Abstract

Dandelion flowers (DF) are a rich source of many phytochemicals which can reduce oxidative stress in the human body. The aim of this study was to assess the influence of dried and powdered DF addition into wheat flour (WF) on dough and bread properties. WF was replaced with DF at levels 0, 1, 2, 3, 4, 5 and 6%. Physical properties of dough and quality of control and supplemented bread were studied. The addition of DF increased water absorption of flour, development time and dough stability during mixing. However, these changes had no positive effect on bread quality. With an increase in the proportion of DF in the bread recipe, the volume of loaves and lightness of crumb decreased while its hardness and yellowness increased. As a result of these changes, the overall sensory acceptability of DF-enriched bread decreased. On the other hand, supplementation of WF with DF increased minerals, fiber and fat content in bread. Most importantly, DF enhanced the antioxidant capacity of bread and increased content of phenolics. Total phenolic content ranged from 1.00 mg GAE/g dry mass (DM) for control bread to 3.45 mg GAE/g DM when wheat flour was replaced with 6% of DF. To summarize, we showed that DF can be a valuable ingredient for bread fortification. However, the amount of WF replaced with DF should not exceed 2–3% while taking into account the sensory results.

1. Introduction

Bread is a staple food product in the daily diet of most people. A large portion of bread is made from refined flour. Such bread is attractive to consumers due to its soft texture, light-colored crumb, crispy crust and easy digestibility [1]. However, during the milling of wheat grain into white flour, many nutritionally valuable compounds such as vitamins, minerals, dietary fiber and other phytochemicals are lost, which means that bread made from such flour is energy-dense food but low in biologically active compounds, and consequently has limited ability to protect the human body from various diseases [2]. For this reason, it is reasonable to enrich wheat flour (WF) with natural and compound additives that are rich in phenolics. Flours from nonbread cereals and pseudocereals [3,4], legumes [5], oilseeds [6,7], herbs and spices [8,9,10,11], fruits and vegetables in various forms, e.g., dried or extracts [12,13,14], are valuable additives to wheat bread.

Dandelion (Taraxacum officinale F.H. Wigg) is a plant with an exceptionally valuable chemical composition. It occurs in Europe as a common weed [15]. Dandelion contains protein, fiber, fat, phenolic compounds, flavonoids, terpenoids, glycosides and various vitamins and minerals, including ß-carotene, provitamin A, vitamins C and D, B vitamins, iron, silicon, magnesium, sodium, zinc, manganese, copper and phosphorus [16,17,18,19]. In food production, various anatomical parts of this plant (roots, leaves and flowers) can be used as a rich source of many phytochemicals and minerals for human nutrition [17]. Roots of Taraxacum officinale are a rich in inulin, a polysaccharide with probiotic properties, used for the microbiological production of fructose syrup [20]. The roots are also used for the production of tea and, after roasting, as a coffee substitute [21]. Root extracts can also be applied as a natural preservative, delaying oxidation in food products [22]. Young leaves of dandelion are usually eaten raw as an ingredient in cocktails or salads, e.g., in combination with lettuce or chives. They can also be cooked and, after draining, eaten with butter and sprinkled with pepper and salt. Dried leaves are used to prepare various soft drinks and wine. Dandelion flowers (DF) can be used as an additive during production of wines and desserts, and their extracts are used as flavoring ingredients for various food products, e.g., dairy desserts, cheeses, candies and cookies [15]. In earlier studies [23], we successfully used dried and powdered Taraxacum officinale roots as an additive to wheat bread. These are the first studies aimed at determining the possibility of using dried DF powder as an additive to bread. The specific objectives of this work were (i) to determine the physical properties of dough with the addition of DF and (ii) to study the influence of physicochemical and sensory properties of DF-enriched bread.

2. Materials and Methods

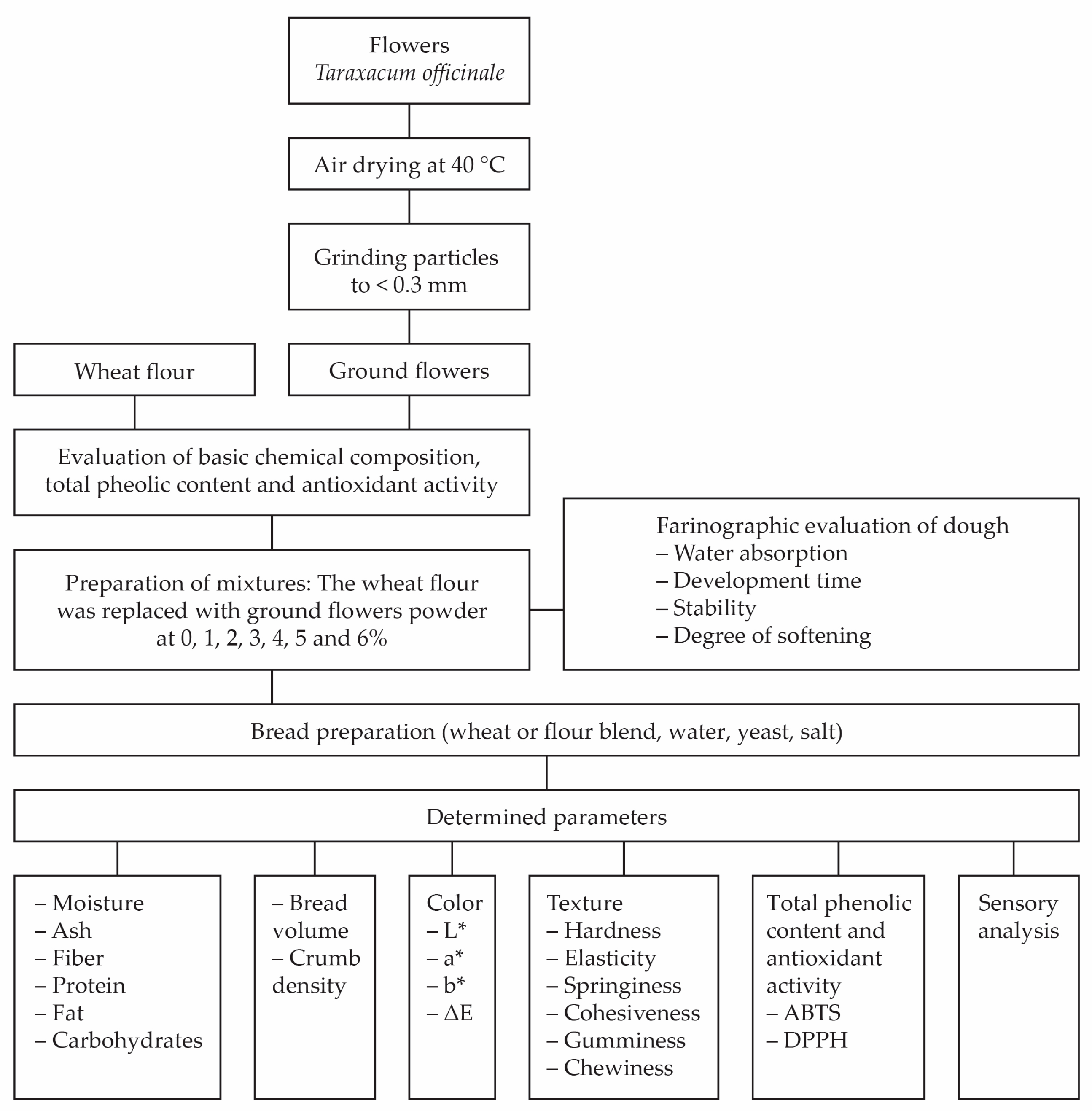

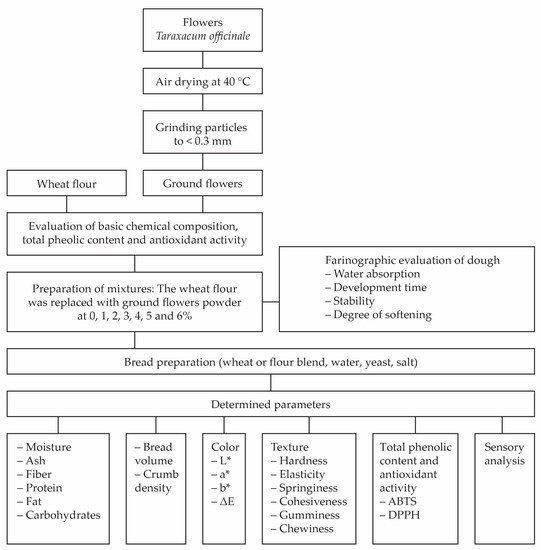

The experiment was performed according to the scheme presented in Figure 1. For WF, DF and obtained bread, the basic chemical composition was determined. Moreover, the physical properties of dough were determined using farinograph tests, and the physicochemical properties of bread were studied.

Figure 1.

Graphical scheme of conducted studies. L*, a*, b* and ΔE—lightness, redness, yellowness and total color difference, respectively; ABTS and DPPH—antiradical activities.

2.1. Raw Materials

The basic raw material for the preparation of bread dough was WF type 750 (Polskie Młyny Sp. z o.o., Warsaw, Poland), fresh pressed yeast (Lallemand Sp. z o.o., Józefów, Poland), table salt (Cenos Sp. z o.o., Września, Poland) and DF. Taraxacum officinale flowers came from experimental microplots of IUNG-PIB in Puławy (Poland). After harvesting, flowers were dried in the laboratory dryer (SL W 1000 TOP, POL-EKO Apparatus, Wodzisław Śląski, Poland) at 40 °C until they reached 10% moisture content and then powdered in the impact mill WŻ-1 (Baking Industry Research Institute, Bydgoszcz, Poland) to produce particles smaller than 0.3 mm.

2.2. Basic Chemical Composition

AACC standards were used for determination of the basic chemical composition of WF, DF and bread samples [24]. The contents of the following compounds were determined: moisture (MC) (Method 44-15.02), fat (FA) (Method 30-10.01), ash (AS) (Method 08-01.01), protein (PR) (Method 46-10.01) and total dietary fiber content (TDF) (Method 32-05.01). Moreover, the content of digestible carbohydrates (DC) was calculated:

2.3. Farinograph Properties of Dough

The blends of WF with DF were prepared before the determination of dough properties. The WF was replaced with DF at 0, 1, 2, 3, 4, 5 and 6%. The assay was performed using a Farinograph-E model 810114 with a mixer for 50 g flour (Brabender Gmbh & Co. KG, Duisburg, Germany) according to AACC Method 54-21 [24]. The device cooperated with a computer equipped with Farinograph v.5 program (Brabender Gmbh & Co. KG, Duisburg, Germany) for the calculation of farinograph indices.

2.4. Bread Preparation

The direct method was used for dough preparation [7]. The basic bread dough recipe included 500 g of WF, 15.0 g of yeast, 7.5 g of salt, and water. Water addition was calculated based on farinographic water absorption. WF was replaced with DF in the amount of 0% (CS), 1% (D1), 2% (D2), 3% (D3), 4% (D4), 5% (D5) and 6% (D6). The dough ingredients were mixed (SP-800A mixer, Spar Food Machinery, Taiwan) for 4 min at speed 2 and then transferred to a D-32 fermentation chamber (Sveba Dahlen, Sweden). The total fermentation time was 1.5 h, but after 60 min, the dough was mixed for 1 min. The fermented dough was divided into 250 g pieces, shaped by hand and placed in the molds for final proofing. Baking was carried out in a baking oven (DC-32E, Sveba Dahlen, Fristad, Sweden) at 230 °C for 30 min. After baking, the loaves were weighed and cooled before analysis.

2.5. Volume, Density and Yield of Bread

After 2 h of baking, the breads were weighed, their volume was determined, and crumb-specific weight and yield of bread were calculated [7]. The volume was determined using a 3D scanner (NextEngine, West Los Angeles, CA, USA), calculated using a computer program (MeshlLab, ISTI-CNR Research Centre, Rome, Italy) and then converted into 100 g of bread. The density of the crumb was also calculated [25].

2.6. Texture of Crumb

Texture analyzer type TA.XT2i (Stable Microsystem, Surrey, UK) was used to assess the mechanical properties of the bread crumb according to Texture Profile Analysis (TPA). The assay was performed according to the methodology provided in [26]. Cylindrical samples (diameter 22 mm) were cut from slices of bread 20 mm thick, which were subjected to compression testing using a head equipped with a mandrel with a diameter of 25 mm, with the speed of the mandrel at 1 mms−1. A 40% penetration of the sample was used with a 45 s interval between the first and second compression. From the obtained curves, hardness, elasticity, springiness, cohesiveness, gumminess and chewiness were determined.

2.7. Color Coordinates

The color coordinates of the crumb were determined by the reflection method in the CIE-L*a*b* system, where L* means lightness, a* red/green saturation and b* yellow/blue saturation. A CR-200 colorimeter (Konica Minolta, Osaka, Japan) was used for evaluation. The total color difference (ΔE) was calculated between the bread made of WF and the DF-enriched bread [27].

2.8. Total Phenolics Content (TPC) and Antioxidant Capacity (AC)

Methanolic extracts of WF, DF and bread samples were prepared before the determination of TPC and AC. TPC was determined using the method described in [28] and expressed as milligrams gallic acid equivalent (GAE) per gram of dry mass (DM). Antioxidant capacities against ABTS and DPPH radicals were determined [29]. The results of AC were expressed as the EC50 index (mg DM/mL). This index shows the concentration that induces a response halfway between the baseline and the maximum AC of a sample [30].

2.9. Sensory Evaluation

The sensory analyses of the bread samples were performed using a 9-point hedonic scale, with scores ranging from 1 (dislike extremely) to 9 (like extremely) [31]. Bread samples were assessed by 46 panelists (25 women and 21 men between 21 and 56 years old) for appearance, color, smell, taste and texture. Consequently, the overall acceptability of tested bread samples was determined. Before the test, participants received information about the study’s purpose and gave their consent in accordance with the university’s ethics committee. The analysis was performed at 20 °C in a room with white lighting.

2.10. Statistical Analyses

At least three replicates of each test were performed. Statistica 13.3 software (TIBCO Software, Palo Alto, CA, USA) was used to perform a statistical evaluation of the data. Analysis of variance (ANOVA) was performed, and the Tukey test was used for the determination of significant differences between means (α = 0.05).

3. Results and Discussion

3.1. Basic Chemical Composition

WF contained 0.71% ash, 2.93% fiber, 12.86% protein, 1.73% fat and 81.77% available carbohydrates. When compared with WF, DF was richer in all components except carbohydrates; ash content, fiber content and fat content were several times higher than in WF. Consequently, minerals, total dietary fiber and fat content increased with the addition of DF in the bread samples, whereas available carbohydrates decreased (Table 1). The chemical composition of bread depends strongly on used additives. Recently, many papers have been published on the nutritional value of bread enriched with various unconventional additives [32,33,34]. Odunlade et al. [35] found that partial replacement of WF with vegetable leaf powder from African eggplant, pumpkin and amaranths increases the protein, fiber, fat and ash content in enriched bread. Mafu et al. [36] incorporated cricket powder into wholemeal wheat bread. They showed that this additive can be used as a valuable source of protein in a bread recipe. A similar trend was observed when cricket powder was incorporated into gluten-free bread [37]. Other authors [38] revealed that enriching wheat bread with dried and powdered grape pomace had no significant influence on protein content, but the fiber, ash and fat content was increased in enriched loaves.

Table 1.

Basic chemical composition of WF, DF and bread (% DM).

3.2. Physical Properties of Dough

The farinograph is an often-used tool to assess the baking properties of WF. It records the physical properties of the dough such as resistance to deformation and changes in dough consistency during dough kneading. The farinograph properties of dough often show significant correlations with bread quality features and especially with bread crumb characteristics [39]. The partial replacement of WF with DF changed all determined dough properties (Table 2). Flour water absorption linearly increased from 5.67% (CP) to 61.23% (D6) with an increase in DF in the dough (r = 0.989, p < 0.05). A similar relationship was found between the development time of the dough and the percentage of DF in the bread recipe (r = 0.943, p < 0.05). These relationships can be caused by the higher fiber content in dandelion flour compared with WF. Fiber-rich additives lead to an increase in water absorption of flour and dough development time [40]. The stability of dough during mixing also increased as a result of DF incorporation into the bread recipe. However, this relationship was not linear. This parameter is correlated with flour baking strength. Flour with a long stability time generally requires a longer kneading time and is more suitable for hearth bread production [39]. DF had relatively little influence on the degree of dough softening when the level of the replacement of WF was from 2% to 4%. When flour was replaced with 1%, 5% and 6% of DF, a noticeable decrease in the degree of dough softening was found. This parameter corresponds to the susceptibility of dough to the resistance of mixing. A strong negative correlation was found between this parameter and the stability of dough during mixing (r = −0.915, p < 0.05). Presented results suggest that dried and powdered DF had a positive effect on dough rheological properties and strengthened the dough’s tolerance to overmixing. According to published data, different fiber-rich additives usually increase the water absorption of WF blends and make the wheat dough more stable during mixing [41,42]. Interestingly, powdered dandelion roots (DR) had the reverse effect on the physical properties of wheat dough as determined by using a farinograph. Recently, Cacak-Pietrzak et al. [23] found that replacement of WF with DR (from 1 to 6%) caused a decrease in the water absorption of flour blends and decreased the dough mixing tolerance.

Table 2.

Physical properties of control wheat dough and DF-enriched dough samples.

3.3. Basic Characteristics of Control and Enriched Bread

The yield of bread linearly increased with the addition of DF (r = 0.983, p < 0.001) from 143% (CS) to 147.9% (D6) (Table 3). It was caused by higher water absorption of DF-enriched flour. In addition, moisture content of crumb increased with DF percentage in the bread recipe from 43.7% (CS) to 46.8% (D6) (r = 0.900, p = 0.006). The addition of DF had a negative influence on bread volume as a result of weakening the gluten network structure. Bread volume decreased linearly with the level of DF in bread (r = −0.989, p < 0.001). Consequently, the crumb density increased from 0.273 g/cm3 for CS to 0.352 g/cm3 for D6. The volume of a loaf is an important quality parameter because it influences final gas retention in the loaf and affects consumer preference [27]. Although consumers usually prefer higher volume and low-density crumb with soft texture, the reduction in bread volume influences the glycemic response and causes a reduction in glycemic index [28]. Interestingly, farinograph data (Table 2) showed that DF strengthened the dough and increased water absorption of flour blends, development time and stability of dough, especially for D5 and D6 samples. However, these changes had no positive effect on bread volume. Thus, it can be concluded that although dough kneading of DF-enriched wheat dough strengthened the dough structure, during the next steps of bread production such as fermentation and baking, the reverse effect occurs, and the weakening of dough is observed. Consequently, the volume of bread decreased. Incorporation of nongluten ingredients into WF leads to the interactions of proteins with used additives, and during dough mixing and resting, the loss of some proteins from the gluten network is observed [43]. On the other hand, the addition of some hydrocolloids as gluten substitutes can have a positive effect on the volume of bread [44,45].

Table 3.

Basic characteristics of control and DF-enriched bread.

3.4. Bread Texture

Bread texture is an important parameter for consumers’ acceptance. This feature can be modified both by using additives and through processing. Replacement of WF with DF at a level higher than 2% significantly increased crumb hardness compared with the control sample (Table 4). It resulted from a lower volume of bread, which consequently produced a denser and more compact crumb. The coefficient of correlation between the volume of bread and crumb hardness was significant and negative (r = −0.907, p = 0.005). Crumb hardness ranged from 6.08 N (CS) to 10.63 N (D6). On the other hand, DF incorporation into bread had little influence on crumb elasticity and no significant impact on the springiness and cohesiveness of bread. Both gumminess and chewiness linearly decreased with the percentage of DF, mainly as a result of the increase in crumb hardness. The negative influence of different plant additives on wheat bread texture, as a result of gluten weakening, was observed by many authors [46,47]. However, this effect is not always observed. Recently, Dziki et al. [48] showed that the replacement of WF with parsley leaf powder in the range of 1–5% does not have a negative influence on crumb hardness. This characteristic results mainly from used ingredients, bread density and moisture content. The additives which strongly increase crumb moisture have little influence on crumb hardness because water is a plasticizer, and higher water content in bread results in softer crumb [49].

Table 4.

Texture of control and DF-enriched bread samples.

3.5. Crumb Color

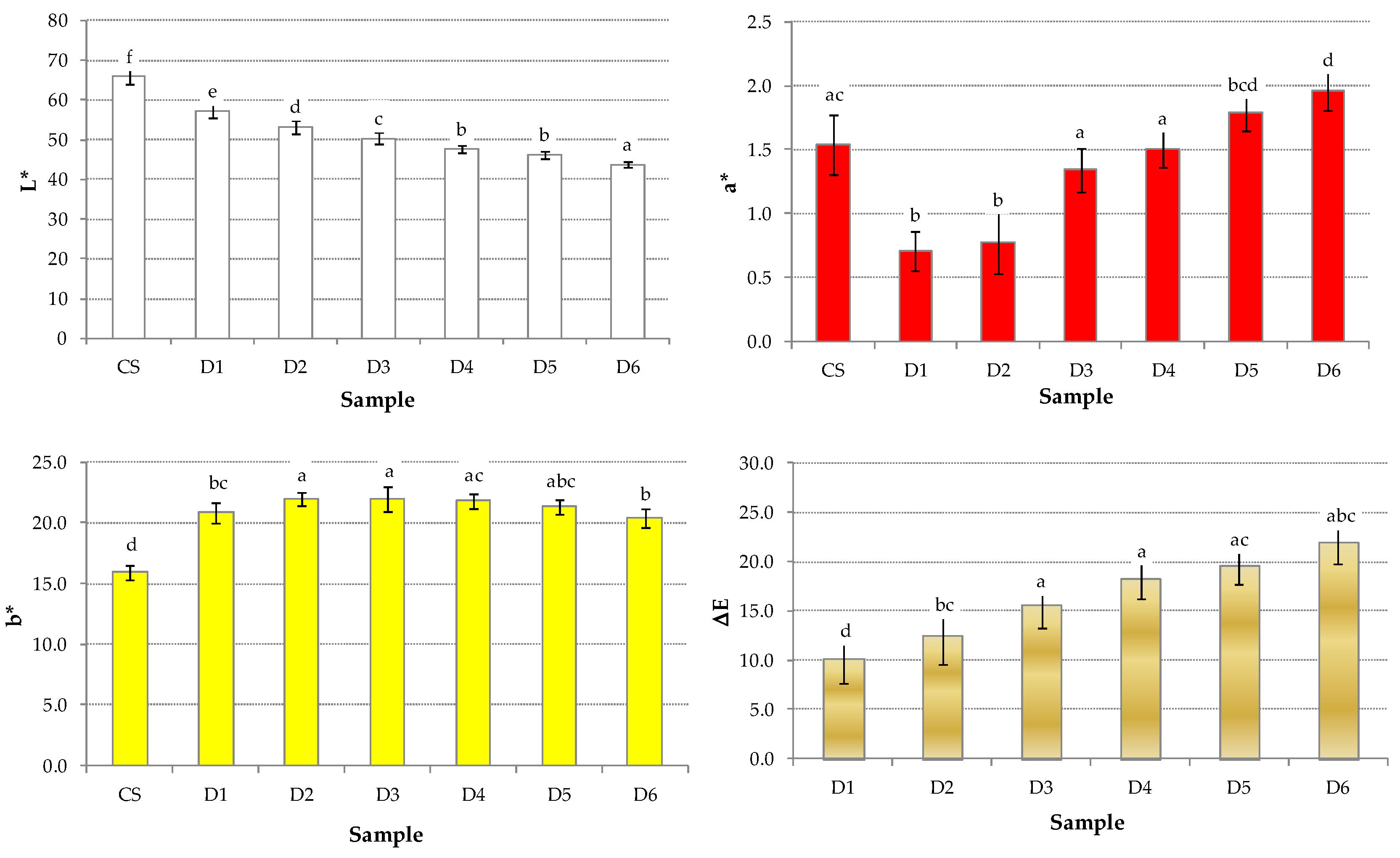

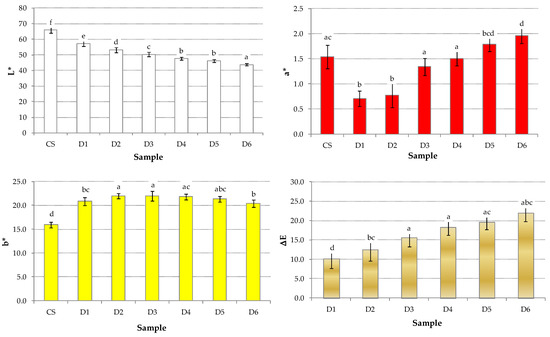

Color is an important determinant of food acceptability and is related to the AC of plant food [50]. DF caused significant changes in color of the crumb (Figure 2). Lightness (L*) of bread samples decreased from 65.8 to 43.8 with the increased level of DF (r = 0.967, p < 0.05). The highest change in L* was found when WF was replaced with 1% of DF (decrease to 57.2). The redness (a*) of the crumb decreased when 1% and 2% of WF were replaced with DF. On the other hand, a higher level of WF replacement resulted in increased a* values, and crumb with 3, 4 and 5% of DF was characterized by similar hardness as the crumb of control bread. The highest redness was noted for the D6 sample (1.97) and the lowest for D1 bread (0.71). Enrichment of WF with DF resulted in increased yellowness (b*) of the crumb. However, no linear relationship was found between percentage of DF in the bread recipe and b* of bread. This parameter ranged from 15.9 for control bread to 22.0 when 3% of WF was replaced with powdered dandelion. ΔE between the control bread and enriched loaves changed from 10.1 to 22.1 and increased linearly with the addition of DF (r = 0.99, p < 0.05). This indicates that the replacement of WF with DF at the level of 1% caused noticeable changes in the color of the crumb. DF are a rich source of carotenoids, especially lutein epoxide, responsible for the yellow color of dandelion petals [51]. These compounds are mainly responsible for color changes of the crumb. Recently, Cacak-Pietrzak et al. [23] showed that dandelion roots also decreased the lightness and redness of wheat bread crumb but decreased yellowness. However, the range of these changes was lower compared with DF-enriched bread.

Figure 2.

Color coordinates and total color difference (ΔE) of bread samples. CS, D1, D2, D3, D4, D5, D6—control bread and bread with 1, 2, 3, 4, 5 and 6% of DF, respectively. Data are presented as means with standard deviations (n = 6). Values of each parameter with different letters (a–f) are significantly different (p < 0.05).

3.6. TPC and AC

Dandelion flowers are a rich source of phytochemicals, especially flavonoids such as luteolin O-hexoside and luteolin [52], and phenolic acids [53]. Phenolic compounds provide many health benefits. They can protect vitamins, lipids and proteins from oxidation and consequently decrease their biological degeneration [54]. The total phenolic content in DF was 32.08 ±1.45 mg GAE/g DM. However, antiradical activity against DPPH and ABTS expressed by EC50 index amounted to 8.20 ± 0.27 mg DM/mL and 8.63 ± 0.35 mg DM/mL, respectively. Replacement of WF with DF resulted in a linear increase of TPC in all enriched bread samples (r = 0.986, p < 0.05). TPC ranged from 1.00 mg GAE/g DM for control bread to 3.45 mg GAE/g DM for D6 bread (Table 5). Importantly, bread with 2% and 3% of DF characterized about twofold higher TPC compared with the unfortified product. The antiradical activity also increased with the percentages of DF in the bread recipe. Both in the case of DPPH and ABTS, the values of EC50 decreased as the content of DF in bread samples increased. It indicates that AC increased from 614.8 to 141.9 mg DM/mL and from 129.7 to 87.9 mg DM/mL in the case of DPPH and ABTS, respectively. A similar tendency was found when powdered dandelion root was used as an additive to WF [23]. However, from comparing our results with the results obtained for bread enriched with dandelion root, it can be concluded that DF more effectively increased the AC of the bread sample when the same amounts of flour were replaced with these additives. Further, other studies confirm that DF as a component of foods could potentially bring many benefits for human health [55]. Phenolic fractions from DF are recognized as a better source of phytochemicals, especially flavonoids, than leaves and can be a very promising source of many bioactive compounds with increased AC, beneficial for the prevention of diseases associated with high oxidative stress [56].

Table 5.

Total phenolic content and antioxidant activity of control and enriched bread.

3.7. Sensory Evaluation Results

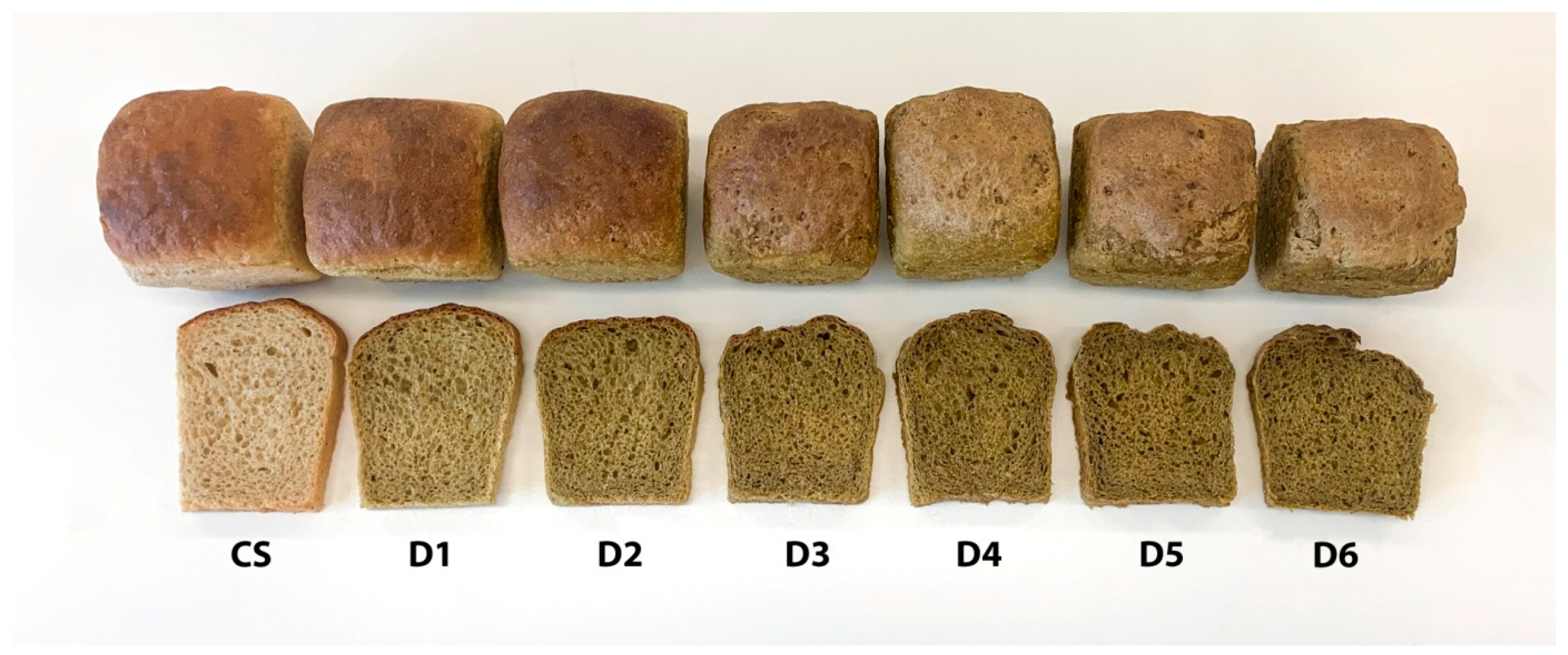

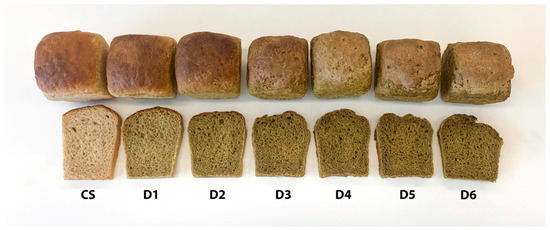

The appearance of control bread (CS) and DF-enriched breads is presented in Figure 3. CS received the highest scores for all sensory attributes, such as smell, taste, texture, appearance and color. Consequently, the overall acceptability of CS was the highest (8.0 points). DF decreased the scores for all attributes. However, the highest decrease was observed in smell and appearance, especially when WF was replaced with DF at a level higher than 2%. When 3% of WF was replaced with DF, the enriched bread was slightly acceptable. In contrast, D4, D5 and D6 bread samples were assessed as neither like nor dislike, dislike slightly and dislike moderately for most of the sensory attributes, respectively (Table 6). The surface of the bread for these samples was nonhomogeneous, exhibiting holes and cracks, and the shape of the loaves was more irregular compared with other breads. Moreover, the crumb was more compact as a result of the higher density of enriched loaves. At 3% and higher addition of DF, a difference in taste was noticeable compared to the control bread due to the appearance of a bitter and grassy aftertaste. The aftertaste became more intense with the increase in the content of DF. Recently, other studies showed that also for powdered dandelion roots, the acceptable level of this addition in the bread recipe should not exceed 3% of WF replacement [23]. Sensory acceptability is a key determinant of food consumption. Enrichment of WF with different additives can increase [57] or decrease [58] the overall acceptability of bread. The negative effect of enrichment on the volume of bread and texture of the crumb is most often observed [58,59,60].

Figure 3.

Picture of control and enriched bread samples. CS, D1, D2, D3, D4, D5, D6—control bread and bread with 1, 2, 3, 4, 5 and 6% of DF, respectively.

Table 6.

Sensory results of control and DF-enriched bread.

4. Conclusions

The partial replacement (from 1 to 6%) of WF with powdered flowers of Taraxacum officinale increased flour water absorption, development time and stability of the dough. However, the only positive effect of these changes was on bread yield. DF decreased the volume of bread and increased crumb hardness but enhanced the nutritional value of loaves. Ash content, total dietary fiber and fat content increased with the level of DF in the loaf recipe. In addition, the color of the crumb also changed after the fortification of bread with DF, particularly in decreased lightness and increased yellowness. Moreover, addition of DF increased TPC and AC of bread but decreased the linking scores for all sensory attributes. Replacement of WF with 2–3% of DF seems to be a compromise between the quality and increased health properties of DF-enriched bread.

Author Contributions

Conceptualization, G.C.-P. and D.D.; methodology, G.C.-P.; software, U.G.-D.; validation, G.C.-P. and D.D.; formal analysis, M.W. and A.K.; investigation, G.C.-P., U.G.-D., A.K., A.S. and M.W.; resources, G.C.-P.; data curation, G.C.-P.; writing—original draft preparation, G.C.-P. and D.D.; writing—review and editing, G.C.-P. and D.D.; visualization, G.C.-P. and D.D.; supervision, D.D.; project administration, G.C.-P.; funding acquisition, G.C.-P. and D.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to thank for using research equipment purchased as part of the “Food and Nutrition Centre—modernisation of the WULS campus to create a Food and Nutrition Research and Development Centre (CZi Z)” cofinanced by the European Union from the European Regional Development Fund under the Regional Operational Programme of the Mazowieckie Voivodeship for 2014–2020 (Project No. RPMA.01.01.00-14-8276/17).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Conte, P.; Fadda, C.; Piga, A.; Collar, C. Techno-functional and nutritional performance of commercial breads available in Europe. Food Sci. Technol. Int. 2016, 22, 621–633. [Google Scholar] [CrossRef] [PubMed]

- Capurso, A.; Capurso, C. The mediterranean way: Why elderly people should eat wholewheat sourdough bread—A little known component of the mediterranean diet and healthy food for elderly adults. Aging Clin. Exp. Res. 2020, 32, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Derkanosova, N.M.; Stakhurlova, A.A.; Pshenichnaya, I.A.; Ponomareva, I.N.; Peregonchaya, O.V.; Sokolova, S.A. Amaranth as a bread enriching ingredient. Foods Raw Mater. 2020, 8, 223–231. [Google Scholar] [CrossRef]

- Cotovanu, I.; Ungureanu-Iuga, M.; Mironeasa, S. Investigation of Quinoa Seeds Fractions and Their Application in Wheat Bread Production. Plants 2021, 10, 2150. [Google Scholar] [CrossRef] [PubMed]

- Angioloni, A.; Collar, C. High legume-wheat matrices: An alternative to promote bread nutritional value meeting dough viscoelastic restictions. Eur. Food Res. Technol. 2012, 234, 273–284. [Google Scholar] [CrossRef]

- de Lamo, B.; Gómez, M. Bread Enrichment with Oilseeds. A Review. Foods 2018, 7, 191. [Google Scholar] [CrossRef] [PubMed]

- Romankiewicz, D.; Hassoon, W.H.; Cacak-Pietrzak, G.; Sobczyk, M.; Wirkowska-Wojdyła, M.; Ceglińska, A.; Dziki, D. The effect of chia seeds (Salvia hispanica L.) addition on quality and nutritional value of wheat bread. J. Food Qual. 2017, 2017, 7352631. [Google Scholar] [CrossRef]

- Cacak-Pietrzak, G.; Różyło, R.; Dziki, D.; Gawlik-Dziki, U.; Sułek, A.; Biernacka, B. Cistus incanus L. as an Innovative Functional Additive to Wheat Bread. Foods 2019, 8, 349. [Google Scholar] [CrossRef] [PubMed]

- Dziki, D.; Cacak-Pietrzak, G.; Gawlik-Dziki, U.; Sułek, A.; Kocira, S.; Biernacka, B. Effect of Moldavian dragonhead (Dracocephalum moldavica L.) leaves on the baking properties of wheat flour and quality of bread. CyTA J. Food 2019, 17, 536–543. [Google Scholar] [CrossRef]

- Dziki, D.; Cacak-Pietrzak, G.; Hassonn, W.H.; Gawlik-Dziki, U.; Sułek, A.; Różyło, R.; Suger, D. The fruit of sumac (Rhus coriaria L.) as a functional additive and salt replacement to wheat bread. LWT Food Sci. Technol. 2021, 136, 110346. [Google Scholar] [CrossRef]

- Wójcik, M.; Różyło, R.; Łysiak, G.; Kulig, R.; Cacak-Pietrzak, G. Textural and sensory properties of wheat bread fortified with nettle (Urtica dioica L.) produced by scalded flour method. J. Food Process. Preserv. 2021, 45, e15851. [Google Scholar] [CrossRef]

- Boubaker, M.; Damergi, C.; Marzouk, C.B.; Blecker, C.; Bouzouita, N. Effect of artichoke (Cynara scolymus L.) by-product in the quality and total phenol content of bread. Mediterr. J. Chem. 2016, 5, 548–553. [Google Scholar] [CrossRef]

- Prokopov, T.; Chonova, V.; Slavov, A.; Dessev, T.; Dimitrov, N.; Petkova, N. Effects on the quality and health-enhancing properties of industrial onion waste powder on bread. J. Food Sci. Technol. 2018, 55, 5091–5097. [Google Scholar] [CrossRef] [PubMed]

- Czubaszek, A.; Czaja, A.; Sokół-Łętowska, A.; Kolniak-Ostek, J.; Kucharska, A.Z. Changes in antioxidant properties and amounts of bioactive compounds during simulated in vitro digestion of wheat bread enriched with plant extracts. Molecules 2021, 26, 6292. [Google Scholar] [CrossRef] [PubMed]

- González-Castejón, M.; Visioli, F.; Rodriguez-Casado, A. Diverse biological activities of dandelion. Nutr. Rev. 2012, 70, 534–547. [Google Scholar] [CrossRef] [PubMed]

- García-Carrasco, B.; Fernández-Dacosta, R.; Dávalos, A.; Ordovás, J.M.; Rodriguez-Casado, A. In vitro hypolipidemic and antioxidant effects of leaf and root extracts of Taraxacum officinale. Med. Sci. 2015, 3, 38–54. [Google Scholar] [CrossRef] [PubMed]

- Pāduret, S.; Amariei, S.; Gutt, G.; Piscuc, B. The evaluation of Dandelion (Taraxacum officinale) Properties as a Valuable Food Ingredient. Rom. Biotech. Lett. 2016, 21, 11569–11575. [Google Scholar]

- Molinu, M.G.; Piluzza, G.; Campesi, G.; Sulas, L.; Re, G.A. Antioxidant Sources from Leaves of Russian Dandelion. Chem. Biodivers. 2019, 16, e19002. [Google Scholar] [CrossRef]

- Savych, A.; Bilyk, O.; Vaschuk, V.; Humeniuk, I. Analysis of inulin and fructans in Taraxacum officinale L. roots as the main inulin-containing component of antidiabetic herbal mixture. Pharmacia 2021, 68, 527–532. [Google Scholar] [CrossRef]

- Rawat, H.K.; Soni, H.; Kango, N.; Kumar, C.G. Continuous generation of fructose from Taraxacum officinale tap root extract and inulin by immobilized inulinase in a packed-bed reactor. Biocatal. Agric. Biotechnol. 2017, 9, 134–140. [Google Scholar] [CrossRef]

- Lis, B.; Olas, B. Pro-health activity of dandelion (Taraxacum officinale L.) and its food product—History and present. J. Funct. Foods 2019, 59, 40–48. [Google Scholar] [CrossRef]

- Kenny, O.; Chandralal, M.H.; Brunton, N.P. Quantitative UPLC-MS/MS analysis of chlorogenic acid derivatives in antioxidant fractionates from dandelion (Taraxacum officinale) root. Int. J. Food Sci. Technol. 2015, 50, 766–773. [Google Scholar] [CrossRef]

- Cacak-Pietrzak, G.; Dziki, D.; Gawlik-Dziki, U.; Sułek, A.; Kalisz, S.; Sujka, K. Effect of the Addition of Dried Dandelion Roots (Taraxacum officinale F.H. Wigg.) on Wheat Dough and Bread Properties. Molecules 2021, 26, 7564. [Google Scholar] [CrossRef] [PubMed]

- AACC. American Association of Cereal Chemistry Approved Methods, 10th ed. St. Paul. Available online: http://methods.aaccnet.org/toc.aspx (accessed on 10 November 2022).

- Belyaev, A.G.; Kovaleva, A.E.; Pyanikova, E.A. The influence of fireweed powder on the quality of wheat bread. Proc. Vor. State Univ. Eng. Technol. 2019, 80, 254–258. (In Russian) [Google Scholar] [CrossRef]

- Gámbaro, A.; Giménez, A.; Ares, G.; Gilardi, V. Influence of enzymes on the texture of brown pan bread. J. Texture Stud. 2006, 37, 300–314. [Google Scholar] [CrossRef]

- Różyło, R.; Wójcik, M.; Dziki, D.; Biernacka, B.; Cacak-Pietrzak, G.; Gawłowski, S.; Zdybel, A. Freeze-dried elderberry and chokeberry as natural colorants for gluten-free wafer sheets. Int. Agrophysics 2019, 33, 217–225. [Google Scholar] [CrossRef]

- Różyło, R.; Szymańska-Chargot, M.; Gawlik-Dziki, U.; Dziki, D. Spectroscopic, mineral, and antioxidant characteristics of blue colored powders prepared from cornflower aqueous extracts. Food Chem. 2021, 346, 128889. [Google Scholar] [CrossRef]

- Sujka, K.; Cacak-Pietrzak, G.; Sułek, A.; Murgrabia, K.; Dziki, D. Buckwheat Hull-Enriched Pasta: Physicochemical and Sensory Properties. Molecules 2022, 27, 4065. [Google Scholar] [CrossRef]

- Singh, A.; Raju, R.; Mrad, M.; Reddell, P.; Münch, G. The reciprocal EC50 value as a convenient measure of the potency of a compound in bioactivity-guided purification of natural products. Fitoterapia 2020, 143, 104598. [Google Scholar] [CrossRef]

- Wichchukit, S.; O’Mahony, M. The 9-point hedonic scale and hedonic ranking in food science: Some reappraisals and alternatives. J. Sci. Food Agric. 2015, 95, 2167–2178. [Google Scholar] [CrossRef]

- Bender, D.; Schönlechner, R. Innovative approaches towards improved gluten-free bread properties. J. Cereal Sci. 2020, 91, 102904. [Google Scholar] [CrossRef]

- Betoret, E.; Rosell, C.M. Enrichment of bread with fruits and vegetables: Trends and strategies to increase functionality. Cereal Chem. 2020, 97, 9–19. [Google Scholar] [CrossRef]

- Sukhikh, S.; Ivanova, S.; Dolganyuk, V.; Pilevinova, I.; Prosekov, A.; Ulrikh, E.; Noskova, S.; Michaud, P.; Babich, O. Evaluation of the Prospects for the Use of Microalgae in Functional Bread Production. Appl. Sci. 2022, 12, 12563. [Google Scholar] [CrossRef]

- Odunlade, T.V.; Famuwagun, A.A.; Taiwo, K.A.; Gbadamosi, S.O.; Oyedele, D.J.; Adebooye, O.C. Chemical Composition and Quality Characteristics of Wheat Bread Supplemented with Leafy Vegetable Powders. J. Food Qual. 2017, 2017, 9536716. [Google Scholar] [CrossRef]

- Mafu, A.; Ketnawa, S.; Phongthai, S.; Schönlechner, R.; Rawdkuen, S. Whole Wheat Bread Enriched with Cricket Powder as an Alternative Protein. Foods 2022, 11, 2142. [Google Scholar] [CrossRef]

- Kowalczewski, P.Ł.; Gumienna, M.; Rybicka, I.; Górna, B.; Sarbak, P.; Dziedzic, K.; Kmiecik, D. Nutritional value and biological activity of gluten-free bread enriched with cricket powder. Molecules 2021, 26, 1184. [Google Scholar] [CrossRef]

- Tolve, R.; Simonato, B.; Rainero, G.; Bianchi, F.; Rizzi, C.; Cervini, M.; Giuberti, G. Wheat bread fortification by grape pomace powder: Nutritional, technological, antioxidant, and sensory properties. Foods 2021, 10, 75. [Google Scholar] [CrossRef]

- Abd-El-Khalek, M.; Youssif, M. Correlation Between Dough Rheological Properties and Pan Bread Crumb Quality Characteristics. Egypt. J. Agric. Sci. 2018, 69, 353–369. [Google Scholar] [CrossRef]

- Morsy, M.K. Physicochemical and Sensory Properties of Functional Biscuits Fortified with Oat Flour. Ann. Agric. Sci. Moshtohor 2022, 60, 63–72. [Google Scholar] [CrossRef]

- Purhagen, J.K.; Sjöö, M.E.; Eliasson, A.C. Fibre-rich additives-the effect on staling and their function in free-standing and pan-baked bread. J. Sci. Food Agric. 2012, 92, 1201–1213. [Google Scholar] [CrossRef]

- Miś, A.; Grundas, S.; Dziki, D.; Laskowski, J. Use of farinograph measurements for predicting extensograph traits of bread dough enriched with carob fibre and oat wholemeal. J. Food Eng. 2012, 108, 1–12. [Google Scholar] [CrossRef]

- Ooms, N.; Delcour, J.A. How to impact gluten protein network formation during wheat flour dough making. Curr. Opin. Food Sci. 2019, 25, 88–97. [Google Scholar] [CrossRef]

- Salehi, F. Improvement of gluten-free bread and cake properties using natural hydrocolloids: A review. Food Sci. Nutr. 2019, 7, 3391–3402. [Google Scholar] [CrossRef] [PubMed]

- Bourekoua, H.; Gawlik-Dziki, U.; Różyło, R.; Zidoune, M.N.; Dziki, D. Acerola fruit as a natural antioxidant ingredient for gluten-free bread: An approach to improve bread quality. Food Sci. Technol. Int. 2021, 27, 13–21. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Sun, H.; Mu, T. Effects of sweet potato leaf powder on sensory, texture, nutrition, and digestive characteristics of steamed bread. J. Food Process. Preserv. 2022, 46, e16697. [Google Scholar] [CrossRef]

- Wang, X.; Lao, X.; Bao, Y.; Guan, X.; Li, C. Effect of whole quinoa flour substitution on the texture and in vitro starch digestibility of wheat bread. Food Hydrocoll. 2021, 119, 106840. [Google Scholar] [CrossRef]

- Dziki, D.; Hassoon, W.H.; Biernacka, B.; Gawlik-Dziki, U. Dried and Powdered Leaves of Parsley as a Functional Additive to Wheat Bread. Appl. Sci. 2022, 12, 7930. [Google Scholar] [CrossRef]

- Różyło, R.; Dziki, D.; Gawlik-Dziki, U.; Cacak-Pietrzak, G.; Miś, A.; Rudy, S. Physical properties of gluten-free bread caused by water addition. Int. Agrophysics 2015, 29, 353–364. [Google Scholar] [CrossRef]

- Cömert, E.D.; Mogol, B.A.; Gökmen, V. Relationship between color and antioxidant capacity of fruits and vegetables. Curr. Res. Food Sci. 2020, 2, 1–10. [Google Scholar] [CrossRef]

- Grauso, L.; Emrick, S.; de Falco, B.; Lanzotti, V.; Bonanomi, G. Common dandelion: A review of its botanical, phytochemical and pharmacological profiles. Phytochem. Rev. 2019, 18, 1115–1132. [Google Scholar] [CrossRef]

- Dias, M.I.; Barros, L.; Alves, R.C.; Oliveira, M.B.P.P.; Santos-Buelga, C.; Ferreira, I.C.F.R. Nutritional composition, antioxidant activity and phenolic compounds of wild Taraxacum sect. Ruderalia. Food Res. Int. 2014, 56, 266–271. [Google Scholar] [CrossRef]

- Wirngo, F.E.; Lambert, M.N.; Jeppesen, P.B. The physiological effects of dandelion (Taraxacum officinale) in type 2 diabetes. Rev. Diabet. Stud. 2016, 13, 113–131. [Google Scholar] [CrossRef] [PubMed]

- Schütz, K.; Carle, R.; Schieber, A. Taraxacum—A review on its phytochemical and pharmacological profile. J. Ethnopharmacol. 2006, 107, 313–323. [Google Scholar] [CrossRef] [PubMed]

- Majewski, M.; Lis, B.; Juśkiewicz, J.; Ognik, K.; Borkowska-Sztachańska, M.; Jedrejek, D.; Stochmal, A.; Olas, B. Phenolic fractions from dandelion leaves and petals as modulators of the antioxidant status and lipid profile in an in vivo study. Antioxidants 2020, 9, 131. [Google Scholar] [CrossRef]

- Jędrejek, D.; Kontek, B.; Lis, B.; Stochmal, A.; Olas, B. Evaluation of antioxidant activity of phenolic fractions from the leaves and petals of dandelion in human plasma treated with H2O2 and H2O2/Fe. Chem. Biol. Interact. 2017, 262, 29–37. [Google Scholar] [CrossRef]

- Iglesias-Puig, E.; Haros, M. Evaluation of performance of dough and bread incorporating chia (Salvia hispanica L.). Eur. Food Res. Technol. 2013, 237, 865–874. [Google Scholar] [CrossRef]

- Korus, A.; Witczak, M.; Korus, J.; Juszczak, L. Dough Rheological Properties and Characteristics of Wheat Bread with the Addition of Lyophilized Kale (Brassica oleracea L. var. sabellica) Powder. Appl. Sci. 2023, 13, 29. [Google Scholar] [CrossRef]

- Pycia, K.; Pawłowska, A.M.; Kaszuba, J.; Żurek, N. Walnut Male Flowers (Juglans regia L.) as a Functional Addition to Wheat Bread. Foods 2022, 11, 3988. [Google Scholar] [CrossRef]

- Alotaibi, H.N.; Anderson, A.K.; Sidhu, J.S. Influence of lutein content of marigold flowers on functional properties of baked pan bread. Ann. Agric. Sci. 2021, 66, 162–168. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).