1. Introduction

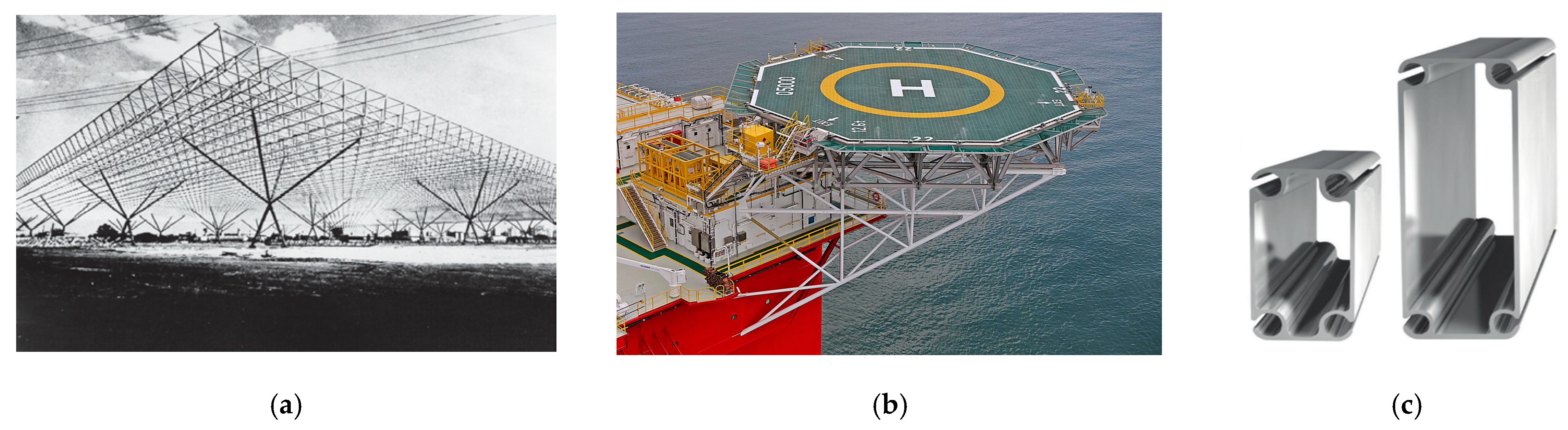

In the increasing demand for sustainable and lightweight construction materials, aluminium has emerged as a key player due to its unique physical properties, manufacturing flexibility, and long-term durability. Its excellent strength-to-weight ratio, corrosion resistance, and full recyclability make it an attractive alternative to traditional materials, particularly when reduced weight and environmental performance are critical. Aluminium is the only light metal used in construction for load-bearing structures. Although steel is traditionally more used, aluminium is competitive due to its advantages related to the manufacturing process, physical properties, and technological features [

1,

2]. Aluminium is often a competitive choice where the following preconditions are important: low weight (

Figure 1a) [

1], corrosion resistance and durability (

Figure 1b) [

3], and the functionality of the structural form (

Figure 1c) [

4,

5].

The low specific weight of aluminium allows for easier and faster execution, cheaper transport, and a reduction in the foundation structure. Due to its natural corrosion resistance, structures made of aluminium practically do not need to be protected or maintained against corrosion, which significantly reduces investment costs in the long term and places aluminium alloys at the very top of the list of modern and environmentally friendly materials. The extrusion process ensures the functionality of a wide range of structural profile shapes, which achieves economical profiles adapted to a specific purpose. However, extruded members are dimensionally limited and insufficient when members with a higher load-bearing capacity are required. Modern automated (robotic) welding processes can produce aluminium members with tapered cross-sections that allow the realisation of larger spans, more rational material use, and a reduction in production costs.

The main problem of aluminium in terms of sustainability is the large amount of energy required to produce the raw material and the significant CO

2 emissions. The production of one tonne of steel causes the emission of 1.85 tonnes of CO

2 [

6], while the production of one tonne of aluminium emits between 12 and 17 tonnes of CO

2 [

7]. Some producers have started producing aluminium based on hydropower, with a maximum carbon footprint of 4 tonnes of CO

2 per tonne of aluminium [

7]. If we look at the broader view in terms of life cycle analysis, it can be shown that aluminium is a material that can adapt to future requirements from the aspect of sustainable development [

8]. Despite its initially high embodied energy, aluminium offers long-term sustainability benefits through the following important aspects:

Low weight = lower carbon footprint during transport and assembly and generally lower material consumption per weight (aluminium is almost 3 times lighter than steel due to their material densities—steel 7850 kg/m3/aluminium 2700 kg/m3);

Smaller foundations = lower carbon footprint due to concrete production/transport/installation;

Relatively high mechanical properties = although the modulus of elasticity is significantly lower than that of steel (3 times), the strength of some alloy products can reach values on a par with low-strength carbon steel, which is still significantly higher compared to other construction materials.

Corrosion resistance = durability is guaranteed, the fact that there is no need for corrosion protection causing a significant energy footprint when building new structures and maintaining existing ones [

9];

Fully recyclable = aluminium can be recycled an infinite number of times [

3], and aluminium recycling requires only 5% of the energy compared to the production of primary aluminium; thus, aluminium deserves the title of a ‘green metal’ [

10]. In Europe, 42% of aluminium cans, 85% of construction aluminium, and 95% of aluminium in the automotive industry are recycled [

11].

One of the main reasons for the decreasing use of aluminium in construction is the lack of standards for the design of aluminium structures [

1]. The first recommendations for the design of aluminium structures in Europe were issued in 1978 by the ‘European Convention for Constructional Steelwork’ [

12]. Today, a set of standards under the common name Eurocode 9 are used for the design of aluminium structures in Europe, and the basic part of the mentioned set is EN 1999-1-1:2007 [

13]. Numerous parts of this standard were taken from the standards for the design of steel structures. As these are two different materials, this approach resulted in a standard that does not provide optimal reliability. The second-generation (2G) standard for the design of aluminium structures, EN 1999-1-1:2023 [

14], definitely brings progress, but numerous issues have not yet been resolved due to the insufficient experimental and probabilistic background. The REAL-fit project aims to establish a robust experimental and statistical foundation to address these challenges and support the ongoing development of more reliable design standards for aluminium structures. This includes systematic data collection on mechanical properties—particularly those of welded aluminium components—comprehensive analysis of variability and reliability indicators, and integration of these results into probabilistic design frameworks of Eurocode.

The aim of the paper is to present the scientific and methodological foundations, key activities, and first-year results of the ongoing REAL-fit project aimed at improving the reliability and sustainability of aluminium structural design. It is hoped that the research carried out within the REAL-fit project will provide a solid benchmark for the harmonisation and possible improvement of existing standards for the design of aluminium structures in terms of their efficiency and reliability.

Section 2 highlights topics such as the probabilistic background of mechanical properties, modern welding processes, structural behaviour of welded members and joints, and advanced design methods. These issues are reviewed, and possible solutions regarding sustainable building requirements are proposed.

Although the project’s success can only be assessed after its completion, the results of the first year of the REAL-fit project presented in

Section 3 are promising. The optimised, pulsed alternating current MIG welding process (AC-MIG-P) generally has a narrower weld zone and fewer plate deformations than the traditional pulsed direct current MIG welding process (DC-MIG-P). The database of mechanical properties of aluminium alloys has been expanded quantitatively (2 times more data) and qualitatively (new alloys and properties of the welded material) and is now a much more reliable basis for further probabilistic analyses. The experimental results obtained on longitudinally welded members and the preliminary numerical simulations of welded beam-to-column joints indicate the potential for optimising design procedures. Applying the direct design method (DDM) to aluminium portal frames under gravity loading shows that the total weight of the structure can be significantly reduced compared to the traditional approach.

2. Current Design Approach

2.1. Codification of Aluminium Structures

In general, codification is always based on available data from research and practice and is ultimately the result of a great effort by the international technical and scientific community. The codification process results in a standard—a tool that combines ease of use, economy, conservatism, and other conflicting aspects at its publication. Each new version of the standards is driven by the constant need to align with recent developments and to improve the existing standards to increase their efficiency and reliability.

Codification in aluminium structures in civil engineering is a rather complex and lengthy process [

12]. The current state of codification in the field of aluminium structures in Europe is provided by the 2G version of Eurocode 9 and reflects the current state of engineering practice and scientific research. This 2G version of Eurocode 9 brings many improvements and new technical aspects and is of great importance to stakeholders and practitioners. Its role in promoting the use of aluminium in structural applications, particularly the fact that there is a code for the design of aluminium structures, is an important achievement, notwithstanding the inevitable shortcomings.

The REAL-fit project aims to analyse and potentially improve some aspects of the codification, which are listed as points for consideration in the following sections. However, this study also highlights important non-codified aspects, such as the direct design method, life cycle assessment, and life cycle cost analysis, which are very important for structures made of this lightweight material.

2.2. Mechanical Properties of Structural Aluminium Alloys

The current and new European standards for the design of aluminium structures [

13,

14] exhibit a critical limitation regarding the mechanical property values of aluminium alloys, particularly their statistical representativeness. From the design point of view, the two most important properties are the 0.2% proof strength (f

o) and the tensile strength (f

u). Due to the welding, mechanical properties are reduced within the heat-affected zone (HAZ) area, and it is necessary to know their reduced values within the HAZ (f

o,HAZ and f

u,HAZ). The specified standards [

13,

14] do not provide characteristic values of the specified properties but minimum (guaranteed) values that do not have a probabilistic background, which may lead to conservative values of the specified properties and uneconomic design.

Indeed, before the development of the 2G standard for the design of aluminium structures [

14], there was no database of the important aluminium mechanical properties that would provide a basis for their statistical characterisation. Within the European subcommittee CEN/TC 250/SC 09, Skejić et al. [

15] collected and statistically processed more than 12,000 tensile test results and thus created a robust dataset for determining statistically validated characteristic values of the mechanical properties of aluminium alloys. The collected database [

15] refers only to non-welded specimens. Dokšanović et al. [

16] collected and statistically processed a database of tensile test results of welded and unwelded aluminium coupons. However, the database is not extensive enough to reliably determine the values of the reduced mechanical properties in the HAZ (f

o,HAZ and f

u,HAZ). Several studies [

17,

18] have shown that mechanical properties can be reduced by using modern welding processes from the field of mechanical engineering, allowing for the development of reliable, economically and environmentally sustainable welded aluminium structures. Accurate knowledge of reduced values is essential for reliable welded aluminium structure design. Standards [

13,

14] define the extent of the HAZ, but these rules are still based on laboratory investigations conducted in the 1970s [

19], which no longer reflect current welding technologies or alloy compositions. Therefore, it is necessary to harmonise the mentioned standards [

13,

14] with the latest knowledge in the field of aluminium alloy welding.

In this context, there is a strong need to investigate and probabilistically evaluate the mechanical properties of welded aluminium alloys. Furthermore, it is necessary to systematically analyse the extent and influence of the heat-affected zone (HAZ) in both butt and fillet welds, especially for modern welding methods currently not covered by Eurocode 9.

2.3. Design Rules for Longitudinally Welded Members

The lack of standards [

13,

14] is also related to the stability design of aluminium columns. Aluminium members are prone to stability loss due to their low modulus of elasticity and the material nonlinearity, especially if they are slender [

20,

21]. The buckling resistance of members depends primarily on three factors: the initial bow, the stress–strain curve of the material, and the value of the residual stresses [

22]. In welded aluminium members, welding causes a significant introduction of residual stresses [

23], which are one of the main factors in calculating buckling resistance. EN 1999-1-1:2007 [

13] implicitly accounts for residual stresses in the cross-section and other types of imperfections via buckling curves, which are the most important as they define the ratio of buckling resistance to cross-section resistance.

The 2G standard EN 1999-1-1:2023 [

14] introduces a new design procedure for aluminium members subjected to compression with six new buckling curves—three for extruded and three for longitudinally welded members. From the current state-of-the-art review of Čudina and Skejić [

24], it can be concluded that the buckling curves for welded members are based on only one parametric numerical analysis conducted by Misiek et al. [

22], and the numerical models in these analyses were calibrated on outdated laboratory tests [

12,

19]. The last tests that investigated the influence of welding on the resistance of aluminium members under compression and the distribution of residual stresses in the cross-section were conducted in the 1970s [

12,

19]. Although, more recently, Wu and Zhang conducted laboratory tests of longitudinally TIG welded aluminium members under compression [

25], these tests were not considered when establishing the buckling curves given in EN 1999-1-1:2023 [

14]. Over the last 40 years, new welding methods have been developed, like pulsed MIG-P welding, friction stir welding, and laser welding, which can achieve the joining of connecting components with significantly reduced heat input. The question arises as to how reliable and economical the design procedure given in the EN 1999-1-1:2023 [

14] is.

Consequently, the revision of design methods for designing longitudinally welded aluminium members under compression should be based on an extensive experimental programme that implements modern welding methods. Such an experimental programme must encompass the characterisation of the extent of the HAZ, measurement of residual stresses, and determination of buckling resistance of longitudinally welded compression members. This will allow the revision of existing standardised procedures and probabilistically based recommendations for standardising modern welding methods that are not ‘aggressive’ towards the base material.

2.4. Design Rules for Welded and Hybrid Joints

Optimising the rules for the joint structural design is necessary to enable an economical design of aluminium structures. Valčić and Skejić presented a brief state-of-the-art review on aluminium joints in [

26]. Although not fully applicable to aluminium, the component method used for the design of steel joints has been slightly modified and utilised for the design of aluminium beam-to-column joints [

27,

28]. A lot of research has been conducted on aluminium joints made with mechanical fasteners [

29,

30,

31,

32,

33,

34,

35,

36,

37,

38], while only a few refer to welded joints [

39]. In addition to the significantly different behaviour of aluminium in welding compared to steel, aluminium alloys show nonlinear behaviour even at small deformations and have limited ductility, affecting such joints’ resistance [

40].

One of the first studies on the behaviour of welded aluminium connections was carried out by Soetens [

41] and Matusiak [

42]. Both analysed the HAZ and its influence on the behaviour and strength of welded connections. Chan and Porter Goff [

43] experimentally investigated the effects of the zone of reduced strength on cruciform welded connections in terms of failure mode, ductility, and resistance and demonstrated that weld defects can significantly reduce the ultimate resistance of mentioned connections. Another study on cruciform connections and tubular T-connections was conducted by Zhang et al. [

44]. The authors applied a new, holistic approach to modelling (a combination of thermal–mechanical and mechanical analysis) and proved that modern welding techniques lead to smaller qualitative and quantitative reductions in the HAZ. Cheng et al. [

18] provided a comprehensive review of welding techniques that could improve the behaviour of welded aluminium connections. Early attempts at numerical investigations of aluminium beam-to-column welded joints were made by Wang et al. [

45], who reproduced the laboratory tests conducted by Matusiak [

42]. De Matteis et al. [

27] proposed a numerical model with a detailed characterisation of the HAZ that, relatively accurately, reproduces the behaviour of T-connections. Taking all the above research into account, it should be noted that there are still no experimental studies on the behaviour of full-scale welded beam-to-column joints.

Some recommendations for future research regarding the calibration of the component method from steel to aluminium are proposed by De Matteis et al. in [

28]. In order to enable the optimisation of standardised rules for the design of welded aluminium beam-to-column joints, comprehensive (experimental and numerical) investigations should be carried out on the behaviour of welded aluminium beam-to-column joints. The focus should be on determining the extent of the HAZ, the reduction in the mechanical properties within this zone, and the overall behaviour of the joint in the form of a complete moment –rotation (M-ɸ) curve.

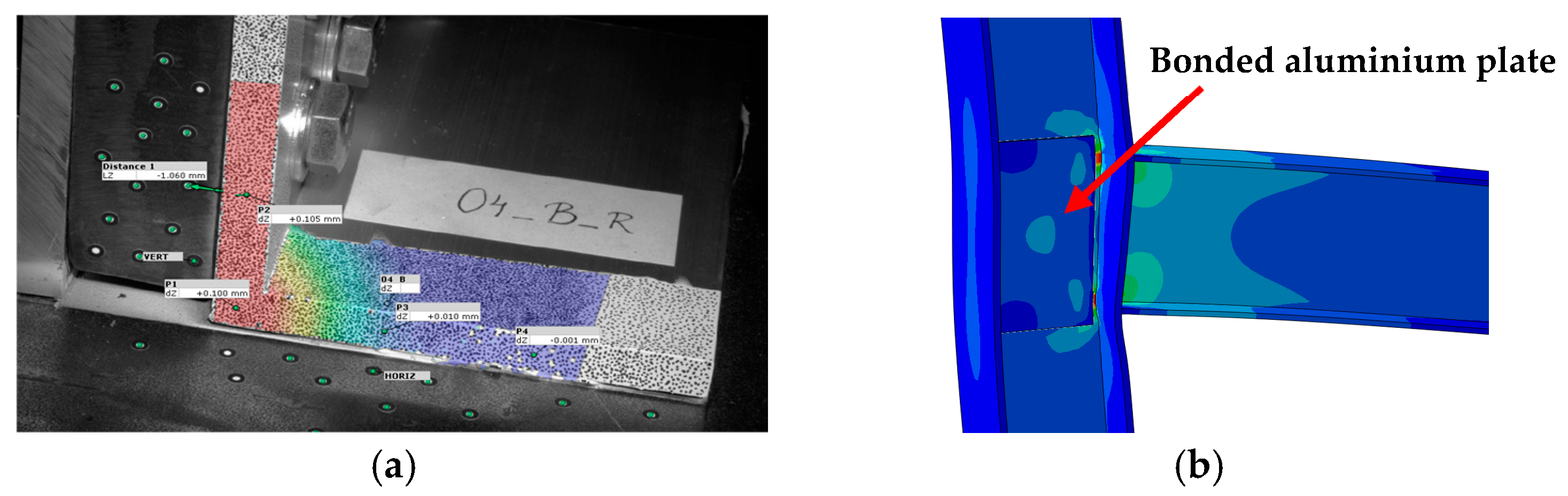

Nowadays, the use of bonded joints is increasing due to the numerous advantages they offer compared to traditional joining techniques (uniform stress distribution, ease of fabrication, possibility of joining different materials, stability of the mechanical properties of the base material) [

46,

47]. Aluminium adhesive T-connections, which are the subject of research in [

46,

48,

49], indicate the high ductility and resistance of such connections. To better understand the behaviour and research the possibility of application in construction, Skejić et al. conducted a laboratory test on adhesively bonded aluminium angles under tension, as shown in

Figure 2a, and the results showed a high resistance of such joints. The large scatter of results obtained for the same type of adhesive raises a number of questions that need to be investigated before its application in load-bearing aluminium structures. Preliminary parametric numerical analyses of beam-to-column joints showed that adhesives have the potential to strengthen joints, as demonstrated in

Figure 2b. There are no normative design rules for such innovative hybrid joints, so the research carried out in the REAL-fit project will contribute to a better understanding of their behaviour and reliability.

Despite the improvements made in developing 2G Eurocode 9 [

14], the application rules for the component method have not yet been evaluated probabilistically. Particular attention should be paid to welded and bonded aluminium structural joints, and this should be done systematically at experimental, numerical, and probabilistic levels.

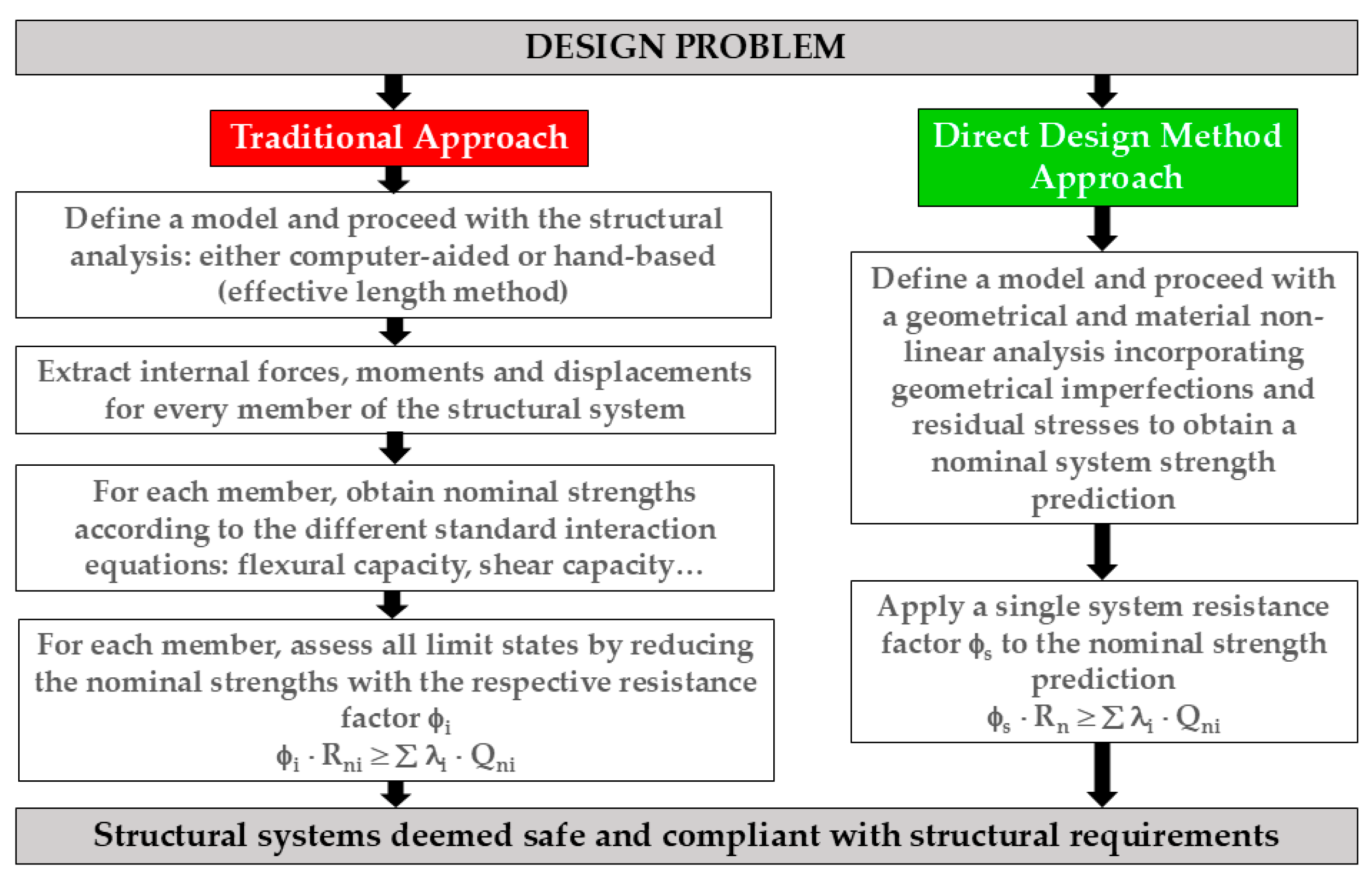

2.5. Design Approach

The traditional approach to structural design, through an elastic global structural analysis, cannot accurately predict the complex interactions between members, nor capture the inelastic redistribution of internal forces. Consequently, it cannot accurately predict the ultimate load capacity of a structural system or its failure mode. As an alternative, the modern approach through the direct design method (DDM) includes geometric and material nonlinearities. Consequently, it represents an ‘advanced analysis’ that leads to a more efficient structure design procedure with a more uniform level of structural system reliability. The difference between the traditional and the modern design approach (DDM) is shown in

Figure 3.

Particular attention in the DDM is given to the probabilistic assessment of parameters that significantly impact the system’s resistance. All system uncertainties are evaluated probabilistically within the DDM’s framework and included in the system safety partial factor γ

s. The advantages of this approach are visible from several aspects. Firstly, the final load capacity of the system can be estimated directly from the numerical analysis, eliminating the need to check each individual member and joint, which allows the design of lighter and more economical structures. Recent studies [

50,

51,

52,

53,

54,

55,

56] on stainless-steel frame structures show that by applying the DDM approach, 12–15% of the total weight of the structure can be saved compared to the traditional ‘member-based’ approach. On the other hand, the latest research on the application of the DDM in analysing frame structures made of stainless steel [

57] indicates that the serviceability limit state (SLS) is relevant for the design. Therefore, due to the highly nonlinear behaviour of aluminium and its similarity with stainless-steel behaviour, special attention should be directed to assessing aluminium structures from the aspect of the SLS.

Preliminary DDM analyses of aluminium-frame structures [

58] point to potential benefits, but comprehensive studies are still needed to quantify possible material savings. It should be noted that there are still no firm guidelines for the design of structures using the DDM. Therefore, prioritising creating a probabilistically evaluated database for different aluminium structural systems and components should be prioritised.

2.6. Life Cycle Assessment and Cost Analysis

To answer whether aluminium offers a sustainable solution for load-bearing structures, it is necessary to conduct comprehensive studies focusing on environmental and economic parameters. The methods of life cycle assessment (LCA) and life cycle cost analysis (LCCA), according to EN ISO 14,040 [

59] and EN ISO 14,044 [

60] standards, are intended to evaluate the mentioned parameters. LCA is based on a life cycle inventory (LCI) database containing material and energy flow values for relevant products and processes [

61].

According to some sustainability studies [

61,

62,

63,

64,

65,

66], aluminium structures have demonstrated potential as an efficient alternative to other materials.

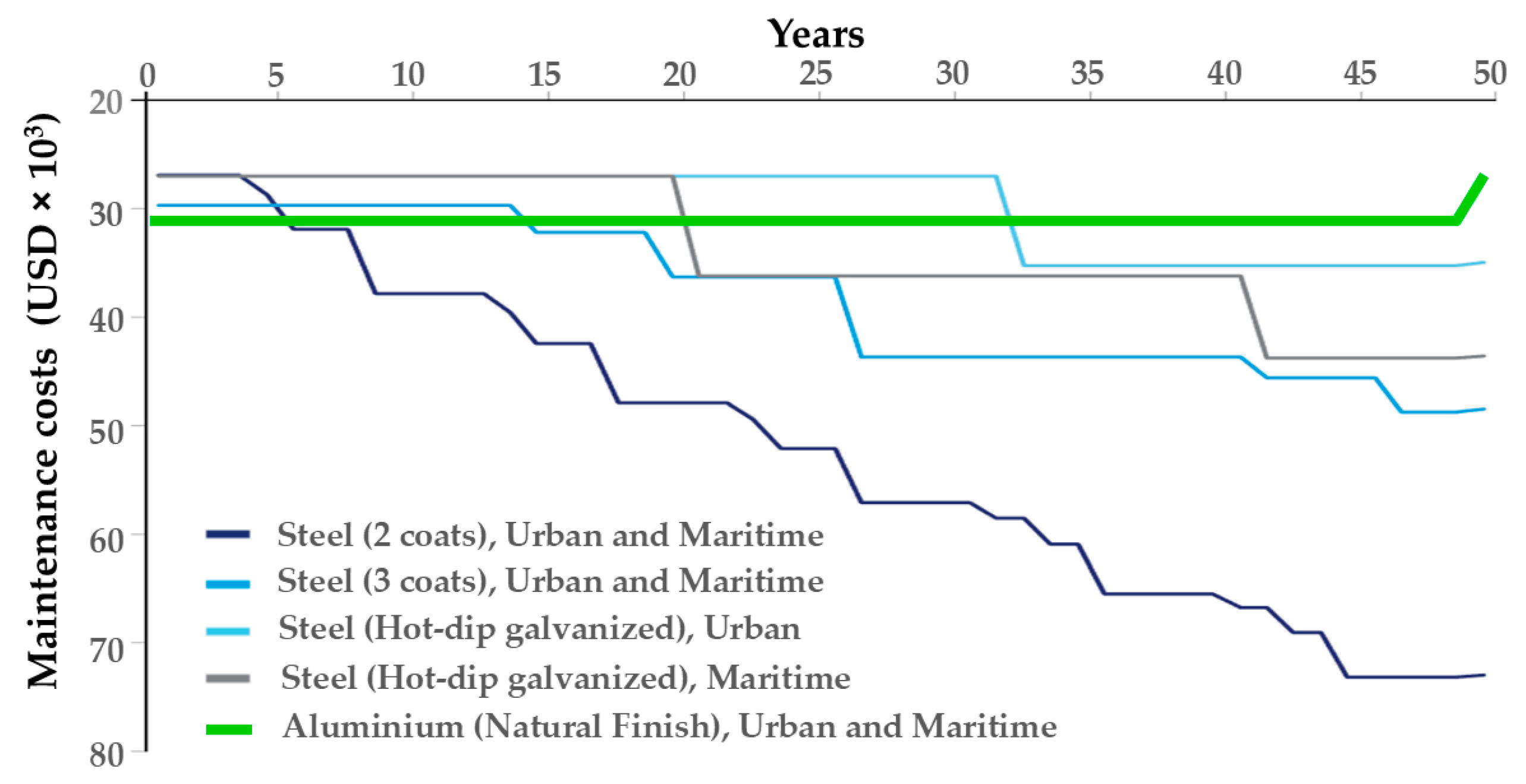

Figure 4 shows the cumulative costs of the analysed bridges during a 50-year lifetime in different types of corrosive environments (urban and marine) [

66]. Four steel bridges with different corrosion protection systems and one aluminium bridge without corrosion protection were analysed. The analysis shows that the maintenance costs of steel bridges increase rapidly and surpass those of the aluminium bridge, which, due to its natural corrosion resistance, requires little to no maintenance throughout its service life.

In the context of LCA and LCCA, optimising structures is of great importance for assessing environmental and economic impacts. The design approach of aluminium structures using the DDM, as seen in

Section 2.5, is the fundamental starting point for a reliable assessment of life cycle analyses and costs. In other words, an innovative approach that integrates the DDM with LCA and LCCA offers a promising framework for structural analysis and evaluating the long-term sustainability of aluminium structures.

3. Research Methodology and Objectives of the REAL-Fit Project

3.1. General

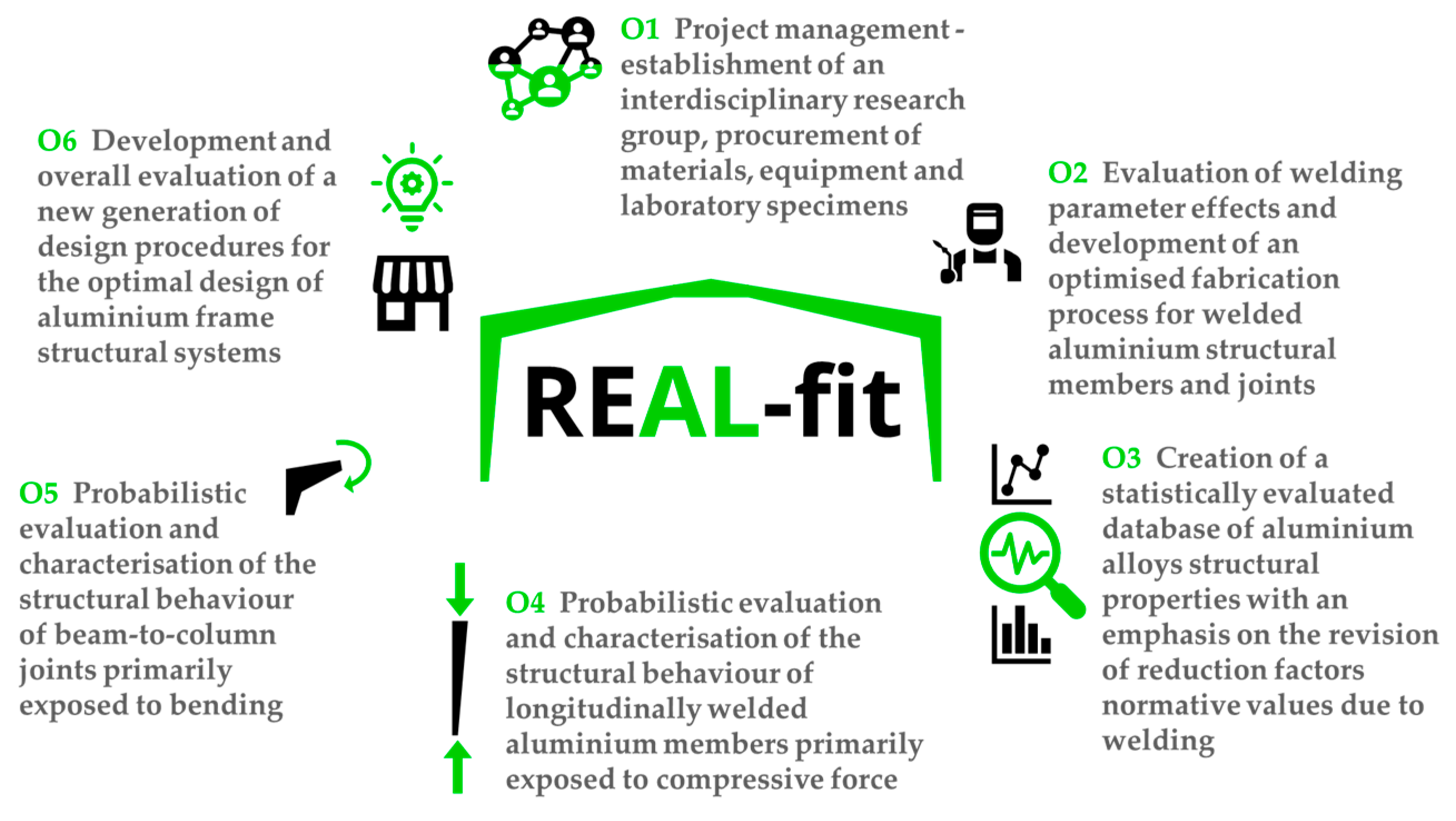

The research methodology within the REAL-fit project consists of analytical, experimental, numerical, and probabilistic methods. It is presented through the scientific research objectives of the project, as shown in

Figure 5. In addition to project management, O1 includes activities related to procuring materials and equipment, and the fabrication of specimens described in O2–O5.

3.2. Optimisation of Welding Processes

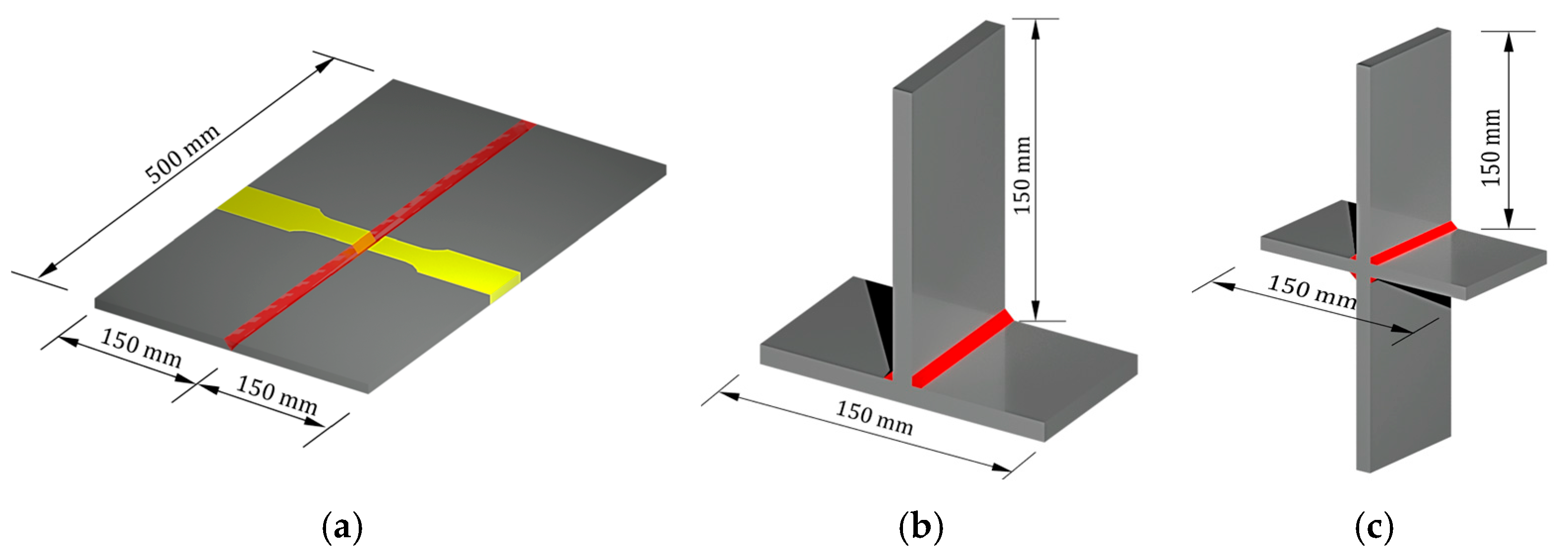

To achieve the optimisation of welding processes, specimens of butt-welded, T- and cruciform-fillet-welded connections were fabricated, as shown in

Figure 6. The scope of testing included three plate thicknesses (6, 8, and 10 mm), two aluminium alloys (AW 6082-T651 and AW 5083-H321), and two welding processes (standard DC-MIG-P and optimised AC-MIG-P). In total, 24 specimens of butt-welded connections, 44 specimens of T-connections, and 24 specimens of cruciform-fillet-welded connections were fabricated and tested at the micro and macro levels.

The specimens were used to determine the extent of the HAZ and to analyse the weld metal microstructure and the HAZ using EDS and SEM techniques. Hardness testing using a standard Reicherter measuring device (HV5) and residual stress measurement were performed using the Pulstec μ-X360 device with a Kuka robotic arm. The mentioned device uses the cosα-method of X-ray diffraction, a fast and non-destructive measurement method. Compared to conventional methods, the results of X-ray diffraction measurements are quantitative, and it is possible to perform measurements in all areas of the weld depending on the collimator. This gives the distribution of residual stresses in the desired orientation of the welded connection.

The optimisation of welding technology based on modified modalities of metal transfer in the electric arc and application of an alternating current in the MIG process (AC-MIG-P) were carried out. Compared to conventional MIG welding processes, such modified processes introduce a smaller amount of heat but with a larger amount of filler metal deposits. The goal of the mentioned tests was to develop an optimised welding process from the aspect of minimum energy, material consumption, and deformation and minimisation of the HAZ, which are still in the framework of Eurocode for the execution of aluminium structures (EN 1090-3 [

67]).

To evaluate the optimised welding process, part of the welded aluminium column and joint specimens (O4 and O5,

Figure 5) were made with the standard, and part with the optimised welding process. After the fabrication of welded I-profile specimens, 24 T specimens were extracted from them and tested using the previously mentioned methods. This correlated the results obtained on the specimens of welded connections with the actual state in the welded profiles. To achieve objective O5, as shown in

Figure 5, 36 cruciform-fillet-welded connections were fabricated, as shown in

Figure 6c. The specified specimens were tested using the previously mentioned methods to characterise the weld between the beam and the column in full-scale joint specimens. Residual stresses were also measured on full-size specimens of welded and printed (Wire and Arc Additive Manufactured (WAAM)) aluminium columns (O4,

Figure 5) and beam-to-column joints (O5,

Figure 5) using the X-ray diffraction method. These tests evaluate the effects of different welding processes at the level of the welded connections, welded and WAAM members, and beam-to-column joints.

3.3. Statistically Evaluated Database of Aluminium Alloy Mechanical Properties

To achieve the O3 objective (see

Figure 5), the existing database of mechanical properties of aluminium alloys [

15] will be expanded through additional tensile testing, data from manufacturers, and a literature review. The test program includes:

Three plate thicknesses (6, 8, and 10 mm);

Two alloys (AW 6082-T651 and AW 5083-H321);

Two coupon cutting orientations—parallel and perpendicular to the plate rolling direction;

Two welding processes (standard/optimised);

Three coupon types: non-welded, butt-welded, and printed (WAAM).

A total of 36 non-welded and 72 butt-welded coupons will be fabricated and tested in uniaxial tension. Butt-welded coupons will be extracted from larger welded assemblies to fulfil objective O2 (see

Figure 6a). Additionally, 12 3D-printed (WAAM) aluminium coupons will be produced to assess the influence of printing direction on mechanical behaviour.

The resulting dataset, supported by statistical analysis, is expected to provide a sound basis for proposing corrections to the currently adopted Eurocode 9 values for mechanical properties and the extent of the HAZ for different welding processes.

3.4. Assessment of Longitudinally Welded Aluminium Members

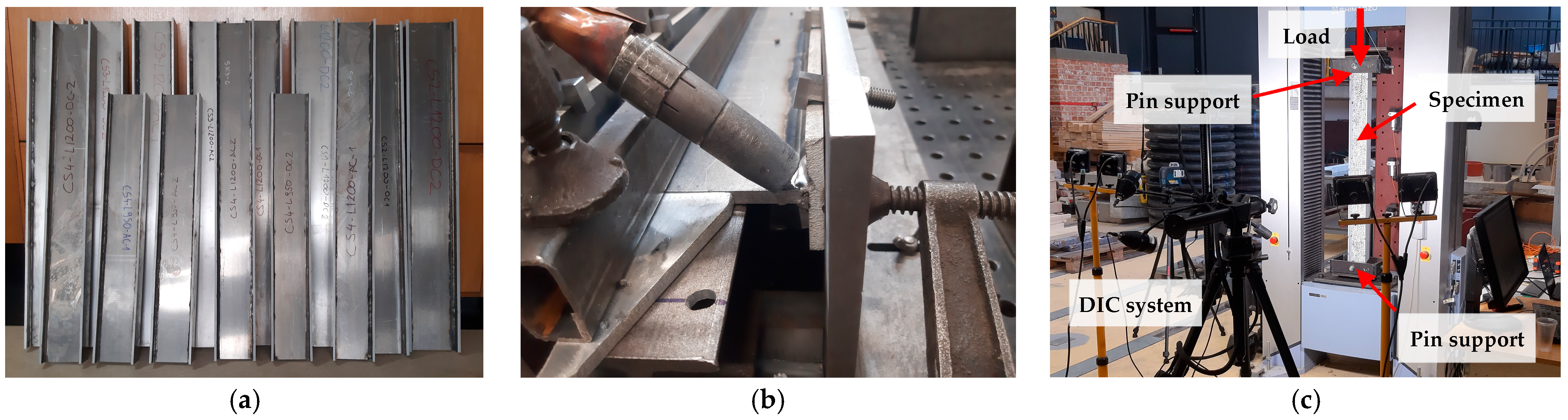

Longitudinally welded aluminium members were tested under centric compression until failure. The test scope included 32 specimens with a constant (

Figure 7a and

Figure 8) and specimens with a tapered cross-section (

Figure 7b). Specimens comprised plates of different thicknesses (6, 8, and 10 mm) and alloys (AW 6082-T651 and AW 5083-H321) and were welded using DC-MIG-P and AC-MIG-P welding processes. The height of the analysed cross-sections ranged from 110 mm to 180 mm, while the flange widths varied between 55 mm and 75 mm. For tapered members, taper ratios of 2 and 3 were used. The majority of specimens had an effective length of 1200 mm, in line with the open height of the testing machine. However, lengths of 950 mm and 650 mm were also included in this study. In addition, four specimens made with Wire and Arc Additive Manufacturing (WAAM) will also be tested under axial compression.

The geometry of all longitudinally welded members was recorded using an optical 3D scanner before they were placed in the testing machine. The testing of specimens was conducted using a Shimadzu AG-300kNX universal testing machine. In addition to a series of draw wires, the digital image correlation (DIC) system was used to measure the field of deformations of specimens during testing. Specifically, a high-resolution GOM ARAMIS optical 3D camera was used for this purpose.

In addition to the results of tests conducted on welded aluminium connections, those of tests conducted on longitudinally welded columns will be used to calibrate numerical models. The purpose of these models is to conduct extensive parametric numerical analyses in order to valorise buckling curves and to evaluate the EN 1999-1-1 [

14] design procedure for longitudinally welded compression members.

The tests conducted within the REAL-fit project will, from the resistance and economy point of view, enable the determination of the optimal welding methods and the adoption of new, experimentally, and probabilistically based design methods for longitudinally welded aluminium members under compression. The influence of different welding methods on the global behaviour of welded aluminium members has not yet been studied, nor has the global behaviour of WAAM aluminium members under compression, which makes the proposed research innovative. The methodologies will be improved by performing second-order probabilistic analyses (STRUREL [

68]) that will allow, for the first time in the world, an argumentative assessment of standardised procedures for designing longitudinally welded aluminium members under compression.

3.5. Assessment of Welded Beam-to-Column Joints

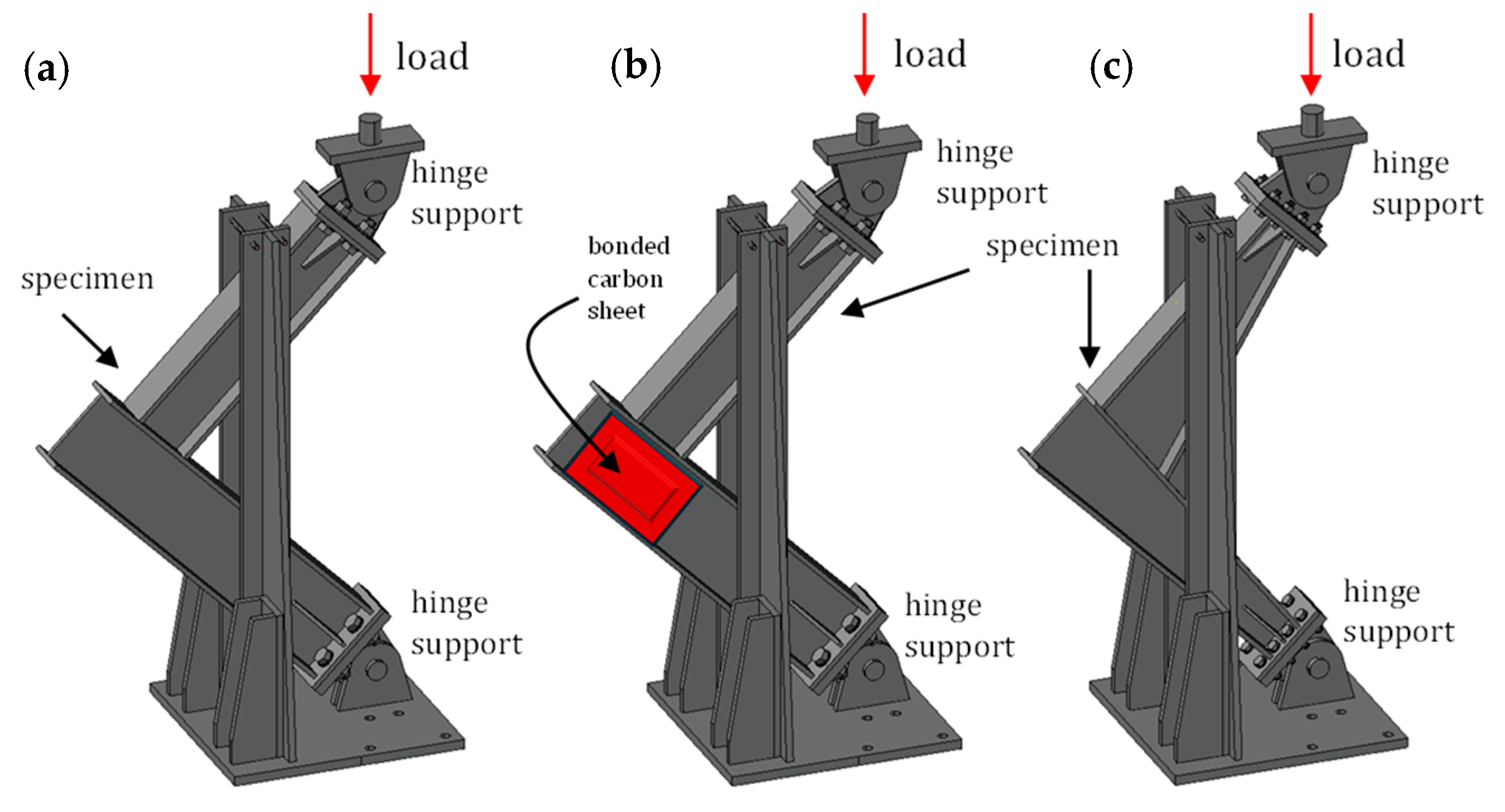

After the preliminary numerical analyses of the welded beam-to-column joints, the experimental part of the research follows, in which the specified joints will be tested in bending until failure, as shown in

Figure 8. The scope of testing of the beam-to-column joints includes cross-sections composed of two different plate thicknesses (8 and 10 mm), two alloys (EN AW 6082-T651 and EN AW 5083-H321), two different welding processes (standard/optimised), and the application of adhesively bonded carbon sheets to strengthen the column web panel. A total of 36 specimens of welded joints will be fabricated and tested: 24 with constant members (

Figure 8a,b) and 12 with tapered cross-section members (

Figure 8c). Joints will be preliminarily designed to achieve the failure of the web components of the columns. Herein lies the justification for joint reinforcement with bonded carbon sheets (

Figure 8b), as an effective and quick solution to the component stability issue.

Figure 8.

Proposed test setup of welded beam-to-column joints: (a) without reinforcement, (b) with reinforcement, (c) with tapered cross-section.

Figure 8.

Proposed test setup of welded beam-to-column joints: (a) without reinforcement, (b) with reinforcement, (c) with tapered cross-section.

The same experimental setup and measurement techniques described for testing columns (

Section 3.4) will be employed for testing the beam-to-column joints. Based on calibrated numerical models, a parametric analysis will be conducted, emphasising the influence of welding/bonding, different geometries, axial load levels, etc. Design methods for the behavioural assessment of the different beam-to-column joints will be evaluated probabilistically (STRUREL [

68]). This will result in an optimal design proposal for the resistance and stiffness of welded aluminium beam-to-column joints and a proposal of partial factors for a practical design at a semi-probabilistic level.

The proposed methodology includes laboratory tests on full-scale specimens of welded aluminium beam-to-column joints, which have not yet been conducted so far. Using bonded carbon sheets as column web reinforcement contributes to the innovative nature of the planned experimental programme.

3.6. Development of Procedures for the Optimal Design of Aluminium Systems

To achieve the last objective (O6,

Figure 5), an original and comprehensive probabilistic analysis will be conducted to evaluate the realistic behaviour of aluminium-frame structural systems. The variability of mechanical and geometrical properties and their influence on the reliability of design methods for designing aluminium structural systems will be investigated. Different geometries of frame systems, load combinations, and targeted reliability indices will be defined for conducting complex numerical simulations utilising the DDM. This modern design approach will be systematically applied for the first time in designing aluminium structures to optimise and predict the ultimate capacity of the entire system, which indicates the innovation of proposed methodology.

To conduct a life cycle assessment (LCA) and life cycle cost analysis (LCCA), the research objectives and scope will be defined, and the latest relevant data necessary for the database formation will be collected. Since LCA results are significantly affected by the data quality in the LCI database, one of the project objectives is to collect and statistically process different databases to obtain a reliable and comprehensive assessment of the sustainable character of aluminium structures.

As research work planned within the REAL-fit project includes detailed analyses of all uncertainties, the implementation of the innovative DDM has a clear and justified goal from the perspective of the economic efficiency and sustainability of aluminium structures. The probabilistic evaluation of aluminium-frame structural systems through the DDM, complemented by LCA and LCCA, represents a novel and integrated methodological approach to provide a more realistic behaviour assessment of aluminium structures throughout their life cycle.

4. Preliminary Results and Expected Outcomes of the REAL-Fit Project

4.1. Valorisation of Welding Processes

To achieve the optimisation of welding processes for different aluminium alloys and plate thicknesses, specimens of welded connections, members, and structural joints will be fabricated and tested at the micro and macro levels.

The optimisation of welding technology is achieved by changing the modalities of metal transfer in the electric arc and by using alternating currents in the MIG process (AC-MIG-P). The optimisation will be carried out to minimise energy, material consumption, and the HAZ, but with welding processes that comply with the Eurocode to execute aluminium structures (EN 1090-3 [

67]). An extensive test campaign will make it possible to evaluate the effects of the different welding processes at the level of the welded connections, the welded and WAAM members, and the welded beam-to-column joints.

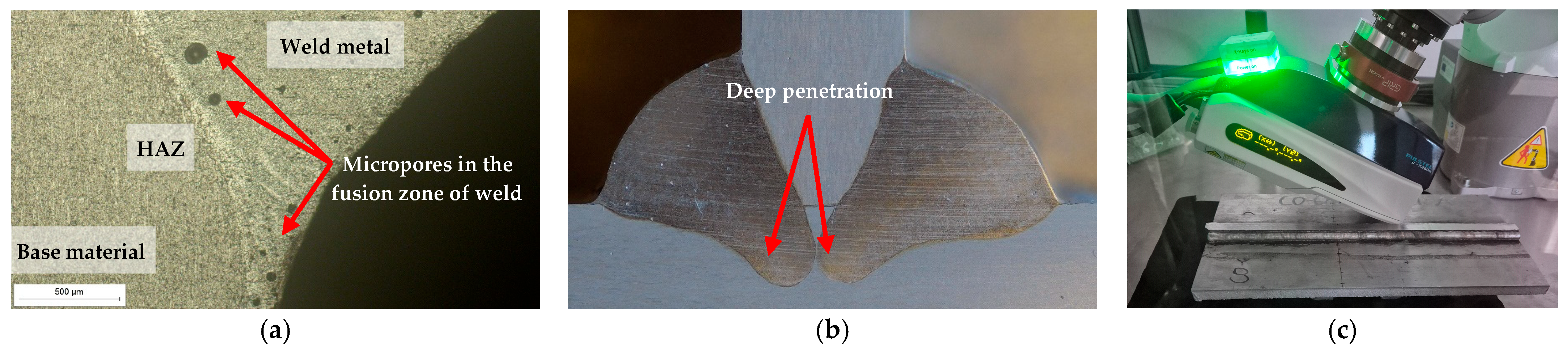

As part of the REAL-fit project, welds of the aluminium alloys EN AW-6082-T651 and EN AW-5083-H321 were tested on a microstructural and macrostructural level and residual stresses were recorded, as shown in

Figure 9. The specimens included butt, fillet (T), and cross joints, and the aim was to identify microstructural changes, the homogeneity of the connections, and possible defects, such as microcracks and gas inclusions within the welds (

Figure 9a). The analysis was carried out using optical microscopy with metallographic preparations that included cutting, grinding, polishing, and etching.

Figure 9b shows the microstructure of the weld root, while

Figure 9b shows the macrostructure of the T-connection weld produced by the DC-MIG-P welding process. Residual stress measurement on the butt-welded connection is shown in

Figure 9c.

The results show considerable differences depending on the welding process and alloy type. For butt weld connections, the AC-MIG-P process resulted in a narrower weld zone and less plate deformation compared to DC-MIG-P. Alloy EN AW-6082-T651 showed more pronounced local changes in the HAZ, including an increase in hardness due to artificial ageing, while connections made from the alloy EN AW-5083-H321 showed a more gradual hardness transition between the weld and the base material.

4.2. Database of Aluminium Alloy Mechanical Properties

The structural properties of aluminium alloys are known to introduce a high level of uncertainty in structural reliability analyses, primarily due to the wide variety of available alloys and tempers [

15]. This variability arises from differences in chemical composition, welding procedures, and heat treatment parameters.

In the current phase of the REAL-fit project, the existing database was upgraded, and statistical analysis was carried out. Within the statistical analysis, a number of mechanical properties of aluminium alloys will be considered, namely nominal yield and tensile strength for the base and weld material, Poisson’s ratio, and modulus of elasticity. Upgrading the database of structural properties of aluminium alloys [

15] can be achieved with additional collected material tensile test results by the manufacturer, a literature review, and tensile tests that are performed on unwelded, butt-welded, and printed (WAAM) coupons.

Before conducting a statistical analysis of the mechanical properties of aluminium, the collected tensile test results of the materials were divided into groups according to the relevant properties given in EN 1999-1-1:2023 [

14]: alloy, temper, product type, and thickness. The Vose ModelRisk software [

69] processed the collected results.

Processed results were fitted to appropriate continuous distributions, and the distribution parameters were estimated using the maximum likelihood estimation (MLE) method. The suitability of the distributions was assessed using the Schwarz Information Criterion (SIC), the Akaike Information Criterion (AIC), and the Hannan–Quinn Information Criterion (HQIC). The distribution model yielding the lowest deviance across all three criteria was selected. Preference was given to the Lognormal and Weibull distributions, as they are recommended for resistance variables according to EN 1990 [

70], ISO 2394 [

71,

72].

From the fitted continuous distribution functions and their estimated parameters, the 0.1% and 0.5% fractiles were determined, representing the two most important fractiles from a design perspective. It should be noted that the 0.1% fractile represents the design value, and the 5% fractile represents the characteristic value. Partial material resistance factors were also determined, which are important since structural Eurocodes apply the format of partial factors within the concept of limit states. Proper calibration of partial factors ensures the desired level of structural reliability.

The compiled and statistically evaluated database will serve as the basis for the probabilistic validation of mechanical property values currently adopted in Eurocode 9. In addition, it will support the ongoing development and evaluation of probabilistic design procedures for aluminium members, joints, and structural systems (Objectives O4–O6, see

Figure 5).

4.3. Longitudinally Welded Aluminium Members

Following the successful fabrication and testing of welded aluminium connections, a series of longitudinally welded aluminium specimens were produced. Under the scope defined in

Section 3.4., a total of 32 specimens with a constant I-shaped cross-section and 8 specimens with a tapered I-shaped cross-section were fabricated to investigate the flexural buckling behaviour of longitudinally welded aluminium members (

Figure 10a). The test specimens were welded using semi-automatic and automatic DC-MIG-P and AC-MIG-P welding processes. Particular attention was paid to minimising the deformation caused by the welding process. To this end, a customised steel fixture was used to clamp the specimens securely during welding and cooling, as shown in

Figure 10b.

Prior to testing, preliminary numerical analyses were conducted for each laboratory test specimen to determine both the lower and upper bounds of the expected buckling resistance and the potential failure modes. These analyses were based on numerical models developed in accordance with the assumed geometry of the laboratory specimens and incorporating data from various sources to account for material and geometrical nonlinearities. This step was crucial to ensure that the hydraulic press’s capacity would not be exceeded and to prevent the occurrence of failure modes other than flexural buckling, which was the primary focus of this phase of the research.

All specimens were subjected to axial compression under displacement-controlled loading at a constant rate of 0.01 mm/s. Loading was terminated once 80% of the maximum compressive force was reached. The test setup allowed free rotation around the minor axis, and no lateral restraints were applied (

Figure 10c). Flexural buckling was the only observed failure mode. A digital image correlation (DIC) system was employed in combination with a series of draw-wire displacement transducers to monitor deformations during testing. Initial geometric imperfections were captured for all specimens before testing using an optical 3D scanner.

The experimentally determined buckling resistances were, for most specimens, very close to the upper bound values obtained from preliminary numerical analyses and in some cases even exceeded them. All recorded resistances were also significantly higher than those calculated using the design provisions prescribed in EN 1999-1-1 [

14]. This can be attributed to two main factors: the actual extent of the heat-affected zone (HAZ) in the tested specimens was much smaller than the assumed values in the numerical models, and the mechanical properties of the material were, in several cases, above the mean values estimated from reference data [

15]. After testing, all specimens exhibited clear lateral deformation consistent with global flexural buckling mode.

Obtained test results will be used to calibrate numerical models on which parametric analyses will be performed to valorise Eurocode 9 buckling curves. The probabilistic evaluation will result in a scientifically based proposal for the optimal design method of welded aluminium members under compression and a proposal of partial factors for a practical design.

4.4. Welded Beam-to-Column Joints

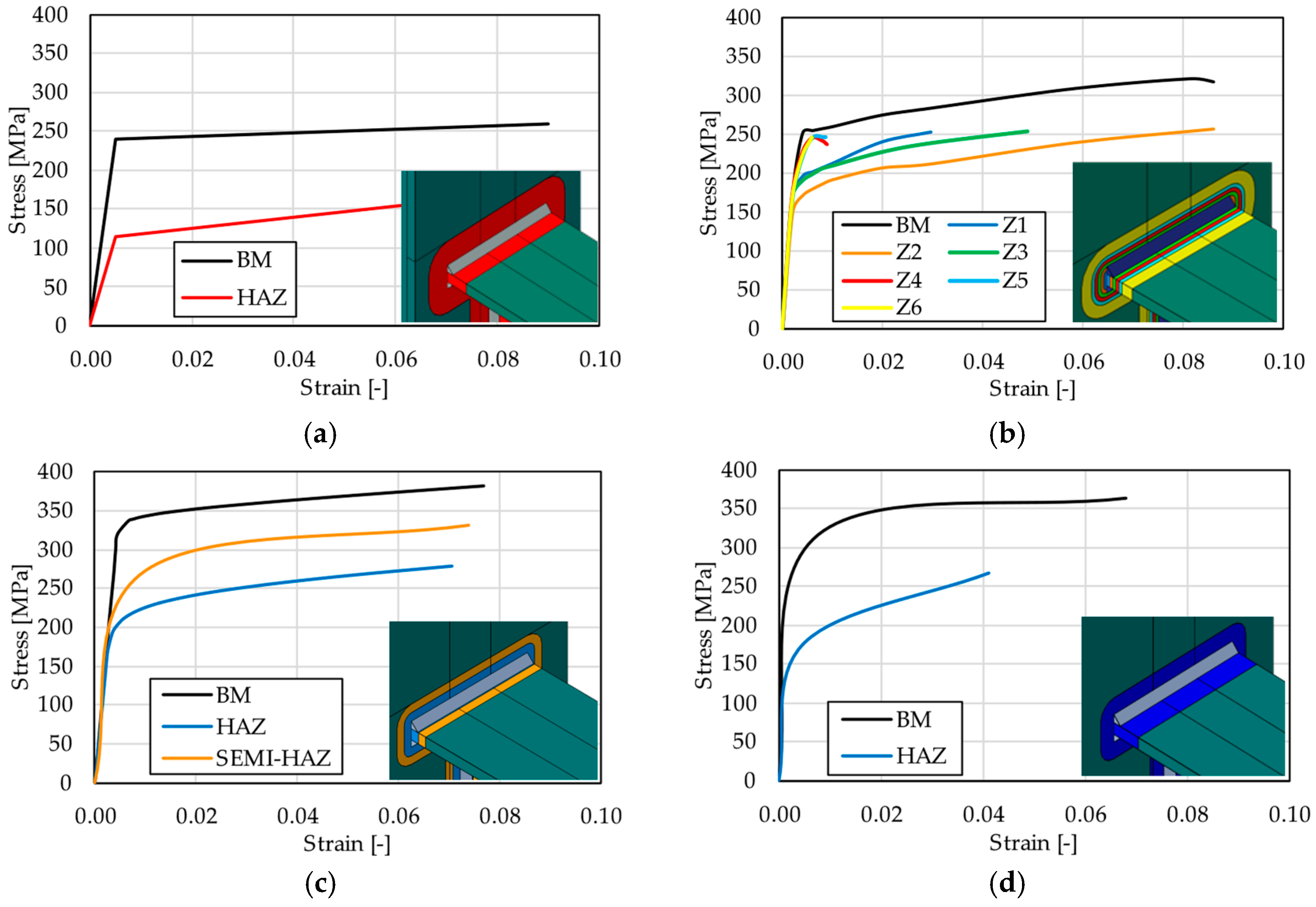

A preliminary parametric numerical study was carried out on 21 models of aluminium beam-to-column welded joints [

39]. Several parameters were varied to obtain the results necessary to gain better insight into the behaviour of welded aluminium structural joints under the influence of the HAZ. In addition to the specifications given in European and American standards for the design of aluminium structures, experimental data from a recent study on the HAZ were also used as input for numerical models (

Figure 11) [

39]. A detailed overview of numerical models and the obtained moment–rotation curves show that the behaviour of some models is not as conservative as assumed in the design standards considered.

The preliminary numerical analyses formed the basis for further numerical simulations and the definition of laboratory joint specimens to be tested in bending to failure. The REAL-fit project will also investigate using adhesives to strengthen weaker components of welded beam-to-column joints.

After the experimental part of the research and the parametric numerical analysis, a second-order probabilistic analysis (through the reliability index) will be performed. Finally, optimal design procedures for the resistance and stiffness of welded aluminium beam-to-column joints, and partial factors for practical design at a semi-probabilistic level, will be proposed.

4.5. Advanced Design of Aluminium Structural Systems

In structural engineering, system-based advanced design methods are increasingly considered practical design approaches for carbon steel and stainless-steel structures. However, extending these methods to aluminium structures has not yet been achieved. Aluminium structures, with their lower modulus of elasticity and limited ductility, and manufacturing processes such as extrusion result in material and geometric uncertainties different from those obtained for steel or stainless-steel alloys. Therefore, it is necessary to carry out independent reliability calibrations for this material.

A pioneering application of the direct design method (DDM) to aluminium portal frames under gravity load [

58] is one of the preliminary results of the REAL-fit project. The methodology adopted in this work involves a combination of advanced nonlinear finite element analyses incorporating actual geometric and material properties with a rigorous system reliability methodology. This approach addresses inherent uncertainties in the ultimate frame resistance by including variables such as the 0.2% proof strength, the modulus of elasticity, cross-sectional properties, initial geometric imperfections of members and frames, and the residual stresses as random variables. Using advanced simulations for two typical aluminium frames featuring two different alloys from the 6xxx series, this study analyses the system reliability of these frames under gravity loading conditions, considering different live-to-dead load ratios. From the derived system reliability indices, suitable system safety and resistance factors are proposed for the direct design of aluminium portal frames in the European and US design frameworks under gravity loads.

The probabilistic assessment of aluminium-frame structural systems through the DDM will be complemented by a life cycle assessment (LCA) and a life cycle cost analysis (LCCA). Finally, the results of such an integral approach, together with the optimisation of materials and production, will guarantee the required, consistent level of structural reliability during construction and throughout the entire lifetime.

5. Conclusions

Structural aluminium alloys offer numerous advantages over traditional construction materials, such as low weight, corrosion resistance, and full recyclability. However, their application is currently limited to relatively short-span structures due to the dimensional constraints of extruded profiles. The use of welded members makes it possible to overcome larger spans and rationalise the material usage, as welding makes it possible to obtain members with variable cross-section height shaped according to their function in the structural system. However, the current design approach for such welded members remains overly conservative and inefficient, being based on outdated test results or lacking experimental validation.

The REAL-fit project evaluates the effects of modern welding techniques on reducing aluminium properties in the welded connection zone. The results of this part of the research will lead to a proposal for an optimised fabrication process for welded aluminium members in terms of minimum energy and material consumption. This optimised welding process will form the basis for research into the global behaviour of welded aluminium members and beam-to-column joints. This research represents one of the first comprehensive efforts to systematically evaluate the global behaviour of welded aluminium members and joints based on modern welding techniques.

The research methodology will be further enhanced through extensive parametric numerical and probabilistic analyses that will enable a scientifically based evaluation of the procedures for designing welded aluminium members and joints in Eurocode 9. In the project’s final phase, all the knowledge gained during the implementation will be used to develop a new holistic approach to evaluate the reliability and sustainability of economic aluminium structures throughout their lifetime. The stated approach will integrate the advanced direct design method with the life cycle assessment and life cycle cost analysis methods.

The systematic development of rules for the design of modern welded aluminium structures, to be carried out in the project REAL-fit, would enable the application of advanced technologies in construction—from design (approach via DDM) to execution (optimised welding process) to end-of-life (LCA and LCCA), and again in this circular process (infinite possibility of 100% recycling). In practical terms, the results of this project will allow greater use of aluminium by designers and investors. The scientific community will benefit from original experimental, numerical, and probabilistic research that has not yet been conducted.

In practical terms, the outcomes of the REAL-fit project will facilitate the broader application of aluminium by making it more accessible and attractive to designers, engineers, and investors. In addition to its scientific contributions, the project will also have tangible societal and economic impacts. It should be noted that this paper focuses on presenting the conceptual and methodological foundations laid during the project’s first year. More detailed technical results—particularly those related to advanced simulations, system reliability, and sustainability assessment—will be addressed in depth in future publications as the project progresses.