3.1.2. Dynamic Compression

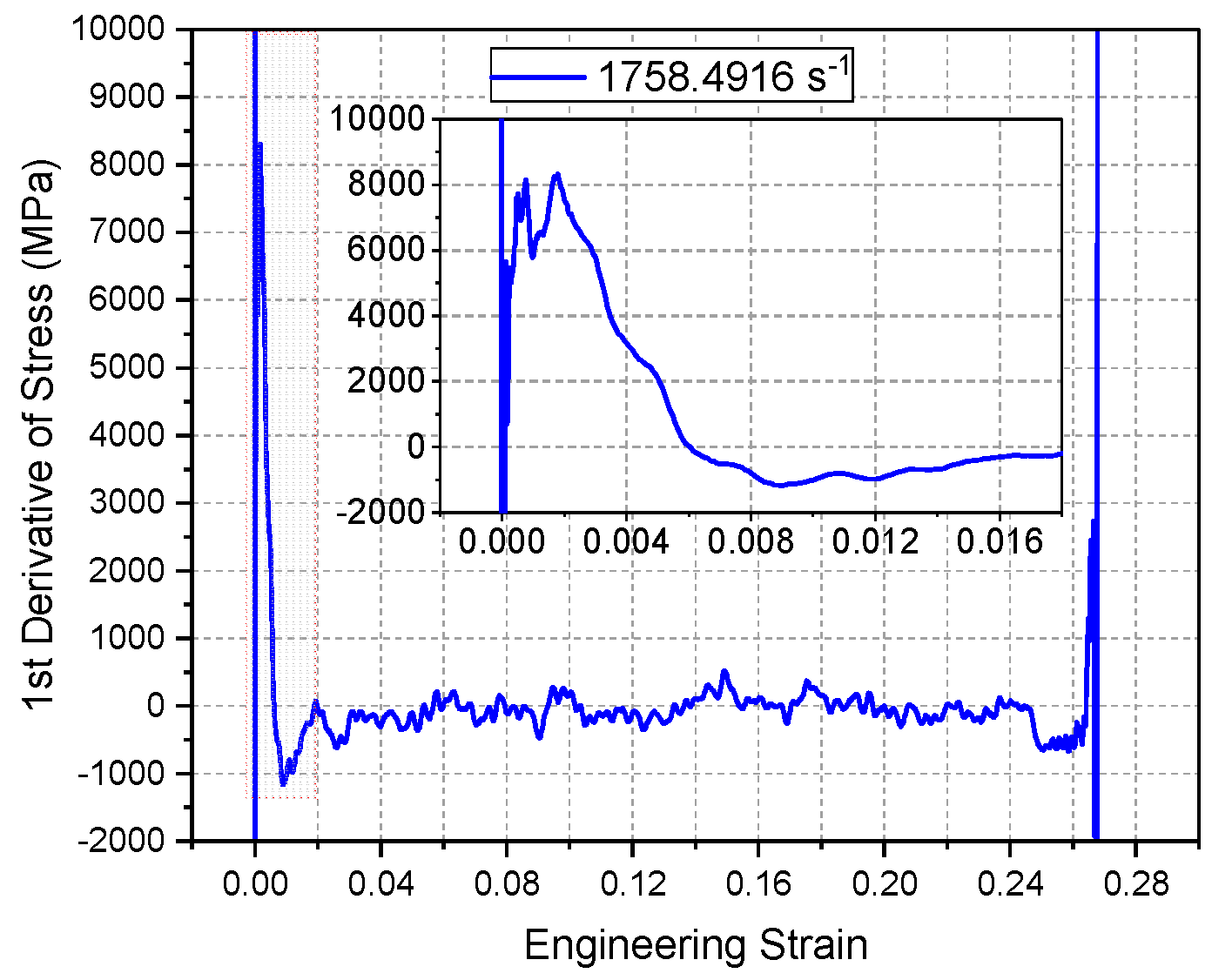

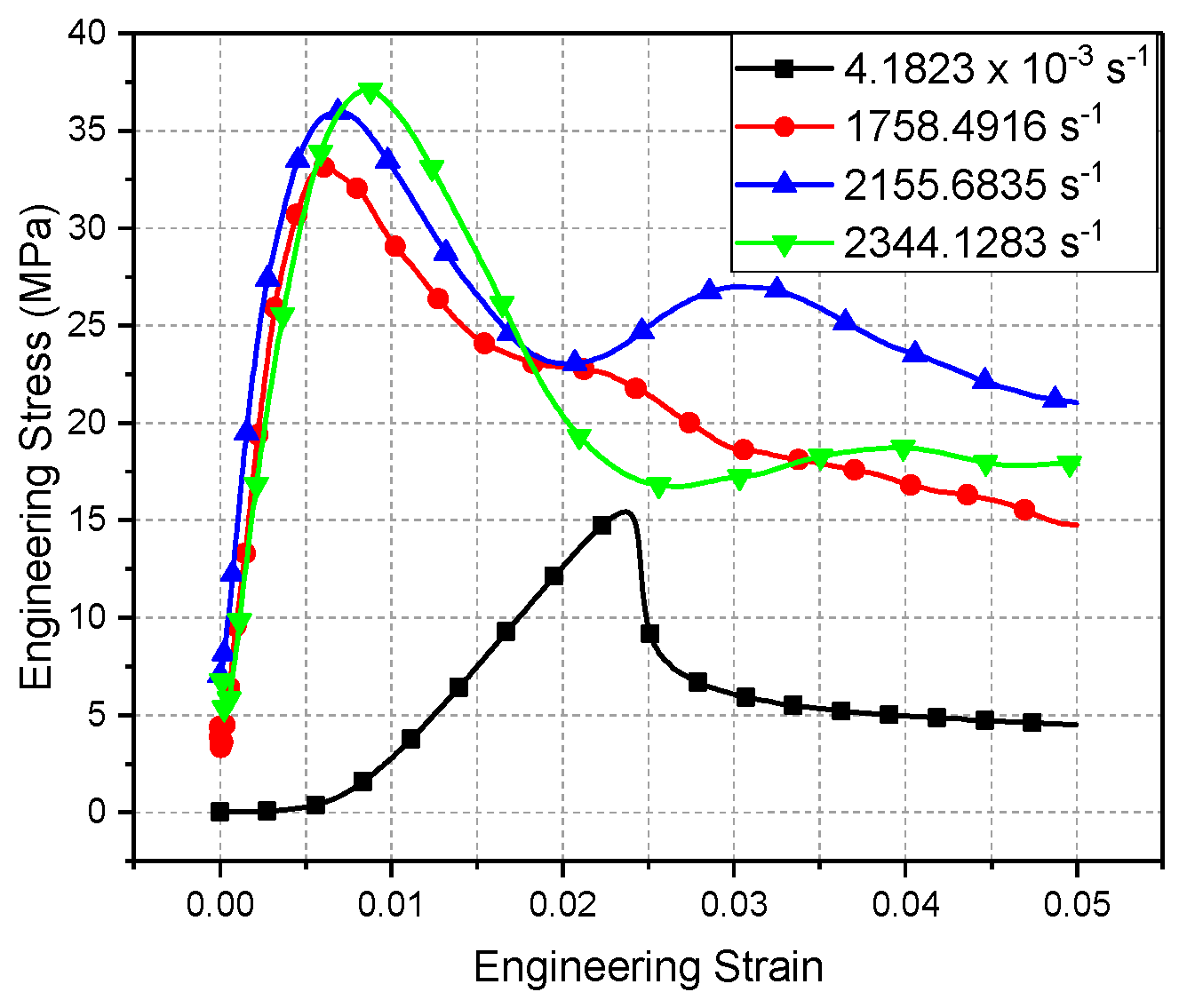

(a) Mechanical Behavior

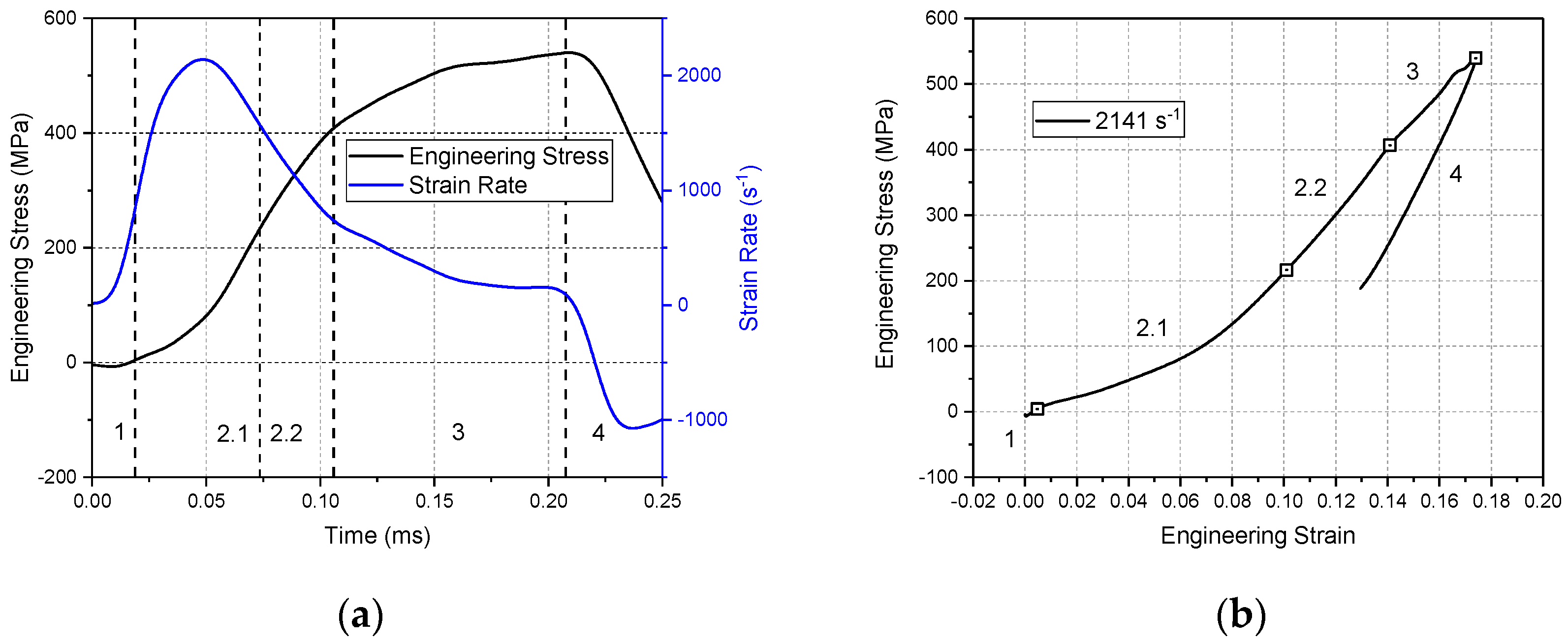

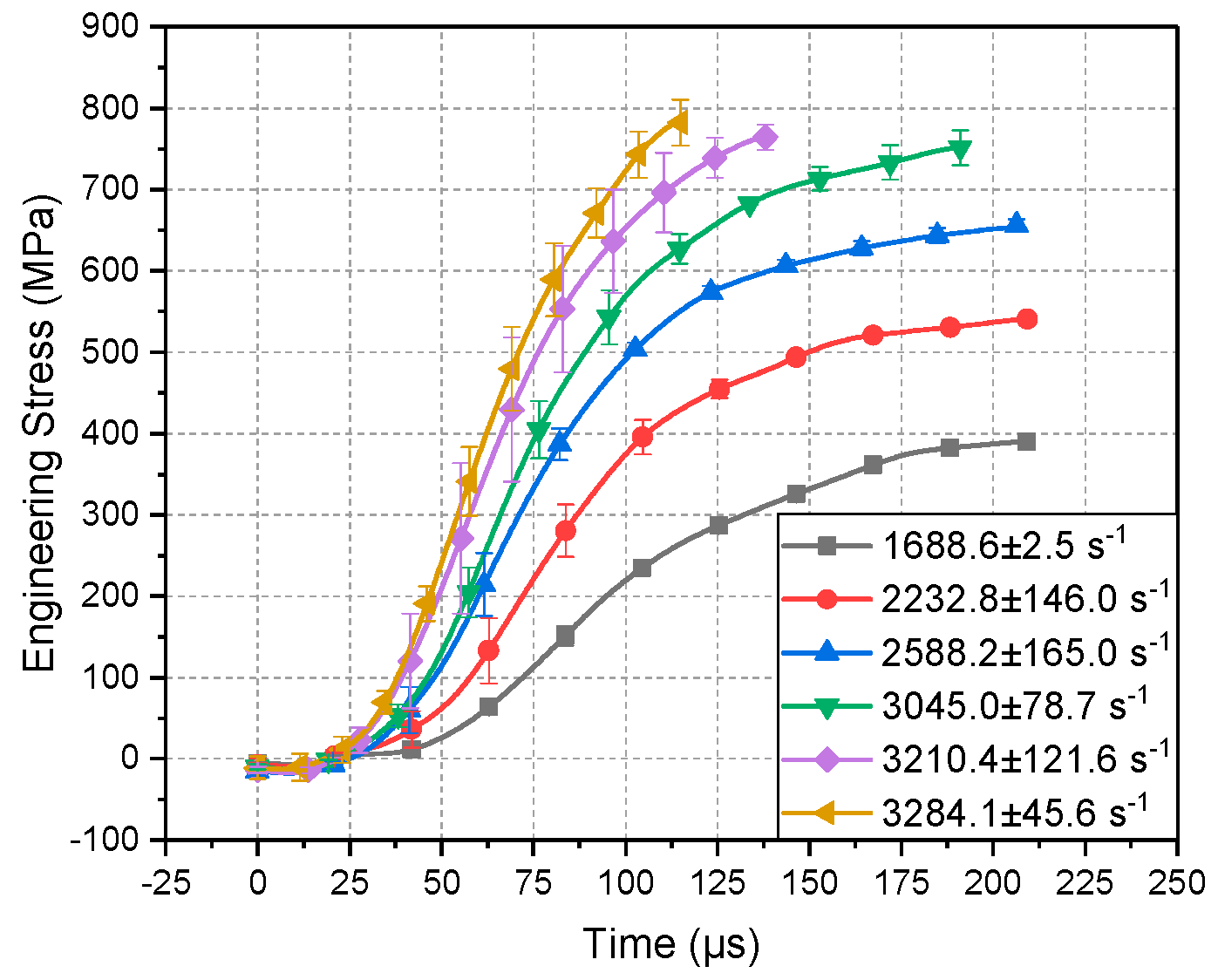

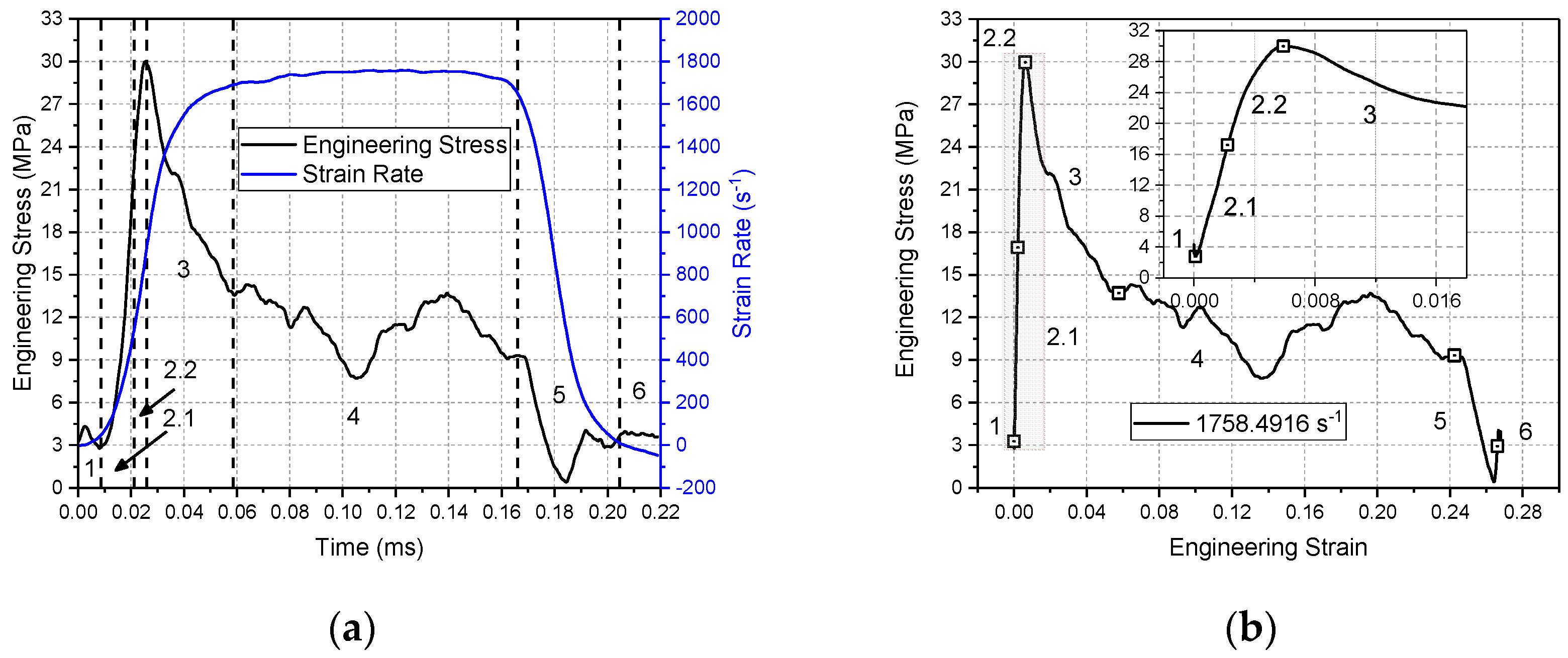

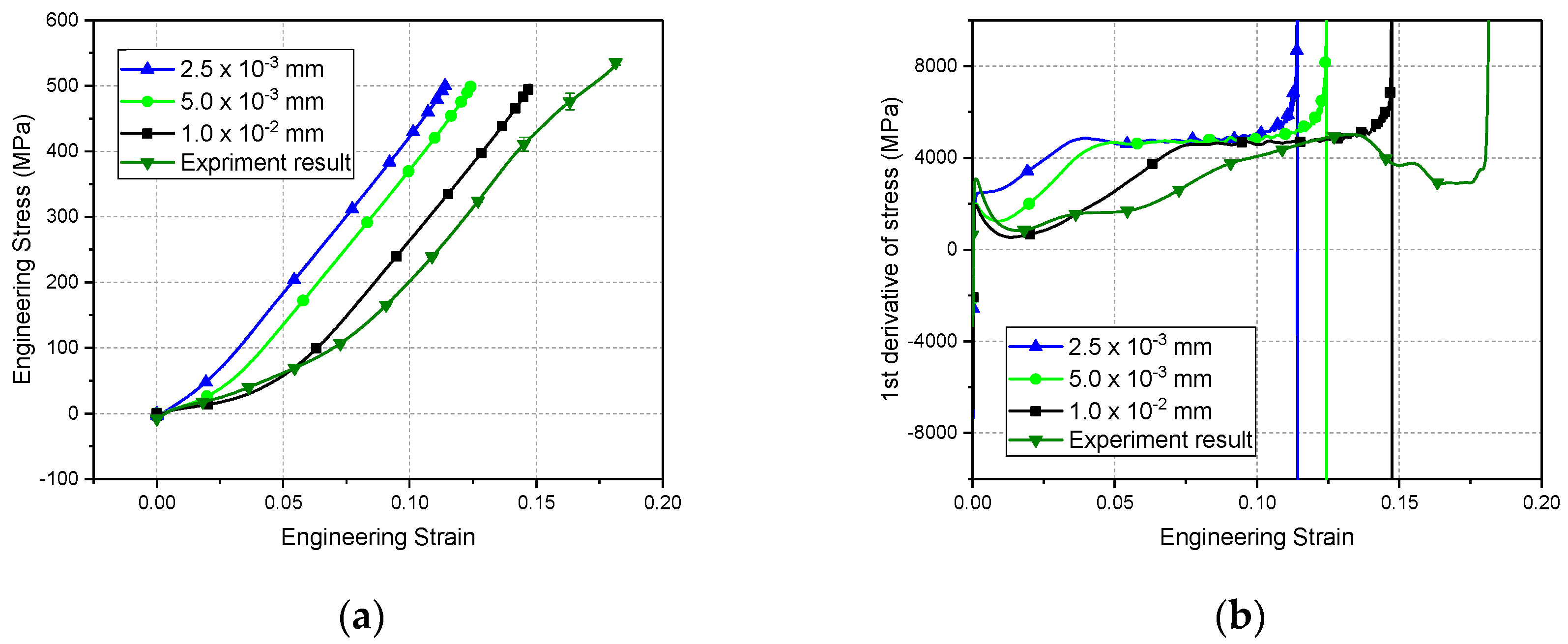

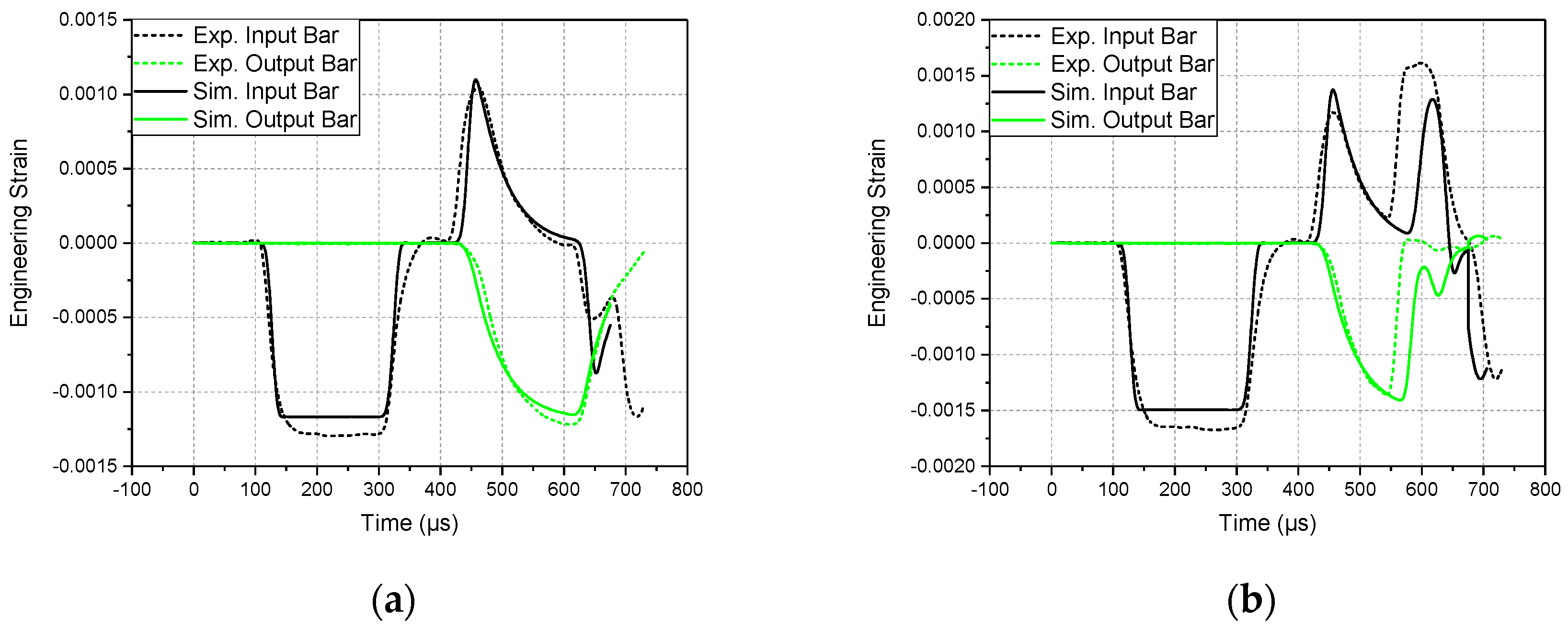

For the non-damaged tests of the Φ9 × 4 specimen under 0.4 MPa, shown in

Figure 7, the stress–strain curve could be divided into four zones [

17].

Zone 1: This period is called the self-installation zone. The strain rate increased rapidly, but the stress fluctuated around 0. This is because the parallelism of the specimen faces in contact with the bars was not 100% guaranteed.

Zone 2: This period is called the under-loading zone. Once the perfect contact was ensured, the strain rate began to drop. As the strain rate increased, the stress increased as well. However, the stress–strain relationship showed two different periods in this zone. During the 2.1 period, the stress–strain curve was not linear, possibly due to the pores among the specimen being compressed. During the 2.2 period, the stress–strain curve was linear and stable, due to the material being more uniform with the specimen yet to be damaged.

Zone 3: This period is called the soften zone. The strain rate tended to zero and the stress tended to an average value. The stress reached the maximum value when the strain rate reached zero. As shown in

Figure 7b, the material behavior showed a softening phenomenon.

Zone 4: This period is called the spring-back zone. The strain rate changed sign, and the stress started to decrease. The specimen began to relax and then recovered. This shows that, even though several fibers were squeezed out, the main body of the specimen suffered no serious damage. Therefore, the specimen still had the ability to spring back.

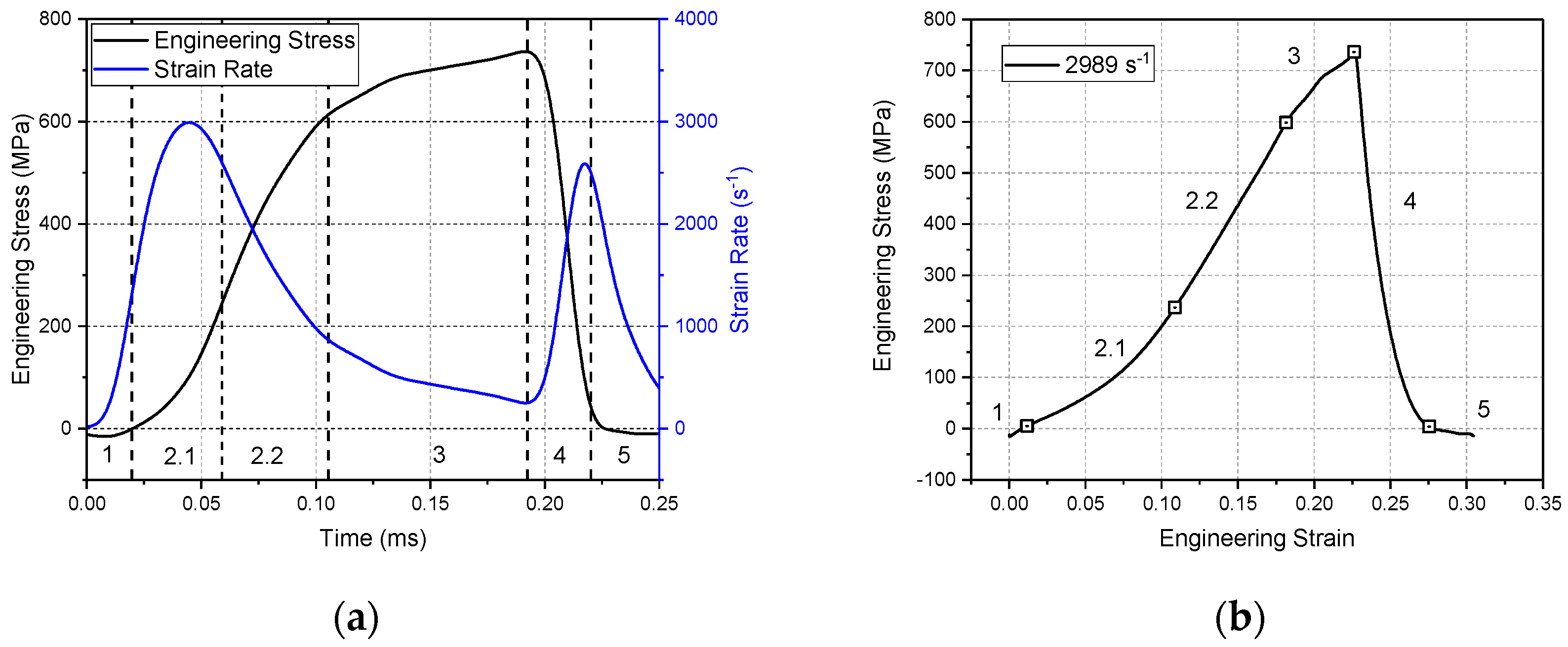

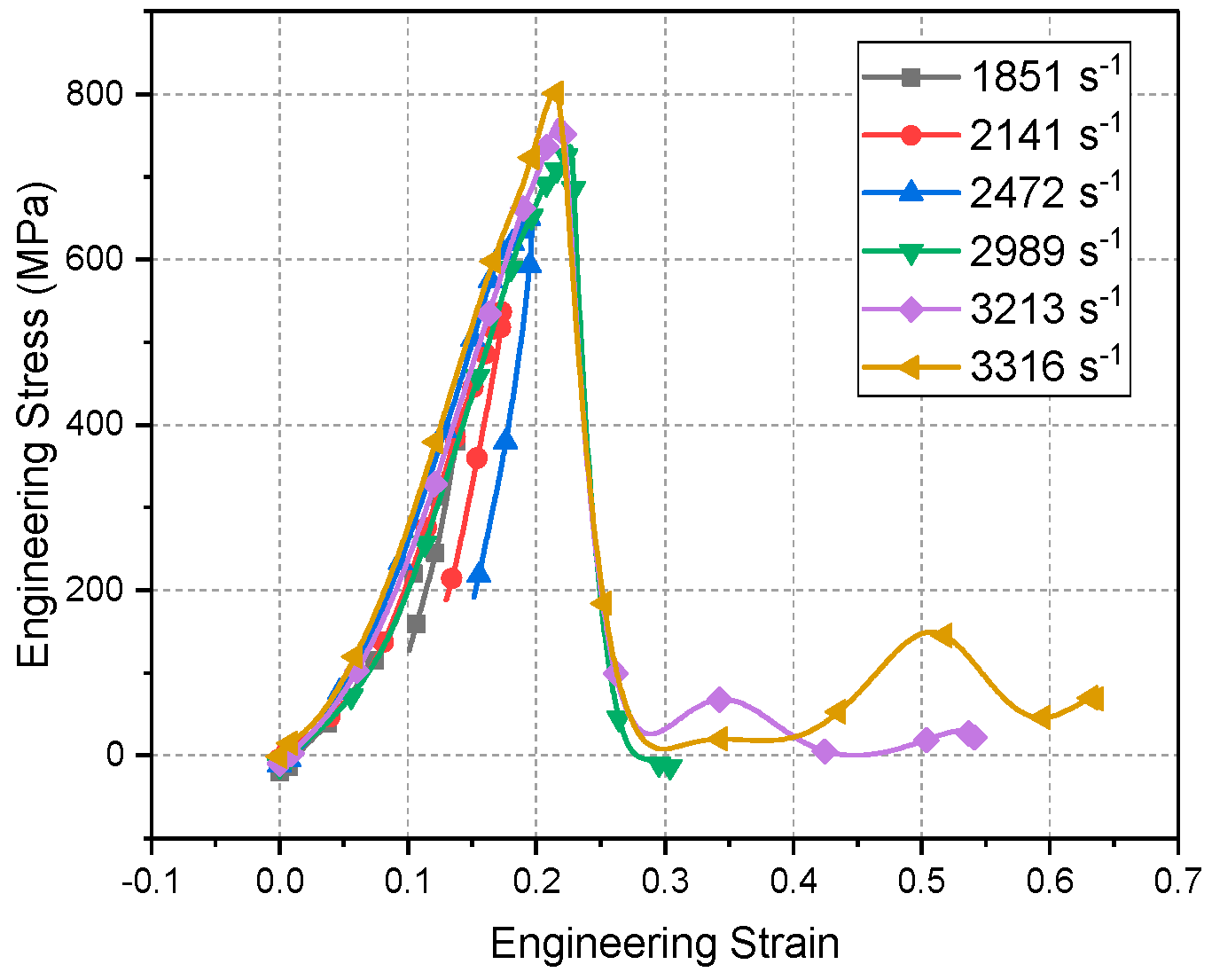

For the damaged tests of the Φ9 × 4 specimen under 0.8 MPa, shown in

Figure 8, the stress–strain curve could be divided into five zones [

17].

Zone 1 and Zone 2 were the same as those for the non-damaged tests.

Zone 3: This period is called the soften zone. As shown in

Figure 8b, there was serious fluctuation in the stress curve. This was possibly because the microscopic damage under higher strain rate was more serious than that under lower strain rate.

Zone 4: This period is called the fracture zone. The accumulation of microscopic damage resulted in the appearance of a macroscopic defect. The fracture of the material generated a rapid fall in the stress with a rapid increase in the strain rate. The presence of a second peak characterized the onset of macroscopic damage [

48]

Zone 5: This period is called the compact zone. The damaged specimen became more compact; the rest of the specimen could hold the loading temporarily, which caused a sharp drop in the strain rate. It is obvious that the spring-back behavior disappeared.

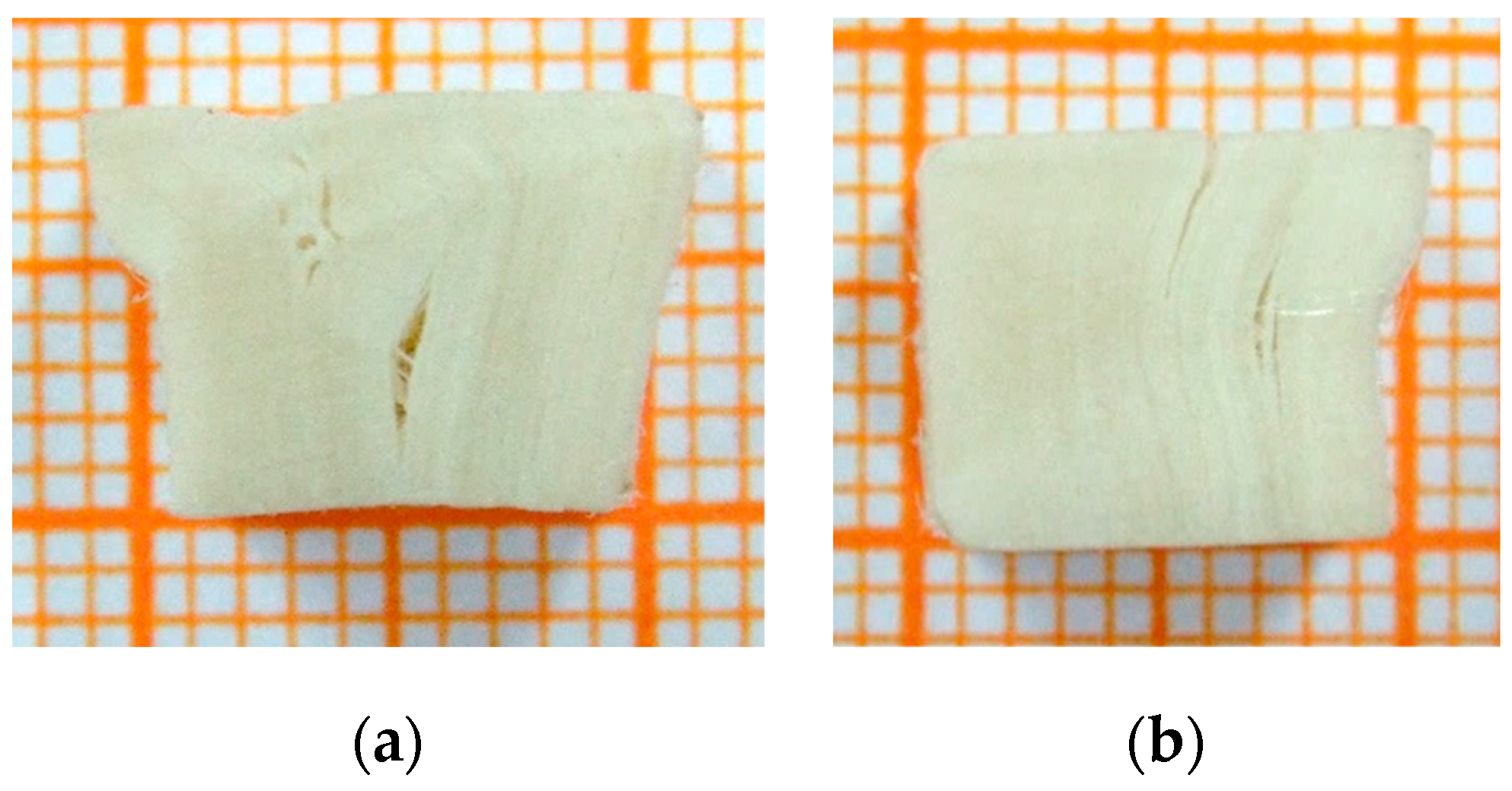

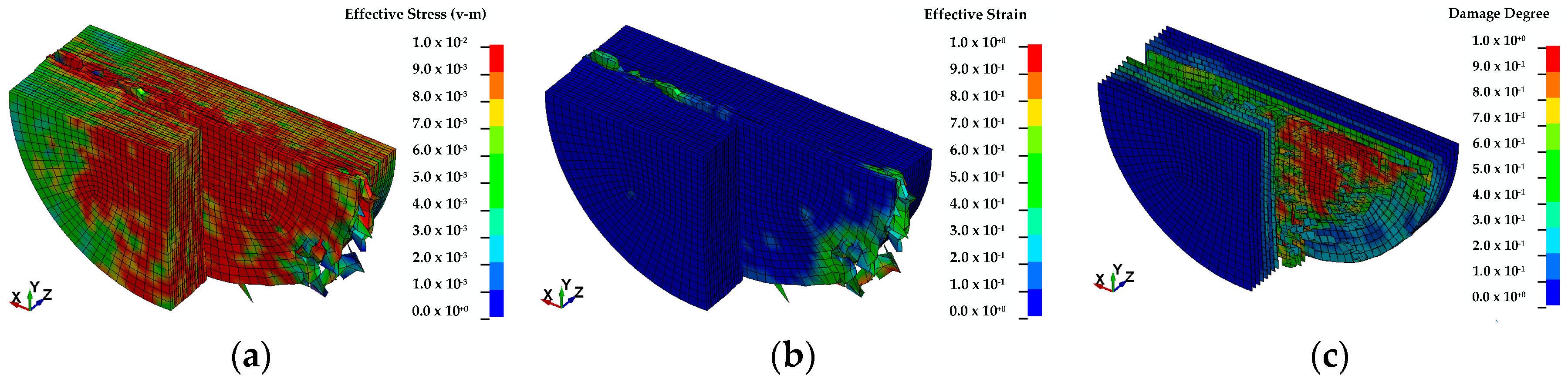

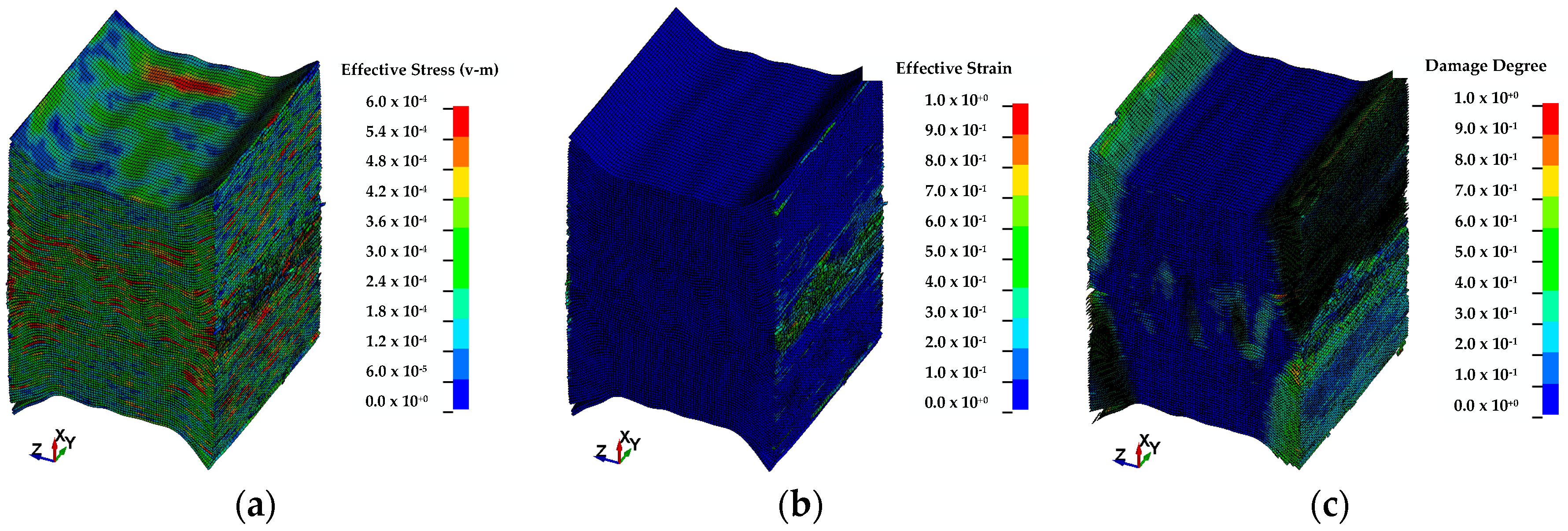

(b) Damage Kinetics

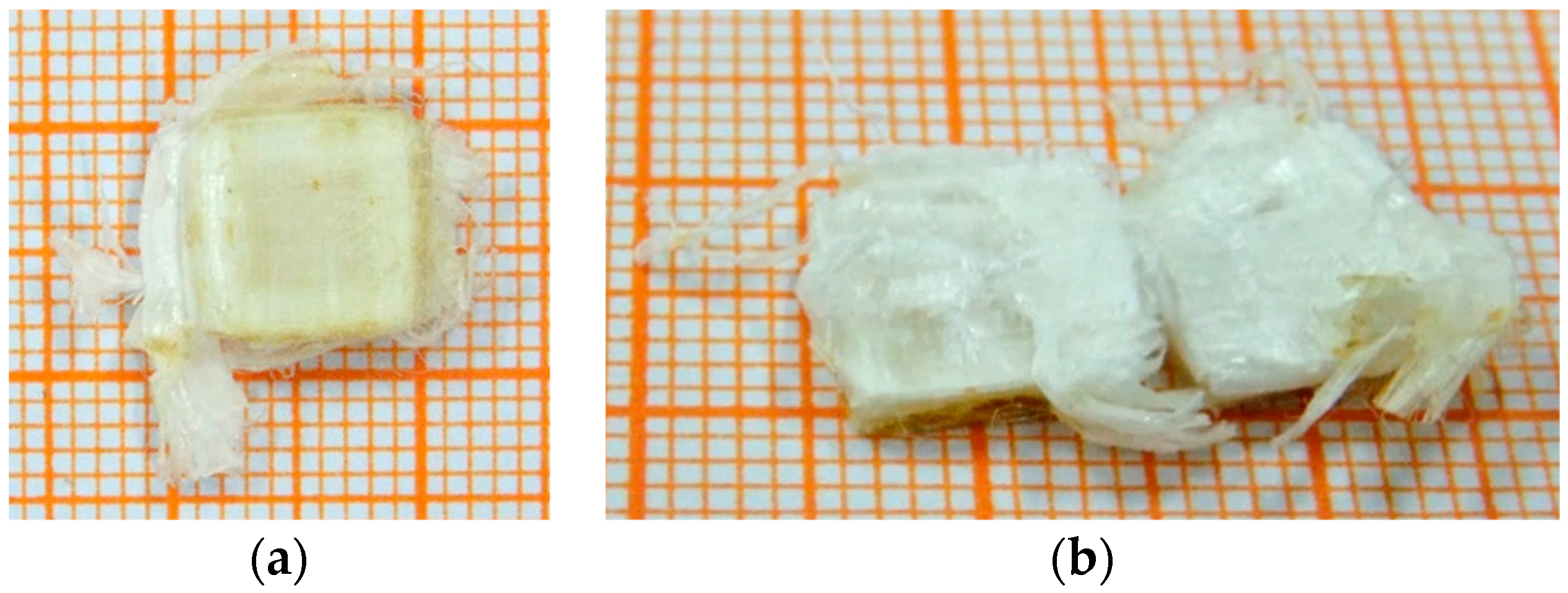

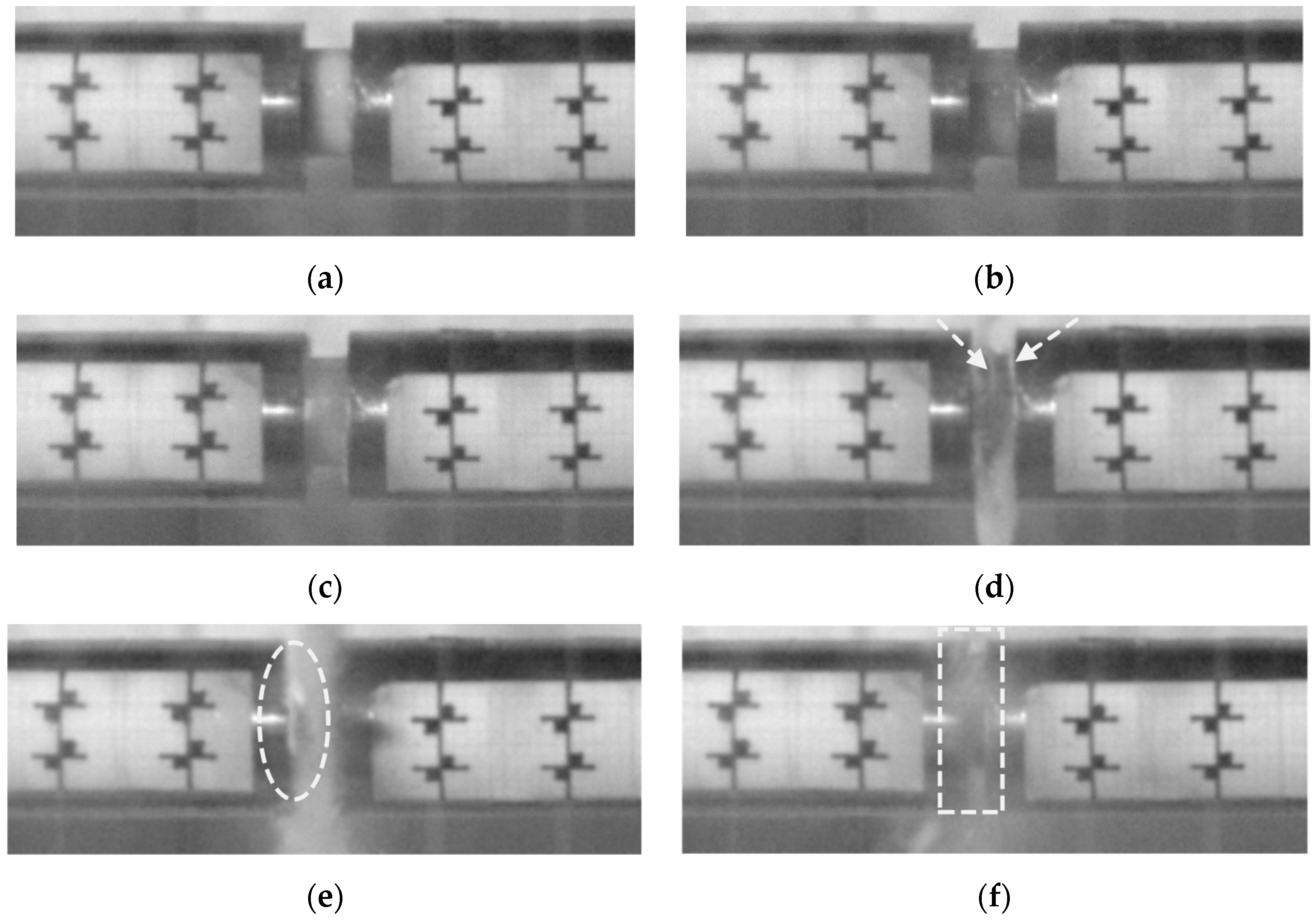

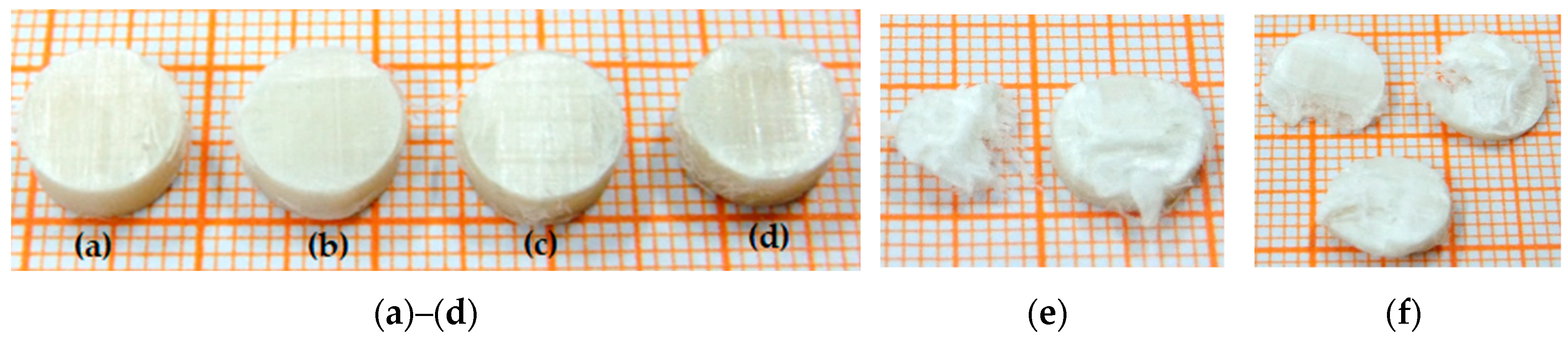

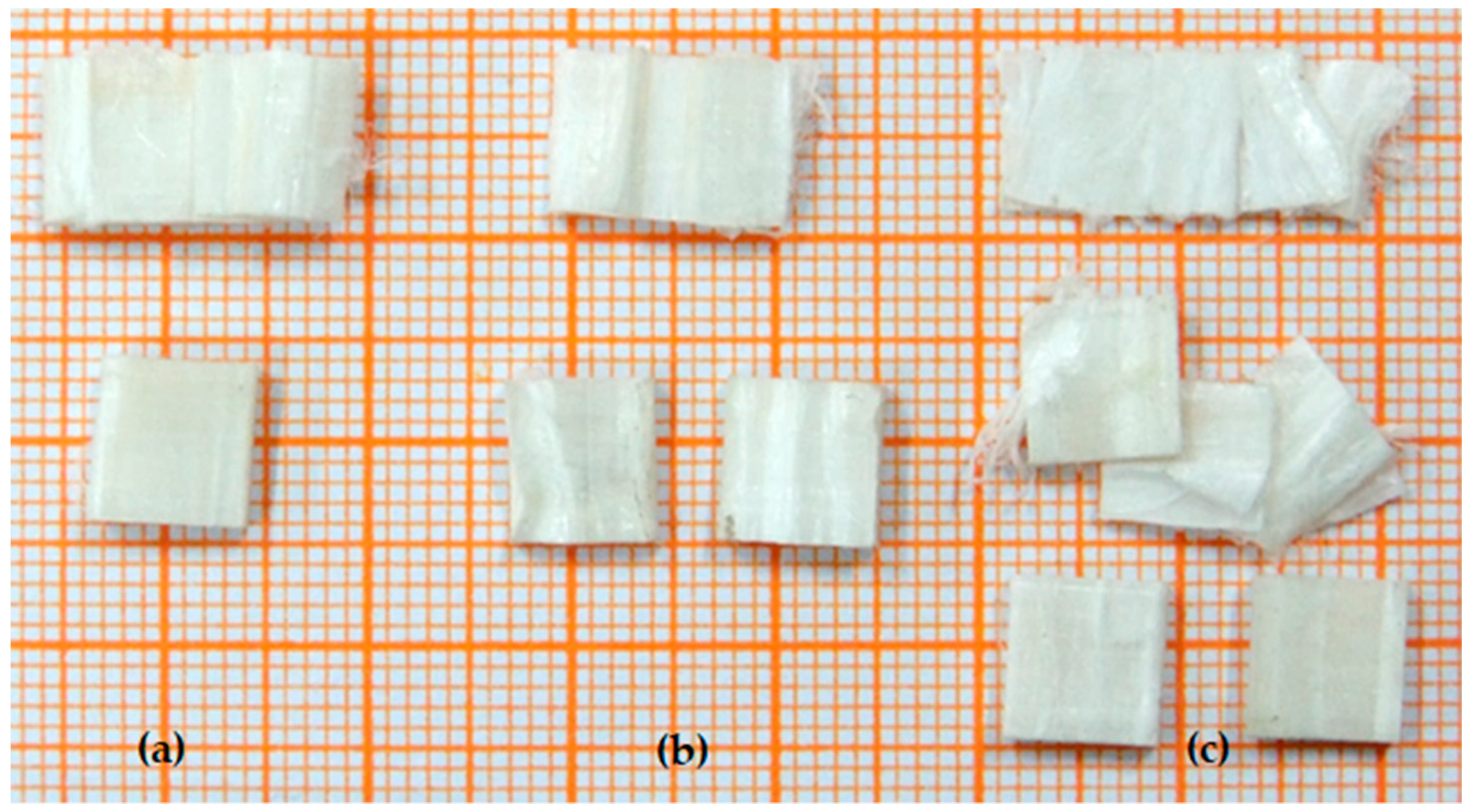

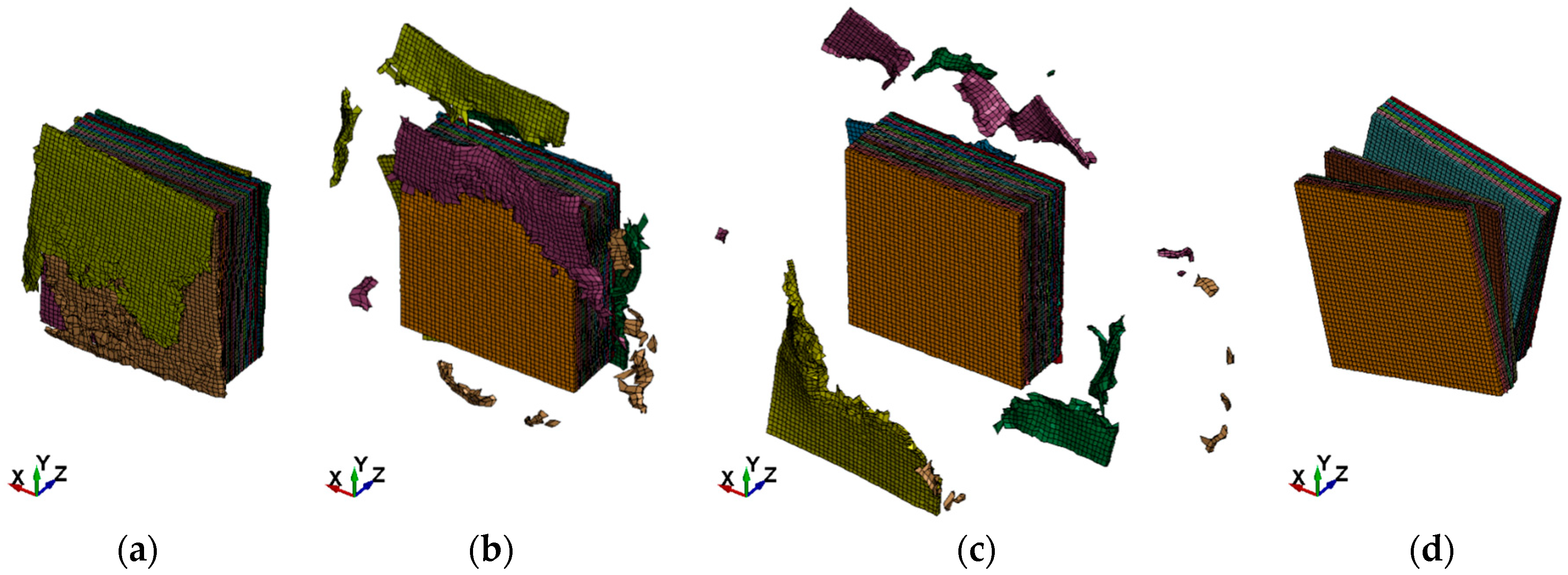

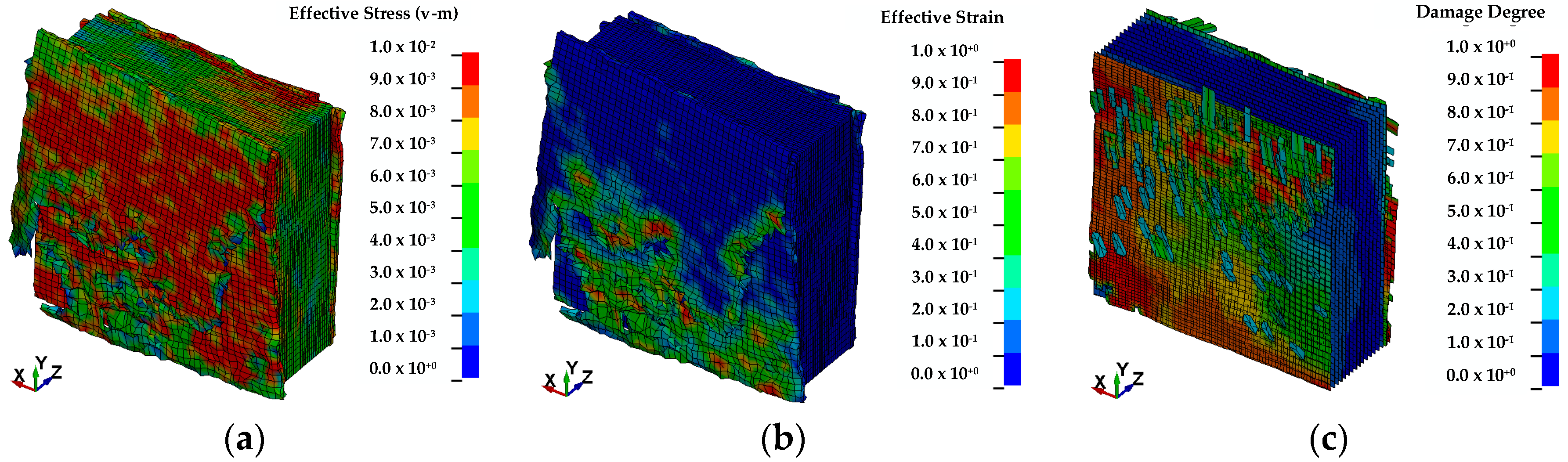

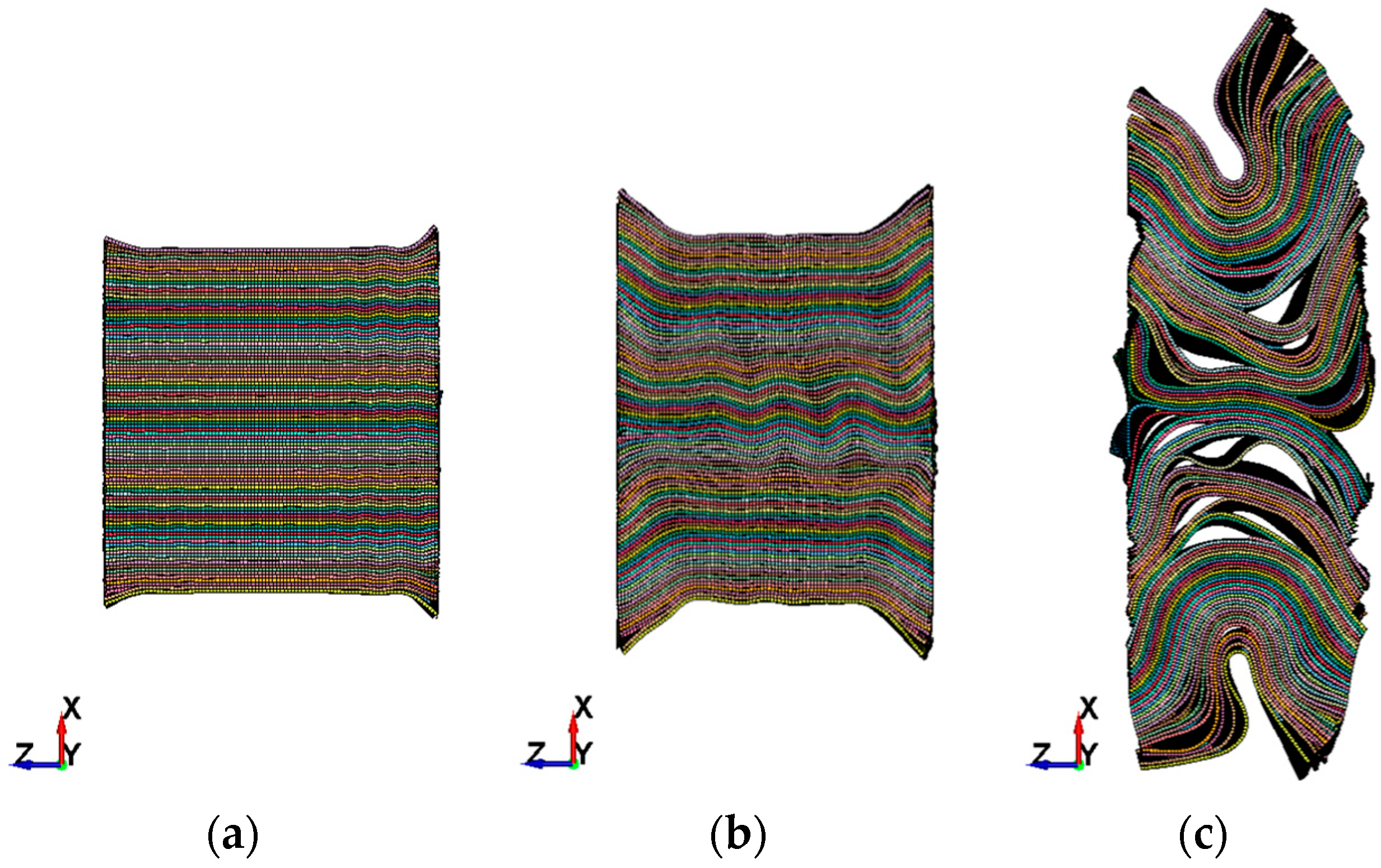

The high-speed camera records show that some fibers were squeezed out from the sides during the loading before the specimen was damaged completely, which can be seen in

Figure 9. This is because the specimens were made of 0°/90° layers, and there were no woven fibers to limit the outward movement. In addition, the friction coefficient of UHMWPE is very low [

10], while the strength of UHMWPE is higher than that of the resin matrix. Thus, the fibers near the side tended to be squeezed out.

As shown in

Figure 9 for the damaged test of the Φ9 × 4 specimen under 1.2 MPa, some features were apparent. A comparison with

Figure 9a–c shows that the specimen became brighter. This was potentially because the space in the specimen was squeezed out and, thus, the specimen became compact. During this period, the input bar moved quickly toward the output bar until around 56.16 μs. Then, the relative speed of the input bar and the output bar became lower; this state was maintained for a while until around 126.88 μs. During this period, small amounts of fibers were squeezed out of the specimen, as indicated by the arrow in

Figure 9d. At 126.88 μs, a large amount of fiber was squeezed out, as indicated in the circle of

Figure 9e. From this moment on, the input bar again moved quickly toward the output bar. This was potentially because, along with large amount of fiber being squeezed out, the specimen began to fail and could not maintain the loading between bars anymore. These large chunks of fibers being squeezed out could also be seen in other records of the damaged tests. During this period, large chunks of fibers were squeezed out constantly along with the moving input bar. Finally, when the input bar stopped moving, only a small portion of the specimen remained between the two bars, as shown in

Figure 9f. Correspondingly, the specimen was damaged completely and there was certainly no spring-back.

As shown in previous SEM micrographs of a specimen near a transmission bar [

22], severe damage was observed in the form of matrix fracture, resulting in delamination of a few layers near the edge and complete exposure of a large number of fiber bundles with negligible matrix bonding. The extent of damage was found to increase with the increase in specimen strain rates. At higher strain rate impact, the specimen exhibited breakage of the fiber–matrix interfacial bond via the occurrence of various failure mechanisms such as fiber breakage, fiber–matrix debonding, matrix cracking, delamination, and exposure of broken fibers due to separation from the reinforcing matrix material. The squeezed fiber bundles, breakage, and delamination can also be seen in

Figure 9. These detailed fracture features could be helpful for establishing a relevant damage model.

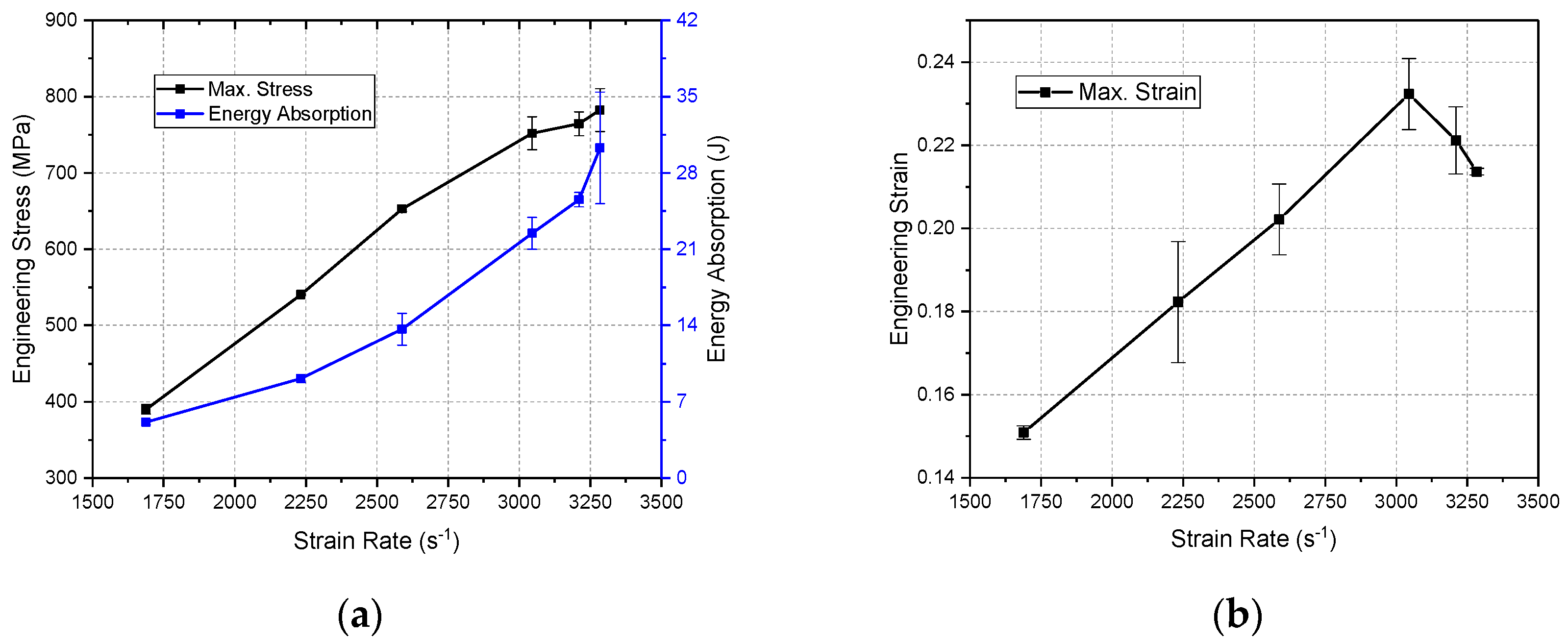

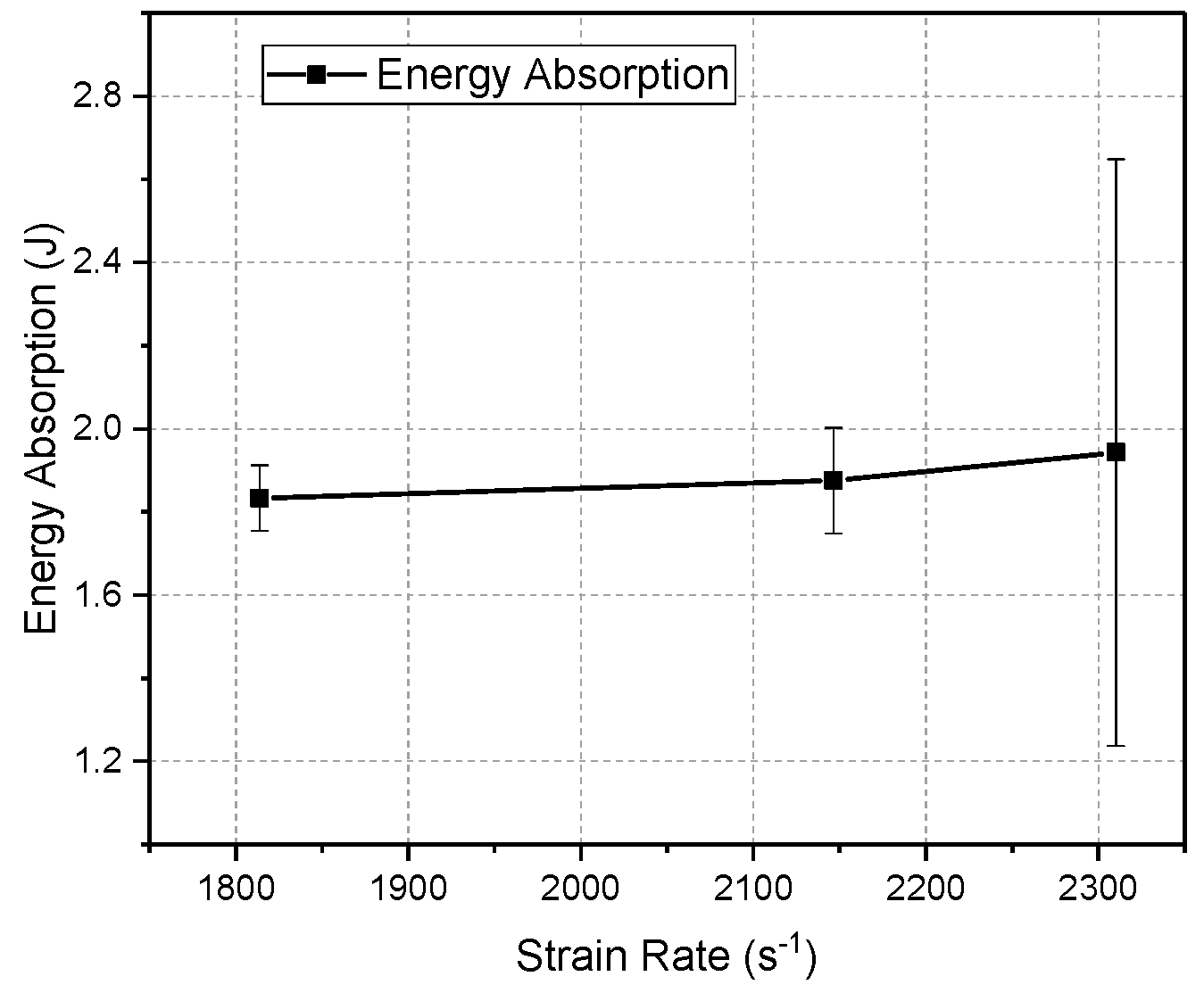

As shown in

Figure 10, the maximum stress of the Φ9 × 4 specimens under different impact pressures increased with the increasing strain rate. If the specimen was not damaged completely, the maximum stress points usually happened around a certain time. If the specimen was damaged completely, the maximum stress points occurred earlier and earlier. Correspondingly, each zone in the damaged tests happened earlier and earlier under higher and higher strain rate.

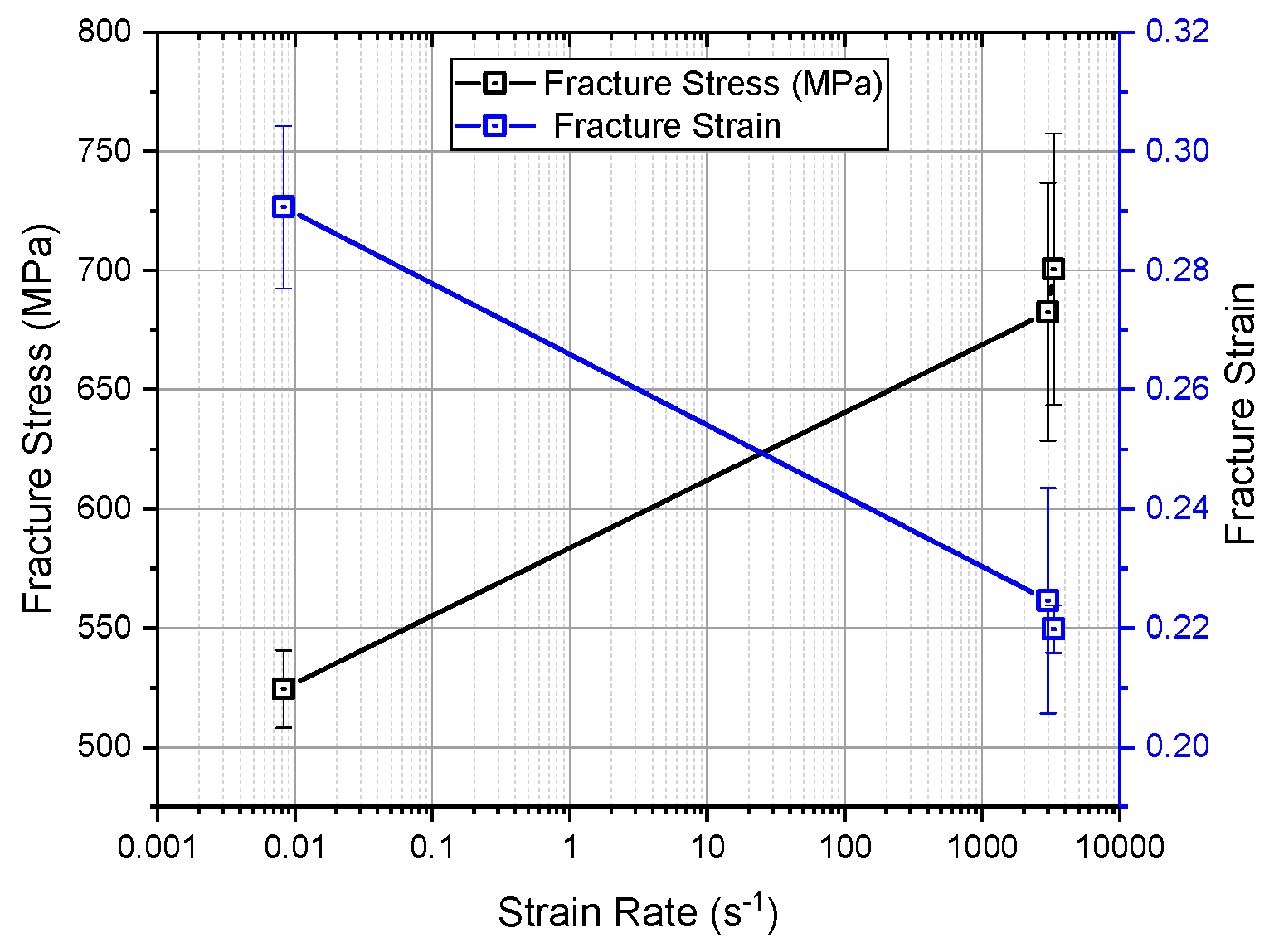

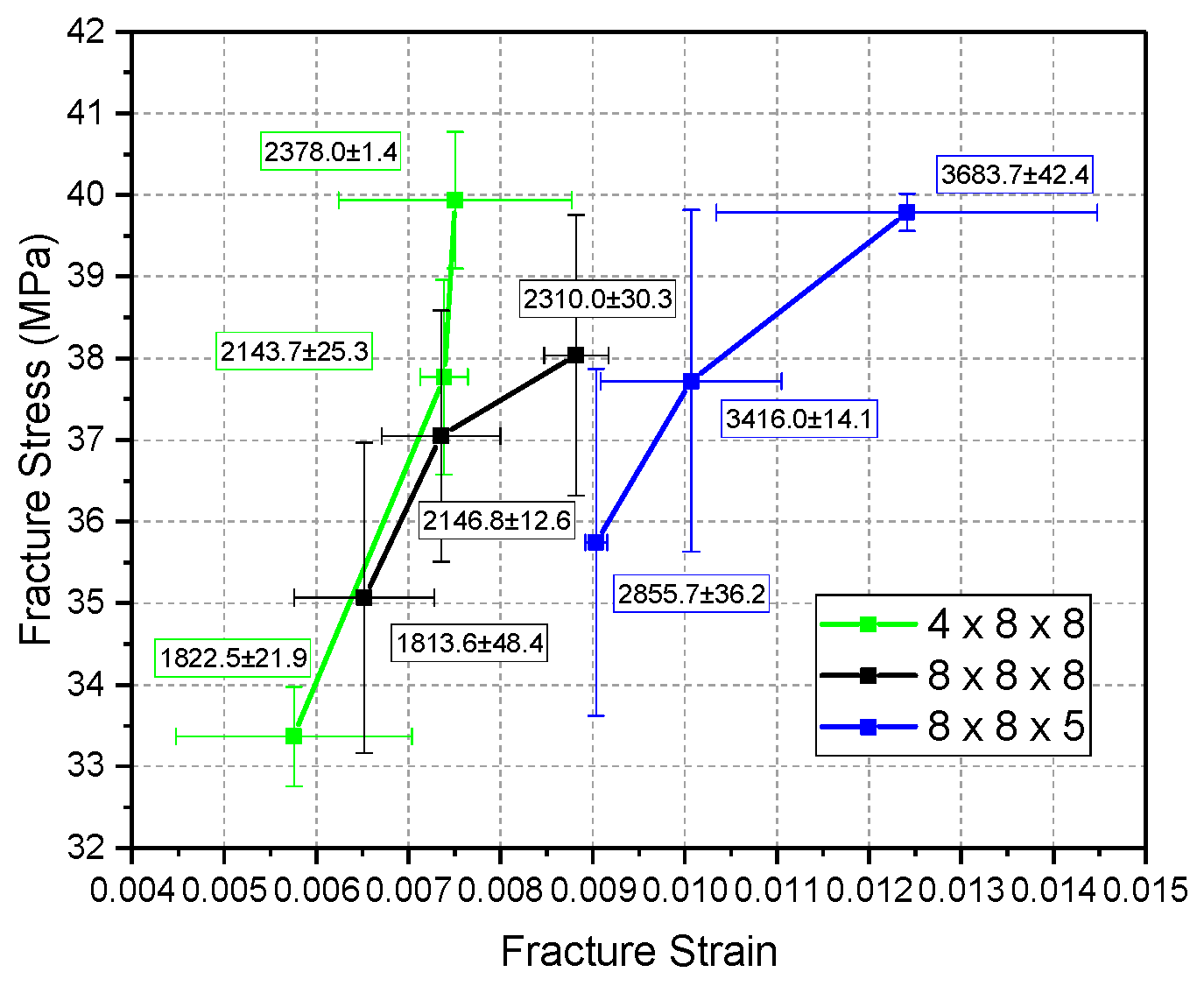

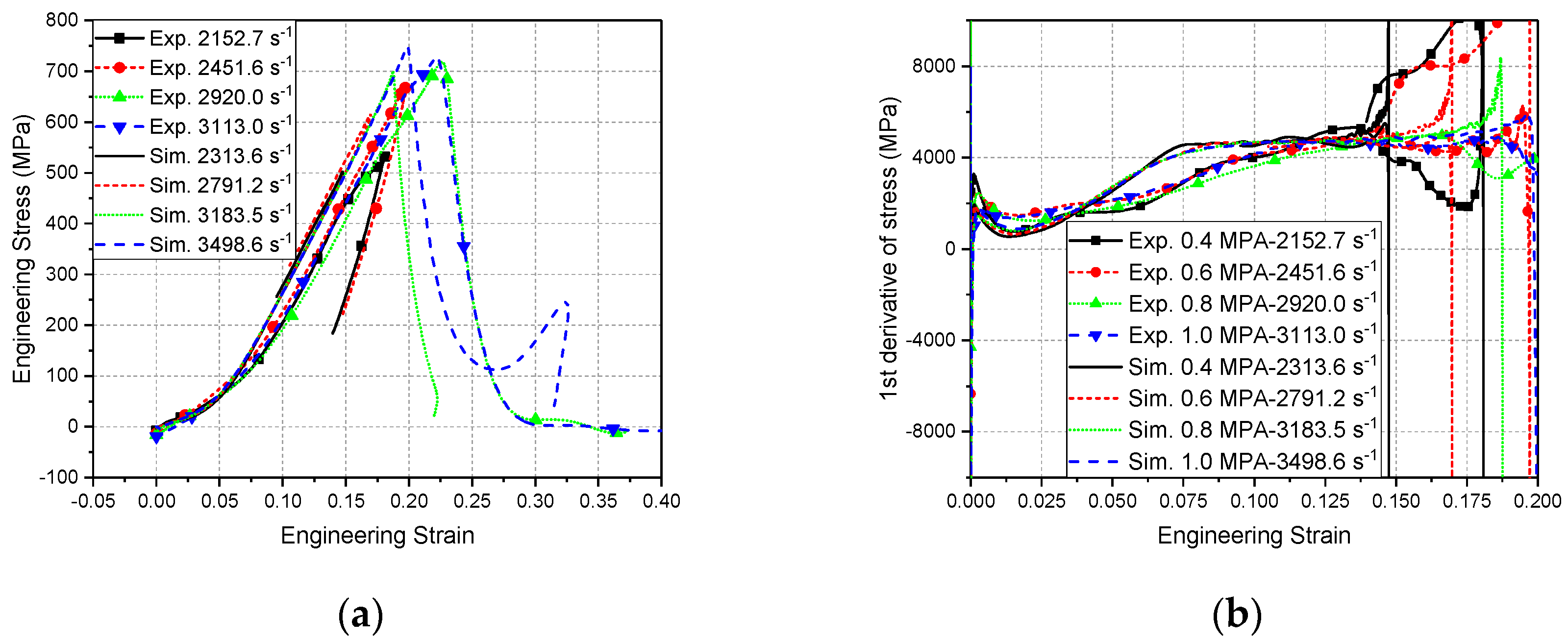

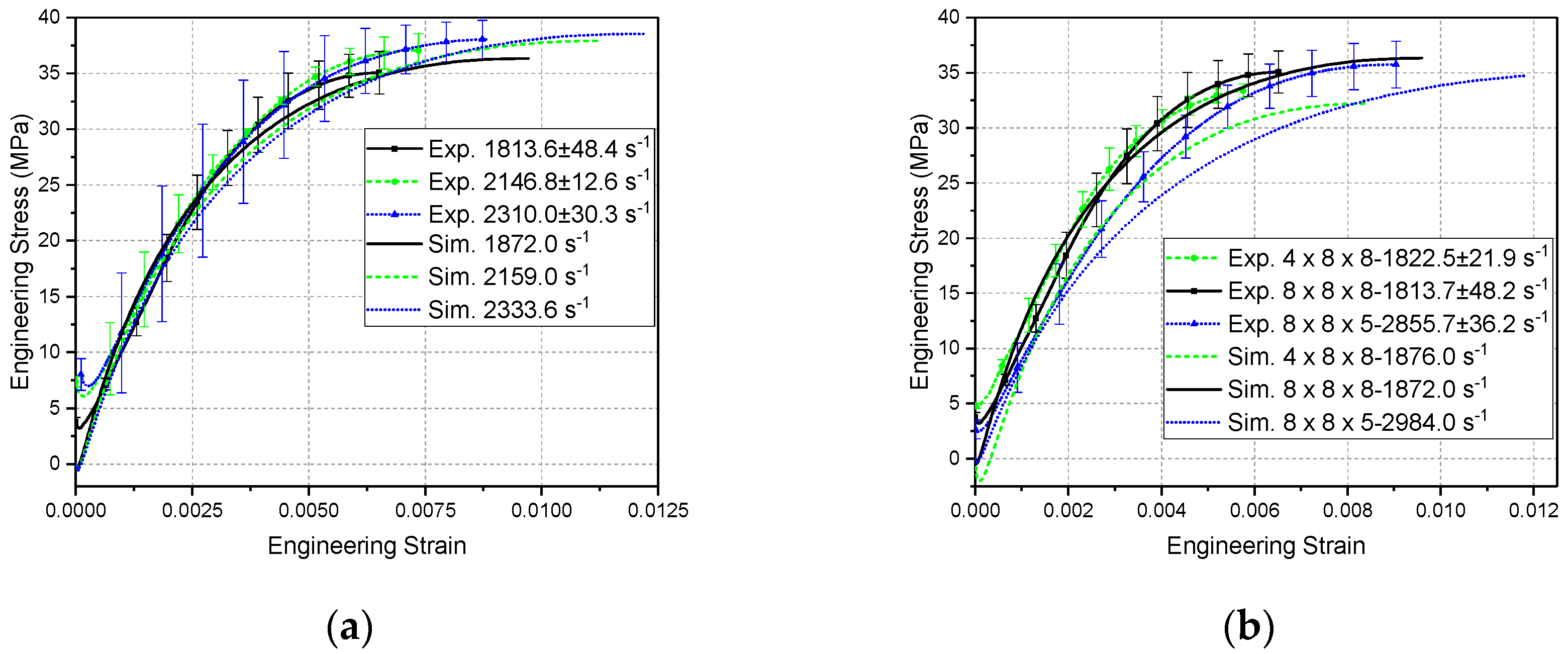

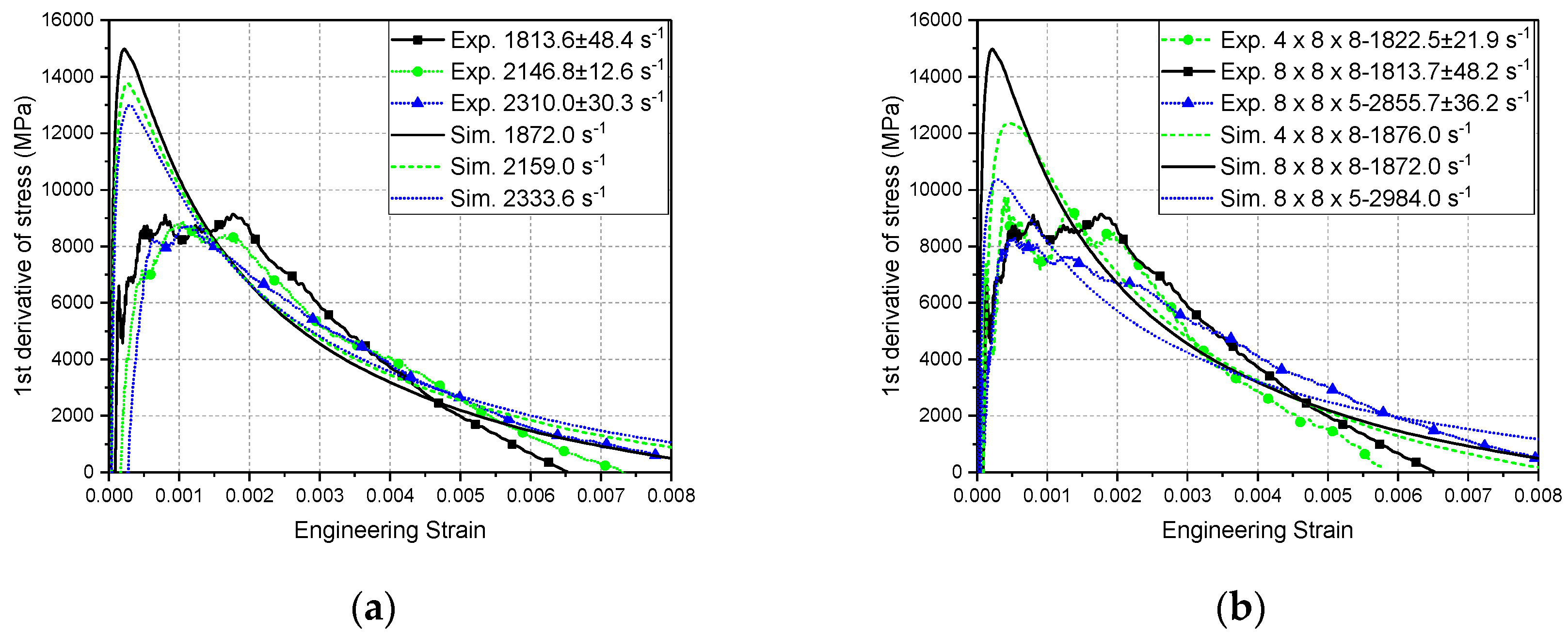

(c) Effect of Strain Rate

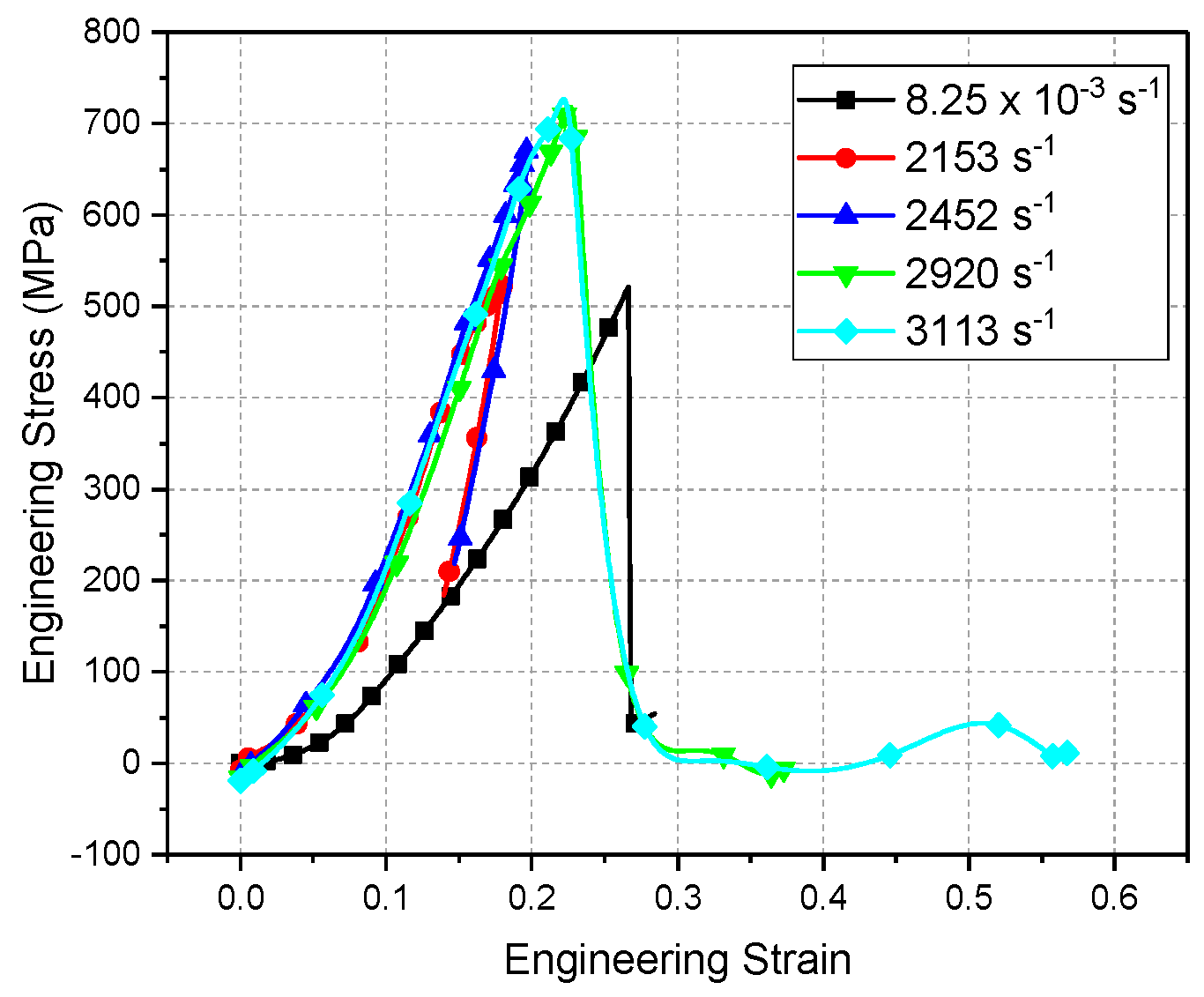

As

Figure 11 shows, as the strain increased, it seems that the stress values under different strain rates increased along the same curve, where only the peak points were different.

If the specimen was not damaged completely, the peak stress refers to the maximum stress that the specimen could sustain under a certain strain rate. After the peak point, the specimen still had the ability to spring back, which could also be seen in the high-speed camera records. However, the spring-back curve was not the same as the loading curve. This was potentially because some fibers were squeezed out of the main body of the specimen and, thus, a certain degree of permanent damage was caused. Furthermore, the slopes of previous spring-back curves under different strain rates were similar [

49], which means that the specimens retained similar properties.

If the specimen was damaged completely, the peak stress refers to the fracture stress of the specimen. As shown in

Figure 11 and

Figure 12a after 2989 s

−1, the fracture stress also increased as the strain rate increased. Furthermore, as the strain rate increased, the soften zone of the stress–strain curve tended toward the linear period. Therefore, the slope of the stress–strain curve in the soften zone was higher and the fracture strain became smaller to some extent as the strain rate increased to 2989, 3213, and 3316 s

−1, as shown in

Figure 11 and

Figure 12b. This phenomenon also occurred in the non-damaged tests of specimens 8 x 8 x 4 when the strain rate became higher. To sum up, with the increasing strain rate, the maximum stress, fracture stress, and energy absorption also increased. In contrast, it seems that the maximum strain increased at first and then decreased when it became fracture strain.

As shown in

Figure 13a–d for the Φ9 × 4 specimens under 0.2–1.2 MPa impact, as the strain rate increased, more fibers were squeezed out. Therefore, the little square at the center of the end face became more and more clear. As to the specimens under 3045.0018 ± 78.6690 s

−1 strain rate, some were non-damaged and some were completely damaged, which means that this strain rate represents the critical fracture value. As for the damaged specimens shown in

Figure 13e,f, the main body was crushed into several relatively big blocks. The traces of the crushed parts indicate that they were damaged by inner shear stress.

As mentioned in Reference [

21], compaction is the major failure mode in the out-of-plane direction, which represents the energy absorption mechanism. Similarly, as more compaction occurs, more fibers are squeezed out and more blocks are crushed; furthermore, with increasing strain rate, the energy absorption also increases. Shi also [

21] found that the laminated angle has an effect on the dynamic energy absorption of composites at higher strain rates. Placing laminae in a well-proportioned manner on the projective plane effectively enhances the energy absorption load under transversal impact. The friction between fibers perhaps has a relationship with the placing angle and energy propagation, which needs deeper study in further work.

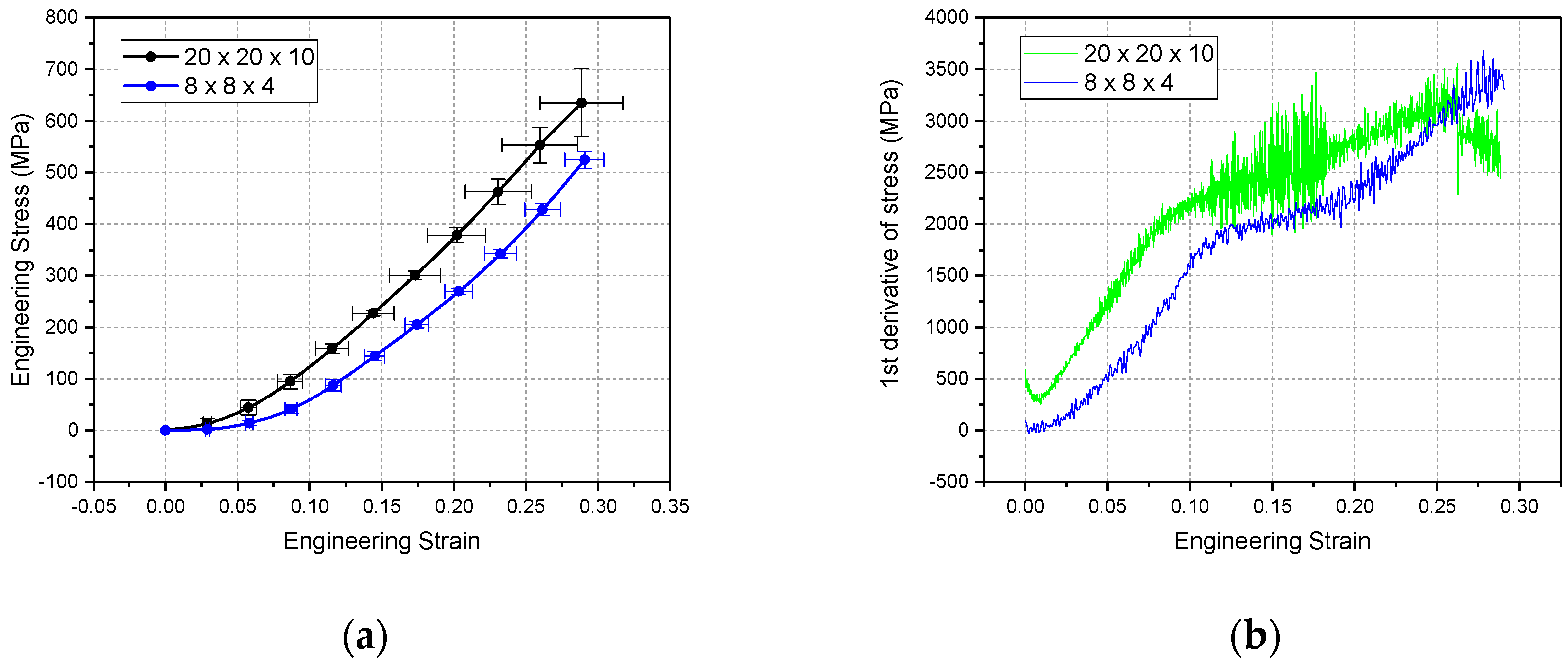

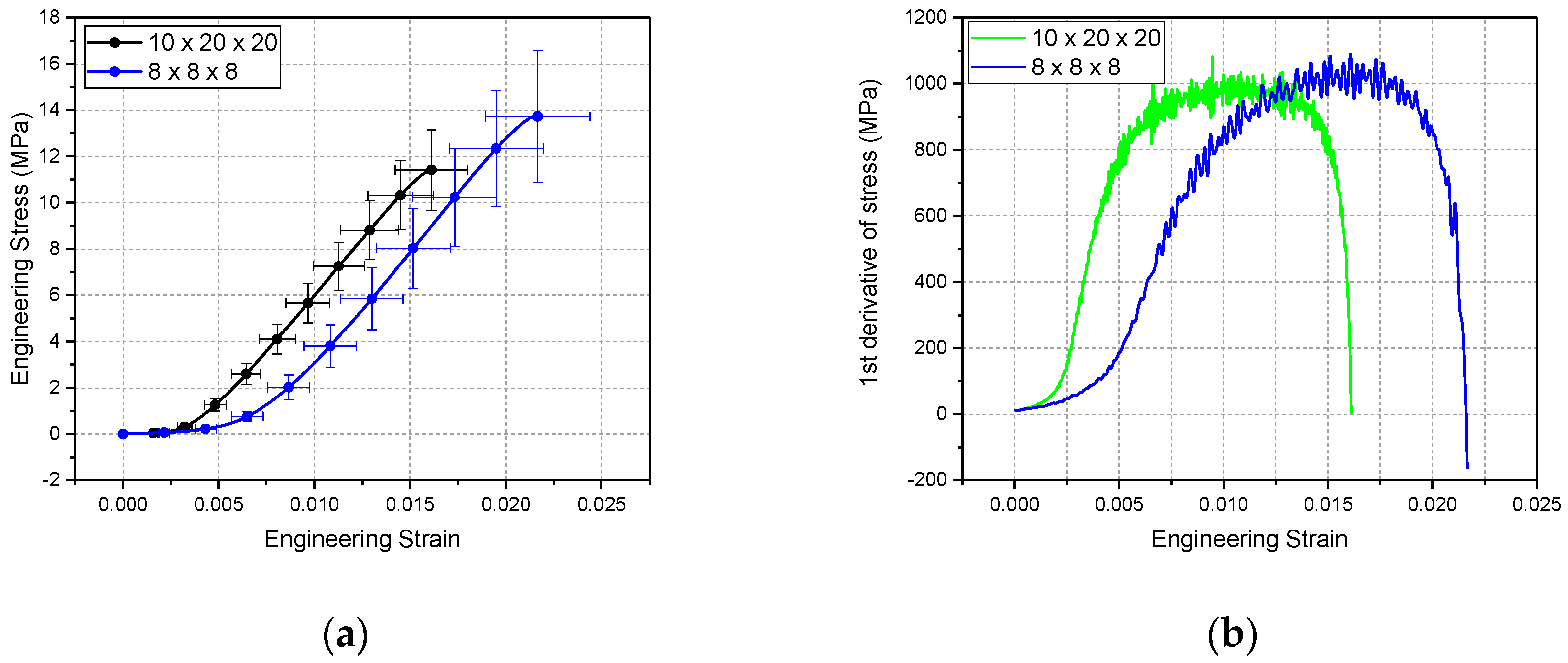

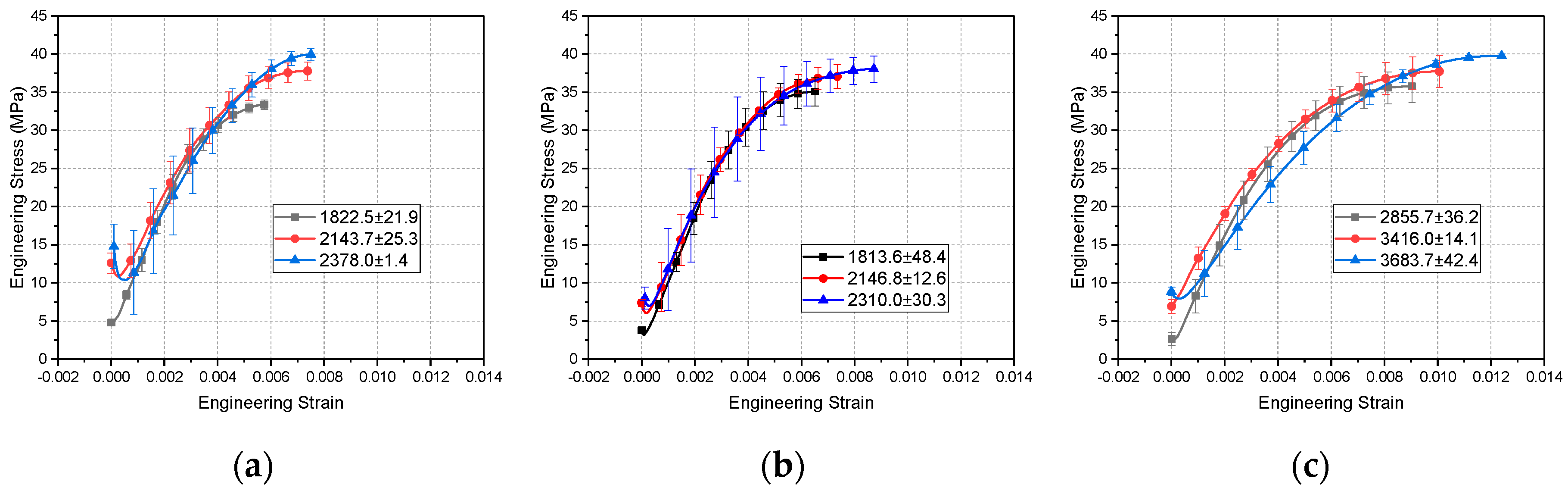

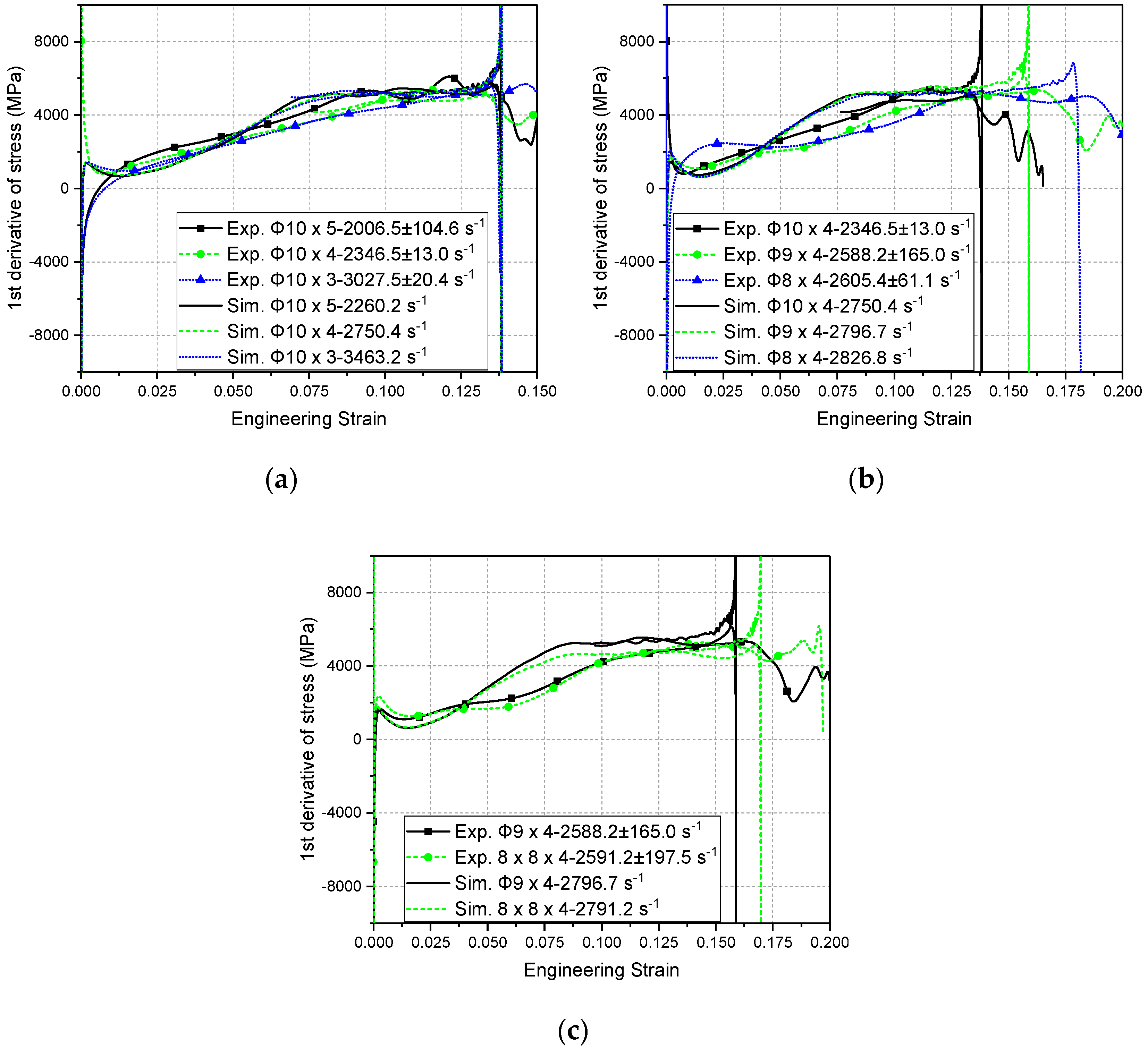

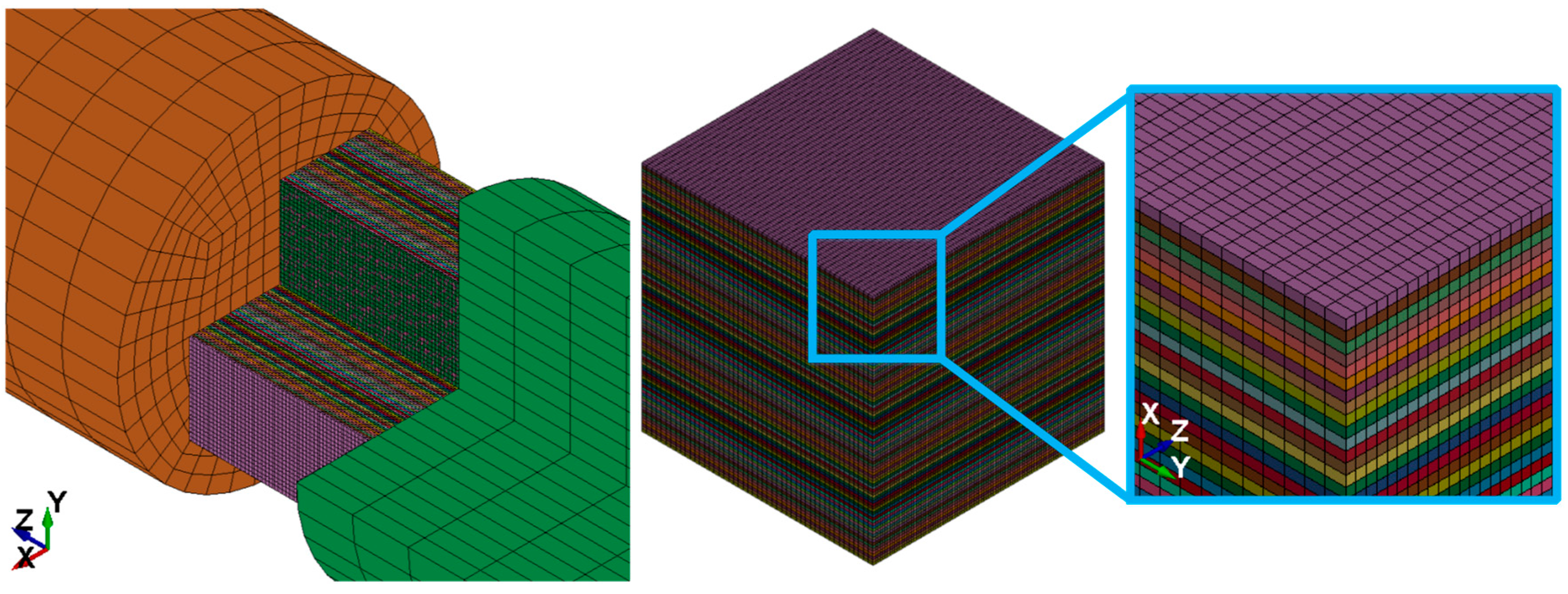

(d) Effect of Size

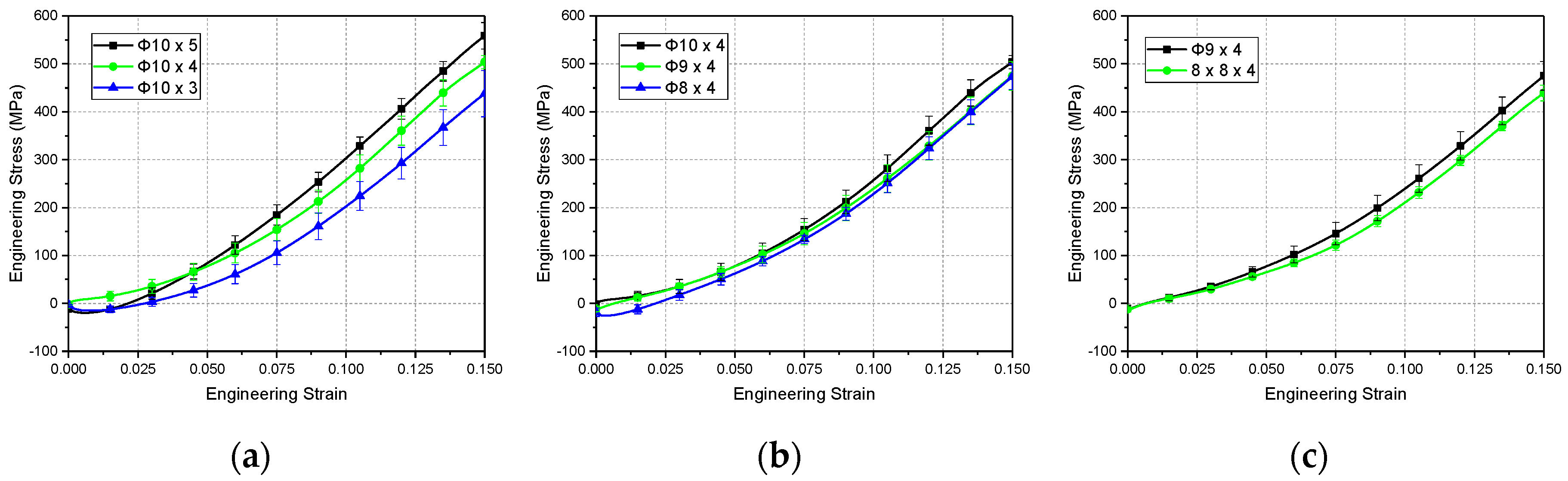

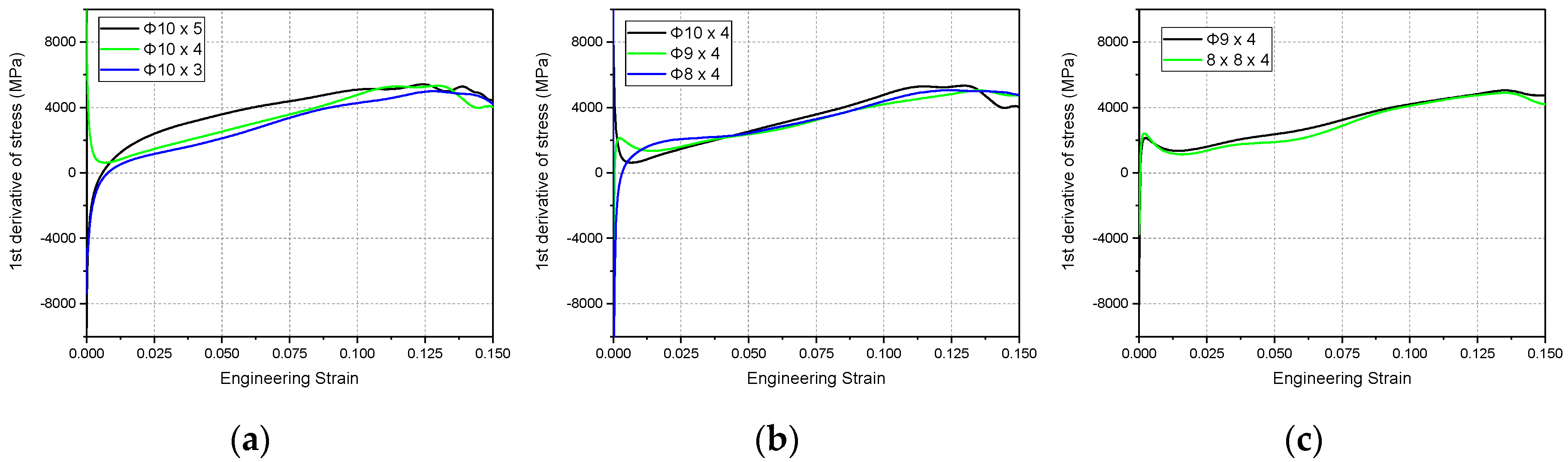

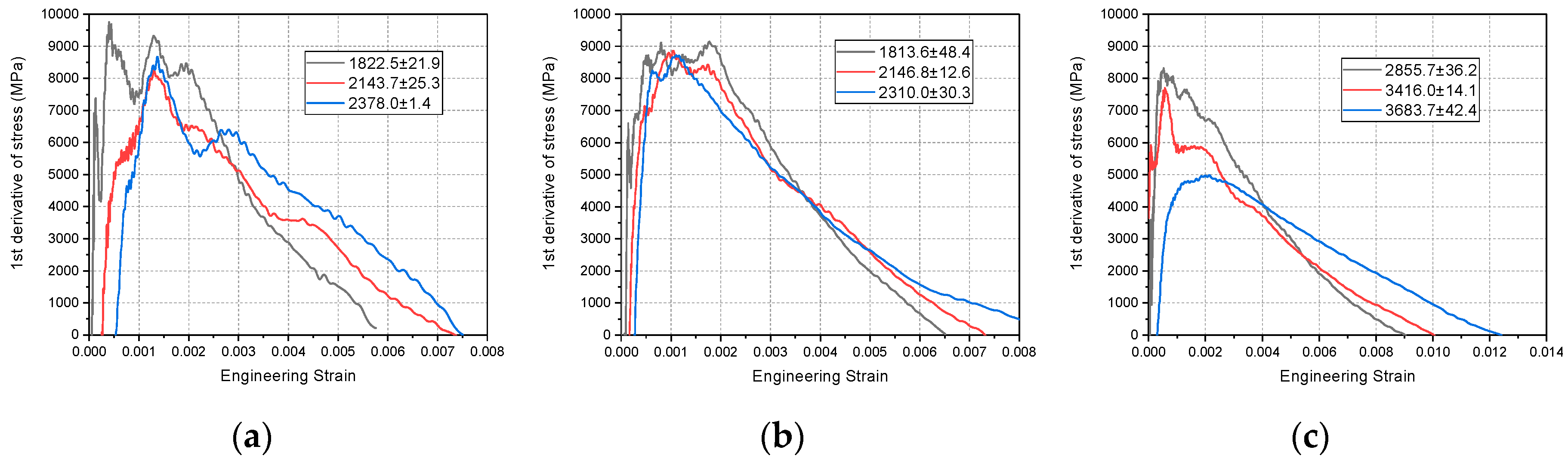

The non-linear and linear periods were mainly considered for size effects. For the influence of thickness, as shown in

Figure 14a, if the thickness was different, the stress–strain relationships were obviously different. As shown in

Figure 15a, with an increase in the thickness, the slope of the non-linear period became steeper and shorter. As shown in

Figure 16b and

Table 2, the thickness seems to not significantly affect the modulus values of the linear period. Therefore, the thickness seems to affect the self-installation zone and the non-linear period, but it seems to not affect the linear period. Since the self-installation zone is inevitable for the SHPB apparatus, the thickness seems to mainly affect the non-linear period.

With regard to the influence of diameter/area, as shown in

Figure 14b, the diameter or area seems to not significantly affect the stress–strain relationship. Considering

Figure 15b and that the modulus of specimens with different diameter in

Table 2 was similar, the diameter or area also seems to mainly influence the non-linear period. The influence of the area was not as obvious as the influence of the thickness. For the influence of shape, as shown in

Figure 14c and

Figure 15c, the stress–strain curves for different shapes were similar, and the slope of the cylindrical specimen was a little bit higher than that of the cuboid specimen in the non-linear period. In general, the thickness had the greatest influence on the non-linear period stress–strain curve, while the shape of the cross-section had the least influence.

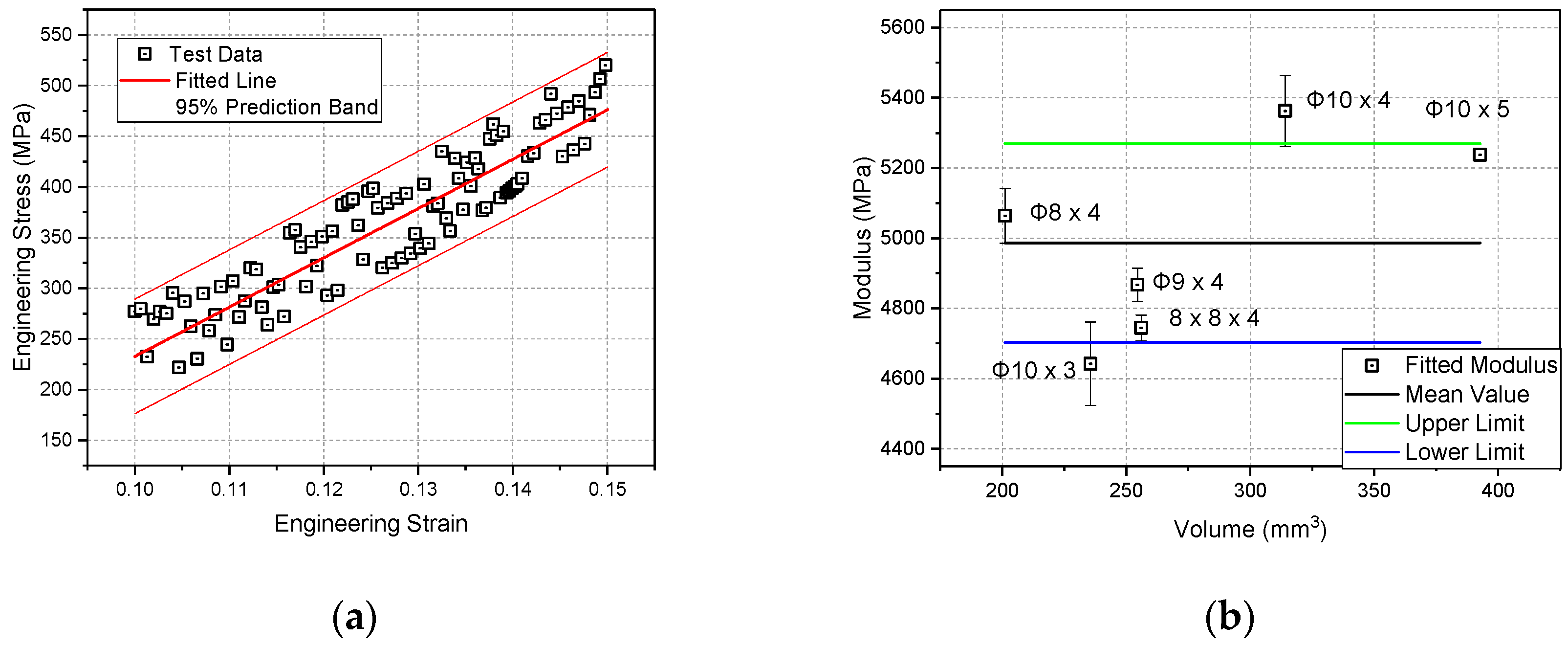

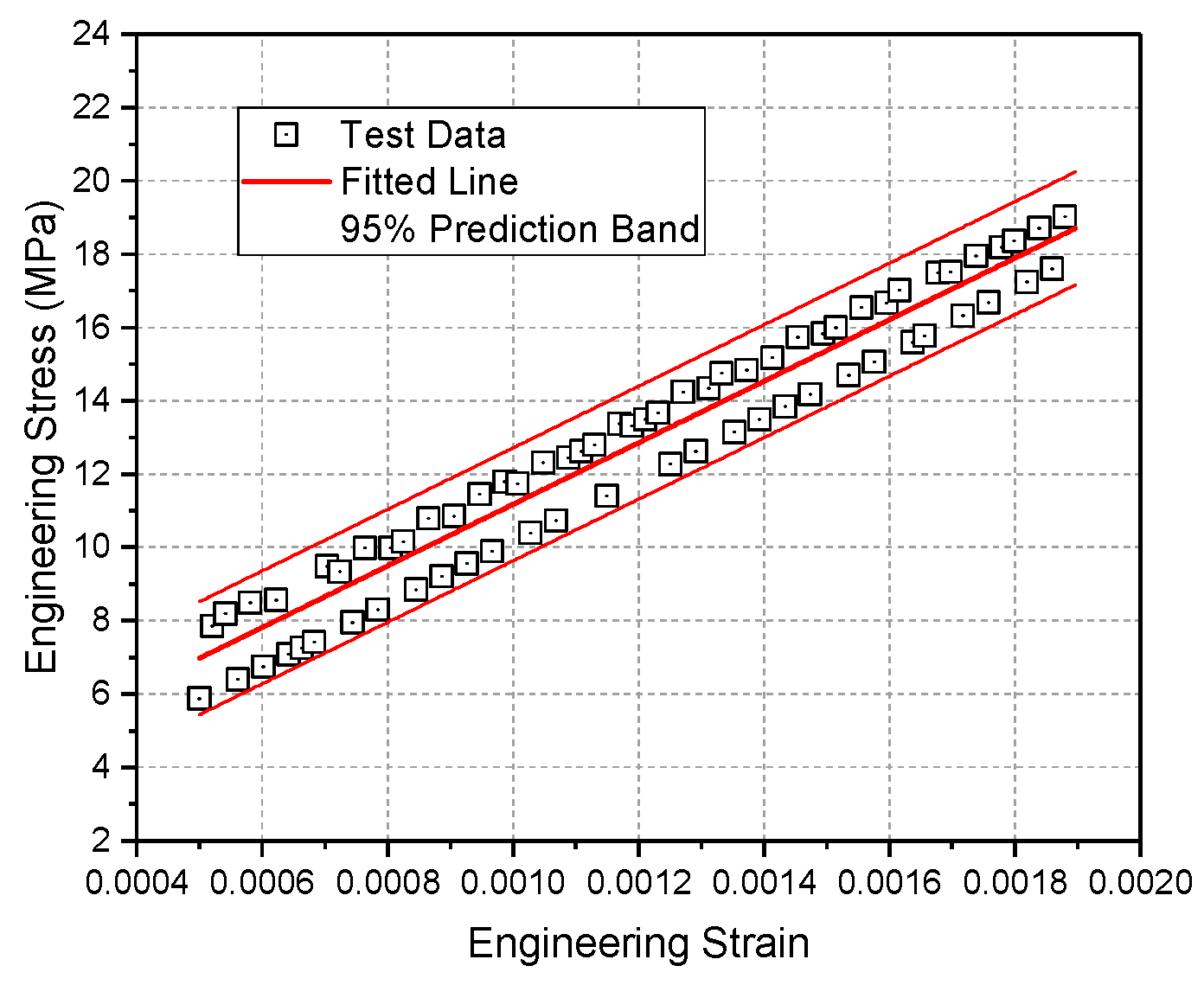

As shown in

Figure 16a, the modulus of these specimens could be fitted using points in the linear period of the stress–strain curves. As shown in

Table 2 and

Figure 16b, the modulus values did not show a strong relationship with the thickness, area, volume, or shape of the specimen. The maximum relative error when comparing the mean values was 7.5458%.