Abstract

A modified plastic Burgers model considering cohesion decay is proposed for frozen soils. A series of triaxial compression and creep tests were conducted on a kind of frozen silty clay for obtaining the model parameters. According to typical triaxial creep strain curves with only a decaying creep stage, a deformation parameter calibration method for a plastic Burgers model is proposed, and the validity of the method was further verified. When the original plastic Burgers model was incorporated with a cohesion decay function, it was shown that the successive development process of frozen soil creep strain from the decaying to non-decaying stage could be described reasonably. The modified model is applicable to frozen ground engineering cases with non-decaying creep involved.

1. Introduction

Creep is one of the main sources contributing to infrastructure deformation in frozen ground engineering [1]. Due to global climate warming and thermal disturbance of engineering activities, considerable creep of warm permafrost layers can often be observed, such as the uneven settlement of embankments and bending of oil pipes in permafrost regions [2,3]. In underground space excavation engineering, considerable creep deformation of the artificial freezing curtain usually develops due to a high stress level or miss-control of the freezing curtain temperature [4,5,6]. The creep law of frozen soils is much more complex than unfrozen soils for inclusions of ice and unfrozen water [5,6], and thus, a precise description of creep deformation development is essential for the operational stability of infrastructures in frozen soil engineering.

To estimate the influence of creep on the stability of frozen soil infrastructures and investigate frozen soils’ creep law, abundant and systematic experimental works have been conducted in the past decades [7,8,9,10]. According to these experimental works, some fundamental and consistent conclusions can be drawn. It was indicated that both decaying and non-decaying creep can be observed, and the evolution of non-decaying creep is dependent on the relationship between the frozen soil’s long-term strength and current stress level [6,11]. The magnitude of the creep strain and strain rate are proportional to the temperature, stress level and pore ice content [12,13,14]. Based on the basic creep law of frozen soils, many research works have focused on the creep models of frozen soils. Empirical models were used in the earlier trials to describe frozen soils’ creep process. For the development of creep strain with only a decay process, simple power functions between the creep strain and stress level and time are constructed to describe the creep strain’s developing process with time [15]; when a non-decaying creep process is involved, the long-term strength, minimum strain rate and failure time of frozen soils are taken into account to simulate the creep strain rate changes from an initial decrease to an essential constant and then sharp increase [16,17]. The empirical model works facilitate the understanding on the creep behavior of frozen soils, while the limitation of empirical data fitting reduces their applicability in universal stress states.

For creep problems under complex stress conditions, theoretical creep models of frozen soils are proposed, with the aid of a conventional soil mechanics framework. Up to now, the available frozen soil theoretical creep models can be generally categorized as microscopic thermodynamic models, viscose–elastic–plastic models, hyperplastic models, hypoplastic models and mechanical elements models [18,19,20,21,22,23]. Among them, mechanical elements models have been intensively developed due to their simple model structure and easy of use in engineering applications. In the framework of the frozen soil element creep models, three basic mechanical elements, i.e., the Hookean spring, Newtonian dashpot and Saint-Venant’s slider, are composed of certain forms to simulate different creep strain development tendencies, by considering the mechanical characteristics of frozen soils [24]. Based on CT scanning digital images of frozen silty samples, Yang et al. [25] defined a damage variable and modified Nishihara’s model to simulate the random distribution of inner flaws in the creep process. Considering the non-linear influence of confining stress on the shear strength of frozen soil, Wang et al. [26] incorporated a parabolic yield function into a Bingham body composed of a Kelvin and Maxwell body in series to simulate the decay process of a frozen silty clay. To describe the creep strain as being further reasonably involved with the non-decaying process, functional multipliers based on a microscopic point of view were defined and incorporated into the elementary creep models. According to the phenomenon that cementation between frozen soil particles becomes weakened with an increase in temperature, stress and time, a breakage ratio was defined and embedded into a Burgers model [27]. It was shown that the non-decaying creep process of a frozen silty clay can be reasonably described when the long-term strength is lower than the current stress level. Based on fractional calculus theory, fractional derivative multipliers were embedded into the Nishihara model to describe the non-decaying creep development due to microscopic damage accumulation under constant overloading [23,28].

From the above elaboration, it is indicated that with different composing forms of mechanical elements and taking the mechanical property degradation of frozen soils into account, the frozen soil creep process under different conditions can be well described. However, among the previous elementary model works, few have been able to provide a clear calibration method for obtaining the elementary model parameters. Most of the model parameters were determined by the so-called ‘trial and error method’ [25,27], which reduces the models’ reliability to some extent. Moreover, it has been proven that the involvement of the non-decaying creep process is due to the continuous degradation of the frozen soil strength under constant stress conditions [6,22]. When the strength approaches and gets lower than the current stress state, the creep strain increases sharply, and the non-decaying creep process happens [22]. Although the influence of strength degradation has been implicitly considered in the non-decaying creep elementary models by embedding different forms of function multipliers, deducing the elementary model form is more complicated, and consequently, the engineering usability of the models is reduced considerably. To further improve the reliability of the elementary models and create a relatively simple model structure, it would be better to try to create a parameter calibration method with a clear physical meaning and directly incorporate the strength degradation function into the plastic part of the elementary model.

In this paper, a series of triaxial creep tests of a frozen silty clay were conducted under different stress levels and temperatures. A parameter calibration method with a clear physical meaning is proposed according to the analysis of the tested results and the plastic Burgers model structure. From the test results of applied stress level and creep failure time, a strength decay function was determined and directly incorporated into the plastic Burgers model to create an elementary model with a concise structure and enable the description of both the decaying and non-decaying creep of frozen soils.

2. Modified Plastic Burgers Model

In the plastic Burgers model [29], total strain is decomposed into three components, i.e., Maxwell (), Kelvin () and plastic () strains, as shown with Formula (1).

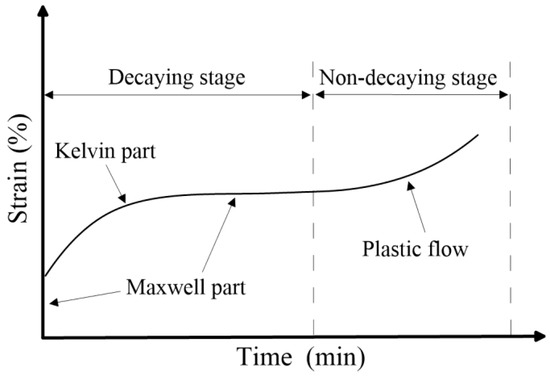

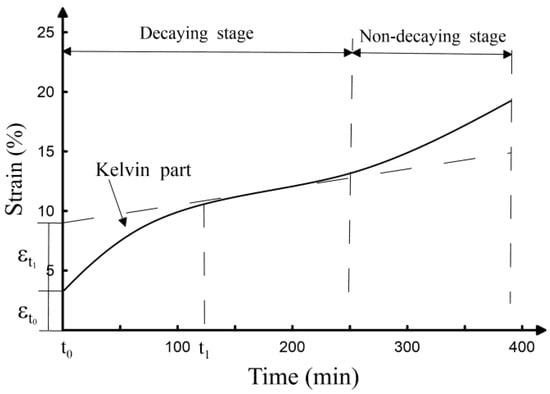

In Formula (1), the Maxwell strain (Formula (2)) is used to describe the instantaneous strain and stable creep stage with a constant strain rate on the typical frozen soil creep curve (Figure 1); the Kelvin strain (Formula (3)) is used for describing the creep strain decrease process; and the plastic strain (Formula (4)) is employed when plastic flow is involved.

Figure 1.

Typical creep curve of the frozen soils [1].

In the above equations, GM and GK are the elastic shear modulus for the Maxwell and Kelvin strains, respectively; HM and HK are the viscosity coefficients of the Maxwell and Kelvin strains, respectively; and g is the plastic potential function. It is expressed as

where σ1, σ2 and σ3 are the minimum, intermediate and maximum principal stresses, respectively; ψ is the dilation angle; λ is equal to zero when the material is under an elastic stress state; and when material plastic flow is taking place, λ is a non-zero parameter, which is determined by the application of the plastic yield condition f = 0 [29]. Here, the Mohr–Coulomb yield criteria are employed, and the plastic yield function f is expressed as

where Nϕ = (1 + sinϕ)/(1 − sinϕ), ϕ is the internal friction angle and C is the cohesion.

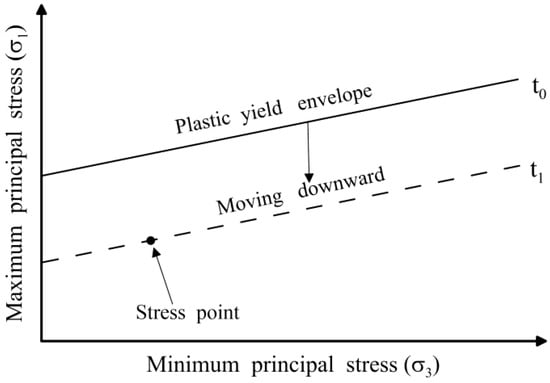

With Formulas (1) to (7), the framework of the plastic Burgers model is introduced in brief. Generally, according to the previous creep model-evaluating works [30], the conventional plastic theory-based creep models are capable of describing a decaying or non-decaying creep process separately. However, such creep models cannot capture the developing process from the decaying to non-decaying creep stages, as shown in Figure 1. This is due to the fixed plastic yield envelope being employed in the conventional plastic models, where the shear strength parameters are constant for a certain kind of soil. For frozen soil, it has been proven by a large amount of experimental work that the cohesion is decaying with time under constant overloading, while the internal friction angle is independent of time [1,22]. Subsequently, the plastic yield envelope moves downward with time in the principal stress coordinates (Figure 2). For an initial stress point lower than the plastic yield envelope, the material is under the elastic stress state, and only the decaying creep process happens; then, with ongoing time, the plastic yield envelope approaches the stress point, gets lower than it (Figure 2), plastic flow gets involved, the plastic strain rate increases sharply and the non-decaying creep process begins (Figure 1). This implies that when the decay of the shear strength parameter of frozen soil is embedded into the plastic Burgers model, the successive developing process from the decaying to non-decaying creep stages can be reasonably described.

Figure 2.

Relative position between a given stress point and the moving plastic yield envelope.

According to the experimental work on frozen soils, the decay of cohesion under triaxial compression test conditions can be expressed by the following power function [22]:

where σ33 is the confining stress and usually taken as a constant; ϕ is the internal friction angle, as shown in Formula (7); and mtn is the decaying function, which shows the decaying law of axial strength under constant confining stress. The decay function parameters m and n are determined through a series of creep test results under constant confining stress. When Formula (8) is substituted into Formula (7), the plastic yield envelope is time-dependent, and the plastic Burgers model is modified for describing the successive development from the decaying to non-decaying creep stages. In the following, a series of triaxial creep tests under different temperatures will be conducted to propose a parameter calibration method, and the validity of the modified model will be further verified.

3. Sample Preparation and Test Procedures

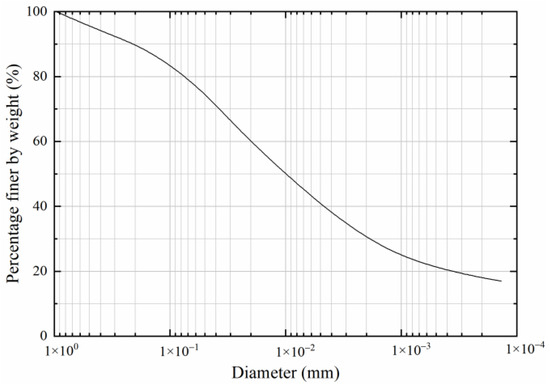

In this work, a kind of silty clay was taken as the study object. A grain size distribution curve of the silty clay is shown in Figure 3. The liquid and plastic limits of the soil were 35.0% and 22.0%, respectively. All the tested samples were remolded and saturated. The samples’ dry density was controlled at 1.76 g/cm3, and the initial pore water content of all the samples was at about 18.0%. After the samples were saturated, they were quickly frozen together in a refrigerator with a rigid mold for guaranteeing homogeneity of the soil skeleton and pore ice distribution.

Figure 3.

Grain size distribution of the tested silty clay.

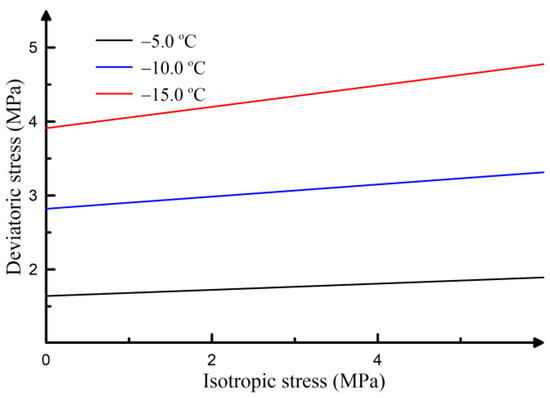

Both the triaxial compression and creep tests were conducted under temperatures of −5.0, −10.0 and −15.0 °C. For the triaxial compression tests at each temperature, an axial strain rate of 1.0%/min and confining stresses of 1.0, 2.0 and 4.0 MPa were applied to each individual sample; for the triaxial creep test at different temperatures, eight levels of constant axial stress were applied on each individual sample at the confining stress of 0.1 MPa. The applied axial stresses under different temperatures are listed in Table 1. According to the triaxial compression test results, the strength envelopes of the tested soil at different temperatures are shown in Figure 4. The triaxial creep test results were used for the calibration of the plastic Burgers model deformation parameters, such as GM, GK, HM and HK, and for obtaining a cohesion decay function.

Table 1.

The applied axial stresses of the triaxial creep tests.

Figure 4.

Strength envelopes of the tested soil at different temperatures.

4. Parameter Calibration Method

4.1. Plastic Burgers Model Deformation Parameters

As expressed in Formula (1), the sum of the Maxwell, Kelvin and plastic Burgers model strains enables the description of the decaying creep process. Correspondingly, the deformation parameters (GM, GK, HM and HK) can be determined on the typical creep curve during the decaying stage. The tested creep curve under a temperature of −5.0 °C and with an axial stress of 1.52 MPa was used to demonstrate the determination of each deformation parameter (Figure 5).

Figure 5.

Creep curve of the tested silty clay under a temperature of −5.0 °C and with an axial stress of 1.52 MPa.

According to Formula (1), the creep strain without the plastic part is expressed as

When time t = 0, Formula (9) becomes

where is the instantaneous strain after overloading is applied, and the Maxwell elastic shear modulus GM is calculated with Formula (10) as

As for the Kelvin strain, its development tendency is dependent upon the law of an exponential function (Formula (9)). Theoretically, when the time t approaches infinity, the exponential function part of the Kelvin strain will approach zero. For a practical creep curve, as shown in Figure 5, when the time is larger than a time point t1, the exponentially functioning part of the Kelvin strain will decrease to be about zero. Here, t1 is the intersection time of the creep strain rate’s non-linearly decreasing section and the straight section with an essentially constant creep strain rate. And thus, the creep strain () after time t1 can be expressed as

Formula (12) is the expression of the straight section on the creep curve, and the intersection (Figure 5) between the straight section extension line and the strain axis is

With Formula (13), the Kelvin elastic shear modulus Gk is calculated as

In the second term on the right side of Formula (12), the σij/2HM is the slope of the straight section (Figure 5). Apparently, the Maxwell viscosity coefficient HM is calculated as

where is the incremental strain after a time step . After GM, GK and HM are determined with Formulas (11), (14) and (15), respectively, the Kelvin viscosity coefficient HK can be calculated with a strain value on the creep strain curve between t0 and t1 (Figure 5). According to Formula (9), the Kelvin viscosity coefficient HK is calculated as

According to Formulas (11), (14)–(16), the plastic Burgers model deformation parameters were determined with the test results and are listed in Table 2.

Table 2.

(a) Deformation parameters under −5.0 °C. (b) Deformation parameters under −10.0 °C. (c) Deformation parameters under −15.0 °C.

4.2. Shear Strength Parameters

The internal friction angle ϕ and dilation angle ψ were obtained with the triaxial compression test result. As elaborated in the conventional soil mechanical community, the internal friction angle is determined by the slope of the plastic yield envelope in the deviatoric vs. isotropic stress coordinates, and the dilation angel is calculated using the slope of the volumetric dilatancy section vs. shear strain curve. The measured internal friction angle and dilation angle under different temperatures are listed in Table 3. As it can be seen, the values of the internal friction angle under different temperatures are much lower than those of the unfrozen soils. This is due to the inclusions of pore ice, which considerably reduce the friction force between soil particles, and a lower value of the internal friction angle can be observed [1,5].

Table 3.

Measured internal friction angle and dilation angle under different temperatures.

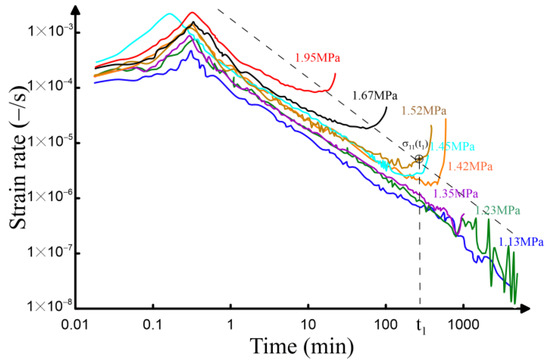

The physical meaning of cohesion is the intersection of the plastic yield envelope on the deviatoric stress axis. For frozen soil, due to the accumulation of microstructural damage and increase in unfrozen water under the influence of constant overloading, the cohesion continuously decreases with time [22,25], and this process can generally be expressed by Formula (8) under triaxial compression conditions. In Formula (8), the decay function mtn can be obtained from the law of the axial strength decrease under constant confining stress. For convenience of elaboration, a series of creep strain rate vs. time curves (Figure 6) under −5.0 °C obtained from the triaxial creep test are demonstrated to show the determination of the decay function mtn. It can be seen in Figure 6 that there exists a minimum strain rate on each curve under relatively higher axis stress, and the corresponding time ti is defined as the creep failure time under the constant axial stress value of σ11(ti). Here, σ11(ti) is actually the axial strength corresponding to the failure time ti. With data fitting of several axial stress and failure time points, the axial strength decay function (Formula (17)) parameters were determined. For the tested soil in this paper, the measured parameters m and n are listed in Table 4.

Figure 6.

Changes in the strain rate vs. time under temperature of −5.0 °C.

Table 4.

Measured strength decay function parameters under different temperatures.

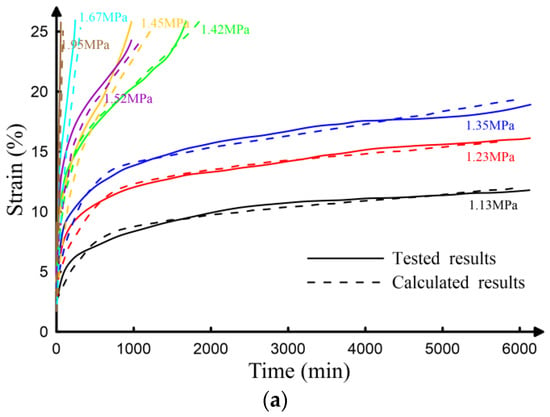

5. Model Verification and Analysis

To demonstrate the validity of the plastic Burgers model deformation parameter calibration method at first, the creep strain of the tested results and calculated results without a plastic part (Formula (9)) under different temperatures are shown in Figure 7. It can be seen from the tested results that the onset time of the non-decaying creep stage, i.e., the time on the creep curve that the slope of the creep strain vs. time changes from essentially constant to quickly increasing, is inversely proportional to the stress level. This is due to the decay of the compression strength (Formula (17) and Figure 6). When the current applied stress is higher than the compression strength, plastic flow happens, and the creep strain rate increases sharply (Figure 6 and Figure 7a). This is the so-called non-decaying creep process. Obviously, a higher applied stress corresponds to a shorter time with the onset of the non-decaying creep process. When the current applied stress is lower than the compression strength, the creep strain curve shows the development process with only a creep strain rate decrease at first which then becomes essentially constant (Figure 6 and Figure 7a). This is the so-called decaying creep process. In other words, for these curves with relatively lower stress levels in Figure 7, the observation time is not long enough for the compression strength to decrease lower than the current applied stress, and subsequently, only the decaying creep process can be observed.

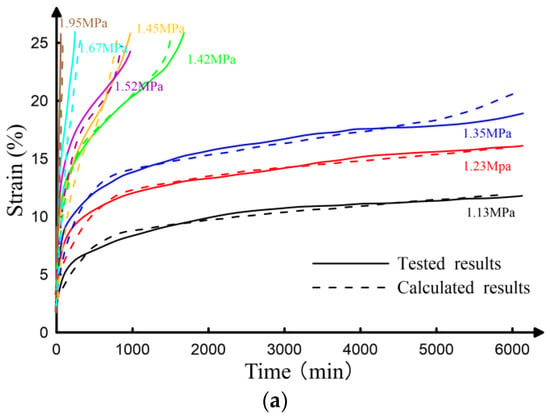

Figure 7.

Tested creep strains and calculated results without a non-decaying creep stage at temperatures of (a) −5.0 °C; (b) −10.0 °C; and (c) −15.0 °C.

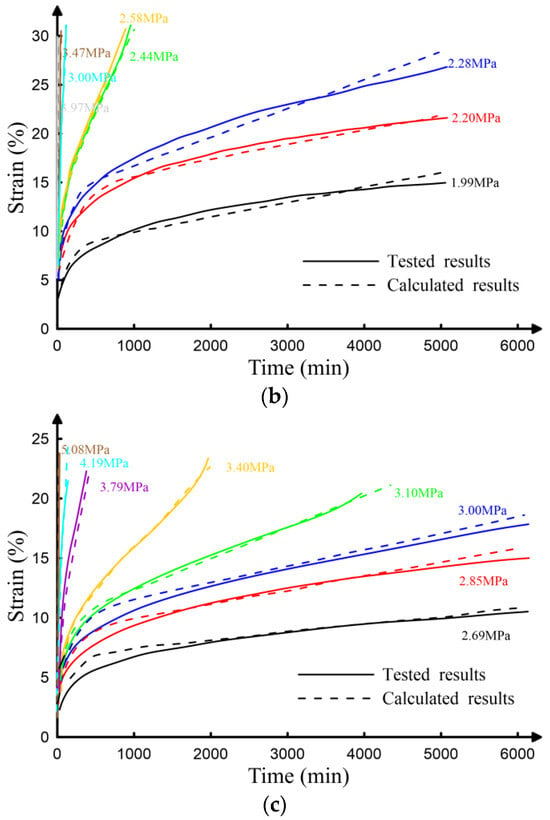

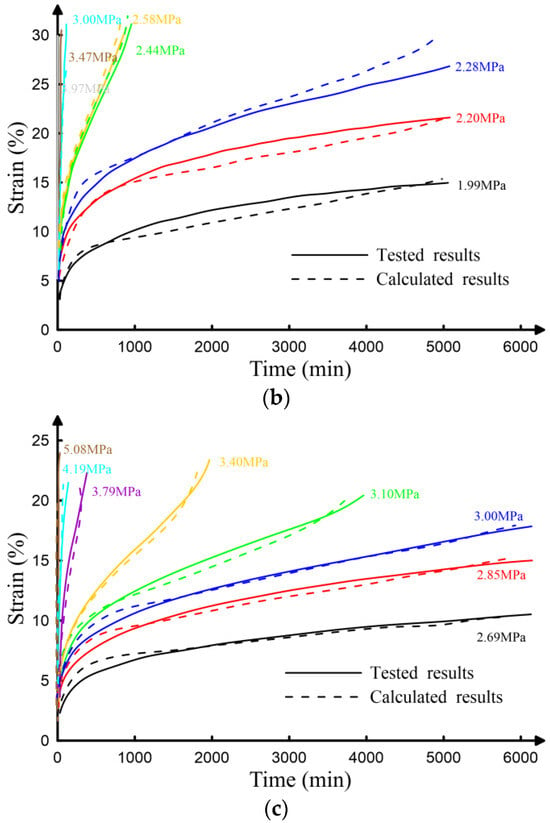

By comparing the tested and calculated results in Figure 7, it can be seen that Formula (9) generally has a good predictive performance when the non-decaying creep stage is not involved. It can be seen in Figure 7 that the calculated results of the initial instantaneous strain, creep strain rate decrease section and essentially constant creep strain rate section generally have good agreement with the tested results under different stress levels. This indicates that the plastic Burgers model deformation parameter calibration method proposed in Section 4.1 is valid under different axial stress levels and temperatures. The deformation parameter calibration method can be further applied in practical engineering calculations. Figure 8 is the comparison of the tested results and calculated results taking the plastic strain into account (Formula (1)). As can be seen in Figure 8, when the cohesion decay function (Formula (8)) was incorporated into the plastic Burgers model, the continuous development process from the decaying to non-decaying creep stage could be reasonably described under different temperatures and axial stress levels. This indicates that the modification of the plastic Burgers model with the cohesion decay function is valid for describing the creep process when non-decay is involved.

Figure 8.

Tested creep strains and calculated results with cohesion decay taken into account at temperatures of (a) −5.0 °C; (b) −10.0 °C; and (c) −15.0 °C.

From the above analysis, it can be concluded that the frozen soil creep process with only a decaying creep stage can be well described by the plastic Burgers model with the proposed deformation parameter calibration method; when the non-decaying creep stage is involved, the cohesion decay function must be incorporated into the plastic Burgers model to describe the whole creep process reasonably. Furthermore, one aspect that should be kept in mind is that the Mohr–Coulomb yield criteria are employed in the proposed model. This implies that the modified model is applicable in situations of lower stress levels. When the confining stress is larger than 10 MPa, the strength envelope of the frozen soils is in the form of a kind of downward curve [1,11]. That is to say, the slope of the strength envelope is confining stress-dependent, and the Mohr–Coulomb yield criteria with a constant strength envelope slope are not applicable.

6. Conclusions

Based on the experimental and theoretical works of this paper, conclusions could be drawn as the following:

- (1)

- A calibration method for obtaining the plastic Burgers model deformation parameters (GM, GK, HM and HK) is proposed with the typical creep curve during the decaying stage. The Maxwell elastic shear modulus GM is calculated by the instantaneous strain under an applied overloading; the Maxwell viscosity coefficient HM is dependent on the slope of the straight section on the creep strain curve; the Kelvin elastic shear modulus GK can be determined according to the intersection between the straight section extension line and the strain axis; and the Kelvin viscosity coefficient HK can be calculated with the strain and time of a point on the creep strain rate’s non-linearly decreasing section of the creep strain curve.

- (2)

- Through a comparative analysis of the triaxial creep test results and the calculated results without plastic strain, the creep strain of the tested frozen silty clay could be well described during the decaying creep stage. It is indicated that the proposed plastic Burgers deformation parameters calibration method is valid.

- (3)

- After incorporation with the cohesion decay function into the plastic Burgers model, the continuous development of creep strain from the decaying to non-decaying stage can be reasonably described. This indicates that the modified plastic Burgers model can be used to predict the creep strain development when the non-decaying creep stage is involved. Due to the Mohr–Coulomb yield criteria with a constant strength envelope slope being employed, the modified model is however limited to situations of low confining stress levels.

Author Contributions

Conceptualization, X.Y.; methodology, X.Y. and L.J.; software, X.Z. and X.L.; validation, X.Z. and X.L.; formal analysis, W.W. and X.Z.; data curation, X.Z. and W.W.; writing—original draft preparation, X.Y., L.J. and W.W.; writing—review and editing, W.W. and L.J.; supervision, X.Y. and L.J.; project administration, X.Y.; funding acquisition, X.Y and L.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partly supported by the National Natural Science Foundation of China (Nos. 42272319, 42101132 and 52378368).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are all available in the article.

Conflicts of Interest

Author Long Jin was employed by the company First Highway Consultants Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Andersland, O.B.; Ladanyi, B. Frozen Ground Engineering; Chapman and Hall: New York, NY, USA, 2004. [Google Scholar]

- Qi, J.L.; Sheng, Y.; Zhang, J.M.; Wen, Z. Settlement of embankments in permafrost regions in the Qinghai-Tibetan plateau. Norwegian J. Geog. 2007, 61, 49–55. [Google Scholar]

- Zhang, D.; Li, Q.M.; Liu, E.L.; Liu, X.Y.; Zhang, G.; Song, B.T. Dynamic properties of frozen silty soils with different coarse-grained contents subjected to cyclic triaxial loading. Cold Reg. Sci. Technol. 2018, 157, 64–85. [Google Scholar] [CrossRef]

- Li, D.W.; Hong, F.J.; He, W.R. Research on visco-elastic-plastic creep model of artificially frozen soil under high confining pressures. Cold Reg. Sci. Technol. 2011, 65, 219–255. [Google Scholar] [CrossRef]

- Darrow, M.M.; Lieblappen, R.M. Visualizing cation treatment effects on frozen clay soils through μ CT scanning. Cold Reg. Sci. Technol. 2020, 175, 103085. [Google Scholar] [CrossRef]

- Kotov, P.; Stanilovskaya, J. Long-term strength of frozen saline soils. Mag. Civ. Eng. 2022, 113, 11307. [Google Scholar]

- Liao, M.K.; Lai, Y.M.; Liu, E.L.; Wan, X.S. A fractional order creep constitutive model of warm frozen silt. Acta Geotech. 2017, 12, 377–389. [Google Scholar] [CrossRef]

- Xu, X.T.; Wang, Y.B.; Yin, Z.H.; Zhang, H.W. Effect of temperature and strain rate on mechanical characteristics and constitutive model of frozen Helin loess. Cold Reg. Sci. Technol. 2017, 136, 44–51. [Google Scholar] [CrossRef]

- Girgis, N.; Li, B.; Akhtar, S.; Courcelles, B. Experimental study of rate-dependent uniaxial compressive behaviors of two artificial frozen sandy clay soils. Cold Reg. Sci. Technol. 2020, 180, 103166. [Google Scholar] [CrossRef]

- Liang, J.; Shen, W.; Lu, D.; Qi, J. A three-stage strength criterion for frozen soils. Cold Reg. Sci. Technol. 2022, 201, 103597. [Google Scholar] [CrossRef]

- Schindler, U.; Cudmani, R.; Chrisopoulos, S.; Schünemann, A. Multi-stage creep behavior of frozen granular soils: Experimental evidence and constitutive modeling. Can. Geotech. J. 2023, 53, 1646–1657. [Google Scholar] [CrossRef]

- Zhao, X.D.; Zhou, G.Q. Experimental study on the creep behavior of frozen clay with thermal gradient. Cold Reg. Sci. Technol. 2013, 86, 127–132. [Google Scholar] [CrossRef]

- Nassr, A.; Esmaeili-Falak, M.; Katebi, H.; Javadi, A. A new approach to modeling the behavior of frozen soils. Eng. Geol. 2018, 246, 82–90. [Google Scholar] [CrossRef]

- Shi, S.; Zhu, F.J.; Feng, D.C.; Zhang, F. Mechanical behaviors and elastoplastic damage constitutive model for heterogeneous frozen soil. Geomech. Energy Environ. 2023, 35, 100490. [Google Scholar] [CrossRef]

- Fish, A.M. Kinetic nature of the long-term strength of frozen soils. In Proceedings of the 2nd International Symposium on Ground Freezing, Norwegian Institute of Technology, Trondheim, Norway, 24–27 June 1980; pp. 95–108. [Google Scholar]

- Assur, A. Some promising trends in ice mechanics. In Physics and Mechanics of Ice; Springer: Berlin, Germany, 1980. [Google Scholar]

- Ting, J.M. Tertiary creep model for frozen sands. J. Geotech. Geoenviron. Eng. 1983, 109, 932–945. [Google Scholar] [CrossRef]

- Wang, P.; Liu, E.; Zhi, B.; Song, B. A macro–micro viscoelastic-plastic constitutive model for saturated frozen soil. Mech. Mater. 2020, 147, 103411. [Google Scholar] [CrossRef]

- He, P.; Cheng, G.D.; Zhu, Y.L. Constitutive theories on viscoelastoplasticity and damage of frozen soil. Sci. China D 1999, 42, 38–43. [Google Scholar] [CrossRef]

- Zhou, Z.W.; Ma, W.; Zhang, S.J.; Du, H.M.; Mu, Y.H.; Li, G.Y. Multiaxial creep of frozen loess. Mech. Mater. 2016, 95, 172–191. [Google Scholar] [CrossRef]

- Xu, G.F.; Wu, W.; Qi, J.L. Modeling the viscous behavior of frozen soil with hypoplastic. Int. J. Numer. Ana. Meth. 2016, 40, 2061–2075. [Google Scholar] [CrossRef]

- Yao, X.L.; Qi, J.L.; Liu, M.X.; Yu, F. A frozen soil creep model with strength attenuation. Acta Geotech. 2017, 12, 1385–1393. [Google Scholar] [CrossRef]

- Li, D.W.; Zhang, C.C.; Ding, G.S.; Zhang, H.; Chen, J.H.; Cui, H.; Pei, W.S.; Wang, S.F.; An, L.S.; Li, P.; et al. Fractional derivative-based creep constitutive model of deep artificial frozen soil. Cold Reg. Sci. Technol. 2020, 170, 102942. [Google Scholar] [CrossRef]

- Hou, F.; Lai, Y.M.; Liu, E.L.; Luo, H.W.; Liu, X.Y. A creep constitutive model for frozen soils with different contents of coarse grains. Cold Reg. Sci. Technol. 2018, 145, 119–126. [Google Scholar] [CrossRef]

- Yang, Y.G.; Lai, Y.M.; Chang, X.X. Experimental and theoretical studies on the creep behavior of warm ice-rich frozen sand. Cold Reg. Sci. Technol. 2010, 63, 61–67. [Google Scholar] [CrossRef]

- Wang, S.H.; Qi, J.L.; Yin, Z.Y.; Zhang, J.M.; Ma, W. A simple rheological element based creep model for frozen soils. Cold Reg. Sci. Technol. 2014, 106–107, 47–54. [Google Scholar] [CrossRef]

- Wang, P.; Liu, E.L.; Song, B.T.; Liu, X.Y.; Zhang, G.; Zhang, D. Binary medium creep constitutive model for frozen soils based on homogenization theory. Cold Reg. Sci. Technol. 2019, 162, 35–42. [Google Scholar] [CrossRef]

- He, J.L.; Niu, F.J.; Jiang, H.Q.; Jiao, C.L. Fractional viscoelastic-plastic constitutive model for frozen soil based on microcosmic damage mechanism. Mech. Mater. 2023, 177, 104545. [Google Scholar] [CrossRef]

- Itasca. Flac Manual: Theoretical Background; Itasca Consulting Group: Minneapolis, MN, USA, 1999. [Google Scholar]

- Yao, X.L.; Liu, M.X.; Yu, F.; Qi, J.L. Evaluation of creep models for frozen soils. Sci. Cold Arid Reg. 2015, 7, 392–398. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).