Integrated Design as a Strategy for Innovating Native Timber Products and Promoting Sustainable Forest Management

Abstract

1. Introduction

2. Literature Review

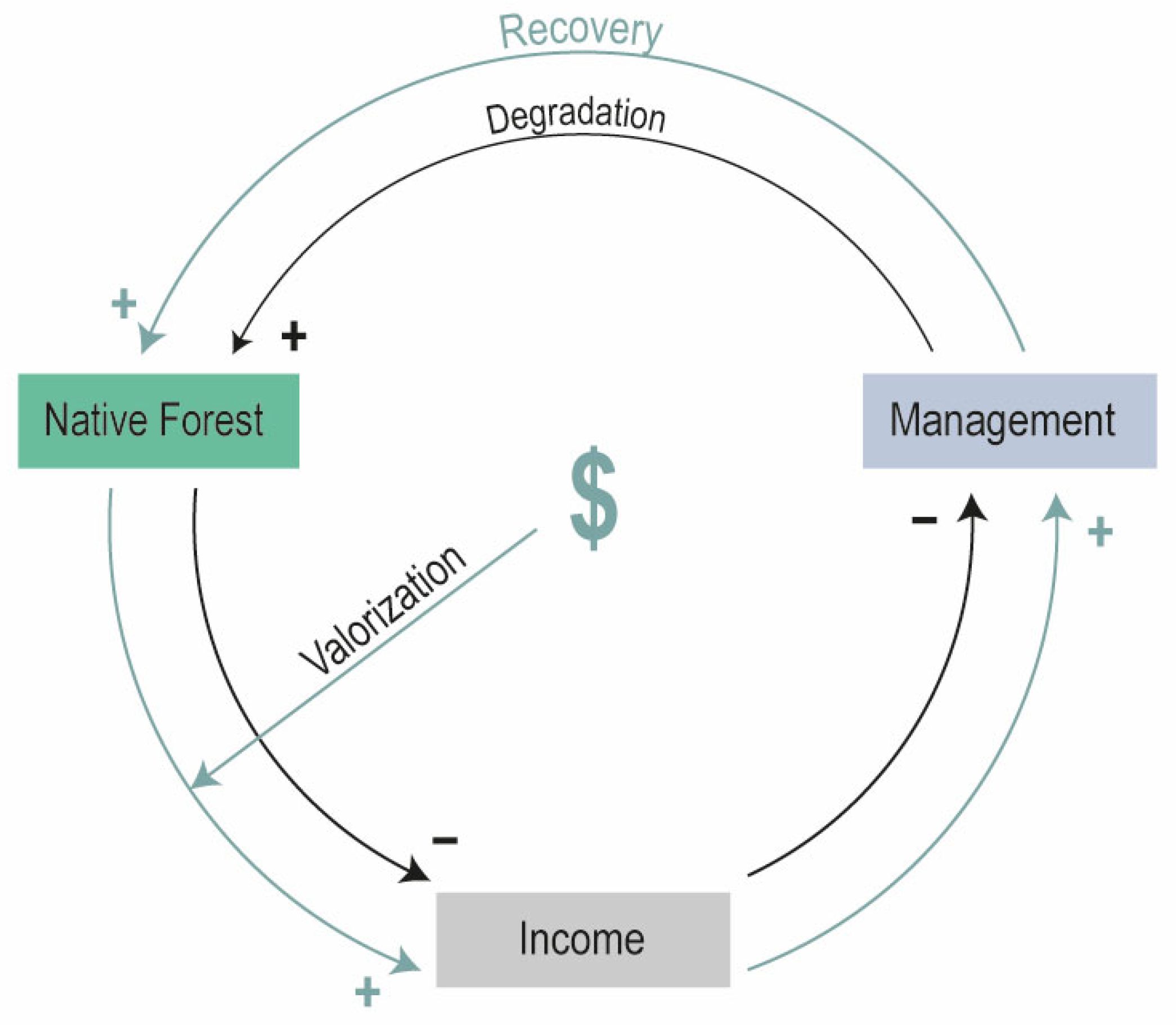

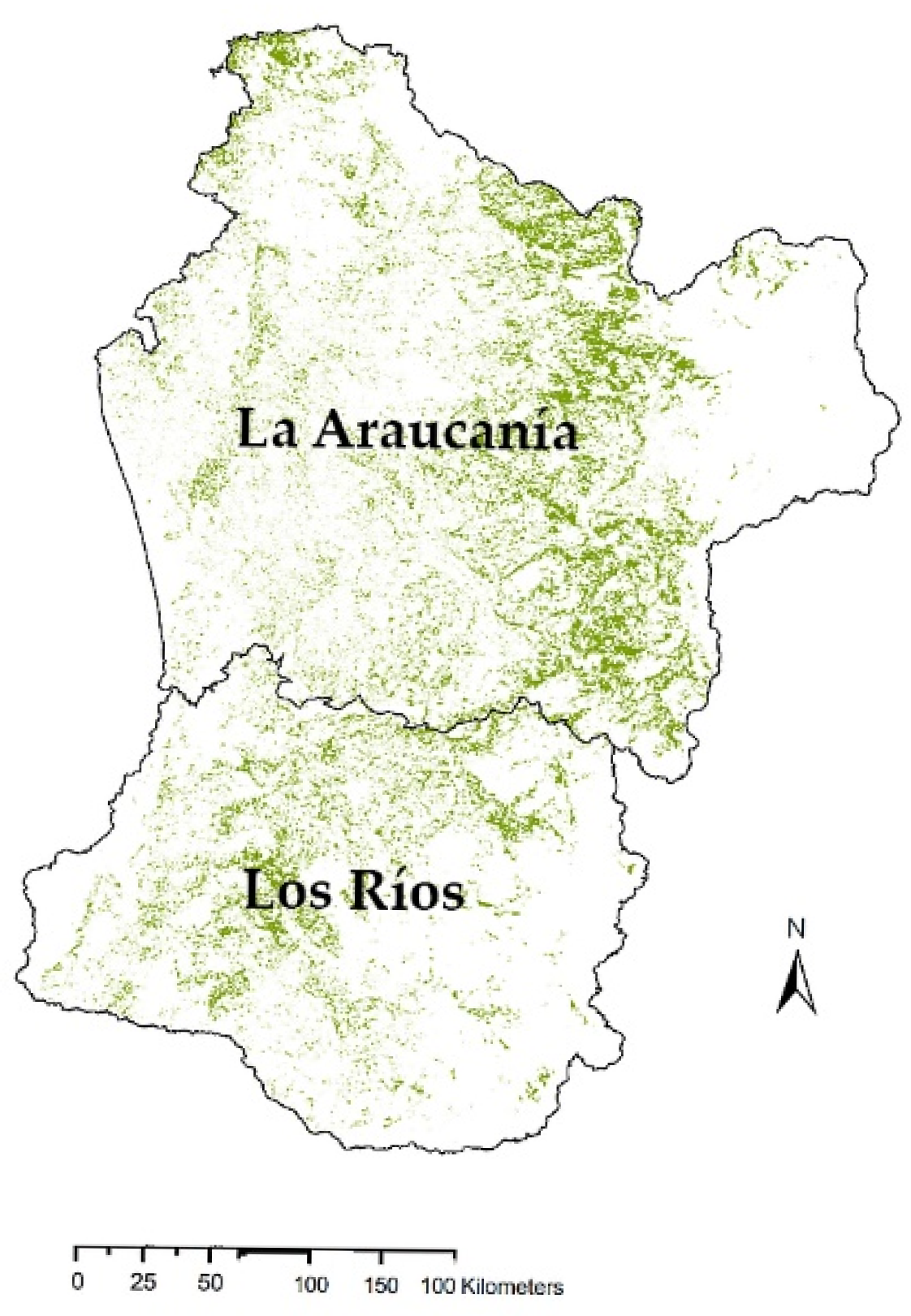

2.1. Forestry Practices in Southern Chile

2.2. State and Pressure on Native Forests

2.3. Native Timber Market

2.4. Public Policies for the Promotion of Wood

3. Methodology

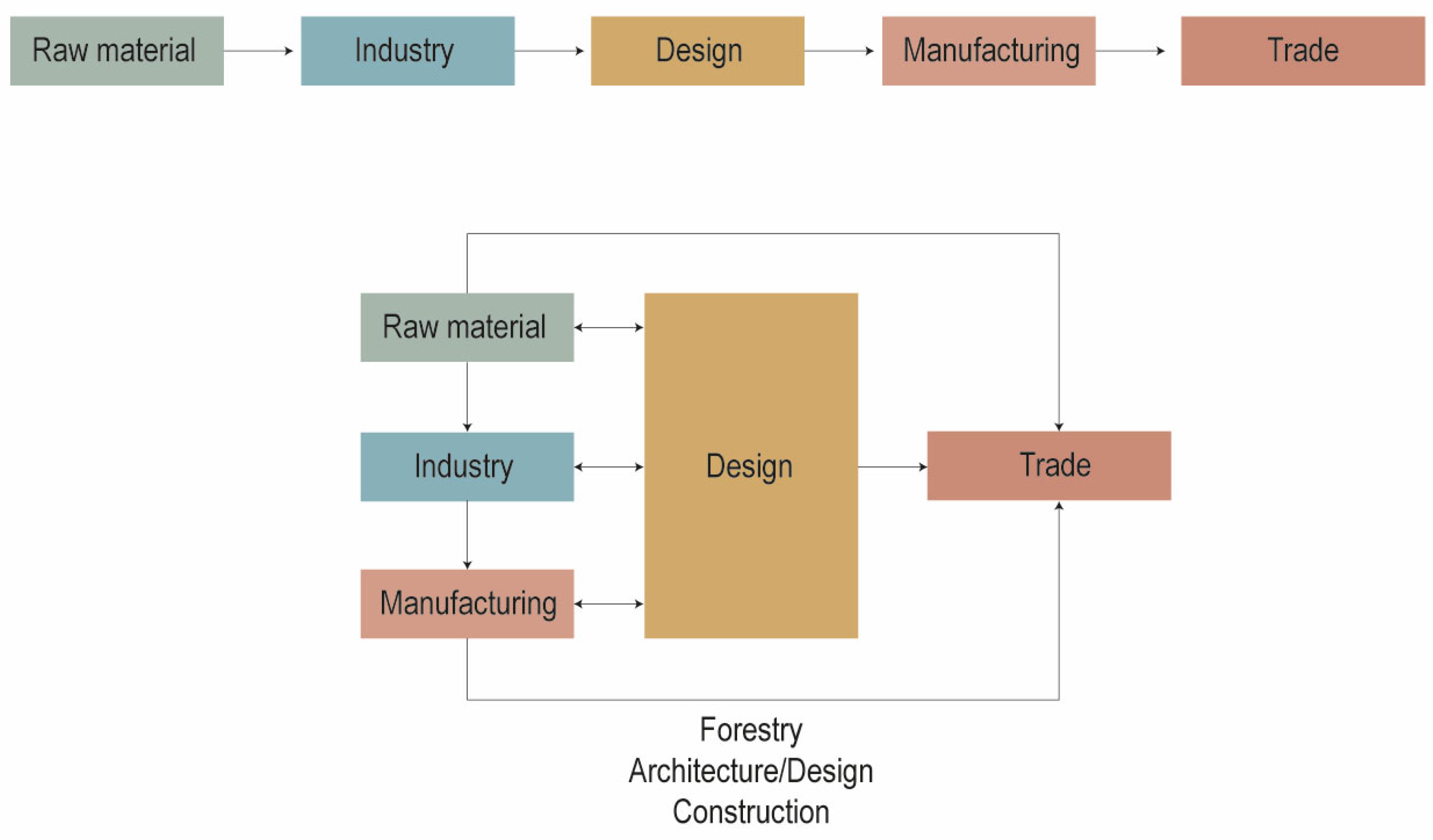

3.1. Characterisation of the Natural Resource, Local Industry, and Market

3.2. Material Selection and Classification

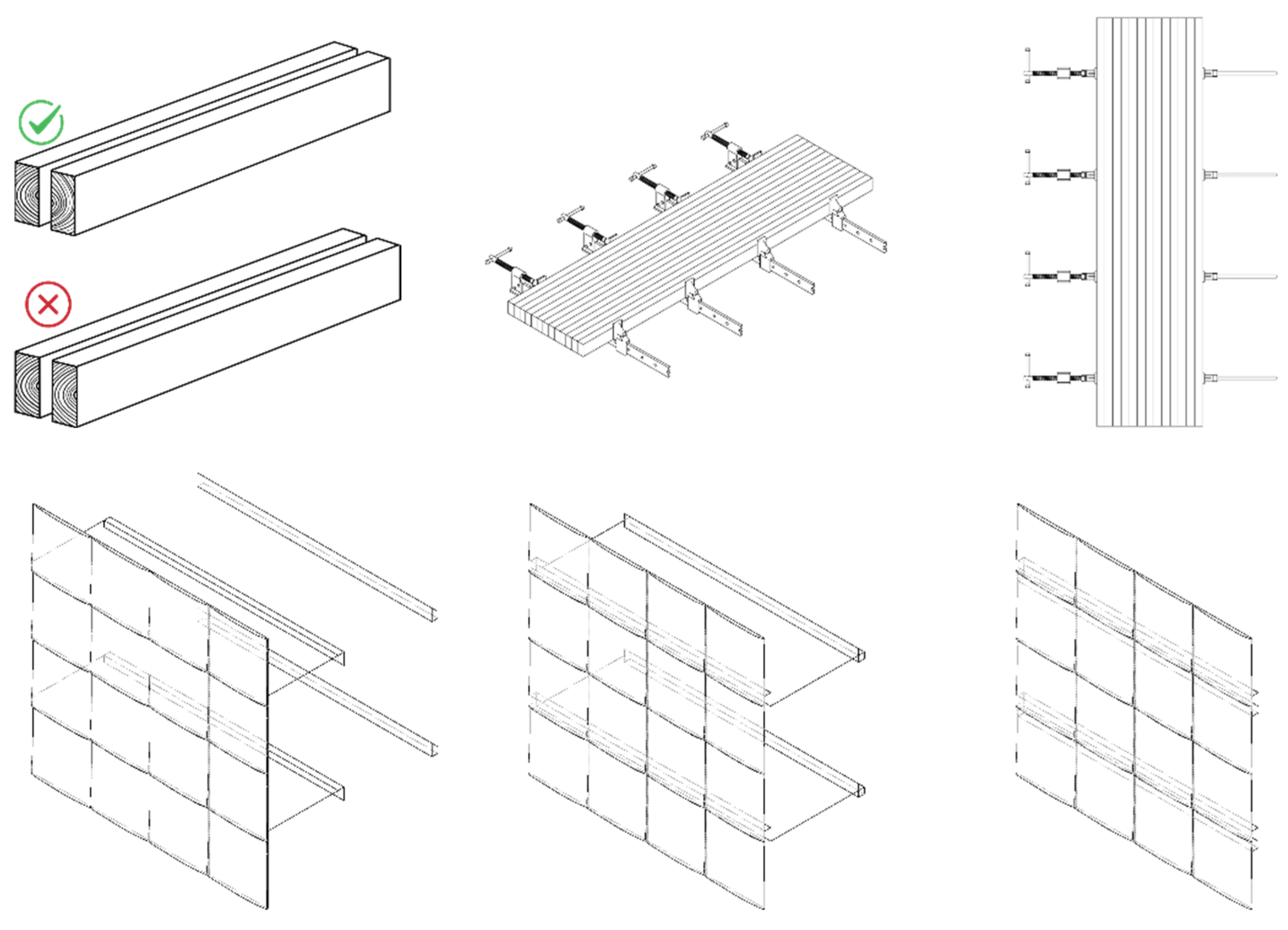

3.3. Design and Manufacturing of Prototypes

3.4. Evaluation of the Value Chain Through the Integrated Design Process

4. Results

4.1. Characterisation of the Resource, Industry, and Local Market

4.2. Prototype Design Validation

4.3. Gaps in the Production Process and Strengthening Proposal

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AIFBN | Agrupación de Ingenieros Forestales por el Bosque Nativo (Association of Forestry Engineers for Native Forests, Chile). |

| CCHC | Cámara Chilena de la Construcción (Chilean Chamber of Construction). |

| CIREN | Centro de Información de Recursos Naturales (Center for Natural Resources Information, Chile). |

| CONAF | Coproración Nacional Forestal (National Forest Corporation, Chile). |

| CORFO | Corporación de Fomento de la Producción (Corporation for the Promotion of Production, Chile). |

| CORMA | Corporación Chilena de la Madera (Chilean Wood Corporation). |

| CTEC | Centro Tecnológico para la Innovación en Productividad y Sustentabilidad en la Construcción (Technology Center for Innovation in Productivity and Sustainability in Construction). |

| GORE | Gobierno Regional (Regional Government. |

| IDP | Integrated Design Process. |

| IFN | Inventario Forestal Nacional (National Forest Inventory, Chile). |

| IMGP | Indice de Madurez de Gestión Empresarial (Business Management Maturity Index). |

| INFOR | Instituto Forestal (Forestry Institute, Chile). |

| MINVU | Ministerio de Vivienda y Urbanismo (Ministry of Housing and Urban Development, Chile). |

| MOP | Ministerio de Obras Públicas (Ministry of Public Works, Chile). |

| SERVIU | Servicio de Vivienda y Urbanización (Housing and Urbanization Service, Chile). |

| SMEs | Small and Medium-sized Enterprises. |

References

- Poblete, P.; Hernández, J. Importaciones Forestales 2023. Boletín N°198; Instituto Forestal: Santiago, Chile, 2024. [Google Scholar]

- Liang, J.; Crowther, T.W.; Picard, N.; Wiser, S.; Zhou, M.; Alberti, G.; Schulze, E.-D.; McGuire, A.D.; Bozzato, F.; Pretzsch, H.; et al. Positive biodiversity-productivity relationship predominant in global forests. Science 2016, 354, aaf8957. [Google Scholar] [CrossRef] [PubMed]

- Hill, S.; Arnell, A.; Maney, C.; Butchart, S.H.M.; Hilton-Taylor, C.; Ciciarelli, C.; Davis, C.; Dinerstein, E.; Purvis, A.; Burgess, N.D. Measuring Forest Biodiversity Status and Changes Globally. Front. For. Glob. Change 2019, 2, 70. [Google Scholar] [CrossRef]

- Steer, T. Sustainable harvesting of native timber for the benefit of habitat health and biodiversity conservation. N. Z. J. For. 2014, 59, 37. [Google Scholar]

- Kok, M.T.J.; Alkemade, R.; Bakkenes, M.; Van Eerdt, M.; Janse, J.; Mandryk, M.; Kram, T.; Lazarova, T.; Meijer, J.; Van Oorschot, M.; et al. Pathways for agriculture and forestry to contribute to terrestrial biodiversity conservation: A global scenario-study. Biol. Conserv. 2018, 221, 137–150. [Google Scholar] [CrossRef]

- Siry, J.P.; Cubbage, F.W.; Ahmed, M.R. Sustainable forest management: Global trends and opportunities. For. Policy Econ. 2005, 7, 551–561. [Google Scholar] [CrossRef]

- Lindenmayer, D.B.; Franklin, J.F.; Lõhmus, A.; Baker, S.C.; Bauhus, J.; Beese, W.; Brodie, A.; Kiehl, B.; Kouki, J.; Pastur, G.M.; et al. A major shift to the retention approach for forestry can help resolve some global forest sustainability issues. Conserv. Lett. 2012, 5, 421–431. [Google Scholar] [CrossRef]

- Ministerio del Medio Ambiente de Chile. Reporte de Acción Nacional de Cambio Climático 2024; Ministerio del Medio Ambiente: Santiago, Chile, 2024; Available online: https://cambioclimatico.mma.gob.cl/wp-content/uploads/2024/12/Reporte-de-accion-nacional-cambio-climatico-2024.pdf (accessed on 18 April 2025).

- Saenz, T. Valorización de los Materiales del Bosque Nativo a Través del Diseño de Elementos Arquitectónicos, Manejo y Uso Sostenible del Bosque Nativo. Master’s Thesis, Pontificia Universidad Catolica de Chile, Santiago, Chile, 2024. [Google Scholar]

- Aye, L.; McNiven, B.; Holzer, D. Fostering integrated design in an academic environment: Process and methods. J. Archit. Urban. 2022, 46, 1–10. [Google Scholar] [CrossRef]

- Dalalah, D.; Khan, S.A.; Al-Ashram, Y. An Integrated Framework for the Assessment of Environmental Sustainability in Wood Supply Chains. Environ. Technol. Innov. 2022, 27, 102429. [Google Scholar] [CrossRef]

- Salah, D.; Paige, R.; Cairns, P. Patterns for integrating agile development processes and user centred design. In Proceedings of the European Conference on Pattern Languages of Programs, Kaufbeuren, Germany, 8–12 July 2015; pp. 1–10. [Google Scholar] [CrossRef]

- Encinas, F.; Truffello, R.; Ubilla, M.; Aguirre-Nunez, C.; Schueftan, A. Perceptions, Tensions, and Contradictions in Timber Construction: Insights from End-Users in a Chilean Forest City. Buildings 2024, 14, 2813. [Google Scholar] [CrossRef]

- Trebilcock, M. Proceso de diseño integrado: Nuevos paradigmas en arquitectura sustentable. Rev. INVI 2009, 24, 16–45. [Google Scholar] [CrossRef]

- Löhnert, G.; Dalkowski, A.; Sutter, W. Integrated Design Process: A Guideline for Sustainable and Solar-Optimised Building Design; IEA International Energy Agency: Berlin, Germany, 2003. [Google Scholar]

- Ashcraft, H. Transforming project delivery: Integrated project delivery. Oxf. Rev. Econ. Policy 2022, 38, 369–384. [Google Scholar] [CrossRef]

- Rankohi, S.; Staub-French, S.; Froese, T. Barriers to the Implementation of Integrated Design Processes—The Case of the Construction Industry in Quebec, Canada. In Proceedings of the Canadian Society of Civil Engineering Annual Conference 2023: Volume 2—Building and Construction Engineering; Springer: Cham, Switzerland, 2023; pp. 12–23. [Google Scholar]

- Eriksson, M.; Motte, D. An Integrative Design Analysis Process Model with Considerations from Quality Assurance. In Proceedings of the 19th International Conference on Engineering Design (ICED13), Seoul, Republic of Korea, 19–22 August 2013; Lund University: Lund, Sweden, 2013. [Google Scholar]

- Luján-Álvarez, C.; Olivas-García, J.M.; Vázquez, S.; Hernández-Salas, J.; Castruita-Esparza, L. Sistema de gestión estratégica forestal participativa para el desarrollo forestal sustentable. Madera Bosques 2021, 27, e2712260. [Google Scholar] [CrossRef]

- Martin Stuven, M.; Büchner, C.; Sagardía Parga, R.; Bahamóndez V., C.; Rojas Ponce, Y.; Guzmán Vargas, F.; Barrientos A., M.; Barrales M., L.; Guiñez, R. Disponibilidad de Madera Nativa en Renovales de Roble-Raulí-Coihue. Instituto Forestal (INFOR), 2020. Available online: https://bibliotecadigital.infor.cl/handle/20.500.12220/30443 (accessed on 17 February 2025).

- Pilquinao, B.; Martin, M.; Büchner, C.; Sagardía, R.; Molina, E.; Schueftan, A.; Barrales, L. Propuesta y Manejo de Bosque Nativo para Diferentes Alternativas de Comercialización de la Madera. Instituto Forestal (INFOR), 2019. Available online: https://corporacionlosrios.cl/index.php/files/687/FIC%20-%C2%A0Propuesta%20y%20manejo%20de%20bosque%20nativo%20para%20diferentes%20alternativas%20de%20comercializacion%20de%20la%20madera/1640/Informe%20final%3A%20Propuesta%20y%20manejo%20de%20bosque%20nativo%20para%20diferentes%20alternativas%20de%20comercializacion%20de%20la%20madera.pdf (accessed on 30 March 2025).

- Schueftan, A.; Aguilera, F.; Aravena, C.; Benedetti, S.; Gallardo, C. Incentivos para Impulsar la Construcción en Madera en Chile. Documento de Divulgación N° 62. Instituto Forestal (INFOR), 2021. Available online: https://bibliotecadigital.infor.cl/bitstream/handle/20.500.12220/31354/31354.pdf?sequence=1&isAllowed=y (accessed on 17 February 2025).

- Otero, L. La Huella del Fuego; Pehuén Editores: Santiago, Chile, 2006. [Google Scholar]

- Gutiérrez, C. Potenciando el Manejo Sustentable del Boque Nativo a Través de la Innovación en el Diseño. Centro de Promoción para Incentivar el Uso de la Madera Nativa en la Región de los Ríos. Memoria de Proyecto de Título; Universidad Austral de Chile: Valdivia, Chile, 2023. [Google Scholar]

- Horn, A. Arquitecturas Mestizas en Territorios de Colonización. Ph.D. Thesis, Universidad Austral de Chile, Valdivia, Chile, 2021. [Google Scholar]

- Morgenstein, A. Arquitectura Mestizas en Territorios de Colonización; Universidad Austral de Chile, Facultas de Filosofía y Humanidades: Valdivia, Chile, 2021. [Google Scholar]

- Luengo, O.F.; Herrera, H.P. Paisaje y patrimonio levantamiento y valorización de piezas rurales en la provincia de Colchagua, Chile. Arquit. SUR 2018, 36, 90–105. [Google Scholar] [CrossRef]

- Galindo, J.; Sabate, J. El valor estructurante del patrimonio en la transformación del territorio. Apunt. Rev. Estud. Sobre Patrim. Cult. J. Cult. Herit. Stud. 2009, 22, 20–33. [Google Scholar]

- Büchner, C.; Martin, M.; Sagardia, R.; Avila, A.; Molina, E.; Rojas, Y.; Muñoz, J.C.; Barros, S.; Rose, J.; Barrientos, M.; et al. Disponibilidad de Madera de Plantaciones de Pinus radiata, Eucalyptus globulus y Eucalyptus Nitens 2017–2047. Informe Técnico N° 220. Instituto Forestal (INFOR), 2018. Available online: https://bibliotecadigital.infor.cl/handle/20.500.12220/28294 (accessed on 17 February 2025).

- Gysling, J.; Kahler, C.; Soto, D. Madera y Construcción: Hacia una Simbiosis Estratégica. Instituto Forestal (INFOR), 2021. Available online: https://bibliotecadigital.infor.cl/handle/20.500.12220/31291 (accessed on 17 February 2025).

- Torres, J.; Keim, H.; Maiz, J.M.; Tirado, R.; Vargas, G. Manejo Forestal del Bosque Nativo: Una Oportunidad de Desarrollo. Alianza por el Bosque Nativo, 2022. Available online: https://cifag.cl/wp-content/uploads/2022/09/Documento-final-Propuestas-MFS-BN-.pdf (accessed on 17 February 2025).

- Mao, L.; Ugalde, F.; Lacy, S.N. The Effects of Replacing Native Forest on the Quantity and Impacts of In-Channel Pieces of Large Wood in Chilean Streams. River Res. Appl. 2016, 33, 73–88. [Google Scholar] [CrossRef]

- Cervantes, A.G.; Robinson, S.C. Explorations into Accessible Wood Identification in Paraguay: Wood Anatomy of Plinia rivularis and Plinia peruviana. Forests 2025, 16, 406. [Google Scholar] [CrossRef]

- Johnson, A.; Clavijo, A.E.; Hamar, G.; Thoms, A.; Price, W.; Lapke, A.; Crotteau, J.; Cerveny, L.K.; Wilmer, H.; Petershoare, L.; et al. Wood Products for Cultural Uses: Sustaining Native Resilience and Vital Lifeways in Southeast Alaska, USA. Forests 2021, 12, 90. [Google Scholar] [CrossRef]

- Corporación Nacional Forestal (CONAF). Catastro de los Recursos Vegetacionales y Uso de la Tierra de Chile. CONAF. Departamento de Monitoreo, 2024. Available online: https://sit.conaf.cl/varios/ESTADISTICAS_CONAF_2024_FINAL.pdf (accessed on 17 February 2025).

- Heltberg, R. Property rights and natural resource management in developing countries. J. Econ. Surv. 2002, 16, 189–214. [Google Scholar] [CrossRef]

- Joshi, O.; Mehmood, S.R. Factors affecting nonindustrial private forest landowners’ willingness to supply woody biomass for bioenergy. Biomass Bioenergy 2011, 35, 186–192. [Google Scholar] [CrossRef]

- Sagardia, R.; Bahamóndez, C.; Avila, A. Los Recursos Forestales en Chile 2023. Inventario Forestal Nacional de Bosques Nativos y Actualización de Plantaciones Forestales. Instituto Forestal (INFOR), 2024. Available online: https://bibliotecadigital.infor.cl/handle/20.500.12220/32724 (accessed on 3 March 2025).

- Thompson, I.; Guariguata, M.; Okabe, K.; Bahamondez, C.; Nasi, R.; Heymell, V.; Sabogal, C. An Operational Framework for Defining and Monitoring Forest Degradation. Ecol. Soc. 2013, 18, 20. [Google Scholar] [CrossRef]

- Zamorano-Elgueta, C.; Cayuela, L.; Benayas, J.M.R.; Donoso, P.J.; Geneletti, D.; Hobbs, R.J. The differential influences of human-induced disturbances on tree regeneration community: A landscape approach. Ecosphere 2014, 5, 1–17. [Google Scholar] [CrossRef]

- Gobierno de Chile. Estrategia de Chile para la implementación de la Agenda 2030. Consejo Nacional para la Implementación de la Agenda 2030. 2023. Available online: https://www.chileagenda2030.gob.cl/storage/docs/Estrategia_de_Implementacion_Agenda2030.pdf (accessed on 15 May 2025).

- Reyes, R. Promotores Socioeconómicos de la Pérdida y Degradación del Bosque Nativo en Chile—Informe Técnico. Organización de las Naciones Unidas para la Alimentación y la Agricultura; Ministerio de Agricultura de Chile, 2021. Available online: https://openknowledge.fao.org/items/421fe13f-e2a9-4095-86ac-963d98be6304 (accessed on 3 March 2025).

- Naciones Unidas. Conferencia INSTRUMENTO no Vinculante Sobre Todos los Tipos de Bosques. 2007. Available online: https://documents.un.org/access.nsf/get?DS=A/RES/62/98&Lang=S&OpenAgent (accessed on 3 March 2025).

- Yudelevich, K.; Brown, M.; Calderon, S.; Elgueta, H. Clasificación Preliminar del Bosque Nativo de Chile; Instituto Forestal: Santiago, Chile, 1967; Available online: https://bibliotecadigital.infor.cl/bitstream/handle/20.500.12220/6518/14213.pdf?isAllowed=y&sequence=1 (accessed on 3 March 2025).

- Donoso, C.; Tipos Forestales de los Bosques Nativos de Chile. Investigación y Desarrollo Forestal. Documento de Trabajo N° 38. CONAF/PNUD/FAO.FO: DP/CHI/76/003. 1981. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/6af2db3c-7749-4097-a185-8fdd671bd2ae/content (accessed on 3 March 2025).

- Instituto Forestal (INFOR). Los Recursos Forestales en Chile 2020. 2021. Available online: https://ifn.infor.cl/ (accessed on 3 March 2025).

- Poblete, P.; Kahler, C.; Bañados, J.C.; Gysling, J. Anuario Forestal 2024. Boletín Estadístico N° 199; Instituto Forestal (INFOR): Santiago, Chile, 2024. [Google Scholar]

- Banco Mundial. La Construcción de Viviendas en Madera en Chile. Un Pilar Para el Desarrollo Sostenible y la Agenda de Reactivación. América Latina y el Caribe. 142. 2020. Available online: https://documents1.worldbank.org/curated/en/224671607109191179/pdf/The-Construction-of-Timber-Houses-in-Chile-A-Pillar-of-Sustainable-Development-and-the-Agenda-for-Economic-Recovery.pdf (accessed on 10 March 2025).

- Plan de Agregación de Valor en el Sector Forestal. Informe Final. Instituto Forestal, Chile, 2015. Available online: https://corporacionlosrios.cl/index.php/proyectos-regionales/755-plan-de-agregacion-de-valor-en-el-sector-forestal-2 (accessed on 10 March 2025).

- Instituto Forestal (INFOR). Bosque Nativo. Boletín Estadístico N°18. Instituto Forestal (INFOR), 2019. Available online: https://wef.infor.cl (accessed on 10 March 2025).

- Roman, B.; Lozada, P.; Ortega, Y.; Neira, E. Analisis de Encadenamientos Productivos de Leña y Madera Nativa en las Regiones de los ríos y los Lagos y Propuestas para su Desarrollo. Fondo de Investigación del Bosque Nativo; Agrupación de Ingenieros Forestales por el Bosque Nativo: Valdivia, Chile, 2017. [Google Scholar]

- Emanuelli y Milla, A. Alternativas de Productos Madereros del Bosque Nativo Chileno; Corporación Nacional Forestal (CONAF) y Sociedad Alemana de Cooperación Técnica (GTZ): Santiago, Chile, 2006. [Google Scholar]

- Pardo, E.; Bañados, J.C.; Troncoso, H.; Poblete, P. La Industria del Aserrío 2024. Boletín Estadístico N°202. Instituto Forestal, Chile, 2024. Available online: https://bibliotecadigital.infor.cl/bitstream/handle/20.500.12220/32765/32765.pdf?isAllowed=y&sequence=1 (accessed on 10 March 2025).

- Poblete, P.; Hernández, J. Exportaciones Forestales Enero—Noviembre 2024; Instituto Forestal (INFOR): Santiago, Chile, 2024. [Google Scholar]

- Ministerio de Agricultura. Chile—CONAF. Sistema Integrado de Monitoreo de Ecosistemas Forestales Nativos (SIMEF). Available online: https://simef.minagri.gob.cl/ (accessed on 10 March 2025).

- Corporación Nacional Forestal (CONAF). Política Forestal 2015–2035. CONAF, 2015. Available online: https://oficinavirtual.conaf.cl/recursos/videos/Politica_Forestal_2015-2035.pdf (accessed on 17 March 2025).

- Comisión Desafíos del Futuro, Ciencia, Tecnología e Innovación del Senado de Chile. Chile Tiene Futuro Desde sus Territorios; Girardi Lavín, G., Ed.; Ediciones Biblioteca del Congreso Nacional de Chile: Valparaíso, Chile, 2022; Available online: https://consejofuturo.senado.cl/wp-content/uploads/2022/09/Chile_tiene_Futuro-.pdf (accessed on 17 March 2025).

- Gobierno Regional de Los Ríos. Estrategia Regional de Desarrollo Región de Los Ríos 2023–2037. Gobierno Regional de Los Ríos: Valdivia, Chile, 2023; Available online: https://www.erdlosrios.cl/wp-content/uploads/2023/06/ERD-LosRios-2037-FINAL-FINAL3.pdf (accessed on 17 March 2025).

- Corporación Nacional Forestal (CONAF). Lanzan Mesa de Fomento a la Industria Forestal de la Región de Los Ríos. 2024. Available online: https://www.conaf.cl/lanzan-mesa-de-fomento-a-la-industria-forestal-de-la-region-de-los-rios/ (accessed on 17 March 2025).

- Centro Tecnológico para la Innovación en la Construcción (CTEC). Desafío Construye Araucanía. Desafio Araucanía. Available online: www.desafioaraucania.cl (accessed on 17 March 2025).

- Gobierno Regional de La Araucanía y CORFO. En La Araucanía Busca Impulsar la Economía Circular. 19 April 2024. Available online: https://www.corfo.cl/sites/cpp/sala_de_prensa/regional/movil/19_04_2024_gobernanza_araucania#:~:text=Ante%20este%20escenario%20es%20que,construcci%C3%B3n%20relevantes%2C%20transportistas%20de%20materiales (accessed on 17 March 2025).

- Toledo, P. Manejo Sostenible y Revalorización del Bosque Nativo. Forest Stewardship Council (FSC) Chile. 2024–2026. Available online: https://cl.fsc.org/sites/default/files/2025-01/MEMORIA%20FSC%20CHILE%202023_MEMBRESIA.pdf (accessed on 24 March 2025).

- American Institute of Architects; AIA California Council. Integrated Project Delivery: A Guide; American Institute of Architects, 2007; Available online: https://assets.aiacontracts.com/ctrzdweb02/zdpdfs/ipd_guide.pdf (accessed on 24 March 2025).

- Lawrence, R.J. Transdisciplinary architectures: Reconnecting theories, research and practices. Archnet-IJAR: Int. J. Archit. Res. 2024, 18, 217–244. [Google Scholar] [CrossRef]

- Ruan, G.; Filz, G.H.; Fink, G. An Integrated Architectural and Structural Design Concept by Using Local, Salvaged Timber. In Proceedings of the IASS Annual Symposium 2020/21 and the 7th International Conference on Spatial Structures, Guilford, UK, 23–27 August 2021; International Association for Shell and Spatial Structures (IASS), 2021. Available online: https://www.researchgate.net/publication/354096064 (accessed on 24 March 2025).

- Svilans, T. Integrated Material Practice in Free-Form Timber Structures. Ph.D. Thesis, Schools of Architecture, Design and Conservation (KADK), The Royal Danish Academy of Fine Arts, Copenhagen, Denmark, 2020. [Google Scholar]

- Menges, A. Performative wood: Integral computational design for timber constructions. In Proceedings of the 29th Annual Conference of the Association for Computer Aided Design in Architecture (ACADIA), Chicago, IL, USA, 24–26 October 2009; Association for Computer Aided Design in Architecture (ACADIA): Fargo, ND, USA, 2009; pp. 66–74. [Google Scholar]

- Jalali, Y. Developing an Integrated Design Support Framework to Enable Mass-Customisation in Multi-Storey Timber Building Projects. Ph.D. Thesis, Faculty of Design, Architecture and Building, University of Technology Sydney (UTS), Ultimo, Australia, 2022. [Google Scholar]

- Pezdevšek, M.; Krajnc, N.; Triplat, M. Factors Influencing Private Forest Owners’ Readiness to Perform Forest Management Services Within a Machinery Ring. Small-Scale For. 2022, 21, 661–679. [Google Scholar] [CrossRef]

- Manzur, M. Levantamiento de Información y Análisis de la Cadena de Valor de la Industria de la Madera Nativa. Instituto Forestal (INFOR), 2019. Available online: https://bibliotecadigital.infor.cl/handle/20.500.12220/20707 (accessed on 24 March 2025).

- Rosenberg, N.; Ince, P.; Skog, K.; Plantinga, A. Understanding the Adoption of New Technology in the Forest Products Industry. For. Prod. J. 1990, 40, 15–22. [Google Scholar]

- Catalan, P.; Cozzens, S. Technology Diffusion Dynamics: The Case of Chile’s Forestry Industry. In Proceedings of the Globelics 7th International Conference, Dakar, Senegal, 6–8 October 2009. [Google Scholar]

- Shikverdiev, A.; Vishnyakov, A.; Romanchuk, N.; Mazur, V. Role of state legal regulation in ensuring the efficient use of forest resources in the far north and equivalent areas. Lex Humana 2023, 15, 260–276. [Google Scholar]

| Property Size (ha) | |||||

|---|---|---|---|---|---|

| Region | ≤50 | 50–200 | 200–100 | >1000 | Total |

| La Araucanía | 63,659 | 62,582 | 65,846 | 94,037 | 286,124 |

| Los Ríos | 15,642 | 29,811 | 42,241 | 43,742 | 131,436 |

| Total | 79,301 | 92,393 | 108,087 | 137,779 | 41,756 |

| % | 19% | 22% | 26% | 33% | 100% |

| Region | Total Area (ha) | Area Excluding Restrictions (ha) |

|---|---|---|

| La Araucanía | 417,023.98 | 330,397.00 |

| Los Ríos | 197,719.71 | 151,493.00 |

| Total | 614,743.63 | 418,890.00 |

| Products | Type of Products (Logs) | Characteristics | |||

|---|---|---|---|---|---|

| Roble-Raulí-Others | Coihue | ||||

| Diameter | Length | Diameter | Length | ||

| (cm) | (m) | (cm) | (m) | ||

| P1 | >34 | 3.6 | >50 | 3.6 | High-value sawlogs |

| P2 | >34 | 2.6 | >34 | 3.6 | Peeler logs |

| P3 | >20 | 2.44 | >30 | 2.44 | short sawlogs |

| P4 | >10 | 2.44 | >10 | 2.44 | pulp logs |

| P5 | >5 | 1 | >5 | 1 | firewood |

| Conservative Scenario—La Araucanía | ||||||

|---|---|---|---|---|---|---|

| Three-Year Periods | High Value (m3) | Sawlog (m3) | Small-Diameter Sawlog (m3) | Pulpwood (m3) | Firewood (m3) | Total (m3) |

| 2020–2022 | 11,419 | 74,826 | 56,721 | 167,588 | 12,769 | 323,323 |

| 2023–2025 | 41,365 | 201,032 | 160,519 | 386,330 | 26,387 | 815,634 |

| 2026–2028 | 47,018 | 220,419 | 172,986 | 401,038 | 26,388 | 867,849 |

| 2029–2031 | 48,686 | 213,654 | 164,706 | 360,398 | 24,192 | 811,635 |

| 2032–2034 | 67,965 | 305,859 | 237,742 | 487,373 | 33,833 | 1,132,773 |

| 2035–2037 | 50,161 | 232,269 | 176,452 | 358,002 | 19,124 | 836,009 |

| 2038–2040 | 62,510 | 295,744 | 225,130 | 437,540 | 20,905 | 1,041,830 |

| 2041–2043 | 84,459 | 407,965 | 312,501 | 574,505 | 28,152 | 1,407,581 |

| 2044–2046 | 68,469 | 325,834 | 255,249 | 445,122 | 29,249 | 1,123,922 |

| 2047–2049 | 92,813 | 421,516 | 322,153 | 550,105 | 61,539 | 1,448,125 |

| Conservative Scenario—Los Ríos | ||||||

|---|---|---|---|---|---|---|

| Three-Year Periods | High Value (m3) | Sawlog (m3) | Small-Diameter Sawlog (m3) | Pulpwood (m3) | Firewood (m3) | Total (m3) |

| 2020–2022 | 4503 | 29,914 | 22,683 | 67,597 | 5163 | 129,858 |

| 2023–2025 | 10,726 | 51,169 | 40,874 | 99,694 | 7088 | 209,551 |

| 2026–2028 | 27,951 | 131,631 | 103,467 | 239,263 | 15,662 | 517,975 |

| 2029–2031 | 18,691 | 82,269 | 63,431 | 138,031 | 9237 | 311,658 |

| 2032–2034 | 36,669 | 165,056 | 128,270 | 262,939 | 18,216 | 611,150 |

| 2035–2037 | 34,048 | 158,195 | 119,560 | 243,367 | 12,294 | 567,465 |

| 2038–2040 | 37,952 | 179,219 | 135,967 | 266,712 | 12,680 | 632,530 |

| 2041–2043 | 40,477 | 195,435 | 149,498 | 275,212 | 13,481 | 674,073 |

| 2044–2046 | 32,570 | 154,650 | 120,883 | 211,172 | 14,262 | 533,537 |

| 2047–2049 | 44,905 | 192,713 | 151,350 | 246,567 | 42,469 | 678,004 |

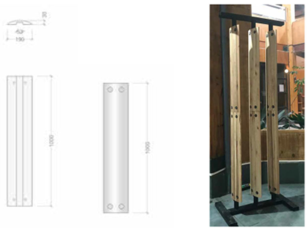

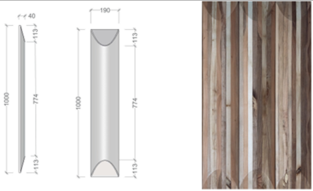

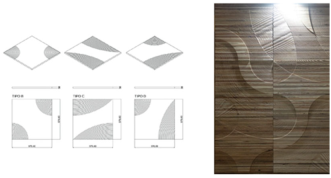

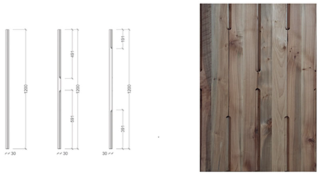

| Name | Module | Image | Description |

|---|---|---|---|

| Louvre |  | Modular exterior louvre system. Each panel is machined in two halves and assembled onto a 50 × 30mm steel structural core, permitting easy site assembly and flat packing of components for logistics. Also facilitates the removal and replacement of damaged components. | |

| Manufactured in roble with exterior grade adhesive and finished with Osmo oil exterior finish to ensure the louvres weather correctly. Requires periodic application of finish to ensure durability. | |||

| Wavy Tile |  | Designed to create a pleasing aesthetic that casts light and shade across the interior wall of a room. Lightweight at under 5 kg per panel permitting easy installation. | |

| Can be manufactured from a range of timber species for interior use. In this case a panel fabricated from a mixture of coigüe, roble and raulí was used. With the promise of further investigation to confirm possible façade shading properties. | |||

| Concave |  | Modular system design to create a continuous undulating surface. Using french cleats to facilitate an easy and economic form to mount continuous units over large wall spans. | |

| Manufactured in both roble and mixed species panels to demonstrate how different species can be used to achieve different aesthetics. | |||

| Convex |  | Modular system design to create a continuous undulating surface. Using french cleats to facilitate an easy and economic form to mount continuous units over large wall spans. | |

| Manufactured in both roble and mixed species panels to demonstrate how different species can be used to achieve different aesthetics. | |||

| Petal |  | Multi component interior divider system. Each petal is individually machined using a CNC router or pantograph router. The petals are then assembled onto a central axis which includes a hidden bearing allowing each composed unit to spin around its central axis allowing for a customisable experience. | |

| 20 mm anodised steel tubes form the central axis allowing for ease of mounting in a variety of spaces. | |||

| Profile |  | Each profile is a variation of the same cut which use the natural form of the router cutter to generate its geometry when combined with diagonal cuts on a table saw. Thus allowing a variety of possible assemblies Using different lengths of positions of cut. | |

| Designed for ease of manufacture with basic timber processing machinery and limited skill levels. | |||

| Radial Groove |  | Modular system that uses a repeated arc cut using a hand router. The position of the arc allows for several panels to be machined separately and joined together to achieve large continuous designs for large wall spans. | |

| Fabricated from mixed species panels Using a variety of grades of timber to demonstrate the capacity to create larger components where necessary. | |||

| Vertical Slot |  | Simple design that uses a variety of basic cuts to the edges of a board to create a repeating pattern. | |

| Made using boards of roble to show even with very basic equipment, such as a hand router in this case, it is possible to make simple designs that can add value to short boards cut from large lengths of timber for construction that have limited value. | |||

| Topography |  | The most geometrically complex design, designed using parametric design and fabricated using a CNC router. It was designed to show SMEs the possibilities made available by incorporating even basic digital design tools into their infrastructure. | |

| The geometry is completely customisable to create a variation of perforations for back-lighting or complementary material backdrops. With the promise of further investigation to confirm possible acoustic baffling properties. | |||

| Links | Gaps | Strengthening Proposals | ||

|---|---|---|---|---|

| Forest Owners | Lack of market information hinders positioning and strategic decision-making, limiting the sector’s ability to identify opportunities and adapt to demand. | Optimization of the value chain from production to commercialization, through comprehensive management covering production, commercialization, finance, operations, communication, and client relations. | ||

Economic fluctuations and a shortage of specialized labor negatively impact operations, while high production costs reduce profitability and competitiveness compared to exotic species. | Business segmentation to apply tailored strategies, along with a systemic approach that aligns operations with market demands, resource optimization, and product development. | |||

Uncertainty caused by territorial conflicts and forest fires affects long-term planning and increases operational risks across the sector. | Promotion of stakeholder collaboration, continuous iteration, and capacity building through training and financial advisory, supporting strategic planning and sustainable forest management in line with the PDI’s objectives. | |||

| Sawmill Owners | Lack of structured management, sectoral coordination, and strategic planning limits market alignment, integration into the value chain, and overall sector consolidation. | Enhancing sector efficiency through continuous improvement, integrated design, and the optimization of internal management and the supply chain, fostering innovation, responsiveness, and financial planning. | ||

Economic dependence, low diversification, and commercial informality increase financial risks, reduce competitiveness, and hinder market differentiation. | Promoting collaborative strategies and stakeholder coordination to strengthen integration, increase bargaining power, and consolidate stable markets through economic diversification and higher value-added exports. | |||

Advancing quality through the implementation of standards, certifications, and technology adoption, ensuring product reliability, competitiveness, and value addition in native wood markets. | ||||

| Wood Processors and Marketers | Financial instability, limited availability and high cost of native wood, and logistical difficulties restrict production capacity and hinder control over the supply chain. | Improving customer experience and service through proactive sales strategies, market segmentation, and enhanced logistical efficiency to boost productivity and expand market reach. | ||

Lack of quality protocols and dependence on vertically integrated sawmills reduce scalability, exclude other stakeholders, and lead to inconsistent products and economic losses. | Strengthening financial planning and resource management to reduce economic vulnerability, while fostering strategic alliances that open access to new markets and enhance competitiveness in line with PDI’s innovation and sustainability goals. |

| Key Barriers in the Native Wood Value Chain | Integrated Model (IDP): Potential | Challenges for Implementation | ||

|---|---|---|---|---|

Disarticulated value chain Structural isolation among forestry, design, and construction actors hinders integrated development. | Enables cross-sector alignment From forest to final product. | Scalability Requires adaptation to limited local infrastructure. | ||

Limited resource utilization Conventional production standards exclude alternative wood types and formats. | Redefines design constraints as opportunities IDP allows rethinking material selection criteria and encourages innovative uses of non-conforming resources. | Standards and certification Lack of standardization and regulation for non-traditional products. | ||

Technological gap in processing capacity Technical limitations restrict the feasibility of advanced or value-added product lines. | Supports incremental innovation IDP encourages design solutions calibrated to existing tools and workflows, fostering feasible innovation pathways. | Investment in technology Needs for drying, impregnation, and manufacturing processes. | ||

Information asymmetries and weak demand articulation Producers operate with limited insight into architectural trends and user preferences. | Facilitates demand-driven innovation IDP links producers with specifiers (architects, designers), enabling product development based on real use cases. | Professional training and culture Shift toward interdisciplinary collaboration. | ||

Perception of low market value Native wood is not generally perceived as a premium or high-performance option. | Builds cultural and symbolic value Through participatory narratives and emphasis on origin, IDP helps reposition native wood as a meaningful material. | Coordinated governance Overcoming institutional duplication and isolated platforms. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schueftan, A.; Martin, M.; Buchner, C.; García, S.; Reyes, M.; Arnett, M. Integrated Design as a Strategy for Innovating Native Timber Products and Promoting Sustainable Forest Management. Buildings 2025, 15, 1886. https://doi.org/10.3390/buildings15111886

Schueftan A, Martin M, Buchner C, García S, Reyes M, Arnett M. Integrated Design as a Strategy for Innovating Native Timber Products and Promoting Sustainable Forest Management. Buildings. 2025; 15(11):1886. https://doi.org/10.3390/buildings15111886

Chicago/Turabian StyleSchueftan, Alejandra, Marjorie Martin, Carlos Buchner, Sol García, Mariela Reyes, and Michael Arnett. 2025. "Integrated Design as a Strategy for Innovating Native Timber Products and Promoting Sustainable Forest Management" Buildings 15, no. 11: 1886. https://doi.org/10.3390/buildings15111886

APA StyleSchueftan, A., Martin, M., Buchner, C., García, S., Reyes, M., & Arnett, M. (2025). Integrated Design as a Strategy for Innovating Native Timber Products and Promoting Sustainable Forest Management. Buildings, 15(11), 1886. https://doi.org/10.3390/buildings15111886