Abstract

The steel liner plays a key role in ensuring the leak-tightness of nuclear containment structures (NCSs). Once the liner is subjected to corrosion, its corrosion effects can severely impact the leak-tight function of the NCS, especially in severe accident scenarios. Therefore, evaluating the corrosion effects of the liner is essential to guaranteeing the safe operation of nuclear power plants. This paper presents a probabilistic safety analysis of the NCS under liner corrosion conditions. Firstly, the corrosion mechanism of the liner is elucidated, and a refined simulation method is developed to investigate the localized corrosion effects of the liner. Utilizing a probabilistic finite element method, the fragility of the NCS under loss-of-coolant accident (LOCA) conditions is evaluated. Finally, the leakage risk of the NCS at different degrees of liner corrosion is discussed. The results indicate that liner corrosion has a significant impact on the median pressure capacity and high-confidence–low-probability pressure capacity of the NCS. With the aggravation of liner corrosion, the safety margin of the NCS decreases, and the total probability of failure increases. Within the scope of this paper, the NCS can fulfill the probabilistic safety requirements.

1. Introduction

The unsustainability of traditional energy systems has imposed environmental pressure worldwide, with urgent global issues such as resource scarcity and climate change escalating. Promoting the advancement of green and low-carbon energy is widely acknowledged as a crucial and effective approach to addressing global environmental issues. Nuclear power offers numerous advantages, including renewability, high energy output, and high efficiency, making it a viable strategy for restructuring the energy structure and promoting sustainable development. A paramount focus in the development strategy for nuclear power lies in ensuring nuclear safety. The nuclear containment structure (NCS) is the final barrier within the safety defense system, and it is primarily designed to guarantee leak-tightness in the event of reactor accidents. Despite the rigorous design of the NCS, it is inevitable that age-related degradation will occur as service time increases. These aging effects have the potential to reduce the NCS’s ability to withstand abnormal accidents. Consequently, the analysis and assessment of the NCS under aging conditions have attracted substantial attention in nuclear engineering. Over the past decades, extensive research efforts have been dedicated to exploring the aging effects on the NCS, including the aging form and aging mechanism of the NCS [1], the long-term behavior and service life prediction of the NCS [2,3,4], the structural response of the aged NCS subjected to overpressure and seismic loads [5,6], a reliability assessment of the aged NCS [7,8], etc. These studies provide significant insights into the establishment of management strategies for aging for nuclear power plants.

The containment steel liner (hereafter, liner) is a layer of gas-tight steel plate anchored to the inner wall of the NCS. The liner is designed to safeguard the leak-tightness of the NCS, while its contribution to the bearing capacity of the NCS is usually neglected. Numerous experimental studies have demonstrated that the cracking of concrete occurs before the tearing of the liner when the NCS is subjected to overpressure loads [9,10,11]. Therefore, the leak-tightness of the NCS in severe accident scenarios is mainly ensured by the liner [12,13]. Liner corrosion represents a primary form of aging-related degradation in the NCS, and the degradation of the material properties of corroded liners can threaten the leak-tight function of the NCS under accident conditions. To examine the impact of liner corrosion on the NCS, the Nuclear Regulatory Commission (NRC) has carried out a systematic study [14]. Firstly, a criterion for predicting the tearing of corroded liners in finite element (FE) simulations was proposed. Subsequently, FE models for typical NCSs were developed. Finally, the effect of liner corrosion on the pressure capacity of these NCSs was evaluated through nonlinear numerical simulations. Utilizing the simulation method provided by the NRC, Smith et al. [15] investigated the effect of different corrosion degrees and corrosion regions on the pressure capacity of a reinforced concrete containment structure. Alhanaee et al. [5] explored the structural behavior of a prestressed concrete containment structure under liner corrosion conditions and evaluated the corrosion impact on its ultimate bearing capacity. Additionally, Spencer et al. [16] assessed the fragility of the NCS with different degrees of liner corrosion in conjunction with the probabilistic method.

To guarantee the safe operation of nuclear power plants, it is important to identify the impact of various forms of aging on the NCS as well as to evaluate the corresponding leakage risks. Since the liner plays a key role in preventing the release of radioactive material, it is necessary to clarify the impact of liner corrosion on the leak-tightness of the NCS in the aging assessment. However, investigations into the NCS under liner corrosion conditions are very limited, with some studies conducted many years ago. Considering the significance of the liner in preventing the release of radioactive material, it is necessary to further investigate the influence of liner corrosion on the leak-tight function of the NCS by using current analytical technology. In addition, the loss-of-coolant accident (LOCA) condition is a critical concern in nuclear engineering. During the LOCA condition, a large amount of hot steam is generated in the NCS, which leads to a simultaneous increase in temperature and pressure inside the NCS [17]. Therefore, the temperature effect under LOCA conditions is also a major concern in the analysis and evaluation of the NCS. However, previous investigations of liner corrosion have primarily concentrated on the internal pressure condition. The influence of the combined effects of liner corrosion and thermal pressure coupling loading on the leak-tight function of the NCS has not been thoroughly investigated. Last but not least, the NCS typically involves various uncertainties during construction and operation, and thus the safety assessment of the NCS under accident conditions should fulfill both deterministic and probabilistic performance objectives [18]. The probabilistic safety assessment (PSA) methodology is widely applied to assess the leakage risk of nuclear power plants under accident or disaster scenarios, and it provides an effective way to specify the probabilistic safety performance of the NCS [19,20]. However, few studies have been carried out to assess the safety performance of the NCS under liner corrosion conditions within the PSA framework.

With the background mentioned above, this paper evaluates the fragility and leakage risk of the NCS under LOCA conditions, considering different liner corrosion conditions. Firstly, the corrosion mechanism of containment liners is elucidated, and a refined simulation method is developed to investigate the localized corrosion effects of the liner. Utilizing the probabilistic FE method, a fragility assessment of the NCS subjected to thermal pressure coupling loads is carried out, and the median pressure capacity and the high-confidence–low-probability capacity (HCLPF) of the NCS under liner corrosion conditions are evaluated. Finally, the leakage risk of the NCS at different degrees of liner corrosion is discussed in detail. The findings in this paper can inform the probabilistic safety assessment (PSA) of the NCS under liner corrosion conditions.

2. Corrosion Mechanisms and Simulation Schemes for Corroded Liner

2.1. Corrosion Mechanism of the Liner

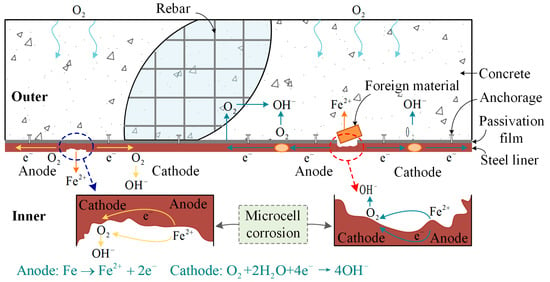

The liner is generally secured to the entire inner wall of the NCS by anchorages to provide the required airtightness of the structure. Liner corrosion can be categorized into two types: inside corrosion (occurring on the side facing the internal environment of the NCS) and outside corrosion (occurring on the side in contact with the concrete wall) [21]. Figure 1 provides a diagram of the corrosion mechanism of the liner. The inside corrosion is primarily caused by the age-related failure of the antirust coating or waterproof layer on the surface of the liner, subsequently exposing the liner to the internal environment of the NCS. In this case, the corrosion mechanism of the liner is similar to the electrochemical corrosion mechanism of carbon steels in atmospheric conditions. Electrochemical corrosion is essentially a redox reaction, including both anodic and cathodic reactions. The anodic reaction involves the transfer of metal ions from the metal to the medium, releasing electrons and causing the dissolution of the liner. The cathodic reaction involves a reduction process of the oxidant (e.g., oxygen) component of the medium, absorbing electrons from the anode. Conversely, the cathodic reaction entails the oxidant (e.g., oxygen) component of the medium absorbing electrons from the anode. Additionally, the rate of inside corrosion is influenced by the humidity and temperature within the NCS.

Figure 1.

Diagram of the corrosion mechanism of the liner.

The outside corrosion mechanism of the liner is the same as that on the inside, but there are differences in the corrosion conditions and processes. Upon contact with the alkaline environment within the concrete, a stable passivation film will form on the surface of the liner. This film can greatly reduce the anodic reaction rate and thus provide a protective barrier against the corrosion of the liner. The outside corrosion of the liner initiates with the destruction of the passivation film, and there are two main aspects that contribute to such destruction. On the one hand, the liner typically serves as an inner mold for the concrete pouring process. During the construction of the NCS, the liner was exposed to the ocean environment for an extended period of time, resulting in localized corrosion on the outer surface of the liner. After the concrete is poured, the local area on the outer surface of the liner fails to develop a dense passivation film. Simultaneously, chloride ions remaining on the surface of the liner will intensify the destruction of the passivation film [22]. On the other hand, some acidic foreign materials (e.g., wood, gloves, etc.) are inadvertently left in the concrete during the construction process. When these materials come into contact with the outer surface of the liner, the pH in the contact area will decrease. When the pH drops to the threshold value (e.g., pH < 10), the passivation film will be destroyed [23]. Once the passivation film is destroyed, the liner becomes vulnerable to electrochemical corrosion in environments where there is an adequate presence of water and oxygen.

2.2. Simulation Scheme for Corroded Liners

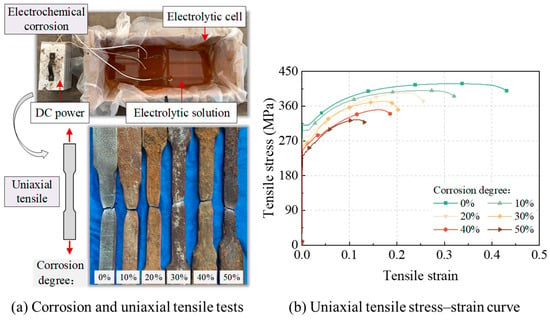

In previous work, we have carried out a series of experiments to investigate the mechanical behavior of typical containment liners under different degrees of corrosion [24]. Figure 2 presents an overview of tests conducted on corroded liners. The results indicate that the effective cross-section of the liner is reduced due to the generation of corrosion products, which results in a decrease in its ability to resist loads. Simultaneously, the non-uniform corrosion process leads to the formation of numerous corrosion pits on the liner (as shown in Figure 2a), which can easily create stress concentration areas on the liner. The localized damage effect caused by corrosion pits can accelerate the formation and extension of cracks in the uncorroded liner, resulting in a degradation of the mechanical properties of the liner. To accurately simulate the real corrosion conditions, it is imperative to explicitly consider both of these corrosion effects. Consequently, the simulation method for liner corrosion provided in this paper is as follows: Firstly, the thickness of corroded liners is thinned according to the severity of the corrosion. Subsequently, the corresponding stress–strain relationships for liners with different degrees of corrosion are applied to the corrosion-affected area. This comprehensive method ensures a detailed and realistic simulation of the corroded liner.

Figure 2.

Overview of tests on corroded liners.

3. Numerical Analysis Model of the NCS

3.1. Basic Parameters of the NCS

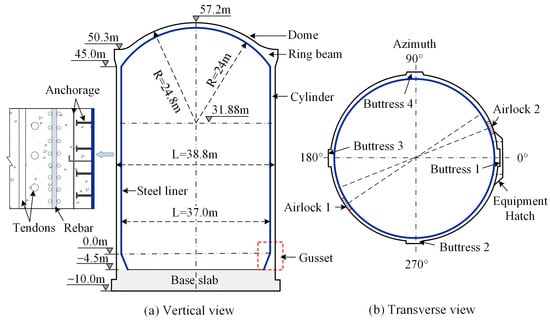

The NCS investigated in this paper is from a “second generation plus” improved nuclear power technology project in China (CPR1000), and this NCS has been in service for nearly 20 years. Figure 3 illustrates its geometrical configuration. The NCS is a single-walled structure with structural configurations including a base slab, gusset, cylinder, ring beam, dome, and steel liner. Furthermore, four buttresses are symmetrically arranged on the outside of the cylinder to anchor the prestressed tendons. The basic geometric dimensions of the NCS are as follows: the heights of the base slab, gusset, and cylinder are 10 m, 4.5 m, and 45 m, respectively; the total height of the ring beam and the dome is 12.2 m; the inner and outer diameters of the cylinder are 37 m and 19.4 m, respectively, with a wall thickness of 0.9 m; the curvature radius of the dome is 24 m and the wall thickness is 0.8 m; and the design thickness of the liner is 6 mm. To fulfill functional requirements, several penetration holes are installed on the NCS, such as personnel airlocks and equipment hatches, etc.

Figure 3.

Geometrical configuration of the NCS.

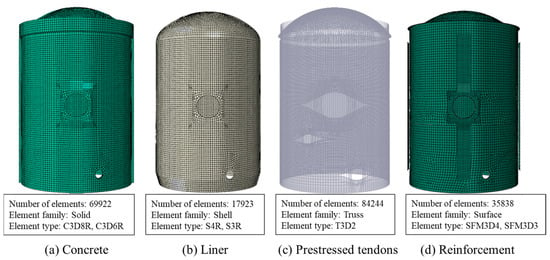

3.2. Numerical Analysis Model of the NCS

Using ABAQUS platform, a numerical analysis model for the NCS is established. The detailed modeling information for each component of the analytical model is illustrated in Figure 4. The reinforcement and prestressed tendons in the NCS are modeled separately and are arranged in the concrete by an embedding technique without taking into account the slip effect. The deformation between the liner and the concrete is assumed to be coordinated, and the liner is created on the inner surface of the concrete by means of a skin technique. To strike a balance between computational efficiency and accuracy, the overall mesh density of the analytical model is set at 800 mm. Furthermore, a finer mesh is implemented in the structural discontinuity areas within the NCS (e.g., penetration holes and ring beam) to ensure a precise representation of these critical regions.

Figure 4.

Overall model of the NCS.

3.3. Material Parameters

3.3.1. Concrete

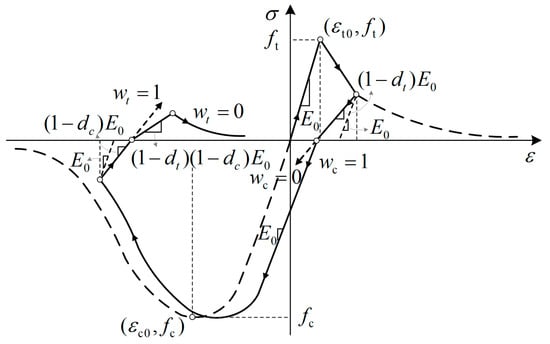

The concrete plastic-damage (CDP) model is considered to be effective in simulating the nonlinear behavior of concrete material, which systematically incorporates the plastic deformation and damage evolution processes of concrete. Through the introduction of damage variables, the CDP model captures the cumulative damage experienced by concrete structures during loading, enabling accurate predictions of structural responses under substantial deformation and high-stress conditions. The diagram of the CDP model is depicted in Figure 5, and its basic expressions are as follows:

where and represent the tensile and compressive stress, respectively; represents the initial modulus of elasticity. and represent the tensile and compressive strain, respectively; and represent the equivalent tensile and compressive plastic strains, respectively.

Figure 5.

Diagram of the CDP model.

The and in Equations (1) and (2) are parameters that express the tensile and compressive damage of concrete and can be determined according to the following equations:

where and represent the calculated variables, which can be determined in accordance with the relevant literature [25].

To fully characterize the CDP model, it is necessary to provide the uniaxial stress–strain relationships of concrete and the corresponding plasticity parameters. In this paper, the constitutive relationships for concrete in uniaxial tension and compression used in the literature [24] are adopted. The plasticity parameters required for the CDP model consist of the dilation angle (Ψ), shape parameter (Kc), flow potential eccentricity (λ), the ratio of biaxial to uniaxial compressive strength (fb0/fc), and the viscosity parameter (μ). These parameters are used to characterize the shape of the yield surface and the flow rules of the concrete. Table 1 shows the plasticity parameters selected for this paper.

Table 1.

Plasticity parameters used in the CDP model.

3.3.2. Steel

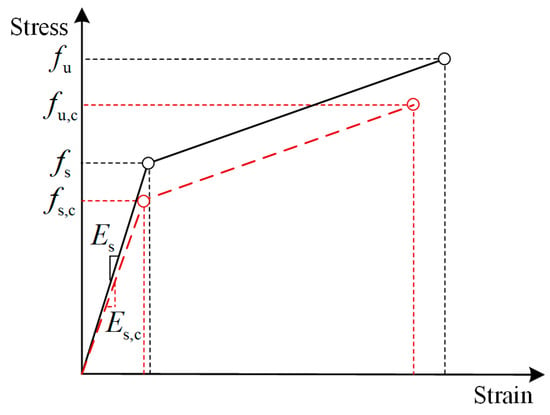

The liner of the NCS is made of P265GH-grade steels (manufacturer, city, and country), and a bi-linear model is employed to characterize its stress–strain behavior, as depicted in Figure 6. To accurately describe the mechanical behavior of the corroded liner, it is necessary to establish the corresponding stress–strain relationships. In this paper, the stress–strain relationship for the corroded liner is modeled by discounting the mechanical parameters of the uncorroded liner. Utilizing the outcomes of uniaxial tensile tests conducted on corroded liners, the mechanical parameters for liners under various degrees of corrosion can be determined through the following equations:

where , , and represent the elastic modulus, yield strength, and ultimate strength of the uncorroded liner, respectively; , , and represent the corresponding parameters under corrosion conditions, respectively. represents the corrosion degree, which is defined in this paper as the reduction rate of the average cross-sectional area of the corroded liner.

Figure 6.

Constitutive model of the liner.

In addition, the reinforcement employed in the NCS consists of HRB400 and HRB335-grade steel, while the 1770-grade strand is utilized for the prestressed tendons. In the analytical model, an ideal elasto-plastic model is used to characterize the stress–strain behavior of both the reinforcement and prestressed tendons, as it can greatly enhance the efficiency of the calculations.

3.4. Boundary Conditions and Loading Procedures

For the overall model of the NCS, the restraining effect of the foundation base slab is simulated by fixing all the degrees of freedom at the bottom of the model. As mentioned previously, the NCS will be subjected to high temperatures and pressures under LOCA conditions. To examine the thermal pressure coupling effect, a sequentially coupled thermal stress analysis technique is adopted to obtain the temperature field and thermal stress of the NCS under LOCA conditions. The temperature field within the NCS under LOCA conditions is computed through transient heat transfer analysis, based on the temperature–time profile provided in the literature [26]. The heat transfer analysis comprises four components: convection between the interior fluid of the NCS and the inner surface of the liner, conduction within the liner, conduction within the concrete, and convection between the ambient environment and the outer surface of the concrete. Referring to the relevant literature [17,26], the thermal expansion coefficient, thermal conductivity, and specific heat of the concrete are taken as 1 × 10−5/°C, 1.4 W/(m·°C), and 879 J/(kg·°C), respectively; the thermal expansion coefficient, thermal conductivity, and specific heat of the liner are taken as 1.2 × 10−5/°C, 45 W/(m·°C), and 500 J/(kg·°C), respectively; and the thermal convection coefficients between the inner and outer surfaces of the NCS and the surrounding fluid are taken as 16 W/(m2·°C) and 8 W/(m2·°C), respectively. In addition, the degradation of the mechanical properties of materials under high temperatures is explicitly taken into account in accordance with the relevant codes [27].

The loading procedure for the NCS encompasses three sequential steps: Firstly, gravity and prestressing loads are applied to the NCS. Subsequently, the nodal temperature field obtained from the heat transfer analysis is applied to the NCS as a thermal load. Finally, a linearly increasing pressure load is applied to the inner surface of the NCS. It should be noted that the cooling method is employed to simulate the tensioning of the prestressed tendons [28], and the thermal expansion coefficient of the prestressed tendons is taken as 1.2 × 10−5/°C.

4. Analysis Program for Liner Corrosion

4.1. Corrosion Analysis Method

A series of aging investigations into the NCS revealed that the liner corrosion is highly localized and the corroded area of the liner is typically small [21,23]. Therefore, the numerical analysis model requires a detailed mesh to reflect the stress concentration in the corrosion-affected area. Given the substantial size and intricate structural complexity of the NCS, employing a detailed mesh in the overall model of the NCS will generate heavy computational work and pose challenges in achieving convergence. To this end, we propose a simulation program for liner corrosion utilizing the sub-modeling technique in ABAQUS 2020. Specifically, a refined sub-model for the critical region (the area most prone to liner corrosion) of the NCS is first established according to the design information. Then, a nonlinear analysis is carried out on the overall model to derive the calculation results. Finally, the node displacement results from the overall model are interpolated to the boundaries of the gusset sub-model. In this way, the corrosion characteristics and the corrosion degrees of the liner can be considered in detail in the sub-model, and the localized corrosion effects of the liner on the NCS can be evaluated by sub-model analysis.

4.2. Sub-Model for the Corroded Liner

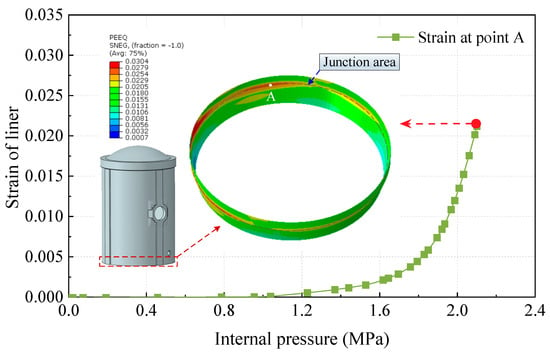

Numerous investigations have shown that the gusset region has high humidity and is prone to water accumulation. Once the waterproofing fails, the liner in this area is vulnerable to electrochemical corrosion in environments where water and oxygen are abundant. So far, several severe corrosion cases have been found in the gusset region of the NCS [14,16,21]. Therefore, the gusset region is taken as the critical region for liner corrosion in this paper. Figure 7 depicts the strain of liners in the gusset region of the overall model under internal pressure. Due to the discontinuity of the stiffness in the gusset region, the maximum strain of the liner is concentrated at the junction of the gusset and cylinder wall. Once liner corrosion develops in this area, the corrosion effects will be the most pronounced. To investigate the most unfavorable case of liner corrosion, we establish a sub-model consisting of the gusset and part of the cylinder wall and set the corrosion area at the junction area between the gusset and the bottom of the cylinder wall, as shown in Figure 8. It should be mentioned that the modeling approach and the material stress–strain relationship for each part in the gusset sub-model are consistent with those in the overall model.

Figure 7.

Strain of liner in the gusset region of the NCS.

Figure 8.

Gusset sub-model and delineation of the corrosion area.

4.3. Validity of Gusset Sub-Model

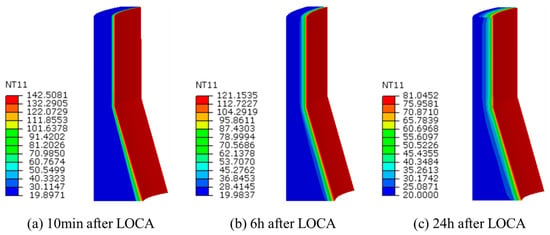

After the gusset sub-model is established, its spatial coordinates are readjusted to match those of the corresponding region in the overall model. Thereby, the boundary conditions of the gusset sub-model are determined based on the corresponding region in the overall model. Utilizing the sub-modeling analytical interface offered by ABAQUS, the node-based sub-modeling technique is applied to transfer the node displacements from the overall model to the boundaries of the gusset sub-model. It is important to note that the sub-modeling analysis also involves the definition of the temperature field. Figure 9 depicts the distribution of the temperature field in the gusset region of the NCS under LOCA conditions. It can be seen that the maximum temperature of the inner wall of the gusset is approximately 145 °C, and the temperature exhibits a nonlinear distribution along the thickness direction of the wall. Furthermore, the temperature of the inner wall decreases as time increases, and the temperature spreads farther in the direction of the wall thickness. Based on the heat transfer results, a LOCA temperature of 145 °C is applied as a thermal load to the gusset region. Meanwhile, it is assumed that the ambient temperature outside the NCS is 20 °C.

Figure 9.

Temperature distribution in the gusset region under LOCA conditions.

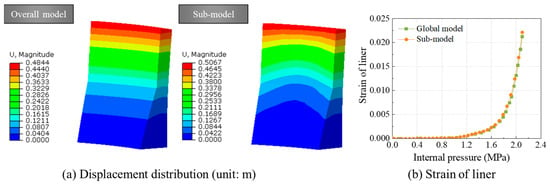

According to the loading procedure described above, nonlinear FE analyses are performed on the overall model and the gusset sub-model to validate the effectiveness of the gusset sub-model. To facilitate the comparison of the analysis results, the mesh density of the gusset sub-model is set to be the same as that of the overall model. As shown in Figure 10, the deformation distributions of both the overall model and the gusset sub-model are similar under the same internal pressure (2.1 MPa), and the difference in the maximum displacement is less than 5%. Moreover, the strains of the liner demonstrate a high degree of similarity throughout the whole pressurization process. Generally, the developed gusset sub-model is effective.

Figure 10.

Verification of the effectiveness of the gusset sub-model.

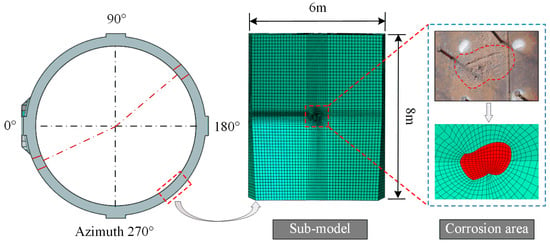

4.4. Definition of the Corrosion Area

Corrosion is usually random and non-uniform, and thus the corrosion shape of the liner also tends to be irregular. In this paper, the corrosion characteristics of the liner detected in an actual nuclear power plant are utilized to simulate the genuine corrosion morphology as accurately as possible [21]. Figure 8 also illustrates the corrosion shape of the liner through graphical processing. After mesh sensitivity analysis, the overall mesh density of the gusset sub-model is taken as 150 mm. Meanwhile, the mesh density of the corrosion area is taken as 10 mm, with a transitional zone surrounding it to reduce the effect of a variation in mesh size [16]. In addition, four groups of corrosion degrees (0%, 10%, 20%, and 30%) are investigated in this paper, and the corresponding thicknesses in the corroded area are set to 6 mm, 5.4 mm, 4.2 mm, and 3 mm, respectively.

4.5. Failure Criteria

It is widely acknowledged that there are two typical failure modes for NCSs subjected to overpressure loads, including functional failure and structural failure [29]. Functional failure refers to the loss of the leak-tight function of the NCS, typically manifested as the tearing of liners. Structural failure refers to the NCS reaching its ultimate load-carrying capacity, typically characterized by the fracture of reinforcements and prestressed tendons. One of the main objectives of this paper is to assess the impact of liner corrosion on the leak-tightness of the NCS, and thus the functional failure criterion is adopted.

To predict the functional failure of the NCS in numerical simulations, the Nuclear Regulatory Commission has established a failure criterion for liners that takes into account corrosion effects [14]. In accordance with Petti et al. [12], a modified version of this failure criterion is employed in this paper, which can be expressed as follows:

where is the multiplied factor strain; is the corrosion factor, which is introduced to quantify the corrosion impact on the ductility of liners, and it can be determined by Equation (7) according to Li et al. [24]; and are the multiaxial stress factor and gauge length factor, which can be determined according to the literature [14]; and is the effective plastic strain, which is calculated by numerical analysis.

With the above factors, the is adjusted to its uniaxial equivalent value, i.e., . A tear is assumed to occur when exceeds the uniaxial ultimate tensile strain of liners. In this case, the NCS is assumed to undergo a functional failure. Additionally, since the liner at the junction of the gusset and cylinder is typically formed through welding, it is necessary to take into account welding effects. According to the relevant literature [30,31], the ultimate tensile strain of the liner in welded areas is assumed to be reduced by 40%, while the yield strength and ultimate strength are assumed to remain unchanged.

5. Fragility and Leakage Risk Assessment of the NCS

5.1. Fragility Assessment Process

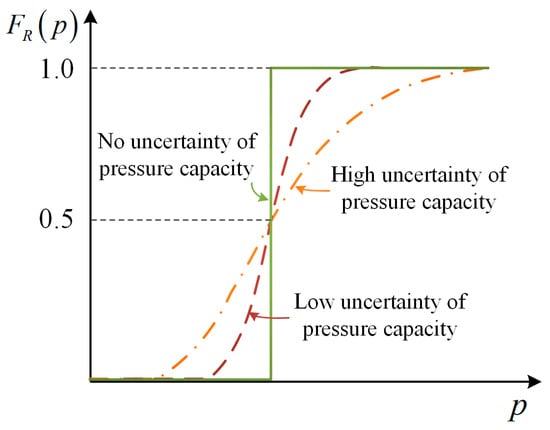

In the PSA framework, one of the main focuses is placed on identifying potential stochastic phenomena within the NCS and quantifying the associated risks to the failure of the NCS. A fragility assessment of the NCS under accident pressure is an essential part of the PSA (Level 2), which provides a quantitative description of the structural performance and limit state of the NCS from a probabilistic perspective [18]. The results of the fragility assessment are typically expressed in the form of a fragility curve, as shown in Figure 11. The center of the fragility curve is determined by the pressure capacity of the NCS, and the slope of the fragility curve depends on the uncertainty associated with the pressure capacity.

Figure 11.

Fragility curves under different uncertainty levels.

Fragility curves for the NCS under accident pressure are typically derived using an analytical method, which is fulfilled by performing structural analyses of the NCS with consideration of the associated uncertainties. In this paper, the primary uncertainties in the NCS are taken into account, including material uncertainty (reflecting the stochastic nature of material properties), modeling uncertainty (reflecting the difference between the analytical model and the actual structure), and load uncertainty (reflecting the variability of accident load) [32]. The basic steps of the analytical method for assessing the fragility of the NCS are as follows: Firstly, random samples describing the components of the NCS are generated by random sampling. Then, a nonlinear FE analysis is performed on each random sample, in conjunction with the sub-modeling technique. Finally, a statistical analysis of the calculated results is carried out to construct the fragility curve of the NCS under different degrees of liner corrosion.

In this paper, the Latin Hypercube Sampling (LHS) method is employed to produce random samples of the NCS. The LHS method is an improved technique from the traditional Monte Carlo simulation, which utilizes an equal probability sampling method for sampling random variables. Firstly, the cumulative probability distribution of each random variable is divided into N intervals. Subsequently, a random selection is made from each interval to obtain a set of variables. Finally, the original sample values are calculated by utilizing the inverse function of the probability distribution associated with each random variable. Assuming that the sampling space is M-dimensional (where M represents the total number of random variables), the completion of the LHS simulation yields an N × M design matrix. Each column in this matrix comprises a random arrangement of a specific random variable, while each row represents a set of random samples for the NCS. The utilization of this equal probability sampling method in LHS enables coverage of a broader probability space with a relatively small number of simulation samples. Consequently, computational efficiency can be significantly enhanced [33]. To clarify the material uncertainty, the mechanical property parameters of the materials employed in the NCS are treated as random variables. Table 2 summarizes the statistical characteristics of the random variables. It is important to note that these statistical parameters are derived from a comprehensive review of the relevant codes and published literature [32,34,35]. Additionally, the compressive strength of concrete is correlated with its elastic modulus and tensile strength, and thus only the compressive strength is treated as a random variable. Utilizing LHS simulation, 30 sets of random samples that describe the material uncertainty of the NCS are generated, and the detailed LHS sample values are provided in Appendix A.

Table 2.

Statistics of random variables.

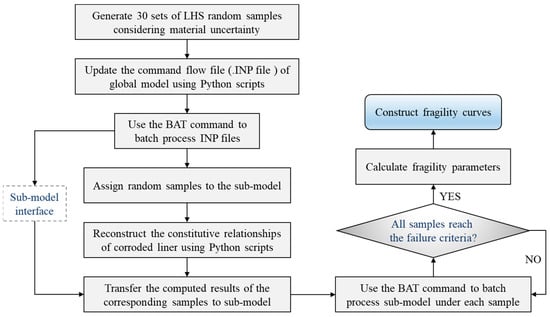

In accordance with the sub-modeling simulation program described in Section 4.1, it is imperative to sequentially perform nonlinear FE analyses for both the overall model of the NCS and the gusset sub-models with different corrosion degrees. In view of the complexity of the computational effort, this paper developed an automated script for fragility assessment of the NCS under liner corrosion conditions. Figure 12 depicts the basic flowchart of the automated script. The modeling and deterministic analyses of the NCS are performed in ABAQUS, while the input and continuous updating of the random variable for each nonlinear analysis are accomplished through the Python compilation environment.

Figure 12.

Flowchart of the automated script for the fragility assessment.

5.2. Fragility Assessment Results

5.2.1. Probability Distribution of the Pressure Capacity of the NCS

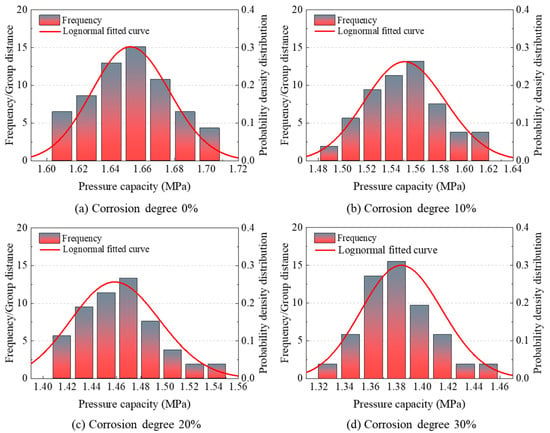

To perform the fragility assessment, it is necessary to clarify the probability distribution of the pressure capacity of the NCS. Figure 13 plots the frequency histogram and the fitted distribution curve of the pressure capacity. It can be found that the pressure capacity of the NCS under different degrees of liner corrosion is in good agreement with the lognormal distribution. Moreover, the Lilliefors test is used to further examine whether the lognormal distribution is persuasive [36]. The results show that the pressure capacity of the NCS under all liner corrosion conditions does not reject the hypothesis of obeying a lognormal distribution at the 5% significance level. In summary, it is reasonable to use a lognormal distribution to characterize the pressure capacity of the NCS under liner corrosion conditions.

Figure 13.

Probability distribution of the pressure capacity.

5.2.2. Fragility Curves of the NCS

The fragility assessment of the NCS under internal pressure is essentially the conditional failure probability of the NCS at a given internal pressure. On the basis that the pressure capacity adheres to a lognormal distribution, the fragility curve can be determined in the following equation:

where is the internal pressure; is the median pressure capacity of the NCS; is the composite logarithmic standard deviation, which can be calculated by the combination rule of the square root of the sum of the squares (SRSS) [37]:

where is the logarithmic standard deviation of the pressure capacity caused by the uncertainty of material properties; is the logarithmic standard deviation of the pressure capacity caused by the modeling uncertainty, which can be taken as 0.12, as suggested by Hoseyni et al. [38].

The fragility parameters and can be determined by the moment estimate value from the 30 samples with the following expressions:

where is the pressure capacity of sample ; is the total number of the samples.

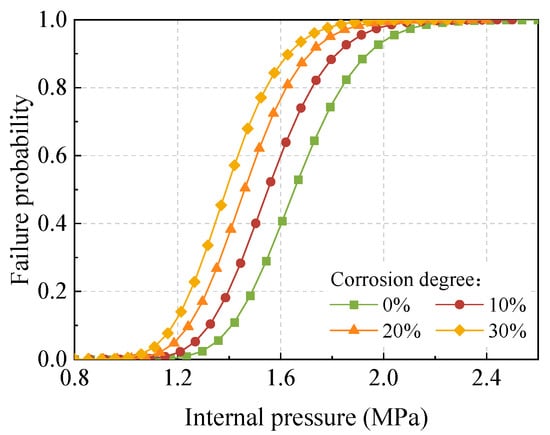

Figure 14 illustrates the fragility curves of the gusset region of the NCS at different degrees of liner corrosion. It can be seen that the fragility curve gradually moves to the left with an increase in corrosion degrees, which indicates that the risk of containment leakage increases under the same internal pressure. Meanwhile, the statistical results of the fragility parameters are summarized in Table 3. Compared to the uncorroded case, the median pressure capacity of the NCS with 10%, 20%, and 30% corrosion degrees of the liner is reduced by 6.26%, 11.72%, and 16.02%, respectively. Moreover, the logarithmic standard deviations in the corroded case are all larger than those in the uncorroded case. In general, the NCS under liner corrosion conditions is susceptible to functional failure at lower levels of accident pressure, and the variability of the pressure capacity is greater in the corroded case than in the uncorroded case.

Figure 14.

Fragility curves of the NCS at different degrees of liner corrosion.

Table 3.

Pressure capacity of the NCS at different degrees of liner corrosion.

5.2.3. HCLPF Capacity of the NCS

The HCLPF capacity is considered to be the most conservative pressure capacity for evaluating the nuclear structures and facilities in a nuclear power plant, representing the pressure capacity corresponding to a failure probability of 5% on the fragility curve with a 95% confidence level [39]. The fragility curves at different confidence levels can be determined using the following equation [40]:

where is the confidence level and is the inverse function of the standard normal distribution function.

Therefore, the HCLPF capacity can be expressed as:

Table 4 summarizes the pressure capacity of the NCS at different confidence levels. Compared with the uncorroded case, the HCLPF capacity with 10%, 20%, and 30% corrosion degrees of the liner is reduced by 6.79%, 12.83%, and 17.35%, respectively. Compared to Table 3, the reduction rate for HCLPF is slightly higher than the reduction rate calculated based on the median pressure capacity of the NCS.

Table 4.

Pressure capacity of the NCS with different confidence levels.

5.3. Leakage Risk Assessment

5.3.1. Probabilistic Safety Margin

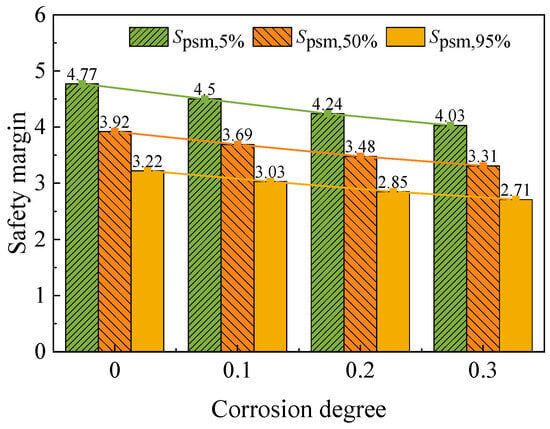

The probabilistic safety margin reflects the capacity of the NCS to withstand beyond-design-basis accidents, and thus it is usually used as an important index in the probabilistic performance assessment of the NCS. The probabilistic safety margin of the NCS with consideration of the confidence level can be calculated as follows:

where is the design pressure of the NCS, and the design pressure for the investigated NCS is 0.42 MPa.

Figure 15 shows the probabilistic safety margins of the NCS at different degrees of corrosion liner. It can be found that the probabilistic safety margin gradually decreases as the corrosion degree and confidence level increase. When the corrosion degree reaches 30%, the probabilistic safety margin with a 95% confidence level drops to 2.71. Within the scope of this paper, the NCS under liner corrosion conditions can satisfy a safety margin of not less than 2.5 [18].

Figure 15.

Probabilistic safety margins of the NCS at different degrees of liner corrosion.

5.3.2. Total Probability of Failure

In the analysis presented above, internal pressure is treated as a deterministic variable. In fact, internal pressure also involves uncertainty, and the degree of uncertainty is associated with factors such as the severity of the accident and the structural form and volume of the NCS. To conduct a comprehensive assessment of the leakage risk, it is necessary to calculate the total probability of failure for the NCS under internal pressure. It should be noted that, in this paper, this failure probability inherently represents the total probability of leakage for the NCS under LOCA conditions. In this case, the internal pressure needs to be treated as a random variable. When the probability distribution and statistical parameters of the internal pressure are known, the total probability of failure for the NCS can be expressed based on the structural reliability theory, as follows:

where represents the probability density function of the pressure capacity of the NCS; represents the probability density function of the internal pressure, and the mean value and logarithmic standard deviation of the internal pressure of the NCS investigated in this paper are 0.663 MPa and 0.3, respectively.

According to Equation (15), the total probability of failure for the NCS at different degrees of liner corrosion is calculated, and the statistical results are presented in Table 5. It is evident from the results that the total probability of failure for the NCS gradually increases as the corrosion intensifies, indicating that liner corrosion can significantly increase the leakage risk of the NCS under LOCA conditions. Generally, the investigated NCS can fulfill the probabilistic performance objective of a total probability of failure not exceeding 0.1 when liner corrosion (the maximum corrosion degree of 30%) occurs in the gusset region.

Table 5.

Total probability of failure for the NCS at different degrees of liner corrosion.

6. Conclusions

Liner corrosion represents a primary form of aging-related degradation in the NCS. Evaluating the corrosion effects of the liner is essential to guaranteeing the safe operation of the NCS. In this paper, the corrosion mechanism of the containment liner is elucidated. Combined with the sub-modeling technique, a refined simulation method is proposed to investigate the localized corrosion effects of the liner on the leak-tight function of the NCS under LOCA conditions. Utilizing a probabilistic FE method, the fragility and leakage risk of the NCS under different degrees of liner corrosion are evaluated in detail. The main conclusions can be drawn as follows:

- (1)

- The fragility curve of the NCS under LOCA conditions gradually moves to the left as the corrosion degree of the liner increases, which indicates that the risk of containment leakage increases under the same internal pressure.

- (2)

- The NCS under liner corrosion conditions is susceptible to functional failure at lower levels of accident pressure. Compared to the uncorroded case, the median pressure capacity of the NCS with 10%, 20%, and 30% corrosion degrees is reduced by 6.26%, 11.72%, and 16.02%, respectively.

- (3)

- The HCLPF capacity reflects the most conservative pressure capacity of the NCS. Compared with the uncorroded case, the HCLPF capacity of the NCS with 10%, 20%, and 30% corrosion degrees of the liner is reduced by 6.79%, 12.83%, and 17.35%, respectively, which is slightly higher than the reduction rates calculated based on the median pressure capacity.

- (4)

- The probabilistic safety margin gradually decreases as the corrosion degree and confidence level increase. When the corrosion degree reaches 30%, the probabilistic safety margin with a 95% confidence level drops to 2.7.

- (5)

- Liner corrosion can significantly increase the total probability of failure of the NCS under LOCA conditions. Within the scope of this paper, the investigated NCS can fulfill the probabilistic safety requirements.

Author Contributions

Conceptualization, X.L.; Methodology, X.L.; Software, X.L.; Validation, X.L.; Formal analysis, X.L.; Investigation, X.L.; Resources, J.G.; Data curation, X.L.; Writing—original draft, X.L.; Writing—review and editing, J.G.; Supervision, J.G.; Project administration, J.G.; Funding acquisition, J.G. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Key R&D Program of China (Grant No. 2019YFB1900903) and the National Natural Science Foundation of China (Grant No. U22B20125). These supports are sincerely acknowledged.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data supporting the findings of this study are available from the corresponding author upon reasonable request, but all personally identifiable information will be identified before transferal.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Table A1.

LHS sample considering material uncertainty (Unit: MPa).

Table A1.

LHS sample considering material uncertainty (Unit: MPa).

| fc | f335 | E335 | f400 | E400 | fp | Ep | fs | Es |

|---|---|---|---|---|---|---|---|---|

| 53.95 | 412.14 | 195,953.9 | 390.39 | 209,923.8 | 1869.47 | 188,789.2 | 320.35 | 202,368.1 |

| 51.78 | 424.46 | 194,770.9 | 449.46 | 202,622.1 | 1777.45 | 199,473.4 | 316.26 | 204,811.5 |

| 36.53 | 373.86 | 195,493.7 | 411.31 | 205,194.2 | 1886.82 | 194,023.5 | 312.51 | 197,666.7 |

| 55.35 | 344.27 | 199,883.2 | 459.56 | 199,662.3 | 1796.41 | 186,391.2 | 283.03 | 199,276.9 |

| 39.66 | 384.3 | 199,147.4 | 445.75 | 192,487.3 | 1819.6 | 198,174.6 | 326.73 | 201,879.5 |

| 49.94 | 387.65 | 201,158.5 | 438.34 | 208,356.7 | 1834.01 | 197,708.1 | 300.6 | 205,878.8 |

| 38.76 | 318.35 | 202,968.9 | 426.72 | 199,219.5 | 1844.34 | 183,712.1 | 354.87 | 189,230.3 |

| 46.2 | 367.35 | 197,469.4 | 444.34 | 190,751.9 | 1873.38 | 195,027.4 | 345.8 | 200,398.1 |

| 42.95 | 381.37 | 210,406.4 | 418 | 196,763.5 | 1880.3 | 196,263.6 | 305.08 | 194,952.5 |

| 35.84 | 375.08 | 200,134 | 453.14 | 207,073.7 | 1902.39 | 202,488.3 | 295.56 | 194,633.8 |

| 40.27 | 391.91 | 213,003.1 | 435.19 | 211,545.4 | 1827.75 | 193,693.1 | 289.51 | 209,357.9 |

| 44.63 | 380.34 | 201,810 | 424.7 | 204,188.8 | 1863.66 | 205,089.5 | 341.48 | 193,913.1 |

| 45.12 | 358.63 | 202,567.4 | 412.1 | 200,140.3 | 1855.71 | 201,687.8 | 307.67 | 186,227.7 |

| 45.79 | 396.18 | 191,617.3 | 470.74 | 204,752.4 | 1822.84 | 208,752.5 | 338.15 | 204,366.6 |

| 41.95 | 412.6 | 207,108.3 | 439.95 | 201,717.4 | 1896.2 | 190,862.9 | 359.37 | 196,453.6 |

| 42.24 | 366.19 | 188,008.1 | 422.56 | 200,972.7 | 1847.3 | 191,538.7 | 318.79 | 196,047.8 |

| 46.44 | 401.56 | 206,127.6 | 456.82 | 203,265.1 | 1916.91 | 191,970.1 | 350.99 | 208,858.6 |

| 50.97 | 333.47 | 193,139.5 | 460.08 | 201,211.2 | 1749.98 | 188,763.3 | 342.68 | 201,428.6 |

| 43.13 | 398.63 | 197,211 | 476.99 | 196,037.9 | 1837.85 | 200,264 | 329.37 | 192,745.6 |

| 48.99 | 361.68 | 198,796.7 | 416.97 | 198,122.3 | 1838.64 | 200,940.1 | 333.69 | 205,215.4 |

| 30.71 | 406.69 | 205,705.8 | 433.92 | 193,788.8 | 1858.64 | 194,732.9 | 328.34 | 200,639.4 |

| 33.63 | 350.32 | 207,932.9 | 430.21 | 206,521.1 | 1911.11 | 192,667 | 323.42 | 198,891.7 |

| 37.86 | 348.14 | 196,594.7 | 420.06 | 191,234.2 | 1808.7 | 180,479.4 | 369.89 | 206,893.3 |

| 43.82 | 444.17 | 204,084.2 | 466.64 | 197,295.4 | 1875.59 | 186,966.1 | 310.3 | 197,005.6 |

| 41.41 | 364.45 | 204,723.8 | 430.84 | 202,362.1 | 1932.24 | 196,983.2 | 323.01 | 203,184.2 |

| 40.38 | 392.55 | 200,521.8 | 447.92 | 186,365.4 | 1803.17 | 195,568.6 | 332 | 202,798.9 |

| 36.93 | 385.84 | 198,085.9 | 437.44 | 194,661 | 1770.61 | 193,101.5 | 313.76 | 198,284 |

| 47.62 | 355.03 | 190,018.8 | 441.72 | 197,560.4 | 1794.57 | 198,805.1 | 298.79 | 192,089.3 |

| 48.4 | 377.85 | 203,567.3 | 401.54 | 195,064.7 | 1812.53 | 189,614.6 | 335.07 | 199,510.6 |

| 33.26 | 370.08 | 194,046 | 406.96 | 198,574.6 | 1852.56 | 204,551.7 | 347.35 | 212,671.2 |

Note: Each row in Table A1 represents a random sample.

References

- Shah, V.N.; Hookham, C.J. Long-Term Aging of Light Water Reactor Concrete Containments. Nucl. Eng. Des. 1998, 185, 51–81. [Google Scholar] [CrossRef]

- Hora, Z.; Patzák, B. Analysis of Long-Term Behaviour of Nuclear Reactor Containment. Nucl. Eng. Des. 2007, 237, 253–259. [Google Scholar] [CrossRef]

- Lundqvist, P.; Nilsson, L.-O. Evaluation of Prestress Losses in Nuclear Reactor Containments. Nucl. Eng. Des. 2011, 241, 168–176. [Google Scholar] [CrossRef]

- Hu, H.T.; Lin, J.X. Ultimate Analysis of PWR Prestressed Concrete Containment under Long-Term Prestressing Loss. Ann. Nucl. Energy 2016, 87, 500–510. [Google Scholar] [CrossRef]

- Alhanaee, S.; Yi, Y.; Schiffer, A. Ultimate Pressure Capacity of Nuclear Reactor Containment Buildings under Unaged and Aged Conditions. Nucl. Eng. Des. 2018, 335, 128–139. [Google Scholar] [CrossRef]

- Saouma, V.E.; Hariri-Ardebili, M.A. Seismic Capacity and Fragility Analysis of an ASR-Affected Nuclear Containment Vessel Structure. Nucl. Eng. Des. 2019, 346, 140–156. [Google Scholar] [CrossRef]

- Kim, S.H.; Choi, M.S.; Joung, J.Y.; Kim, K.S. Long-Term Reliability Evaluation of Nuclear Containments with Tendon Force Degradation. Nucl. Eng. Des. 2013, 265, 582–590. [Google Scholar] [CrossRef]

- Francesco, D.M.; Matteo, F.; Carlo, G.; Federico, P.; Enrico, Z. Time-Dependent Reliability Analysis of the Reactor Building of a Nuclear Power Plant for Accounting of Its Aging and Degradation. Reliab. Eng. Syst. Saf. 2021, 205, 107173. [Google Scholar] [CrossRef]

- Hessheimer, M.F.; Klamerus, E.W.; Lambert, L.D.; Rightley, G.S.; Dameron, R.A. Overpressurization Test of a 1:4-Scale Prestressed Concrete Containment Vessel Model; Nuclear Regulatory Commission: Washington, DC, USA, 2003. [Google Scholar]

- Hanson, N.W.; Schultz, D.M.; Roller, J.J.; Azizinamini, A.; Tang, H.T. Testing of Large-Scale Concrete Containment Structural Elements. Nucl. Eng. Des. 1987, 100, 129–149. [Google Scholar] [CrossRef]

- Hanson, N.W.; Schultz, D.M.; Roller, J.J.; Tang, H.T. Results of Large-Scale Test of Discontinuity Region in a Prestressed Concrete Containment. Nucl. Eng. Des. 1987, 104, 321–328. [Google Scholar] [CrossRef]

- Petti, J.P.; Spencer, B.W.; Graves, H.L., III. Risk-Informed Assessment of Degraded Containment Vessels. Nucl. Eng. Des. 2008, 238, 2038–2047. [Google Scholar] [CrossRef]

- Anderson, P. Concentration of Plastic Strains in Steel Liners Due to Concrete Cracks in the Containment Wall. Int. J. Press. Vessel. Pip. 2008, 85, 711–719. [Google Scholar] [CrossRef]

- Cherry, J.L.; Smith, J.A. Capacity of Steel and Concrete Containment Vessels with Corrosion Damage; Sandia National Laboratories: Albuquerque, NM, USA, 2001. [Google Scholar]

- Smith, J.A.; Cherry, J.L. Analyses of a Reinforced Concrete Containment with Liner Corrosion Damage; Saiadia National Laboratories: Albuquerque, NM, USA, 1999. [Google Scholar]

- Spencer, B.W.; Petti, J.P.; Kunsman, D.M. Risk-Informed Assessment of Degraded Containment Vessels; Nuclear Regulatory Commission: Washington, DC, USA, 2006. [Google Scholar]

- Zhou, Z.; Wu, C.; Meng, S.P.; Wu, J. Mechanical Analysis for Prestressed Concrete Containment Vessels under Loss of Coolant Accident. Comput. Concr. 2014, 14, 127–143. [Google Scholar] [CrossRef]

- Klamerus, E.W.; Bohn, M.P.; Wesley, D.A.; Krishnanswamy, C.N. Containment Performance of Prototypical Reactor Containments Subjected to Severe Accident Conditions; Nuclear Regulatory Commission: Washington, DC, USA, 1996. [Google Scholar]

- Zubair, M.; Zhang, Z.; Khan, S.U.D. Calculation and Updating of Reliability Parameters in Probabilistic Safety Assessment. J. Fusion Energy 2010, 30, 13–15. [Google Scholar] [CrossRef]

- Cho, J.; Lee, S.H.; Bang, Y.S.; Lee, S.; Park, S.Y. Exhaustive Simulation Approach for Severe Accident Risk in Nuclear Power Plants: OPR-1000 Full-Power Internal Events. Reliab. Eng. Syst. Saf. 2022, 225, 108580. [Google Scholar] [CrossRef]

- Dunn, D.S.; Pulvirenti, A.L.; Hiser, M.A. Containment Liner Corrosion Operating Experience Summary Technical Letter Report—Revision 1; U.S. Nuclear Regulatory Commission Office of Nuclear Regulatory Research: Washington, DC, USA, 2011. [Google Scholar]

- Paek, Y.; Kim, S.; Yoon, E. Introduction of Containment Liner Plate (CLP) Corrosion. In Proceedings of the Transactions of the Korean Nuclear Society Spring Meeting, Jeju, Republic of Korea, 17–18 May 2018. [Google Scholar]

- Petti, J.P.; Naus, D.; Sagüés, A.; Weyers, R.E.; Erler, B.A.; Berke, N.S.; Sandia National Laboratories. Nuclear Containment Steel Liner Corrosion Workshop: Final Summary and Recommendation Report; Sandia National Laboratories: Albuquerque, NM, USA, 2011. [Google Scholar]

- Li, X.; Gong, J. Effects of Steel Liner Corrosion on the Leak-Tightness of Prestressed Concrete Containment Structure under Severe Accident Loads. Ann. Nucl. Energy 2023, 180, 109487. [Google Scholar] [CrossRef]

- Birtel, V.; Mark, P. Parameterised Finite Element Modelling of RC Beam Shear Failure. In Proceedings of the 19th Annual International ABAQUS Users Conference, Cambridge, MA, USA, 23–25 May 2006. [Google Scholar]

- Wang, Z.; Yan, J.; Lin, Y.; Fang, T.; Ma, J. Study on Failure Mechanism of Prestressed Concrete Containments Following a Loss of Coolant Accident. Eng. Struct. 2020, 202, 109860. [Google Scholar] [CrossRef]

- EN-1992-1-1:2010; Design of Concrete Structures-Part 1-2: General Rules-Structural Fire Design. The European Union: Brussels, Belgium, 2010.

- Tong, L.; Zhou, X.; Cao, X. Ultimate Pressure Bearing Capacity Analysis for the Prestressed Concrete Containment. Ann. Nucl. Energy 2018, 121, 582–593. [Google Scholar] [CrossRef]

- Hessheimer, M.F.; Dameron, R.A. Containment Integrity Research at Sandia National Laboratories; Sandia National Laboratories: Albuquerque, NM, USA, 2006. [Google Scholar]

- Anderson, P. Analytic Study of the Steel Liner near the Equipment Hatch in a 1:4 Scale Containment Model. Nucl. Eng. Des. 2008, 238, 1641–1650. [Google Scholar] [CrossRef]

- Dameron, R.A.; Zhang, L.; Rashid, Y.R.; Vargas, M.S. Pretest Analysis of a 1:4-Scale Prestressed Concrete Containment Vessel Model; Nuclear Regulatory Commission: Washington, DC, USA, 2000. [Google Scholar]

- Li, X.; Gong, J. Probabilistic Evaluation of the Leak-Tightness Function of the Nuclear Containment Structure Subjected to Internal Pressure. Reliab. Eng. Syst. Saf. 2024, 241, 109684. [Google Scholar] [CrossRef]

- Su, L.; Li, X.X.; Jiang, Y.Y. Comparison of Methodologies for Seismic Fragility Analysis of Unreinforced Masonry Buildings Considering Epistemic Uncertainty. Eng. Struct. 2020, 205, 110059. [Google Scholar] [CrossRef]

- GB50010-2010; Code for Design of Concrete Structures. The Ministry of Construction of the People’s Republic of China: Beijing, China, 2015.

- Balomenos, G.P.; Pandey, M.D. Probabilistic Finite Element Investigation of Prestressing Loss in Nuclear Containment Wall Segments. Nucl. Eng. Des. 2017, 311, 50–59. [Google Scholar] [CrossRef]

- Lilliefors, H.W. On the Kolmogorov-Smirnov Test for Normality with Mean and Variance Unknown. J. Am. Stat. Assoc. 1967, 62, 399–402. [Google Scholar] [CrossRef]

- Huang, Y.; Whittaker, A.S.; Luco, N. A Probabilistic Seismic Risk Assessment Procedure for Nuclear Power Plants: (I) Methodology. Nucl. Eng. Des. 2011, 241, 3996–4003. [Google Scholar] [CrossRef]

- Hoseyni, S.M.; Hoseyni, S.M.; Yousefpour, F.; Karimi, K. Probabilistic Analysis of Containment Structural Performance in Severe Accidents. Int. J. Syst. Assur. Eng. Manag. 2016, 8, 625–634. [Google Scholar] [CrossRef]

- RCC-CW-2015; Rules for Design and Construction of PWR Nuclear Civil Works. French Association for Design, Construction and In- Service Inspection Rules for Nuclear Island Components: Paris, France, 2015.

- Mandal, T.K.; Ghosh, S.; Pujari, N.N. Seismic Fragility Analysis of a Typical Indian PHWR Containment: Comparison of Fragility Models. Struct. Saf. 2016, 58, 11–19. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).