Seismic Performance of a Full-Scale Moment-Frame Housing System Constructed with Recycled Tetra Pak (Thermo-Stiffened Polymeric Aluminum Composite)

Abstract

1. Introduction and Background

2. Methodology

- Phase 1—This phase involved an examination of some mechanical properties of the material (thermo-stiffened polymeric aluminum) and its connections. Tensile strength and elasticity modulus were determined through tensile tests, providing the foundational mechanical properties for the structural system. Additionally, the performance of bolted beam–column connections, critical for shear transfer between components, was analyzed through experimental setups based on [32].

- Phase 2—A finite element model (FEM) was developed using the material properties derived from Phase 1. The FEM simulated all structural components, including beams, girders, columns, and the flooring system. Steel bolts were modeled as linear frame elements to replicate their role in shear transfer between hollow structural elements. The FEM incorporated boundary conditions and loading protocols representative of gravitational and seismic forces. Validation of the model was achieved by comparing its predictions to simplified analytical calculations and, later, experimental results from full-scale testing.

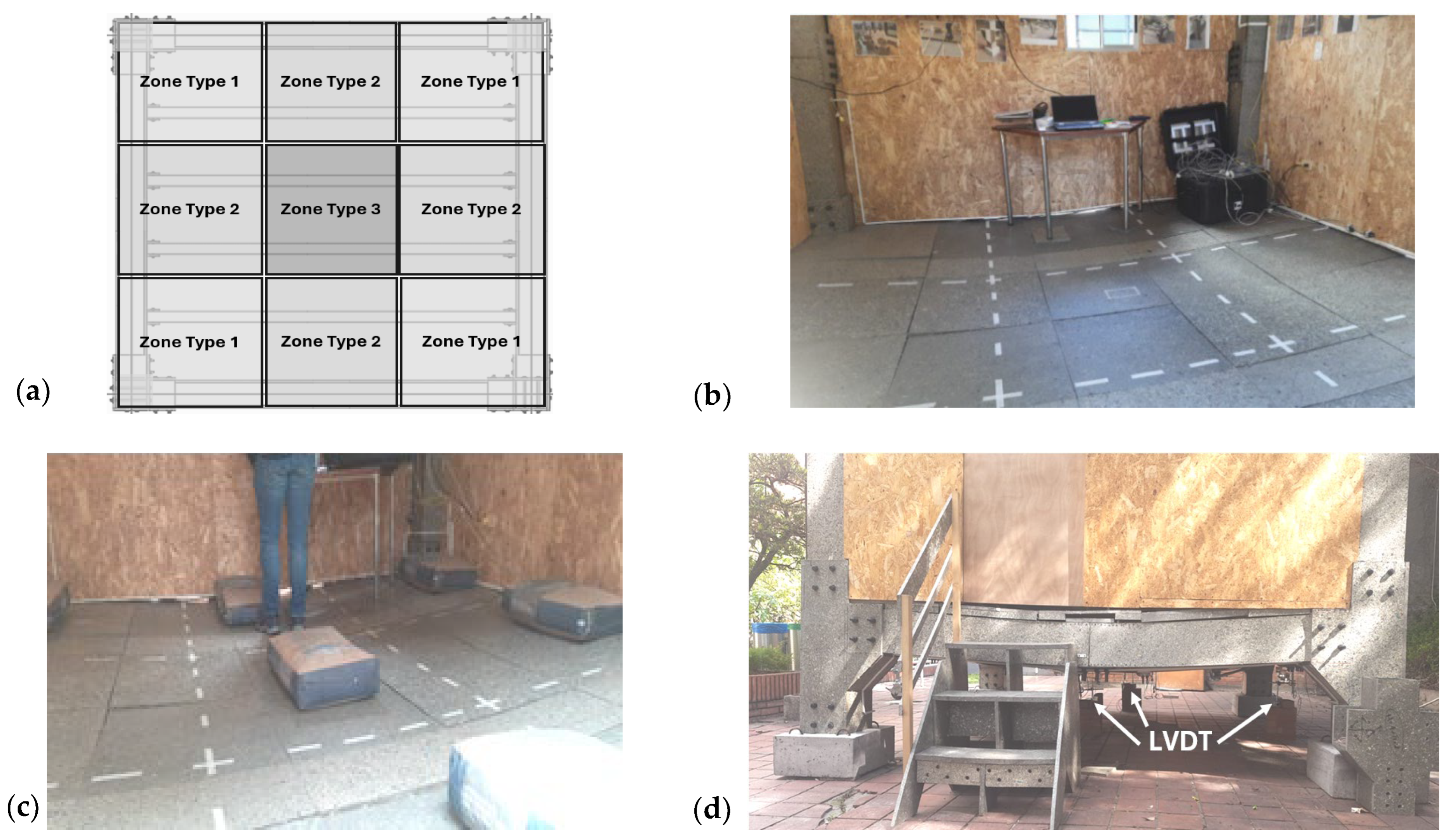

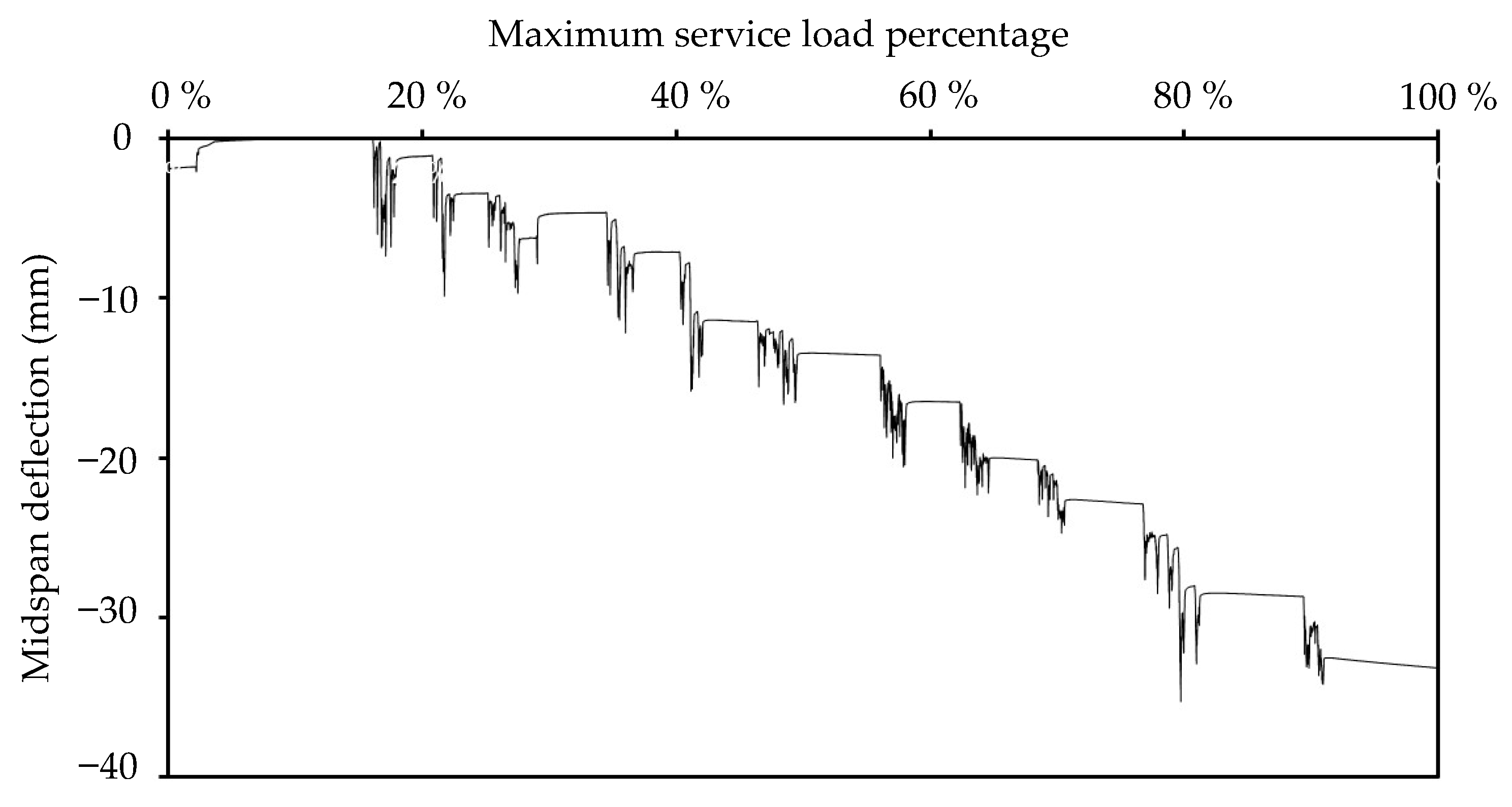

- Phase 3—In this phase, the full-scale prototype of the structural system was subjected to gravitational loading using cement sacks in compliance with standards. Displacement sensors and strain gauges were installed at critical points across the girders, beams, and flooring system to monitor deflections and strains during the loading process. The load was gradually increased to a maximum value of approximately 1.8 kN/m2 and maintained for 24 h to simulate standard conditions. However, for this study, the load was held for 100 h to observe long-term effects on the structural components. After the test, detailed observations of structural pathology were supplemented with photographic evidence.

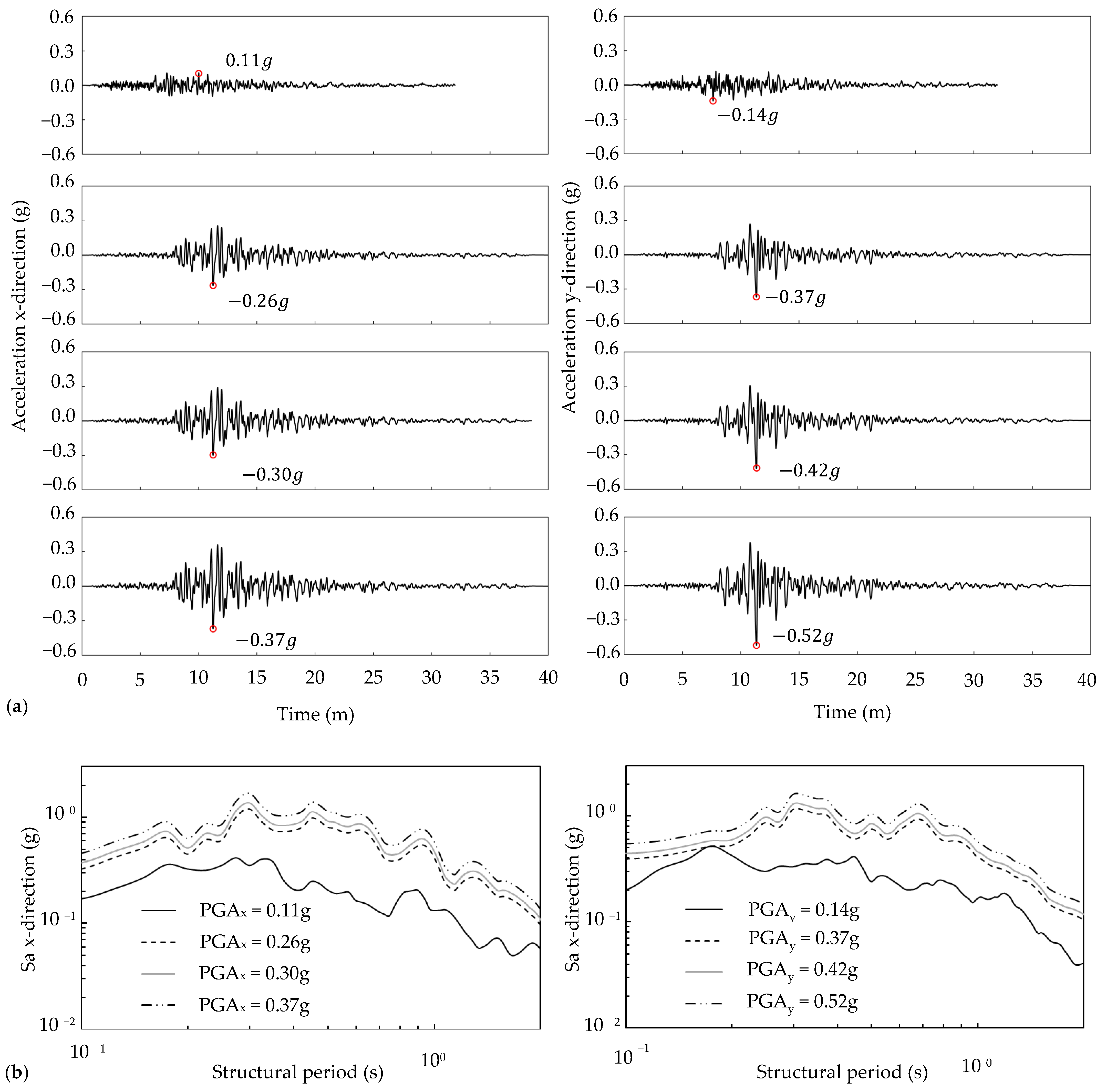

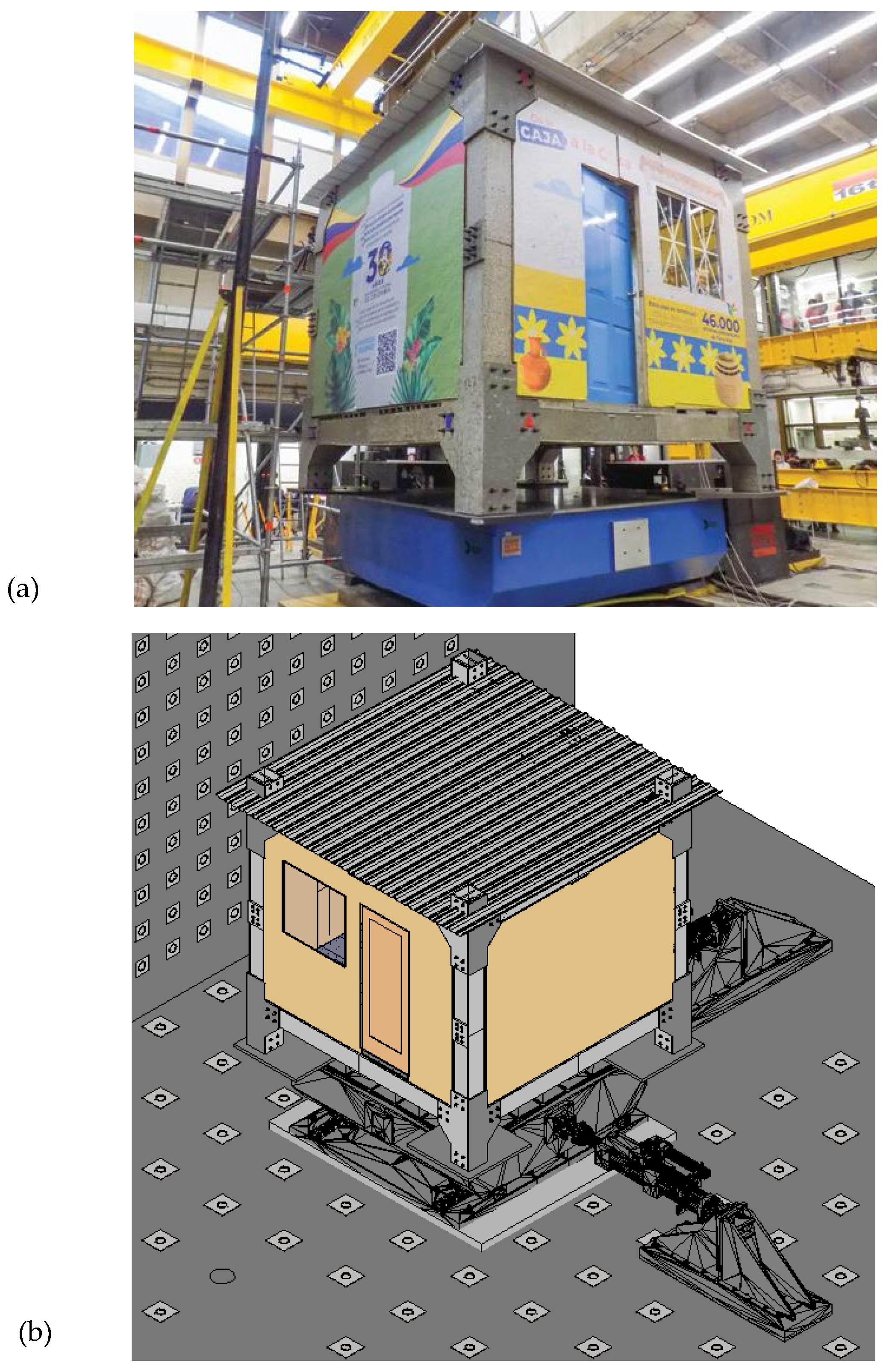

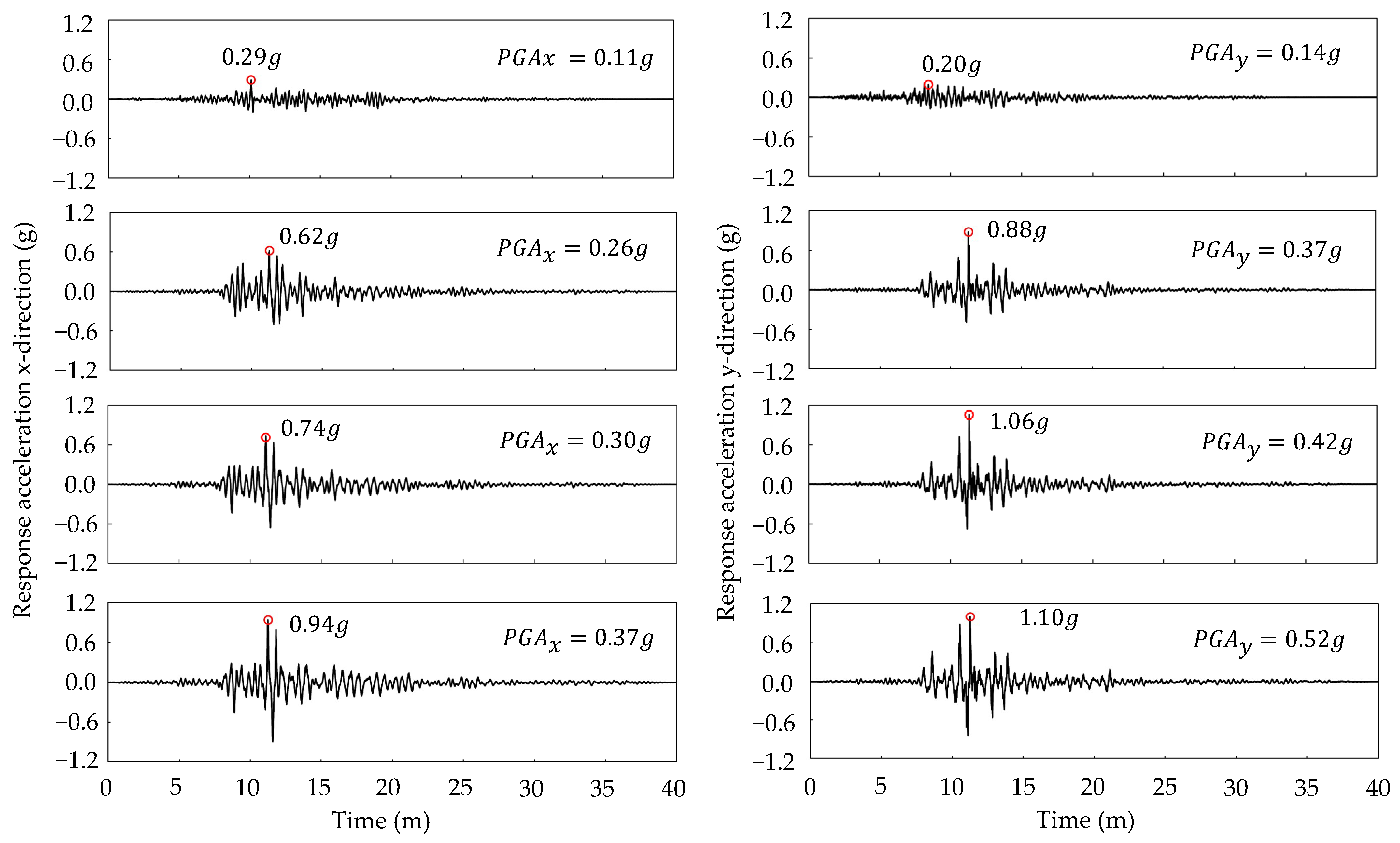

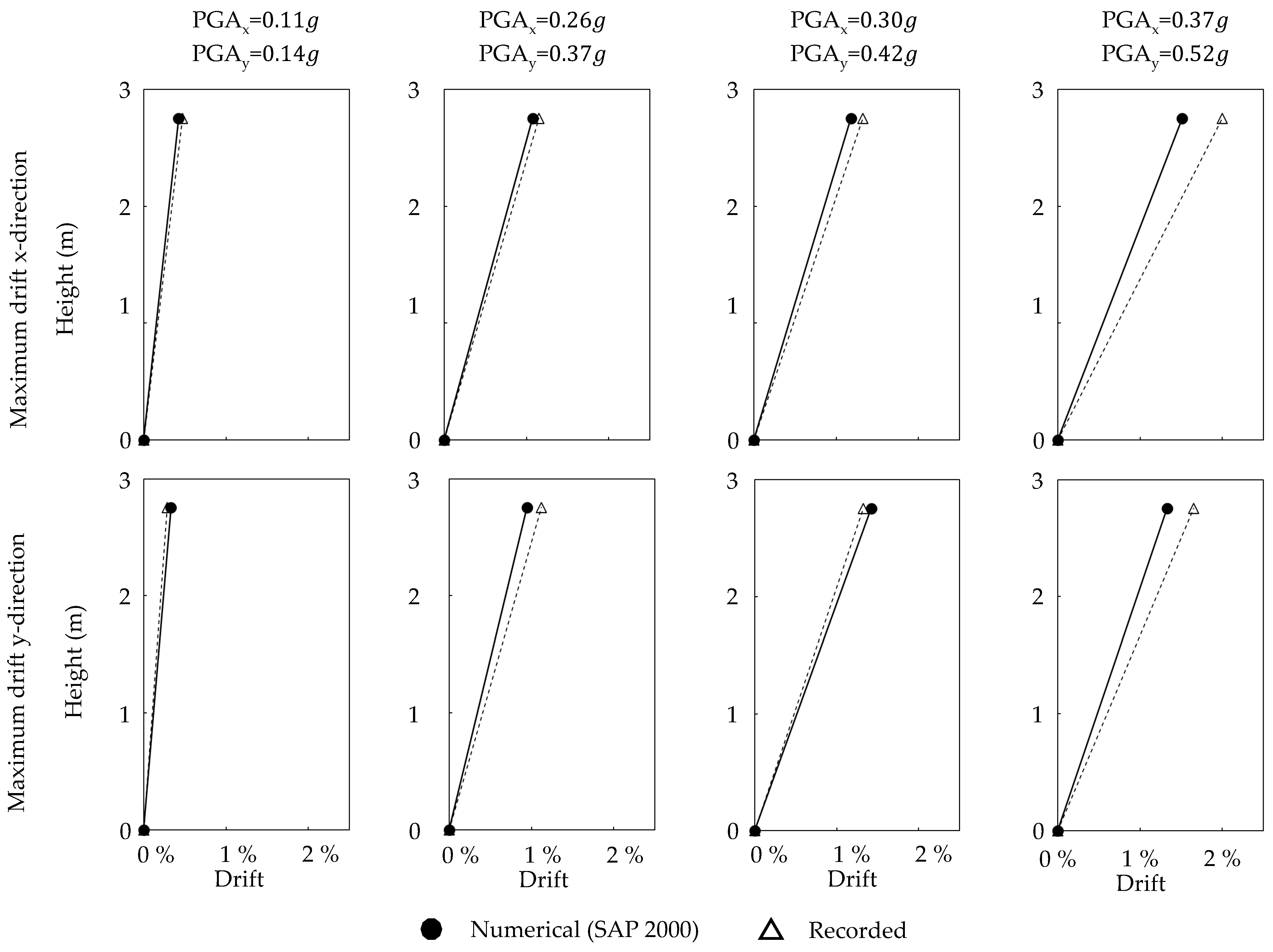

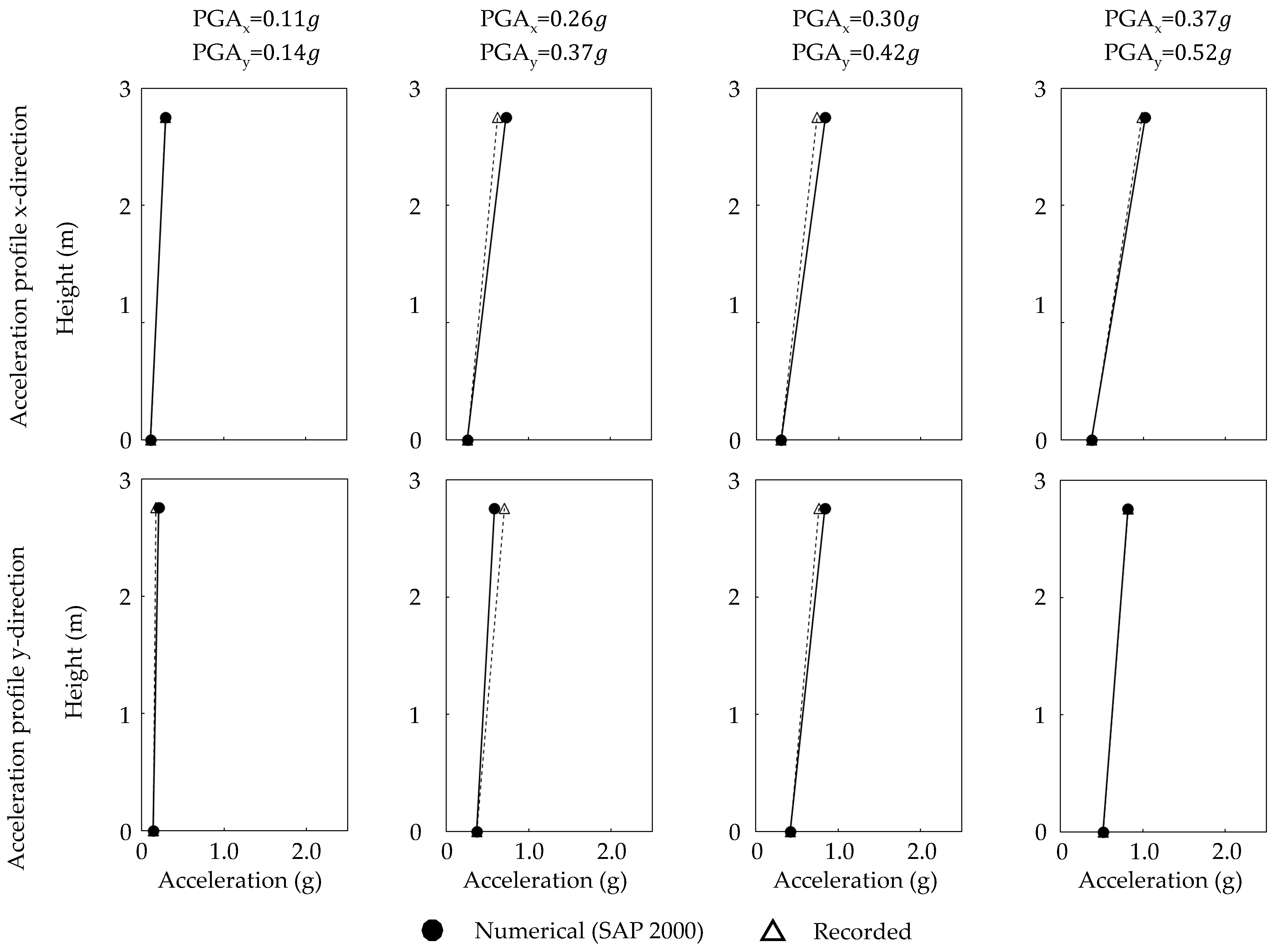

- Phase 4: The prototype was subjected to biaxial shaking table testing to simulate seismic forces. Ground motion records representing return periods of operational level (OL), damage limitation (DL), life safety (LS), and collapse prevention (CP) were applied to the structure. Key measurements, including natural frequencies, peak accelerations, and drift profiles, were recorded to evaluate the dynamic performance of the system. The seismic testing provided important data on the behavior of thermo-stiffened polymeric aluminum materials and connections under multidirectional stress scenarios.

- Phase 5: This phase involved a comprehensive analysis of the experimental and numerical results obtained from the previous phases. Comparisons between the FEM simulations and experimental data highlighted the consistency and reliability of the numerical approach. Key findings emphasized the lightweight and sustainable nature of thermo-stiffened polymeric aluminum materials, alongside their satisfactory mechanical and seismic performance. Conclusions were drawn to highlight the feasibility of thermo-stiffened polymeric aluminum materials systems for sustainable and resilient earthquake-resistant housing. Finally, recommendations for future research are included.

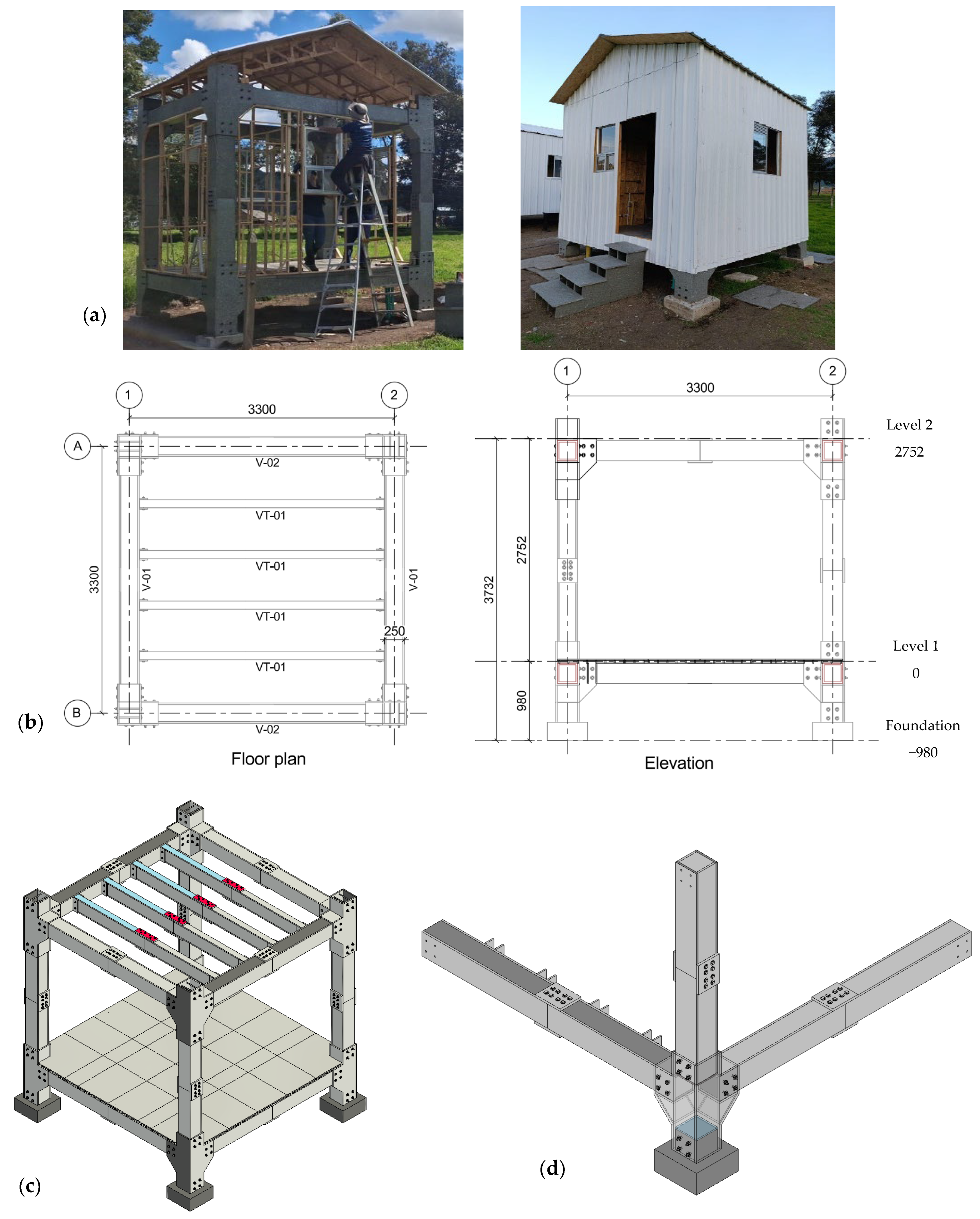

3. Structural Description

4. Mechanical Properties of TSPA and Connection Strength

5. Finite Element Modeling to Evaluate Seismic Performance

6. Vertical Load Testing

7. Biaxial Shaking Table Tests

7.1. Ground Motions for Biaxial Shaking Table Tests

7.2. Test Setup

7.3. Acceleration and Drifts Records

7.4. Acceleration and Drift Profiles Compared to Results of the FEM

8. Conclusions

9. Patents

10. Future Works

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations Environment Programme & Yale Center for Ecosystems + Architecture. Building Materials and the Climate: Constructing a New Future. 2023. Available online: https://wedocs.unep.org/20.500.11822/43293 (accessed on 26 February 2025).

- Robertson, G.L. Recycling of Aseptic Beverage Cartons: A Review. Recycling 2021, 6, 20. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Zulkernain, N.H.; Gani, P.; Chuan, N.C.; Uvarajan, T. Utilisation of plastic waste as aggregate in construction materials: A review. Constr. Build. Mater. 2021, 296, 123669. [Google Scholar] [CrossRef]

- Herrera, J.P.; Bedoya-Ruiz, D.; Hurtado, J.E. Seismic behavior of recycled plastic lumber walls: An experimental and analytical research. Eng. Struct. 2018, 177, 566–578. [Google Scholar] [CrossRef]

- Castañeda-Onofre, F.; Ortega-Robles, J.; Areche-García, J. Uso de tetra pack como elemento constructivo de cubiertas para techos de viviendas. Polo Conoc. 2022, 7, 2334–2357. Available online: https://polodelconocimiento.com/ojs/index.php/es/article/view/4348 (accessed on 26 February 2025).

- Kulkarni, P.; Ravekar, V.; Rao, P.R.; Waigokar, S.; Hingankar, S. Recycling of waste HDPE and PP plastic in preparation of plastic brick and its mechanical properties. Clean. Mater. 2022, 5, 100113. [Google Scholar] [CrossRef]

- Andriani, S.R.; Isnaeni, H.; Kusuma, N.R.; Avandra, E. The Utilizations of Plastic Bottle Waste (PET) in Architecture. IOP Conf. Series Earth Environ. Sci. 2020, 452, 012026. [Google Scholar] [CrossRef]

- Bonocore, G.; De Luca, P. Preparation and Characterization of Insulating Panels from Recycled Polylaminate (Tetra Pak) Materials. Sustainability 2022, 14, 6858. [Google Scholar] [CrossRef]

- Martínez-Barrera, G.; Escobar-Campos, C. Envases Tetra Pak y su uso en materiales de construcción. Pädi Boletín Científico Cienc. Básicas Ing. ICBI 2023, 11, 1–6. [Google Scholar] [CrossRef]

- Quintero, M.; Rodríguez, P.; Rubio, J.; Jaramillo, L.; Nuñez-Moreno, F. Bending and Compression Characterization of Hollow Structural Elements Made of Recycled Tetra Pak-Based Boards (RTPBB) and an Approximated Calculation of the Carbon Footprint Involved in Their Production. Rev. Ing. Construcción 2017, 32, 131–148. [Google Scholar] [CrossRef]

- Da Silva, T.; De Azevedo, A.; Cecchin, D.; Marvila, M.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M.; Klyuev, S.; Szelag, M. Application of PlasticWastes in Construction Materials: A Review Using the Concept of Life-Cycle Assessment in the Context of Recent Research for Future Perspectives. Materials 2021, 14, 3549. [Google Scholar] [CrossRef] [PubMed]

- Foti, D.; Adamopoulos, S.; Voulgarido, E.; Voulgaridis, E.; Passialis, C.; Osakue, S.; Daniel, G. Microstructure and compressive strength of gypsum-bonded composites with papers, paperboards and Tetra Pak recycled materials. J. Wood Sci. 2019, 65, 42. [Google Scholar] [CrossRef]

- Gulhane, S.; Gulhane, S. Analysis of Housing Structures Made from Recycled Plastic. IRA-Int. J. Technol. Eng. 2017, 7, 45–55. [Google Scholar] [CrossRef]

- Envapack. En Colombia se Construye la Primera Vivienda Sostenible a Partir de Envases Tetra Pak. 2022. Available online: https://www.envapack.com/2022/05/en-colombia-se-construye-la-primera-vivienda-sostenible-a-partir-de-envases-tetra-pak/ (accessed on 26 February 2025).

- Ahmed, N. Utilizing plastic waste in the building and construction industry: A pathway towards the circular economy. Constr. Build. Mater. 2023, 383, 131311. [Google Scholar] [CrossRef]

- Arsitektur, U.K.I.D.T.; Kurniawan, S.; Finaldy, C.R.; Tresnakalingga, G. Prefabricated House Development With Tetra Pak Carton Recycling Processing. Int. J. Res. Appl. Technol. 2022, 2, 218–225. [Google Scholar] [CrossRef]

- Allam, Z.; Jones, D.S. Towards a Circular Economy: A Case Study of Waste Conversion into Housing Units in Cotonou, Benin. Urban Sci. 2018, 2, 118. [Google Scholar] [CrossRef]

- Bekhta, P.; Lyutyy, P.; Hiziroglu, S.; Ortynska, G. Properties of Composite Panels Made from Tetra-Pak and Polyethylene Waste Material. J. Polym. Environ. 2016, 24, 159–165. [Google Scholar] [CrossRef]

- Gallego, S.M.; Aponte, Á.G.; Sierra, R.B.; Marín, J.F.S. Evaluation of Mechanical Properties of Composites Manufactured from Recycled Tetra Pak® Containers. Rev. Tecnura 2020, 24, 36–46. [Google Scholar] [CrossRef]

- Bal, B. Mechanical Properties of Wood-Plastic Composites Produced with Recycled Polyethylene, Used Tetra Pak® Boxes, and Wood Flour. BioResources 2022, 17, 6569–6577. Available online: https://bioresources.cnr.ncsu.edu/resources/mechanical-properties-of-wood-plastic-composites-produced-with-recycled-polyethylene-used-tetra-pak-boxes-and-wood-flour/ (accessed on 26 February 2025). [CrossRef]

- Wendimu, T.; Furgasa, B.; Hajji, B. Suitability and Utilization Study on Waste Plastic Brick as Alternative Construction Material. J. Civ. Constr. Environ. Eng. 2021, 6, 9–12. [Google Scholar] [CrossRef]

- Awoyera, P.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Belmokaddem, M.; Mahi, A.; Senhadji, Y.; Yilmaz-Pekmezci, B. Mechanical and physical properties and morphology of concrete containing plastic waste as aggregate. Constr. Build. Mater. 2020, 257, 119559. [Google Scholar] [CrossRef]

- Adnan, H.; Dawood, A. Recycling of plastic box waste in the concrete mixture as a percentage of fine aggregate. Constr. Build. Mater. 2021, 284, 122666. [Google Scholar] [CrossRef]

- Aneke, F.; Shabangu, C. Green-efficient masonry bricks produced from scrap plastic waste and foundry sand. Case Stud. Constr. Mater. 2021, 14, e00515. [Google Scholar] [CrossRef]

- Biswas, W.K.; Zhang, X. Techno-Assessment of the Use of Recycled PlasticWaste in RE. Sustainability 2021, 13, 8678. [Google Scholar] [CrossRef]

- Haque, M. Sustainable use of plastic brick from waste PET plastic bottle as building block in Rohingya refugee camp: A review. Environ. Sci. Pollut. Res. 2019, 26, 36163–36183. [Google Scholar] [CrossRef]

- Intelligent Living. Mexican Engineer Builds ‘Plastic Houses’ Resistant To Earthquakes. 2019. Available online: https://www.intelligentliving.co/plastic-houses-resistant-earthquakes/ (accessed on 26 February 2025).

- Chheda, D. Using Recycled Plastic Composites to Develop Earthquake Resilient Housing for the Region of Kutch, India. A Thesis in Architecture. The Pennsylvania State University, The Graduate School College of Arts and Architecture. 2016. Available online: https://etda.libraries.psu.edu/catalog/xk81jk36q (accessed on 26 February 2025).

- El Financiero. Ingeniero Mexicano Construye Casas ’de Plástico’ Resistentes a Sismos. 2019. Available online: https://www.elfinanciero.com.mx/nacional/ingeniero-mexicano-construye-casas-de-plastico-resistentes-a-sismos/ (accessed on 26 February 2025).

- Fuentes, J. Caracterización Experimental de la Respuesta Estructural de Conexiones a Cortante Viga-Columna Fabricadas con Material Aglomerado de Tetra Pak Ante la Acción de Cargas Cíclicas. Trabajo Presentado Para la Obtención del Título de Magister en Ingeniería Civil. Advisors: Núñez F. and Ruiz D. Pontificia Universidad Javeriana. 2017. Available online: https://repository.javeriana.edu.co/handle/10554/47307 (accessed on 26 February 2025).

- Hardash, S.; Bjorhovde, R. Gusset Plate Design Utilizing Block-Shear Concepts. University of Arizona, Department of Civil Engineering and Engineering Mechanics. Tucson (AZ). 1984. Available online: https://www.aisc.org/globalassets/aisc/research-library/gusset-plate-design-utilizing-block-shear-concepts.pdf (accessed on 26 February 2025).

- Ip, K.; Chung, K. Failure Modes of Bolted Cold-Formed Steel Connections under Static Shear Loading. In Advances in Steel Structures (ICASS’99); Elsevier: Amsterdam, The Netherlands, 1999; pp. 269–276. [Google Scholar] [CrossRef]

- ASTM E196-06; Standard Practice for Gravity Load Testing of Floors and Low Slope Roofs. ASTM-American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- ASCE7-22; Minimum Design Loads for Buildings and Other Structures. Structural Engineering Institute—SEI: Reston, VA, USA, 2022. Available online: https://www.asce.org/publications-and-news/civil-engineering-source/article/2021/12/02/updated-asce-7-22-standard-now-available (accessed on 13 February 2025).

- Barrera, N.; Ruiz, D.; Reyes, J.; Alvarado, Y.; Carrasco-Beltrán, D. Seismic Performance of a 1:4 Scale Two-Story Rammed Earth Model Reinforced with Steel Plates Tested on a Bi-Axial Shaking Table. Buildings 2023, 13, 2950. [Google Scholar] [CrossRef]

- Mostafaei, H.; Mostofinejad, D.; Ghamami, M.; Wu, C. Fully automated operational modal identification of regular and irregular buildings with ensemble learning. Structures 2023, 58, 105439. [Google Scholar] [CrossRef]

- Alcaldía de Bogotá. Decreto 523 de 2010 (Reglamentario de Apartes del Título A2 del Decreto 926 de 2010), por Medio del Cual se Reglamenta Microzonificación Sísmica Para la Ciudad de Bogotá D.C. 2010. Available online: https://www.scg.org.co/wp-content/uploads/DECRETO-523-DE-2010-MICROZONIFICACION-BOGOTA.pdf (accessed on 26 February 2025).

- Bavandi, M.; Amiri, G.G.; Rajabi, E.; Moghadam, A.S. Study of the resilience index for steel moment frames with reversible connections. Structures 2023, 47, 814–828. [Google Scholar] [CrossRef]

| Load Step | Details | Load (kN) | Distr. Equivalent (kN/m2) | % of Service Load |

|---|---|---|---|---|

| 1 | 50 kg in each zone type | 4.41 | 0.417 | 28.2 |

| 2 | +50 kg in each zone type | 8.82 | 0.834 | 56.3 |

| 3 | +25 kg in each zone type | 11.03 | 1.044 | 70.4 |

| 4 | +25 kg in each zone type | 13.24 | 1.253 | 84.5 |

| 5 | +25 kg in each zone type | 15.44 | 1.462 | 98.6 |

| 6 | Final load of 22.3 kg in Zone Type 3. | 15.67 | 1.483 | 100.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nuñez-Moreno, F.; Ruiz, D.M.; Aristizabal-Vargas, S.; Gutierrez-Quintero, C.; Alvarado, Y.A. Seismic Performance of a Full-Scale Moment-Frame Housing System Constructed with Recycled Tetra Pak (Thermo-Stiffened Polymeric Aluminum Composite). Buildings 2025, 15, 813. https://doi.org/10.3390/buildings15050813

Nuñez-Moreno F, Ruiz DM, Aristizabal-Vargas S, Gutierrez-Quintero C, Alvarado YA. Seismic Performance of a Full-Scale Moment-Frame Housing System Constructed with Recycled Tetra Pak (Thermo-Stiffened Polymeric Aluminum Composite). Buildings. 2025; 15(5):813. https://doi.org/10.3390/buildings15050813

Chicago/Turabian StyleNuñez-Moreno, Federico, Daniel M. Ruiz, Sebastián Aristizabal-Vargas, Camilo Gutierrez-Quintero, and Yezid A. Alvarado. 2025. "Seismic Performance of a Full-Scale Moment-Frame Housing System Constructed with Recycled Tetra Pak (Thermo-Stiffened Polymeric Aluminum Composite)" Buildings 15, no. 5: 813. https://doi.org/10.3390/buildings15050813

APA StyleNuñez-Moreno, F., Ruiz, D. M., Aristizabal-Vargas, S., Gutierrez-Quintero, C., & Alvarado, Y. A. (2025). Seismic Performance of a Full-Scale Moment-Frame Housing System Constructed with Recycled Tetra Pak (Thermo-Stiffened Polymeric Aluminum Composite). Buildings, 15(5), 813. https://doi.org/10.3390/buildings15050813