Aloe Vera-Based Concrete Superplasticizer for Enhanced Consolidation with Limestone Calcined Clay Cement

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mix Design and Sample Preparation

2.3. Methods

2.3.1. Setting Time and Consistency

2.3.2. Slump Flow, V-Funnel, and L-Box

2.3.3. Yield Stress

2.3.4. Compressive Strength

2.3.5. Bulk Density

3. Results and Discussion

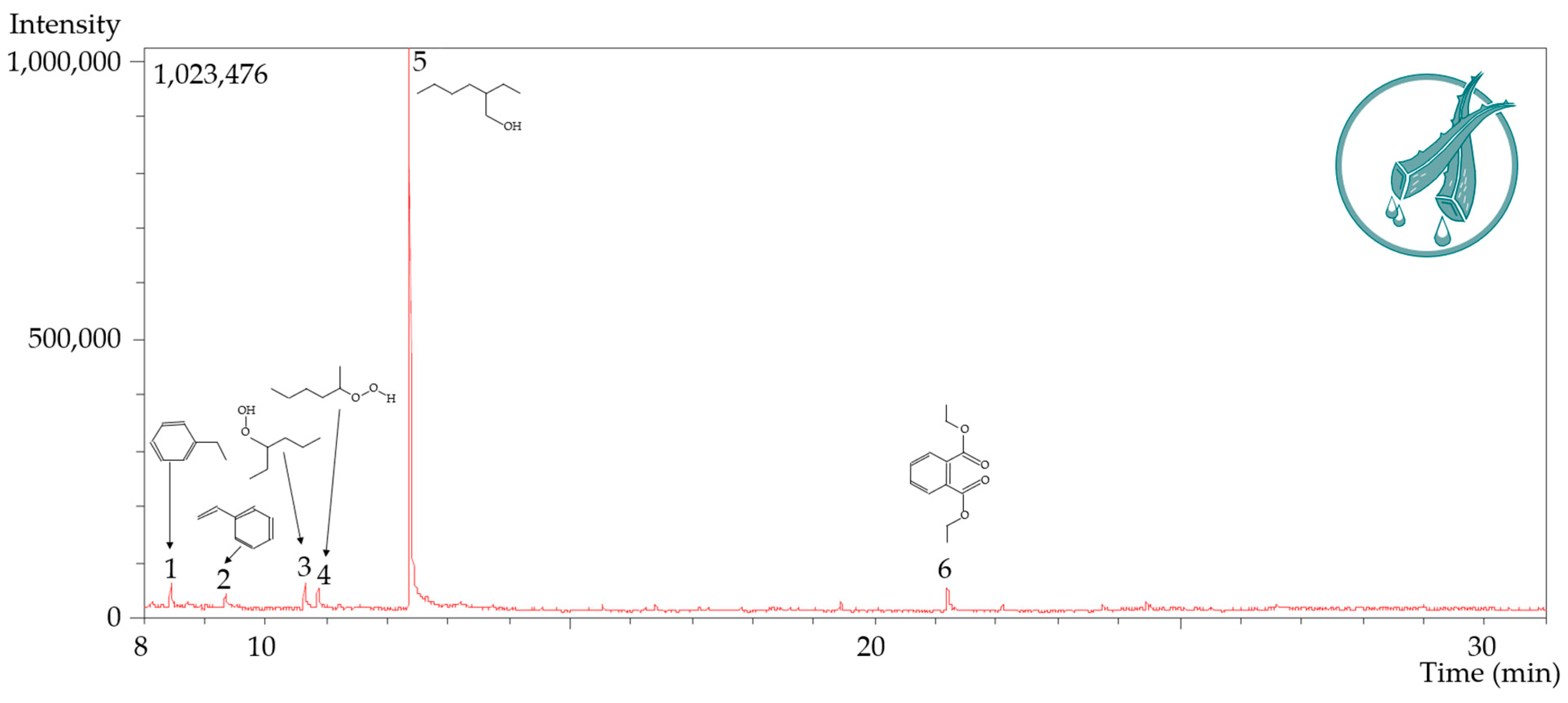

3.1. Characterization of Aloe Vera Mucilage

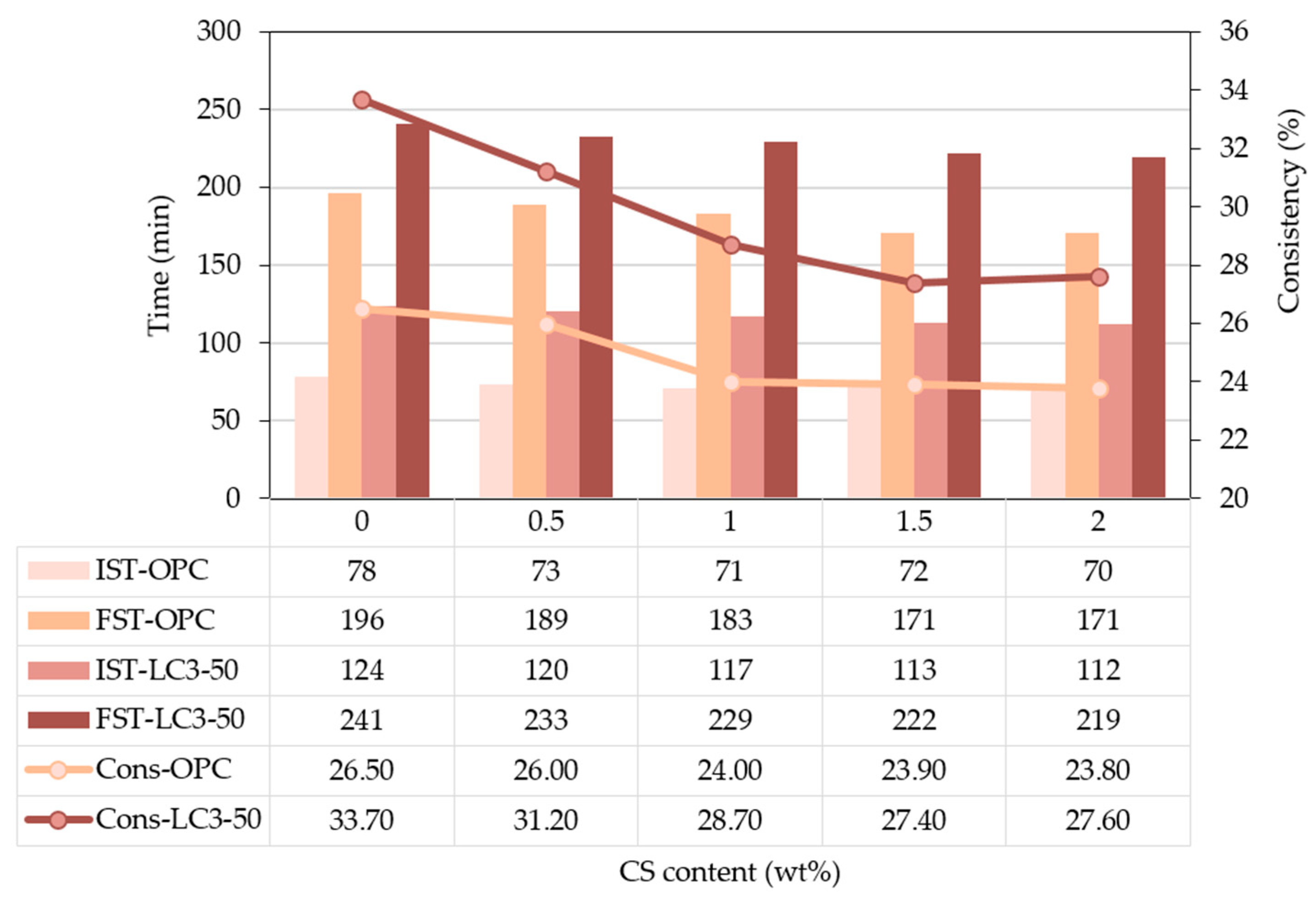

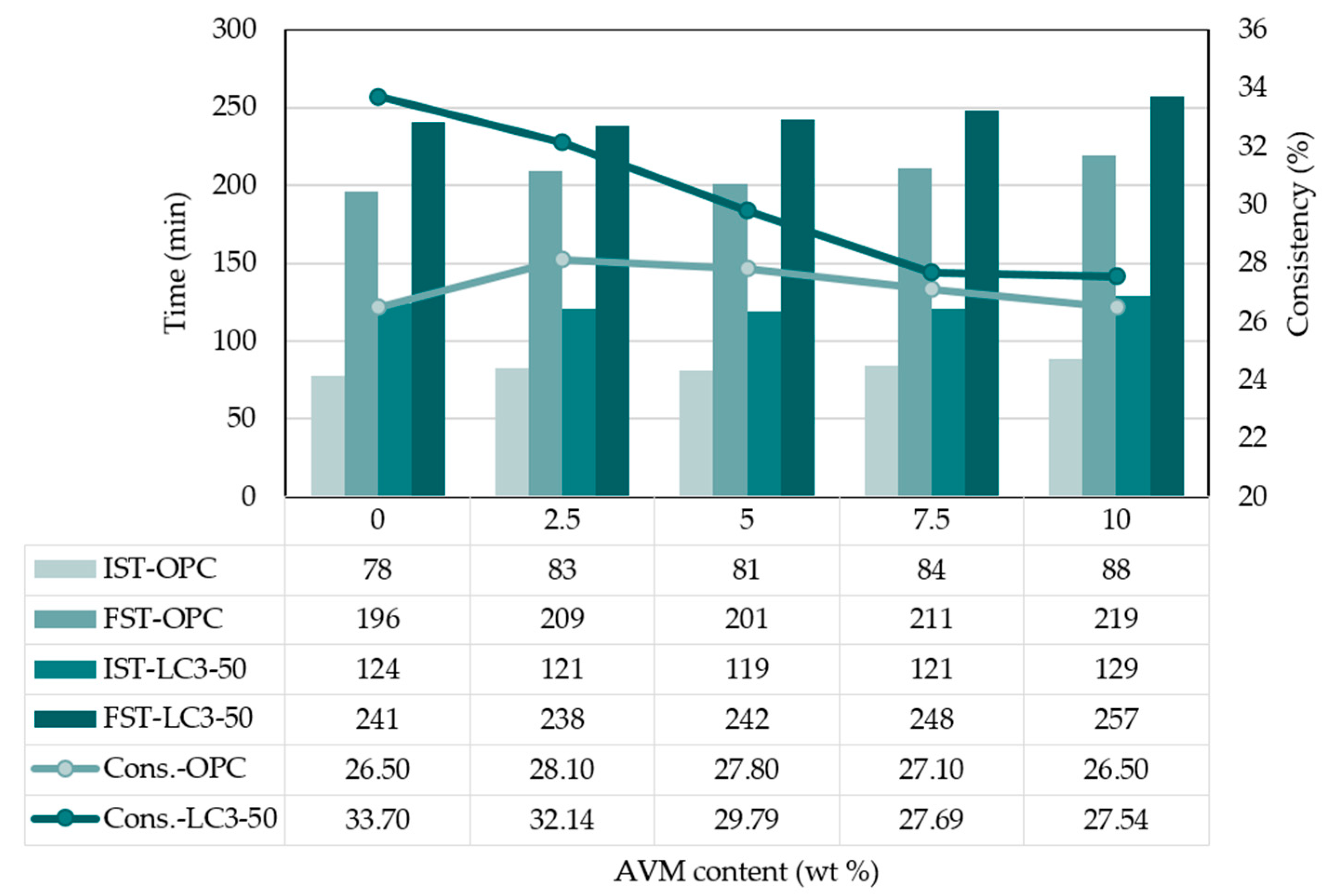

3.2. Setting Time and Consistency

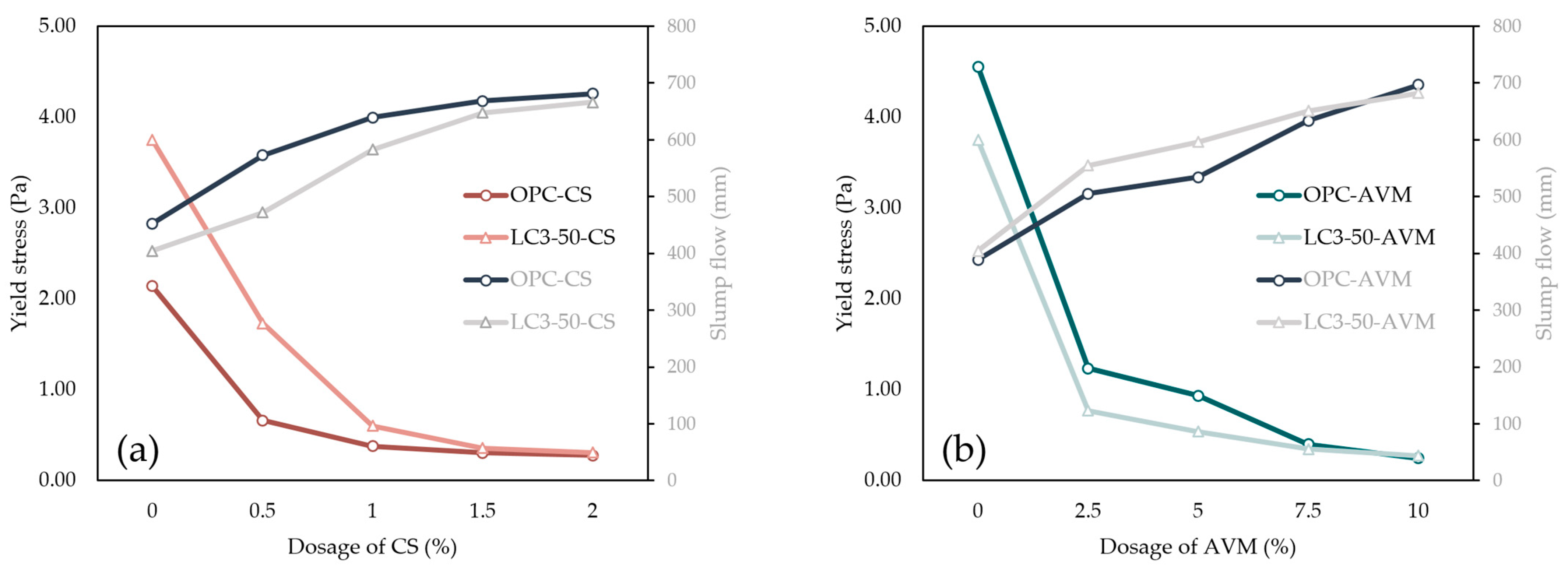

3.3. Slump Flow Test, V-Funnel Test, and L-Box Test

3.4. Yield Stress

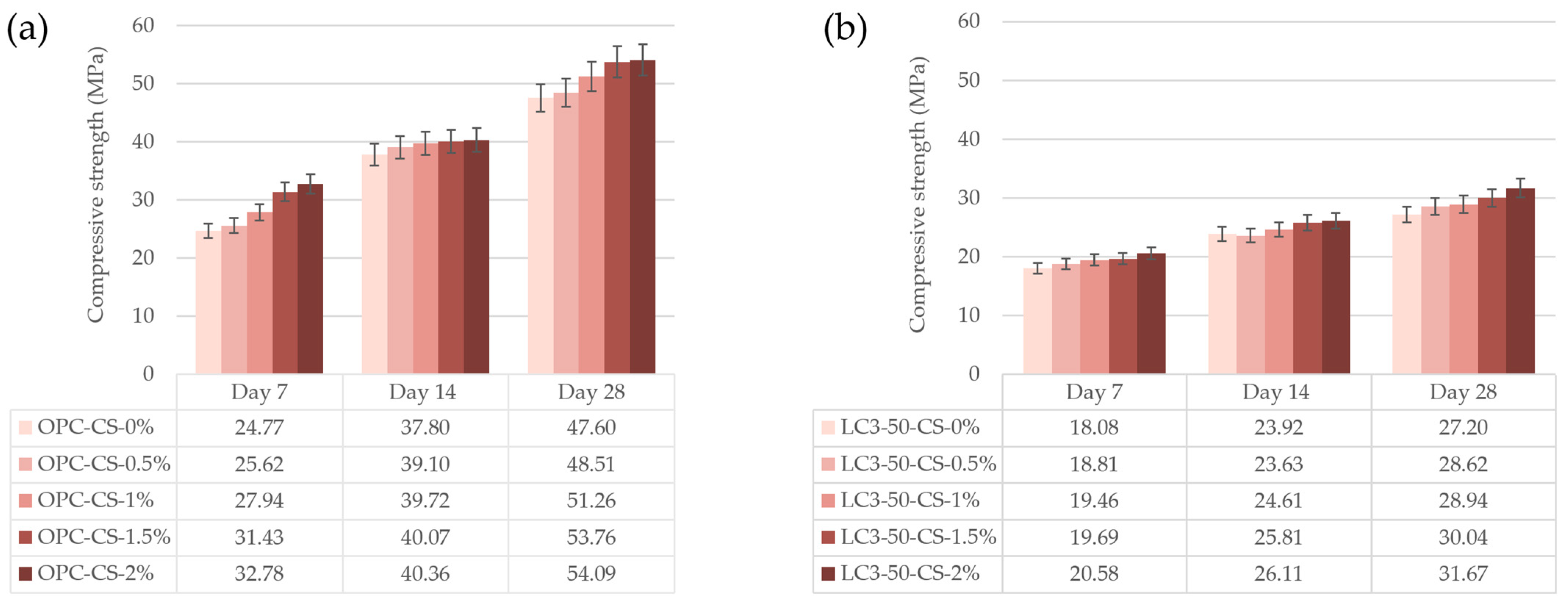

3.5. Compressive Strength

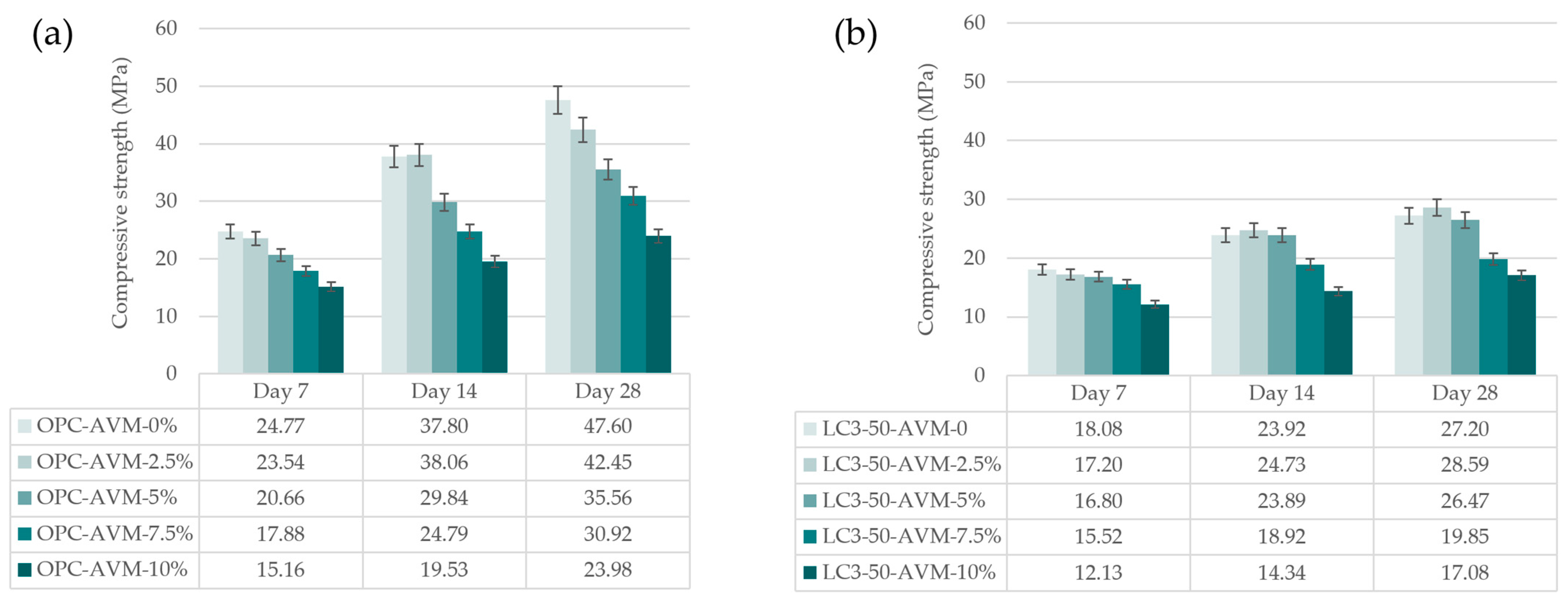

3.6. Bulk Density

4. Conclusions

- Setting time: The setting time of OPC and LC3-50 increased with the percentage dosage of AVM, suggesting the potential of AVM as a set retarder.

- Workability: In terms of workability (slump flow, V-funnel, and L-Box), the results at a 10 wt.% AVM dosage are well comparable with a 2 wt.% CS dosage in OPC and LC3-50 systems. AVM recorded a slump flow of 672.5 ± 23.25 mm and 656.5 ± 9 mm compared to the control for both OPC and LC3-50 cement systems.

- Yield stress: The percentage dosage of AVM relatively reduced the yield stress, indicating that AVM acts as a plasticizer and can be used to improve the workability and rheology of concrete systems.

- Compressive strength: AVM improved compressive strength at small dosages (2.5 wt.%), with 42.45 ± 1.04 MPa for OPC and 28.59 ± 1.39 MPa for LC3-50 at 28 days. However, further increases in dosage reduced overall compressive strength for both systems. At 7.5 wt.%, AVM achieved allowable structural concrete strength of 30.92 ± 1.55 MPa and 19.85 ± 0.99 MPa for OPC and LC3-50 systems after water curing for 28 days, respectively.

- Density: The density of SCC concrete prepared using 2.5 wt.% of AVM resulted in a bulk density comparable to conventional structural concrete but reduced with an increase in AVM contents.

- Optimal usage: The findings suggest that AVM is a potential admixture for making SCC at a 7.5 wt.% addition to concrete, achieving favorable workability and providing allowable structural concrete strength. However, long-term durability properties of such SCC should be evaluated for a comprehensive understanding of its performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kiran, K.; Naresh, J. Determination of fresh and hardened state properties of Self Compacting Concrete using GGBFS and RHA. Int. J. Innov. Res. Sci. Eng. Tech. 2018, 7, 6491–7005. [Google Scholar] [CrossRef]

- Siddique, R. Self-Compacting Concrete: Materials, Properties and Applications; Woodhead Publishing: Sawston, UK, 2019. [Google Scholar]

- Karakurt, C.; Dumangöz, M.J.M. Rheological and durability properties of self-compacting concrete produced using marble dust and blast furnace slag. Materials 2022, 15, 1795. [Google Scholar] [CrossRef] [PubMed]

- Dey, S.; Kumar, V.V.P.; Goud, K.R.; Basha, S.K.J. State of art review on self compacting concrete using mineral admixtures. J. Build. Pathol. Rehabil. 2021, 6, 18. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Lv, K.; Wu, L.J.C.; Materials, B. A review on mixture design methods for self-compacting concrete. Constr. Build. Mater. 2015, 84, 387–398. [Google Scholar] [CrossRef]

- Okamura, H.; Ouchi, M. Self-compacting concrete. J. Adv. Concr. Technol. 2003, 1, 5–15. [Google Scholar] [CrossRef]

- Tejaswini, G.L.S.; Rao, A.V. A detailed report on various behavioral aspects of self-compacting concrete. Mater. Today Proc. 2020, 33, 839–844. [Google Scholar] [CrossRef]

- Kumar, M.A.; Magesh, R.; Selvapraveen, S.; Vignesh, M. Assessment on fresh properties and hardened properties of self compacting concrete. AIP Conf. Proc. 2020, 2235, 020021. [Google Scholar]

- Meko, B.; Ighalo, J.O.; Ofuyatan, O.M. Enhancement of self-compactability of fresh self-compacting concrete: A review. Clean. Mater. 2021, 1, 100019. [Google Scholar] [CrossRef]

- Kalaimani, R.; Subha, C.; Reymond, D.J. Investigation on Strength Characteristics of Self Compacting Concrete incorporated with AR Glass Fibers. E3S Web Conf. 2023, 387, 03005. [Google Scholar] [CrossRef]

- Mahajan, G. Experimental Investigation on Properties of Self Compacting Concrete Using Mineral Admixtures. 2016. Available online: http://ir.aiktclibrary.org (accessed on 22 December 2023).

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Kafodya, I.; Basuroy, D.; Marangu, J.M.; Kululanga, G.; Maddalena, R.; Novelli, V.I. Mechanical performance and physico-chemical properties of limestone calcined clay cement (LC3) in Malawi. Buildings 2023, 13, 740. [Google Scholar] [CrossRef]

- Marangu, J.M. Physico-chemical properties of Kenyan made calcined Clay-Limestone cement (LC3). Case Stud. Constr. Mater. 2020, 12, e00333. [Google Scholar] [CrossRef]

- Marangu, J.M.; Riding, K.; Alaibani, A.; Zayed, A.; Thiong’o, J.K.; Wachira, J.M. Potential for Selected Kenyan Clay in Production of Limestone Calcined Clay Cement. In Proceedings of the Calcined Clays for Sustainable Concrete: Proceedings of the 3rd International Conference on Calcined Clays for Sustainable Concrete; Springer: Singapore, 2020; pp. 19–25. [Google Scholar]

- Odhiambo, V.O.; Scheinherrová, L.; Abuodha, S.O.; Mwero, J.N.; Marangu, J.M. Effects of Alternate Wet and Dry Conditions on the Mechanical and Physical Performance of Limestone Calcined Clay Cement Mortars Immersed in Sodium Sulfate Media. Materials 2022, 15, 8935. [Google Scholar] [CrossRef] [PubMed]

- Muzenda, T.R.; Hou, P.; Kawashima, S.; Sui, T.; Cheng, X. The role of limestone and calcined clay on the rheological properties of LC3. Cem. Concr. Compos. 2020, 107, 103516. [Google Scholar] [CrossRef]

- Canbek, O.; Xu, Q.; Mei, Y.; Washburn, N.R.; Kurtis, K.E. Predicting the rheology of limestone calcined clay cements (LC3): Linking composition and hydration kinetics to yield stress through Machine Learning. Cem. Concr. Res. 2022, 160, 106925. [Google Scholar] [CrossRef]

- Athman, C.M.; Abuodha, S.O.; Nyomboi, T. USE of GUM Arabic as a Superplasticizer in Self-Compacting Concrete. Int. J. Innov. Sci. Mod. Eng. 2018, 5, 8–13. [Google Scholar]

- Isik, I.E.; Ozkul, M.H.; Materials, B. Utilization of polysaccharides as viscosity modifying agent in self-compacting concrete. Constr. Build. Mater. 2014, 72, 239–247. [Google Scholar] [CrossRef]

- Oni, D.; Mwero, J.; Kabubo, C. The effect of cassava starch on the durability characteristics of concrete. Open J. Civ. Eng. 2020, 14, 289–301. [Google Scholar] [CrossRef]

- Surjushe, A.; Vasani, R.; Saple, D.J. Aloe vera: A short review. Indian J. Dermatol. 2008, 53, 163. [Google Scholar] [CrossRef]

- Pegu, A.J.; Sharma, M.A. Review on Aloe vera. Int. J. Trend. Sci. Res. Dev. 2019, 3, 35–40. [Google Scholar] [CrossRef]

- Aburto-Moreno, Z.; Alvarado-Quintana, H.; Vásquez-Alfaro, I. Influencia del aloe-vera sobre la resistencia a la compresión, infiltración, absorción capilar, tiempo de fraguado y asentamiento en un concreto estructural. SCIENDO 2018, 21, 105–118. [Google Scholar] [CrossRef][Green Version]

- Herrera-Hernandez, H.; Franco-Tronco, M.I.; Miranda-Hernandez, J.G.; Hernandez-Sanchez, E.; Espinoza-Vazquez, A.; Fajardo, G. Aloe-vera gel as potential corrosion inhibitor for concrete steel reinforcement. Av. Cienc. Ing. 2015, 6, 9–23. [Google Scholar]

- Oggu, A.; Madupu, L.N.K.S. Study on properties of porous concrete incorporating aloevera and marble waste powder as a partial cement replacement. Mater. Today Proc. 2022, 52, 1946–1951. [Google Scholar] [CrossRef]

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2023.

- ASTM C494/C494M-17; Standard Specification for Chemical Admixtures for Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- KS EAS 148-1; Cement—Test Methods—Part 1: Determination of Strength. Kenya Bureau of Standards: Nairobi, Kenya, 2017.

- EFNARC. The European Guidelines for Self-Compacting Concrete Specification, Production and Use; EFNARC: Flums Hochwiese, Switzerland, 2005. [Google Scholar]

- ASTM C138/C138M-17a; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2023.

- KS EAS 148-3; Cement-Test Methods Part 3: Determination of Setting Times and Soundness. Kenya Bureau of Standards: Nairobi, Kenya, 2017.

- ASTM C1749-17a; Standard Guide for Measurement of the Rheological Properties of Hydraulic Cementious Paste Using a Rotational Rheometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- Pierre, A.; Lanos, C.; Estelle, P. Extension of spread-slump formulae for yield stress evaluation. Appl. Rheol. 2013, 23, 63849. [Google Scholar]

- Scheinherrová, L.; Pommer, V.; Vejmelková, E.; Černý, R. Comparison of water removal methods from cement paste at early age. AIP Conf. Proc. 2021, 2343, 030010. [Google Scholar]

- Sebbar, N.; Bozzelli, J.W.; Bockhorn, H. Kinetic Study of Di-Tert-Butyl Peroxide: Thermal Decomposition and Product Reaction Pathways. Int. J. Chem. Kinet. 2015, 47, 133–161. [Google Scholar] [CrossRef]

- Moo-Young, M. Comprehensive Biotechnology; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- McGinty, D.; Scognamiglio, J.; Letizia, C.S.; Api, A.M. Fragrance material review on 2-ethyl-1-hexanol. Food Chem. Toxicol. 2010, 48, S115–S129. [Google Scholar] [CrossRef]

- Wakayama, T.; Ito, Y.; Sakai, K.; Miyake, M.; Shibata, E.; Ohno, H.; Kamijima, M. Comprehensive review of 2-ethyl-1-hexanol as an indoor air pollutant. J. Occup. Health 2019, 61, 19–35. [Google Scholar] [CrossRef]

- Ahmed, W.A.; Yarmo, A.; Salih, N.; Derawi, M.D.; Yusop, M.R.; Salimon, J. Synthesis and lubricity properties analysis of branched dicarboxylate esters based lubricant. Malays. J. Anal. Sci. 2015, 19, 106–117. [Google Scholar]

- Bodaghi, A. An overview on the recent developments in reactive plasticizers in polymers. Polym. Adv. Technol. 2020, 31, 355–367. [Google Scholar] [CrossRef]

- Stamatelatou, K.; Pakou, C.; Lyberatos, G. Occurrence, toxicity, and biodegradation of selected emerging priority pollutants in municipal sewage sludge. Compr. Biotech. 2011, 6, 473–484. [Google Scholar]

- Ataman Chemicals, “2-Ethylhexanol,” Information Society Services Human Resources. Available online: https://www.atamanchemicals.com/2-ethylhexanol_u24548/ (accessed on 12 December 2023).

- Wang, Y.; Qian, H. Phthalates and their impacts on human health. Healthcare 2021, 9, 603. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.; Lin, L. Exposure science: Contaminant mixtures. Ency. Envir. Health 2011. [Google Scholar] [CrossRef]

- Bhandari, I.; Kumar, R.; Sofi, A.; Nighot, N.S. A systematic study on sustainable low carbon cement–Superplasticizer interaction: Fresh, mechanical, microstructural and durability characteristics. Heliyon 2023, 9, e19176. [Google Scholar] [CrossRef] [PubMed]

- Flatt, R.J. Interparticle Forces and Superplasticizers in Cement Suspensions. Ph.D. Thesis, EPFL, Lausanne, Switzerland, 1999. [Google Scholar]

- 48. Hirata, T.; Branicio, P.; Ye, J.; Zheng, J.; Tomike, Y.; Lange, A.; Plank, J.; Sullivan, M. Atomistic dynamics simulation to solve conformation of model PCE superplasticisers in water and cement pore solution. Adv. Cem. Res. 2017, 29, 418–428. [Google Scholar] [CrossRef]

- Pan, J.; Feng, K.; Wang, P.; Chen, H.; Yang, W. Retardation and compressive strength enhancement effect of upcycling waste carrot as bio-admixture for cement mortars. J. Build. Eng. 2022, 62, 105402. [Google Scholar] [CrossRef]

- Singh, N.B.; Singh, S.P.; Sarvehi, R. Effect of phenols on the hydration of Portland cement. Adv. Cem. Res. 1989, 2, 43–47. [Google Scholar] [CrossRef]

- Zhu, W.; Feng, Q.; Luo, Q.; Bai, X.; Lin, X.; Zhang, Z. Effects of pce on the dispersion of cement particles and initial hydration. Materials 2021, 14, 3195. [Google Scholar] [CrossRef]

- Zhang, K.; Mezhov, A.; Schmidt, W. Effect of Polycarboxylate Superplasticizer in Ordinary Portland Cement and Sulfate Resistant Cement. J. Mater. Civ. Eng. 2023, 35, 04023113. [Google Scholar] [CrossRef]

- Yu, J.; Wu, H.-L.; Mishra, D.K.; Li, G.; Leung, C.K.Y. Compressive strength and environmental impact of sustainable blended cement with high-dosage Limestone and Calcined Clay (LC2). J. Clean. Prod. 2021, 278, 123616. [Google Scholar] [CrossRef]

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J. J Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Scrivener, K.; Avet, F.; Maraghechi, H.; Zunino, F.; Ston, J.; Hanpongpun, W.; Favier, A. Impacting factors and properties of limestone calcined clay cements (LC3). Green Mater. 2018, 7, 3–14. [Google Scholar] [CrossRef]

- Chang, J.; Jiang, T.; Cui, K. Influence on compressive strength and CO2 capture after accelerated carbonation of combination β-C2S with γ-C2S. Constr. Build. Mater. 2021, 312, 125359. [Google Scholar] [CrossRef]

- Bederina, M.; Makhloufi, Z.; Bouziani, T. Effect of limestone fillers the physic-mechanical properties of limestone concrete. Phys. Procedia 2011, 21, 28–34. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Santhanam, M.; Gettu, R.; Pillai, R. Perspectives on blended cementitious systems with calcined clay-limestone combination for sustainable low carbon cement transition. Indian Concr. J. 2020, 94, 31–45. [Google Scholar]

- Nalet, C.; Nonat, A. Effects of functionality and stereochemistry of small organic molecules on the hydration of tricalcium silicate. Cem. Concr. Res. 2016, 87, 97–104. [Google Scholar] [CrossRef]

- Opara, H.E.; Eziefula, U.G.; Eziefula, B.I. Comparison of physical and mechanical properties of river sand concrete with quarry dust concrete. SSP J. Civ. Eng. 2018, 13, 127–134. [Google Scholar] [CrossRef]

- Hospodarova, V.; Junak, J.; Stevulova, N. Color pigments in concrete and their properties. Pollack Periodica 2015, 10, 143–151. [Google Scholar] [CrossRef]

| Type of Mix | Superplasticizer | Dosage/wt.% | Slump Flow/mm | Observations | Ref. |

|---|---|---|---|---|---|

| SCC + limestone filler | Arabic gum | 2–12 | 400–800 | Optimal at 8%, reduced compressive strength | [19] |

| SCC + fly ash | Welan gum | ≤0.01 * | 600–670 | A minimum slump-flow of 600 mm using binder contents of 350, 400, or 450 kg | [20] |

| Xathan gum | ≤0.004 * | 610–670 | |||

| Starch ether | ≤0.5 * | 590–670 | |||

| Ordinary concrete | Cassava starch | 0.4–2 | 98–18 | Viscosity-modifying agent, less susceptible to sulphate attack, no impact on compressive strength | [21] |

| Ordinary concrete | Aloe vera | 2–6 | 75–6 | Increase of 41% of compressive strength was achieved with 2 wt.% compared to reference | [24] |

| Ordinary concrete | Aloe vera | Coating | Not relevant | Corrosion inhibitor for steel rebar, > 83% inhibition efficiency | [25] |

| Porous concrete + marble waste powder | Aloe vera | 0.25 | Not relevant | Along with 30% cement replacement with marble waste powder, an increase in the compressive strength was observed | [26] |

| Raw Material | SO3 | Al2O3 | Fe2O3 | CaO | SiO2 | MgO | LOI * |

|---|---|---|---|---|---|---|---|

| OPC | 1.14 | 5.43 | 3.68 | 64.83 | 21.64 | 2.5 | 0.78 |

| LC3-50 | 2.54 | 11.99 | 3.98 | 44.53 | 30.14 | 1.31 | 5.51 |

| L | 0.33 | 0.47 | 0.42 | 90.68 | 1.42 | 0.59 | 6.09 |

| Description | Property |

|---|---|

| Appearance | Whitish to light brown clear to cloudy liquid |

| Specific gravity at 25 °C | 1.073 g/cm3 |

| pH value | 5.0–7.0 |

| Chloride content | “chloride-free” to EN 934-2 |

| Trials | CA (kg/m3) | FA (kg/m3) | OPC/LC3-50 (kg/m3) | L (kg/m3) | w/c * | w/p * | CS/AVM |

|---|---|---|---|---|---|---|---|

| TR1 | 1078.00 | 562.13 | 363.38 | 224.22 | 0.43 | 0.8 | 1.82 |

| TR2 | 1078.00 | 562.13 | 363.38 | 224.22 | 0.48 | 0.9 | 3.63 |

| TR3 | 970.20 | 644.57 | 331.41 | 204.49 | 0.48 | 0.9 | 4.97 |

| TR4 | 862.40 | 732.64 | 351.14 | 216.67 | 0.48 | 0.8 | 3.51 |

| TR5 | 862.40 | 732.64 | 351.14 | 216.67 | 0.48 | 0.9 | 7.02 |

| TR6 | 970.20 | 644.57 | 331.41 | 204.49 | 0.48 | 0.9 | 4.97 |

| TR7 | 970.20 | 644.57 | 331.41 | 204.49 | 0.48 | 0.9 | 6.62 |

| TR8 | 970.20 | 644.57 | 331.41 | 204.49 | 0.50 | 1.0 | 4.97 |

| TR9 | 970.20 | 644.57 | 331.41 | 204.49 | 0.48 | 0.9 | 6.62 |

| Trials | d (mm) | Relative Slump | H2/H1 (mm) | V-Funnel (s) | Observations * | Further Testing |

|---|---|---|---|---|---|---|

| TR1 | 398.5 | 0.99 | 0 | 15+ | S | No |

| TR2 | 432.5 | 1.16 | 0 | 15+ | S | No |

| TR3 | 615.0 | 2.07 | 0.68 | 8 | F; S-V | No |

| TR4 | 497.5 | 1.49 | 0 | 15 | S | No |

| TR5 | 762.5 | 2.81 | 0.88 | 6 | F; B | No |

| TR6 | 515.0 | 1.57 | 0.18 | 13 | H-V | No |

| TR7 | 672.5 | 2.36 | 0.81 | 8 | F | Yes |

| TR8 | 762.5 | 2.81 | 0.83 | 5 | F; B | No |

| TR9 | 659.0 | 2.30 | 0.20 | 6 | F; B | No |

| Peak Report TIC | ||||||

|---|---|---|---|---|---|---|

| Peak# | R.Time | Area | Area% | Height | Height % | Name |

| 1 | 8.465 | 84,270 | 4.12 | 42,596 | 3.75 | Ethylbenzene |

| 2 | 9.356 | 73,891 | 3.61 | 23,475 | 2.07 | Styrene |

| 3 | 10.649 | 87,366 | 4.27 | 44,871 | 3.96 | Hydroperoxide, 1-ethylbutyl |

| 4 | 10.867 | 57,727 | 2.82 | 30,394 | 2.68 | Hydroperoxide, 1-methylpentyl |

| 5 | 12.376 | 1,651,585 | 80.74 | 956,651 | 84.33 | 1-Hexanol, 2-ethyl- |

| 6 | 21.189 | 90,686 | 4.43 | 36,440 | 3.21 | Diethyl Phthalate |

| Mix Type | % CS Dosage | Slump Flow (mm) | V-Funnel (s) | L-Box (h2/h1) | Observations |

|---|---|---|---|---|---|

| OPC-CS | 0 | 452.5 | No flow | 0 | No flow |

| 0.5 | 572.5 | High viscosity | 0 | No flow | |

| 1 | 639.5 | 11 | 0.46 | Flowing but viscous | |

| 1.5 | 668.5 | 9 | 0.88 | Flowing, no bleeding | |

| 2 | 681.5 | 8 | 0.94 | Flowing | |

| LC3-50-CS | 0 | 404.5 | No flow | 0 | No flow |

| 0.5 | 472.0 | High viscosity | 0 | No flow | |

| 1 | 583.0 | 13 | 0.43 | Flowing but viscous | |

| 1.5 | 647.5 | 10 | 0.60 | Flowing | |

| 2 | 666.0 | 9 | 0.88 | Flowing |

| Mix Type | % AVM Dosage | Slump Flow (mm) | V-Funnel (s) | L-Box (h2/h1) | Observations |

|---|---|---|---|---|---|

| OPC-AVM | 0 | 389.0 | No flow | 0 | No flow |

| 2.5 | 505.0 | High viscosity | 0 | No flow | |

| 5 | 534.0 | 14 | 0 | Highly viscous | |

| 7.5 | 633.5 | 9 | 0.81 | Flowing | |

| 10 | 697.0 | 5 | 0.83 | Flowing | |

| LC3-50-AVM | 0 | 404.5 | No flow | 0 | No flow |

| 2.5 | 555.0 | High viscosity | 0 | No flow | |

| 5 | 596.5 | 14 | 0 | Highly viscous | |

| 7.5 | 651.0 | 8 | 0.82 | Flowing | |

| 10 | 682.5 | 5 | 0.94 | Flowing |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nyabuto, A.O.; Abuodha, S.O.; Mwero, J.N.; Scheinherrová, L.; Marangu, J.M. Aloe Vera-Based Concrete Superplasticizer for Enhanced Consolidation with Limestone Calcined Clay Cement. Appl. Sci. 2024, 14, 358. https://doi.org/10.3390/app14010358

Nyabuto AO, Abuodha SO, Mwero JN, Scheinherrová L, Marangu JM. Aloe Vera-Based Concrete Superplasticizer for Enhanced Consolidation with Limestone Calcined Clay Cement. Applied Sciences. 2024; 14(1):358. https://doi.org/10.3390/app14010358

Chicago/Turabian StyleNyabuto, Andrew Onderi, Silvester Ochieng Abuodha, John Nyiro Mwero, Lenka Scheinherrová, and Joseph Mwiti Marangu. 2024. "Aloe Vera-Based Concrete Superplasticizer for Enhanced Consolidation with Limestone Calcined Clay Cement" Applied Sciences 14, no. 1: 358. https://doi.org/10.3390/app14010358

APA StyleNyabuto, A. O., Abuodha, S. O., Mwero, J. N., Scheinherrová, L., & Marangu, J. M. (2024). Aloe Vera-Based Concrete Superplasticizer for Enhanced Consolidation with Limestone Calcined Clay Cement. Applied Sciences, 14(1), 358. https://doi.org/10.3390/app14010358