time gaps is shown in Figure 3.

Figure 3.

Stability index variation according to intervehicle time gap.

5.4. Evaluation of Drivers’ Psychological Stability According to Presence of See-Through Functionality

The second experiment was conducted to verify whether the provision of see-through functionality significantly enhanced psychological stability. The system instructed participants to select a comfortable time gap twice, once with the see-through functionality enabled and once without it. The distribution of the time gaps selected by the drivers for each condition is listed in Table 5.

Table 5.

Changes in drivers’ psychological stability based on availability of see-through functionality.

When the see-through functionality was not provided, the participants selected an average time gap of 0.915 s, corresponding to an intervehicle distance of approximately 22.9 m. When see-through functionality was provided, the selected average time gap was reduced to 0.865 s, which is equivalent to approximately 21.6 m.

To verify whether the difference between the two mean time gaps was statistically significant, the Wilcoxon signed-rank test—a widely used nonparametric statistical method for analyzing paired sample data, such as pre/post comparisons—was conducted. The dataset used in this study consisted of 20 paired samples. Because the normality assumption was not satisfied, the use of this nonparametric test was deemed appropriate [26].

The results of the Wilcoxon signed-rank test indicated that the difference between the two means was statistically significant at the 95% confidence interval. This confirmed that the see-through functionality, which provided real-time traffic information from the leading vehicle to the following vehicle within the platoon, had a statistically significant positive effect on the psychological stability of the following drivers. Table 6 presents the results of Wilcoxon signed-rank tests.

Table 6.

Results of the Wilcoxon signed rank test (95% confidence interval).

5.5. Post-Experiment Survey for Validation of Stability Index

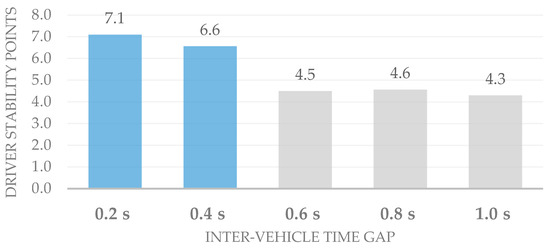

As the final step of the experiment, a post-survey was conducted to verify whether the stability index accurately reflected the drivers’ actual psychological states. The survey was administered verbally using a 9-point scale. A survey response exceeding the median value of 5 points was interpreted as indicating that the driver experienced psychological anxiety.

The survey results showed a trend similar to that of the stability index derived from the driving simulator experiments. Specifically, as the time gap increased, the Driver Stability points decreased, indicating a reduction in the anxiety level. Notably, when the time gap was reduced to less than 0.6 s (15 m), the anxiety level significantly increased; whereas, when the time gap exceeded 0.6 s, the improvement in psychological stability was marginal. This trend is consistent with those of the stability index analysis.

Therefore, the post-survey results verified that the proposed stability index, based on physiological signals, effectively represented the drivers’ actual psychological states. A summary of the post-survey results is presented in Table 7, and a visualization of the Driver Stability points is shown in Figure 4.

Table 7.

Changes in following drivers’ psychological stability according to time gap variation.

Figure 4.

Driver stability points from the post-survey.

6. Conclusions and Future Work

6.1. Conclusions

When developing a novel technology, it is essential to consider not only its technical aspects but also its user-centric factors to ensure successful deployment. In the case of truck platooning, a type of autonomous driving technology, although substantial technical progress has been made, studies focusing on user perspectives remain insufficient. In particular, as truck platooning is introduced, the intervehicle time gap is projected to decrease compared to that in manual trucking, which may pose a risk to drivers’ psychological stability.

Accordingly, this study developed a new quantitative evaluation index, namely, the stability index, to assess the psychological stability of following drivers during truck platooning with respect to the intervehicle time gap. The results of a quantitative analysis using the stability index showed that when the time gap was less than 0.6 s (15 m), drivers experienced a considerable decline in psychological stability. Meanwhile, increasing the time gap beyond 0.6 s did not have a significant impact on enhancing psychological stability.

To verify whether this index appropriately reflected the drivers’ actual psychological states, a post-experiment survey was conducted, and the results were compared with the quantitative evaluation results. The survey results were highly consistent with the quantitative results obtained using the stability index, confirming that the index effectively captured changes in the drivers’ psychological stability during truck platooning.

Additionally, this study analyzed whether the see-through functionality, which provides real-time forward traffic information from the leading vehicle to the following drivers, positively influences psychological stability. The drivers expressed more psychological stability even under shorter time gap conditions with the see-through functionality. The difference between the two experimental conditions was verified as statistically significant using the Wilcoxon signed-rank test, confirming that the see-through functionality has a statistically significant positive effect on improving drivers’ psychological stability.

The proposed stability index and see-through functionality can serve as practical tools for the development of truck platooning systems that consider drivers’ psychological stability and can be used as a basis for determining the optimal time gap. Furthermore, the proposed stability index may be generalized to other autonomous driving applications where the user’s psychological state is of critical importance. For instance, in adaptive cruise control or general vehicle platooning scenarios, drivers may experience psychological discomfort due to shortened headways or limited forward visibility. In such cases, the stability index could serve as a valuable tool for quantitatively evaluating driver comfort across various operational settings.

With the adoption of autonomous driving technology, driving environments are gradually shifting from being driver-centered to system-centered. However, the psychological stability of drivers and passengers, who remain inside the vehicles, must not be overlooked. Therefore, it is crucial to create an environment that ensures psychological comfort along with the technical development of autonomous driving. From this perspective, the proposed stability index is considered suitable as an evaluation metric for users’ psychological stability and should contribute to the advancement of autonomous driving technology that incorporates user-centric considerations.

6.2. Limitations and Future Works

In this study, a quantitative evaluation index for assessing the psychological stability of following drivers in truck platooning situations was developed using a driving simulator, and experiments were conducted to analyze the effect of the see-through functionality on the psychological stability of drivers. However, this study had several limitations.

First, owing to temporal and logistical constraints, only 20 participants could be recruited. Consequently, the representativeness of the experimental results may be limited. Since the outcomes may vary depending on participant characteristics such as age and gender, a sufficient sample size is required to ensure the generality and transferability of the findings. Future research should address this limitation by replicating the experiment with a larger sample to improve the reliability and external validity of the findings.

Second, to prevent variations in the experimental results caused by factors unrelated to the purpose of the experiment, experimental conditions, such as vehicle speed, number of platooning vehicles, and position of the experimental vehicle within the platoon, were fixed during the simulator-based experiments. However, because truck platooning occurs under diverse conditions in real traffic environments, future studies should enhance the reliability of the findings by conducting experiments under diverse scenarios and conditions.

Finally, this study was conducted in a driving simulator environment due to challenges related to experimental control, safety concerns, and cost, rather than under real-road conditions. While the simulator provides a safe and repeatable setting for testing, it has inherent limitations in replicating the full realism of real-road environments. As a result, the experiments may not fully capture edge cases or complex interactions that can occur in actual road conditions. To reduce these uncertainties and to validate and complement the simulation results, future studies should incorporate real-road experiments, thereby enhancing the ecological validity and applicability of the findings.

Author Contributions

Conceptualization, H.C., Y.K., S.O. and I.Y.; methodology, H.C. and Y.K.; validation, H.C. and Y.K.; formal analysis, H.C. and Y.K.; investigation, S.O. and I.Y.; resources, S.O. and I.Y.; writing—original draft preparation, H.C.; writing—review and editing, Y.K.; visualization, H.C. and Y.K.; supervision, S.O. and I.Y.; project administration, S.O. and I.Y.; funding acquisition, I.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Korea Institute of Police Technology (KIPoT) grant funded by the Korea government (KNPA) (No. 092021C29S01000, Development of Traffic Congestion Management System for Urban Network).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated during the present study are available from the author, Yejin Kim (e-mail: jinyyyy@ajou.ac.kr), upon request.

Conflicts of Interest

Author Hyonbae Cho was employed by the company Korea Expressway Corporation. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Tsugawa, S.; Jeschke, S.; Shladover, S.E. A review of truck platooning projects for energy savings. IEEE Trans. Intell. Veh. 2016, 1, 68–77. [Google Scholar] [CrossRef]

- Willemsen, D.M.C.; Schmeitz, A.J.C.; Mascalchi, E. EU ENSEMBLE project: Specification of an interoperable solution for a support function for platooning. IEEE Trans. Intell. Transp. Syst. 2023, 24, 5705–5718. [Google Scholar] [CrossRef]

- Shladover, S.E. Introduction to truck platooning. In Proceedings of the ITS World Congress, Montreal, QC, Canada, 29 October–2 November 2017. [Google Scholar]

- Törnell, J.; Sebben, S.; Söderblom, D. Influence of inter-vehicle distance on the aerodynamics of a two-truck platoon. Int. J. Automot. Technol. 2021, 22, 747–760. [Google Scholar] [CrossRef]

- Cheng, H.; Wang, Y.; Chong, D.; Xia, C.; Sun, L.; Liu, J.; Gao, K.; Yang, R.; Jin, T. Truck platooning reshapes greenhouse gas emissions of the integrated vehicle-road infrastructure system. Nat. Commun. 2023, 14, 4495. [Google Scholar] [CrossRef] [PubMed]

- Bergenhem, C.; Shladover, S.; Coelingh, E.; Englund, C.; Tsugawa, S. Overview of platooning systems. In Proceedings of the 19th ITS World Congress, Vienna, Austria, 22–26 October 2012. [Google Scholar]

- Axelsson, J. Safety in vehicle platooning: A systematic literature review. IEEE Trans. Intell. Transp. Syst. 2016, 18, 1033–1045. [Google Scholar] [CrossRef]

- Vissers, J.; Banspach, J.; Liga, V.; Tang, T.; Nordin, H.; Julien, S.; Martinez, S.; Villette, C. V1 Platooning Use-Cases, Scenario Definition and Platooning Levels, D2.2 of H2020 Project ENSEMBLE. 2018. Available online: https://platooningensemble.eu/storage/uploads/documents/2021/03/24/ENSEMBLE-D2.2_V1-Platooning-use-cases,-scenario-definition-and-platooning-levels_FINAL.pdf (accessed on 15 April 2025).

- Jeong, S.; Baek, Y.; Son, S.H. Distributed urban platooning towards high flexibility, adaptability, and stability. Sensors 2021, 21, 2684. [Google Scholar] [CrossRef] [PubMed]

- European Road Transport Research Advisory Council. Automated Driving Road Map. ERTRAC Task Force “Connectivity and Automated Driving”, Version 5. 2015. Available online: https://www.ertrac.org/wp-content/uploads/2022/07/ERTRAC_Automated-Driving-2015.pdf (accessed on 15 April 2025).

- Tsugawa, S. An overview on an automated truck platoon within the energy ITS project. IFAC Proc. Vol. 2013, 46, 41–46. [Google Scholar] [CrossRef]

- Manawadu, U.; Ishikawa, M.; Kamezaki, M.; Sugano, S. Analysis of individual driving experience in autonomous and human-driven vehicles using a driving simulator. In Proceedings of the IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Busan, South Korea, 7–11 July 2015; IEEE Publications: New York, NY, USA, 2015; pp. 299–304. [Google Scholar] [CrossRef]

- Su, C.; Deng, W.; Sun, H.; Wu, J.; Sun, B.; Yang, S. Forward collision avoidance systems considering driver’s driving behavior recognized by Gaussian Mixture Model. In Proceedings of the IEEE Intelligent Vehicles Symposium, Los Angeles, CA, USA, 11–14 June 2017; IEEE Publications: New York, NY, USA, 2017; pp. 535–540. [Google Scholar] [CrossRef]

- Huang, L.; Zhao, X.; Li, Y.; Rong, J. Driving simulator-based study to quantify typical diagrammatic guide sign efficiency along urban expressway interchanges. J. Transp. Saf. Sec. 2020, 12, 839–862. [Google Scholar] [CrossRef]

- Guo, X.; Jiang, Y.; Kim, I. Interacting with autonomous platoons: Human driver’s adaptive behaviors in planned lane changes. In Systems and Information Engineering Design Symposium (SIEDS); IEEE Publications: Charlottesville, VA, USA, 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Tang, T.Q.; Gui, Y.; Zhang, J. ATAC-Based Car-Following Model for Level 3 Autonomous Driving Considering Driver’s Acceptance. IEEE Trans. Intell. Transport. Syst. 2022, 23, 10309–10321. [Google Scholar] [CrossRef]

- Wang, C.; Xu, C.; Peng, C.; Tong, H.; Ren, W.; Jiao, Y. Predicting the duration of reduced driver performance during the automated driving takeover process. J. Intell. Transp. Syst. 2024, 29, 218–233. [Google Scholar] [CrossRef]

- Zheng, R.; Nakano, K.; Kato, S.; Ogitsu, T.; Yamabe, S.; Aoki, K.; Suda, Y. Human–machine interface system for simulation-based automatic platooning of trucks. In Proceedings of the 16th International IEEE Conference on Intelligent Transportation Systems (ITSC 2013), The Hague, Netherlands, 6–9 October 2013; IEEE Publications: New York, NY, USA, 2013; pp. 535–539. [Google Scholar] [CrossRef]

- Zheng, R.; Yamabe, S.; Nakano, K.; Suda, Y. Biosignal analysis to assess mental stress in automatic driving of trucks: Palmar perspiration and masseter electromyography. Sensors 2015, 15, 5136–5150. [Google Scholar] [CrossRef] [PubMed]

- Heikoop, D.D.; de Winter, J.C.F.; van Arem, B.; Stanton, N.A. Effects of platooning on signal-detection performance, workload, and stress: A driving simulator study [App]. Appl. Ergon. 2017, 60, 116–127. [Google Scholar] [CrossRef] [PubMed]

- Gerrits, B.; Mes, M.; Schuur, P. Simulation of real-time and opportunistic truck platooning at the port of Rotterdam. In Proceedings of the Winter Simulation Conference (WSC), National Harbor, MD, USA, 8–11 December 2019; IEEE Publications: New York, NY, USA, 2019; pp. 133–144. [Google Scholar] [CrossRef]

- Shin, E.; Kim, M.G.; Lee, C.; Kang, H.B. Driver’s status recognition using multiple wearable sensors. KIPS Trans. Comput. Comm. Syst. 2017, 6, 271–280. [Google Scholar] [CrossRef]

- Kim, J.; Shin, M. Utilizing HRV-derived respiration measures for driver drowsiness detection. Electronics 2019, 8, 669. [Google Scholar] [CrossRef]

- Shi, H.; Yang, L.; Zhao, L.; Su, Z.; Mao, X.; Zhang, L.; Liu, C. Differences of heart rate variability between happiness and sadness emotion states: A pilot study. J. Med. Biol. Eng. 2017, 37, 527–539. [Google Scholar] [CrossRef]

- Rein, G.; Atkinson, M.; McCraty, R. The physiological and psychological effects of compassion and anger. J. Adv. Med. 1995, 8, 87–105. [Google Scholar]

- Rosner, B.; Glynn, R.J.; Lee, M.L.T. The Wilcoxon signed rank test for paired comparisons of clustered data. Biometrics 2006, 62, 185–192. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).