Development of a Novel High-Temperature Al Alloy for Laser Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

3. Results

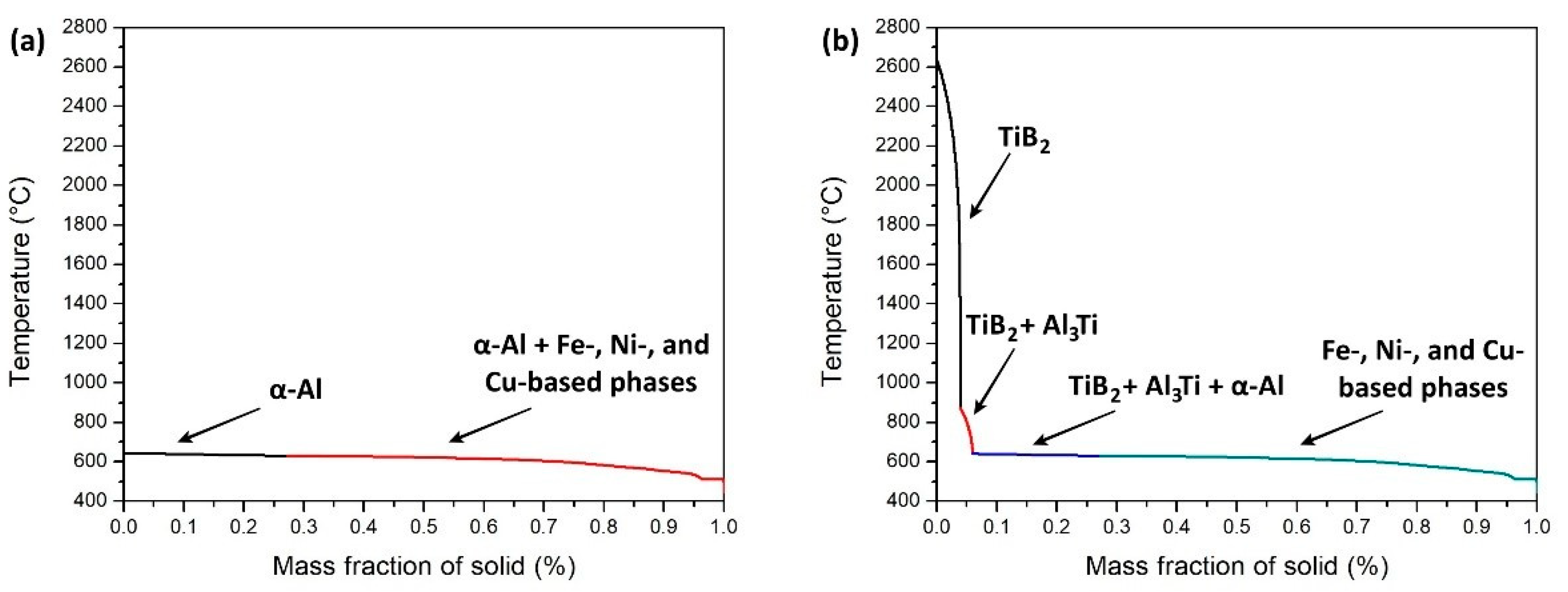

3.1. Simulation

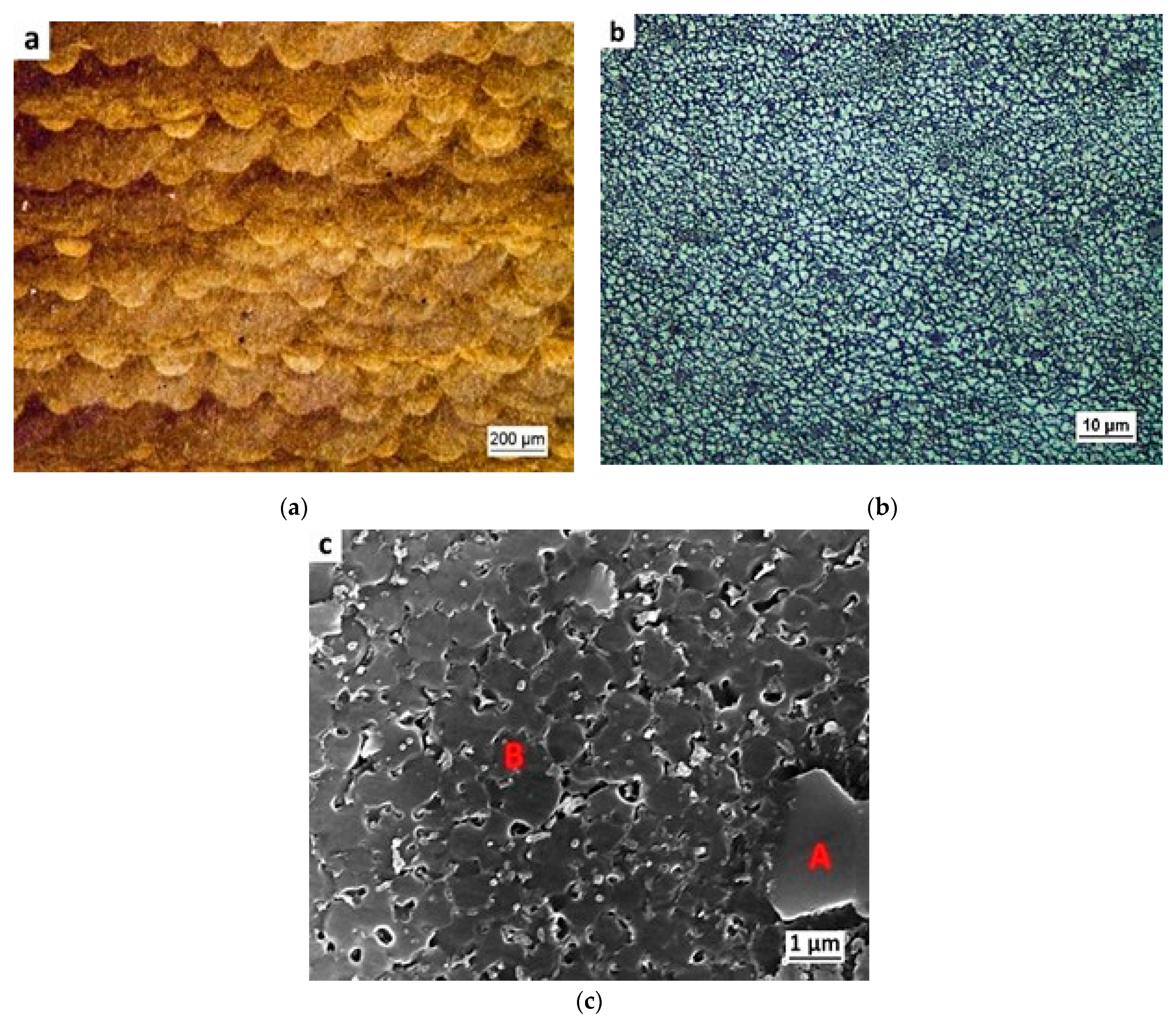

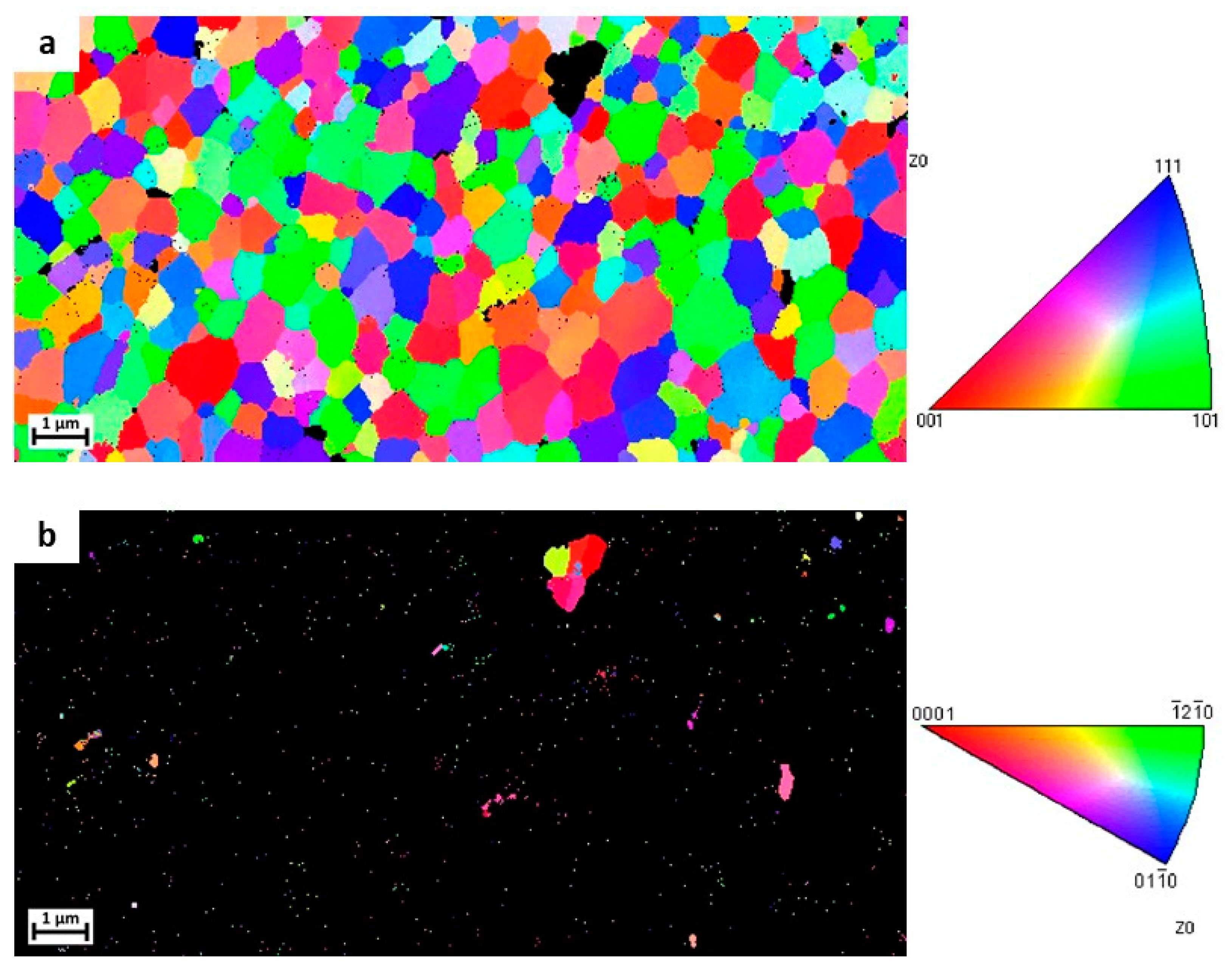

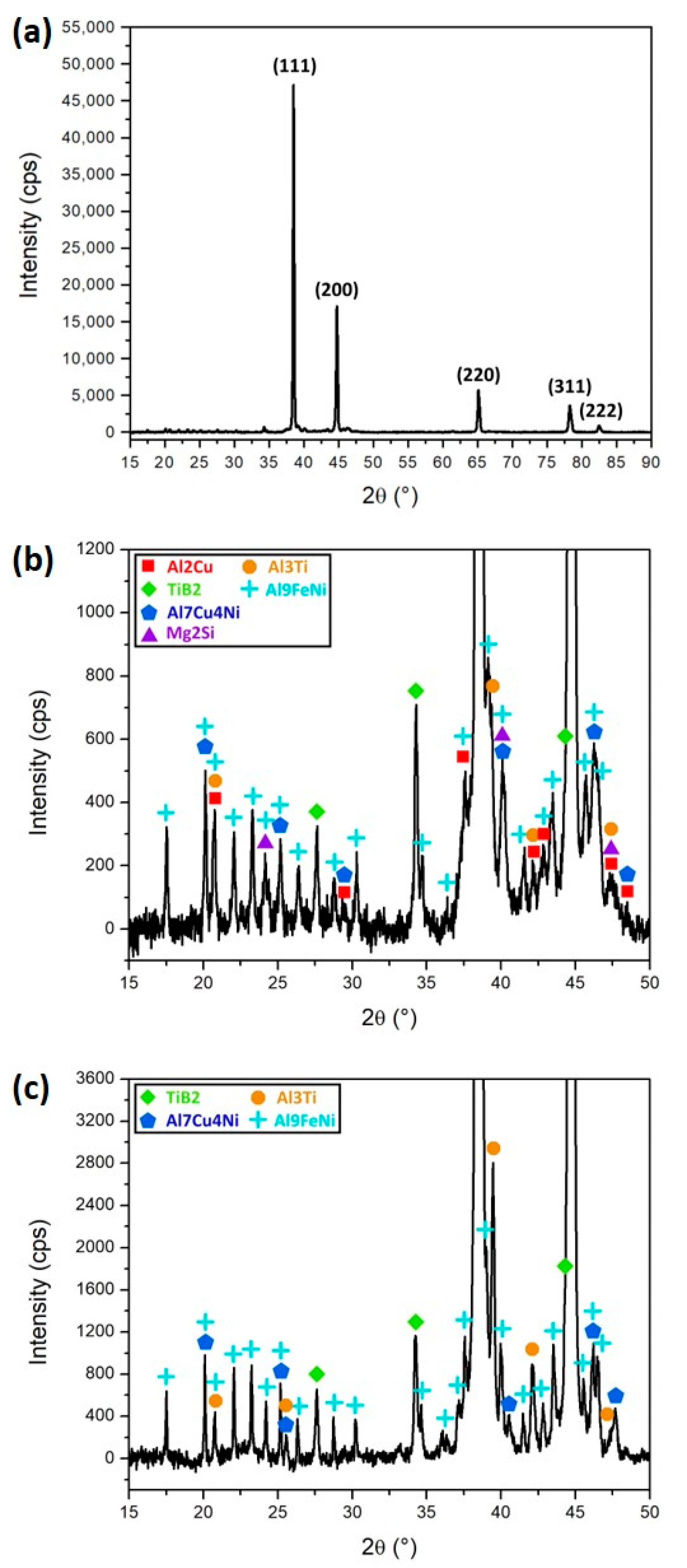

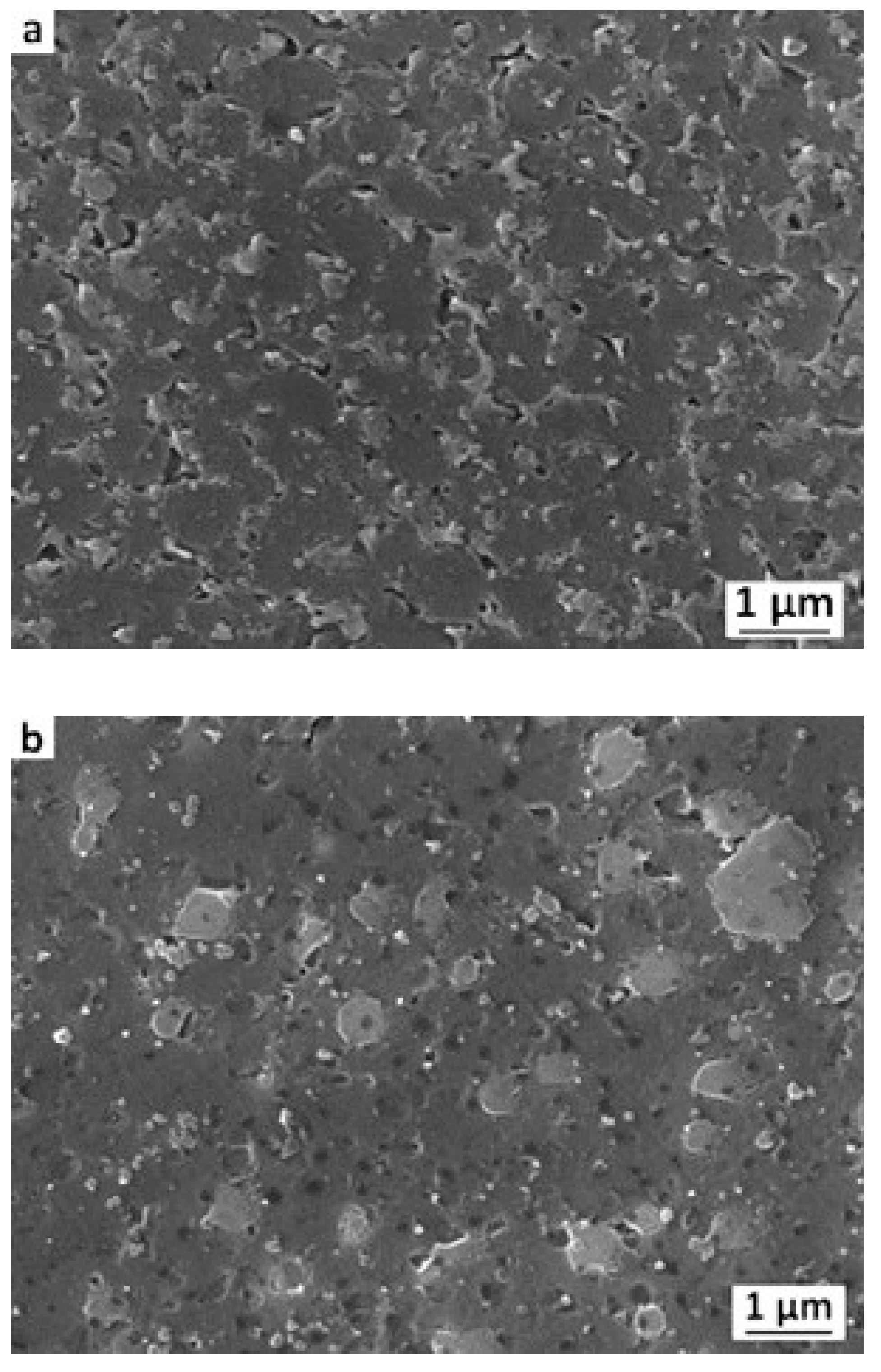

3.2. Microstructure

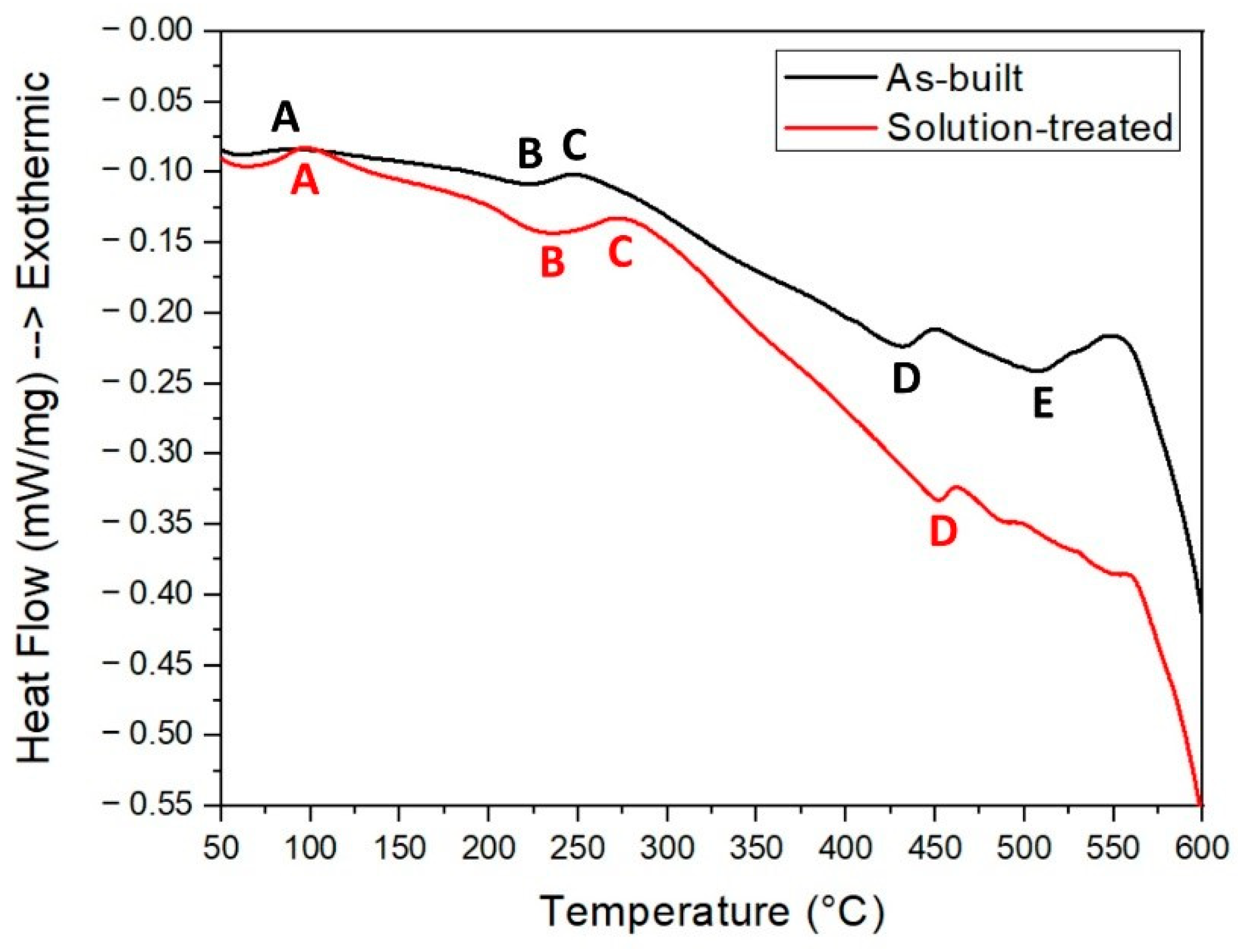

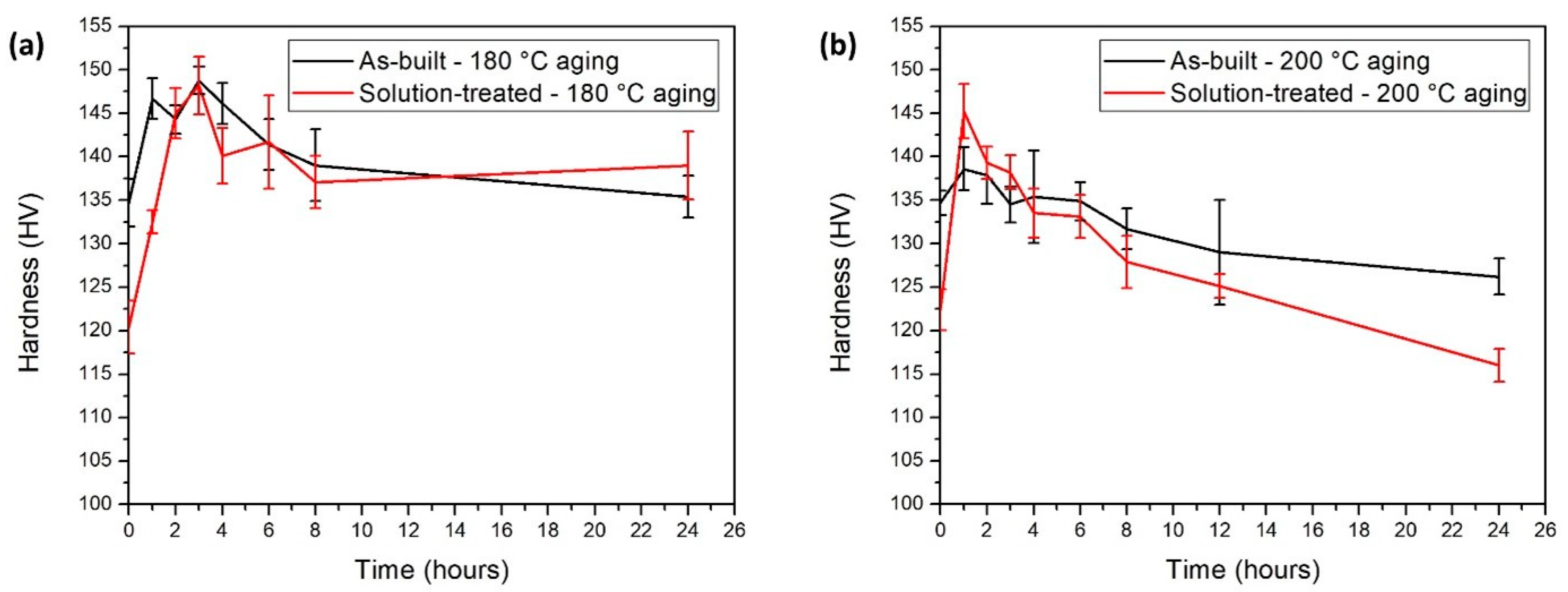

3.3. Aging Response

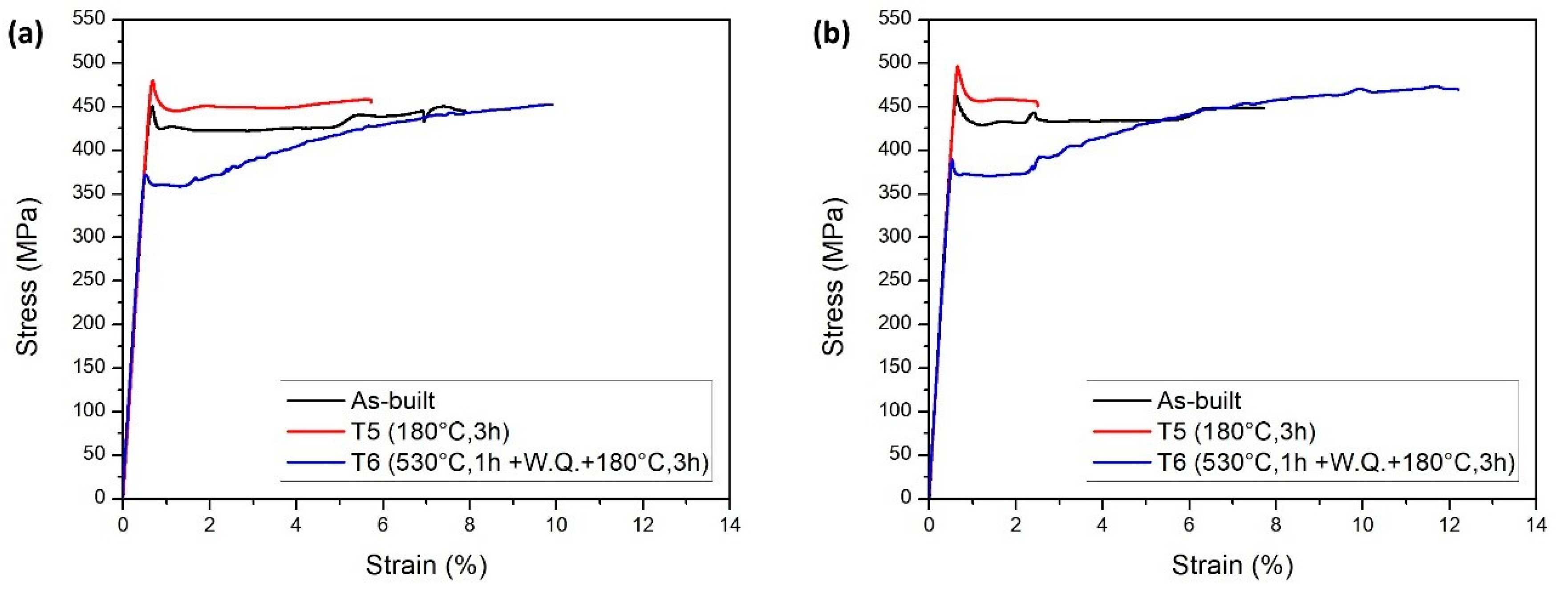

3.4. Mechanical Properties

4. Discussion

5. Conclusions

- The addition of titanium and boron positively affects the processability of the 2618 Al alloy produced by L-PBF process. TiB2 and Al3Ti particles promote the formation of an equiaxed microstructure and the suppression of the solidification cracking phenomenon.

- Solidification and cooling rates induced by L-PBF processing are fast enough to generate supersaturated solid solutions with aging potential, as shown by DSC and aging curves.

- Solution treatment modifies the microstructure of the material, leading to the dissolution of micro-segregation at cell boundaries and to the formation of coarser particles.

- At room temperature, as-built XY-specimens show UYS and UTS of 461 MPa and 447 MPa, respectively. The T5 samples achieve UYS and UTS of 495 MPa and 460 MPa and, after T6 temper, of 392 MPa and 470 MPa, respectively.

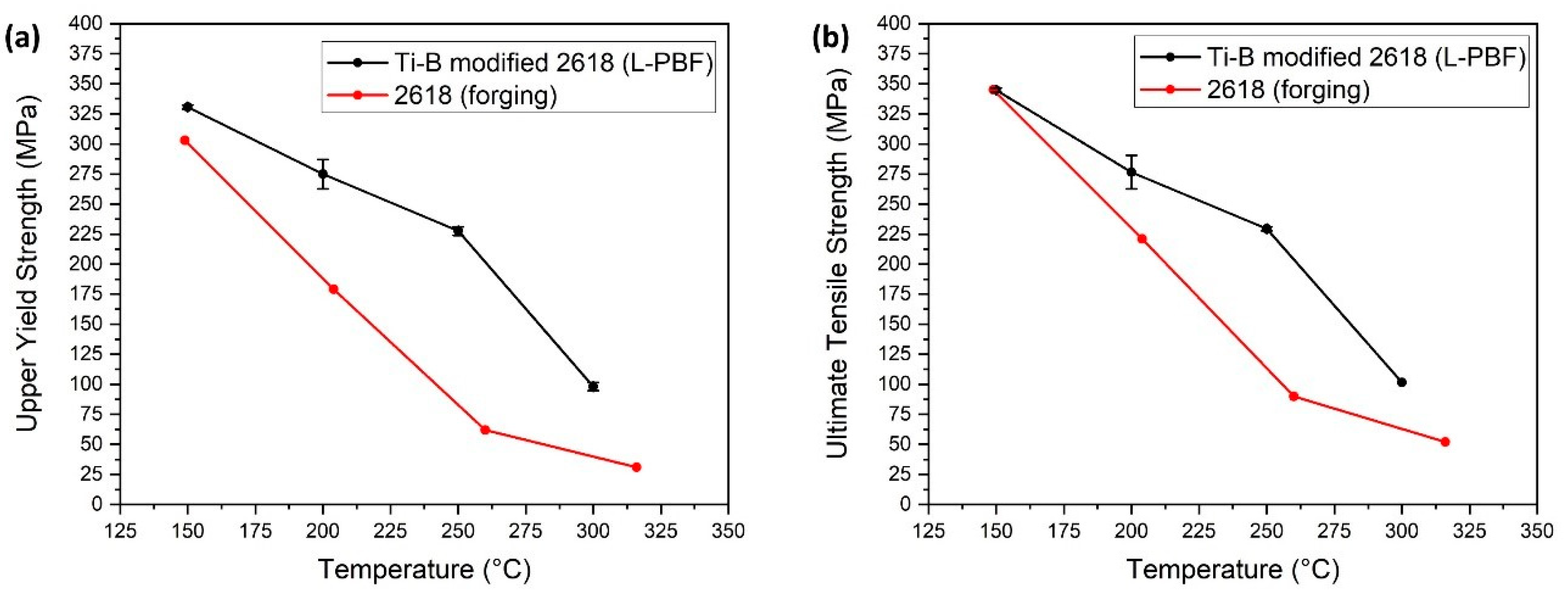

- At high temperature, the Ti-B modified 2618 alloy printed by L-PBF process shows higher mechanical properties with respect to the conventional alloy produced by forging.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.Z.; Yhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Koutny, D.; Palousek, D.; Pantelejev, L.; Hoeller, C.; Pinchler, R.; Tesicky, L.; Kaiser, J. Influence of scanning strategies on processing of aluminum alloy EN AW 2618 using selective laser melting. Materials 2018, 11, 298. [Google Scholar] [CrossRef] [PubMed]

- Uddin, S.Z.; Espalin, D.; Mireles, J.; Morton, P.; Terrazas, C.; Collins, S.; Murr, L.E.; Wicker, R. Laser powder bed fusion fabrication and characterization of crack-free aluminum alloy 6061 using in-process powder bed induction heating. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 7–9 August 2017; pp. 214–227. [Google Scholar]

- Montero-Sistiaga, M.L.; Martens, R.; Vrancken, B.; Wang, X.; Van Hooreweder, B.; Kruth, J.-P.; Van Humbeeck, J. Changing the alloy composition of Al7075 for better processability by selective laser melting. J. Mater. Process. Technol. 2016, 238, 437–445. [Google Scholar] [CrossRef]

- Kou, S. Solidification and liquation cracking issues in welding. JOM 2003, 55, 37–42. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Casati, R.; Coduri, M.; Riccio, M.; Rizzi, A.; Vedani, M. Development of a high strength Al-Zn-Si-Mg-Cu alloy for selective laser melting. J. Alloys Compd. 2018, 801, 243–253. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Nie, X.; Yin, J.; Hu, Z.; Zeng, X. Effect of Zirconium addition on crack, microstructure and mechanical behavior of selective laser melted Al-Cu-Mg alloy. Scr. Mater. 2017, 134, 6–10. [Google Scholar] [CrossRef]

- Wang, P.; Gammer, C.; Brenne, F.; Niendorf, T.; Eckert, J.; Scudino, S. A heat treatable TiB2/Al-3.5 Cu-1.5 Mg-1Si composite fabricated by selective laser melting: Microstructure, heat treatment and mechanical properties. Compos. Part B Eng. 2018, 147, 162–168. [Google Scholar] [CrossRef]

- ASTM Committee on Mechanical Testing. Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2013; pp. 1–28. [Google Scholar]

- ASTM International. Experiment: Heat Treatment—Quenching & Tempering. Mater. Sci. Eng. 2016, 31. [Google Scholar] [CrossRef]

- Elgallad, E.M.; Shen, P.; Zhang, Z.; Chen, X.-G. Effects of heat treatment on the microstructure and mechanical properties of AA2618 DC cast alloy. Mater. Des. 2014, 61, 133–140. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.N.; Alarcon, A.Z.; Vedani, M. Aging Behavior of High-Strength Al Alloy 2618 Produced by Selective Laser Melting. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2017, 48, 575–579. [Google Scholar] [CrossRef]

- Lecis, N.; Fiocchi, J.; Vedani, M.; Bonollo, F.; Fabrizi, A.; Casati, R. Effect of ball milling on the ageing response of Al2618 composites reinforced with SiC and oxide nanoparticles. J. Alloys Compd. 2016, 693, 909–920. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A.; Morri, A.; Di Sabatino, M. Effect of thermal exposure on the residual hardness and tensile properties of the EN AW-2618A piston alloy. Mater. Sci. Eng. A 2015, 639, 288–297. [Google Scholar] [CrossRef]

- Nunes, R.; Adams, J.H.; Ammons, M.; Avery, H.S. Properties and Selection: Non-ferrous Alloys and Special-Purpose Materials; ASM International: Almere, The Netherlands, 1998; Volume 157. [Google Scholar] [CrossRef]

| Ti | B | Cu | Mg | Fe | Ni | Si | Al |

|---|---|---|---|---|---|---|---|

| 3.5 | 1.2 | 2.3 | 1.6 | 0.8 | 1.1 | 0.3 | Bal. |

| Layer Thickness [mm] | Platform Temperature [°C] | Hatch Distance [mm] | Laser Power [W] | Scanning Speed [mm/s] | Volumetric Energy Density [J/mm3] |

|---|---|---|---|---|---|

| 0.050 | 60 | 0.11 | 325 | 1000 | 59.09 |

| Spots | Ti | B | Cu | Mg | Fe | Ni | Si |

|---|---|---|---|---|---|---|---|

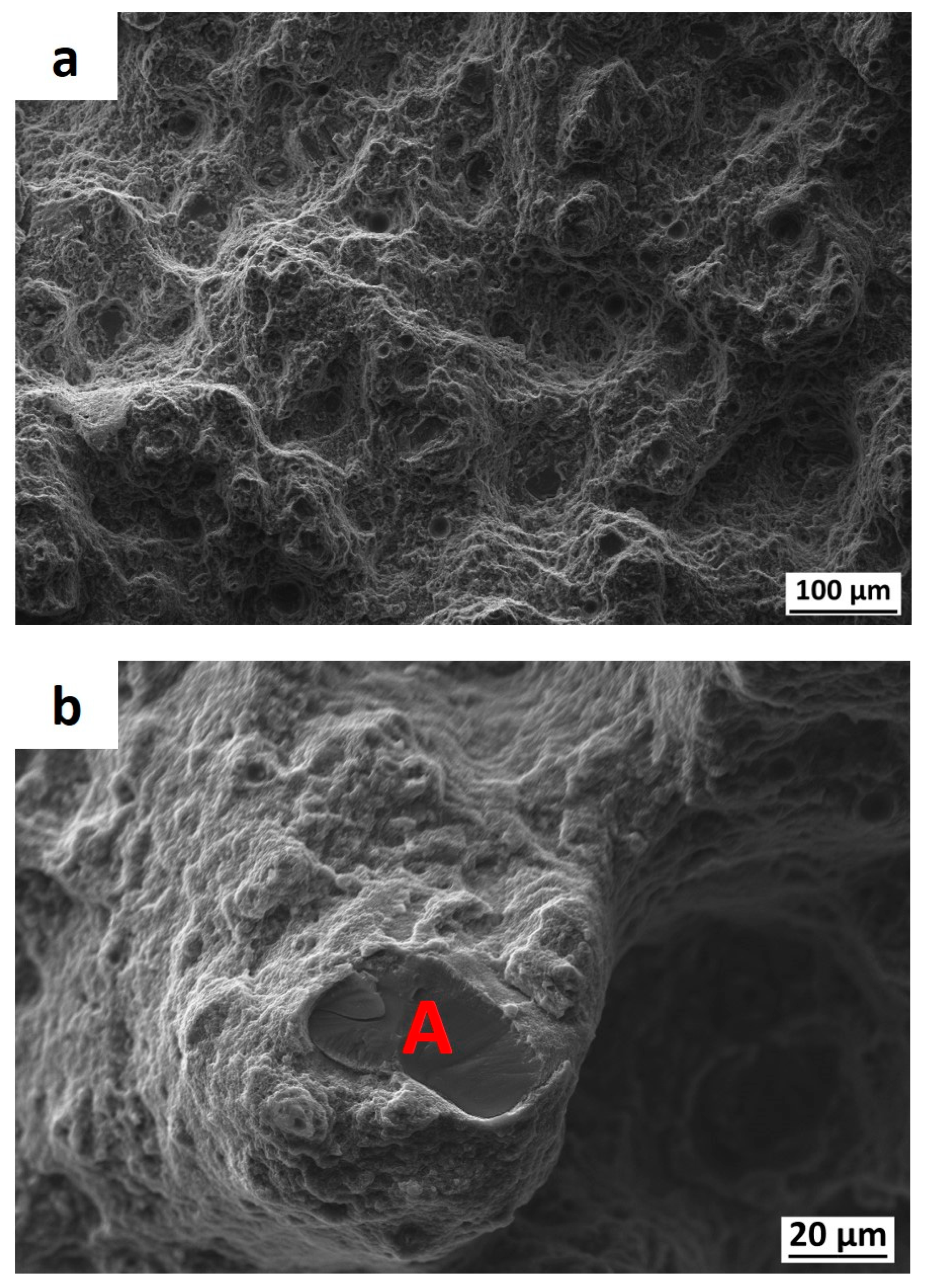

| Spot A (wt.%) | 11.6 | 25.0 | 1.7 | 1.0 | 0.6 | 0.8 | 0.3 |

| Spot B (wt.%) | 4.5 | - | 2.7 | 1.1 | 1.0 | 1.4 | - |

| Peaks | As-Built | Solution Treated |

|---|---|---|

| Peak A | 84.1 | 96.8 |

| Peak B | 221.2 | 235.4 |

| Peak C | 248.2 | 272.0 |

| Peak D | 431.5 | 452.2 |

| Peak E | 507.6 | - |

| Samples | Upper Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Fracture [%] |

|---|---|---|---|

| XY–as-built | 461.2 (±0.9) | 447.8 (±0.9) | 7.3 (±0.5) |

| Z-as-built | 447.7 (±2.6) | 448.3 (±2.2) | 7.2 (±0.2) |

| XY-T5 | 495.6 (±0.5) | 460.5 (±1.3) | 2.5 (±0.4) |

| Z-T5 | 478.5 (±0.9) | 460.2 (±1.6) | 6.1 (±0.9) |

| XY-T6 | 392.1 (±6.3) | 470.7 (±7.9) | 10.5 (±1.0) |

| Z-T6 | 375.1 (±9.3) | 453.8 (±3.9) | 8.8 (±1.1) |

| Temperature [°C] | Upper Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Fracture [%] |

|---|---|---|---|

| 150 | 330.7 (±1.7) | 344.8 (±1.8) | 12.5 (±1.0) |

| 200 | 274.8 (±12.2) | 276.5 (±14.0) | 19.3 (±0.3) |

| 250 | 227.5 (±3.5) | 229.3 (±1.8) | 14.2 (±2.2) |

| 300 | 98.0 (±3.5) | 101.5 (±0.0) | 22.0 (±1.0) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belelli, F.; Casati, R.; Riccio, M.; Rizzi, A.; Kayacan, M.Y.; Vedani, M. Development of a Novel High-Temperature Al Alloy for Laser Powder Bed Fusion. Metals 2021, 11, 35. https://doi.org/10.3390/met11010035

Belelli F, Casati R, Riccio M, Rizzi A, Kayacan MY, Vedani M. Development of a Novel High-Temperature Al Alloy for Laser Powder Bed Fusion. Metals. 2021; 11(1):35. https://doi.org/10.3390/met11010035

Chicago/Turabian StyleBelelli, Filippo, Riccardo Casati, Martina Riccio, Alessandro Rizzi, Mevlüt Y. Kayacan, and Maurizio Vedani. 2021. "Development of a Novel High-Temperature Al Alloy for Laser Powder Bed Fusion" Metals 11, no. 1: 35. https://doi.org/10.3390/met11010035

APA StyleBelelli, F., Casati, R., Riccio, M., Rizzi, A., Kayacan, M. Y., & Vedani, M. (2021). Development of a Novel High-Temperature Al Alloy for Laser Powder Bed Fusion. Metals, 11(1), 35. https://doi.org/10.3390/met11010035