Carbonated Aggregates and Basalt Fiber-Reinforced Polymers: Advancing Sustainable Concrete for Structural Use

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Properties

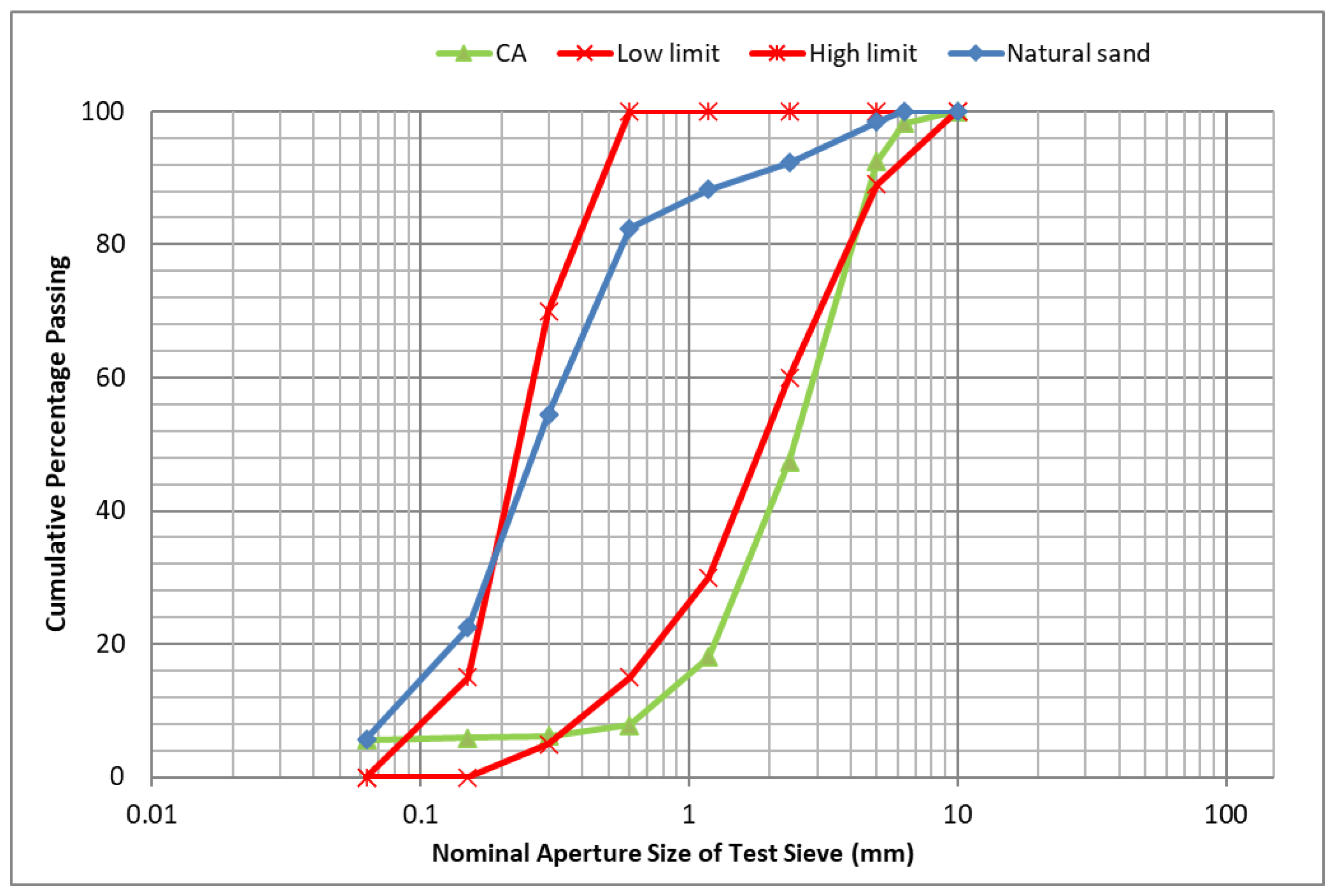

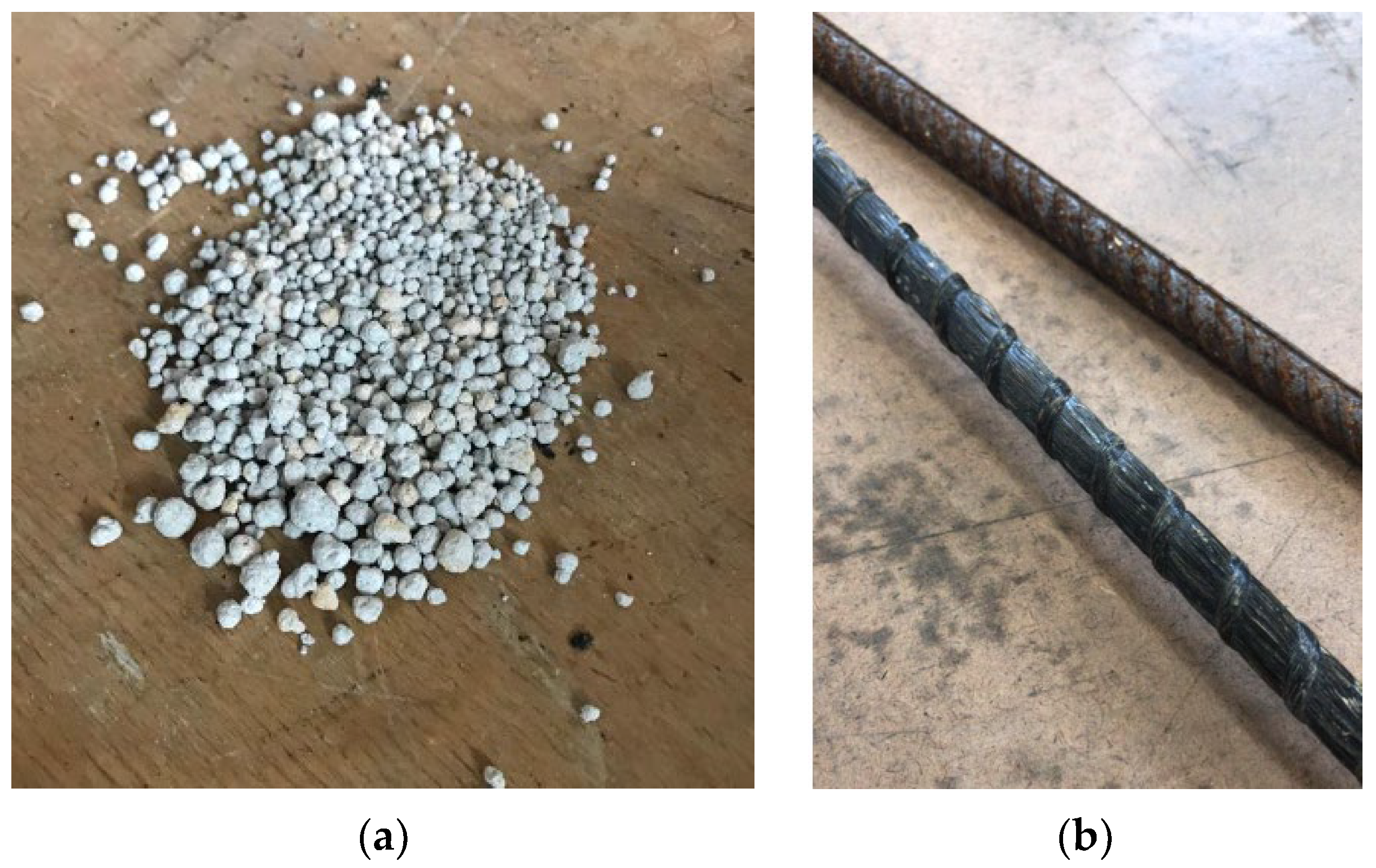

2.1.1. Carbonated Aggregates

2.1.2. Basalt FRP

2.2. Concrete Mix Design

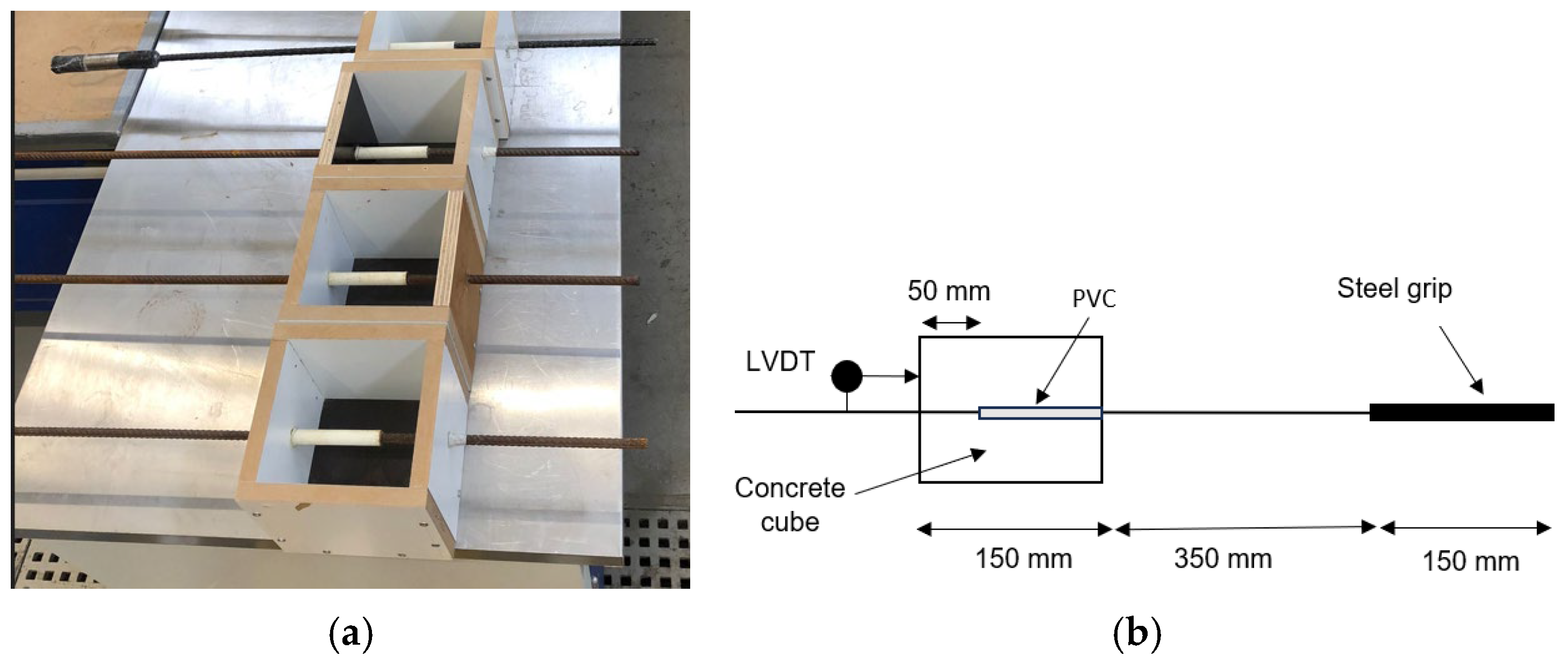

2.3. Pull-Out Tests

2.4. Slab Tests

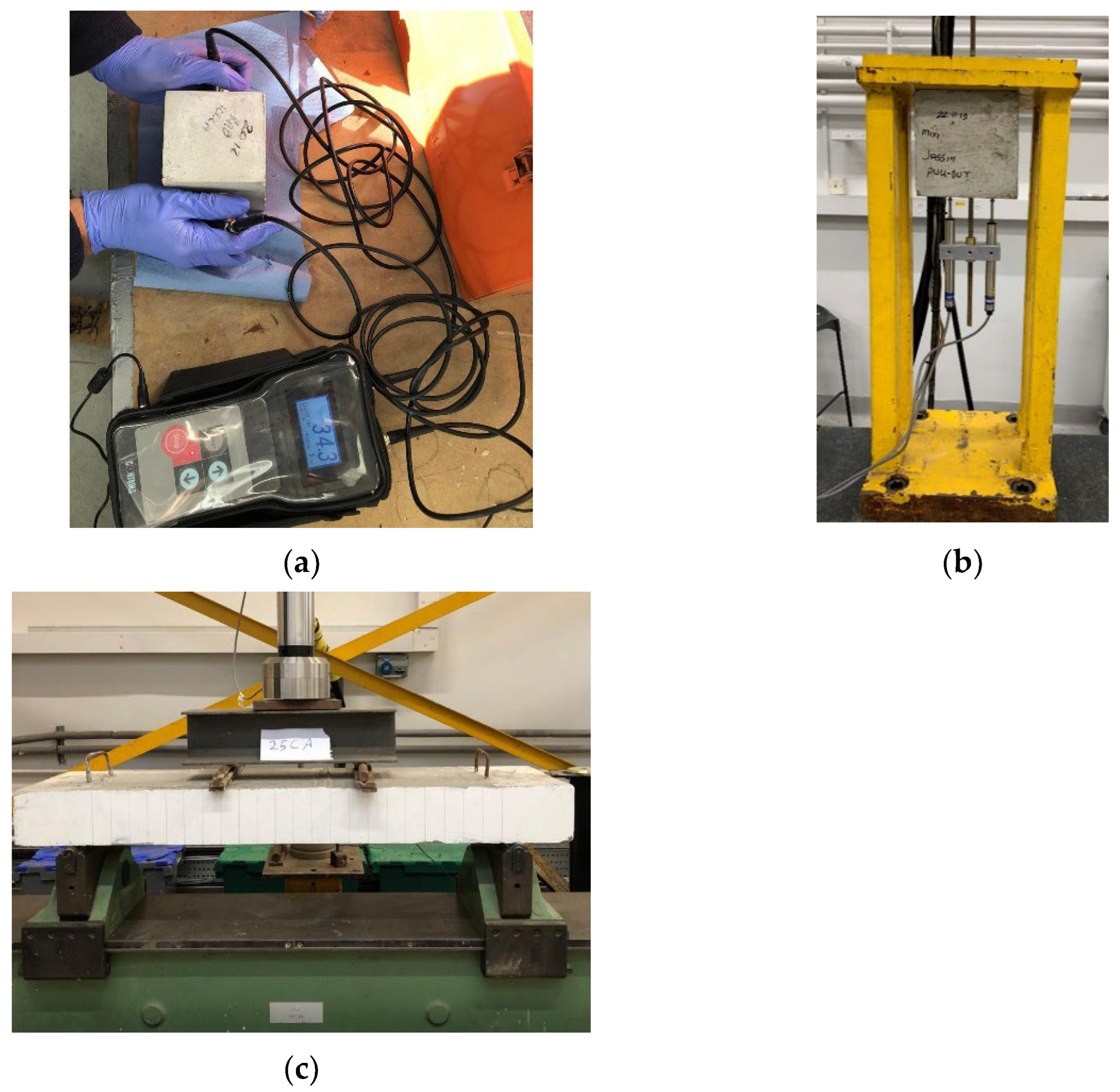

2.5. Instrumentation and Testing Procedure

3. Results and Discussion

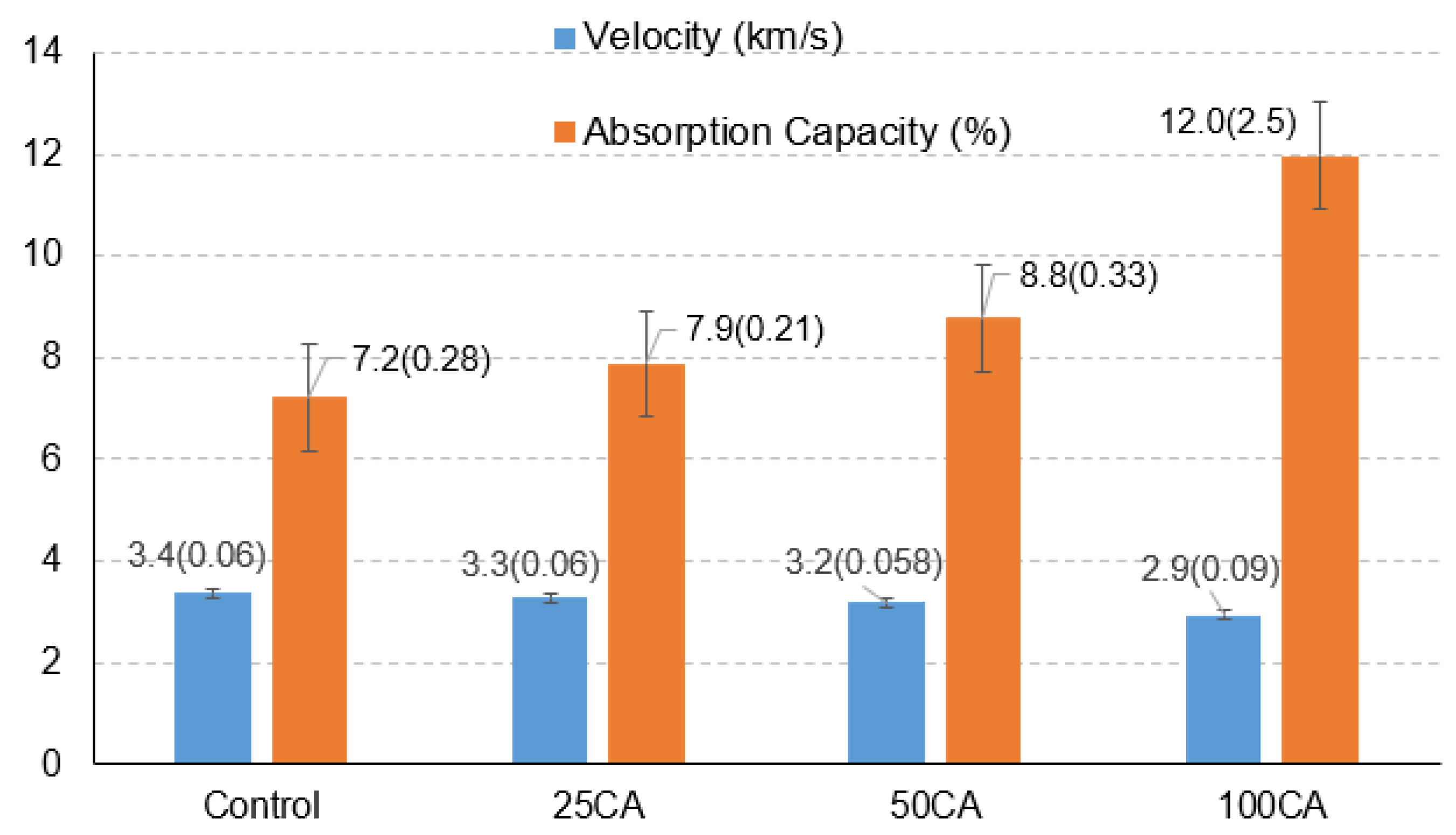

3.1. UPV and Absorption Capacity

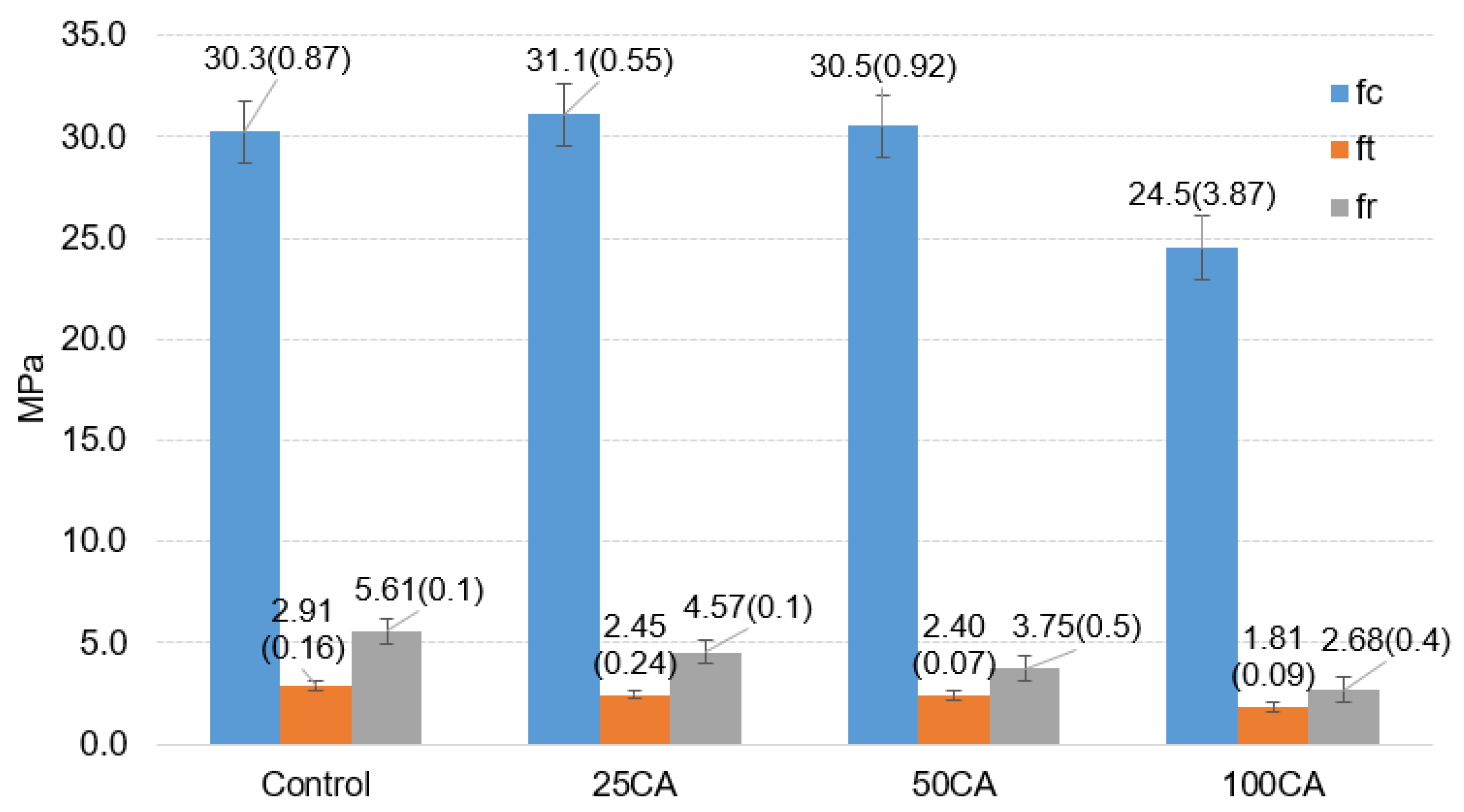

3.2. Mechanical Properties of Concrete

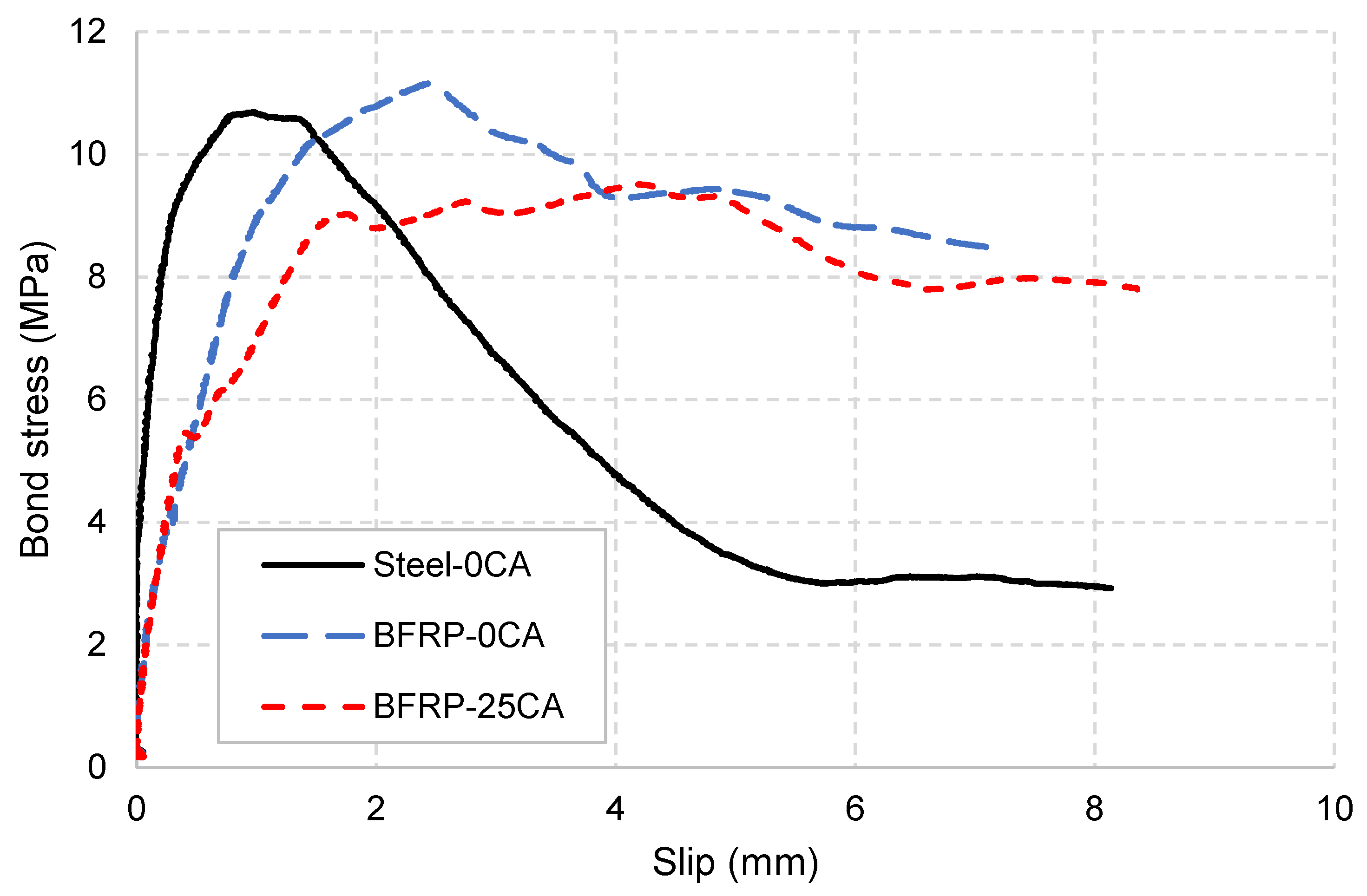

3.3. Pull-Out Tests Results

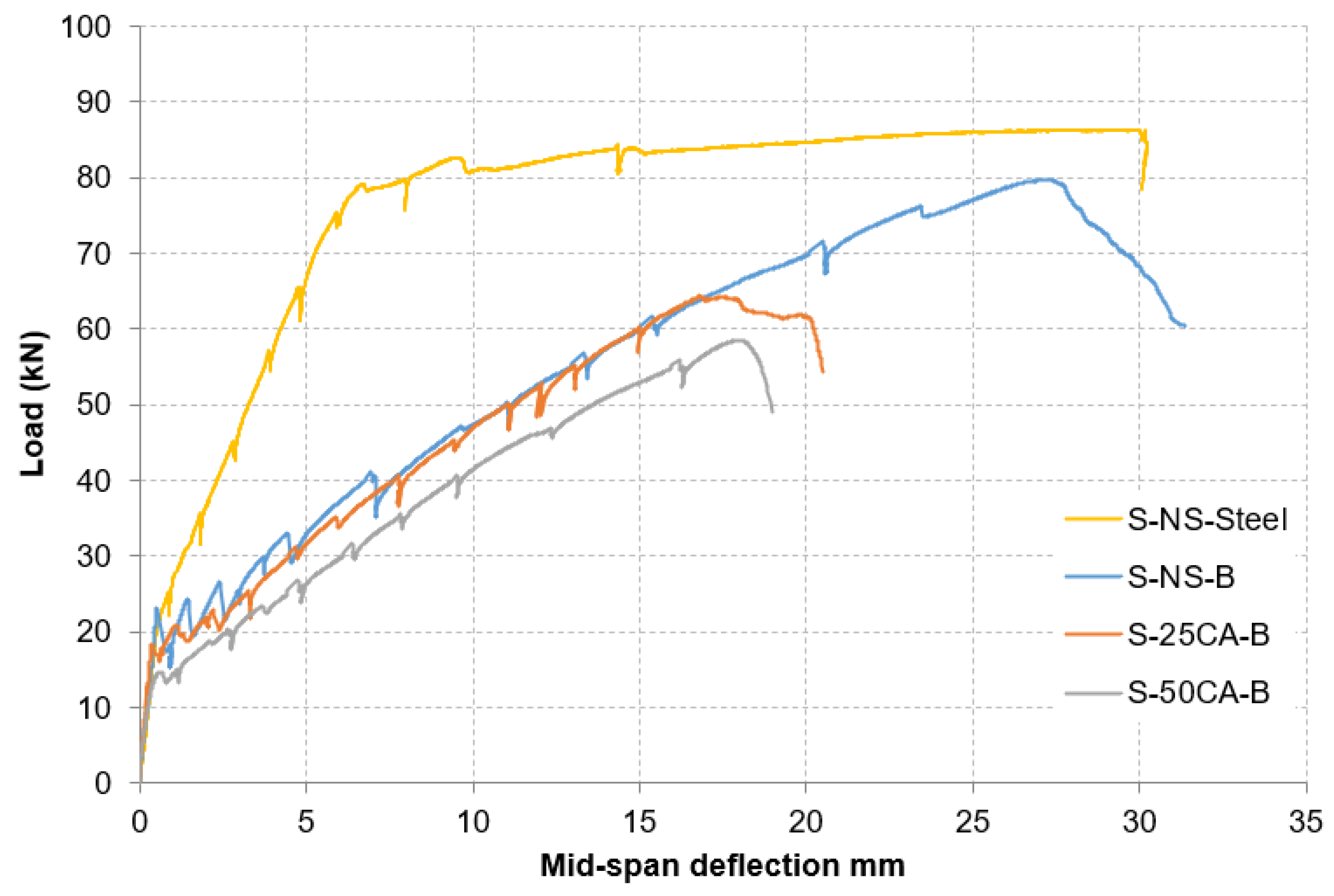

3.4. Slab Tests Results

3.4.1. Load–Deflection Response

3.4.2. Ultimate Load Capacity

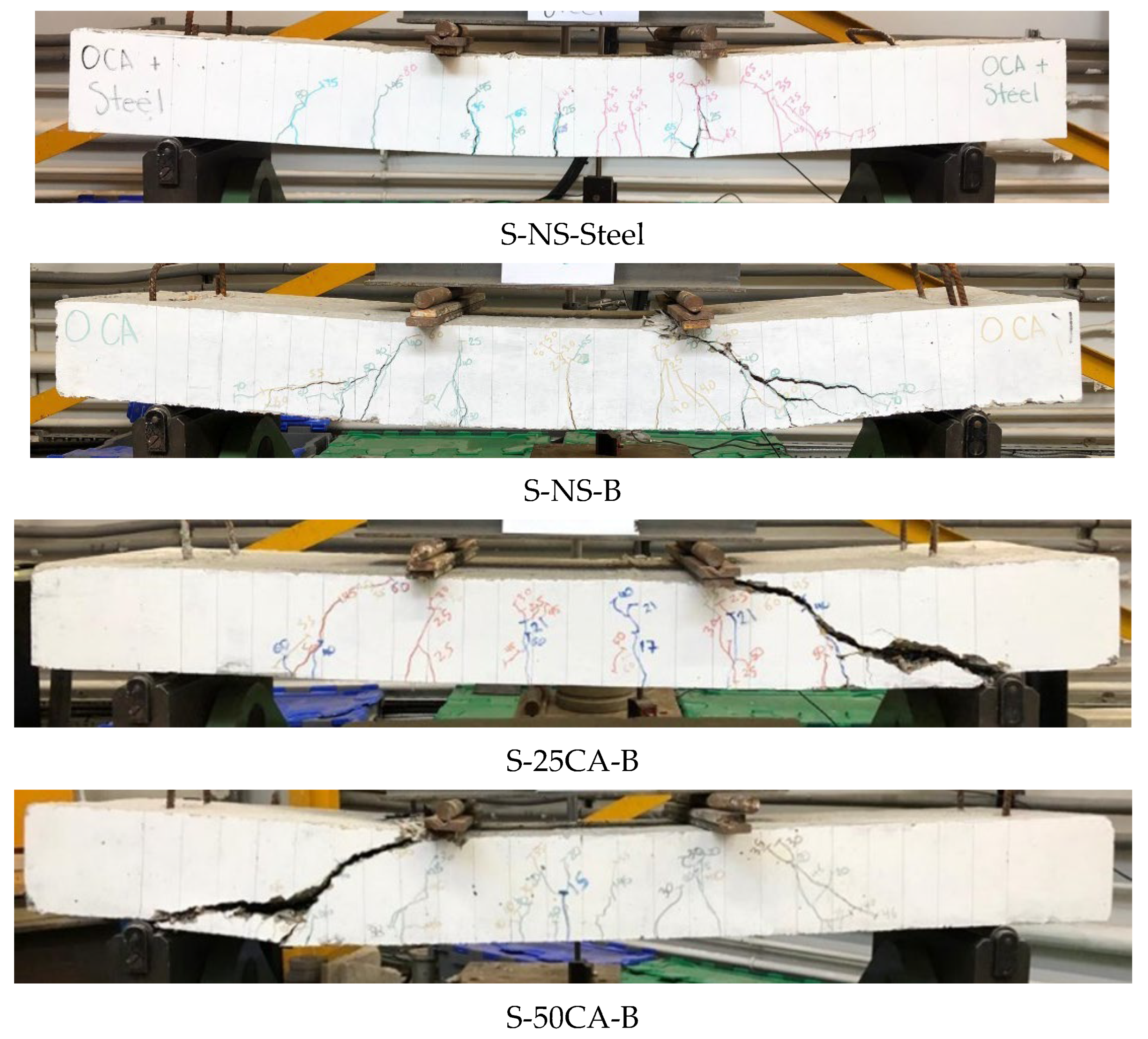

3.4.3. Cracking Behaviour

3.5. Carbon FootPrint Analysis

3.5.1. System Boundary

3.5.2. Inventory Analysis

3.5.3. Impact Analysis

4. Conclusions

- Replacing natural sand (NS) with the CA affected the homogeneity and internal integrity of the concrete mix. This was evidenced by the 4.5% and 13.3% reduction in ultrasonic pulse velocity (UPV) for concrete samples containing 50% CA and 100% CA since the CA is lighter and slightly more porous than the NA.

- Compressive strength increased by 3% at 25% CA and 1% at 50% CA. As CA replacement levels increased, the splitting tensile strength was 14%, 18%, and 38%, and the flexural strength was 19%, 33%, and 52% lower than that for the control mix at 25%, 50%, and 100% replacement, respectively.

- The stiffness of the steel-reinforced slabs (S-NA-Steel) was much higher than that of the BFRP-reinforced slabs due to the much lower elastic module of BFRP. The deflection at the ultimate load for the slab BFRP slab was four times lower than that for the steel RC slab.

- The inclusion of the CA in concrete had a slight effect on the overall performance of the slabs reinforced with the BFRP. All BFRP one-spanning slabs exhibited linear behavior until the ultimate load capacity with the sudden failure of the slabs. However, the ultimate load capacity was notably influenced.

- Both BFRP and steel reinforcement exhibit similar ultimate bond capacities, with a slight decrease in BFRP’s capacity with concrete mix with 25% CA compared control mix, suggesting a compromised bond behavior, especially with higher CA content.

- The incorporation of BFRP and CA can have an impact on the carbon savings of concrete slabs, which incorporate them. For example, using 50% CA in concrete reinforced with Basalt FRP reduced the embodied carbon of the slab by 9.7%, in comparison with the steel RC slab.

- Further studies are needed to investigate the effect of CA inclusion on the compressive stress–strain behaviour, ultimate strain, workability, and the elastic modulus of concrete. Additionally, the strength development of concrete containing CA at different ages (7, 14, and 56 days) requires further investigation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kong, D.; Lei, T.; Zheng, J.; Ma, C.; Jiang, J. Strengthening of the ITZ in recycled aggregate concrete. In Proceedings of the Xi’an International Conference on Architecture and Technology, Proceedings–Architecture in Harmony, Xi’an, China, 23–25 September 2006; pp. 614–617. [Google Scholar]

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Shamass, R.; Rispoli, O.; Limbachiya, V.; Kovacs, R. Mechanical and GWP assessment of concrete using Blast Furnace Slag, Silica Fume and recycled aggregate. Case Stud. Constr. Mater. 2023, 18, e02164. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A comprehensive review on recycled aggregate and recycled aggregate concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Upshaw, M.; Cai, C.S. Critical review of recycled aggregate concrete properties, improvements, and numerical models. J. Mater. Civ. Eng. 2020, 32, 03120005. [Google Scholar] [CrossRef]

- Folino, P.; Xargay, H. Recycled aggregate concrete–Mechanical behavior under uniaxial and triaxial compression. Constr. Build. Mater. 2014, 56, 21–31. [Google Scholar] [CrossRef]

- Tahar, Z.; Ngo, T.; Kadri, E.H.; Bouvet, A.; Debieb, F.; Aggoun, S. Effect of cement and admixture on the utilization of recycled aggregates in concrete. Constr. Build. Mater. 2017, 149, 91–102. [Google Scholar] [CrossRef]

- Thomas, J.; Thaickavil, N.N.; Wilson, P.M. Strength and durability of concrete containing recycled concrete aggregates. J. Build. Eng. 2018, 19, 349–365. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of recycled concrete aggregate and their influence in new concrete production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Singh, R.; Nayak, D.; Pandey, A.; Kumar, R.; Kumar, V. Effects of recycled fine aggregates on properties of concrete containing natural or recycled coarse aggregates: A comparative study. J. Build. Eng. 2022, 45, 103442. [Google Scholar] [CrossRef]

- Shima, H. New technology for recovering high quality aggregate from demolished concrete. In Proceedings of the 5th International Symposium on East Asian Recycling Technology, Tsukuba, Japan, 15–17 June 1999. [Google Scholar]

- Li, J.; Xiao, H.; Zhou, Y. Influence of coating recycled aggregate surface with pozzolanic powder on properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 1287–1291. [Google Scholar] [CrossRef]

- Silva, R.V.; Neves, R.; De Brito, J.; Dhir, R.K. Carbonation behaviour of recycled aggregate concrete. Cem. Concr. Compos. 2015, 62, 22–32. [Google Scholar] [CrossRef]

- Lu, Z.; Tan, Q.; Lin, J.; Wang, D. Properties investigation of recycled aggregates and concrete modified by accelerated carbonation through increased temperature. Constr. Build. Mater. 2022, 341, 127813. [Google Scholar] [CrossRef]

- Tang, Y.; Xiao, J.; Zhang, H.; Wang, D.; Zhang, M.; Zhang, J. Effect of accelerated carbonation of fully recycled aggregates on fracture behaviour of concrete. Cem. Concr. Compos. 2024, 148, 105442. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, M.; Wang, Y.; Zhang, M. Roles of carbonated recycled fines and aggregates in hydration, microstructure and mechanical properties of concrete: A critical review. Cem. Concr. Compos. 2023, 138, 104994. [Google Scholar] [CrossRef]

- Zhan, B.J.; Xuan, D.X.; Poon, C.S. Enhancement of recycled aggregate properties by accelerated CO2 curing coupled with limewater soaking process. Cem. Concr. Compos. 2018, 89, 230–237. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, H.; Tang, Y.; Deng, Q.; Wang, D.; Poon, C.S. Fully utilizing carbonated recycled aggregates in concrete: Strength, drying shrinkage and carbon emissions analysis. J. Clean. Prod. 2022, 377, 134520. [Google Scholar] [CrossRef]

- Cramer, S.D.; Covino Jr, B.S.; Bullard, S.J.; Holcomb, G.R.; Russell, J.H.; Nelson, F.J.; Laylor, H.M.; Soltesz, S.M. Corrosion prevention and remediation strategies for reinforced concrete coastal bridges. Cem. Concr. Compos. 2002, 24, 101–117. [Google Scholar] [CrossRef]

- Chemrouk, M. The deteriorations of reinforced concrete and the option of high performances reinforced concrete. Procedia Eng. 2015, 125, 713–724. [Google Scholar] [CrossRef]

- Hu, J.Y.; Zhang, S.S.; Chen, E.; Li, W.G. A review on corrosion detection and protection of existing reinforced concrete (RC) structures. Constr. Build. Mater. 2022, 325, 126718. [Google Scholar] [CrossRef]

- Soltani, M.; Safiey, A.; Brennan, A. A state-of-the-art review of bending and shear behaviors of corrosion-damaged reinforced concrete beams. Struct. J. 2019, 116. [Google Scholar] [CrossRef]

- Rodrigues, R.; Gaboreau, S.; Gance, J.; Ignatiadis, I.; Betelu, S. Reinforced concrete structures: A review of corrosion mechanisms and advances in electrical methods for corrosion monitoring. Constr. Build. Mater. 2021, 269, 121240. [Google Scholar] [CrossRef]

- Breysse, D. Deterioration processes in reinforced concrete: An overview. In Non-Destructive Evaluation of Reinforced Concrete Structures; Woodhead Publishing: Sawston, UK, 2010; pp. 28–56. [Google Scholar]

- Naidu Gopu, G.; Joseph, S.A. Corrosion behavior of fiber-reinforced concrete—A review. Fibers 2022, 10, 38. [Google Scholar] [CrossRef]

- Al-Jabari, M. Waterproofing coatings and membranes. In Integral Waterproofing of Concrete Structures: Advanced Protection Technologies of Concrete by Pore Blocking and Lining; Woodhead Publishing: Sawston, UK, 2022; p. 393. [Google Scholar]

- Li, S.; Jiang, J.; Geng, Y.; Hu, J.; Sui, S.; Liu, A.; Hu, M.; Shan, Y.; Liu, Z. Application of silane protective materials in the concrete durability improvement in recent years: A review. Eng. Fail. Anal. 2024, 160, 108140. [Google Scholar] [CrossRef]

- Thissen, P.; Bogner, A.; Dehn, F. Surface treatments on concrete: An overview on organic, inorganic and nano-based coatings and an outlook about surface modification by rare-earth oxides. RSC Sustain. 2024, 2, 2092–2124. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, J. Recent progress and challenges of using smart corrosion inhibitors in reinforced concrete structures. Constr. Build. Mater. 2024, 411, 134595. [Google Scholar] [CrossRef]

- Rabi, M.; Cashell, K.A.; Shamass, R. Flexural analysis and design of stainless steel reinforced concrete beams. Eng. Struct. 2019, 198, 109432. [Google Scholar] [CrossRef]

- Rabi, M.; Cashell, K.A.; Shamass, R. Ultimate behaviour and serviceability analysis of stainless steel reinforced concrete beams. Eng. Struct. 2021, 248, 113259. [Google Scholar] [CrossRef]

- Rabi, M.; Cashell, K.A.; Shamass, R.; Desnerck, P. Bond behaviour of austenitic stainless steel reinforced concrete. Eng. Struct. 2020, 221, 111027. [Google Scholar] [CrossRef]

- Rabi, M.; Shamass, R.; Cashell, K.A. Experimental investigation on the flexural behaviour of stainless steel reinforced concrete beams. Struct. Infrastruct. Eng. 2023, 19, 1847–1859. [Google Scholar] [CrossRef]

- Rabi, M.; Shamass, R.; Cashell, K.A. Description of the constitutive behaviour of stainless steel reinforcement. Case Stud. Constr. Mater. 2024, 20, e03013. [Google Scholar] [CrossRef]

- Khodadadi, N.; Roghani, H.; Harati, E.; Mirdarsoltany, M.; De Caso, F.; Nanni, A. Fiber-reinforced polymer (FRP) in concrete: A comprehensive survey. Constr. Build. Mater. 2024, 432, 136634. [Google Scholar] [CrossRef]

- Harle, S.M. Durability and long-term performance of fiber reinforced polymer (FRP) composites: A review. Structures 2024, 60, 105881. [Google Scholar] [CrossRef]

- Coppola, L.; Beretta, S.; Bignozzi, M.C.; Bolzoni, F.; Brenna, A.; Cabrini, M.; Candamano, S.; Caputo, D.; Carsana, M.; Cioffi, R.; et al. The improvement of durability of reinforced concretes for sustainable structures: A review on different approaches. Materials 2022, 15, 2728. [Google Scholar] [CrossRef] [PubMed]

- Ascione, F.; Maselli, G.; Nesticò, A. Sustainable materials selection in industrial construction: A life-cycle based approach to compare the economic and structural performances of glass fibre reinforced polymer (GFRP) and steel. J. Clean. Prod. 2024, 475, 143641. [Google Scholar] [CrossRef]

- Das, S.C.; Nizam, M. Applications of fiber reinforced polymer composites (FRP) in civil engineering. Int. J. Adv. Struct. Geotech. Eng. 2014, 3, 299–309. [Google Scholar]

- Rabi, M.; Jweihan, Y.S.; Abarkan, I.; Ferreira, F.P.V.; Shamass, R.; Limbachiya, V.; Tsavdaridis, K.D.; Santos, L.F.P. Machine learning-driven web-post buckling resistance prediction for high-strength steel beams with elliptically-based web openings. Results Eng. 2024, 21, 101749. [Google Scholar] [CrossRef]

- Rabi, M.; Abarkan, I.; Shamass, R. Buckling resistance of hot-finished CHS beam-columns using FE modelling and machine learning. Steel Constr. 2024, 17, 93–103. [Google Scholar] [CrossRef]

- Rabi, M.; Ferreira, F.P.V.; Abarkan, I.; Limbachiya, V.; Shamass, R. Prediction of the cross-sectional capacity of cold-formed CHS using numerical modelling and machine learning. Results Eng. 2023, 17, 100902. [Google Scholar] [CrossRef]

- Jain, R.; Lee, L. (Eds.) Fiber Reinforced Polymer (FRP) Composites for Infrastructure Applications: Focusing on Innovation, Technology Implementation and Sustainability; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Mohamed, O.A.; Al Hawat, W.; Keshawarz, M. Durability and mechanical properties of concrete reinforced with basalt fiber-reinforced polymer (BFRP) bars: Towards sustainable infrastructure. Polymers 2021, 13, 1402. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Rangappa, S.M.; Siengchin, S. Basalt fibers: An environmentally acceptable and sustainable green material for polymer composites. Constr. Build. Mater. 2024, 436, 136834. [Google Scholar] [CrossRef]

- Brik, V. Advanced concept concrete using basalt fiber/BF composite rebar reinforcement. IDEA Proj. 2003, 86, 71. [Google Scholar]

- Sim, J.; Park, C. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Pavlović, A.; Donchev, T.; Petkova, D.; Staletović, N. Sustainability of alternative reinforcement for concrete structures: Life cycle assessment of basalt FRP bars. Constr. Build. Mater. 2022, 334, 127424. [Google Scholar] [CrossRef]

- Pedraza, J.; Zimmermann, A.; Tobon, J.; Schomäcker, R.; Rojas, N. On the road to net zero-emission cement: Integrated assessment of mineral carbonation of cement kiln dust. Chem. Eng. J. 2021, 408, 127346. [Google Scholar] [CrossRef]

- Lachemi, M.; Şahmaran, M.; Hossain, K.M.A.; Lotfy, A.; Shehata, M. Properties of controlled low-strength materials incorporating cement kiln dust and slag. Cem. Concr. Compos. 2010, 32, 623–629. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of cement kiln dust (CKD) in cement mortar and concrete—An overview. Resour. Conserv. Recycl. 2006, 48, 315–338. [Google Scholar] [CrossRef]

- Carey, P. Unlocking Circularity for EfW: The Power of Carbonation. Carbon8. 2022. Available online: https://www.carbon8.co.uk (accessed on 30 August 2023).

- BS EN 933-1; Tests for Geometrical Properties of Aggregates: Part 1. Determination of Particle Size Distribution. Sieving Method. British Standards Institution: London, UK, 2021.

- BS 812; Testing of Aggregates Part 2: Method of Determination of Density. British Standards Institution: London, UK, 1995.

- ISO 10406-1:2008; Fibre-Reinforced Polymer (FRP) Reinforcement of Concrete—Test Methods—Part 1: FRP Bars and Grids. International Standard Organization: Geneva, Switzerland, 2008.

- Teychenné, D.C.; Franklin, R.E.; Erntroy, H.C.; Marsh, B.K. Design of Normal Concrete Mixes; HM Stationery Office: London, UK, 1975. [Google Scholar]

- BS EN 12390-4; Testing Hardened Concrete. Compressive Strength. Specification for Testing Machines. British Standards Institution: London, UK, 2019.

- ACI 440.3R-04; Guide Test Methods for Fiber-Reinforced Polymers (FRPs) for Reinforcing or Strengthening Concrete Structures; ACI Com-mittee 440. American Concrete Institute: Farmington Hills, MI, USA, 2004.

- BS EN 12504-4; Testing Concrete—Determination of Ultrasonic Pulse Velocity. British Standards Institution: London, UK, 2004.

- Räsänen, A.; Huuhka, S.; Pakkala, T.; Lahdensivu, J. Methods for evaluating the technical performance of reclaimed bricks. Case Stud. Constr. Mater. 2022, 17, e01504. [Google Scholar] [CrossRef]

- Raza, S.S.; Fahad, M.; Ali, B.; Amir, M.T.; Alashker, Y.; Elhag, A.B. Enhancing the Performance of Recycled Aggregate Concrete Using Micro-Carbon Fiber and Secondary Binding Material. Sustainability 2022, 14, 14613. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, J.; Wang, Z.; Zhao, T.; Wang, Z. A review of the interfacial transition zones in concrete: Identification, physical characteristics, and mechanical properties. Eng. Fract. Mech. 2024, 300, 109979. [Google Scholar] [CrossRef]

- Prokopski, G.; Halbiniak, J. Interfacial transition zone in cementitious materials. Cem. Concr. Res. 2000, 30, 579–583. [Google Scholar] [CrossRef]

- Ramagiri, K.K.; Chintha, R.; Bandlamudi, R.K.; Kara De Maeijer, P.; Kar, A. Cradle-to-gate life cycle and economic assessment of sustainable concrete mixes—Alkali-activated concrete (Aac) and bacterial concrete (bc). Infrastructures 2021, 6, 104. [Google Scholar] [CrossRef]

- Antonietta Aiello, M.; Leone, M.; Pecce, M. Bond performances of FRP rebars-reinforced concrete. J. Mater. Civ. Eng. 2007, 19, 205–213. [Google Scholar] [CrossRef]

- Baena, M.; Torres, L.; Turon, A.; Barris, C. Experimental study of bond behaviour between concrete and FRP bars using a pull-out test. Compos. Part B Eng. 2009, 40, 784–797. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Z.; Zhang, C.; Wang, X.; Li, J.; Liang, Y.; Chu, S. Bond behavior of BFRP bars with basalt-fiber reinforced cement-based composite materials. Struct. Concr. 2021, 22, 154–167. [Google Scholar] [CrossRef]

- Nepomuceno, E.; Sena-Cruz, J.; Correia, L.; D’Antino, T. Review on the bond behavior and durability of FRP bars to concrete. Constr. Build. Mater. 2021, 287, 123042. [Google Scholar] [CrossRef]

- Issa, M.A.; Ovitigala, T.; Ibrahim, M. Shear behavior of basalt fiber reinforced concrete beams with and without basalt FRP stirrups. J. Compos. Constr. 2016, 20, 04015083. [Google Scholar] [CrossRef]

- Al-Zu’bi, M.; Shamass, R.; Ferreira, F.P.V. Mechanical performance and life cycle assessment of BFRP-reinforced AAC slabs strengthened with basalt macro-fibers. Constr. Build. Mater. 2025, 461, 139917. [Google Scholar] [CrossRef]

- Shamass, R.; Cashell, K.A. Experimental investigation into the flexural behaviour of basalt FRP reinforced concrete members. Eng. Struct. 2020, 220, 110950. [Google Scholar] [CrossRef]

- Gibbon, O.P.; Orr, J.J.; Archer-Jones, C.; Arnold, W.; Green, D. How to Calculate Embodied Carbon; The Institution of Structural Engineers: London, UK, 2022. [Google Scholar]

- Jayasinghe, A.; Orr, J.; Ibell, T.; Boshoff, W.P. Minimising embodied carbon in reinforced concrete beams. Eng. Struct. 2021, 242, 112590. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C. Inventory of Carbon & Energy: ICE (Vol. 5); Sustainable Energy Research Team, Department of Mechanical Engineering, University of Bath: Bath, UK, 2008. [Google Scholar]

| Natural Coarse Aggregates | Natural Sand | CA | |

|---|---|---|---|

| Saturated surface dry density SSD (kg/m3) | 2413 | 2416 | 1980 |

| Specific gravity | 2.4 | 2.4 | 1.98 |

| Water absorption rate % | 1.7 | 4.44 | 16.4 |

| Mix | Cement (kg/m3) | Natural Sand (kg/m3) | NCA (kg/m3) | CA (kg/m3) | Free Water (kg/m3) | Additional Water for CA SSD (kg/m3) |

|---|---|---|---|---|---|---|

| Control | 463 | 700 | 927 | 0 | 250 | 0 |

| 25 CA | 463 | 525 | 927 | 144 | 250 | 5 |

| 50 CA | 463 | 350 | 927 | 289 | 250 | 10 |

| 100 CA | 463 | 0 | 927 | 578 | 250 | 20 |

| Specimen | Mean Measured Compressive Strength, fc (MPa) | Failure Mode | (MPa) | Slip at Ultimate Bond Strength (mm) | ||

|---|---|---|---|---|---|---|

| Mean Value | Standard Deviation | Mean Value | Standard Deviation | |||

| Steel-0 CA | 30.3 | Pull-out | 10.3 | 0.44 | 1.01 | 0.05 |

| BFRP-0 CA | 30.3 | Pull-out | 10.7 | 0.47 | 2.94 | 0.59 |

| BFRP-25 CA | 31.1 | Pull-out | 9.44 | 0.99 | 3.51 | 0.74 |

| Slab | fc (Mpa) | Pcr (kN) | Pu (kN) |

|---|---|---|---|

| S-NS-B | 36.3 (0.7) | 23 | 80 |

| S-25CA-B | 31.6 (0.41) | 17 | 64.4 |

| S-50CA-B | 34.0 (0.62) | 15 | 58.5 |

| S-NS-Steel | 36.7 (0.52) | 25 | 83.3 |

| Material | 10 mm BFRP Rebar | 10 mm Steel Rebar | Carbonated Aggregates | Natural Sand | Coarse Aggregate | Water | Cement |

|---|---|---|---|---|---|---|---|

| A1–A3 | 2.6 | 1.2 | −0.0918 | 0.0048 | 0.005 | 0.001 | 0.73 |

| Ref. | EPD * | [73] | EPD | [74] | [74] | [74] | [74] |

| Slab | Material | Quantity (kg) | A1–A3 | Contribution to Emission (%) |

|---|---|---|---|---|

| Steel-reinforced OPC slab | 10 mm steel bars | 3.14 | 3.70 | 4.2 |

| Cement | 115.75 | 84.5 | 93.5 | |

| Sand | 175 | 0.84 | 0.9 | |

| Aggregate | 231.75 | 1.16 | 1.3 | |

| Water | 62.5 | 0.063 | 0.06 | |

| Total | 858 | 90.3 | ||

| BFRP-reinforced OPC slab | 10 mm BFRP bars | 0.785 | 2.00 | 2.3 |

| Cement | 115.75 | 84.50 | 95.4 | |

| Sand | 175 | 0.84 | 0.9 | |

| Aggregate | 231.75 | 1.16 | 1.3 | |

| Water | 62.5 | 0.06 | 0.1 | |

| Total | 858 | 88.6 | ||

| BFRP-reinforced OPC slab with 25% CA | 10 mm BFRP bars | 0.785 | 2.04 | 2.4 |

| Cement | 115.75 | 84.50 | 99.3 | |

| Sand | 131.25 | 0.63 | 0.7 | |

| Aggregate | 231.75 | 1.16 | 1.4 | |

| Water | 62.5 | 0.06 | 0.1 | |

| CA | 36 | −3.30 | −3.9 | |

| Total | 577.25 | 85.1 | ||

| BFRP-reinforced OPC slab with 50% CA | 10 mm BFRP bars | 0.785 | 2.04 | 2.5 |

| Cement | 115.75 | 84.50 | 103.6 | |

| Sand | 87.5 | 0.42 | 0.5 | |

| Aggregate | 231.75 | 1.16 | 1.4 | |

| Water | 62.5 | 0.06 | 0.1 | |

| CA | 72.25 | −6.63 | −8.1 | |

| Total | 569.8 | 81.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shamass, R.; Limbachiya, V.; Ajibade, O.; Rabi, M.; Lopez, H.U.L.; Zhou, X. Carbonated Aggregates and Basalt Fiber-Reinforced Polymers: Advancing Sustainable Concrete for Structural Use. Buildings 2025, 15, 775. https://doi.org/10.3390/buildings15050775

Shamass R, Limbachiya V, Ajibade O, Rabi M, Lopez HUL, Zhou X. Carbonated Aggregates and Basalt Fiber-Reinforced Polymers: Advancing Sustainable Concrete for Structural Use. Buildings. 2025; 15(5):775. https://doi.org/10.3390/buildings15050775

Chicago/Turabian StyleShamass, Rabee, Vireen Limbachiya, Oluwatoyin Ajibade, Musab Rabi, Hector Ulises Levatti Lopez, and Xiangming Zhou. 2025. "Carbonated Aggregates and Basalt Fiber-Reinforced Polymers: Advancing Sustainable Concrete for Structural Use" Buildings 15, no. 5: 775. https://doi.org/10.3390/buildings15050775

APA StyleShamass, R., Limbachiya, V., Ajibade, O., Rabi, M., Lopez, H. U. L., & Zhou, X. (2025). Carbonated Aggregates and Basalt Fiber-Reinforced Polymers: Advancing Sustainable Concrete for Structural Use. Buildings, 15(5), 775. https://doi.org/10.3390/buildings15050775