The influence of pavement design extends far beyond the initial construction phase, affecting not only structural longevity but also the operational efficiency of vehicles using the roadway. Pavement performance—defined by parameters such as fatigue resistance, rutting behaviour, and stiffness—directly impacts surface roughness and deformation, which in turn influence fuel consumption, maintenance, and deterioration of vehicle parts that need to be produced. As a result, the energy required for vehicle operation becomes an essential component of total life-cycle energy demand.

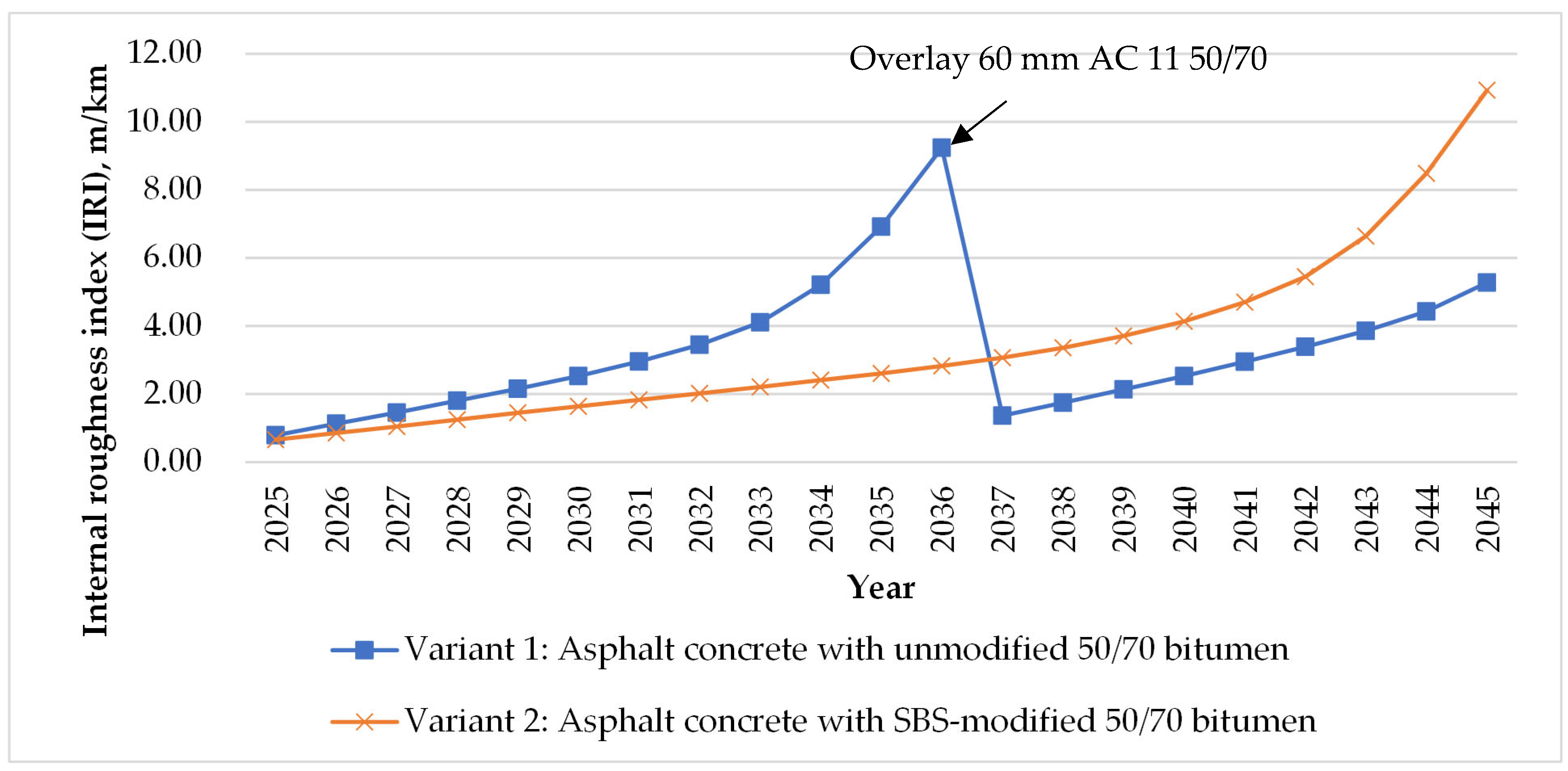

This chapter evaluates the impact of binder modification on pavement performance and the associated energy consumption of the vehicle fleet. The performance of both evaluated variants is assessed over a 20-year analysis period (2025–2045), based on mechanistic design and performance prediction using the HDM-4 framework. Both pavement variants are subjected to identical traffic and environmental conditions. The average annual daily traffic (AADT) is 6894 vehicles, with a composition of 4167 passenger cars and 2182 heavy articulated trucks. The remaining vehicles include vans, buses, and medium commercial vehicles. A compound annual traffic growth rate of 1.5% was applied to passenger cars and 1.0% to the remaining vehicle classes, based on regional forecasts. The cumulative traffic loading was converted to equivalent standard axle loads (ESALs) for the bearing capacity evaluation.

3.2.3. Calculation Principles for Vehicle Operational Energy Consumption

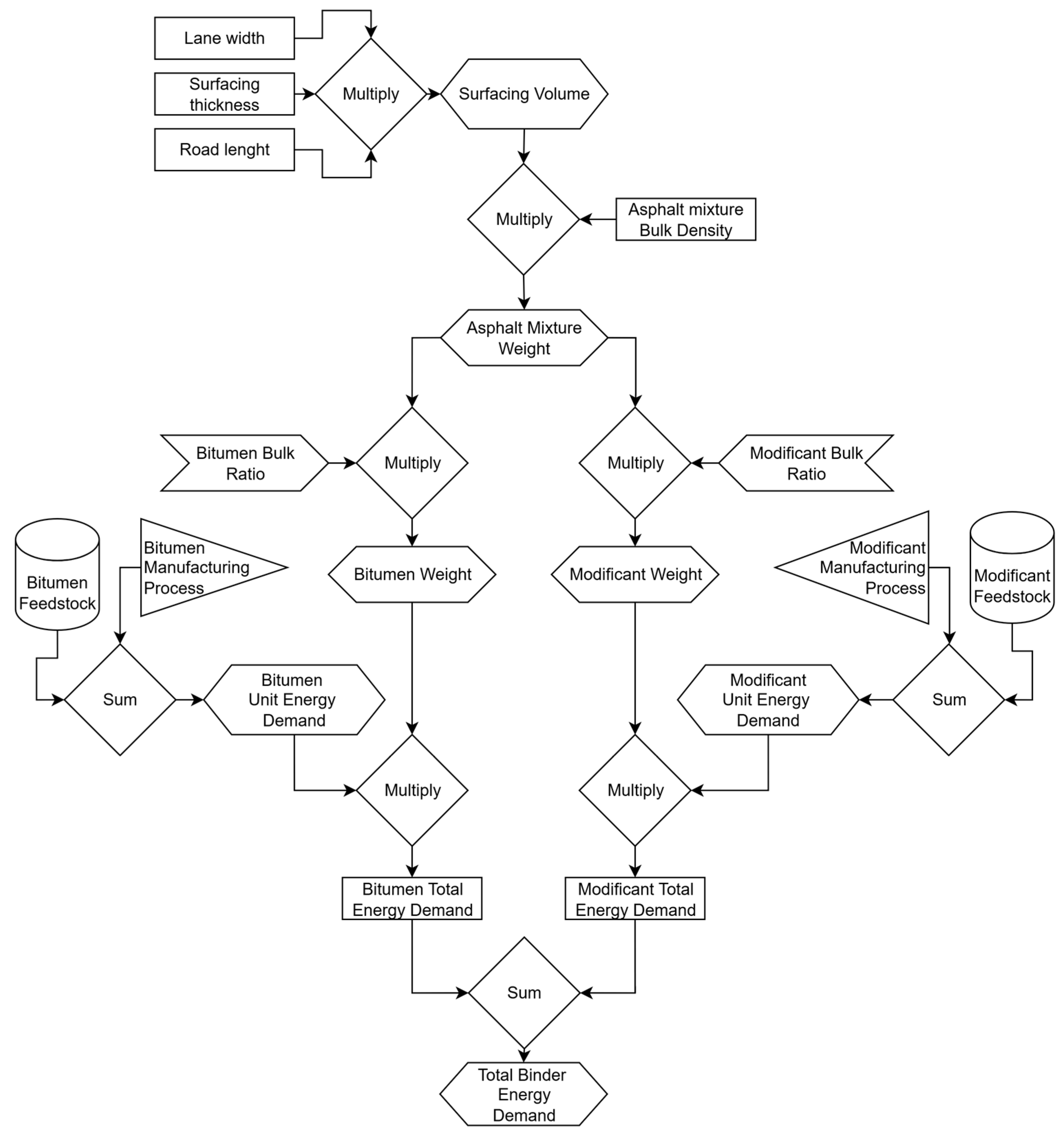

The energy consumed by vehicles during operation constitutes a major component of total life-cycle energy demand for road infrastructure. Vehicle propulsion is driven by a net force that overcomes resistive forces such as rolling resistance, air drag, gradient resistance, and inertial forces. While the propulsion force acts at the tire–pavement interface, its source lies in the combustion of fuel within the engine.

Each fuel type possesses a specific calorific value, known as the energy content of propulsion fuel (ECPF), expressed in megajoules per liter (MJ/L). These values may vary depending on fuel formulation, blending components, and octane rating; however, typical values are well-established and are presented in

Table 10. The values in

Table 10 and

Table 11 represent widely used parameters for fuel properties and vehicle fleet composition, which are generally accessible from national statistics or technical handbooks. Since such parameters can differ depending on regional fleet characteristics and energy supply structures, researchers applying this methodology are encouraged to source the most context-appropriate data available in their country. In this study, the presented values were used to calculate operational energy demand in accordance with Equations (2)–(6).

Importantly, the energy content of fuel reflects only the energy stored in the final delivered product. The fuel production process itself—comprising extraction, refining, blending, and distribution—also requires substantial energy input. These upstream energy demands are expressed through a fuel-cycle energy use factor (FCEU), representing the energy required to produce one unit of fuel energy. The complete fuel-cycle energy demand is computed as the sum of the operational fuel energy and the upstream production energy, and representative values are listed in

Table 11.

Thus, the total operational energy consumption per kilometer, which accounts for both direct combustion energy and fuel-cycle losses, is calculated as follows:

where

EOTk is operation energy consumption for vehicle type k (MJ/km);

FCTk is fuel consumption during trip for vehicle type

k (L/km);

ECPF is energy content of propulsion fuel (MJ/L); and

FCEU is fuel-cycle energy use factor (MJ/MJ of delivered fuel).

In addition to fuel, vehicles powered by internal combustion engines consume lubricating oil, which contributes to operational energy use. Oil is either gradually consumed due to mechanical operation or replaced at regular intervals due to contamination. Oil consumption during operation is typically modeled as a function of fuel consumption.

Oil replacement due to contamination is distance-based, often linked to manufacturer maintenance schedules. As with fuel, lubricating oil has a defined energy content, and its production also requires energy input. The standard value for the energy content of lubricating oil, including its production energy, is approximately 47.7 MJ per liter [

39].

The lubricating oil-related energy consumption per vehicle type is calculated as follows:

where

EOILk is energy consumption due to lubricating oil for vehicle type

k (MJ);

OCTk is lubricating oil consumption (liters); and

ECLO is energy content of lubricating oil (MJ/L), typically 47.7 MJ/L [

39].

Vehicle tires suffer material loss during the operation of the vehicle due to friction from circumferential, lateral, and normal forces acting on the wheel. The rate of tread wear is usually expressed as a consumption of a new tire equivalent. The energy content of a tire is usually 32 MJ/kg of tire material [

39]. The following Equation (4) is used to calculate energy consumption due to tire wear:

where

ETYRk is tire energy consumption of vehicle k (MJ/km),

TCk is number of equivalent new tires consumed per km,

ECT is energy content of a tire, and

TWk is tire weight of vehicle type

k (kg per tire).

Spare parts and associated labour are closely related to vehicle operation. Vehicles sustain damage to components such as transmission, suspension, brake pads, and discs, and many others. The requirements for these parts depend mostly on vehicle age (in kilometers) and pavement surface, i.e., ride quality. Acceleration noise (acceleration and deceleration frequency and intensity) and road alignment also play a part in the consumption of spare parts. Spare parts consumption is expressed as a fraction of the new vehicle price. This fraction can be converted by a 1:1 ratio from energy demand for spare parts to energy demand for the construction of a new car. The following Equation (5) is used to calculate energy demand for spare parts and Equation (6) for production of a new car:

where

ESPk is energy for spare parts consumption of vehicle k (MJ/km),

SPCk is spare part consumption as a proportion of new vehicle price, and

EVPk is vehicle production energy use (MJ/km).

where

ENVPRODk is total energy used in the production of vehicle type k, and

PVSLk is predicted vehicle service life of vehicle type k (km).

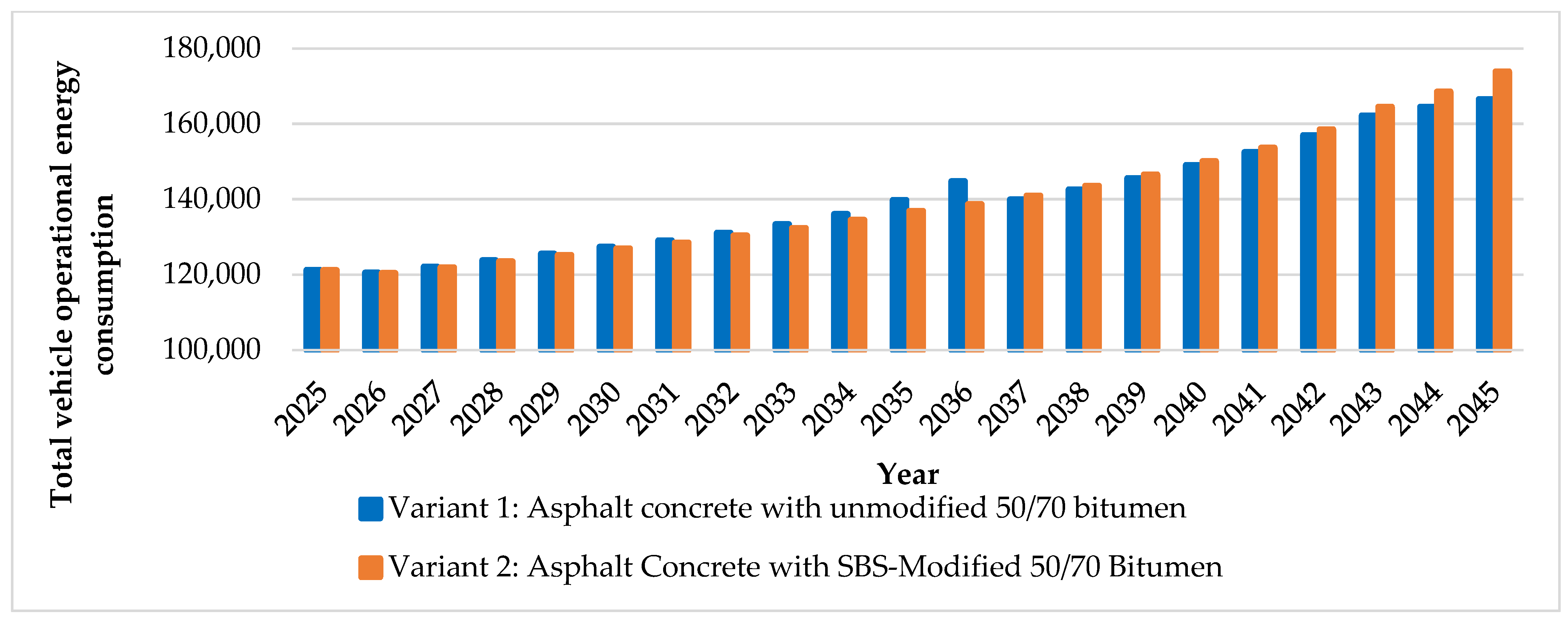

Figure 6 presents the annual total operational energy consumption of the vehicle fleet for both pavement variants over the 20-year analysis period (2025–2045). For consistency and to avoid speculative assumptions, present-day fleet energy consumption values were applied uniformly across the analysis horizon, analogous to the use of fixed prices in life-cycle cost analysis (LCCA).

The results clearly reflect the dynamic relationship between pavement performance and energy demand. As pavement surface condition deteriorates—most notably through increasing roughness and deformation—vehicle rolling resistance and fuel consumption rise accordingly, leading to higher operational energy use. This trend is particularly evident in Variant 1, where the progressive deterioration of the unmodified pavement culminates in a marked increase in energy consumption prior to rehabilitation in 2037. Following the overlay intervention, pavement roughness is restored to near-initial levels, resulting in an immediate and observable reduction in vehicle energy demand. In contrast, Variant 2, which incorporates the SBS-modified binder, maintains lower operational energy consumption during the initial years due to its superior fatigue resistance and slower deterioration. However, in the later years of the analysis period—particularly after 2037—its energy consumption exceeds that of Variant 1, which benefits from restored pavement condition following rehabilitation.

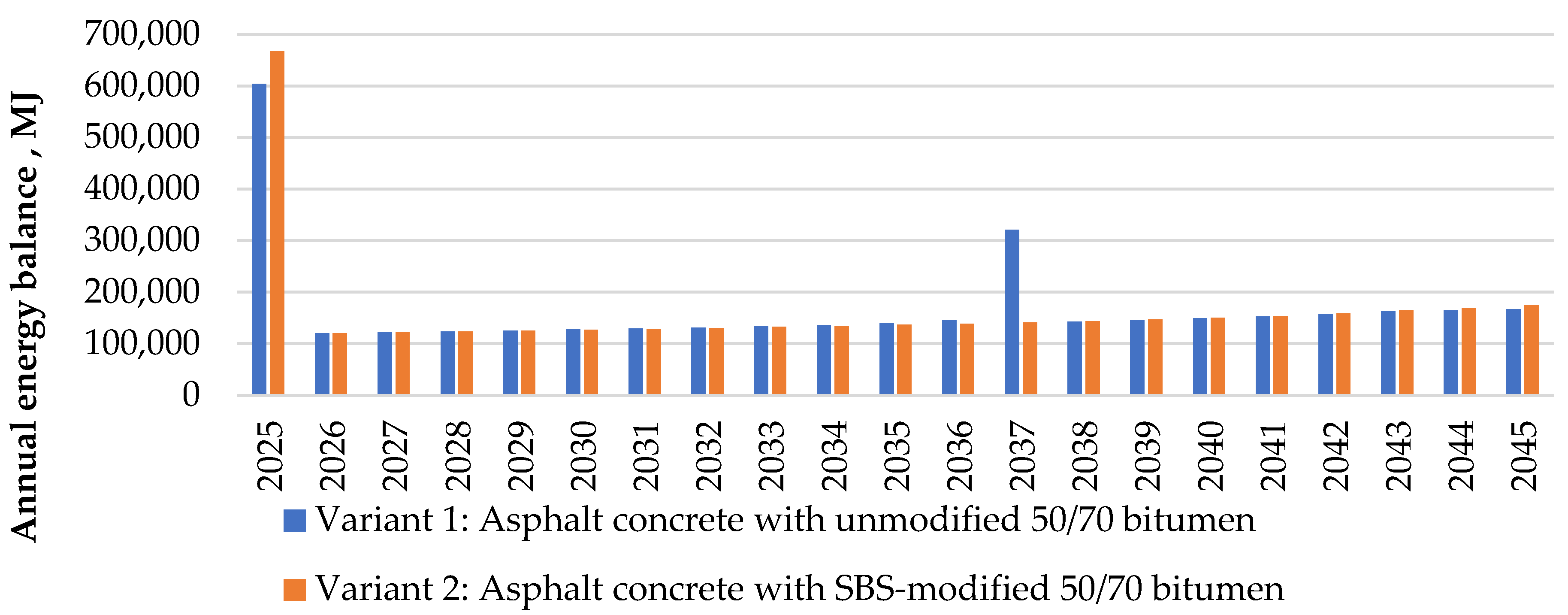

To synthesize the comparative findings,

Table 12 and

Figure 7 present the annual energy demand for each variant, segmented into initial construction (binder-related energy), operational energy (vehicle fleet consumption), and—where applicable—rehabilitation energy. For Variant 1, the energy demand includes both the binder energy in the original pavement layer (482,171.44 MJ in the year of its construction, 2025) and the binder energy associated with the 60 mm asphalt overlay applied during rehabilitation in 2037 (180,809.90 MJ). Variant 2 includes only the initial binder energy (546,168.74 MJ in the year of its construction, 2025), as no rehabilitation is required within the analysis horizon.

The columns Vehicle Fleet Operational Energy Consumption represent the annual energy requirements of the traffic stream for both variants. These values were calculated using Equations (2)–(6) for all vehicle classes, which remain identical in both scenarios. Therefore, the only factor influencing the differences in operational energy consumption between Variant 1 and Variant 2 is the progression of pavement condition, not traffic demand.

The column Annual Energy Balance Difference is the net energy difference between Variant 1 and Variant 2 for each year. The column Cumulative Energy Balance represents the running total of these annual differences over the entire analysis period.

The results demonstrate that although Variant 2 begins with a higher construction-phase energy input due to the energy-intensive SBS polymer (approximately 13.3% higher than Variant 1), it consistently offers lower operational energy consumption in the early and middle years. After 2037, following the rehabilitation of Variant 1, this trend reverses; however, the additional operational energy demand in Variant 2 does not outweigh the energy demand of the rehabilitation works required in Variant 1.

By the end of the evaluation period in 2045, the Cumulative Energy Balance reaches +110,671.75 MJ, indicating that the SBS-modified pavement resulted in a net reduction of over 110 GJ in life-cycle energy consumption when compared to the conventional 50/70 binder. This saving is equivalent to approximately 2850 L of diesel fuel, or the annual operational energy consumption of about eight average passenger cars. This outcome highlights the long-term energy efficiency advantages of early-stage material improvements, even when they entail higher initial energy investment.