Abstract

Based on the methods of non-equilibrium thermodynamics, it was found that the implementation of spontaneous processes with positive entropy production during friction leads to an increase in the wear intensity. Non-spontaneous processes with negative entropy production lead to a decrease in wear intensity. The tribological characteristics of diamond-like carbon (DLC) with different silicon content were studied. The wear intensity practically does not correlate with the friction coefficient. It is shown that DLC with the highest content of diamond-like inclusions (sp3) in the coating has the highest wear rate. In the same DLC, the most intense sp3–sp2 transformation during friction was observed. The sp3–sp2 transformation is a spontaneous process.

1. Introduction

Diamond-like carbon (DLC) is a promising coating material for improving tribological performance in various friction units. In [1,2], this is associated with a low coefficient of friction, high hardness, and wear resistance. This combination of properties is possible due to the structure of DLC films. Carbon forms a wide variety of crystalline and disordered structures because it can exist in three hybrid forms: sp3 (as in diamond), sp2 (as in graphite), and sp1. DLC films are a metastable form of amorphous carbon with a significant proportion of sp3 type carbon bonds. It is assumed that sp2 bonds are located in clusters embedded in a matrix with sp3 bonds [3]. In [4], DLC coatings were classified into several types depending on the proportion of sp3 bonds (they can reach almost 90%) and the hydrogen content (up to 50–60%).

To improve the mechanical and tribological properties, doping films with metals [5,6,7] is widely used. For this purpose, titanium is often used as a carbide-forming element. Depending on the content of Ti and the form in which it exists in DLC films, its effect on tribological behavior is different. At a low concentration (up to ~2 wt. %), titanium carbide (TiC) nanoparticles are formed, which positively affects the friction characteristics, while at higher concentrations of titanium has a negative effect [8,9]. The presence of Ti in an amorphous form leads to an increased content of the carbon sp2 bond and a reduced internal stress, which also contributes to the improvement of tribological characteristics [10]. Diamond-like carbon coatings doped with Ti (no more than 0.46 wt. %) showed both an acceptable wear rate and good adhesion to the substrate [11]. Other researchers also obtained an improvement in the characteristics of films upon metal doping [12,13,14]. Metals in DLC can have a catalytic effect, intensifying the formation of diamond- or graphite-like structures, as well as the transition of structures with sp3-bonds to structures with sp2-bonds [7].

It is often postulated that friction is reduced by the formation of a solid lubricant on the DLC surface due to graphitization [15,16] or coating doping with various elements [16,17]. Graphitization of surface layers, as one of the main mechanisms for reducing friction in contact with DLC, occurs due to the amorphization of surface carbon layers and the formation of clusters with a graphite-like structure under the action of high pressures and temperatures in real contact zones [17,18]. However, according to [19], the transition of diamond-like structures to graphite-like ones is a spontaneous process, which leads to an increase in wear intensity.

At the initial stage of friction, the surfaces are run in to each other. There is a change in geometric parameters: an increase in the contact area, a change in roughness, texture, contact shape, and others. Simultaneously with changes in geometry, physicochemical transformations occur, resulting in the formation of secondary structures [20]. According to [21,22,23], the nature of these transformations determines the tribological characteristics, including the wear intensity. Transformations can be spontaneous (entropy production is positive) or non-spontaneous (entropy production is negative). In the first case, the wear rate increases; in the second case, it decreases [19].

The purpose of this study is to analyze, on the basis of theory and experiment, the processes occurring during friction of silicon doped DLC coatings and to relate them to tribological characteristics.

2. Theoretical Prediction

The intensity of wear of interacting bodies decreases with decreasing entropy production [19,24]. Entropy production during friction can be represented as the following two terms:

here —part of the entropy production without taking into account the physicochemical transformations on the friction surface (mainly heat distribution); —part of the production of entropy due to physical and chemical transformations; X1 and X2 are thermodynamic forces causing heat flux and chemical transformations, respectively; J1 and J2 are thermodynamic fluxes of heat and physicochemical transformations, respectively.

According to [25]:

here T is the absolute temperature; λ is the coefficient of thermal conductivity; B is the contact area; K is the coefficient of friction; p is the load; v is the sliding velocity; A is the affinity of a chemical reaction; η is the reaction rate constant; k is the Boltzmann constant; h is Planck’s constant; ΔG* is the free activation energy of a chemical reaction; R is the gas constant.

From (1) and (2), it follows that the total entropy production () is:

It follows from (3) that the first term can be only positive due to its quadratic form. The second term can become negative or positive. Its sign depends on the sign of the affinity of the reaction (A). When A > 0 the transformation is spontaneous, when A < 0 the transformation is not spontaneous. Non-spontaneous process (A < 0) leads to a decrease in the entropy production, therefore, to a decrease in the wear intensity. Spontaneous process (A > 0) leads to an increase in the entropy production, hence to an increase in the intensity of wear.

In [26], an example of a decrease in wear intensity during friction of copper and graphite with the current collection is given when a non-spontaneous process with negative affinity is realized. A non-spontaneous process was the reduction (by copper) of carbon from carbon dioxide. This reaction, which takes place during the friction of copper in air, is described in [27].

Paper [28] presents an example of an increase in wear intensity during friction of synthetic diamond and aluminum-titanium alloy during a spontaneous process with a positive affinity. The spontaneous process involved the transformation of diamond into graphite. Without friction, the transformation of diamond into graphite occurs at a temperature of about 850 °C. During friction, this transition was carried out at a temperature of 50–70 °C. An aluminum-titanium alloy was selected in [28] as a catalyst for this transformation. However, pressing the diamond to the alloy and heating to 800 °C did not lead to a phase transition of diamond into graphite without friction. Such a transition at a low temperature occurred only during friction.

3. Materials and Methods of Experimental Study

Coatings were applied to a tetrahedral hard alloy plate 12 × 12 mm2 in size and 3 mm thick. The alloy consists of WC (88%), TaC (2%), and Co (10%). Coatings were applied by cathode-arc evaporation using a Platit π311 unit (Platit AG, Selzach, Switzerland). To provide interface adhesion, the lower (CrAlSi)N layer was created in an argon and nitrogen atmosphere using Cr and AlSi cathodes. The sublayer thickness was 2–3 µm. The top layer was a silicon doped DLC coating with a thickness of 2 μm. For DLC, a plasma-enhanced chemical vapor deposition technique using acetylene (C2H2) and tetramethylsilane (Si(CH3)4) was used. The silicon content in the coating was controlled by changing the flow rate of tetramethylsilane and analyzed for cross sections (Table 1). During the deposition of the lower (CrAlSi)N layer, the samples were heated to a temperature of 450 °C, then cooled to 180 °C for DLC deposition.

Table 1.

Tested samples.

The tests were performed using tribotester UMT-3 by CETR (Campbell, CA, USA), according to the “ball-plane” scheme with reciprocating motion.

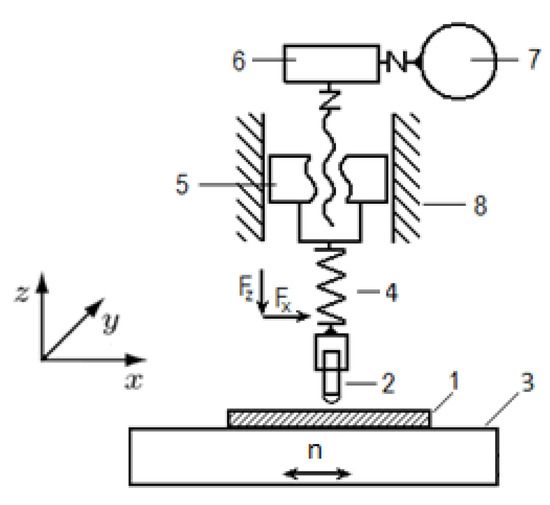

The scheme of the UMT-3 tribotester is shown in Figure 1.

Figure 1.

Scheme of UMT-3.

Plate 1 is rigidly fixed on the object stage 3, which is set to reciprocating movement from the engine by means of the crank mechanism of the tribotester. The ball 2 is rigidly fixed in its holder, mounted on the elastic element 4, which in turn is kinematically connected to the screw loading mechanism 5 through the gearbox 6 and the motor 7. The elastic element is a 2-component sensor designed to measure in real time the normal and friction forces acting on the samples (Fz and Fx respectively). The measuring system was equipped with a feedback function of the electric motor 7 with a force sensor, which allows you to maintain a normal load Fz at a constant level.

For testing, an industrial ball made of steel 52,100 with a diameter of 4 mm was used. The tests parameters were the following: 2 values of load (1 and 5 N), amplitude 6.5 mm, frequency 7.7 Hz. Temperature and humidity corresponded to room conditions. With these parameters, the average sliding velocity was 0.1 m/s. All tests lasted 60 min. The experiments were made with 2 repetitions. The deviation in the friction coefficient between repetitions did not exceed 7%.

Atomic force microscopy was used to study the surface of coatings and friction tracks in the PeakForce QNM (Quantitative Nanomechanical mapping) mode on a Dimension FastScan microscope (Bruker, Billerica, MA, USA). CSG10_SS cantilevers (TipsNano, Zelenograd, Russia) with a tip radius of 8 nm and cantilever stiffness of 0.21 N/m were used. Measurement of the adhesion force (Fad) on the initial surface of the coatings and in the friction tracks was carried out by taking force curves, which were the dependences of the cantilever deviations on the distance between the probe and the sample. The work of adhesion γ (specific surface energy) was calculated as Fad per unit contact area: γ = 2 Fad/(2πR) [29].

Raman scattering (RS) spectra were recorded using a Senterra Raman microscope (Bruker, Billerica, MA, USA). The spectra were generated by radiation with a wavelength of 532 nm and a power of 20 mW. The registration of the spectra was made in the spectral range 600 ÷ 2500 cm−1. The intensities of the D and G bands, their positions, and the ID/IG ratio were analyzed.

Optical and scanning electron microscopy (SEM) were used to analyze the surface. For SEM studies, the FEI “Quanta-650” with secondary and reflected electron detectors was used.

4. Results and Discussions

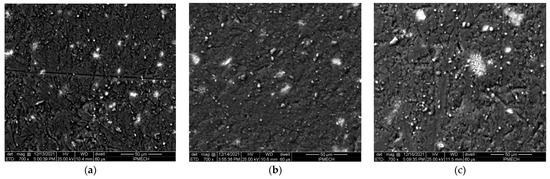

Figure 2 presents initial surfaces of samples. The material has pores (white spots in the images). The porosity of sample C was noticeably higher than that of samples A and B.

Figure 2.

SEM-images of samples (secondary electrons): (a)—sample A, (b)—sample B, (c)—sample C. Magnification 700.

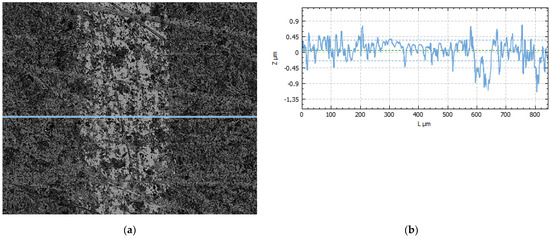

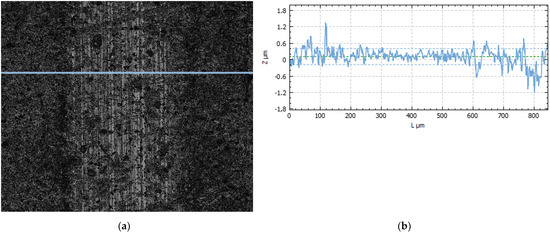

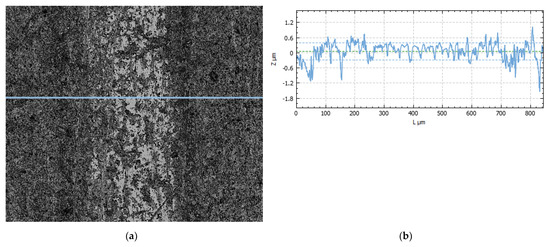

Friction tracks are presented in Figure 3, Figure 4 and Figure 5, both photos and profiles. Really, we have almost no wear depth, but some smoothing occurs during friction contact. Table 2 shows the average width of the friction tracks for different AMS and different loads, as well as the intensity ratio of the ID/IG Raman spectroscopy bands. The ID/IG ratio was used to characterize the degree of defectiveness of the DLC coating. A decrease in the ID/IG ratio characterizes an increase in disorder and is associated with an increase in the contribution of the sp3 hybridization of carbon [30]. The G band, located at a lower wavenumber, was attributed to the strengthening of the sp3 bond in the structure [31]. The sp3 bond structure was disordered and constrained, which increases the compressive stress in the coating.

Figure 3.

Photo (a) and profile (b) of sample A surface after test.

Figure 4.

Photo (a) and profile (b) of sample B surface after test.

Figure 5.

Photo (a) and profile (b) of sample C surface after test.

Table 2.

Average track width, μm.

Measuring the width of the friction tracks allows a comparative analysis of the wear of the samples. The highest wear was typical for sample B, the minimum wear was typical for sample C. The same trend was obtained for the ID/IG ratio. Interestingly, the sample B had the highest ID/IG ratio, i.e., the highest content of sp3 bonds, and, consequently, diamond-like structures, had the highest wear. This was due to the most intense transition of structures with sp3 bonds to structures with sp2 bonds, i.e., diamond-like structures to graphite-like structures.

This was confirmed by measuring the specific surface energy and adhesion force. The dependence of adhesion forces and specific surface energy on the Si content both in the initial state and in the friction track have a similar form. Sample C had the lowest specific surface energy in the initial state, and A in the friction track. Sample B had the maximum value in both cases. In the friction track, the adhesion forces and the specific surface energy increased significantly due to the formation of soft amorphous layers.

Thus, the highest wear intensity was characteristic of DLC, which had the highest content of diamond-like structures. This DLC was characterized by the most intense transition of diamond-like structures to graphite-like structures. This was consistent with the main ideas in Section 2 (Theoretical prediction).

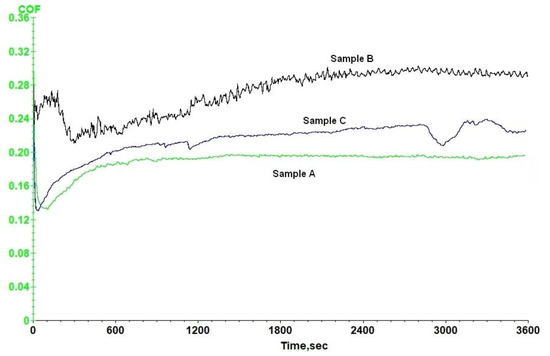

Figure 6 shows the dependence of the coefficient of friction on time for 3 samples.

Figure 6.

The dependence of the coefficient of friction on time.

It follows from Figure 6 that the coating B had the highest friction coefficient, which had the highest wear and the most intense transition from a diamond-like structure to a graphite-like structure. This was inconsistent with the assumption that DLC graphitization leads to an improvement in tribological characteristics [15,16].

5. Conclusions

Friction and wear tests were performed for three DLC coatings differing in silicon content (0.8, 5, 10% Si(CH3)4). DLC with the highest initial content of diamond-like structures and with the most intensive transformation of diamond-like structures into graphite-like structures having the highest wear intensity. For comparative analysis of the wear intensity, the width of friction tracks was used, since the wear was very small.

Using the methods of non-equilibrium thermodynamics and the theory of self-organization, it was shown that the intensification of spontaneous processes (positive entropy production) during friction led to an increase in wear intensity, and the intensification of non-spontaneous processes (negative entropy production) during friction led to a decrease in wear intensity. The transformation of diamond-like structures into graphite-like structures was a spontaneous process.

The coating with the maximum content of diamond-like structures had the highest wear rate. In this case, the most intense sp3–sp2 transformations occurred. The fact was in perfect correlation with the theoretical prediction.

Author Contributions

Conceptualization, I.G. and E.T.; methodology, I.G. and E.T.; experiment, A.M. (Alexei Mezrin) (friction tests), T.K. and V.L. (AFM), A.R. (Raman); formal analysis, I.G.; writing—original draft preparation, I.G.; writing—review and editing, E.T., T.K., and A.M. (Alexander Mironov); visualization, A.M. (Alexei Mezrin); supervision, E.T.; project administration, E.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by RFBR and BRFBR, grant number 20-58-00007 (F20R-217), and by the Russian Science Foundation (Section 2), grant number 21-79-30058.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Memming, R.; Tolle, H.J.; Wierenga, P.E. Properties of polymeric layers of hydrogenated amorphous carbon produced by a plasma-activated chemical vapour deposition process II: Tribological and mechanical properties. Thin Solid Film. 1986, 143, 31–41. [Google Scholar] [CrossRef]

- Grill, A. Tribology of diamondlike carbon and related materials: An updated review. Surf. Coat. Technol. 1997, 94, 507–513. [Google Scholar] [CrossRef]

- Robertson, J. Classification of Diamond-like Carbons. In Tribology of Diamond-Like Carbon Films: Fundamentals and Applications; Donnet, C., Erdemir, A., Eds.; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008; pp. 13–24. [Google Scholar]

- Jacob, W.; Möller, W. On the structure of thin hydrocarbon films. Appl. Phys. Lett. 1993, 63, 1771–1773. [Google Scholar] [CrossRef]

- Dimigen, H.; Hübsch, H.; Memming, R. Tribological and electrical properties of metal-containing hydrogenated carbon films. Appl. Phys. Lett. 1987, 50, 1056–1058. [Google Scholar] [CrossRef]

- Qiang, L.; Zhang, B.; Zhou, Y.; Zhang, J. Improving the internal stress and wear resistance of DLC film by low content Ti doping. Solid State Sci. 2013, 20, 17–22. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Wang, D.Y.; Wu, W.T. Catalysis effect of metal doping on wear properties of diamond-like carbon films deposited by a cathodic-arc activated deposition process. Thin Solid Film. 2002, 420, 241–247. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, L.; Shao, W.; Chen, Z.; Wang, S.; Xing, X.; Yang, Q. Mechanical and tribological behaviors of Ti-DLC films deposited on 304 stainless steel: Exploration with Ti doping from micro to macro. Diam. Relat. Mater. 2020, 107, 107870. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, M.; Yang, Y.; Zhang, Y.; Yan, F.; Li, H. Excellent mechanical, tribological and anti-corrosive performance of novel Ti-DLC nanocomposite thin films prepared via magnetron sputtering method. Carbon 2019, 151, 136–147. [Google Scholar] [CrossRef]

- Dhandapani, V.S.; Kang, K.M.; Seo, K.J.; Kim, C.L.; Kim, D.E. Enhancement of tribological properties of DLC by incorporation of amorphous titanium using magnetron sputtering process. Ceram. Int. 2019, 45, 11971–11981. [Google Scholar] [CrossRef]

- Bootkul, D.; Saenphinit, N.; Supsermpol, B.; Aramwit, C.; Intarasiri, S. Synthesis of Ti-doped DLC film on SS304 steels by Filtered Cathodic Vacuum Arc (FCVA) technique for tribological improvement. Appl. Surf. Sci. 2014, 310, 293–299. [Google Scholar] [CrossRef]

- Cui, L.; Guoqing, L.; Wenwu, C.; Zongxin, M.; Chengwu, Z.; Liang, W. The study of doped DLC films by Ti ion implantation. Thin Solid Film. 2005, 475, 279–282. [Google Scholar] [CrossRef]

- Pauschitz, A.; Kvasnica, S.; Jisa, R.; Bernardi, J.; Koch, T.; Roy, M. Tribological behaviour of Ti containing nanocomposite DLC films under milli-Newton load range. Diam. Relat. Mater. 2008, 17, 2010–2018. [Google Scholar] [CrossRef]

- Ma, G.; Gong, S.; Lin, G.; Zhang, L.; Sun, G. A study of structure and properties of Ti-doped DLC film by reactive magnetron sputtering with ion implantation. Appl. Surf. Sci. 2012, 258, 3045–3050. [Google Scholar] [CrossRef]

- Weicheng, K.; Zhou, Y.; Jun, H. Effect of carburizing treatment on microstructural, mechanical and tribological performances of Cr doped DLC coating deposited on Ti6Al4V alloy. Ceram. Int. 2021, 47, 34425–34436. [Google Scholar] [CrossRef]

- Li, A.; Chen, Q.; Wu, G.; Wang, Y.; Lu, Z.; Zhang, G. Probing the lubrication mechanism of multilayered Si-DLC coatings in water and air environments. Diam. Relat. Mater. 2020, 105, 107772. [Google Scholar] [CrossRef]

- Cloutier, M.; Harnagea, C.; Hale, P.; Seddiki, O.; Rosei, F.; Mantovani, D. Long-term stability of hydrogenated DLC coatings: Effects of aging on the structural, chemical and mechanical properties. Diam. Relat. Mater. 2014, 48, 65–72. [Google Scholar] [CrossRef]

- Robertson, J.; O’reilly, E.P. Electronic and atomic structure of amorphous carbon. Phys. Rev. B 2014, 35, 2946. [Google Scholar] [CrossRef]

- Gershman, I.S.; Bushe, N.A. Elements of Thermodynamics and Self-Organization during Friction. In Self-Organization during Friction. Advanced Surface Engineered Materials and Systems Designed; Fox-Rabinovich, G., Totten, G.E., Eds.; Taylor & Francis Group: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2006; Chapter 2; pp. 13–58. [Google Scholar] [CrossRef]

- Klamecki, B.E. Energy dissipation in sliding. Wear 1982, 77, 115–128. [Google Scholar] [CrossRef]

- Klamecki, B.E. An entropy-based model of plastic deformation energy dissipation in sliding. Wear 1984, 96, 319–329. [Google Scholar] [CrossRef]

- Klamecki, B.E. A thermodynamic model of friction. Wear 1980, 63, 113–120. [Google Scholar] [CrossRef]

- Klamecki, B.E. Wear—An entropy production model. Wear 1980, 58, 325–330. [Google Scholar] [CrossRef]

- Gershman, I.S.; Bushe, N.A. Realization of dissipative self-organization of friction surface in tribosystems. J. Frict. Wear 1995, 16, 61–70. [Google Scholar]

- Kondepudi, D.; Prigogine, I. Modern Thermodynamics: From Heat Engines to Dissipative Structures; John Wiley & Sons: New York, NY, USA, 1999. [Google Scholar]

- Gershman, I.S.; Gershman, E.I. Catalytic effect during friction. J. Frict. Wear 2011, 32, 431–436. [Google Scholar] [CrossRef]

- Heinecke, G. Tribochemistry; Akademie-Verlag: Berlin, Germany, 1984. [Google Scholar] [CrossRef]

- Ashkinazi, E.E.; Ral’chenko, V.G.; Frolov, V.D.; Basov, A.A.; Konov, V.I.; Gershman, I.S. Friction of CVD diamond on intermetallide. J. Frict. Wear 2008, 29, 277–281. [Google Scholar] [CrossRef]

- Lamprou, D.A.; Smith, J.R.; Nevell, T.G.; Barbu, E.; Stone, C.; Willis, C.R.; Tsibouklis, J. A comparative study of surface energy data from atomic force microscopy and from contact angle goniometry. Appl. Surf. Sci. 2010, 256, 5082–5087. [Google Scholar] [CrossRef] [Green Version]

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design, 10th ed.; McGraw-Hill Education: New York, NY, USA, 2014; p. 1109. [Google Scholar]

- Wu, M.; Tian, X.; Li, M.; Gong, C.; Wei, R. Effect of additional sample bias in Meshed Plasma Immersion Ion Deposition (MPIID) on microstructural, surface and mechanical properties of Si-DLC films. Appl. Surf. Sci. 2016, 376, 26–33. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).