Experimental Investigation on Physical and Mechanical Behaviors of Paraffin Microcapsule Phase-Change Energy-Storage Concrete

Abstract

1. Introduction

2. Materials and Methods

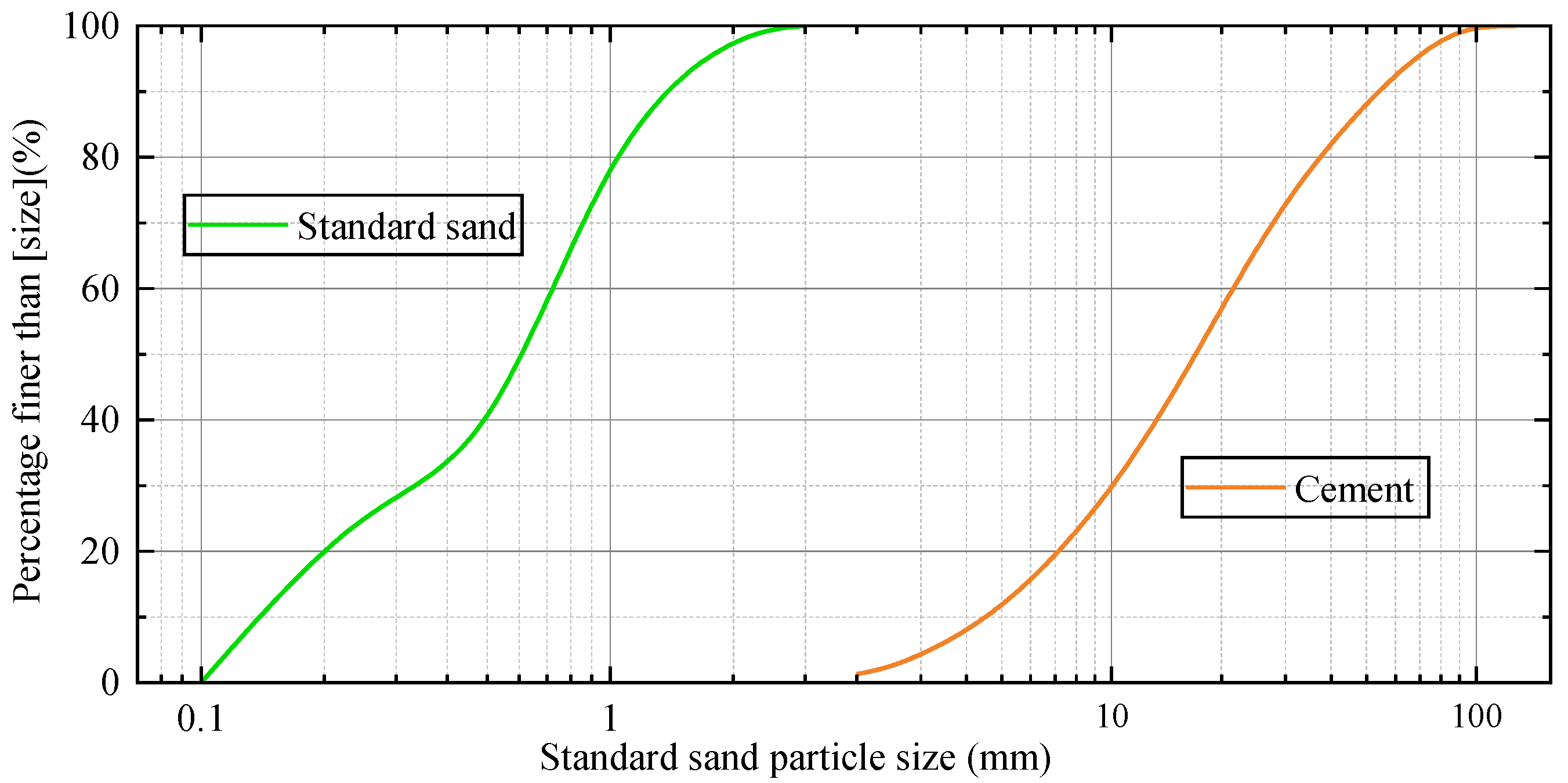

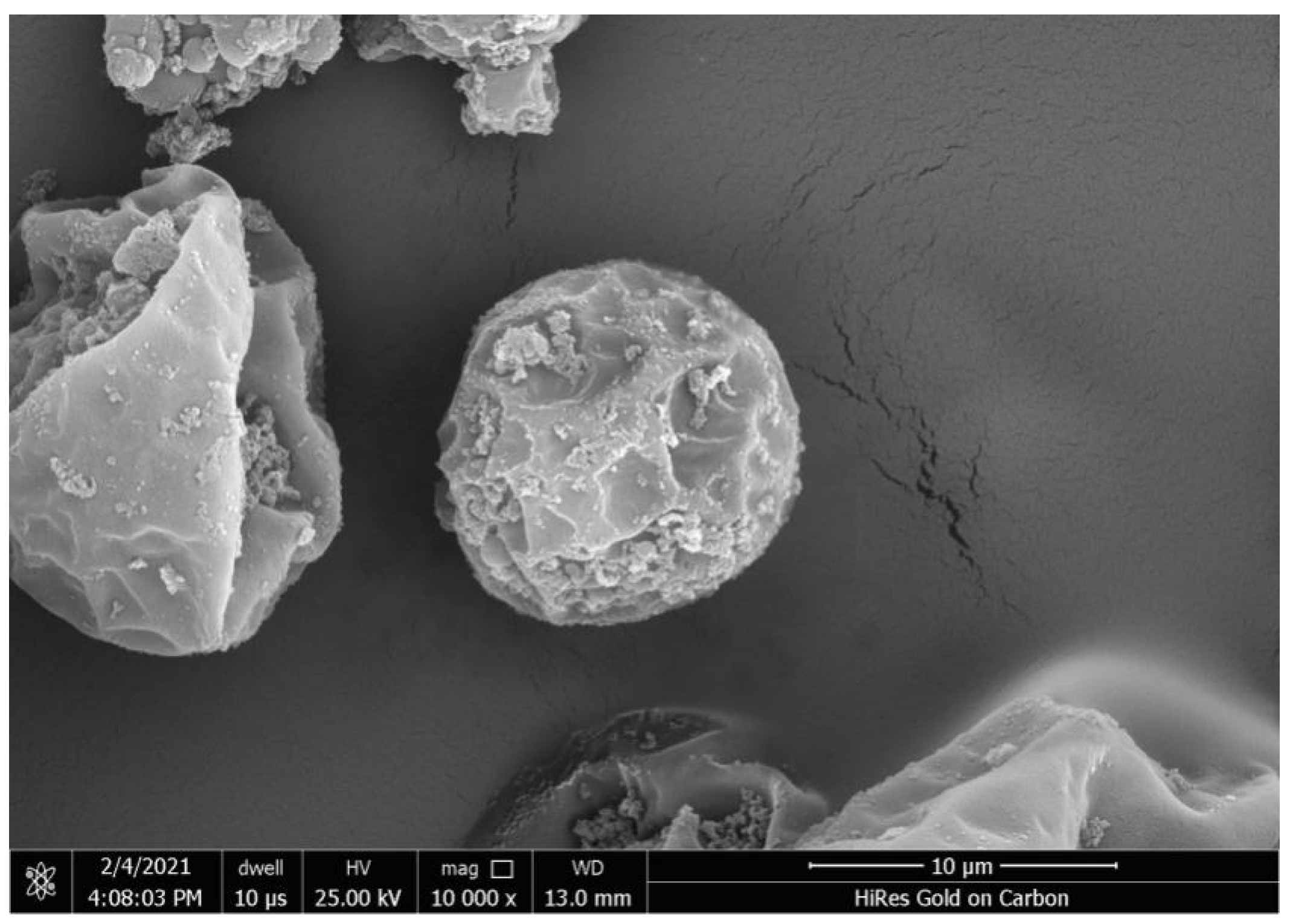

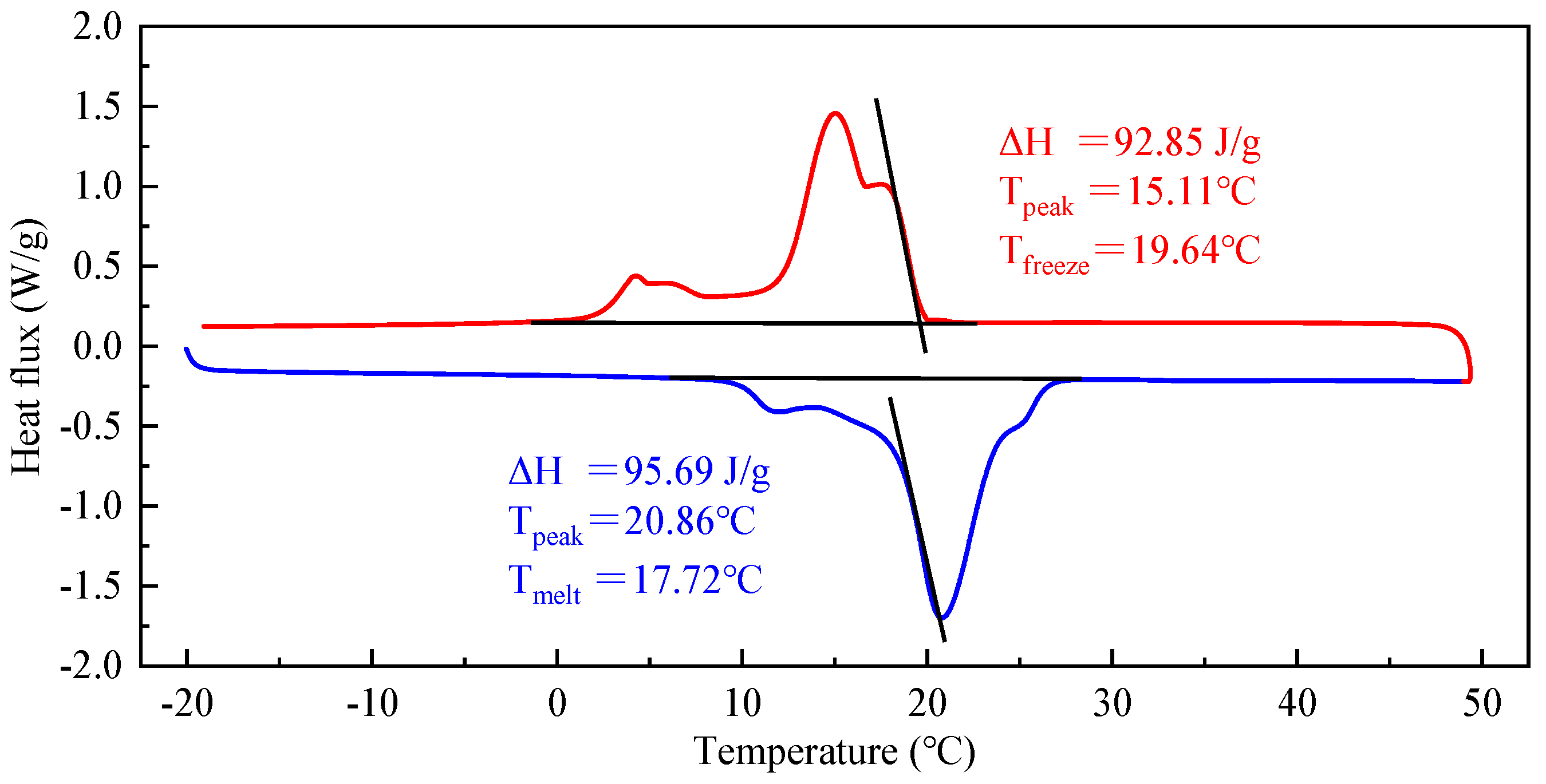

2.1. Experimental Materials

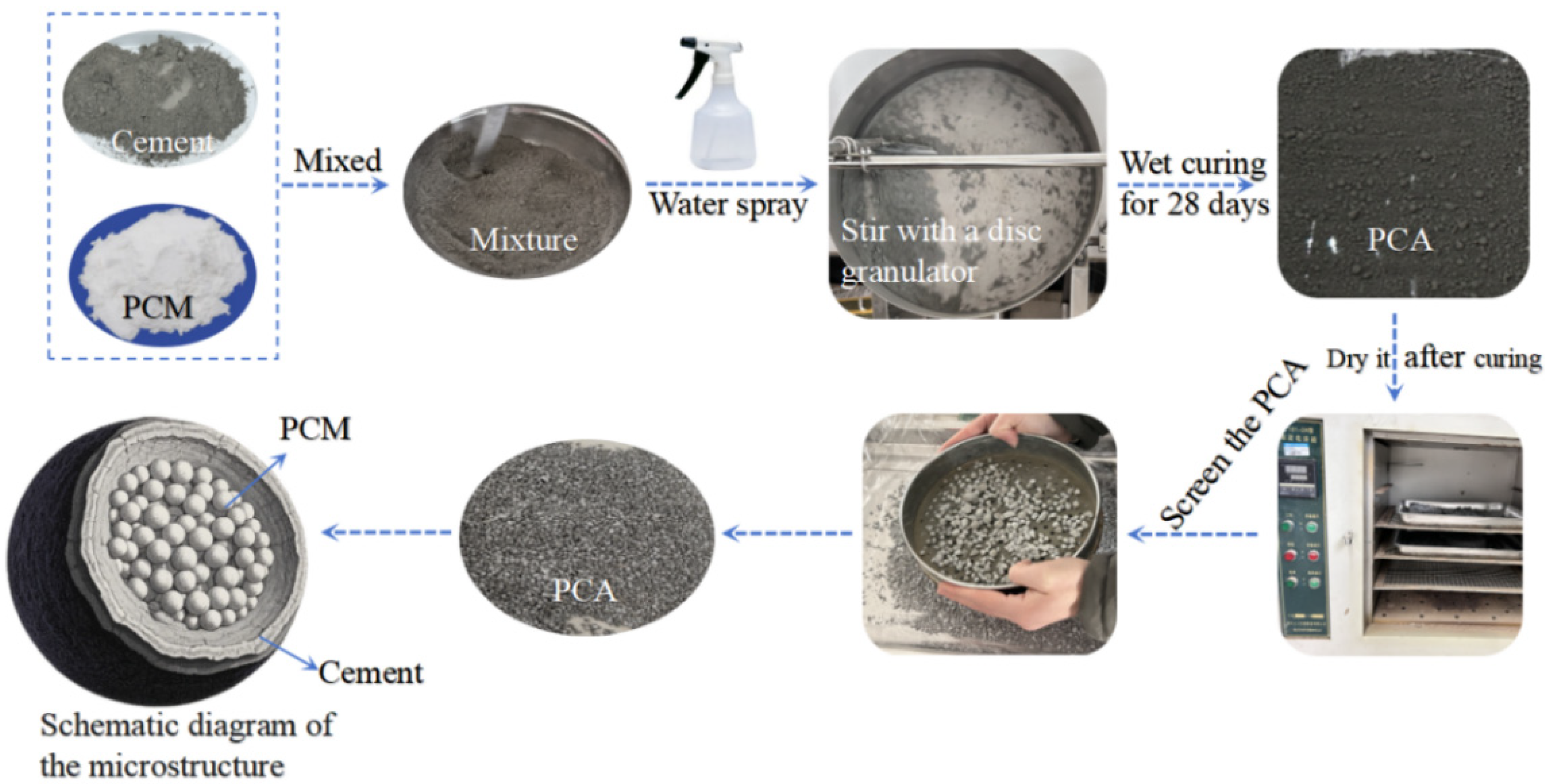

2.2. Preparation of PCA

2.3. Mix Proportion Design

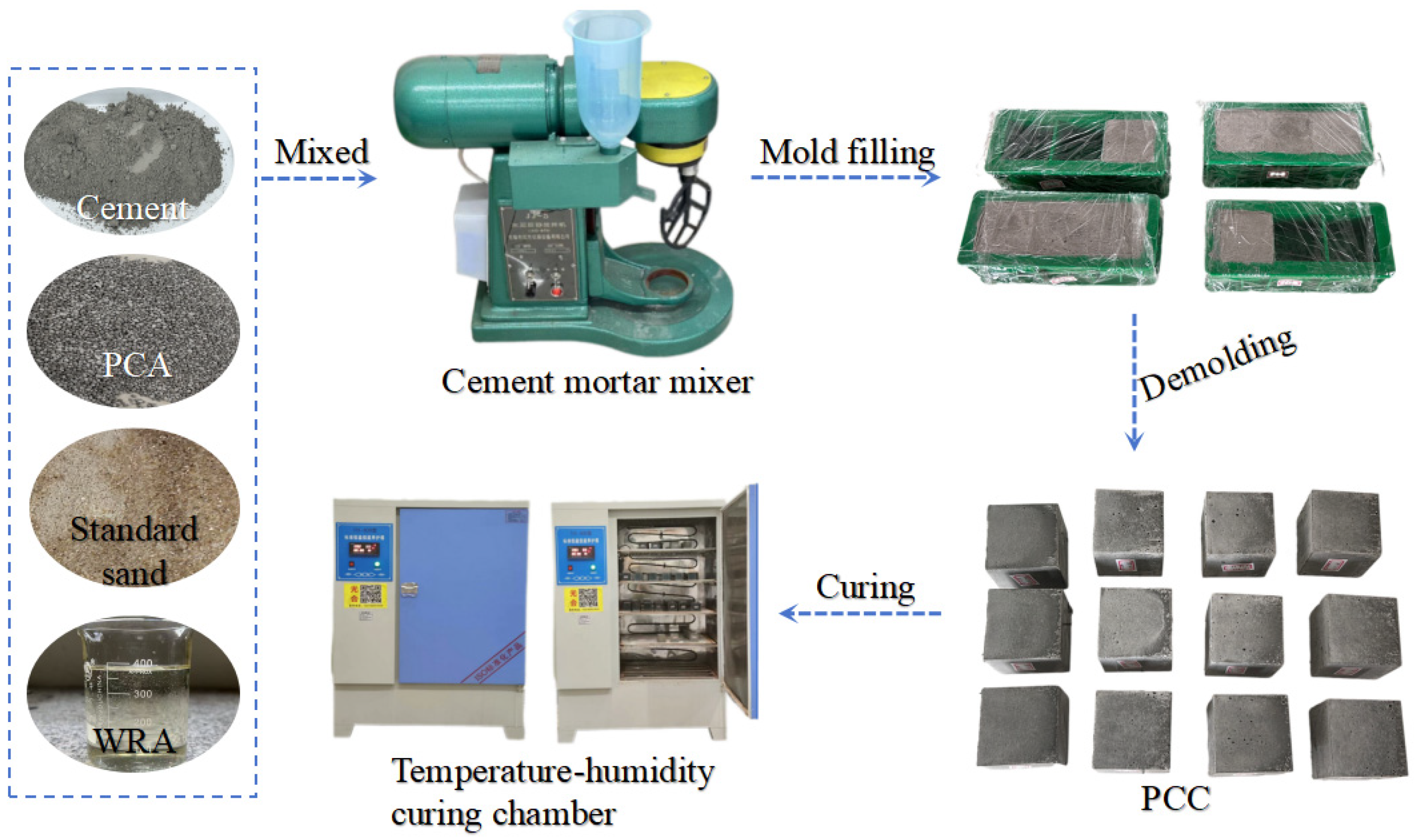

2.4. Preparation of PCC Specimens

2.5. Experimental Methods

2.5.1. Apparent Density

2.5.2. Water-Absorption Test

2.5.3. Compressive Strength Test

2.5.4. Ultrasonic Pulse Test

2.5.5. Microstructure Test

2.5.6. Thermal-Conductivity-Measurement Test

3. Results and Discussion

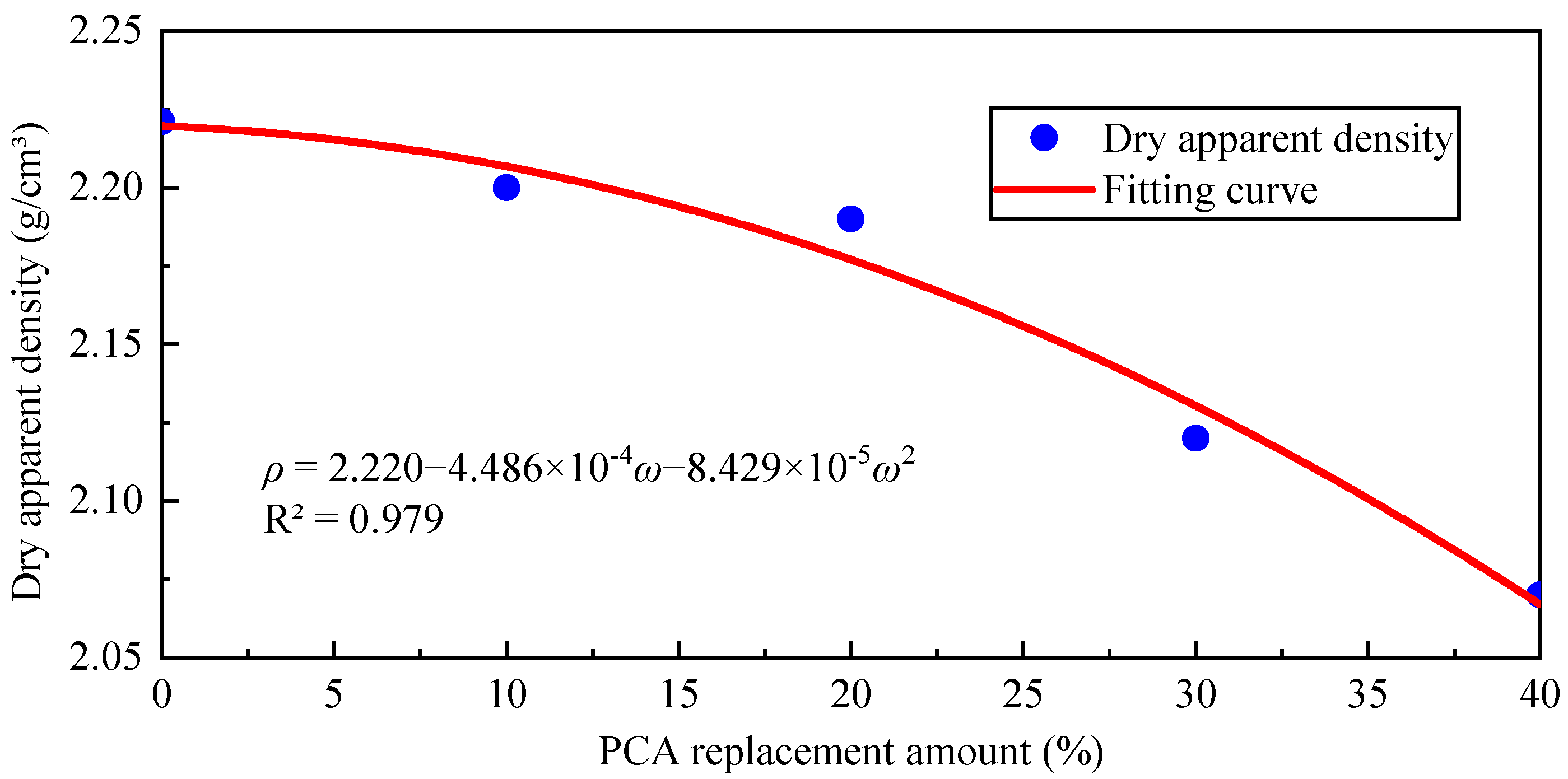

3.1. Analysis of Apparent Density

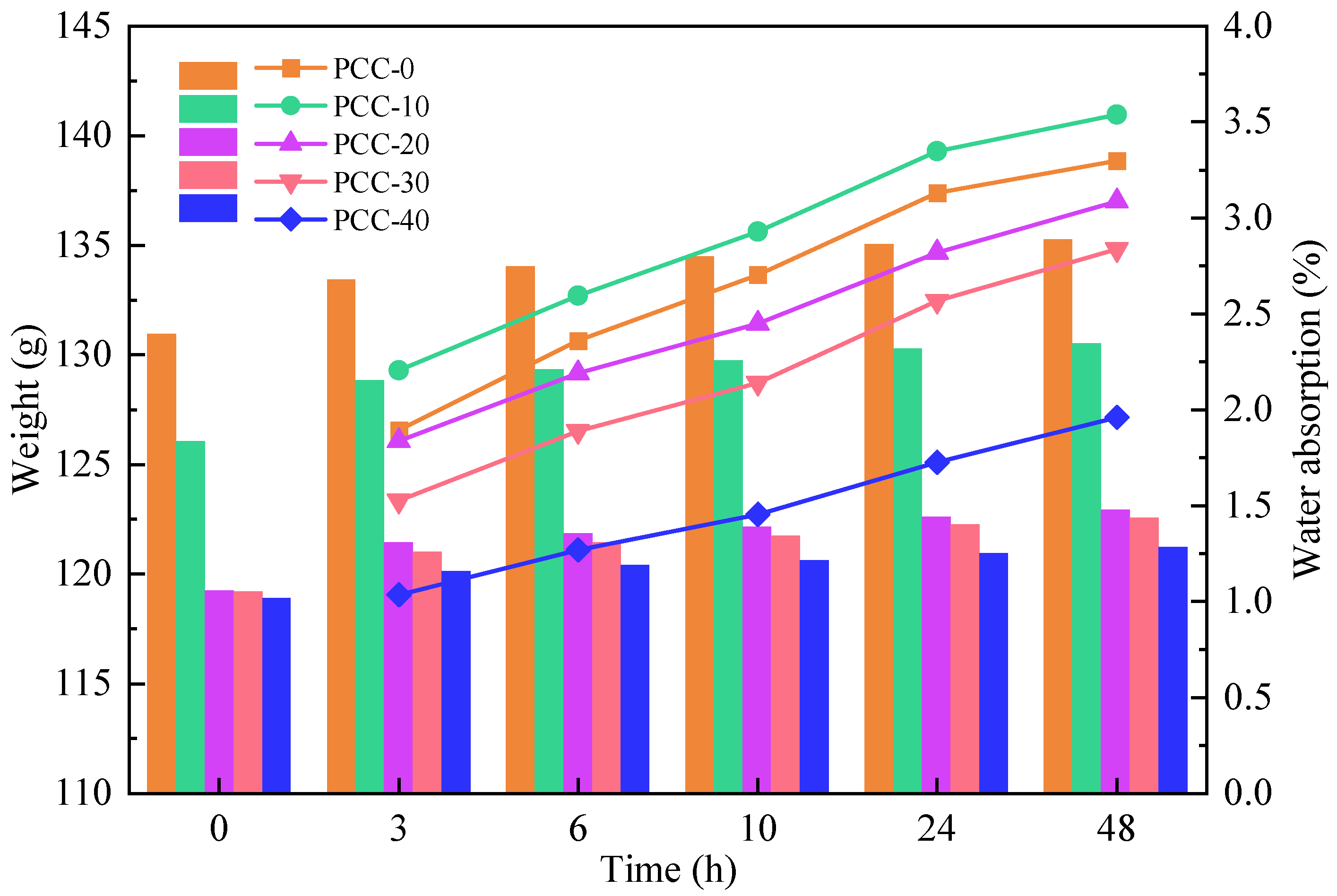

3.2. Analysis of Water Absorption

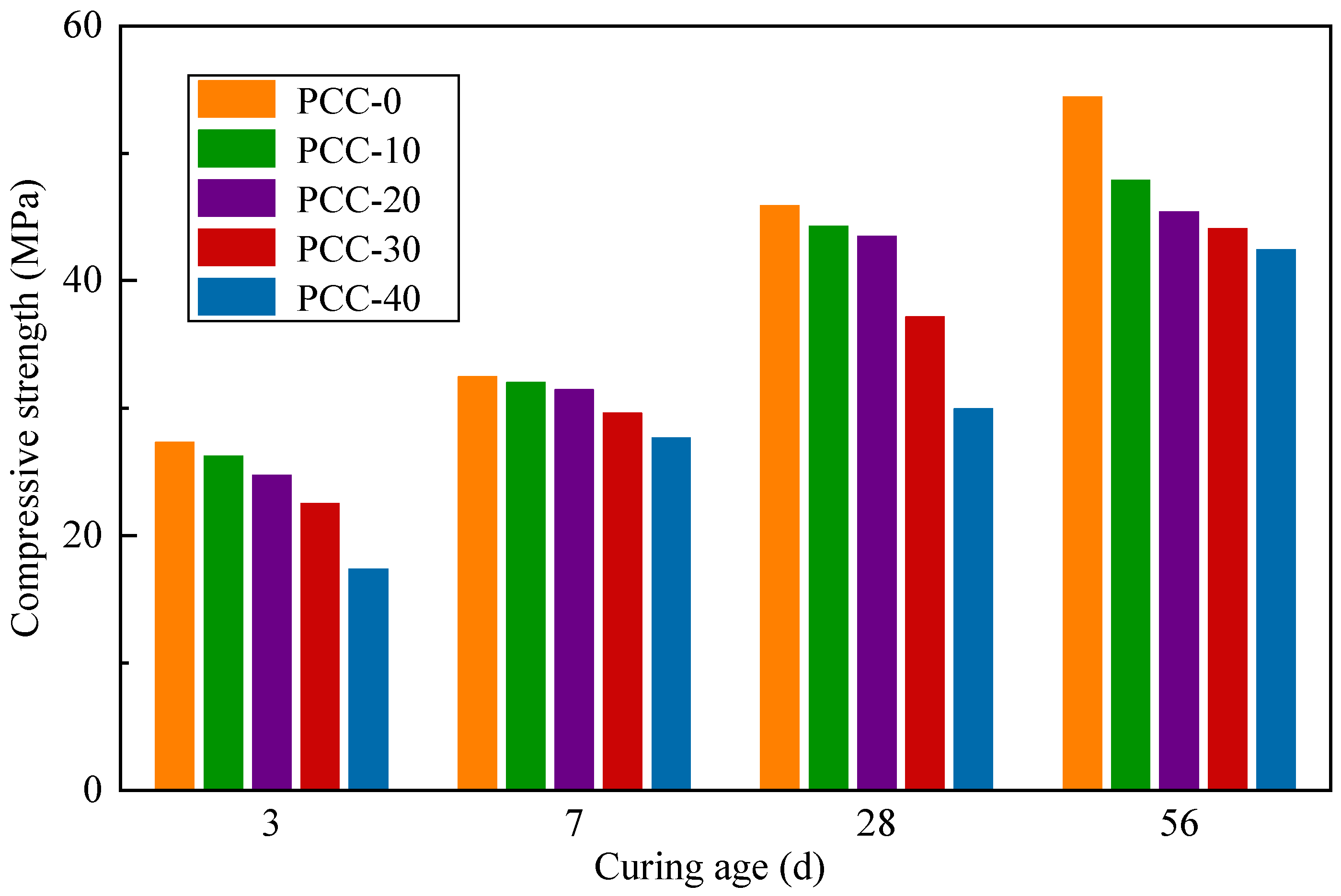

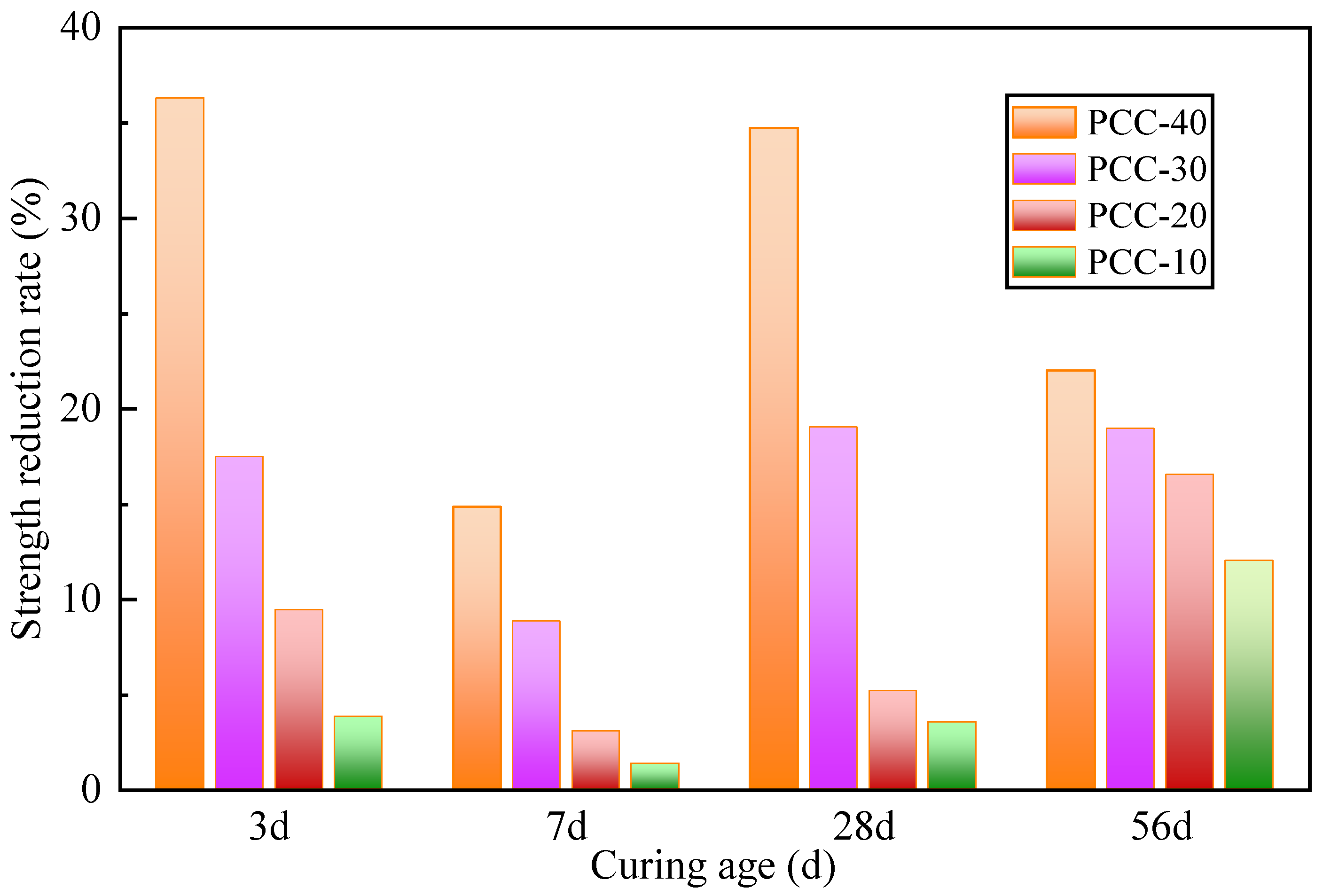

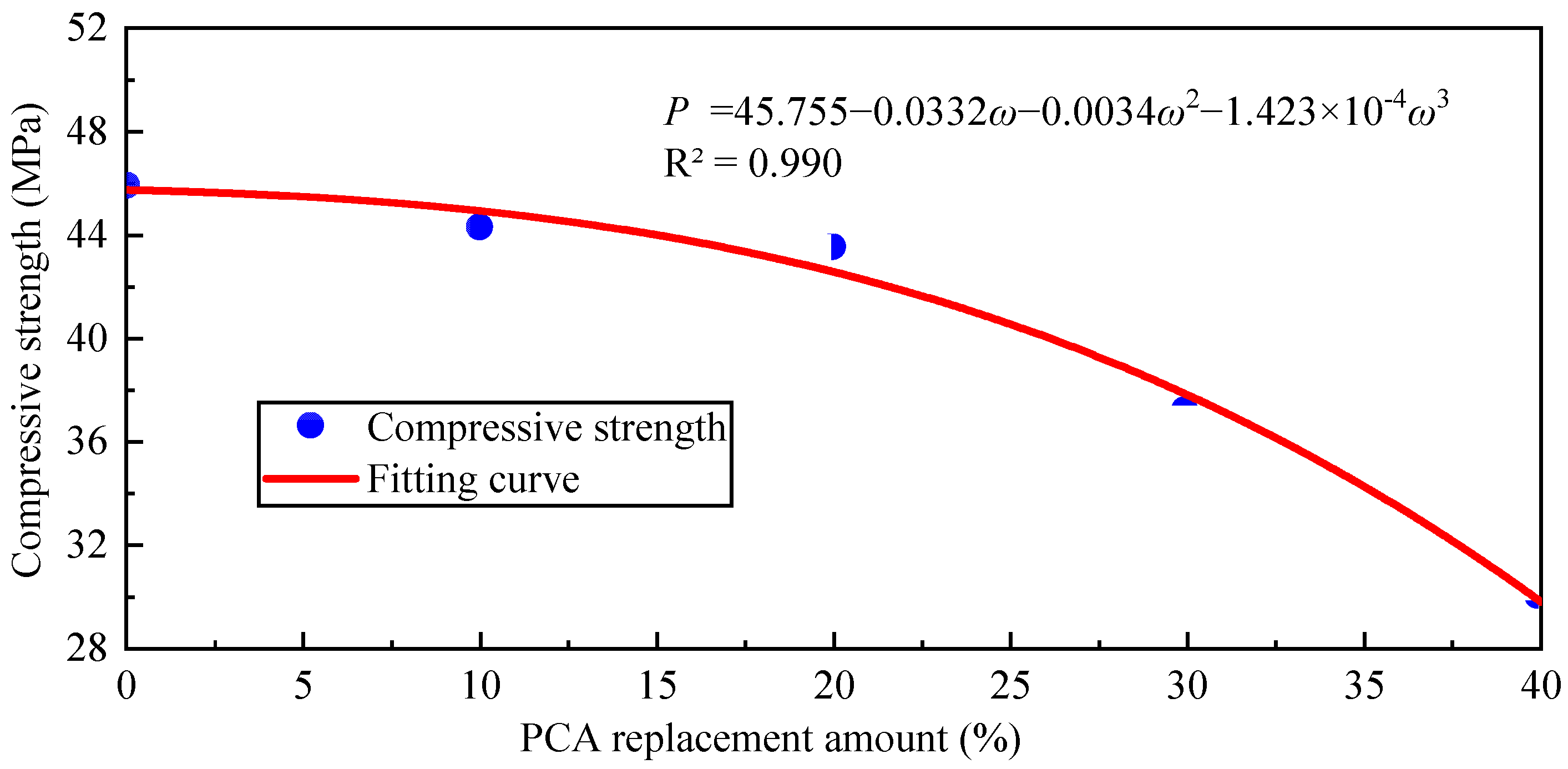

3.3. Analysis of Compressive Strength

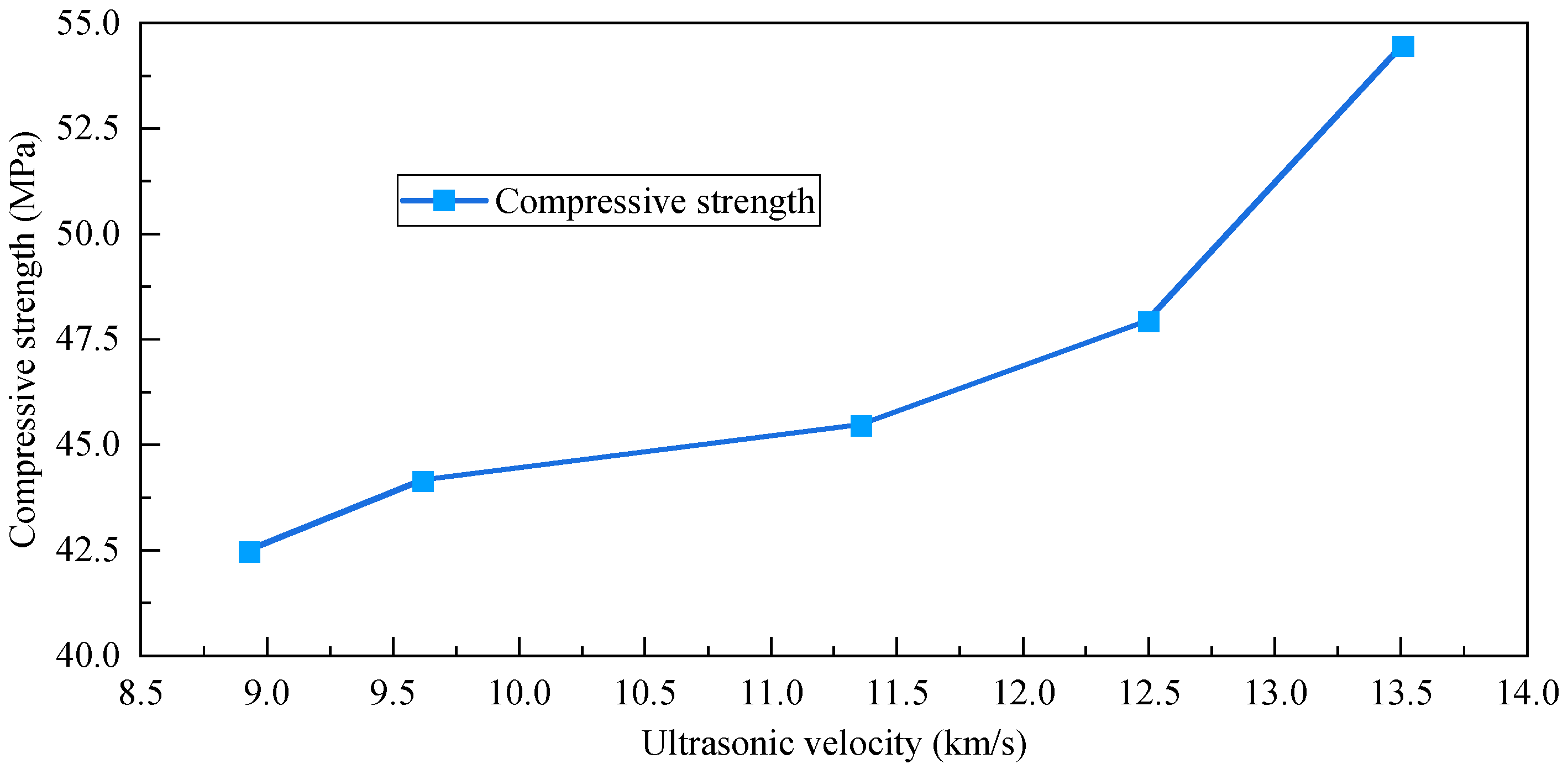

3.4. Analysis of Ultrasonic Pulse Test

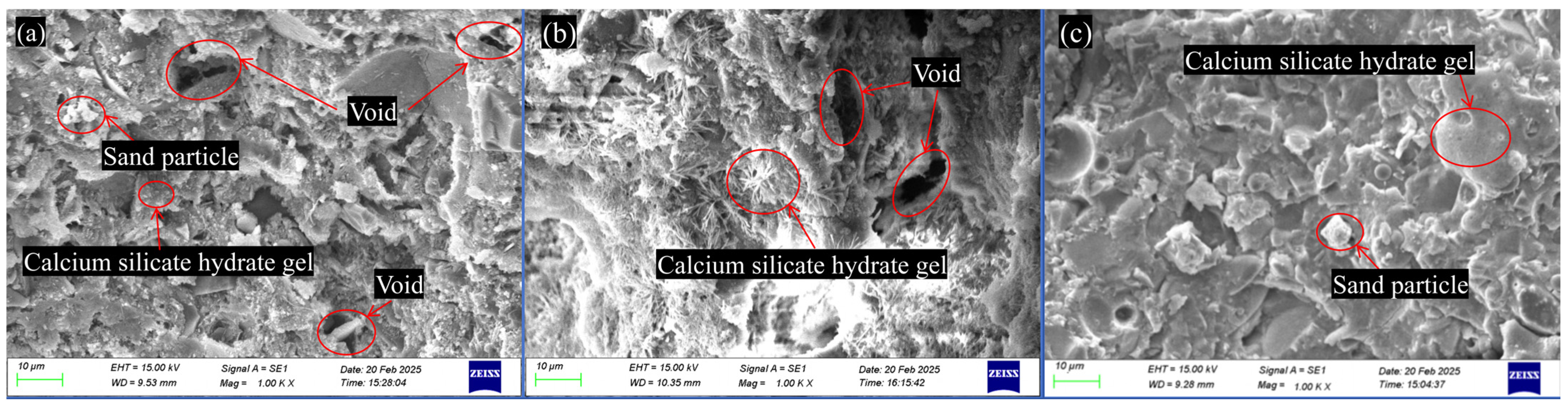

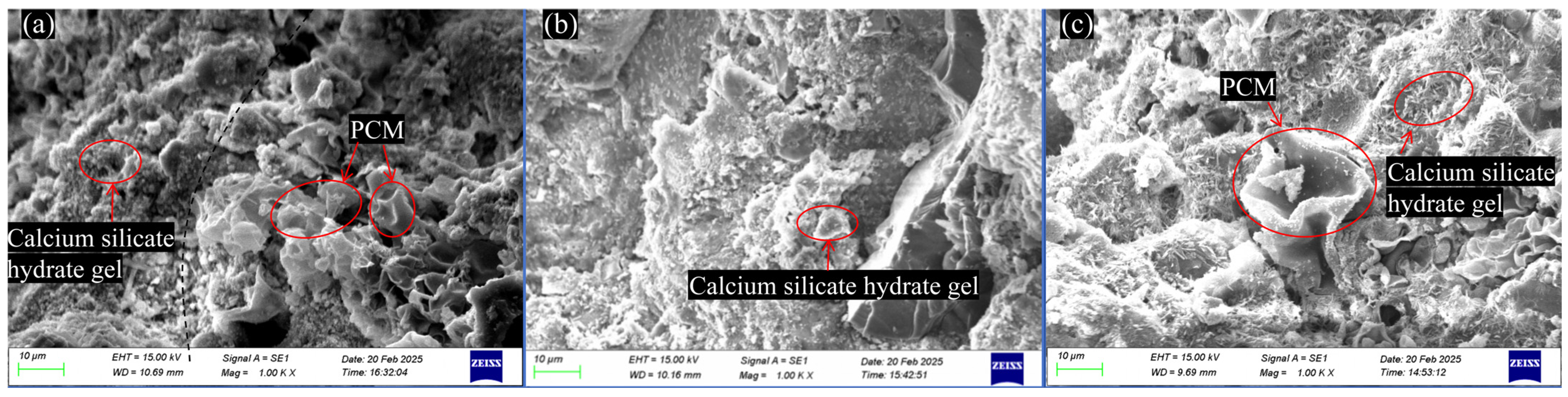

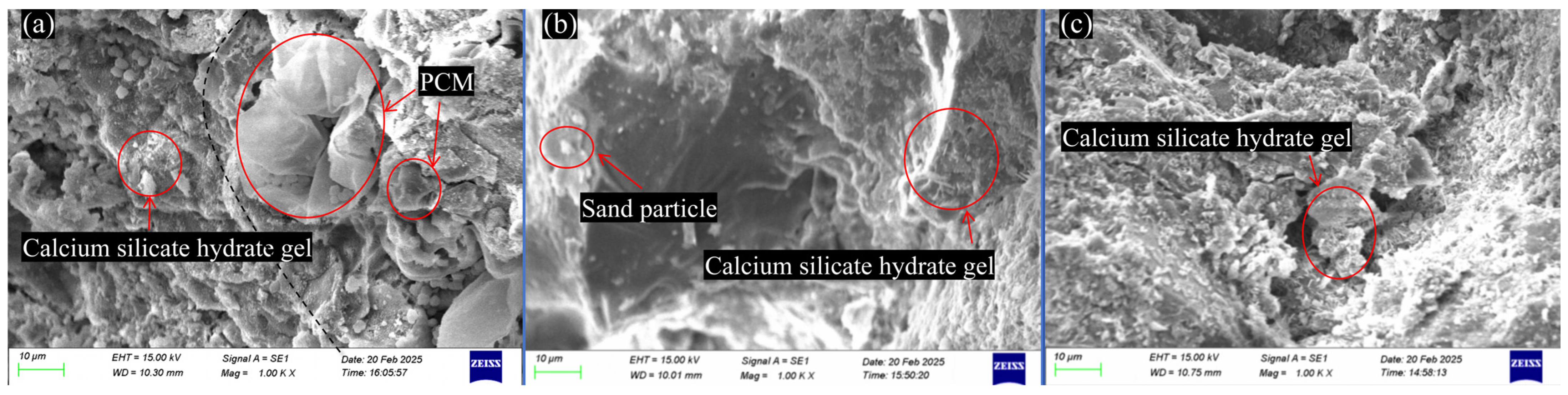

3.5. Analysis of Microstructure

3.6. Analysis of Thermal Conductivity

4. Conclusions

- The addition of PCA significantly reduced the apparent density, water absorption, compressive strength, and thermal conductivity of PCC. The materials with low thermal conductivity can effectively delay heat transfer, which is beneficial for the insulation of buildings and the relative stability of indoor temperature. When PPC is used as a building insulation filling material, further increasing the content of PCA cannot significantly reduce thermal conductivity, but one can attempt to increase the content of PCM in PCA to reduce thermal conductivity.

- The addition of PCA increases the porosity inside the concrete, and there are microcracks and loose structures in the interface transition zone, resulting in a decrease in its compactness. The ultrasonic velocity drop reaches 33.93% when the PCA content is 40%, while the decrease in the specimen strength does not exceed 35%, with a strength value of 30 MPa, and if the mix proportion is further optimized, it can meet the strength requirements of general building structure concrete. When the PCA content is high, it has a significant impact on the internal microstructure and physical and mechanical properties of the specimen.

- Due to the complex composition of PCC and the involvement of multiple factors in its physical and mechanical properties, the study of the influence of PCA content on its physical and mechanical properties by controlling a single variable, as explained in this paper, inevitably has certain limitations. In future research, more attention should be paid to the study of multiple factors on its properties, with a focus on the influence of high PCA content on specimen strength, and improvement measures should be proposed to facilitate the application of this material in engineering structures.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arun Kumar, B.; Sangeetha, G.; Srinivas, A.; Awoyera, P.O.; Gobinath, R.; Venkata Ramana, V. Models for predictions of mechanical properties of low-density self-compacting concrete prepared from mineral admixtures and pumice stone. In Soft Computing for Problem Solving; Das, K., Bansal, J., Deep, K., Nagar, A., Pathipooranam, P., Naidu, R., Eds.; Springer: Singapore, 2020; Volume 1057, pp. 677–690. [Google Scholar] [CrossRef]

- Khan, P.S.; Reddy, M.R.; Osman, S. An experimental study of the mechanical properties of glass fiber reinforced high strength concrete partially replacing cement with nano silica. Int. J. Eng. Technol. 2018, 5, 4597–4602. [Google Scholar]

- Venkatreddy, P.; Krishna, A.S.; Yadav, G.S. Experimental investigation on RCC by using multiple admixtures. Int. J. Eng. Technol. 2018, 7, 14–16. [Google Scholar] [CrossRef][Green Version]

- Awoyera, P.; Gobinath, R.; Haripriya, S.; Kulandaisami, P. New light weight mortar for structural application: Assessment of porosity, strength and morphology properties. In Proceedings of the 1st International Conference on Emerging Trends in Engineering (ICETE 2019), Hyderabad, India, 22–23 March 2019; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- China Building Energy Efficiency Association. China research report on carbon emissions in urban and rural construction fields (2024 Edition). J. Build. Energy Effic. (Chin. Engl.) 2025, 53, 154. (In Chinese) [Google Scholar]

- Xiao, G. Research on Intelligent Management Platform for Energy Enterprises Based on Big Data Technology. J. Phys. Conf. Ser. 2020, 1549, 042039. [Google Scholar] [CrossRef]

- Jeon, J.; Lee, J.; Seo, J.; Jeong, S.G.; Kim, S. Application of PCM Thermal Energy Storage System to Reduce Building Energy Consumption. J. Therm. Anal. 2013, 111, 279–288. [Google Scholar] [CrossRef]

- Drissi, S.; Ling, T.; Mo, H.K.; Eddhahak, A. A review of microencapsulated and composite phase change materials: Alteration of strength and thermal properties of cement-based materials. Renew. Sustain. Energy Rev. 2019, 110, 467–484. [Google Scholar] [CrossRef]

- Hall, C.; Hoff, D.W. Water Transport in Brick, Stone and Concrete; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Cervero, R.; Sullivan, C. Green TODs: Marrying Transit-Oriented Development and Green Urbanism. Int. J. Sustain. Dev. World Ecol. 2011, 18, 210–218. [Google Scholar] [CrossRef]

- Joulin, A.; Zalewski, L.; Lassue, S.; Naji, H. Experimental investigation of thermal characteristics of a mortar with or without a micro-encapsulated phase change material. Appl. Therm. Eng. 2014, 66, 171–180. [Google Scholar] [CrossRef]

- Karaipekli, A.; Sarı, A.; Biçer, A. Thermal regulating performance of gypsum/(C18–C24) composite phase change material (CPCM) for building energy storage applications. Appl. Therm. Eng. 2016, 107, 55–62. [Google Scholar] [CrossRef]

- Zhang, Y.; Ding, J.; Wang, X.; Yang, R.; Lin, K. Influence of additives on thermal conductivity of shape-stabilized phase change material. Sol. Energy Mater. Sol. Cells 2006, 90, 1692–1702. [Google Scholar] [CrossRef]

- Cabeza, L.; Castell, A.; Barreneche, C.; De Gracia, A.; Fernández, A.I. Materials used as PCM in thermal energy storage in buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Ling, T.; Poon, C. Use of phase change materials for thermal energy storage in concrete: An overview. Constr. Build. Mater. 2013, 46, 55–62. [Google Scholar] [CrossRef]

- Kousksou, T.; Arid, A.; Jamil, A.; Zeraouli, Y. Thermal behavior of building material containing microencapsulated PCM. Thermochim. Acta 2012, 550, 42–47. [Google Scholar] [CrossRef]

- Li, M. A nano-graphite/paraffin phase change material with high thermal conductivity. Appl. Energy 2013, 106, 25–30. [Google Scholar] [CrossRef]

- Xiao, X.; Zhang, P.; Li, M. Preparation and thermal characterization of paraffin/metal foam composite phase change material. Appl. Energy 2013, 112, 1357–1366. [Google Scholar] [CrossRef]

- Xu, B.; Li, Z. Paraffin/diatomite/multi-wall carbon nanotubes composite phase change material tailor-made for thermal energy storage cement-based composites. Energy 2014, 72, 371–380. [Google Scholar] [CrossRef]

- Xu, B.; Ma, H.; Lu, Z.; Li, Z. Paraffin/expanded vermiculite composite phase change material as aggregate for developing lightweight thermal energy storage cement-based composites. Appl. Energy 2015, 160, 358–367. [Google Scholar] [CrossRef]

- Qiao, J.; Song, Z. Preparation and performance study of concrete with low phase change material admixture. Concrete 2023, 11, 20–28. (In Chinese) [Google Scholar]

- Huang, W.; Zhang, J.; Wang, J.; Zheng, Y.; Ma, J.; Ding, F. Performance analysis of paraffin microcapsules and phase change concrete based on microporous cenospheres. Constr. Build. Mater. 2023, 409, 134030. [Google Scholar] [CrossRef]

- Wang, X.; Liu, S.; Lei, W.; Zhang, C.Y. Thermal properties and infrared stealth performance of paraffin phase change microcapsules. Mater. Rep. 2022, 36, 239–243. (In Chinese) [Google Scholar] [CrossRef]

- Jia, Z.; Cunha, S.; Aguiar, J.; Guo, P. The effect of phase change materials on the physical and mechanical properties of concrete made with recycled aggregate. Buildings 2023, 13, 2601. [Google Scholar] [CrossRef]

- Chen, R.; Shangguan, H.; Zhang, W.; Yang, K. Finite element method simulation study on the temperature field of mass concrete with phase change material. Buildings 2024, 14, 2755. [Google Scholar] [CrossRef]

- Erdene, B.E.P.; Pareek, S.; Koenders, E.; Mankel, C.; Löher, M.; Xiao, P. Evaluation of the thermal performance of fly ash foam concrete containing phase change materials (PCMs). Buildings 2023, 13, 2481. [Google Scholar] [CrossRef]

- Zhang, H.; Xing, F.; Cui, H.; Chen, D.Z.; Ouyang, X.; Xu, S.Z.; Wang, J.X.; Huang, Y.T.; Zuo, J.D.; Tang, J.N. A novel phase-change cement composite for thermal energy storage: Fabrication, thermal and mechanical properties. Appl. Energy 2016, 170, 130–139. [Google Scholar] [CrossRef]

- Cunha, S.; Lima, M.; Aguiar, B.J. Influence of adding phase change materials on the physical and mechanical properties of cement mortars. Constr. Build. Mater. 2016, 127, 1–10. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castellón, C.; Nogués, M.; Medrano, M.; Leppers, R.; Zubillaga, O. Use of microencapsulated PCM in concrete walls for energy savings. Energy Build. 2006, 39, 113–119. [Google Scholar] [CrossRef]

- Sun, D.; Wang, L. Utilization of paraffin/expanded perlite materials to improve mechanical and thermal properties of cement mortar. Constr. Build. Mater. 2015, 101, 791–796. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, M.; Jiang, Z.; Li, S. Preparation and physical performance of structure-function integrated phase change materials. Concrete 2025, 1, 104–108. (In Chinese) [Google Scholar] [CrossRef]

- Qiu, B.; Zhang, N. Preparation, properties and structure of a phase change aggregate based on expanded perlite. Refrig. Air Cond. 2023, 37, 650–655. (In Chinese) [Google Scholar]

- Zhu, L. Experimental Study on the Mechanical-Thermal Properties of Light-Weight Aggregate Concrete Mixed with Microcapsule Phase Change Materials and Theoretical Model Construction. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2022. (In Chinese) [Google Scholar] [CrossRef]

- Tian, Y.; Qin, Z.; Lin, Z.; Shen, P.; Chen, L.; Chen, G.; Zhang, L.; Gao, J.; Liu, S.; Yang, N.; et al. Study on the physical mechanical properties and freeze-thaw resistance of energy storage concrete with artificial phase change aggregate. J. Build. Eng. 2025, 99, 111506. [Google Scholar] [CrossRef]

- Abdul, A.S.G.; Shima, S.J.; Zainal, S.A. Waste Materials as the Potential Phase Change Material Substitute in Thermal Energy Storage System: A Review. Chem. Eng. Commun. 2020, 207, 687–707. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019. (In Chinese)

- Adesina, A.; Awoyera, P.; Sivakrishna, A.; Kumar, K.R.; Gobinath, R. Phase change materials in concrete: An overview of properties. Mater. Today Proc. 2020, 27, 391–395. [Google Scholar] [CrossRef]

- Jiang, C.; Ye, J.; Chen, Y.; Yang, Z.; Li, F. Study on properties of new phase change energy storage foam concrete thermal insulation partition board materials for buildings. New Build. Mater. 2024, 51, 112–117. (In Chinese) [Google Scholar]

- Wang, W.; Ma, Q.; Bai, M.; Ma, Y.; Wu, Z. Experimental study and analysis on the compressive and tensile strength and thermal conductivity of phase change concrete with activated carbon energy storage aggregates. Sci. Technol. Eng. 2016, 16, 95–99. (In Chinese) [Google Scholar]

- Chengdu Hongji Building Materials Co., Ltd. C30 Phase Change Energy Storage Concrete Using High-Titanium Slag as Phase Change Carrier and Preparation Method Thereof. Chinese Patent CN201811588816.5, 26 April 2019. (In Chinese). [Google Scholar]

- Li, J. Research status of phase change energy storage concrete. Sichuan Build. Mater. 2017, 43, 25–27. (In Chinese) [Google Scholar] [CrossRef]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford Publishing: London, UK, 1997. [Google Scholar] [CrossRef]

- Xia, M.; Qin, Z.; Wang, Z.; Li, D.; Ji, A.; He, J.; Lv, X.; Li, C. Study on thermophysical properties of fiber-reinforced subgrade soil in seasonal frozen soil region. Water Power 2023, 49, 106–111. (In Chinese) [Google Scholar]

- Peng, Y. Preparation and Thermodynamic Performance Analysis of Cement-Based Phase Change Microcapsule Energy Storage Concrete. Master’s Thesis, Dalian Ocean University, Dalian, China, 2024. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, J.; Nie, Z.; Guo, Z.; Yang, J.; Zheng, Z. Review on preparation and properties of phase change concrete. J. Jiangsu Univ. (Nat. Sci. Ed.) 2020, 41, 588–595. (In Chinese) [Google Scholar] [CrossRef]

- China Railway Sixth Bureau Group Hohhot Railway Construction Co., Ltd. Temperature-Controlled Phase Change Aggregate and Its Preparation Method and Application. Chinese Patent CN202410035305.X, 10 May 2024. (In Chinese).

- Xie, Z.; Kou, Y.; Shi, Q.; Tian, Y. Synthesis and temperature control performance of silica gel waste composite phase change materials. Chem. J. Chin. Univ. 2025, 46, 37–45. (In Chinese) [Google Scholar] [CrossRef]

- Liao, Y. Study on Fire Resistance Performance of Phase Change Energy Storage Concrete Walls. Master’s Thesis, Shanghai Normal University, Shanghai, China, 2023. (In Chinese) [Google Scholar] [CrossRef]

| Oxide | Na2O | MgO | Al2O3 | SiO2 | K2O | CaO | Fe2O3 | CO2 | Other |

|---|---|---|---|---|---|---|---|---|---|

| Mass percentage | 0.71 | 2.42 | 4.99 | 23.17 | 0.82 | 41.52 | 2.88 | 22.57 | 0.92 |

| Experimental Group Number | Cement/g | Standard Sand/g | PCA/g | Water/g | Water-Reducing Agent/g | Water-Cement Ratio |

|---|---|---|---|---|---|---|

| PCC-0 * | 892.5 | 2682.76 | 0.00 | 338.8 | 44.62 | 0.38 |

| PCC-10 | 892.5 | 2414.48 | 141.88 | 338.8 | 44.62 | 0.38 |

| PCC-20 | 892.5 | 2146.21 | 283.74 | 338.8 | 44.62 | 0.38 |

| PCC-30 | 892.5 | 1877.93 | 425.64 | 338.8 | 44.62 | 0.38 |

| PCC-40 | 892.5 | 1609.66 | 567.52 | 338.8 | 44.62 | 0.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Qin, Z.; Liu, S.; Chen, L.; Chen, G.; Xu, E.; Zhang, L.; Tian, Y.; Liu, Z.; Li, Y.; et al. Experimental Investigation on Physical and Mechanical Behaviors of Paraffin Microcapsule Phase-Change Energy-Storage Concrete. Buildings 2025, 15, 1907. https://doi.org/10.3390/buildings15111907

Wang D, Qin Z, Liu S, Chen L, Chen G, Xu E, Zhang L, Tian Y, Liu Z, Li Y, et al. Experimental Investigation on Physical and Mechanical Behaviors of Paraffin Microcapsule Phase-Change Energy-Storage Concrete. Buildings. 2025; 15(11):1907. https://doi.org/10.3390/buildings15111907

Chicago/Turabian StyleWang, Dongxue, Zipeng Qin, Shixing Liu, Lefeng Chen, Guoxun Chen, Erjin Xu, Liangbin Zhang, Yan Tian, Zhengzheng Liu, Yifan Li, and et al. 2025. "Experimental Investigation on Physical and Mechanical Behaviors of Paraffin Microcapsule Phase-Change Energy-Storage Concrete" Buildings 15, no. 11: 1907. https://doi.org/10.3390/buildings15111907

APA StyleWang, D., Qin, Z., Liu, S., Chen, L., Chen, G., Xu, E., Zhang, L., Tian, Y., Liu, Z., Li, Y., Lei, S., Pan, J., Qiu, P., & Zhou, X. (2025). Experimental Investigation on Physical and Mechanical Behaviors of Paraffin Microcapsule Phase-Change Energy-Storage Concrete. Buildings, 15(11), 1907. https://doi.org/10.3390/buildings15111907