Abstract

Accurate prediction of endpoint carbon at the dynamic control stage in the converter is crucial for achieving smelting targets. Currently, there are two main methods for converter endpoint prediction: the data-driven method and the mechanism-based method. Data-driven methods exhibit high accuracy but are vulnerable to data quality variations and lack interpretability. Mechanism-based methods provide great interpretability but face challenges in precisely identifying key parameters in the mechanism formula. Inspired by the design concept of physics-informed neural networks (PINNs), an integrated data-driven and mechanism-based method for endpoint carbon prediction in BOF (dmPINNs, data-driven and mechanism-based physics-informed neural networks) is proposed, which has four parts: feature extraction, mechanism-based calculation, data-driven prediction, and integrated prediction. We identify key parameters of the mechanism formula through the neural network to obtain the specified formula for each heat and supervise the training process of the neural network through the mechanism formula to ensure interpretability. Experimental results show that, within the ±0.012% error range, the hit rate of endpoint carbon content using dmPINNs improved by 5.23% compared with the traditional data-driven method and has greater robustness with the supervision of the mechanism formula.

1. Introduction

Converter steelmaking is one of the main steelmaking methods in the steel production industry. Converter steelmaking is a highly complex process involving the reaction of multiple elements and the conversion of multiple phases at high temperatures [1].

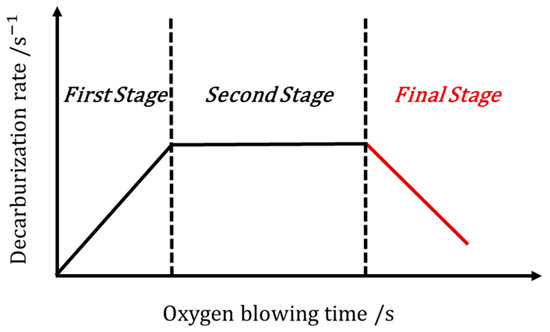

The decarburization process is one of the most important processes in BOF converter steelmaking, and is divided into three stages. In the first stage, Si and Mn are oxidized ahead of carbon. As the content of silicon (Si) and manganese (Mn) in the molten steel decreases, the decarburization rate gradually increases. In the second stage, oxygen is mainly consumed for the decarburization, and the decarburization rate reaches the maximum and remains stable. At the third or final stage, the carbon content gradually decreases and the decarburization rate decreases.

The diagram of the decarbonization in the BOF process is shown in Figure 1 [2].

Figure 1.

The diagram of the decarbonization in the BOF process.

The final stage is also called the dynamic control stage, which is from the time of TSC sublance detection to the endpoint in BOF, where TSC (temperature sampling carbon) is a composite functional sublance probe that integrates temperature measurement, carbon determination, and sampling. The accurate control of endpoint carbon is often achieved at this stage, and our research focuses on the dynamic control stage.

Accurate prediction of the converter endpoint at the final stage is essential for achieving smelting targets and ensuring product quality. Carbon content is one of the most important endpoint indicators. The control of endpoint carbon content is important. High carbon content will lead to an increase in the content of sulfur (S) and phosphorus (P). That can lead to a decrease in FeO content in slag, affecting the dephosphorization effect and increasing carbon segregation, making desulfurization more difficult.

The traditional mechanism-based method for endpoint carbon prediction in BOF uses the exponential mechanism equation at the final stage.

There are two main methods for the prediction of the converter endpoint: the data-driven method and the mechanism-based method. Data-driven methods can discover hidden patterns and correlation relationships inside the data, but they are vulnerable to data quality variations. They lack interpretability due to the absence of mechanism knowledge. Mechanism-based methods, from the mechanism knowledge in the metallurgical field, offer much interpretability. However, the great challenge is to identify unmeasurable key parameters in the mechanism formula accurately, which cannot be directly observed or measured.

This paper aims to devise a prediction method that integrates the advantages of both data-driven and mechanism-based methods, thereby overcoming the limitations of each method.

2. Related Work

2.1. Data-Driven Methods

Data-driven methods have been widely used in endpoint prediction [3,4,5]. Park et al. [6] proposed a converter steelmaking endpoint temperature prediction model based on the least squares support vector machine (LSSVM) and artificial neural network (ANN). The root mean square error (RMSE) of the LSSVM and ANN models were 15.91 and 17.24, respectively, which were better than the classical partial least squares (PLS) model’s RMSE value of 21.31. After selecting input parameters through sensitivity analysis, the RMSE reached 13.21. Liu et al. [7] proposed a dynamic analysis method based on a mixed kernel least squares support vector machine (DM-HKLSSVM) for real-time prediction in the converter steelmaking process, using a multistage modeling strategy. The model can dynamically predict the temperature and other elements in the converter steelmaking process, and its prediction performance is better than SVR, RVM, KELM, DSAE, and other methods. The MAPE of predicting carbon content is 3.45 (%). Luo et al. [8] designed a convolutional neural network based on flame color images. By analyzing the flame characteristics of the converter steelmaking process and combining it with the convolutional neural network to output the endpoint carbon content, the hit rate in the ±0.02% error range was 86.50%.

2.2. Mechanism-Based Methods

Representative studies on mechanism-based methods are as follows. Dering et al. [9] proposed a first-principle-based dynamic model for BOF. They considered the main physical and chemical processes involved in BOF and considered models for slag formation and energy balance to extend the previous work, making the model more comprehensive. They implemented their model as a DAE (differential algebraic equation) system, and the dynamic model can effectively predict the decarbonization reaction process in BOF. The drawback is that the model includes some assumptions and simplified calculations. Yue et al. [10] established prediction models for the endpoint carbon, phosphorus, manganese elements, and temperature of the converter using the decarburization index equation, thermal equilibrium, and thermodynamic equations at the end of the converter blowing process. The hit rate of endpoint carbon content prediction reached 87.60% within the error range of ±0.015%, and the hit rate of temperature prediction reached 85.40% within the error range of ±10 °C. This method takes the influence of thermodynamic factors into account, but the drawback is that it adopts an exhaustive attack method to deal with unmeasurable key parameters in the mechanism formula. Wang et al. [2] proposed a continuous prediction model of carbon content of 120 t BOF based on the explicit finite difference method. The proposed model can accurately predict the change in carbon content in the converter-blowing process. The drawback is that the model is relatively complex, and many assumptions are introduced.

2.3. Integrated Methods

Both data-driven methods and mechanism-based methods have certain advantages and disadvantages.

In the metallurgical field, numerous data-driven methods have been applied for prediction tasks. However, due to their black-box nature, these methods offer limited transparency and poor interpretability. Mechanism-based methods contain the mechanism knowledge, providing good interpretability. This mechanism knowledge serves as an essential theoretical foundation for guiding actual production. However, the identification of unmeasurable key parameters in the mechanism formula for each heat remains challenging because the parameters are primarily influenced by factors like mass transfer coefficients and reaction interfaces.

Gu et al. [11] proposed an improved CBR model using time-series data (CBR_TM) to predict the converter endpoint carbon content and temperature. The performance of CBR_TM is better than the models based on SVR and BPNN, and the hit rate is higher. Gu et al. [12] finally proposed a real-time dynamic carbon content prediction model based on CBR and LSTM, which is close to an integrated method. They integrated the carbon integral model and exponential decay model of carbon into the prediction. However, the mechanism-based part of their method is a small proportion. Zhou et al. [13] proposed a mechanism-data, hybrid-driven, model-building method for RH decarbonization. They determined the weight parameters of decarbonization at different sites using a just-in-time algorithm and introduced them into the decarbonization formula. This method improves the prediction accuracy and applicability of the RH decarbonization model. Carlucci et al. [14] proposed a parameter identification method based on dimensional analysis and least squares linear regression for the unmeasurable key parameters in the mechanism formula. This method is based on historical data, and combined with dimensional analysis and least squares regression to identify unmeasurable parameters. This parameter identification method improves the accuracy, robustness, and reliability of the dynamic control model for converter steelmaking. However, the disadvantage is that this method is not very suitable for highly nonlinear dynamic control processes and cannot avoid the decrease in the identification accuracy of unmeasurable parameters caused by outliers and noise in the data.

In recent years, Raissi et al. [15] proposed the concept of physics-informed neural networks (PINNs), which offer a way to integrate empirical prior knowledge and physical laws into data-driven models as a constraint, enhancing interpretability and robustness. Inspired by the design concept of PINNs, this paper proposes an integrated data-driven and mechanism-based method for endpoint carbon prediction in BOF (dmPINNs, data-driven and mechanism-based physics-informed neural networks).

The proposed method incorporates the decarbonization mechanism formula into the neural network. The unmeasurable parameters in the mechanism formula are identified by dmPINNs for each heat. Each heat is described by the mechanism formula with different key parameters from different working conditions. The training process of the data-driven neural network is constrained by the mechanism formula to ensure that the model adheres to the underlying mechanism principles of the decarbonization process. The integrated method proposed exhibits good interpretability, robustness, and accuracy.

3. Methods

In this section, we discuss the proposed integrated models (dmPINNs). After briefly introducing the mechanism formula of decarbonization and the theory of physics-informed neural networks, we present the design of the neural network and the loss function of the integrated method. Finally, we describe the training flowchart of the integrated method.

3.1. Design of Mechanism Formula

3.1.1. Common Nomenclature

Common nomenclature used in this paper are shown in Table 1.

Table 1.

Common nomenclature used in this paper.

3.1.2. Mechanism Formula

Robertson, and Tao et al. [16,17] proposed a mechanism formula for the dynamic control process after TSC sub-lance detection in converter steelmaking:

where , represent the oxygen blowing amount at time , . , represents the coolant weight at time , . And represents the time of TSC sub-lance detection. represents the carbon content in the molten steel at time , and represents the oxygen content per unit weight of coolant.

The carbon content of molten steel at time can be calculated using Equation (1).

During the dynamic control process, the heat state in BOF is relatively stable, so coolant is rarely used to adjust the temperature. Without considering the oxygen content of the coolant added at this stage, this formula can be simplified in the form of Equation (3) [14]:

represents the oxygen consumption from time to time as . Equation (3) is transformed into Equation (5).

Equation (5) is chosen as the mechanism constraint in the integrated neural network dmPINNs.

3.2. Physics-Informed Neural Networks

Physics-informed neural networks (PINNs) are a network structure that integrates mechanisms for supervised learning tasks and have been widely used in solving problems with physical constraints [18,19,20,21].

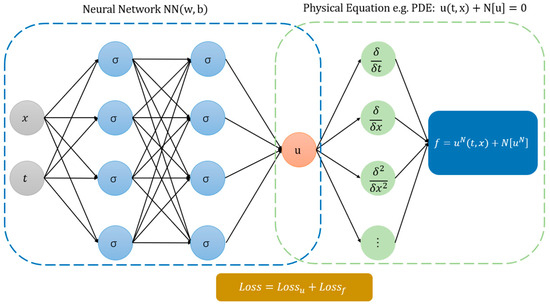

The structure of PINNs is shown in Figure 2.

Figure 2.

A simple and classic structure of PINNs. The grey parts are neurons of the input layer of the neural network, the light-blue parts are neurons of the hidden layer, the orange part is neuron of the output layer, the green parts are differential results of automatic differentiation and the deep blue part is the residual error of the PDE.

PINNs introduce control equations that reflect mechanism constraints into neural networks and adds them in the form of loss function, thereby transforming the solution process or parameter identification process into an optimization problem.

For general nonlinear PDEs:

where is the implicit solution of the partial differential equation, is a nonlinear differential operator, is the temporal coordinate, and is a subset of Euclidean space , is the final temporal coordinate.

Define as the neural network approximates . And define as Equation (7):

The loss function of PINNs can be designed as Equation (8):

In the method proposed by Raissi et al. [15], the initial and boundary data loss and configuration point loss are usually in the form of mean square error MSE:

where represents initial and boundary training data, and represents collocation points.

PINNs approach by designing neural networks to minimize . At the same time, while is approximating , the mechanism constraints of Equation (6) are enforced on collocation points, then the loss of the physical-information-based part of the also approaches the minimum . In this way, PINNs introduce mechanism constraints for supervising neural network training.

Compared with data-driven neural networks, PINNs incorporate mechanism constraints into the training process, enabling them to obtain models with good interpretability and robustness based on fewer data samples guided by prior knowledge.

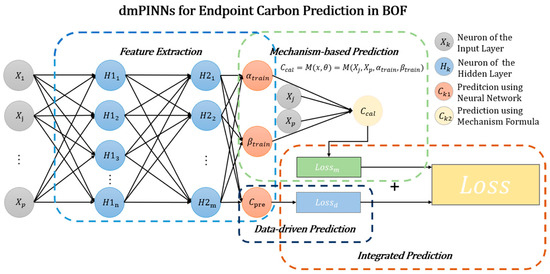

3.3. Design of dmPINNs

Inspired by the concept of PINNs, the network structure of dmPINNs is designed and shown in Figure 3. The values in the dmPINNs are described in Table 1.

Figure 3.

Structure of dmPINNs. And , in the figure is Equation (5).

3.3.1. Network Structure

The proposed network has four parts: feature extraction, mechanism-based calculation, data-driven prediction, and integrated prediction. The input of the model (, , …, ) are measurable data from the converter steelmaking process, such as the weight of hot metal in the converter, weight of flux, and temperature of hot metal.

First of all, a feature extraction part is designed to simulate different working conditions for different heats in BOF. Then we utilize the extracted features to identify the unmeasurable parameters , in the mechanism Equation (5). The feature extraction part is the foundation of the data-driven part and the mechanism-based part subsequently.

In the data-driven part, the latent features extracted from the data are fully utilized to predict the endpoint carbon content . And in the mechanism-based part, the identified unmeasurable parameters , , along with two input data acquired prior to the dynamic control stage: and , which are in network structure, are substituted into the mechanism formula, and is calculated.

Finally, in the integrated prediction part, the result of the data-driven part and the mechanism-based part are fused to obtain an integrated prediction result.

To evaluate the performance of the model, we calculate the data-driven loss using and true values , and the mechanism formula loss using and true values . Their calculation process will be explained in Equations (12) and (13) in the next section. The overall loss function is designed as the weighted sum of and . As approaches the true value, decreases, driving the unmeasurable parameters towards the optimization for the working condition of each heat that can minimize the discrepancy between and the true value, leading to a decrease in . Then, the final endpoint carbon content prediction result is designed as the weighted sum of and derived from the mechanism-based and data-driven parts.

3.3.2. Loss Function

The loss function of dmPINNs is Equation (11), which is as follows:

where as the loss of data-driven part, which is similar to the initial and boundary data loss of classical PINNs. is the loss of the mechanism-based part and is similar to collocation point loss in classical PINNs.

Unlike traditional PINNs that typically use the form of mean square error , mean absolute error is used in the form of and to reduce the impact of outliers:

where is the number of training data.

and are set as constants for all heats. And for heat number , the unmeasurable parameters , identified by dmPINNs along with two input data acquired prior to the dynamic control stage: and , are entered into the mechanism formula. Then the endpoint carbon content in the mechanism-based part is calculated.

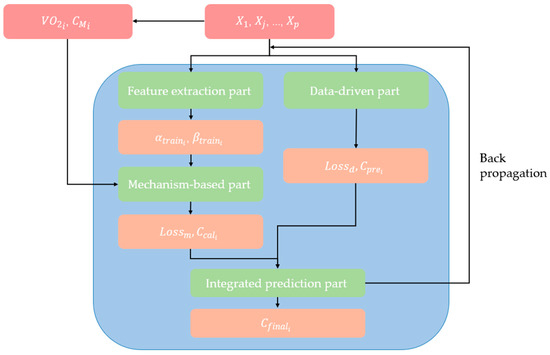

3.3.3. Training Process Description

The training process description of dmPINNs is shown in Table 2.

Table 2.

The training process description of dmPINNs.

The training flow chart of dmPINNs is also shown in Figure 4.

Figure 4.

The training flow chart of dmPINNs. The red parts are the input data, the orange parts are the process data or output data, the green parts are the four different parts of dmPINNs.

4. Experiments

In this section, based on the network structure and loss function proposed in Section 3, comparative experiments are designed to compare dmPINNs with traditional data-driven methods, and experiments with varying noise proportions added to an important input (the carbon content in hot metal) are designed to investigate the accuracy and robustness of dmPINNs.

4.1. Data and Preprocessing

4.1.1. Data

The data used in this paper is based on the real converter steelmaking process from a large steelmaking plant, which is abbreviated as S due to confidentiality reasons. The data is a collection of measurable data obtained through various methods, including the heat number, the weight of the hot metal, the weight of scrap, the weight of the heat-generating agent, the weight of flux, total blowing time, the temperature of the hot metal, the carbon content () in the hot metal, the silicon content () in the hot metal, the manganese content () in the hot metal, the phosphorus content () in the hot metal, the sulfur content () in the hot metal, the temperature of molten steel measured by TSC, the carbon content of molten steel measured by TSC, and the endpoint carbon content measured by TSO, etc.

There are 16 main influencing factors which are considered as the input for the dmPINNs, namely: (, , …, ), and TSO measurement result of carbon content () is used as the true label for the endpoint carbon content. Statistical results of influencing factors are shown in Table 3.

Table 3.

Statistical results of influencing factors.

We use the temperature of molten steel measured by TSC () instead of the temperature of molten metal entering the converter as one of the input factors because reflects the more recent smelting state of the furnace more accurately.

4.1.2. Imputation of Missing Values

To ensure data integrity and reliability, we perform imputation of missing values. For some missing data, such as weight of flux A (CaO) , we adopt a neighboring value imputation method. For another subset of missing data, such as carbon content in molten iron , either linear interpolation or analysis of the probability density distribution of other highly correlated data (such as silicon in molten iron) is employed to achieve the imputation.

4.1.3. Handling of Outliers

In our preprocessing, we directly remove significant outliers but retain minor outliers to validate the robustness of the integrated method more effectively.

After preprocessing the dataset, we get 1017 heats of valid data.

4.2. Experiments Setting

4.2.1. Dataset

This paper uses a back propagation neural network (BPNN) with a structure of 16 × 20 × 10 × 3 as the basic architecture to extract features from the input data and predict the endpoint carbon content of the data-driven part directly, and uses the hyperbolic tangent function Tanh as the activation function. At the end of the feature extraction part, the unmeasurable parameters , predicted by the neural network are mapped to the prior knowledge interval (empirical range) of the unmeasurable parameters (1,2) and (20,40) to accelerate convergence, and we appropriately expand this prior knowledge interval to cope with extreme data. During the training process, an Adam algorithm is used with an initial learning rate of 0.0001. The dataset consists of 1017 data sets, with a ratio of 7:3 for training and testing data and a quantity of 711:306 for each.

Equation (15) for the final prediction result of is as follows:

If the difference between and the true value falls within three error ranges: ±0.009 (%), ±0.012 (%), and ±0.02 (%), it is considered a hit in the corresponding error range.

The calculation method of hit rate is Equation (16).

where is the number of hits in testing data, and is the number of testing data.

4.2.2. Noise

In the experiment to demonstrate the robustness of the integrated method, this paper adds noise that follows a Gaussian distribution to different proportions of data in the training data. Taking the carbon content of molten steel () measured by TSC as an example, the following is the formula for the variation of noise data:

where represents the before introducing the noise, represents the after introducing the noise, represents the average value of the data in column , represents a random number that follows a Gaussian distribution with a mean of 0 and a standard deviation of 0.1. The proportion of data with added noise is 10%, and 20%, respectively. The factors with added noise are and , to simulate the inaccurate measurement components caused by the aging of the sublance.

5. Experiments Result and Discussion

5.1. Experiments Result

5.1.1. Hit Rate

In order to compare the hit rate of the traditional data-driven prediction and the integrated prediction, the data-driven prediction method using BPNN is compared against dmPINNs. The results of this experiment are summarized in Table 4.

Table 4.

Hit rate of different prediction methods.

In terms of hit rate, dmPINNs achieved hit rates of 69.80%, 81.37%, and 93.52% in the error ranges of ±0.009 (%), ±0.012 (%), and ±0.02 (%), respectively, which were better than those achieved by the traditional data-driven method BPNN in these ranges. The improved hit rates are 6.80%, 5.23%, and 1.04%, respectively. In a narrower error range, dmPINNs have a greater improvement.

Hit rates of dmPINNs_cal were 69.45%, 80.00%, and 93.35%, respectively. The hit rates of dmPINNs_pre were 66.67%, 78.63%, and 93.85%, respectively, which were better than BPNN in these ranges.

5.1.2. Model Degradation with Addition of Noise

We compare the degradation of prediction in the hit rate of BPNN and dmPINNs, with 10% and 20%, respectively, and noise added to the dataset to compare robustness. The experimental results are shown in Table 5.

Table 5.

Hit rate and the degradation of hit rate of different methods with the addition of noise.

As the noise data increases from 0% to 20%, the hit rate degradation of dmPINNs is lower than BPNN. The robustness of dmPINNs against noise and outliers is stronger.

5.2. Discussion

5.2.1. Analysis of Prediction Results

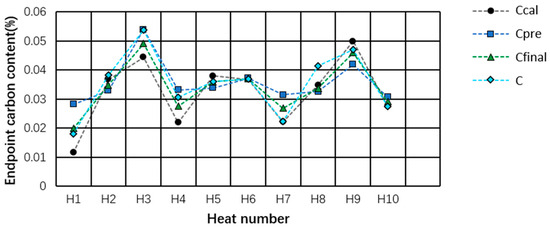

Table 6 shows the identified unmeasurable parameters, the prediction results of the mechanism-based part and data-driven parts in the integrated method, the final prediction results of the integrated method, and the true values for 10 sets of heat data in the test data.

Table 6.

Prediction result of representative heats.

Taking Heat H6 as an example, two unmeasurable parameters are identified by dmPINNs and the direct prediction value of the endpoint carbon content through the data-driven part can be obtained at the same time, which are , , in Table 7.

Table 7.

Parameters and values of Heat H6.

The mechanism formula with two unmeasurable parameters can be obtained, as well as the two input data obtained before the start of the dynamic control stage, which are and in Table 7.

Then the values of and can be calculated using Equation (18), and are shown in Table 7.

Figure 5 shows the distribution of the prediction results of the mechanism-based part , the data-driven part , the final prediction results of the integrated method and the true values .

Figure 5.

Distribution of the prediction results of different parts of dmPINNs and the true value of endpoint carbon content.

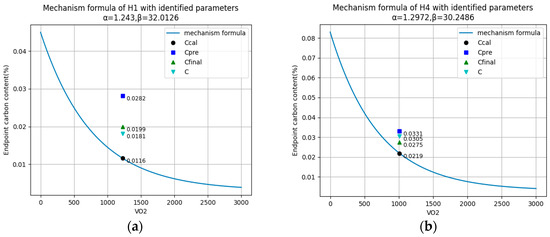

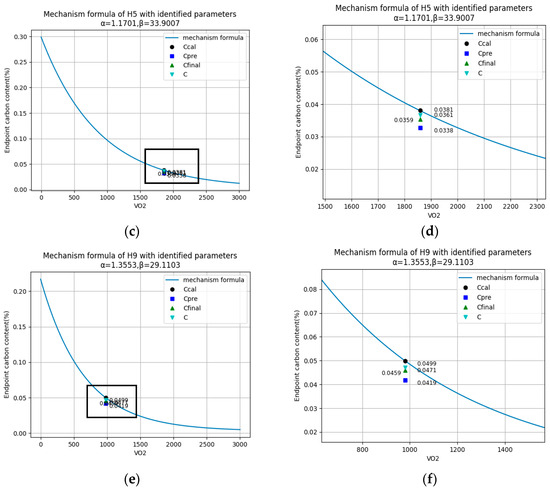

Figure 6.

Detailed prediction results of each part in dmPINNs. (a,b,c,e) are the complete prediction results of four heats. The two curves in panel (d) and panel (f) are the details of the rectangle at the left in (c,e).

We take panel (b) of Figure 6 as an example to explain the elements in each panel. The title represents the mechanism formula with identified parameters , of Heat H4. Ccal in the figure represents the prediction result of the mechanism-based part , which is 0.0219 (%). Cpre represents the prediction result of the data-driven part , which is 0.0331 (%). Cfinal represents the final prediction result of the integrated method , which is 0.0275 (%). C represents the true value, which is 0.0305 (%). The curve in the figure represents the specified mechanism formula with identified parameters from dmPINNs.

Among the two components of the integrated prediction results, the prediction results of the mechanism-driven part can, in most cases, be closer to the true values. This suggests that after the unmeasurable parameters have been identified, the mechanism-based part can reach more accurate prediction.

Under the integrated guidance of the mechanism and data, the final prediction results exhibit a greater hit rate than either of the two parts alone. The integrated method introduces mechanism constraints during the training process, not only ensuring each heat is described by the designed mechanism formula with different parameters from different working conditions but also exerting an impact on the neural network’s training, in turn, providing a valuable guiding effect.

5.2.2. Application of dmPINNs in Other Steelmaking Plants

We applied dmPINNs to the data from another large steel-making plant, which is abbreviated as T due to confidentiality reasons, to observe the performance in Table 8.

Table 8.

Hit rate on the data of different steelmaking plants.

The hit rates of dmPINNs on the data of different steelmaking plants S and T are better than the hit rates of the traditional data-driven method in the error ranges above. dmPINNs also have a greater improvement in a narrower error range.

The experimental results above show that the integrated method outperforms the traditional data-driven method in both hit rates and robustness.

6. Conclusions

This paper first analyzes the advantages and disadvantages of mechanism-based methods and data-driven methods, which are two main methods of endpoint prediction in BOF. Aiming at the dynamic control process after sublance detection at the third stage of the converter steelmaking decarbonization process, an integrated data-driven and mechanism-based method for endpoint carbon prediction in BOF (dmPINNs) is proposed based on the concept of PINNs. The mechanism formula with the identified unmeasurable parameters can be obtained through neural networks and then used to guide data-driven training to achieve the integrated method. In terms of prediction performance, the hit rate and robustness of dmPINNs are better than data-driven methods. In terms of hit rate, dmPINNs have higher hit rates in the error ranges of ±0.009 (%), ±0.012 (%), and ±0.02 (%), and have a greater improvement in a narrower error range. In terms of robustness, as the noise data increases from 0% to 20%, the hit rate degradation of dmPINNs is lower than the traditional data-driven method.

The data used as input for the neural network in this paper are not time series values. In the future, the unmeasurable parameters in the mechanism formula can be further optimized by combining time series data about top-blowing or bottom-blowing in BOF. More accurate thermodynamic calculations and dynamic simulations can be utilized to identify the unmeasurable parameters in the decarburization formula. Meanwhile, the idea of the integrated method can be applied to other prediction tasks such as temperature prediction in BOF and the endpoint prediction of RH and EAF.

Author Contributions

Conceptualization, Y.X.; methodology, Y.X. and H.W.; investigation, Y.X.; data curation, H.W. and A.X.; writing—original draft preparation, Y.X.; writing—review and editing, Y.X., H.W. and A.X.; project administration, H.W.; funding acquisition, H.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Science and Technology Major Project, grant number 2022ZD0119201.

Data Availability Statement

Data is unavailable due to privacy. Some of the data provided in this study are from third parties, and some are from our own research. All data has not been stored in the database.

Acknowledgments

We acknowledge the support of Jinyan Liu and the contribution of Huan Xie.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Dogan, N.; Brooks, G.A.; Rhamdhani, M.A. Comprehensive model of oxygen steelmaking part 1: Model development and validation. ISIJ Int. 2011, 51, 1086–1092. [Google Scholar] [CrossRef]

- Wang, D.; Gao, F.; Xing, L.; Chu, J.; Bao, Y. Continuous Prediction Model of Carbon Content in 120 t Converter Blowing Process. Metals 2022, 12, 151. [Google Scholar] [CrossRef]

- Wang, H.; Xu, A.; AI, L.; Tian, N. Prediction of endpoint phosphorus content of molten steel in BOF using weighted K-Means and GMDH neural network. J. Iron Steel Res. Int. 2012, 19, 11–16. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, H. A two-step case-based reasoning method based on attributes reduction for predicting the endpoint phosphorus content. ISIJ Int. 2015, 55, 1035–1043. [Google Scholar] [CrossRef]

- Wang, X.; Xing, J.; Dong, J.; Wang, Z. Data driven based endpoint carbon content real time prediction for BOF steelmaking. In Proceedings of the 2017 36th Chinese Control Conference (CCC), Dalian, China, 26–28 July 2017; pp. 9708–9713. [Google Scholar]

- Park, T.C.; Kim, B.S.; Kim, T.Y.; Jin, B., II. Comparative study of estimation methods of the endpoint temperature in basic oxygen furnace steelmaking process with selection of input parameters. Korean J. Met. Mater. 2018, 56, 813–821. [Google Scholar] [CrossRef]

- Liu, C.; Tang, L.; Liu, J.; Tang, Z. A dynamic analytics method based on multistage modeling for a BOF steelmaking process. IEEE Trans. Autom. Sci. Eng. 2018, 16, 1097–1109. [Google Scholar] [CrossRef]

- Luo, T.; Liu, H.; Wu, Q.; Wang, B. Prediction method of carbon content in BOF endpoint based on convolutional neural network. Inf. Technol. 2018, 42, 150–155. [Google Scholar]

- Dering, D.; Swartz, C.; Dogan, N. Dynamic modeling and simulation of basic oxygen furnace (BOF) operation. Processes 2020, 8, 483. [Google Scholar] [CrossRef]

- Yue, F.; Bao, Y.P.; Cui, H.; Gao, S.Y.; Li, B.H.; Zhang, J. Sub-lance control-based predication model for BOF end-point. Steelmaking 2009, 25, 38–40. [Google Scholar]

- Gu, M.; Xu, A.; Yuan, F.; He, X.; Cui, Z. An improved CBR model using time-series data for predicting the end-point of a converter. ISIJ Int. 2021, 61, 2564–2570. [Google Scholar] [CrossRef]

- Gu, M.; Xu, A.; Wang, H.; Wang, Z. Real-time dynamic carbon content prediction model for second blowing stage in BOF based on CBR and LSTM. Processes 2021, 9, 1987. [Google Scholar] [CrossRef]

- Zhou, C.; He, Y.; Liu, J.; Yang, F.; Xiao, M.; Yuan, J. Mechanism-data hybrid driven model building method for RH decarbonization. China Metall. 2023, 33, 54–60+111. [Google Scholar]

- Carlucci, A.P.; Ficarella, A.; Indiveri, G.; Presicce, P. An improved parameter identification schema for the dynamic model of LD converters. J. Process Control 2015, 31, 64–72. [Google Scholar] [CrossRef]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics-informed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J. Comput. Phys. 2019, 378, 686–707. [Google Scholar] [CrossRef]

- Robertson, K.J.; Balajee, S.R.; Shearer, J.M.; Bradley, J.E. The sublance dynamic control operation and its effect on the performance of the Inland Steel Company’s No. 4 BOF shop. In Proceedings of the Steelmaking Conference Proceedings, Chicago, IL, USA, 2–5 April 1989; Volume 72, pp. 159–166. [Google Scholar]

- Tao, J.; Wang, X.; Chai, T.Y. Intelligent control method and application for BOF steelmaking process. In Proceedings of the IFAC World Congress, Barcelona, Spain, 21–26 July 2002; Volume 14, pp. 17–19. [Google Scholar]

- Zobeiry, N.; Humfeld, K.D. A physics-informed machine learning approach for solving heat transfer equation in advanced manufacturing and engineering applications. Eng. Appl. Artif. Intell. 2021, 101, 104232. [Google Scholar] [CrossRef]

- Wang, S.; Teng, Y.; Perdikaris, P. Understanding and mitigating gradient flow pathologies in physics-informed neural networks. SIAM J. Sci. Comput. 2021, 43, A3055–A3081. [Google Scholar] [CrossRef]

- Pang, G.; D’Elia, M.; Parks, M.; Karniadakis, G.E. nPINNs: Nonlocal Physics-Informed Neural Networks for a parametrized nonlocal universal Laplacian operator. Algorithms and Applications. J. Comput. Phys. 2020, 422, 109760. [Google Scholar] [CrossRef]

- Jagtap, A.D.; Kharazmi, E.; Karniadakis, G.E. Conservative physics-informed neural networks on discrete domains for conservation laws: Applications to forward and inverse problems. Comput. Methods Appl. Mech. Eng. 2020, 365, 113028. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).