Abstract

Steel wire ropes are key load-bearing components in systems such as mine hoisting, bridge cableways, elevators, and cranes, and frictional wear is among the earliest occurring and most easily accumulated form of damage. Under actual working conditions, micro-relative sliding occurs both along the internal wires of the rope and at the contact surfaces with sheaves and ropes, leading to frictional wear, crack propagation, and fatigue failure. Frictional wear, a complex phenomenon influenced by structural layout, contact load, vibration conditions, lubrication, and environmental corrosion, critically determines the service life and load-bearing capacity of steel wire ropes. Recent experimental and numerical studies have significantly clarified the fundamental mechanisms and patterns of internal and external frictional wear in steel wire ropes, offering theoretical support for the distribution of wear, fatigue evolution, and fracture behavior. Meanwhile, non-destructive testing techniques have emerged as a vital tool for the real-time monitoring of wear conditions in steel wire ropes. This review summarizes the research progress on the generation, characteristics, effects, and protection of frictional wear in steel wire ropes, and proposes future directions for tribology and service safety research of steel wire ropes.

1. Introduction

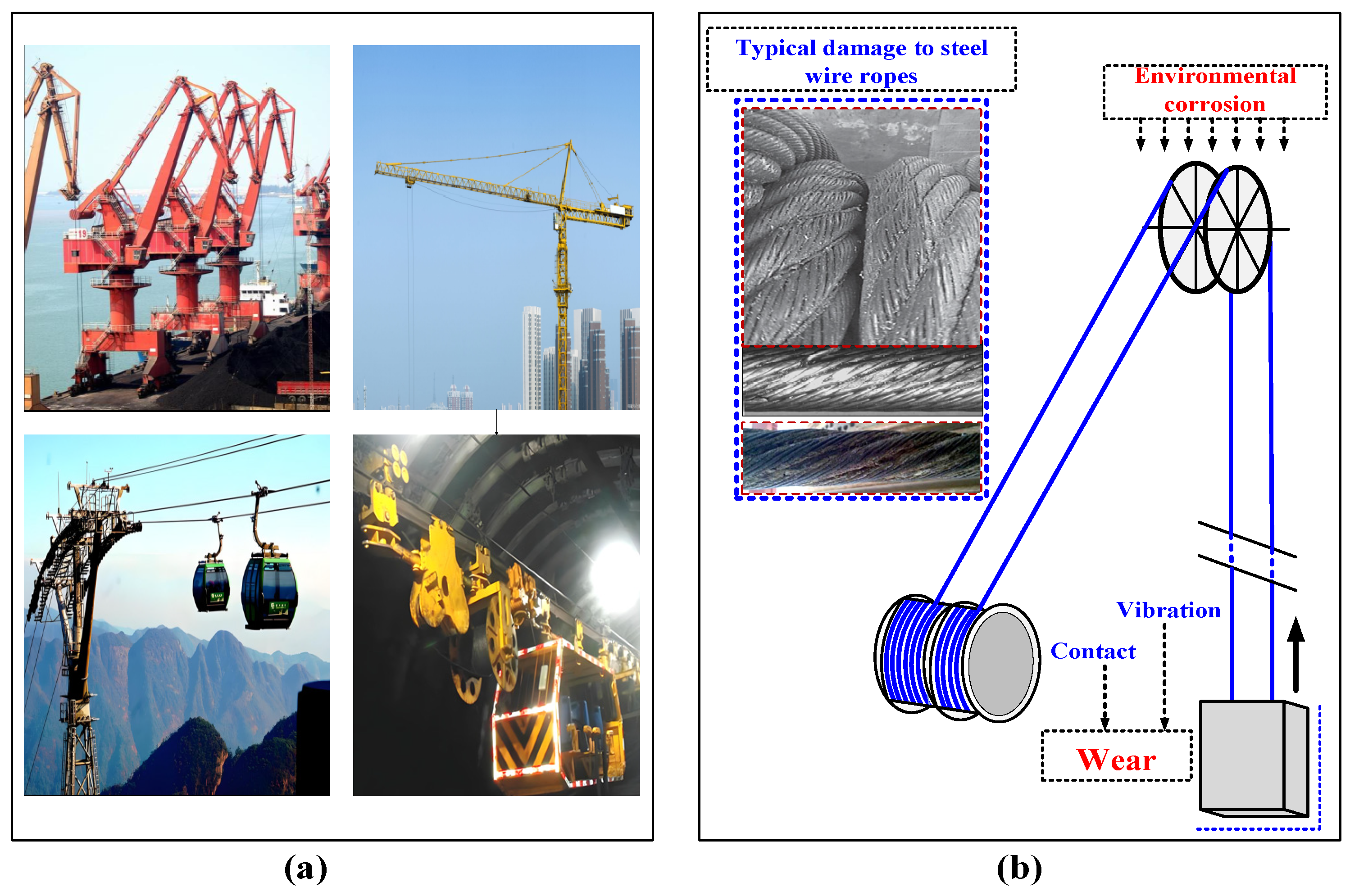

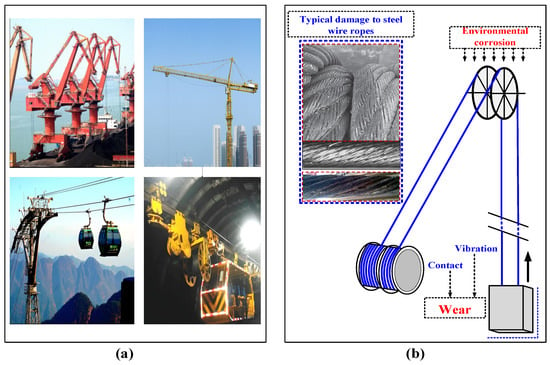

Wire rope is a high-strength flexible component composed of multiple layers of steel wires twisted into strands, which are then helically laid together to form the rope. It is characterized by low weight, good flexibility, high load-carrying and tensile capacities, high reliability, excellent fatigue resistance, and strong impact resistance. In practical applications, wire ropes serve as essential traction and transportation elements and are widely used in transportation systems, mine hoisting, bridge support, cable cars and ropeways, elevator lifting systems, cranes, ships, and aviation. Figure 1 illustrates typical application scenarios for wire ropes across various fields, as well as the structural configuration of a wire-rope hoisting system. For instance, in mine hoisting systems, wire ropes are responsible for lowering materials, lifting personnel, and hoisting coal and gangue, and thus constitute a crucial guarantee for the safe and efficient operation of the system. In many application fields, wire ropes serve as critical load-bearing components, and damage or failure can result in severe accidents, posing serious threats to personnel safety and causing substantial economic losses.

Figure 1.

Steel wire rope: (a) applications in various fields, (b) schematic diagram of a hoisting system.

Wire ropes are typically subject to the combined effects of system configuration, operational characteristics, and the natural environment. Wear, corrosion, and fatigue are the most common damage and failure modes of wire ropes under practical operating conditions, leading to a reduction in the effective cross-sectional area and to wire breakage, thereby severely compromising the rope’s load-bearing capacity [1]. Among these, wear is particularly pronounced in multi-layer winding applications. With the exploitation of deep underground and deep-sea resources, the transportation distances for materials and personnel have increased rapidly, leading to the widespread use of multi-layer wound wire ropes. During multi-layer winding and guiding processes, frequent contact interactions occur between ropes, ropes and sheaves, and wires, leading to significant sliding wear and fretting fatigue. During operation, the transverse and longitudinal vibrations of the wire rope further induce dynamic loads. Considering environmental factors, wire ropes are often exposed to outdoor service environments and inevitably endure harsh conditions such as rain, snow, high temperatures, and dust. These mechanical contacts and vibrations, together with lubrication degradation and environmental corrosion, exacerbate the risk of wear, damage, and even fracture of wire ropes, which, in severe cases, may lead to catastrophic accidents involving equipment failure and loss of life.

In recent years, extensive experimental and numerical studies have further elucidated the friction and wear behavior of wire ropes. Harris et al. [2] carried out a large number of experiments to explore the impact of contact load on fretting wear of steel wires and discovered that stress fatigue caused by wear can readily lead to wire-rope fracture and failure. Zhang et al. [3] investigated the fatigue and fracture failure behavior of steel wires under fretting wear, with a particular focus on the relationships among fatigue life, fretting cycle count, and contact load. Styp–Rekowski et al. [4] experimentally analyzed the wear evolution of mine hoisting wire ropes and demonstrated that electromagnetic inspection techniques can identify areas with severe wear. Hu et al. [5] calculated the fretting parameters of steel wires in typical contact areas and simulated the wear evolution process under tensile loads with different stress ratios using the finite element method. They found that during the running-in stage, the wear rate between steel wires was high and decreased rapidly. Waterhouse et al. [6] experimentally investigated the wear loss of steel wires under different contact stresses and discovered a linear relationship between the two. Additionally, wear and bending stress in steel wires could lead to crack initiation. Shen et al. [7] conducted fretting wear tests on two cross-contact steel wires under conditions with a friction lubricant added. The results indicated that normal load and fretting amplitude significantly influenced the fretting state, and the addition of lubricant effectively reduced wear. Tytko et al. [8] adopted a stochastic method to explain the wear degree of steel wire ropes and found that the random distribution of stresses on individual wires and the random variability of the working environment had the greatest impact on the characteristics of the continuous wear process. Lee et al. [9] proposed an algorithm considering the interference between the steel wire rope and the lifting body, calculated static and dynamic friction forces in the friction model, and determined the contact forces applied to the lifting body under different environmental conditions. Considering the extensive use of wire ropes in marine engineering, Périer et al. [10] conducted fretting fatigue wear tests on steel wires in seawater solutions to investigate the interaction between fatigue and corrosion, and observed pronounced corrosion features on the worn areas and fracture surfaces. To further explore the effect of bending fatigue on internal wear of wire ropes, Urchegui et al. [11] carried out a series of bending fatigue tests. The fatigue life of the wire ropes was subsequently evaluated based on the wear depth and wear volume. In numerical simulations, Argatov et al. [12] integrated contact stresses under cyclic bending conditions with the Archard wear model, thereby proposing a theoretical framework that describes how wear evolution influences rope structural performance. Chen et al. [13] combined elastic contact theory with the Archard wear model to develop a mathematical model of wear evolution in crossed-wire contacts, revealing process-dependent variations in wear depth and contact stress. Although relevant research is ongoing, wire-rope breakage accidents caused by wear still persist across various operating conditions, resulting in considerable economic repercussions and injuries. The main reason is that the coupled mechanisms of vibration-, corrosion-, and impact-induced wear in wire ropes remain only partially clarified, making accurate identification of wear states and scientific assessment of damage severity difficult. Therefore, it is urgently necessary to further clarify the tribological behavior of wire ropes and further develop methods for wear-feature identification, damage detection, and safe-remaining useful life prediction to fundamentally address the challenge of achieving safe and efficient wire-rope operation.

To this end, as driven by the urgent demand for the economical, safe, and efficient service of wire ropes, this review focuses on the safety hazards arising from frictional wear and performance degradation under complex operating conditions and harsh environments. It reviews the mechanisms of friction and wear in wire ropes as well as research on service-performance detection and evaluation, offering essential foundational data and theoretical support for ensuring the efficient and reliable use of wire ropes, reducing damage, and prolonging their service life. Instead of predominantly focusing on isolated failure modes such as internal fretting fatigue, this manuscript establishes a comprehensive framework along the axes of “Generation–Characteristics–Effects–Protection”. It uniquely integrates the often-overlooked mechanisms of external sliding wear and the coupled influence of complex in-service conditions—specifically vibration, impact, and corrosion—with traditional internal fretting analysis. Furthermore, this review bridges the gap between tribological theory and engineering maintenance by synthesizing damage evolution patterns with state-of-the-art non-destructive testing (NDT) techniques. The detailed discussions on failure mechanisms, life prediction, and damage detection in this review are essential means to achieve the ultimate goal of wire rope protection. Accurate identification of failure modes and precise assessment of health states provide the decision-making basis for implementing systematic protective measures.

To ensure a comprehensive and systematic overview of the field, a literature survey was conducted using major academic databases, including Web of Science, Elsevier, WILEY and Google Scholar. The search scope covered the period from 1990 to 2024, with a particular focus on advancements made in the last decade. Key search terms included combinations of ‘wire rope,’ ‘friction and wear,’ ‘fretting friction,’ ‘fatigue failure,’ and ‘non-destructive testing.’ Studies lacking theoretical depth or distinct engineering relevance were excluded from the review. The selected literature was subsequently organized into a framework defined by three primary axes: (1) the distinction between internal inter-wire fretting and external sliding wear; (2) the influence or coupling effects of environmental factors and dynamic conditions on friction; and (3) the evolution from damage accumulation to life prediction and detection.

2. Mechanical Properties of Steel Wire Ropes

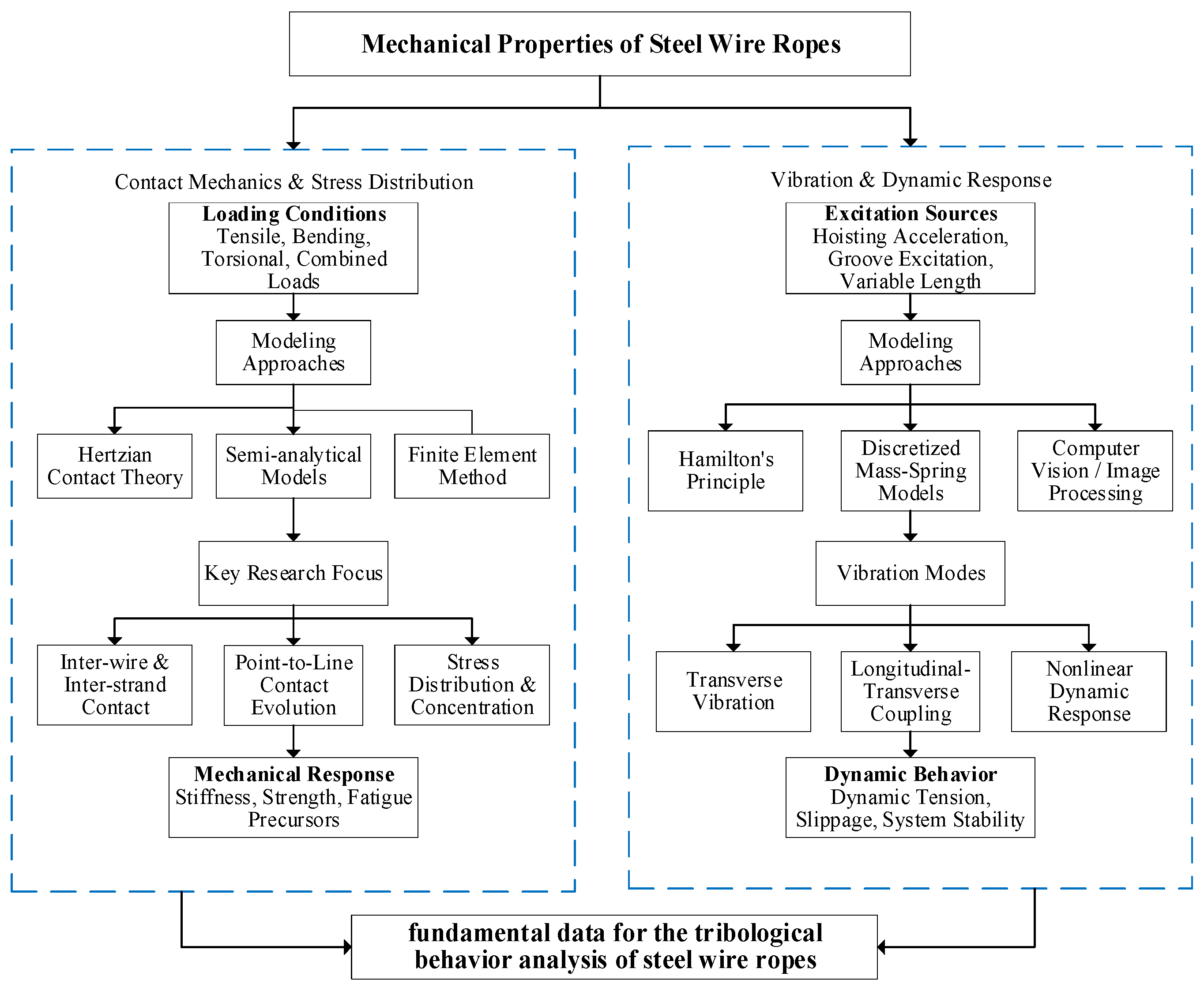

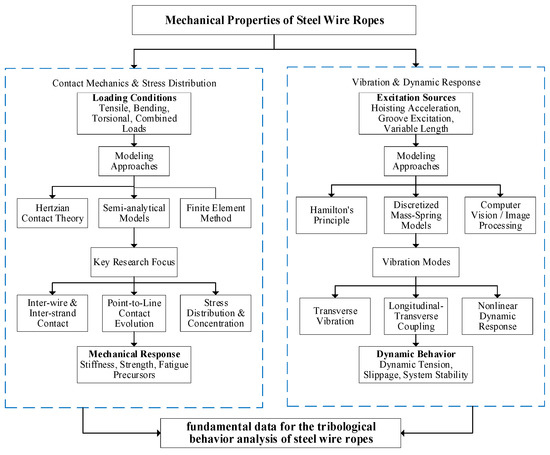

Steel wire ropes exhibit outstanding mechanical properties and are extensively employed in power transmission and load-bearing components of mechanical equipment. Under actual operating conditions, they are susceptible to complex contact and impact vibrations, which may lead to wear and undermine their structural integrity. To provide a clear overview of these research domains, Figure 2 illustrates the technical roadmap of this section. It outlines the logical progression, including static contact load characteristics and dynamic vibration characteristics, which collectively constitute the complex mechanical environment that induces friction, wear, and fatigue.

Figure 2.

Technical roadmap of mechanical property research for steel wire ropes.

2.1. Contact Load Characteristics of Steel Wire Ropes

The complex structure of steel wire ropes results in multiple contact points and intricate stress patterns during service, including interactions between wires and between wires and the rope core. Under the combined effects of various loads, wires experience diverse contact stress configurations and relative motion, leading to localized stress concentration and accelerated friction and wear.

To obtain a deeper understanding of the mechanisms of contact force between the internal wires of wire ropes, researchers first conducted a series of modeling and numerical analyses, starting from microscopic contact behavior. Chen et al. [14] developed a fully coupled contact model for core–wire and wire–wire interactions in wire ropes using a semi-analytical method, and examined the contact pressure and deformation characteristics of internal wires, revealing that the variations in load lead to transitions in contact states, thereby influencing the mechanical property and fatigue behavior of wire ropes. On this basis, to investigate the multi-state contact behavior of wire ropes, Chen et al. [15] further developed a mathematical model incorporating the coexistence of point contact and line contact, accounting for the multi-state contact characteristics among wires in a three-layer wire rope, which enables accurate and efficient evaluation of the distributions of key performance parameters induced by different types of wire contacts. In addition, Kumar et al. [16], based on Hertzian contact theory, derived an analytical expression for the maximum contact stress in multi-layer strands with a metallic core, providing a theoretical basis for the quantitative assessment of wire contact mechanics. Wang et al. [17,18] utilized Simulink-based simulation techniques to calculate the tensile force, relative slip, and contact force among the internal wires of hoisting wire ropes, thereby obtaining the stress–strain distributions of these wires. The variation in fretting parameters leads to distinct fretting regimes, resulting in different stress distributions and abrupt changes in stress near the trailing edge. Focusing on coupled tensile and bending loads, Phillips et al. [19] formulated a mathematical model to explore the stress characteristics of wires within multi-layer steel-core wire ropes undergoing simultaneous tension and bending. By quantifying the stress distribution of each wire under tensile, torsional, and bending combined loads, they found that the maximum wire stress can reach 1.5 to 3 times the nominal rope stress. Furthermore, the type of load and rope structure significantly influences the stress distribution and fatigue behavior. Usabiaga et al. [20], based on beam assumptions and general thin-walled rod theory, proposed a novel theoretical model for wire ropes subjected to combined tensile and torsional loading, and compared the results with classical theories. Considering contact damage and geometric structural characteristics, Ru et al. [21] proposed a theoretical model to calculate the stress–strain states of steel cable structures under various loading conditions, and analyzed the contact forces and mechanical losses of strands under tensile and bending loads, and found that a smaller lay length leads to larger contact forces. In terms of modeling and simulation of wire-rope mechanical characteristics, Chen et al. [22], based on ABAQUS/Explicit and Feyrer’s theory, proposed a refined wire-rope modeling approach that accounts for system structural features and analyzed the stress–strain distribution of wire ropes under axial loading. Under axial loading, the stress distribution in the steel wires of a locked coil wire rope is non-uniform, with the stress in the central wire being greater than that in the outer wires.

Although these semi-analytical and numerical models have significantly improved the accuracy of contact stress prediction, a limitation persists: most models rely on idealized geometric assumptions. In reality, manufacturing imperfections and uneven load sharing among strands result in a stochastic contact distribution that deviates from theoretical predictions. Therefore, the trend is shifting from deterministic static analysis to coupled dynamic simulations that can account for geometric non-linearity and random structural irregularities.

Given the complex coupled deformations that wire ropes experience in service, extensive research has been conducted to investigate their overall mechanical performance. Liu et al. [23] examined the axial mechanical properties of a typical 7 × 7 wire rope with different lay directions and found that the lay direction mainly affects the strand torque, with minimal influence on the tensile force of the wires. In order to simulate the structural response of wire ropes more accurately, Elata et al. [24] developed a new mechanical response simulation model for wire ropes with an independent wire-rope core, which can predict inter-rope force interactions, stiffness, strength, and fatigue life. The model effectively simulates the stiffness response of ropes under combined tensile and torsional loads and reveals the stress distribution at the wire level and the load transfer mechanism. Based on the structural characteristics of simple helical strands, Zhang et al. [25] considered Poisson’s ratio effects, inter-wire contact deformation, and spatial helical contact between wires, and established a semi-analytical method to investigate stress relaxation in wire rope strands under tensile loading. Their study revealed that under constant tensile strain, the axial stress, contact pressure, and twisting moment decay over relaxation time. Decreasing the axial strain or helix angle, or increasing the outer wire diameter, is beneficial for reducing creep strain and axial stress, although these adjustments lead to increments in contact deformation and pressure. Cappa [26] performed tensile tests on wire ropes under static and quasi-static axial loads, analyzing the stress variation characteristics of internal wires in both damaged and undamaged conditions. The study revealed that steel wire ropes exhibit uneven load distribution under static and quasi-static tensile loading. Furthermore, when an external wire is severed, its load-bearing capacity is significantly lower than the theoretical predictions outlined in Italian regulations. Onur [27] integrated experimental research with theoretical analysis to study the mechanical response of prestressed wire rope strands under tensile loading, and used a linear regression model to predict the force–strain and stress–strain relationships.

2.2. Vibration Characteristics of Steel Wire Ropes

As a key component of hoisting equipment, wire ropes inevitably generate vibrations during operation due to changes in dynamic parameters and the structural properties of the hoisting equipment itself. This alters their stress characteristics, consequently posing a threat to the safety and stability of the hoisting equipment. Furthermore, as a complex, elastic, flexible component, wire ropes undergo nonlinear vibrations triggered by multiple excitation sources during operation. This readily causes dynamic slippage and impact collisions within the wire rope contact pairs, serving as a key factor inducing wire rope damage.

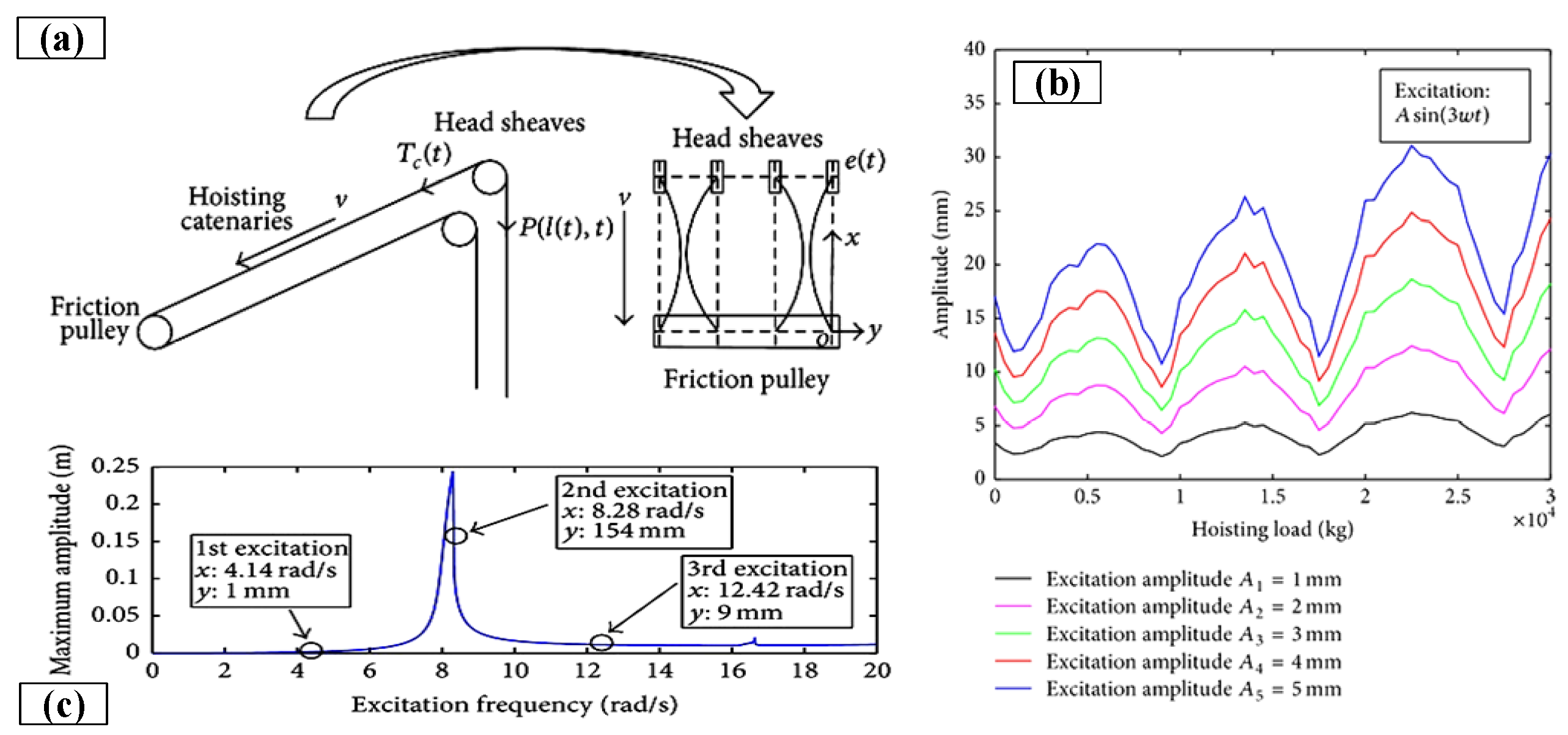

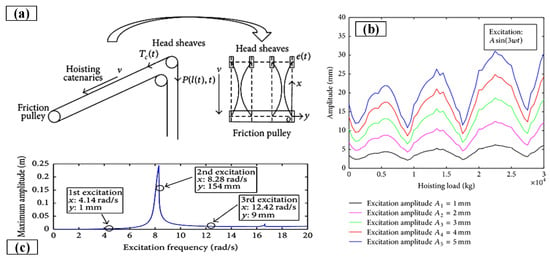

To investigate the vibration characteristics of wire ropes in service, Peng et al. [28] established the vibration equations of a wire-rope hoisting system based on Hamilton’s principle and studied the effects of different groove excitations on the transverse vibration behavior of suspended ropes. Their work recorded the transverse oscillations of overhead wire ropes and proposed an effective image-processing method to obtain the vibration response at a specific point along the rope. To examine the influence of hoisting loads on the vibration of the rope–sheave system, Yao et al. [29] established a dynamic model for the transverse vibrations of hoisting wire-rope catenaries and conducted numerical analyses to systematically investigate the effect of hoisting load on transverse vibration characteristics. Figure 3 [29] illustrates the diagram of the transverse vibration model of hoisting catenaries, along with the varying maximum amplitudes under different loads, demonstrating that as the hoisting load increases, the transverse vibration amplitude decreases significantly, and the vibration stability of the system is enhanced. Steinboeck et al. [30] proposed utilizing the transverse degrees of freedom of wire ropes to characterize transverse–longitudinal coupled vibration behavior and developed a corresponding mathematical model to investigate the evolution of coupled vibrations in moving suspended ropes. Kaczmarczyk et al. [31,32] formulated a dynamic model of a wire-rope–mass system equipped with a tuned mass damper to explore the nonlinear vibration characteristics of wire ropes; additionally, considering the vibration behavior of wire ropes in high-speed elevator systems, they developed a Gaussian and non-Gaussian random response model, capable of predicting time-varying transverse vibration behavior of wire ropes. This model sets bounds on system dynamic responses by determining the variance of the transverse displacements of wire ropes treated as flexible, continuous bodies. Addressing the coupled vibration problems of wire ropes in mine friction hoisting rigid–flexible multibody systems during operation, Zhang et al. [33,34] combined theoretical modeling with experimental studies to analyze the effects of time-varying curvature and the length of wire ropes on the nonlinear dynamic characteristics of hoisting systems, and investigated the dynamic behavior of flexible shaft-guiding wire ropes under multi-point constraints, revealing the influence of different constraints on the transverse stiffness of guide ropes. Emrani et al. [35] utilized MATLAB/Simulink to develop a dynamic model for a wire-rope hoisting system and optimized its structural parameters. Modeling and simulation analysis indicates that the dynamic tension of wire ropes in hoisting systems is significantly influenced by acceleration, variations in rope length, cross-sectional characteristics, and material elastic modulus, with notable tension fluctuations occurring during startup and speed-change phases. While the aforementioned studies effectively capture macroscopic vibration amplitudes under varying loads, they often decouple vibration from tribological degradation. There is a notable gap in understanding how vibration-induced dynamic tension specifically correlates with micro-fretting wear rates at the wire interfaces. Future research needs to bridge this gap by integrating tribo-dynamic coupling effects, rather than treating vibration and wear as separate physical processes.

Figure 3.

(a) Diagram of the transverse vibration model of hoisting catenaries; (b) maximum amplitude at the center of the catenary with varying hoisting load; (c) amplitude–frequency curve of the transverse vibrations in a catenary [29].

The service life of wire ropes is fundamentally governed by a set of key variables: contact pressure, relative slip amplitude, cyclic loading frequency, and lubrication status. The interaction of these variables dictates the regime transition at the contact interface. High contact pressure combined with minute oscillatory slip typically induces fretting fatigue and crack initiation, whereas macroscopic relative sliding under vibration-induced dynamic tension promotes external sliding wear and fretting wear.

3. Friction and Wear Characteristics of Steel Wire Ropes

Wire-rope wear is a continuously accumulating and deteriorating process that directly degrades the mechanical performance of the rope and exhibits a certain degree of concealment and latency during service. The factors influencing the friction and wear of wire ropes mainly include contact parameters, contact modes, and the contact environment. A wire rope is formed by helically winding a certain number of steel wires around a central wire at a specific lay angle to form a strand, and then helically winding several strands around a core (such as a fiber core or a strand core) at a different lay angle. Therefore, the fundamental unit of friction and wear in a wire rope is the individual steel wire, and the primary wear modes include internal fretting wear between wires and external wear on the entire rope surface.

3.1. Inter-Wire Fretting Friction Characteristics Within a Steel Wire Rope

Wire rope is a complex spatial helical structure. When it is subjected to external forces, the wires inside the rope experience combined effects such as tension, bending, torsion, and compression. Micrometer-level relative sliding occurs between individual wires, and this fretting behavior induces fretting damage in the wire rope. Fretting behavior is generally classified into three fundamental types: fretting wear, fretting fatigue, and fretting corrosion. During lifting or transmission operations, wire ropes undergo repeated tensile loading, bending, and dynamic loading, which cause fretting wear between the wires. Furthermore, continuous fretting wear causes crack initiation, propagation, and fracture in the fretting contact regions of the wires, resulting in fretting fatigue and accelerating the fatigue failure of the wire rope.

Fretting friction behavior is a key factor determining the service life of wire ropes, and numerous factors influence fretting friction during their operation. To reveal the most fundamental inter-wire contact characteristics, Zhang et al. [36] employed a self-developed experimental apparatus to investigate the effect of contact angle on the fretting fatigue behavior of steel wires, demonstrating that the crossing angle between wires affects the wear mechanism. When the contact angle decreases from 90° to 18°, the contact area increases, the contact stress decreases, the wear coefficient and total wear volume reduce, the coefficient of friction (COF) lowers, and the fretting fatigue life extends. Taking into account the fretting friction between internal wires of wire ropes, Cruzado et al. [37,38,39] examined the impacts of contact pressure and crossing angle on the fretting wear behavior of steel wires and established a finite element model of fretting wear scars. The fretting wear behavior of steel wires is significantly influenced by contact pressure and crossing angle. Under constant load, a smaller crossing angle reduces contact pressure, leading to decreased wear volume, wear coefficient, and COF. However, when the contact pressure is kept constant, the wear intensity remains largely independent of the crossing angle, while the wear volume is proportional to the applied load. This linear relationship forms the basis of the classic Archard wear law, which is widely used to quantify material loss in numerical models:

In this equation, V represents the wear volume, P is the normal load, s is the total relative sliding distance, H is the hardness of the material, and K is the dimensionless wear coefficient. Although this model offers a fundamental approach for calculating the wear volume, its direct application to wire ropes is challenging because the wear coefficient K is not constant; it fluctuates due to varying lubrication regimes and the evolution of fretting debris.

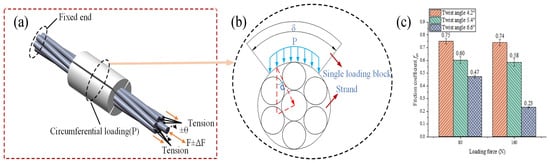

The actual structure of a wire rope is far more complex than a simple crossed-wire contact, as the internal wires exhibit multi-state contact characteristics under helical stranding; therefore, the influence of structural factors must be further considered. Peng et al. [40] investigated the fretting behavior induced by the helical stranding of wires within a rope strand. Figure 4 [40] illustrates the loading states of the wires and the COFs under different axial loads, revealing the effects of axial load on the fretting tribological characteristics of helically contacting wires. To elucidate the relative motion between internal wires of wire ropes, Nabijou et al. [41] calculated the maximum relative slip between strands and between wires during rope bending, providing important reference data for the analysis of friction and wear in wire ropes. Kumar et al. [42] experimentally found that material properties, structural configuration, fatigue, inter-wire contact, and lubrication conditions all influence inter-wire fretting wear. Based on the operating conditions of mine hoisting systems, Wang et al. [43,44] studied the effects of dynamic parameters and terminal loads on the fretting behavior of internal wires in wire ropes. Steel wires in wire ropes exhibit elliptical wear scars and parabolic wear depth profiles during fretting fatigue. The maximum wear depth and wear coefficient decrease with an increase in fatigue cycles, and larger relative displacements can mitigate damage. While simplified crossed-wire setups allow for precise parameter control, they cannot fully replicate the complex, multi-state contact evolution that occurs within a helical strand under bending. Consequently, wear coefficients derived from fixed-angle tests may overestimate or underestimate the actual damage accumulation in service, highlighting the need for more representative multi-wire test rigs.

Figure 4.

(a) Force diagram of rope strands; (b) force diagram of section of rope strand; (c) coefficients of friction (COFs) of different twist angles and lateral loads [40].

Figure 4.

(a) Force diagram of rope strands; (b) force diagram of section of rope strand; (c) coefficients of friction (COFs) of different twist angles and lateral loads [40].

Apart from structural and mechanical factors, the fretting inter-wire fretting behavior of steel wire ropes, which operate as load-bearing elements in harsh environments for extended periods, are easily influenced by environmental factors such as corrosion. The combined effects of corrosion and wear further influence their fatigue life. Wang et al. [45] introduced service environment factors for steel wire ropes and investigated the pull–torsion-coupled fretting fatigue characteristics of wires in air, as well as in alkaline, neutral, deionized water, and acidic electrolyte solutions. They found that in acidic electrolyte solutions, the degree of electrochemical corrosion and the depth of fatigue wire cracks were significant. Perier et al. [46] investigated the impact of water on the fretting friction performance between two steel wires, showing that in the water environment, the COF of the wire rope during the large slip stage and transition stage was significantly lower than in air. Water acts as a lubricant, reducing the COF, expanding the contact area, and decreasing crack initiation. Huang et al. [47], using a self-designed fretting wear testing device, studied the fretting friction and wear behavior of internal helical contact wires under different corrosive media and time-varying conditions. They discovered that the type of corrosion and exposure duration significantly affected the evolution of the inter-wire COF and the fretting state. Consequently, evaluating wire rope safety in harsh environments requires a holistic approach that accounts for the dynamic interaction between the corrosion product film and the fretting contact interface, rather than assessing friction and corrosion in isolation.

3.2. External Friction Characteristics of Wire Ropes

Throughout the whole service life of a wire rope, external wear is the most direct and observable form of degradation affecting its safety. External wear not only results in a loss of cross-sectional area but also accelerates the initiation and propagation of fatigue cracks, ultimately leading to a reduction in load-carrying capacity. A comprehensive grasp of the external tribological behavior and wear mechanisms of wire ropes under different operating conditions is of great engineering significance for enhancing their longevity and operational dependability, as evidenced by detailed studies on the subject.

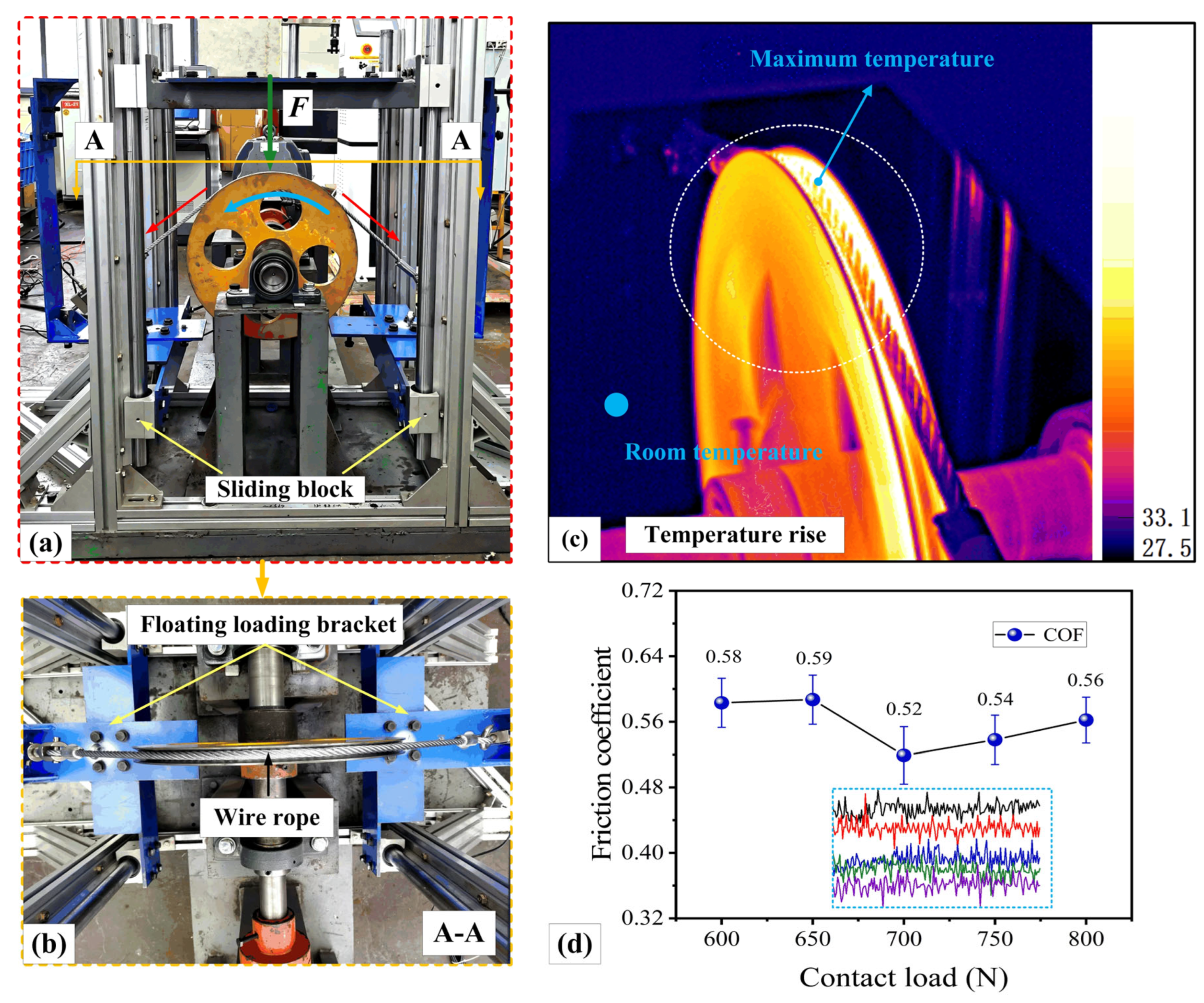

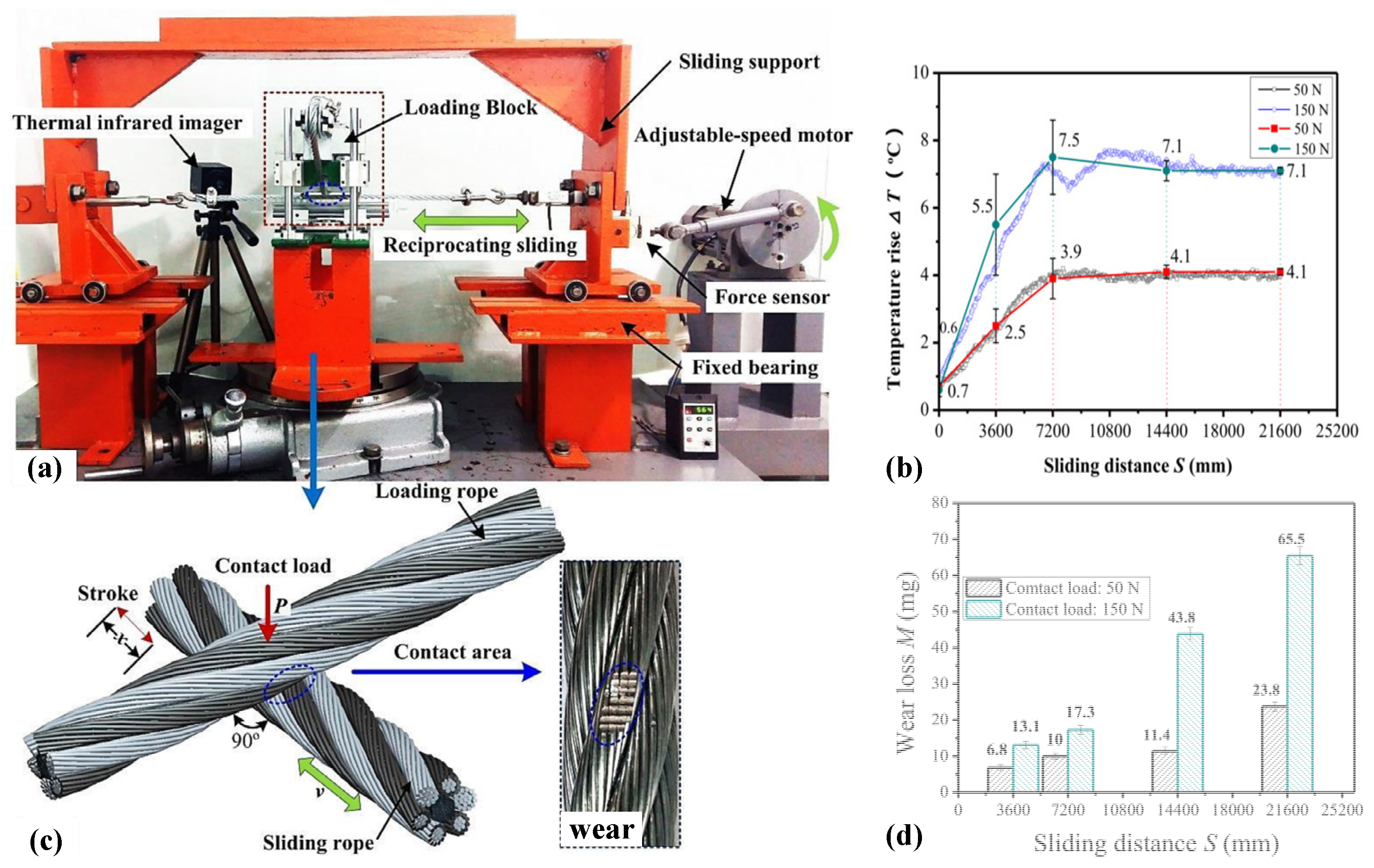

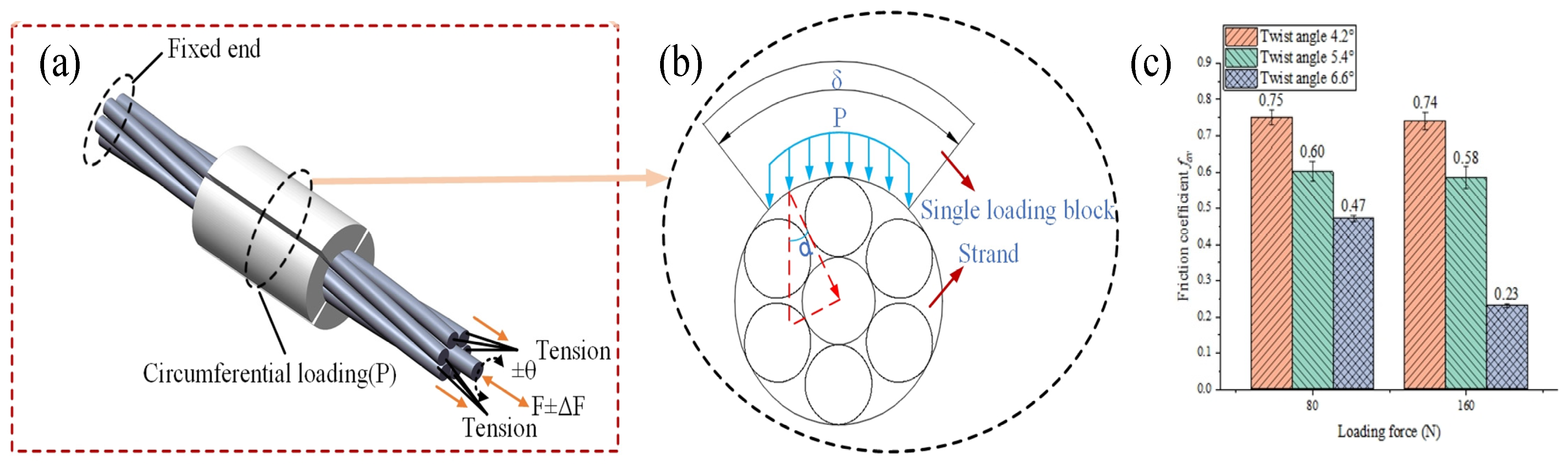

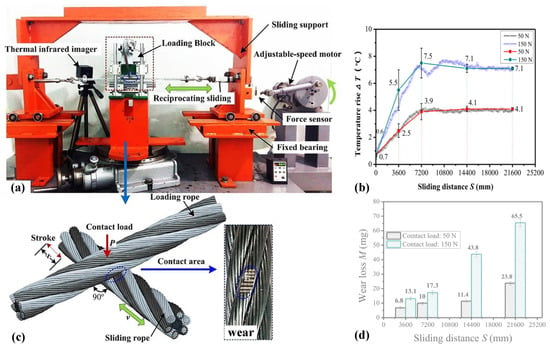

During service, wire ropes inevitably experience frictional interactions with mating components, leading to friction-induced damage. During operation over drums and sheaves, sliding friction is unavoidable, leading to significant external wear. Chang et al. [48,49] utilized a self-developed friction and wear test rig to examine the tribological behavior of wire ropes at the contact interfaces with drums and sheaves, and explored the frictional response of steel wire ropes under various environmental conditions. Figure 5 [49] shows the temperature rise in the rope–pulley contact area and the variation in the COF between the wire rope and the pulley under different sliding conditions. The contact load mainly affects the surface wear degree of the wire rope, and the influence on the COF in the stable stage is relatively small. The fluctuation in the COF with contact load is mainly determined by an increase in the temperature in the friction region and the surface wear characteristics of wear scars. This study provides a basis for further understanding the distribution characteristics of external wear. In practical service, wire ropes are often subjected to bending and variable tensile loads, which further complicates the wear mechanisms. Regarding the friction performance, it should be modeled as a time-varying parameter coupled with thermal evolution and contact severity. This dynamic characteristic is particularly vital for deep-well hoisting systems where friction stability dictates safety. Zhang et al. [50] conducted an analysis on the wear distribution of wire ropes under bending conditions, focusing on the impact of various sheave diameters. Their study revealed that the most severe wear regions are mainly concentrated on the outer-layer wires of the outer strands, the contacting wires between outer strands, and the contact regions between the core strand and outer strands. Moreover, increasing the sheave diameter can effectively reduce the overall wear depth of the wire rope. This suggests that the friction performance of wire ropes is not solely determined by material hardness, but rather is structurally governed by the matching relationship between the rope construction and the sheave geometry. In contrast to these sliding-dominated regimes, Oksanen et al. [51] conducted experimental research and finite element analysis on the frictional contact behavior and wear mechanisms between ductile iron drums and wire ropes under rolling–sliding conditions, finding that under rolling contact, the initiation depth of wear surface cracks is more significantly influenced by the magnitude of contact pressure rather than thermal factors.

Figure 5.

(a,b) Structure of friction test rig; (c) infrared thermal imaging of wire rope and pulley; (d) average COF in the relatively stable stage [49].

In friction hoisting systems, the interaction between the wire rope and the friction lining introduces additional complexities related to dynamic loads and environmental media. Wang et al. [52,53,54] conducted theoretical analysis and experimental investigations into the dynamic friction transmission, contact interface evolution, and creep behavior between the hoisting wire rope and the friction lining. The study found that an increase in hoisting parameters leads to an increase in the slip angle, creep amplitude, and creep speed between the wire rope and the lining. Guo et al. [55] investigated the dynamic contact stress distribution between the friction lining and the wire rope during deep-well friction hoisting, finding that the range of the friction angle decreases as the COF increases, and increases with a larger terminal mass ratio; an excessively high terminal mass ratio can expand the friction angle range, thereby raising the risk of wire rope slip. While these studies elucidated the mechanical dependencies under dry conditions, Feng [56,57] highlighted the critical role of environmental factors and material properties. Their investigations into friction linings demonstrated that under wet conditions, water acts as a lubricant. The presence of water played a role in lubricating the surface, which resulted in a reduction in the friction coefficient. In addition, water absorbed onto the surface of the lining to produce an absorbent layer, and the load-carrying capacity of the absorbent layer exerted a more intuitive effect on the friction coefficient.

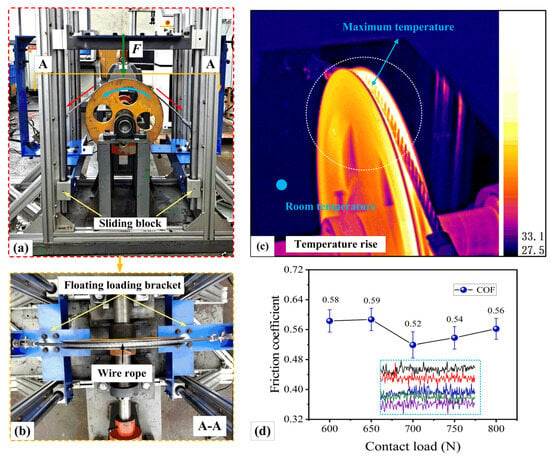

In order to further clarify the rope-to-rope friction behavior between strands, Peng et al. [58] utilized a self-developed rope–rope friction apparatus to explore the impacts of various sliding parameters and impact behavior on tribological performance under crossed sliding conditions. Based on this research, Chang et al. [59] further explored the influence of lay direction and lay angle on the evolution of sliding wear, noting that the contact position significantly affects the wear distribution characteristics. They also examined the evolution of friction and wear behavior in rope–rope sliding contacts under different sliding distances, contact loads, and stroke length. Figure 6 [59] illustrates the contact patterns between wire ropes as well as the variations in temperature rise and wear mass loss of the wire ropes under different conditions. They found that wear severity increases with increasing sliding distance, and the wear is an intensifying process. Zhang et al. [60] experimentally investigated the impacts of longitudinal vibration on the friction and wear behavior of multilayer-wound wire ropes, revealing that vibration amplitude has a stronger influence on the COF and oxidative wear than vibration frequency, and that vibration can significantly alter contact temperature rise and wear mechanisms. Peng et al. [61] further investigated the friction behavior of wire ropes used in ultra-deep mine hoisting under impact loading, indicating that under lubricated conditions the COF remains relatively stable and is weakly affected by load and speed, whereas under dry friction conditions the COF decreases with increasing speed; moreover, the maximum COF under impact conditions is significantly lower than that under steady contact. The structural configuration of wire ropes also affects their wear performance. Wang et al. [62] conducted a comparative analysis of the tribological characteristics of round-strand and triangular-strand wire ropes during the interlayer transition stage, and found that the triangular-strand structure exhibits a lower COF, superior wear resistance, and higher residual strength after wear, attributed to its more favorable contact geometry. Although optimizing the strand structure provides a static geometric advantage, it results in a distinct reduction in the COF under impact. Future research must therefore focus on developing dynamic tribological models that can account for the transient changes in contact temperature and geometry under complex hoisting loads.

Figure 6.

(a) Sliding friction test rig; (b) the evolution of temperature rise under different contact loads; (c) contact form and wear scar; (d) the evolution of wear mass loss for the wire rope under different conditions [59].

Environmental factors serve as significant external influences on the tribological behavior of wire ropes. Peng et al. [63] observed that low-temperature conditions increase the COF and shift the wear mechanism from oxidative and abrasive wear to fatigue and adhesive wear, whereas oil–water lubrication can significantly alleviate wear aggravation. In addition, Chang et al. [64] conducted a comparative study on the impact of freshwater, seawater, and dilute sulfuric acid corrosive environments on the frictional performance of wire ropes and pointed out that sulfuric acid corrosion has the most pronounced negative effects on the COF, temperature rise, and residual strength, with a particularly significant wear-accelerating effect. These findings highlight that environmental factors not only accelerate the wear rate but also fundamentally alter the dominant failure mechanisms. Consequently, ignoring environmental variables in life prediction models will lead to dangerous overestimations of rope safety, underscoring the need for damage evolution criteria that integrate electrochemical corrosion with tribological behaviors.

4. Damage and Failure of Wire Ropes

The load-carrying capacity of wire ropes is affected by wear, while factors such as corrosion, fatigue, impact loading, and lubrication failure further degrade their performance during service. When these degradations reach certain thresholds, wire ropes may experience failure and fracture. Consequently, their service life, safety, and reliability are progressively constrained by these factors throughout operation. To investigate the effects of damage mechanisms, such as friction and wear, on the structural integrity of wire ropes and to ensure their reliability, many researchers have conducted studies on the strength attenuation and life prediction of wire ropes.

4.1. Degradation of Wire Rope Properties

During service, wire ropes are exposed to the combined impacts of long-term fatigue loading, frictional wear, and complex environmental factors, leading to the inevitable degradation of their mechanical properties. As service time increases, this degradation negatively impacts the rope’s load-carrying capacity and service life, ultimately leading to failure. Property degradation is not only concealed and cumulative, but also often accompanied by irreversible damage evolution. Therefore, a thorough understanding of the mechanisms and governing factors of wire-rope property degradation is of great importance for improving the reliability and safety of engineering equipment and for effectively ensuring the safe and reliable operation of wire ropes.

Wear can affect the tensile properties of wire ropes and ultimately lead to fracture failure. Chang et al. [65] discussed the characteristics of surface wear scars induced by rope-to-rope sliding contact using both quantitative and qualitative approaches. A series of tensile fracture tests was conducted to investigate the influence of wear-related parameters on the load-carrying capacity of ropes and to analyze the fracture failure behaviors of ropes with different wear scars. Wang et al. [62] performed tensile breaking tests on wire ropes worn during the interlayer transition stage and established a nonlinear fitting relationship between wear depth and residual tensile load-carrying capacity. To examine the effect of external wear on the tensile performance of wire ropes, Chang et al. [48] carried out experimental studies on surface wear occurring when wire ropes pass over sheaves. They discovered that more severe wear leads to weaker load-carrying capacity and a higher likelihood of tensile fracture.

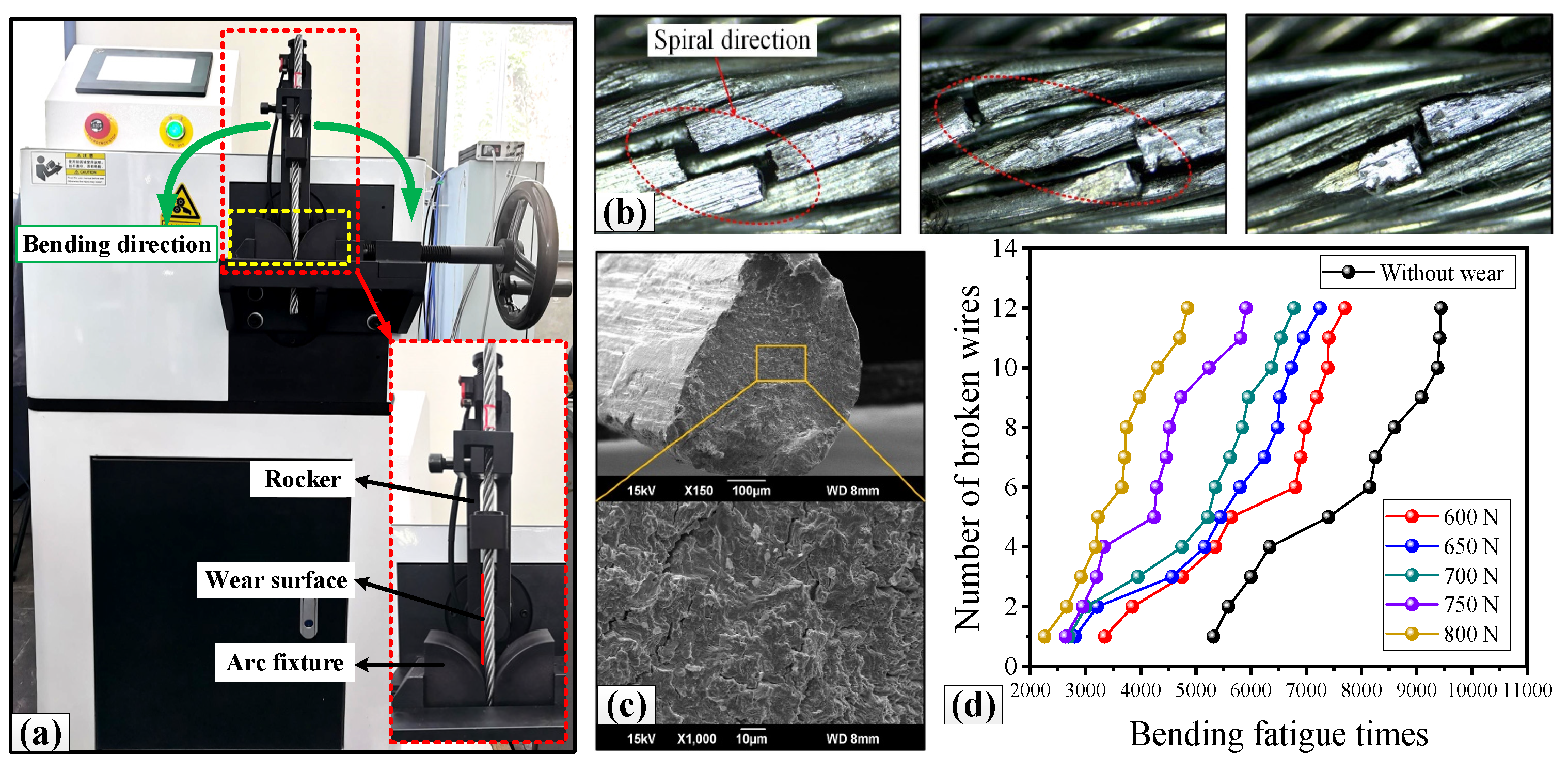

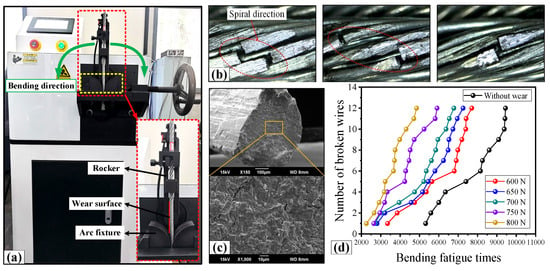

Wear also affects the fatigue failure of wire ropes. Fatigue failure is a common yet complex problem, typically caused by the combined action of different time-varying bending and axial forces. Schrems [66] investigated the fatigue failure of non-rotating wire ropes used in underground mine skip hoisting systems and found that the dominant failure mechanism of individual wires within the rope is strongly related to the contact stress at inter-strand wear locations. Axially loading and unloading the rope produces high compressive stresses at the contact sites, which in turn produce large alternating tensile stresses on the opposite side of the wire. Hobbs et al. [67] conducted extensive tensile and bending fatigue tests on wire ropes, analyzing the effects of load, cycle count, and bending amplitude on fatigue failure. Beretta et al. [68] proposed a fatigue strength prediction model for wire ropes and performed fatigue failure analyses on two different types of wire ropes. Chang et al. [49] combined rope–pulley sliding friction wear tests with bending fatigue tests to demonstrate that surface wear induced by different contact loads significantly reduces the bending fatigue life of wire ropes, and the degradation of bending fatigue resistance becomes more severe with increasing load. Figure 7 [49] illustrates the bending fatigue morphologies and the corresponding fatigue curves of the wire ropes, showing that an increase in contact load reduces the maximum bending fatigue cycles of the worn steel wire rope. Its bending fatigue life decreases with an increase in sliding contact load, and the primary fracture failure mechanism is brittle fracture.

Figure 7.

(a) Bending fatigue tester for the wire rope; (b) distribution characteristics of broken wire; (c) Fracture characteristics; (d) variation curves of broken wire number with bending fatigue times [49].

In addition, wear reduces the cross-sectional area of steel wires, weakens their load-carrying capacity, and accelerates the ultimate fracture failure of wire ropes. Singh et al. [69] explored the causes of two wire-rope failure cases by examining parameters such as physical inspection results, wear and corrosion conditions, lubrication status, macro- and microstructural features, and chemical composition, and found that the primary failure causes were excessive wear and corrosion, which led to a reduction in rope diameter and inadequate lubrication. To study the influence of surface wear on the fracture failure behavior of mine hoisting wire ropes, Chang et al. [70] conducted tensile tests and finite element simulations, which revealed that wear induces significant plastic deformation and a temperature rise in wire ropes. Severely worn outer-layer wires were found to fracture earlier than internal wires, and irregular wear scars caused stress concentration and non-uniform stress distribution, thereby accelerating wire-rope failure. The failure mechanism shifts from surface-wear-dominated strength loss to internal-fatigue-dominated fracture as service time increases. However, the existing literature often lacks quantitative criteria to identify this critical transition point. The interaction between surface wear scars and internal fretting fatigue creates a complex damage synergy that accelerates failure non-linearly, which challenges traditional linear damage accumulation models.

Lubrication protection plays a crucial role in the safe service of wire ropes. Lubrication conditions affect the contact configurations between wire ropes and between individual wires, thereby influencing friction and wear behavior and the associated wear mechanisms. Lubrication failure can significantly aggravate wear damage in wire ropes and greatly shorten their service life. McColl et al. [71,72] conducted friction and wear experiments on steel wires under different lubrication conditions and found that lubrication can effectively reduce the COF, with grease lubrication forming a protective layer on the contact surfaces. Based on experimental data, they combined a modified Archard wear model with finite element software to propose an effective method for calculating wire wear.

4.2. Life Prediction of Wire Ropes

As wire ropes accumulate fatigue damage, frictional wear, and corrosion degradation during long-term service, their damage evolution exhibits complex nonlinear characteristics and is significantly affected by the coupled effects of contact modes and environmental conditions. Accurate evaluation of the residual bearing capacity of damaged wire ropes and prediction of their remaining useful life are therefore crucial to ensuring safe operation. The accuracy of life prediction models heavily depends on the understanding of the wear mechanisms, such as inter-wire fretting and external sliding, which serve as the physical basis for damage accumulation.

To avoid waste from premature wire rope replacement and to prevent hoisting accidents from delayed replacement, the performance assessment and reliability evaluation of wire ropes are critical. To accurately evaluate wire-rope safety, Slesarev et al. [73] proposed a method for determining probabilistic characteristics to detect existing damage in heterogeneous wire-rope structures and to estimate strength degradation and remaining life during fault-free operation based on the probability of errors in nondestructive testing. Considering the random occurrence of wire breaks in suspension-bridge cables, Cremona [74] developed a probabilistic method for residual strength assessment of wire ropes based on simple mechanical and statistical models, enabling more accurate evaluation of safety factors. Mouhib et al. [75] conducted static tensile tests on wire-rope cores. They analyzed the effects of different core damage states on the mechanical behavior of wire ropes using pre-fabricated broken wires, thereby enabling reliability evaluation based on material life and damage. By establishing an association model between damage and the reliability of the central core strand of steel wire ropes, they found that damage accumulation leads to a decline in fracture energy, and the critical life fraction corresponds to the acceleration point of damage, which can provide a basis for predictive maintenance.

Accurately predicting the remaining service life of worn wire ropes is essential. On the one hand, it helps determine appropriate replacement times and reduces waste caused by early replacements; on the other hand, it prevents safety accidents arising from delayed replacement of worn ropes and ensures safe, efficient equipment operation. To investigate the influence of inter-wire fretting wear on service life, Schrems [66] investigated the effect of wear on the fatigue life of wire ropes and found that the contact between wire ropes and sheaves has a significant impact on service life. Wang et al. [17] used finite element simulation to analyze the effects of different fretting parameters on wire stress distribution and crack initiation behavior, and predicted fretting fatigue life by examining the evolution of wire wear depth. Sasaki et al. [76] investigated contact pressure and fretting fatigue behavior through finite element force analysis and fretting fatigue experiments on steel wires, analyzing the influence of various parameters and environments on service life; the fatigue life of wire ropes was found to generally decrease with increasing crossing angle, contact load, and torsional angle. Peterka et al. [77] established an evolution prediction model for the characteristic parameters of steel wire ropes by analyzing the patterns of nondestructive testing signals over service time, enabling the prediction of their service life and effectively extending their usable lifespan. Despite the progress in life prediction, a significant limitation remains in the universality of these models. Deterministic models excel in specific wear scenarios but struggle with the stochastic nature of wire breaks, whereas probabilistic models depend heavily on extensive historical data, which is often unavailable for new rope designs. The current research direction aims to fuse these approaches, utilizing physics-informed machine learning to combine the interpretability of mechanical models with the data-driven capabilities of statistical methods.

Fatigue loading is a crucial factor that reduces the service life of wire ropes. Understanding the influence mechanism of the fatigue mechanical behavior of wire ropes on their service life can effectively ensure their safety and reliability. Giglio et al. [78,79] conducted bending fatigue tests on aircraft life-saving wire ropes passing over guide wheels, analyzing the stress and strain state variation characteristics of the wire ropes, and estimated the remaining service life of the ropes based on the fretting fatigue properties of the wires. Raoof et al. [80] investigated the influence of wire rope length on its service life based on axial fatigue test data and revealed the distribution patterns of the axial fatigue life of wire ropes. Ridge et al. [81] conducted tensile and torsional fatigue tests on mooring wire ropes for coastal use, examining their fatigue failure mechanisms and determining the tensile–torsional fatigue life of the ropes.

5. Damage Detection of Wire Ropes

During long-term service, the health condition of wire ropes exhibits time-varying characteristics, and their structural integrity degrades nonlinearly as cumulative wear-induced damage accumulates. Improper maintenance may lead to premature scrapping or excessive use of wire ropes, resulting in resource waste and potential safety hazards. At present, both domestic and international studies have identified damage and defects in wire ropes, both qualitatively and quantitatively. Based on the damage mechanisms identified and the life evolution patterns, protection strategies can be targeted effectively. Accurate detection of wire-rope damage states and a clear understanding of the effects of different damage modes on the mechanical properties of wire ropes are the prerequisites and fundamental guarantees for achieving precise prediction of wire-rope remaining useful life.

Currently, instrument-based damage detection is the mainstream, scientifically reliable approach, as it enables the detection of internal and external damage without breaking or destructively testing the wire rope. Among these methods, electromagnetic testing is the most widely used technique for detecting wire-rope damage. To address the challenge of quantifying broken wires, Mazurek et al. [82] investigated wire-rope flaw detection using the geomagnetic field and analyzed the influence of sensor arrangement on defect detection. Liu et al. [83] conducted experimental studies on local broken-wire (LF) defects using Hall sensors and magnetic flux leakage (MFL) techniques, designing a detection device and comparing the effects of different filtering methods on detection performance. Zhang et al. [84] proposed a novel quantitative method for detecting internal and surface defects in wire ropes by overcoming the limitations of induction-coil magnetic flux detection and Hall-sensor-based MFL techniques. Using the designed two-stage Radial Basis Function (RBF) neural network, surface and internal defects can be accurately distinguished, and the defect width, cross-sectional loss rate, and depth can be quantitatively identified. To address the weak signal problem encountered in MFL-based nondestructive testing of wire ropes under electromagnetic interference, Yan et al. [85,86] proposed two approaches to enhance leakage magnetic signals caused by defects: a simplified MFL detection circuit based on a single Hall sensor for magnetic field measurement, and the use of an iron core as the framework for the detection coil assembly.

In recent years, to address the challenges posed by complex service environments, diverse damage types, and the susceptibility of traditional nondestructive testing methods to noise interference, researchers have increasingly explored detection technologies with higher accuracy and greater intelligence. Cao et al. [87] investigated the application of eddy current testing to the nondestructive evaluation of wire ropes and proposed a wire-breakage identification method based on a radial basis function neural network, along with the development of an experimental eddy current sensor and a computer-based measurement system. With advances in image processing, visual inspection methods have been widely applied. Larsson et al. [88] utilized Charge-Coupled Device (CCD) cameras to detect surface abrasion on steel wires, where the captured wire reflectance intensity signal exhibited a significant correlation with the tensile force signal, enabling the accurate identification of lubrication failure and demonstrating applicability to steel wire materials with varying reflective properties. Zhou et al. [89] presented a novel wire-rope damage detection method based on texture feature extraction from surface images. This method validates the effectiveness and practicality of texture features in the classification of surface damage on wire ropes. To further improve detection accuracy, Lu et al. [90] combined magnetic flux leakage testing with infrared thermography and enhanced wire-breakage identification through feature fusion. Considering the harsh service conditions of wire ropes, strong noise interference, and large, complex defect datasets, Zhang et al. [91] proposed a novel inspection method based on a convolutional denoising autoencoder and isolation forest; the structure of the inspection system is shown in Figure 8 [91], and its effectiveness was experimentally validated. With the rapid development of artificial intelligence, Zhou et al. [92] established a deep-learning-based framework for wire-rope damage detection, which significantly improves detection intelligence and accuracy through image preprocessing and deep convolutional neural networks. These advanced methods generally exhibit high sensitivity, strong recognition capability, and potential for automated processing. While electromagnetic testing techniques are highly sensitive to wire breakage and internal defects, and image-based methods enhance intelligent recognition of surface damage, limitations remain in adaptability to complex operating conditions, equipment cost, and real-time performance. While instrument-based detection methods have diversified, each technique presents distinct limitations regarding practical applicability. Electromagnetic methods (MFL), although mature, struggle to accurately quantify internal damage due to signal saturation and noise. Conversely, computer vision and deep learning offer high sensitivity for surface defects but are ‘blind’ to internal core degradation and require large labeled datasets. Therefore, relying on a single modality is becoming insufficient. The emerging trend is unmistakably moving towards multi-sensor fusion technologies, which combine the internal penetrability of magnetic testing with the surface precision of visual imaging to achieve comprehensive health monitoring.

Figure 8.

System structure of the hauling rope flaw detection in mine cableways [91].

The emerging trend is unmistakably moving towards multi-sensor fusion technologies, which combine the internal penetrability of magnetic testing with the surface precision of visual imaging to achieve comprehensive health monitoring. A detailed comparison of these detection techniques, summarizing their principles, capabilities, and limitations, is presented in Table 1.

Table 1.

Comparison of mainstream non-destructive testing (NDT) techniques for wire ropes.

6. Existing Challenges

The tribological behavior of wire ropes involves a complex interdependence between internal contact mechanics, external environmental factors, and dynamic service conditions. Table 2 systematically summarizes the key damage mechanisms, operating conditions, degradation consequences, and corresponding mitigation and monitoring strategies. This consolidated framework highlights the links between specific service environments and damage mechanisms, serving as a foundational guide for the discussion on existing challenges.

Table 2.

Overview of tribological mechanisms, operating conditions, consequences, and mitigation or monitoring methods for wire ropes.

With the continuous advancement of tribological research on wire ropes, various theoretical methods and analytical techniques have become increasingly mature. However, studies on the tribological behavior characteristics of wire ropes still face several unresolved issues, as outlined below:

- Current domestic and international studies based on dynamic theories have investigated the dynamic response and load-bearing characteristics of wire rope systems. Nevertheless, the excitation modes and boundary conditions adopted in most established models are relatively simplified. Existing research mainly focuses on the vibration behavior of hoisting systems and the stress–strain distribution under different loads, whereas the actual service conditions of wire ropes are far more complex. Studies addressing the influence of system vibration on dynamic contact behaviors—such as impact, collision, and slip at contact interfaces—remain limited.

- The contact characteristics of wire ropes directly determine their friction and wear behavior. At present, most studies give insufficient consideration to the effects of vibration and impact on contact behavior. Although research on internal inter-wire friction and wear began relatively early, investigations into external wear of wire ropes remain inadequate. Moreover, the contact configurations and environmental conditions used in experiments differ significantly from those in real service conditions. Wear behavior is highly sensitive to environmental factors and exhibits strong coupling and multiple forms, which greatly increase the difficulty of maintenance and damage-state detection.

- Although systematic studies have been conducted on typical damage characteristics and failure mechanisms of wire ropes, experimental conditions often differ substantially from actual service environments. In particular, the effects of lubrication state variations under different load conditions, the interaction and coupling mechanisms among different damage types, and their cumulative evolution characteristics have not yet been thoroughly investigated. The impact of strongly coupled damage on the residual load-bearing capacity of wire ropes remains unclear, which is critical for ensuring safe operation and maintenance under harsh working conditions.

- Although existing methods—such as magnetic flux leakage detection and image processing—can accurately detect wire breakage defects, research on wear state detection remains extremely limited. In service, wire ropes usually suffer from multiple types and degrees of damage. Current studies tend to investigate the effects of wire breakage, wear, and corrosion on mechanical properties in isolation, and the interrelationships among these damage modes remain unclear. Furthermore, limited attention has been paid to detecting early-stage degradation and failure of surface lubricants, and existing inspection and maintenance strategies lack effective decision-making criteria for evaluating the overall service condition of wire ropes.

7. Summary and Outlook

This review provides a comprehensive review and analysis of the mechanical behavior, friction and wear characteristics, damage and failure mechanisms, and condition monitoring of wire ropes. The main conclusions are summarized as follows:

- Studies on the mechanical properties of wire ropes have revealed their complex stress states under tensile, bending, torsional loads, and vibration excitation. Various theoretical models have been proposed to predict internal stresses and contact behaviors, providing essential theoretical support for understanding the mechanical basis of friction-induced damage.

- Inter-wire fretting wear is characterized as a concealed and latent form of damage in wire ropes. Its frictional characteristics and fatigue evolution are strongly influenced by structural configuration, loading conditions, and environmental media. A relatively complete experimental and numerical analysis framework has gradually been established.

- External frictional wear directly leads to surface cross-sectional loss and strength degradation of wire ropes. Different contact modes (vibration and impact), lubrication conditions, and corrosive environments determine the diversity of wear mechanisms and wear distribution, significantly impacting safe operational reliability.

- The accumulation of wire rope damage manifests as progressive degradation of properties and an increased risk of failure. Fracture behavior, fatigue life evaluation, and prediction under multiple damage states have been extensively studied, laying a theoretical foundation for maintenance scheduling and performance management strategies.

- Advances in electromagnetic testing, image recognition, and intelligent technologies have significantly improved the identification of broken wires and surface wear defects. Damage detection methods are evolving toward intelligent, visualized, and quantitative approaches, providing strong technical support for wire rope safety condition monitoring.

Looking ahead, tribological research on wire ropes should address more severe service conditions such as deep-sea, deep-earth, and high-speed heavy-load applications. Further efforts are required to elucidate the mechanisms underlying damage mutations induced by internal and external inter-wire fretting behavior and dynamic contact responses. Meanwhile, quantitative correlation models between wear morphology and degradation degree should be developed to achieve accurate mapping from friction parameter evolution to structural performance degradation. In addition, the development of highly adaptive lubrication and surface protection technologies is needed to achieve stable friction reduction and enhanced wear resistance in extreme environments. By integrating advanced testing techniques for real-time friction state monitoring and fatigue life prediction, tribological studies can ultimately ensure safety throughout the full life cycle of wire ropes, providing a solid theoretical and engineering basis for controlling wear-induced failure and achieving highly reliable service.

Author Contributions

Conceptualization, L.X. and G.L.; methodology, L.X. and K.H.; formal analysis, Y.P. and K.H.; investigation, Z.Z. and Y.T. and R.D.; writing—original draft preparation, L.X.; writing—review and editing, Y.P. and X.C.; supervision, Z.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Key Laboratory of Intelligent Operation and Maintenance of High-parameter Lifts, State Administration for Market Regulation (JSTJ-IOMHL-202505). This project is also supported by the National Natural Science Foundation of China (Grant No. 52475234 and 52175068).

Data Availability Statement

Not applicable.

Acknowledgments

The authors wish to thank Top-notch Academic Programs Project of Jiangsu Higher Education Institutions (TAPP, China) and the Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD, China).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Singh, R.P.; Mallic, M.; Verma, M.K. Studies on failure behaviour of wire rope used in underground coal mines. Eng. Fail. Anal. 2016, 70, 290–304. [Google Scholar] [CrossRef]

- Harris, S.J.; Waterhouse, R.B.; McColl, I.R. Fretting damage in locked coil steel ropes. Wear 1993, 170, 63–70. [Google Scholar] [CrossRef]

- Zhang, D.K.; Ge, S.R.; Qiang, Y.H. Research on the fatigue and fracture behavior due to the fretting wear of steel wire in hoisting rope. Wear 2003, 255, 1233–1237. [Google Scholar] [CrossRef]

- Styp-Rekowski, M.; Manka, E.; Matuszewski, M.; Madej, M.; Ozimina, D. Tribological problems in shaft hoist ropes wear process. Ind. Lubr. Tribol. 2015, 67, 47–51. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, E.Y.; Jia, F.Y. Mechanical and wear behavior of steel wires in typical contact area under tension–tension fatigue. Tribol. Trans. 2022, 65, 282–295. [Google Scholar] [CrossRef]

- Waterhouse, R.B.; McColl, I.R.; Harris, S.J.; Tsujikawa, M. Fretting wear of a high-strength heavily work-hardened eutectoid steel. Wear 1994, 175, 51–57. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, D.K.; Duan, J.J.; Wang, D.G. Fretting wear behaviors of steel wires under friction-increasing grease conditions. Tribol. Int. 2011, 44, 1511–1517. [Google Scholar] [CrossRef]

- Tytko, A.; Olszyna, G.; Kocór, G.; Szot, M. Some stochastic aspects of safety work of steel wire ropes used in mining-shaft hoists. Sustainability 2023, 15, 7590. [Google Scholar] [CrossRef]

- Lee, H.W.; Roh, M.I.; Ham, S.H. Block erection simulation considering frictional contact with wire ropes. Ocean Eng. 2020, 217, 107904. [Google Scholar] [CrossRef]

- Périer, V.; Dieng, L.; Gaillet, L.; Tessier, C.; Fouvry, S. Fretting-fatigue behaviour of bridge engineering cables in a solution of sodium chloride. Wear 2009, 267, 308–314. [Google Scholar] [CrossRef]

- Urchegui, M.A.; Tato, W.; Gómez, X. Wear evolution in a stranded rope subjected to cyclic bending. J. Mater. Eng. Perform. 2008, 17, 550–560. [Google Scholar] [CrossRef]

- Argatov, I.I.; Gómez, X.; Tato, W.; Urchegui, M.A. Wear evolution in a stranded rope under cyclic bending: Implications to fatigue life estimation. Wear 2011, 271, 2857–2867. [Google Scholar] [CrossRef]

- Chen, Y.P.; Meng, F.M. Numerical study on wear evolution and mechanical behavior of steel wires based on semi-analytical method. Int. J. Mech. Sci. 2018, 148, 684–697. [Google Scholar] [CrossRef]

- Chen, Y.P.; Meng, F.M.; Gong, X.S. Full contact analysis of wire rope strand subjected to varying loads based on semi-analytical method. Int. J. Solids Struct. 2017, 117, 51–66. [Google Scholar] [CrossRef]

- Chen, Y.P.; Tan, H.; Qin, W. Semi-analytical analysis of the interwire multi-state contact behavior of a three-layered wire rope strand. Int. J. Solids Struct. 2020, 202, 136–152. [Google Scholar] [CrossRef]

- Kumar, K.; Botsis, J. Contact stresses in multilayered strands under tension and torsion. J. Appl. Mech. 2001, 68, 432–440. [Google Scholar] [CrossRef]

- Wang, D.G.; Zhang, D.K.; Ge, S.R. Finite element analysis of fretting fatigue behavior of steel wires and crack initiation characteristics. Eng. Fail. Anal. 2013, 28, 47–62. [Google Scholar] [CrossRef]

- Wang, D.G.; Zhang, D.K.; Wang, S.Q.; Ge, S.R. Finite element analysis of hoisting rope and fretting wear evolution and fatigue life estimation of steel wires. Eng. Fail. Anal. 2013, 27, 173–193. [Google Scholar] [CrossRef]

- Phillips, J.W.; Costello, G.A. Analysis of wire ropes with internal-wire-rope cores. J. Appl. Mech. 1985, 52, 510–516. [Google Scholar] [CrossRef]

- Usabiaga, H.; Pagalday, J.M. Analytical procedure for modelling recursively and wire by wire stranded ropes subjected to traction and torsion loads. Int. J. Solids Struct. 2008, 45, 5503–5520. [Google Scholar] [CrossRef]

- Ru, Y.Y.; Yong, H.D.; Zhou, Y.H. Contact force and mechanical loss of multistage cable under tension and bending. Acta Mech. Sin. 2016, 32, 891–904. [Google Scholar] [CrossRef]

- Chen, Z.H.; Guo, L.L.; Liu, H.B.; Chen, H.Y. Finite element study of behaviour and interface force conditions of locked coil wire rope under axial loading. Constr. Build. Mater. 2021, 272, 121961. [Google Scholar] [CrossRef]

- Liu, L.; Zheng, S.M.; Liu, D.B. Effect of lay direction on the mechanical behavior of multi-strand wire ropes. Int. J. Solids Struct. 2020, 185, 89–103. [Google Scholar] [CrossRef]

- Elata, D.; Eshkenazy, R.; Weiss, M.P. The mechanical behavior of a wire rope with an independent wire rope core. Int. J. Solids Struct. 2004, 41, 1157–1172. [Google Scholar] [CrossRef]

- Zhang, M.M.; He, J.; Meng, F.M.; Gong, X.S. Study on stress relaxation of simple spiral strand subjected to tensile load based on semi-analytical method. Adv. Eng. Softw. 2019, 128, 34–45. [Google Scholar] [CrossRef]

- Cappa, P. An experimental study of wire strains in an undamaged and damaged steel strand subjected to tensile load. Exp. Mech. 1988, 28, 346–349. [Google Scholar] [CrossRef]

- Onur, Y.A. Experimental and theoretical investigation of prestressing steel strand subjected to tensile load. Int. J. Mech. Sci. 2016, 118, 91–100. [Google Scholar] [CrossRef]

- Peng, X.; Gong, X.S.; Liu, J.J. The study on crossover layouts of multi-layer winding grooves in deep mine hoists based on transverse vibration characteristics of catenary rope. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2019, 233, 118–132. [Google Scholar] [CrossRef]

- Yao, J.N.; Xiao, X.M. Effect of hoisting load on transverse vibrations of hoisting catenaries in floor type multirope friction mine hoists. Shock Vib. 2016, 2016, 8598749. [Google Scholar] [CrossRef]

- Steinboeck, A.; Baumgart, M.; Stadler, G.; Saxinger, M.; Kugi, A. Dynamical models of axially moving rods with tensile and bending stiffness. IFAC-PapersOnLine 2015, 48, 598–603. [Google Scholar] [CrossRef]

- Kaczmarczyk, S.; Iwankiewicz, R. Nonlinear vibrations of a cable system with a tuned mass damper under deterministic and stochastic base excitation. Procedia Eng. 2017, 199, 675–680. [Google Scholar] [CrossRef]

- Kaczmarczyk, S.; Iwankiewicz, R. Gaussian and non-Gaussian stochastic response of slender continua with time-varying length deployed in tall structures. Int. J. Mech. Sci. 2017, 134, 500–510. [Google Scholar] [CrossRef][Green Version]

- Zhang, N.; Cao, G.H.; Zhu, Z.C.; Wang, K.; Yan, L. Nonlinear dynamics of time-varying curvature balance rope coupled with time-varying length hoisting rope in friction hoisting system. J. Sound Vib. 2023, 567, 117910. [Google Scholar] [CrossRef]

- Yan, L.; Cao, G.H.; Wang, N.G.; Li, J.S. Lateral stiffness and deflection characteristics of guide cable with multi-boundary constraints. Adv. Mech. Eng. 2017, 9, 1687814017711079. [Google Scholar] [CrossRef]

- Emrani, A.; Berrada, A.; Bakhouya, M. Modeling and performance evaluation of the dynamic behavior of gravity energy storage with a wire rope hoisting system. J. Energy Storage 2021, 33, 102154. [Google Scholar] [CrossRef]

- Zhang, D.K.; Yang, X.H.; Chen, K.; Zhang, Z.F. Fretting fatigue behavior of steel wires contact interface under different crossing angles. Wear 2018, 400, 52–61. [Google Scholar] [CrossRef]

- Cruzado, A.; Urchegui, M.A.; Gómez, X. Finite element modeling and experimental validation of fretting wear scars in thin steel wires. Wear 2012, 289, 26–38. [Google Scholar] [CrossRef]

- Cruzado, A.; Hartelt, M.; Wäsche, R.; Urchegui, M.A.; Gómez, X. Fretting wear of thin steel wires. Part 1: Influence of contact pressure. Wear 2010, 268, 1409–1416. [Google Scholar] [CrossRef]

- Cruzado, A.; Hartelt, M.; Wäsche, R.; Urchegui, M.A.; Gómez, X. Fretting wear of thin steel wires. Part 2: Influence of crossing angle. Wear 2011, 273, 60–69. [Google Scholar] [CrossRef]

- Peng, Y.X.; Huang, K.; Ma, C.B.; Zhu, Z.C.; Chang, X.D.; Lu, H.; Zhang, Q.; Xu, C.M. Friction and wear of multiple steel wires in a wire rope. Friction 2023, 11, 763–784. [Google Scholar] [CrossRef]

- Nabijou, S.; Hobbs, R.E. Relative movements within wire ropes bent over sheaves. J. Strain Anal. Eng. Des. 1995, 30, 155–165. [Google Scholar] [CrossRef]

- Kumar, K.; Goyal, D.; Banwait, S.S. Effect of key parameters on fretting behaviour of wire rope: A review. Arch. Comput. Method. Eng. 2020, 27, 549–561. [Google Scholar] [CrossRef]

- Wang, D.G.; Wang, B.; Ge, S.R.; Wu, K.; Chong, H.L.; Zhang, D.K.; Xie, G.X.; Chen, J.H.; Zhang, C.Y.; Deng, H.Y.; et al. Effects of fatigue load characteristics on bending tribo-corrosion-fatigue damage of steel wire ropes in seawater and pure water. Tribol. Int. 2025, 201, 110201. [Google Scholar] [CrossRef]

- Wang, D.G.; Li, X.W.; Wang, X.R.; Zhang, D.K.; Wang, D.A. Dynamic wear evolution and crack propagation behaviors of steel wires during fretting-fatigue. Tribol. Int. 2016, 101, 348–355. [Google Scholar] [CrossRef]

- Wang, D.G.; Song, D.Z.; Wang, X.R.; Zhang, D.K.; Zhang, C.L.; Wang, D.A.; Araújo, J.A. Tribo-fatigue behaviors of steel wires under coupled tension-torsion in different environmental media. Wear 2019, 420, 38–53. [Google Scholar] [CrossRef]

- Périer, V.; Dieng, L.; Gaillet, L.; Fouvry, S. Influence of an aqueous environment on the fretting behaviour of steel wires used in civil engineering cables. Wear 2011, 271, 1585–1593. [Google Scholar] [CrossRef]

- Huang, K.; Peng, Y.X.; Chang, X.D.; Shi, Z.Y.; Zhou, Z.; Lu, H.; Tang, W.; Wang, G.F.; Zhang, X.H. Fretting wear behavior and strength degradation of helical contact steel wire in wire rope under different corrosive media and time-varying conditions. Wear 2024, 550, 205413. [Google Scholar] [CrossRef]

- Chang, X.D.; Peng, Y.X.; Zhu, Z.C.; Cheng, D.Q.; Lu, H.; Tang, W.; Chen, G.A. Tribological behavior and mechanical properties of transmission wire rope bending over sheaves under different sliding conditions. Wear 2023, 514, 204582. [Google Scholar] [CrossRef]

- Chang, X.D.; Chen, X.; Dong, Y.Y.; Lu, H.; Tang, W.; Zhang, Q.; Huang, K. Friction and wear behavior between crane wire rope and pulley under different contact loads. Lubricants 2022, 10, 337. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, D.G.; Song, D.Z.; Zhang, D.K.; Zhang, C.L.; Wang, D.A.; Araújo, J.A. Tribo-fatigue behaviors of steel wire rope under bending fatigue with the variable tension. Wear 2019, 428, 154–161. [Google Scholar] [CrossRef]

- Oksanen, V.; Valtonen, K.; Andersson, P.; Vaajoki, A.; Laukkanen, A.; Holmberg, K.; Kuokkala, V.T. Comparison of laboratory rolling–sliding wear tests with in-service wear of nodular cast iron rollers against wire ropes. Wear 2015, 340, 73–81. [Google Scholar] [CrossRef]

- Wang, D.G.; Zhang, D.K.; Mao, X.B.; Peng, Y.X.; Ge, S.R. Dynamic friction transmission and creep characteristics between hoisting rope and friction lining. Eng. Fail. Anal. 2015, 57, 499–510. [Google Scholar] [CrossRef]

- Wang, D.G.; Wang, D.A. Dynamic contact characteristics between hoisting rope and friction lining in the deep coal mine. Eng. Fail. Anal. 2016, 64, 44–57. [Google Scholar] [CrossRef]

- Wang, D.G.; Li, X.W.; Wang, X.R.; Shi, G.Y.; Mao, X.B.; Wang, D.A. Effects of hoisting parameters on dynamic contact characteristics between the rope and friction lining in a deep coal mine. Tribol. Int. 2016, 96, 31–42. [Google Scholar] [CrossRef]

- Guo, Y.B.; Zhang, D.K.; Wang, D.G.; Liu, Y.; Feng, C.A. Dynamic distribution of contact stress of friction lining in the process of friction transmission. J. Vibroeng. 2016, 18, 4207–4221. [Google Scholar] [CrossRef]

- Feng, C.A.; Zhang, D.K.; Chen, K.; Guo, Y.B. Study on viscoelastic friction and wear between friction linings and wire rope. Int. J. Mech. Sci. 2018, 142, 140–152. [Google Scholar] [CrossRef]

- Feng, C.A.; Zhang, D.K.; Chen, K.; Guo, Y.B. Effect of water on the interfacial contact and tribological properties of hoist linings. J. Tribol. 2018, 140, 061604. [Google Scholar] [CrossRef]

- Peng, Y.X.; Chang, X.D.; Zhu, Z.C.; Wang, D.G.; Gong, X.S.; Zou, S.Y.; Sun, S.S.; Xu, W.X. Sliding friction and wear behavior of winding hoisting rope in ultra-deep coal mine under different conditions. Wear 2016, 368, 423–434. [Google Scholar] [CrossRef]

- Chang, X.D.; Peng, Y.X.; Zhu, Z.C.; Zou, S.Y.; Gong, X.S.; Xu, C.M. Evolution properties of tribological parameters for steel wire rope under sliding contact conditions. Metals 2018, 8, 743. [Google Scholar] [CrossRef]

- Zhang, Q.; Peng, Y.X.; Zhu, Z.C.; Chang, X.D.; Lu, H.; Zhou, Z.; Cao, G.H.; Tang, W.; Chen, G.A. Influence of longitudinal vibration on the friction and wear characteristics of multi-layer winding hoisting wire rope. Wear 2022, 492, 204211. [Google Scholar] [CrossRef]

- Peng, Y.X.; Chang, X.D.; Sun, S.S.; Zhu, Z.C.; Gong, X.S.; Zou, S.Y.; Xu, W.X.; Mi, Z.T. The friction and wear properties of steel wire rope sliding against itself under impact load. Wear 2018, 400, 194–206. [Google Scholar] [CrossRef]

- Wang, G.F.; Peng, Y.X.; Zhu, Z.C.; Wang, D.G.; Tang, W.; Chen, G.A.; Liu, W.H.; Zhang, Q.; Huang, K. Tribological properties and residual strength of wire rope with different strands during the interlayer-transition stage. Wear 2021, 480, 203930. [Google Scholar] [CrossRef]