Research on the Prediction of the Time of Initial Support of Soft Rock Tunnel Based on the Optimized Longitudinal Deformation Profile

Abstract

:1. Introduction

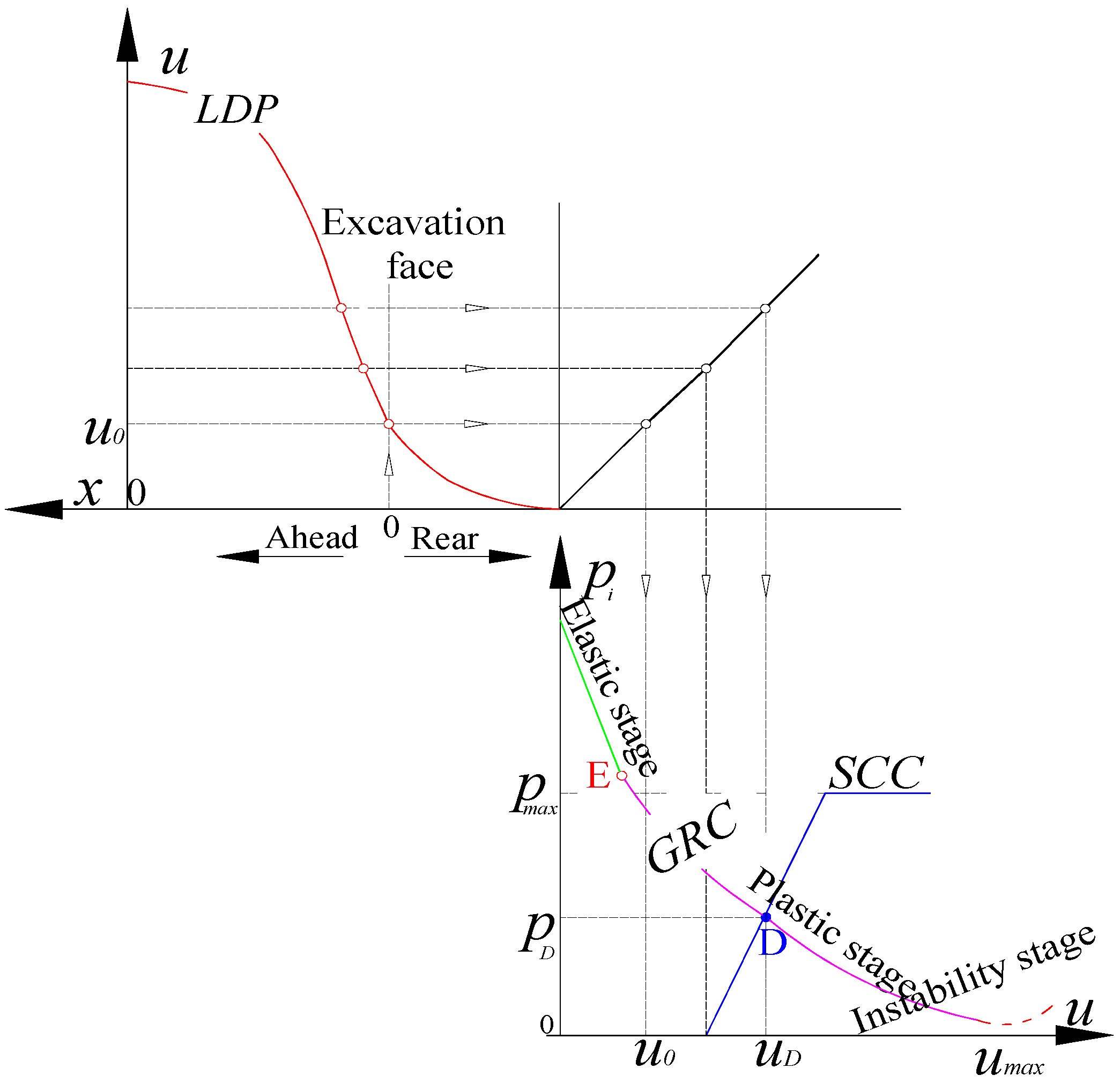

2. Convergence-Confinement Method and Displacement Release Coefficient

2.1. Principles of Convergence-Confinement Method

2.2. Displacement Release Coefficient Analysis

3. Solution and Analysis of Longitudinal Deformation Curve of Surrounding Rock

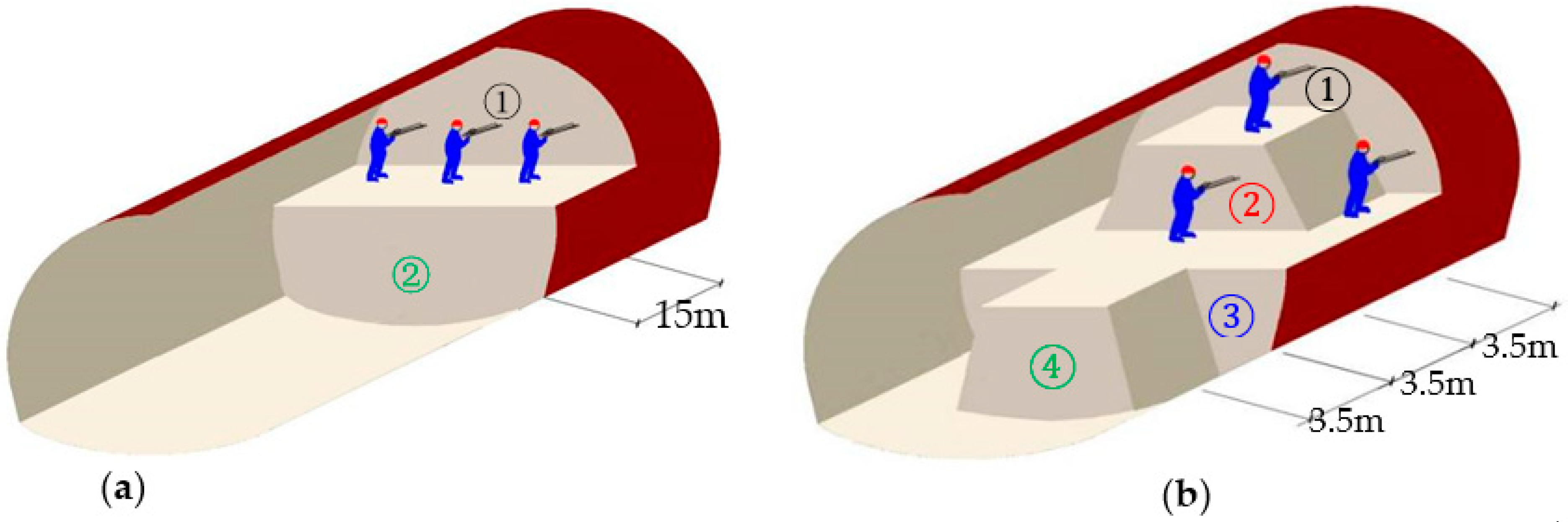

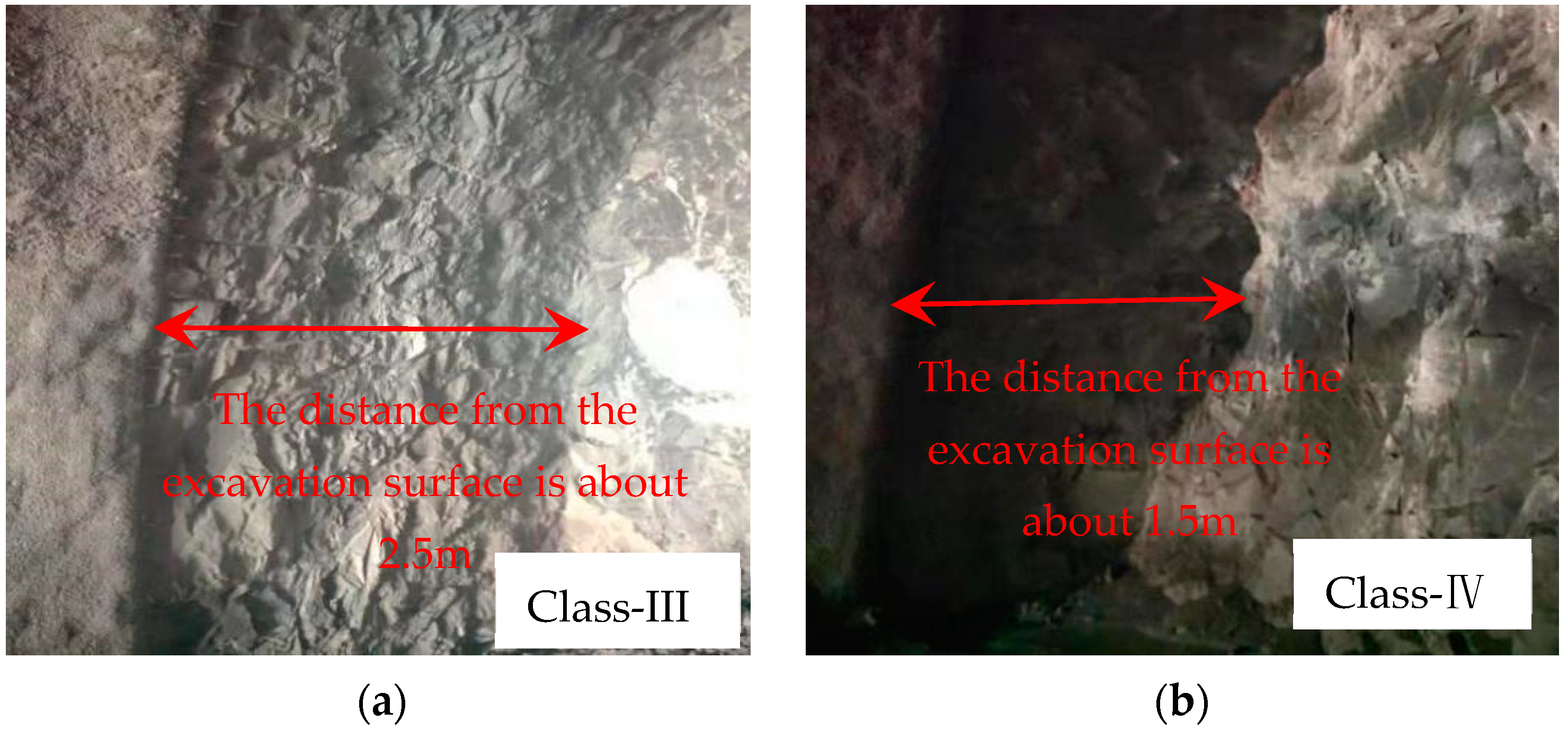

3.1. Project Overview

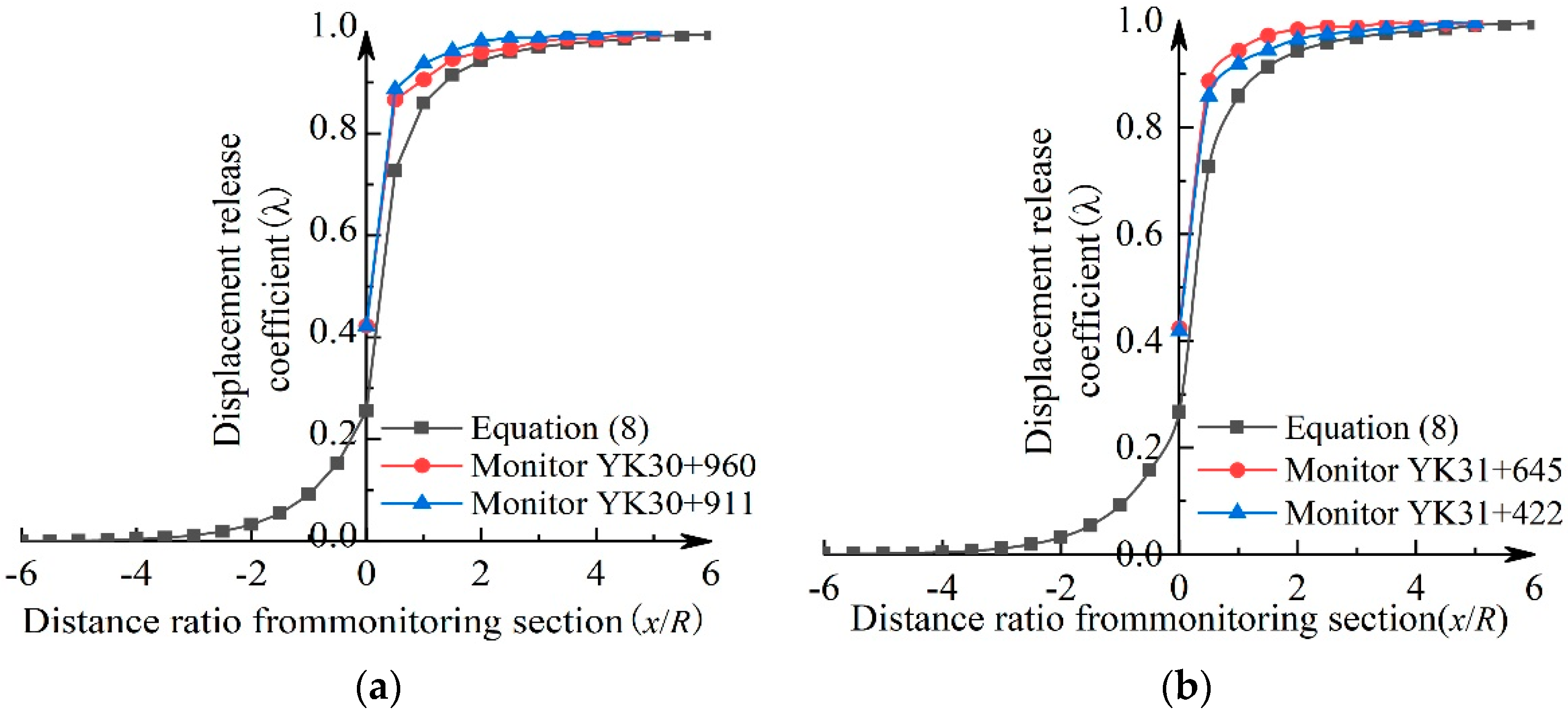

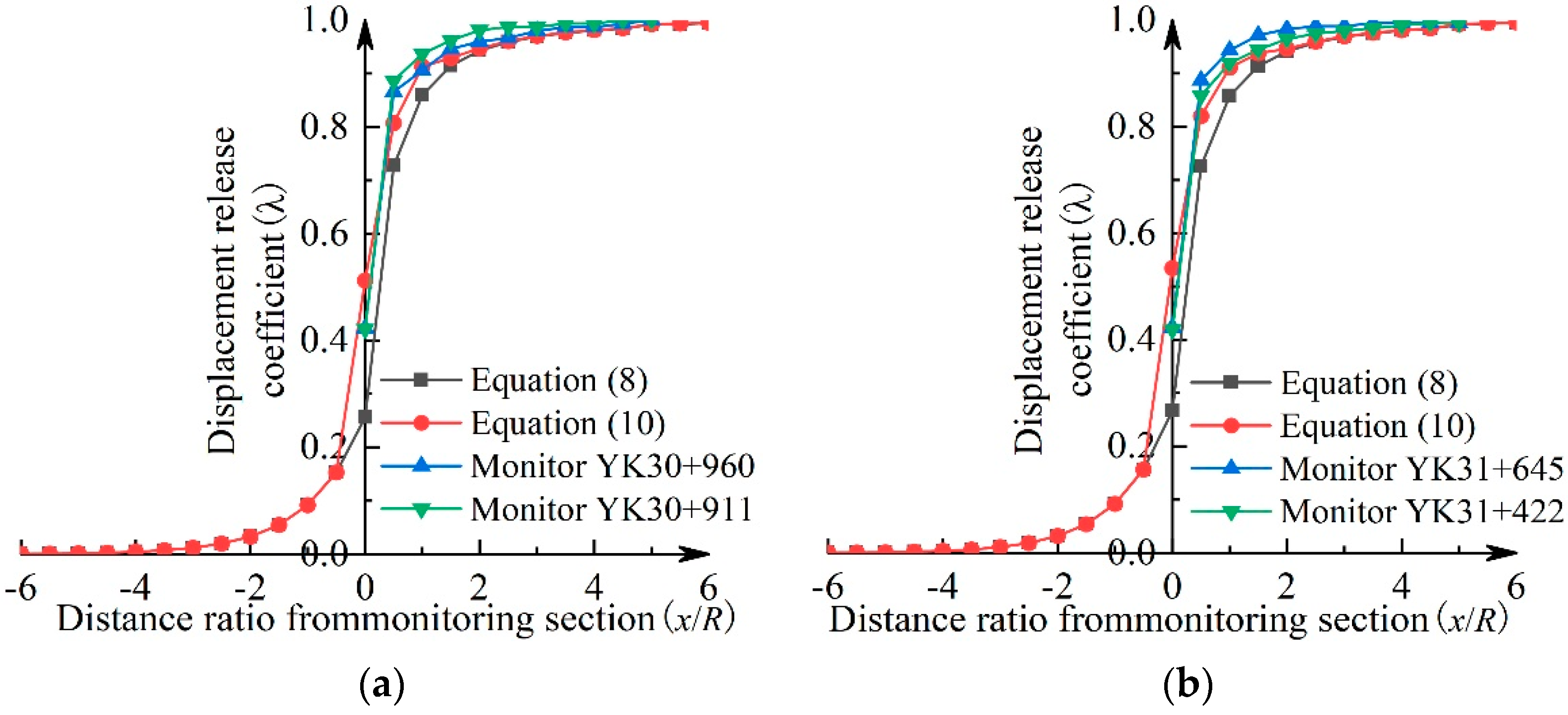

3.2. Data Comparison and Equation Optimization Analysis

3.2.1. Comparative Analysis of Practice and Theory

3.2.2. Equation Optimization and Improvement

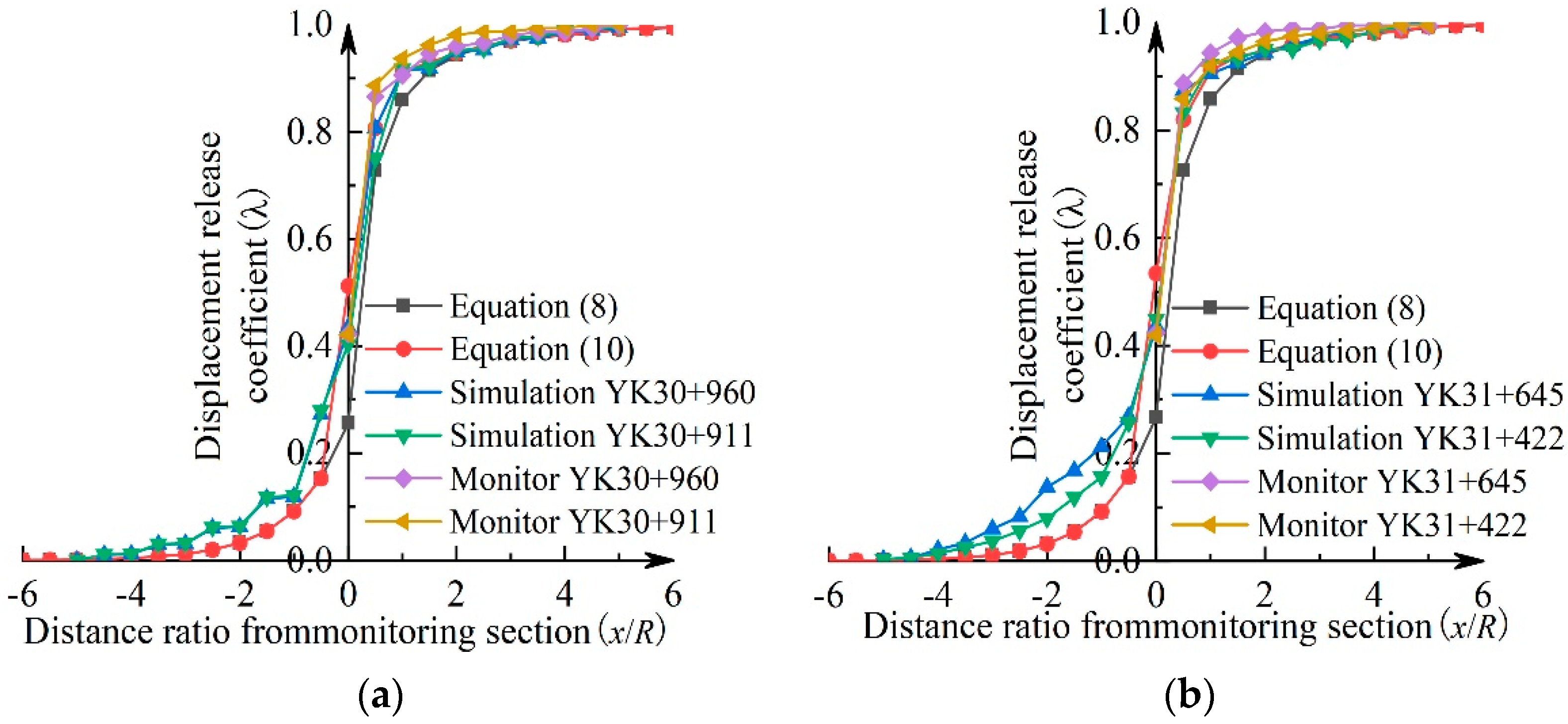

3.2.3. Analysis of Optimization Results of Theoretical Equation

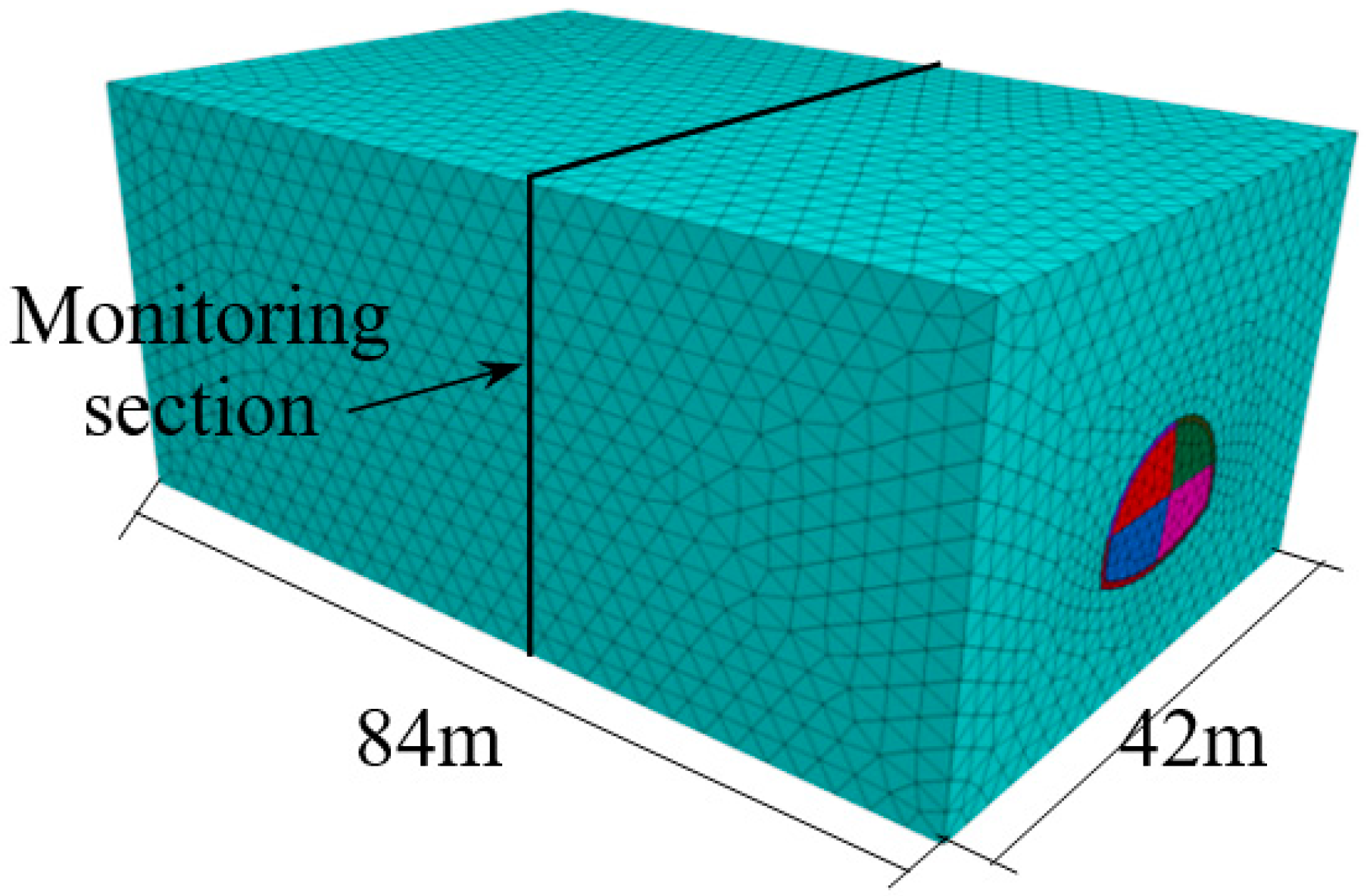

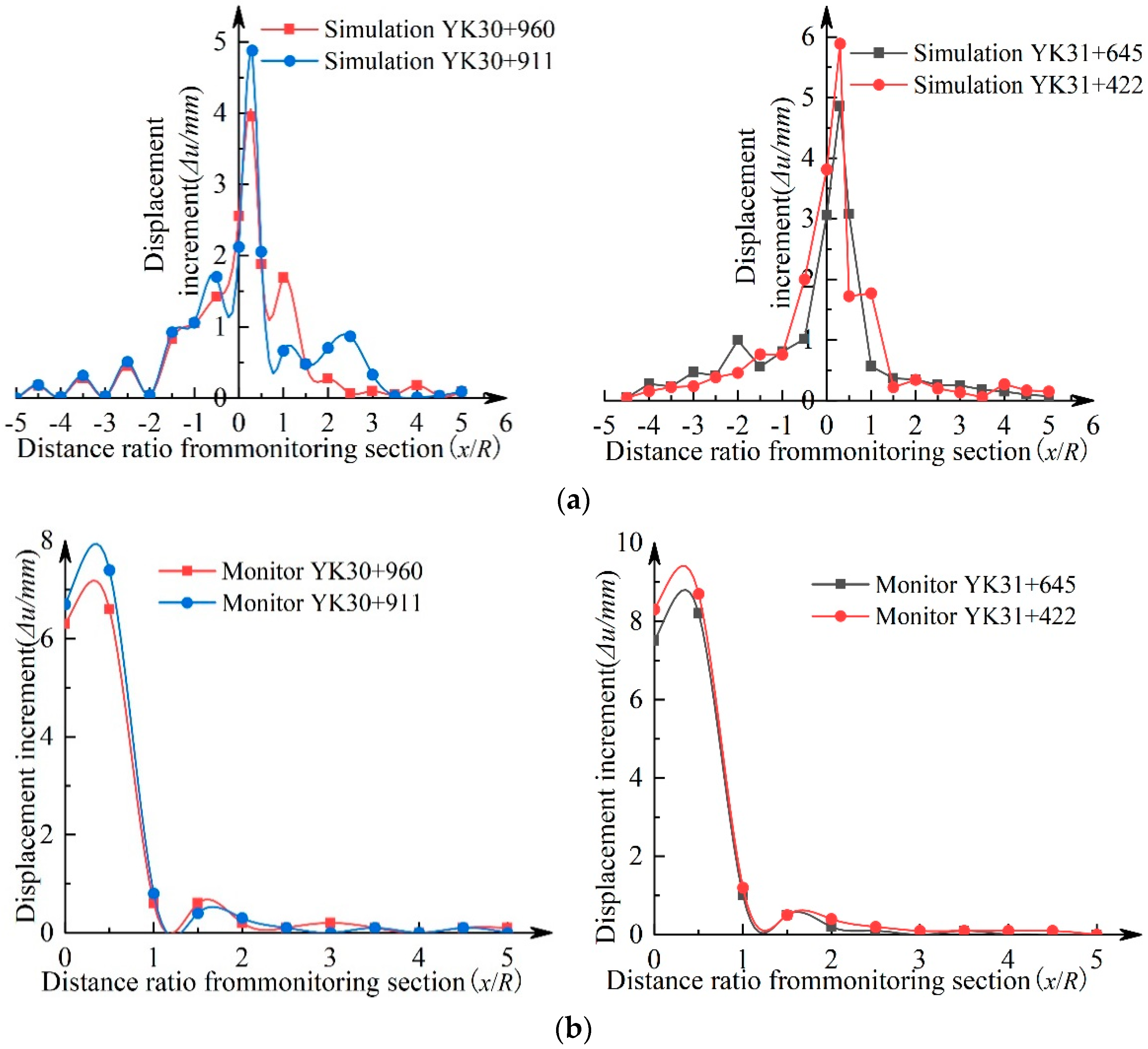

3.3. Numerical Simulation and Verification Analysis

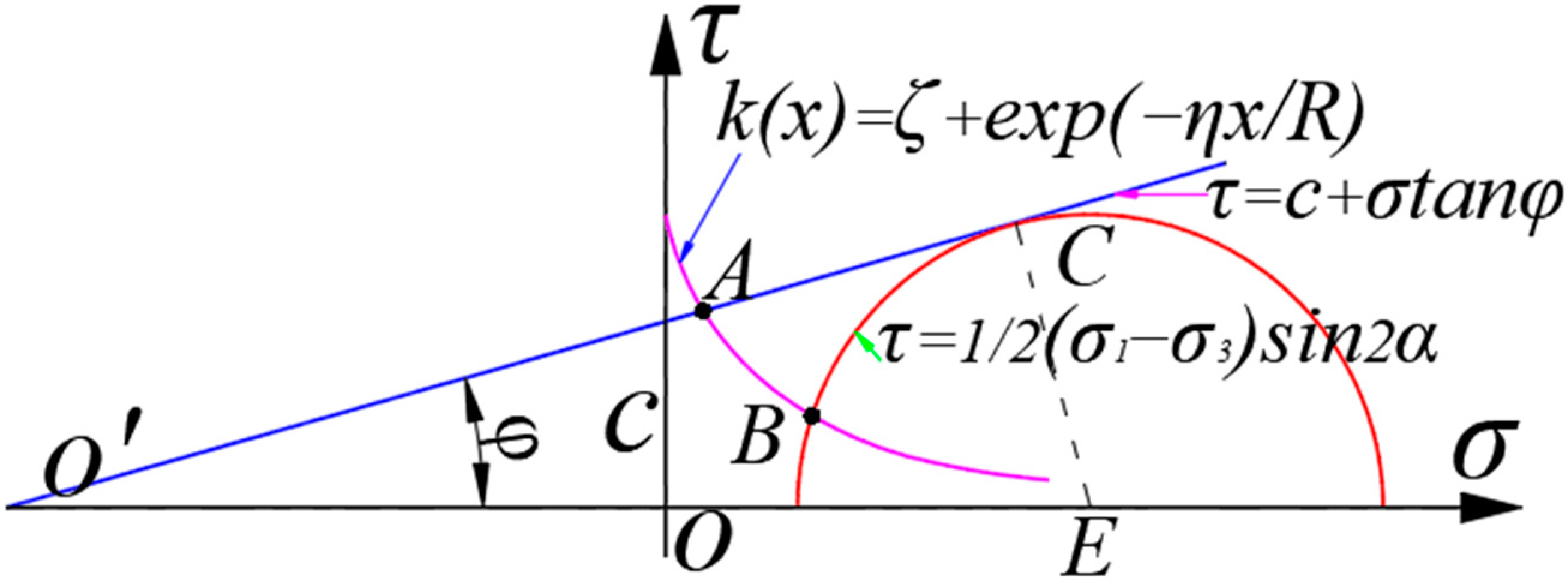

4. Prediction of Initial Expenditure Opportunity

4.1. Theoretical Analysis

4.2. Support Opportunity

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, H.; Liu, J.; Gao, M. Development and Utilization of Special Underground Space; Science Press: Beijing, China, 2018; p. 5. [Google Scholar]

- Oreste, P.P. Analysis of structural interaction in tunnels using the Convergence-Confinement approach. Tunn. Undergr. Space Technol. 2003, 18, 347–363. [Google Scholar] [CrossRef]

- Carranza-Torres, C.; Fairhurst, C. Application of the Convergence-Confinement Method of tunnel design to rock masses that satisfy the Hoek-Brown failure criterion. Tunn. Undergr. Space Technol. 2000, 15, 187–213. [Google Scholar] [CrossRef]

- Fang, Q.; Wang, G.; Yu, F.; Du, J. Analytical algorithm for LDP of a deep tunnel. J. Rock Mech. Geotech. Eng. 2021, 13, 845–854. [Google Scholar] [CrossRef]

- Liang, P.; Gao, Y.; Zhou, Y.; Deng, D. Determination method of reasonable support time for tunnel initial support and its engineering application. Chin. J. Eng. 2022, 44, 265–276. [Google Scholar]

- Tang, X. Analysis on reasonable support timing of deep buried tunnel considering strain softening and dilatancy effect of surrounding rock. Tunn. Construct. 2022, 3, 1–9. [Google Scholar]

- Tang, X. Theoretical Research and Application of Tunnel Convergence-Confinement Method. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2009. [Google Scholar]

- Wang, Y.; Ding, W.; Liu, Z.; Wang, Z.; Li, W. Study on large deformation classification standard and support opportunity of Mu zhai ling tunnel. Chin. J. Undergr. Space Eng. 2020, 16, 1116–1122. [Google Scholar]

- Zhou, J.; Hu, J.; Wang, H.; Yang, X. Mechanical study on reasonable support time of step-by-step support of deep tunnel. Eng. Mech. 2019, 36, 145–152. [Google Scholar]

- Su, K.; Zhang, Y.; Wu, H.; Zhou, L. Study on evolution characteristics of safety factor of surrounding rock and selection method of support time during tunnel excavation. Chin. J. Rock Mech. Eng. 2019, 38, 2964–2975. [Google Scholar]

- Su, K.; Cui, J.; Zhang, Z. Method for selecting the timing of initial support during tunnel construction. J. Cent. South Univ. 2015, 46, 3075–3082. [Google Scholar]

- Zhang, Y.; Su, K.; Zhou, L.; Wu, H. Research on the evolution law of tunnel longitudinal deformation and estimation of support timing based on CCM. Rock Soil Mech. 2017, 38, 471–478. [Google Scholar]

- Unlu, T.; Gercek, H. Effect of Poisson’s ratio on the normalized radial displacements occurring around the face of a circular tunnel. Tunn. Undergr. Space Technol. 2003, 18, 547–553. [Google Scholar] [CrossRef]

- Zhou, S. Determination of Displacement Release Coefficient of Surrounding Rock Considering Spatial Effect. Ph.D. Thesis, Chongqing Univercity, Chongqing, China, 2014. [Google Scholar]

- Wu, Y.; Du, W.; Zhang, G.; Song, Y. The Longitudinal Deformation Profile of a Rock Tunnel: An Elastic Analysis. Math. Probl. Eng. 2021, 2021, 6684035. [Google Scholar]

- Panet, M. Le Calcul des Tunnels par la Méthode Convergence-Confinement; Press I’ecole Natinale des Ponts Chaussees: Paris, France, 1995. [Google Scholar]

- Corbetta, F.; Bernaud, D.; Nguyen Minh, D.N. Contribution à la méthode Convergence-Confinement par le principe de la similitude. Rev. Française Geotech. 1991, 54, 5–11. (In French) [Google Scholar] [CrossRef] [Green Version]

- Vlachopoulos, N.; Diederichs, M.S. Improved Longitudinal Displacement Profiles for Convergence-Confinement Analysis of Deep Tunnels. Rock Mech. Rock Eng. 2009, 42, 131–146. [Google Scholar] [CrossRef]

- Lee, Y.L. Prise en Compte des Non-Linéarités Decomportement des Sols et Roches Dans la Modélisation du Creusement d’un Tunnel; Ecole Nationale des Ponts et Chaussées: Paris, France, 1994. (In French) [Google Scholar]

- Hoek, E.; Brown, E.T. Practical estimates of rock mass strength. Int. J. Rock Mech. Min. 1997, 34, 1165–1186. [Google Scholar] [CrossRef]

- Huang, B.; Du, Y.; Zeng, Y.; Cao, B.; Zou, Y.; Yu, Q. Study on Stress Field Distribution during the Construction of a Group of Tunnels Using the Pile–Beam–Arch Method. Buildings 2022, 12, 300. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, J.; Cai, L.; Lv, W. Study on the timing of secondary lining support of large section tunnel in soft rock. Chin. J. Saf. Sci. Technol. 2018, 14, 116–121. [Google Scholar]

| Rock Grade | Mechanical Parameters | |||||

|---|---|---|---|---|---|---|

| Density (kg/m3) | Young’s Modulus E (Gpa) | Poisson’s Ratio | Internal Friction Angle (0) | Cohesion (Mpa) | Tensile Strength (Mpa) | |

| Ⅲ | 2300 | 6 | 0.3 | 30 | 0.3 | 0.3 |

| Ⅳ | 2000 | 2 | 0.35 | 25 | 0.2 | 0.2 |

| Support | 2400 | 21 | 0.2 | |||

| Fitting Parameters | Ⅲ | IV | ||

|---|---|---|---|---|

| YK30+960 | YK30+911 | YK31+645 | YK31+422 | |

| RMSE | 0.0678 | 0.0706 | 0.0708 | 0.0601 |

| SSE | 0.0456 | 0.0647 | 0.0653 | 0.0470 |

| R-square | 0.7920 | 0.7920 | 0.7794 | 0.8415 |

| Fitting Parameters | Ⅲ | IV | ||

|---|---|---|---|---|

| YK30+960 | YK30+911 | YK31+645 | YK31+422 | |

| RMSE | 0.0310 | 0.0322 | 0.0375 | 0.0361 |

| SSE | 0.0122 | 0.0134 | 0.0183 | 0.0170 |

| R-square | 0.9650 | 0.9549 | 0.9386 | 0.9428 |

| Fitting Parameters | Ⅲ | IV | ||

|---|---|---|---|---|

| YK30+960 | YK30+911 | YK31+645 | YK31+422 | |

| Equation (8) R-square | 0.8439 | 0.876 | 0.7824 | 0.7871 |

| Equation (10) R-square | 0.9383 | 0.9302 | 0.9718 | 0.9597 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Zha, W.; Liu, Z.; Liu, X. Research on the Prediction of the Time of Initial Support of Soft Rock Tunnel Based on the Optimized Longitudinal Deformation Profile. Appl. Sci. 2022, 12, 7221. https://doi.org/10.3390/app12147221

Liang Y, Zha W, Liu Z, Liu X. Research on the Prediction of the Time of Initial Support of Soft Rock Tunnel Based on the Optimized Longitudinal Deformation Profile. Applied Sciences. 2022; 12(14):7221. https://doi.org/10.3390/app12147221

Chicago/Turabian StyleLiang, Yiwen, Wenhua Zha, Zaobao Liu, and Xiaohu Liu. 2022. "Research on the Prediction of the Time of Initial Support of Soft Rock Tunnel Based on the Optimized Longitudinal Deformation Profile" Applied Sciences 12, no. 14: 7221. https://doi.org/10.3390/app12147221

APA StyleLiang, Y., Zha, W., Liu, Z., & Liu, X. (2022). Research on the Prediction of the Time of Initial Support of Soft Rock Tunnel Based on the Optimized Longitudinal Deformation Profile. Applied Sciences, 12(14), 7221. https://doi.org/10.3390/app12147221