1. Introduction

Building Information Modeling (BIM) has significantly affected the construction industry over the past decade [

1]. Various studies have shown the benefits of applying BIM, such as improvements in design and faster and more effective processes, such as cost estimates, energy simulations, and on-site monitoring of tasks [

2,

3].

Similarly, implementing the BIM methodology has also had a relevant impact on the industrialized construction sector. With the help of information-rich construction models and the integration of data from different processes, BIM has provided the industry with great potential to promote the industrialization of construction and even improve the performance of modular construction [

4].

To achieve a successful BIM implementation, one of the most relevant aspects to consider is the standardization of information flows between the different activities, disciplines, and phases of a process, as well as capturing the correct information within each information model [

5]. Standards are fundamental for communication between the various disciplines involved in projects, whether architects, engineers, contractors, specialists, or owners, who work with different nomenclatures, vocabularies, geometries, formats, and data schemas. Therefore, advancing standardization is a key factor in adopting BIM [

6].

Likewise, the development of BIM standards makes it possible to address the different interoperability challenges that occur within the workflows of this methodology. Interoperability is the ability of diverse systems, organizations, and/or individuals to work together, using each other’s parts or equipment, to achieve a common goal, regardless of their differences [

7]. In this way, when BIM systems are interoperable, the different project participants can share and generate information on the different progress and phases of the project [

7].

One of the standards defined within the BIM methodology is the Information Delivery Manual (IDM), which involves the identification and documentation of the processes and requirements for information exchanges within the processes [

8]. ISO 29481-1:2016 [

9] defines this standard to provide a methodology to capture and specify the processes and information flows required during the asset lifecycle [

10]. Likewise, this regulation provides a reliable basis for exchanging information between users so that they can be sure that the information they are receiving is sufficient to carry out the activities within the process [

9].

Ramaji and Memari [

1] present a method to standardize information exchanges in industrialized modular projects, developing an IDM based on the method proposed in the National BIM Standard (NBIMS-US) and incorporating the Product Architecture Model (PAM) concept, whose purpose is to address the additional needs that exist in the development of modular buildings [

1].

On the other hand, Nawari [

5] addresses the challenges and opportunities to advance BIM standards in off-site construction. In this research, an IDM is proposed that provides a concrete description of the off-site construction processes of buildings and the information requirements that must be delivered to allow these projects to be carried out successfully. The proposal of this IDM incorporated exchanges of information between various actors involved: architects, engineers, manufacturers, general contractors, and other subcontractors [

5].

In order to further advance the harmonization of standards in timber construction and framed in the Finnish project “projectGENERIC” and “Puurakentamisen suunnittelun automaatio”, Keskisalo, M. et al. [

11] published a paper whose objective is to map the needs of companies in the object sector with BIM modeling to incorporate them into the BIM object library “Nordic BIM library” and serve as a basis for the harmonization of standards in the construction sector with mass timber.

As part of the project UF-DCP-002 Wood Structural Design to Structural Analysis [

12], an IDM and Model View Definition (MVD) standard for the design of timber structures is proposed. N. Nawari [

6] reviews the state of BIM tools in modeling timber structures and formulates the functional requirements for developing successful BIM models to design timber structures. In particular, this research focused on the exchanges of information between architects and engineers during the preliminary design phase of the project [

6].

According to this research, it is possible to mention that the development and advances in BIM standardization within the off-site timber construction industry have been addressed and explored independently. On the one hand, it has focused on developing the projects themselves, and on the other, requirements and process mappings for off-site construction have been formulated. There is a need for the integration of both processes.

To unite both aspects, Rojas et al. [

13] analyze the IFC defined in the international standard ISO 16739-1:2018 [

14], which, although it is replaced by ISO 16739-1:2024 [

15], does not imply any change in the IFC object of said work, referring to building projects, having produced changes only in the inclusion of aspects related to linear and civil works. Rojas et al. [

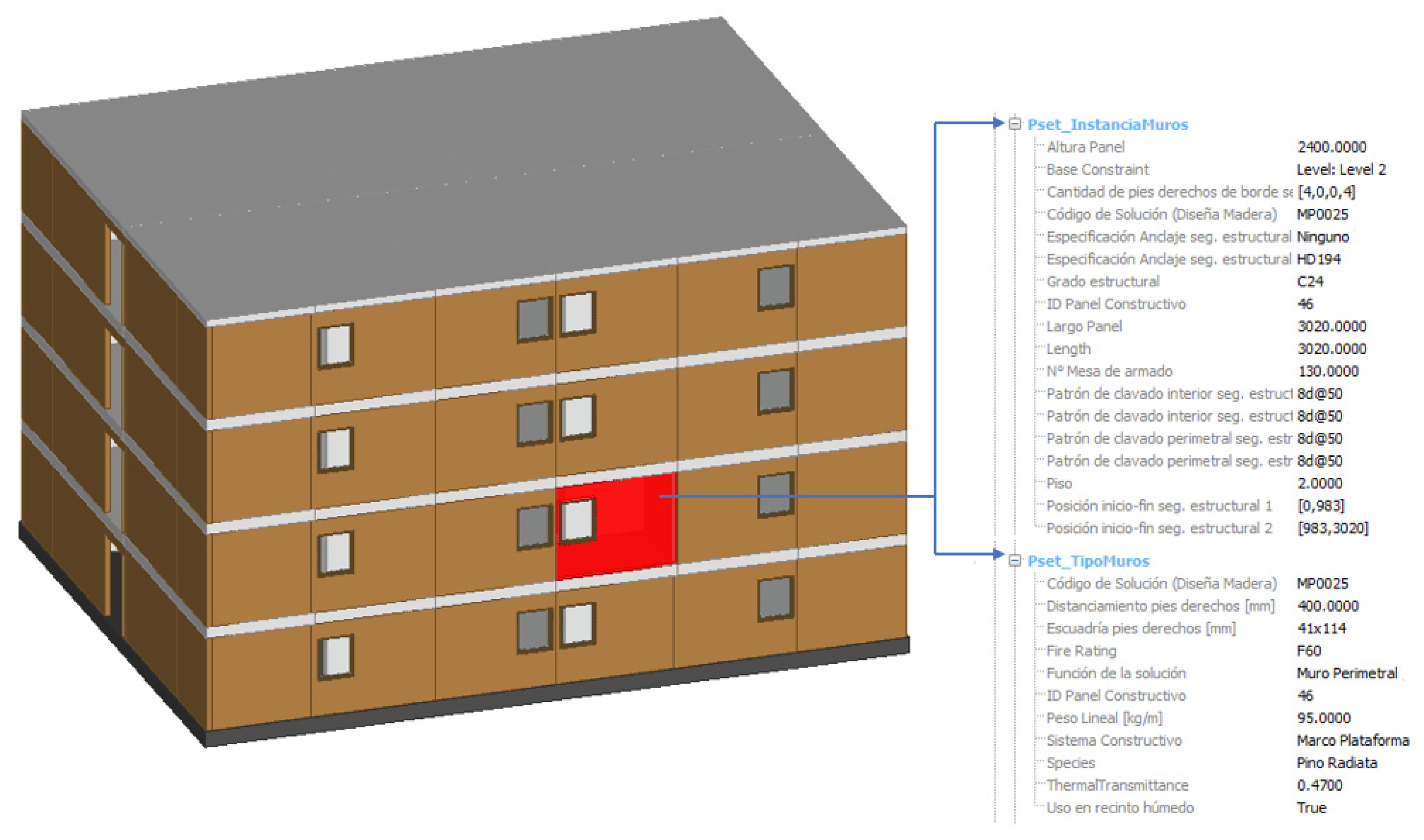

13] propose a new exchange model in which a series of parameters are incorporated that are considered minimum to achieve optimal implementation of the BIM methodology in industrialized construction projects with a timber frame structure.

In this way, having a standardized data model that considers the information requirements for each activity is essential to ensure that information exchanges are carried out better, and with it, the process and development of projects improve themselves. Thus, in the context of adopting the BIM methodology within industrialized timber projects, one of the important challenges is to define the exchanges of information between the different processes, one of these being the commercial evaluation process that occurs in the early stages.

Cost estimation in the early stages is a crucial element in any construction project. An accurate estimate of the initial cost will support project decision-making, considering that the project cost is significantly affected by decisions made in the design phase [

16]. In this way, the commercial evaluation process in the early stages takes on great significance, particularly for industrialized timber projects. This process must consider not only the requirements of a traditional project but also the assumptions and requirements that the design entails, which are necessary for the industrialization, manufacturing, and assembly process.

Regarding the use of BIM in the timber industry and, in general, in the construction industry, it has been based on the use of digital models that have made it possible to facilitate the different processes and activities within the development of projects, since through the use of information models, it has been possible to coordinate the different specialties, improve the visualization of its components, analyze performance, and facilitate the processes of cost estimates, assembly sequence, manufacturing, logistics, and others [

17,

18].

The timber industry has made progress in defining BIM standards, covering the required information exchanges, for example, for the design of timber structures, focusing on information exchanges between architects and engineers during the preliminary design phase of the project [

6]. Similarly, Rojas et al. [

13] proposed an IDM associated with the evaluation process of industrialized timber projects for the system based on light frame (2D) panels. This proposal identifies the phases, actors, and activities present within this process, where the approach was based on the exchange model (EM) required to evaluate the project during the early phases. The EM defines the functional content of the information to be exchanged in a use case. A use case defines the data required in each information exchange scenario between disciplines within a workflow.

Along these lines, it is possible to mention that, although there have been developments of standards that have sought to map the standardization of information flows between processes, the real impact of using these standards and thus valuing the effects and possible improvements (for example, increased efficiency) in the development of activities that are executed during the different phases of the project has not been evaluated.

In this way, this research aims to evaluate the effectiveness and efficiency of the information exchange model (EM-01) proposed for the commercial evaluation of industrialized timber projects. The evaluation process was carried out based on two projects (“case illustrations”) where two experienced professionals from different industrialized timber companies implemented the information exchange model (EM) developed by Rojas et al. [

13] and compared their results with a traditional method that used information based on planimetry, documents, or 2D information.

This study contributes practical insights about incorporating standardized information into the processes and requirements for information exchanges to enhance the accuracy and reliability of early commercial evaluation in industrialized timber projects.

4. Results of the Evaluation of the Use of the EM_01 Exchange Model in the Early Evaluation Process of Industrialized Timber Projects

This section presents the results of the experimental method described in

Section 3. The results are shown for the tested variables associated with the effectiveness, general evaluation, efficiency, and level of uncertainty of the users when carrying out the commercial evaluation process of a timber building project when using the traditional method (based on 2D information) and, on the other hand, when using the EM-01 information exchange model.

The results are based on the charrettes in which the evaluators of the participating companies participated at the time of carrying out the commercial evaluation process of the W and/or Z project. The graphs and conclusions presented below are obtained directly from these questionnaires.

4.1. Effectiveness and Overall Evaluation

First, the results show that it is possible to conduct the project’s commercial evaluation using either of the two methods. Considering that the traditional method is effective since it is the method that is commonly used and is validated by experience, and that quotations obtained are relatively similar by using both methods, this implies that with the exchange model method, obtaining the value of a quote for the project in question is possible, demonstrating its effectiveness.

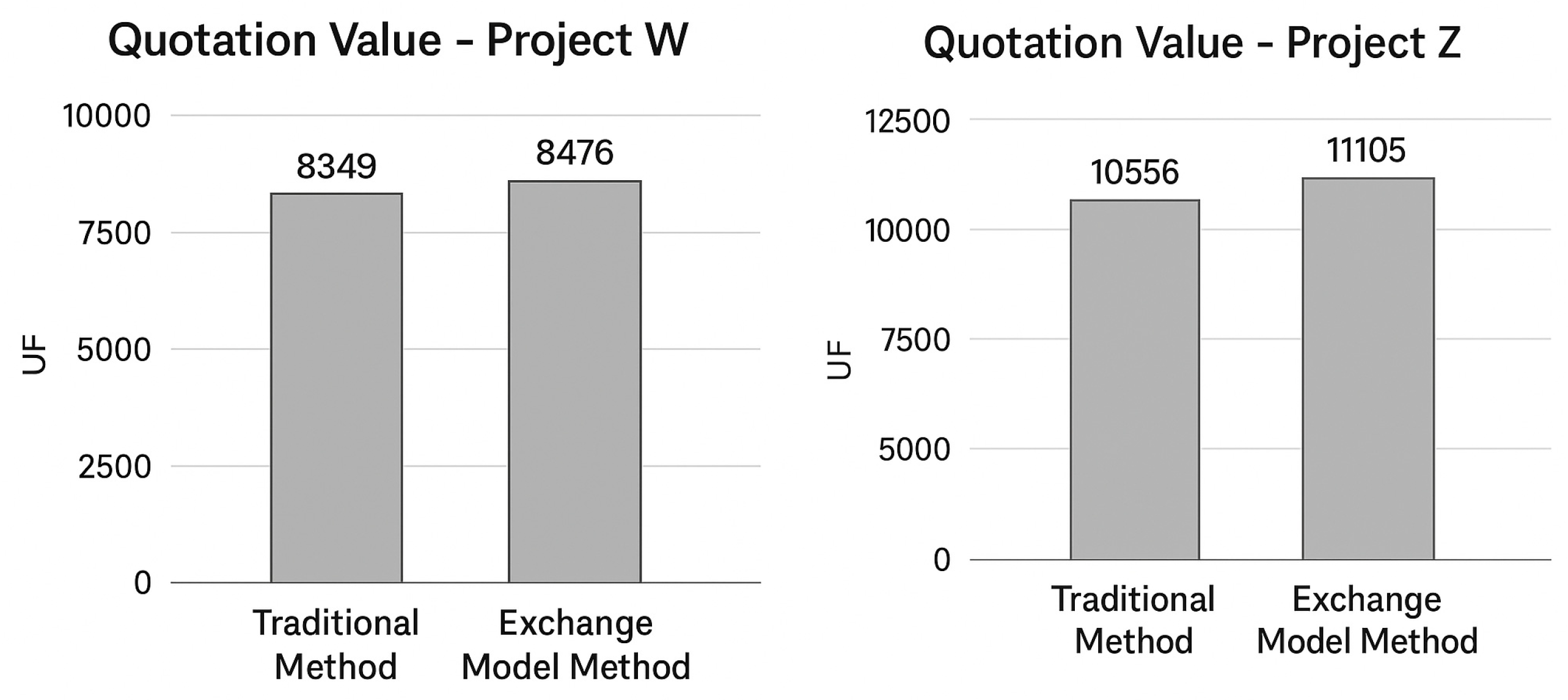

Figure 4 shows the values obtained by both methods for projects W and Z.

According to the evaluators’ opinions, although the commercial evaluation process was possible using any of the methods, the exchange model (method X) has certain advantages over the use of the traditional method. According to the evaluators, one of the main advantages of using the EM_01 model is that there is accurate information to ensure minimum values required for the evaluation, for example, square meters of solutions, type of solutions, acoustic and fire requirements, and number of right feet. Likewise, another advantage of this method is that it allows for greater speed in carrying out the calculations (for example, obtaining the total square meters of the building), where subsequent verification is also not required. Similarly, the EM_01 model allows for more specific and detailed data regarding information associated with manufacturing, for example, the number of panels and configuration of assembly tables, which allows for a better estimation of the project’s manufacturing times and costs.

On the other hand, the evaluators also commented on possible difficulties or disadvantages regarding using this model in contrast to the traditional method. These disadvantages are mainly based on the need for and use of more specific programs (software or applications), where an evaluator may not be familiar with these tools. Also, there is no room for iterations when using the exchange model, and comparing it with projects already executed is not easy. Finally, another disadvantage is that it would be very difficult to detect if the exchange model has an error.

According to

Figure 4, the quotation results obtained using the exchange model method are higher than the traditional method for both projects. Although the difference does not exceed 5% in any of the projects, according to users, this is mainly because the exchange model considers a more conservative structural result than the one considered in the traditional method.

4.2. Efficiency

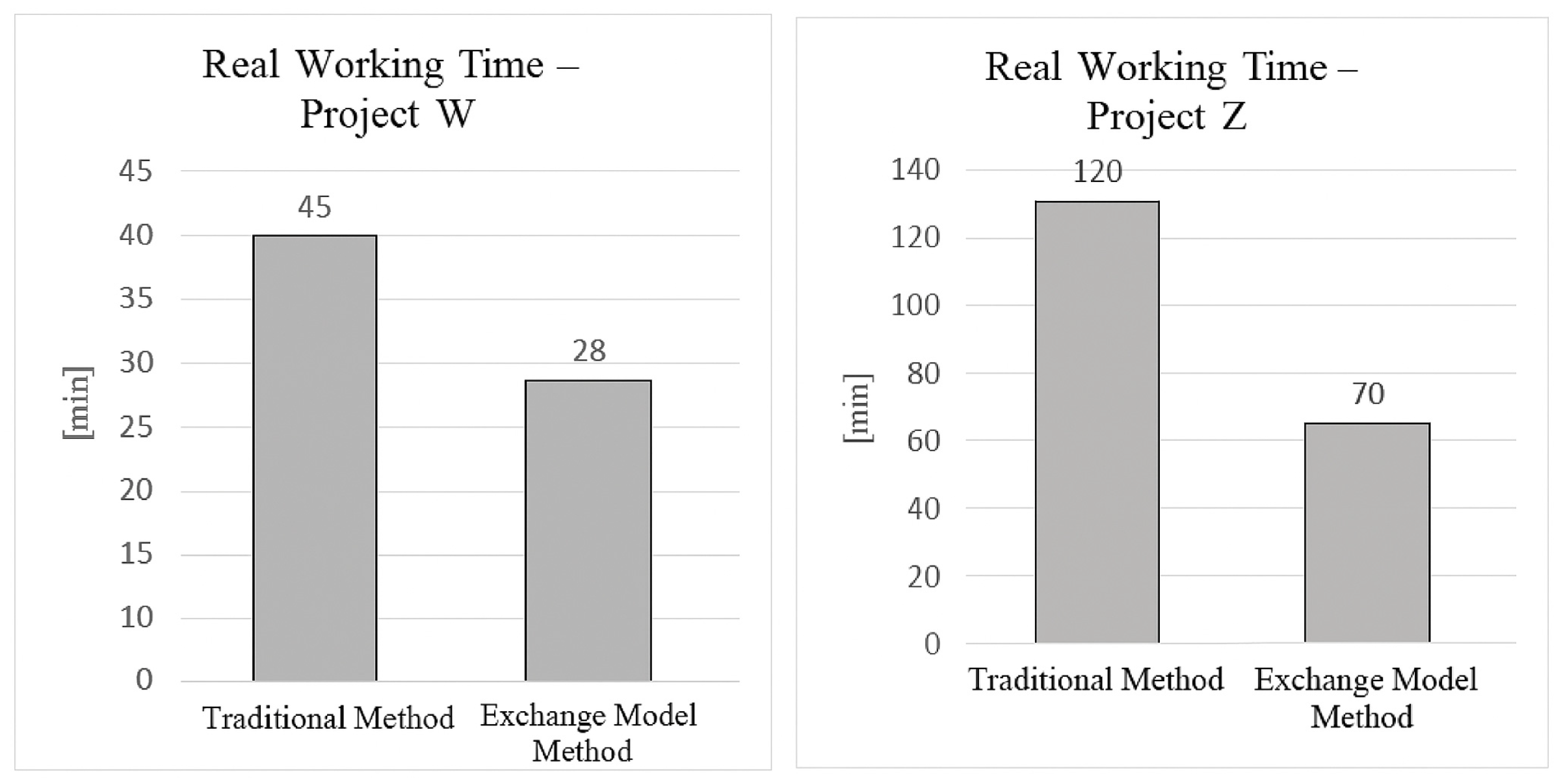

Figure 5 shows the result associated with users’ (actual) work time to evaluate the projects.

The results show that work times are approximately 40% shorter when using the information exchange model than when using the traditional method.

Regarding the response times of the client associated with queries made by the evaluator, in the case of user A, a query was made before the experiment’s start, associated with the evaluation’s scope. For this, the client’s response time was 1 day. Likewise, user B did not consult the client during the evaluation.

Table 10 shows the number of interactions made with the project client.

4.3. Level of Certainty

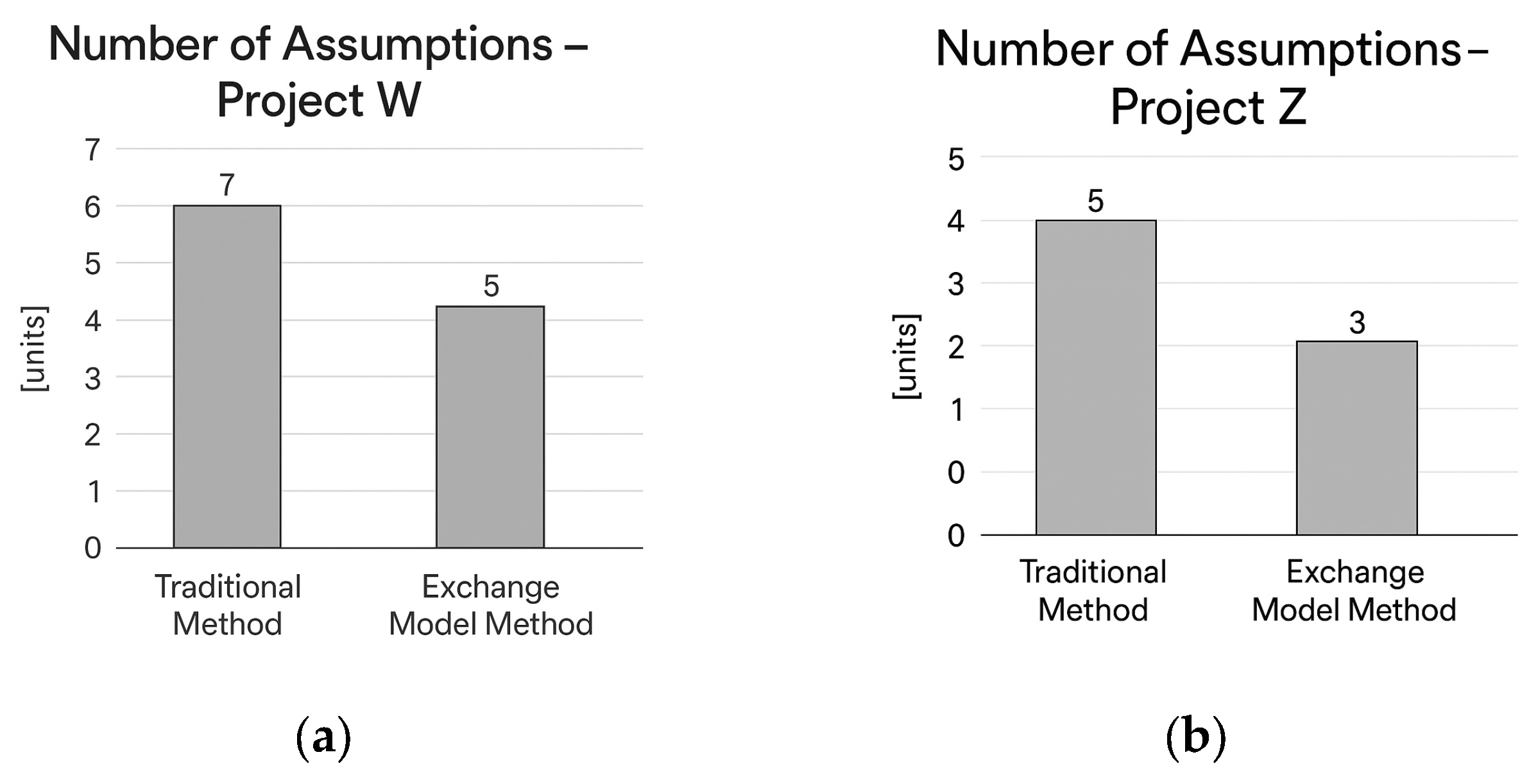

Finally, the evaluation process using both methods was tested concerning the user’s uncertainty level, according to their perception during the process. For this, as a quantitative variable of this aspect, the number of assumptions made during the evaluation was counted (

Figure 6).

According to these results, the quantitative analysis found that the exchange model for the evaluation process in both projects requires fewer assumptions than the traditional method.

To have a qualitative result of the level of uncertainty, users delivered their perception during the evaluation process by using either the traditional method (Y) or the exchange model (X).

Figure 7 introduces the perception scale.

Table 11 shows the result associated with the user’s perception when carrying out the project’s commercial evaluation process using both methods. According to the users’ appreciation of the exchange model method, commercial evaluation is safer than traditional methods. Therefore, this result can be used directly as a budget for the preliminary project.

5. Discussion

To validate the EM_01 information model proposed by Rojas et al. [

13] for commercial evaluation in the early stages of industrialized timber projects, the effectiveness, efficiency, and level of uncertainty were measured, and its performance was compared with the traditional method.

First, the effectiveness results show that it is possible to conduct a commercial evaluation (or quote) of the project with both methods. However, the value of the quote obtained using method X (exchange model) turns out to be 1.5% higher in Project W and 4.9% higher in Project Z, compared with the quote obtained using the traditional method (method Y).

According to users, this is mainly because the exchange model provides more detailed information regarding the building design compared with the traditional method. More information reduces uncertainty in decision-making and, therefore, helps to have a more realistic approximation of the project’s cost in the early stages. In addition, users stated that in the exchange model, the results of structural verification are more conservative than those considered in the traditional method. For example, in the traditional method, a smaller spacing of straight feet and beams is considered, and also a smaller number of structural walls, and therefore fewer anchors, resulting in a lower commercial evaluation based on this method than the exchange model.

On the other hand, the exchange method evaluation process was more efficient than the traditional method, resulting in less work time to make the project quote. According to users, this occurs because identifying certain parameters and variables required to make the quote is very quick to identify and obtain based on a 3D model versus using planimetry in the traditional method. In fact, users stated that many times, the development of a 3D model to deliver a quote is necessary to obtain values of the most accurate variables (for example, square meters of solution, openings) and to be able to iterate more quickly and efficiently with the client.

Regarding the interactions required with the client, the exchange model registered an interaction associated with the scope of the evaluation. In the traditional model, the client did not require any interaction. Based on these results and user reviews, the number of interactions with the client would not be related to the evaluation method used to carry out this process. However, instead, they are associated with the evaluation’s scope definitions and contractual issues, i.e., items to be executed and considerations within the evaluation (assembly, manufacturing).

Finally, the level of uncertainty was tested quantitatively and qualitatively. The quantitative analysis found that when using the exchange model, the number of assumptions made is lower than when the traditional method is used. According to users, the exchange model contains more information and, specifically, the structural design of the building compared with the traditional method. For example, the number of studs and their spacing, the number of panels and their configuration on manufacturing tables, and m2 per type of solution. This has an impact on fewer assumptions during the evaluation process. Another user said it was unnecessary to assume the number of structural walls per axis, the spacing of studs in vertical panels, or the spacing of beams in mezzanines.

The qualitative analysis showed that using the exchange model makes the evaluator perceive a safer and more reliable process. In both cases, this result could be used directly as a budget for the project in the early stages. One of the users commented that using the exchange model gives a “greater ease of calculating parameters that are considered within the evaluation, which makes the process more secure.” Likewise, the user stated that nowadays, the information that is sent to make the quote of a project in the pre-design stages is very vague (from a hand drawing, unclosed planimetry, etc.), which, in the same way, sometimes forces the evaluating users to develop BIM models or 3D models to be able to better visualize the definitions and conditions of the project and, in the face of possible changes, iterate more securely with the client.