Wire Electrical Discharge Machining—A Review

Abstract

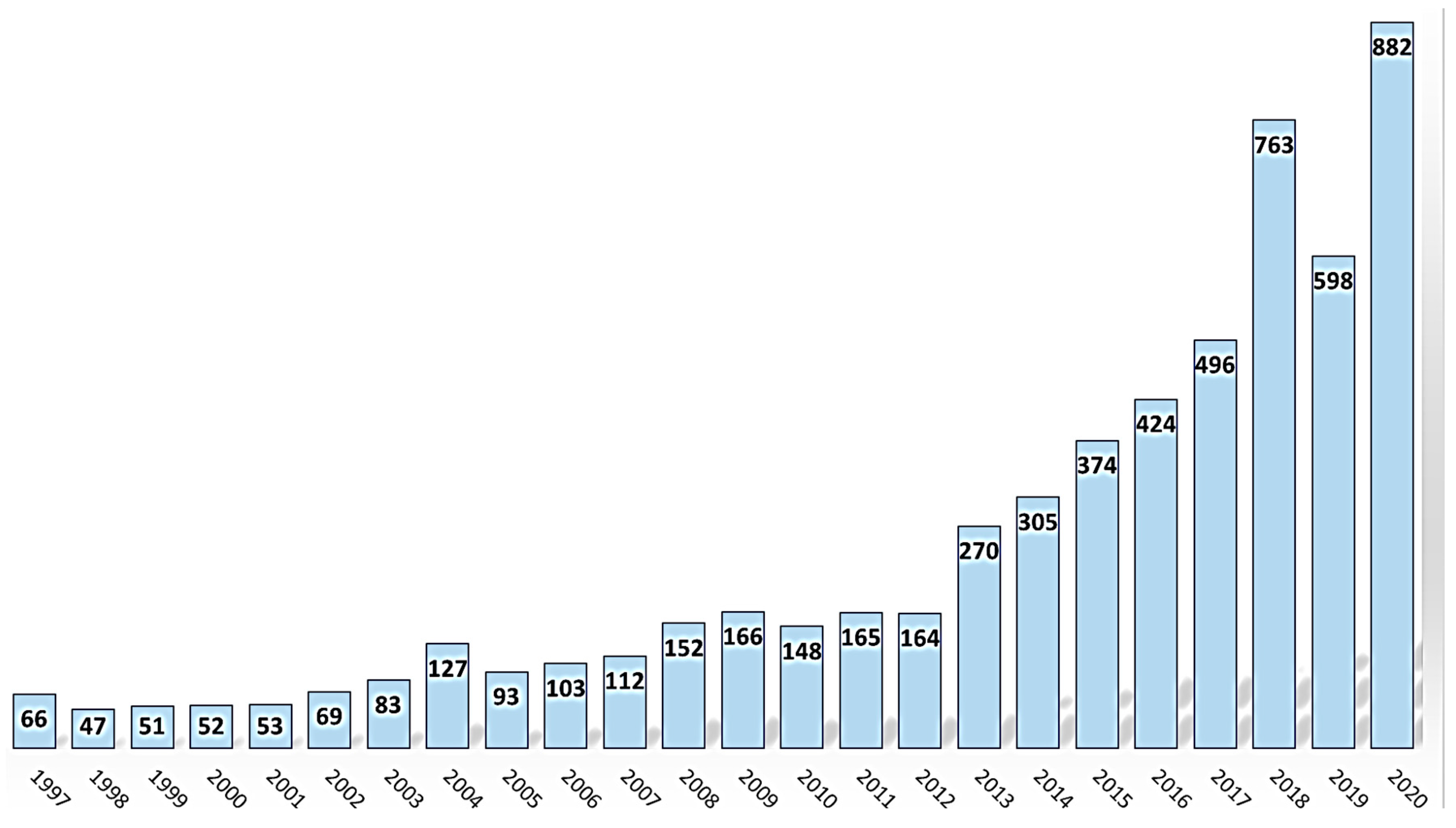

1. Introduction

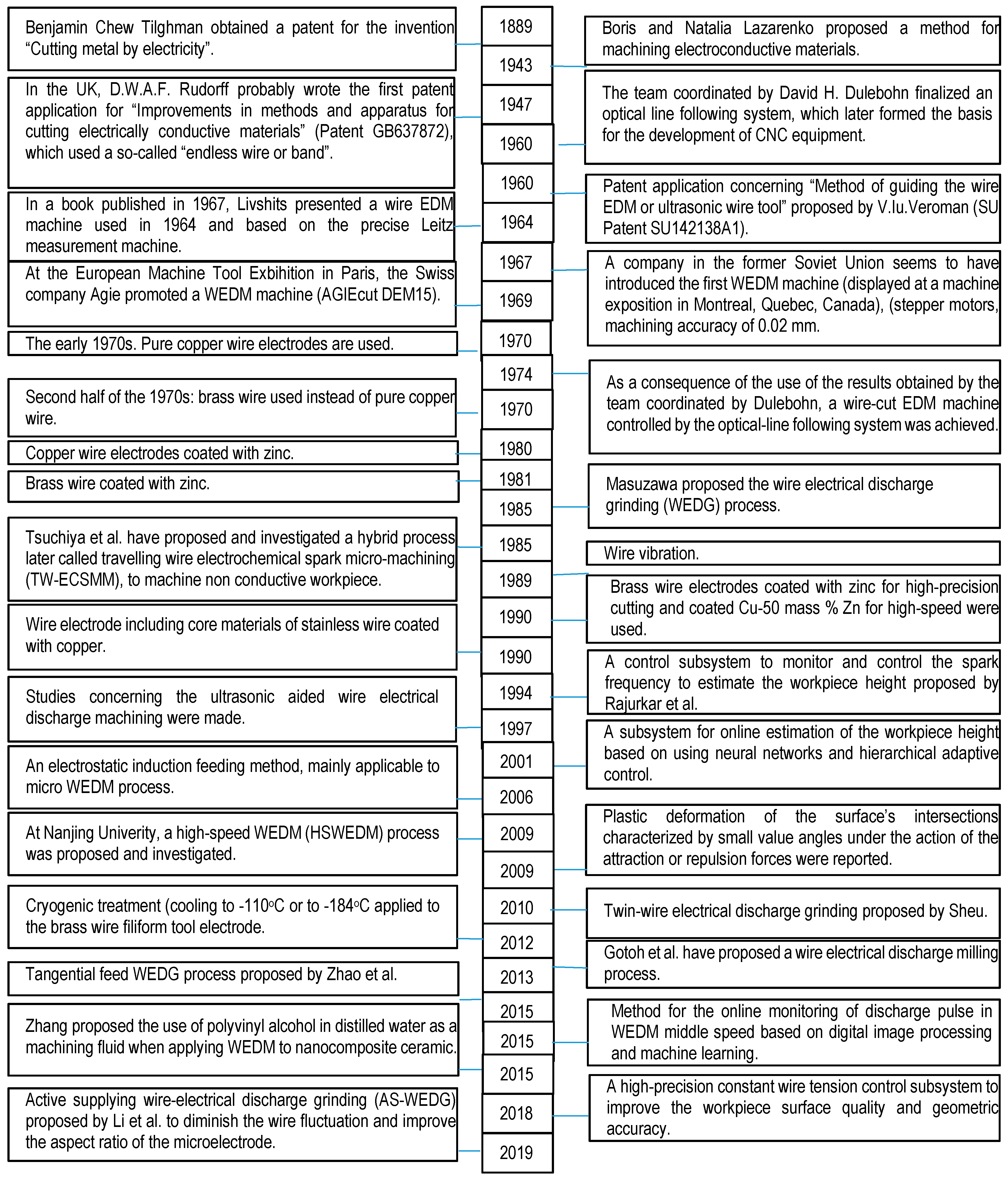

2. Essential Aspects of the WEDM Processes

3. Evolution of WEDM

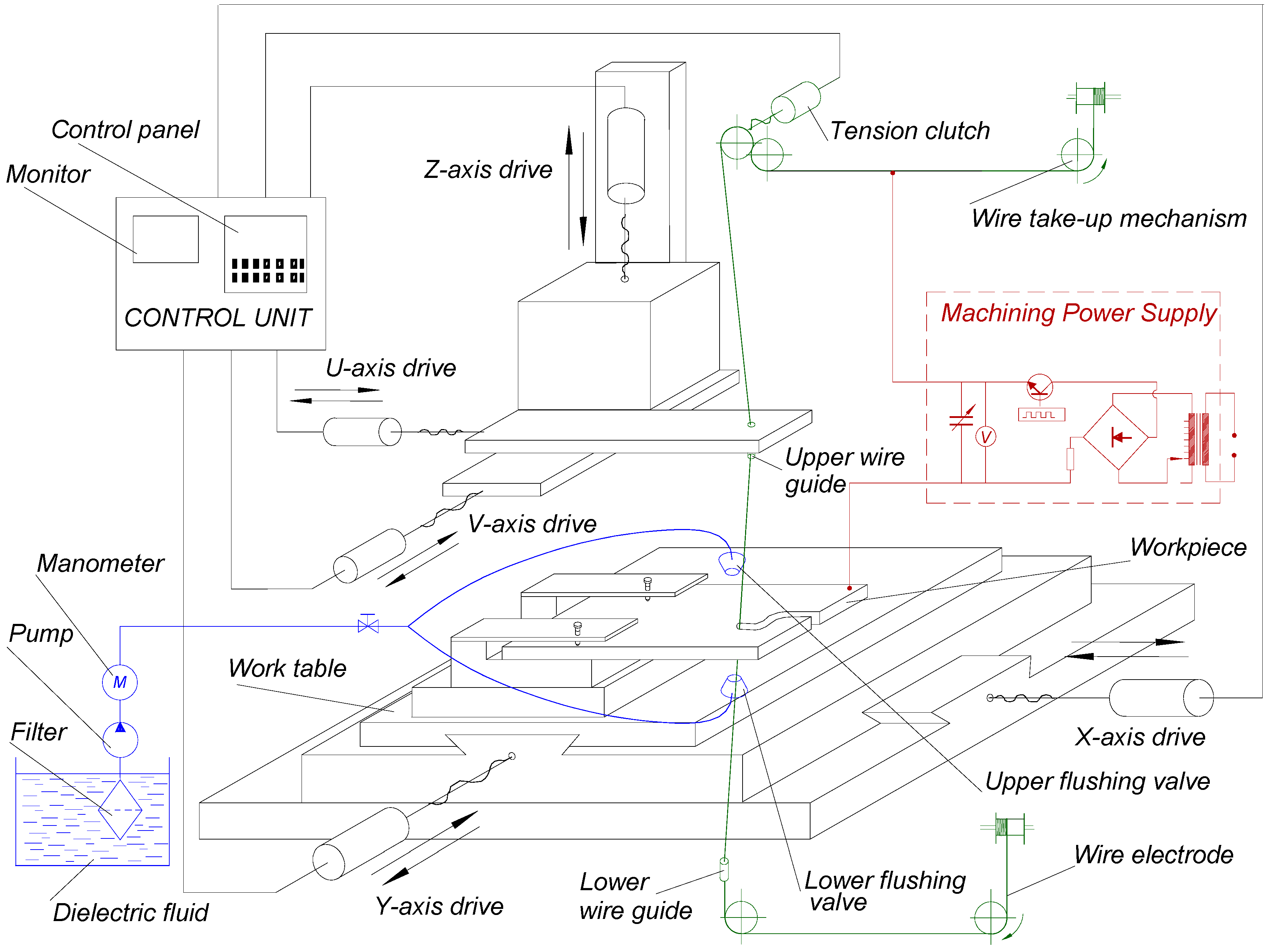

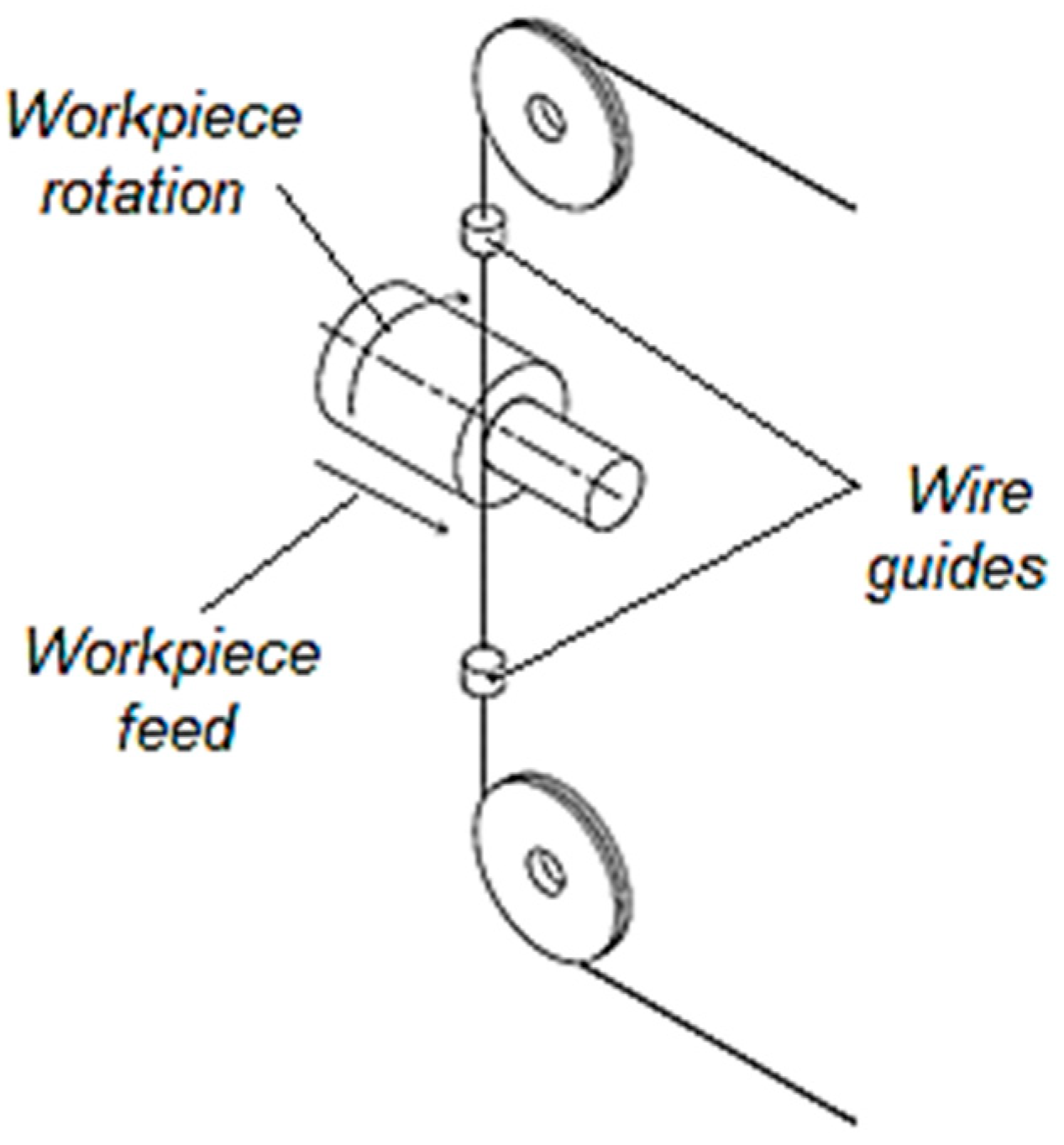

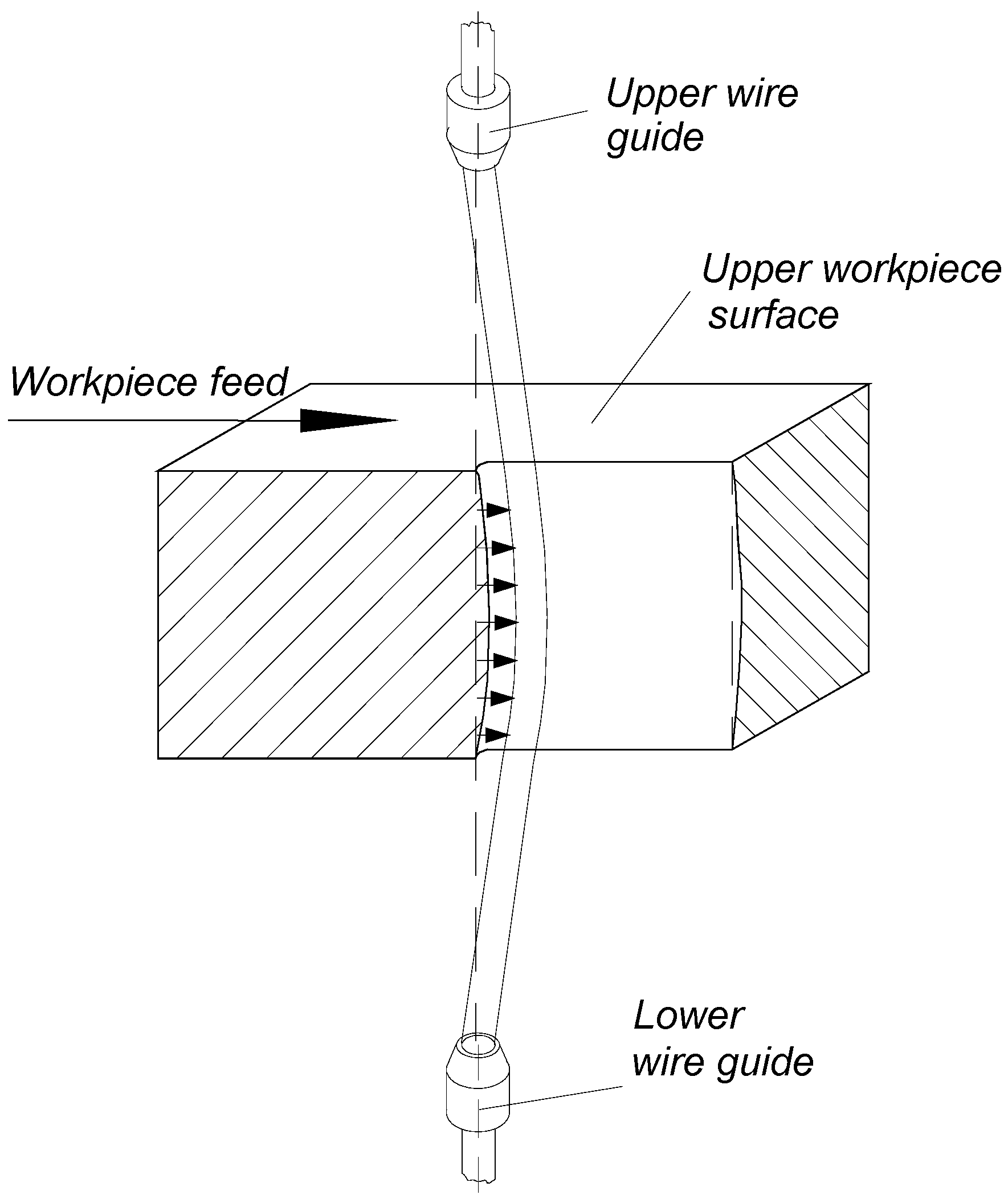

4. WEDM Equipment

- Submerged type WEDM, when the wire electrode and the workpiece are immersed in the dielectric fluid;

- Non-submerged (co-axial flushing) type WEDM, when the dielectric fluid reaches the space around the wire electrode in the machining zone from the top and the bottom nozzles;

- Dry and near dry WEDM, when the dielectric liquid is replaced with a minimum amount of atmospheric gas or other gas. In this case, the ecological requirements are better fulfilled.

5. Improvements in the WEDM Processes and Equipment

5.1. General Classification

- -

- Improvements regarding the machining equipment and its operation;

- -

- The emergence of hybrid machining processes, with the adaptation of machining equipment to the requirements of such processes;

- -

- Improvements of the geometric wire shape and chemical compositions of the wire materials;

- -

- The use of the WEDM process for new materials and including the improvement of the characteristics of the surfaces processed as a result of the application of WEDM;

- -

- Identifying the optimal conditions for the development of the WEDM process.

5.2. Improvements Regarding the Machining Equipment and Its Operation

5.3. Hybrid WEDM Processes

5.4. Improvements Concerning the Wire Tool Electrode Material and Geometrical Characteristics

5.5. Improvements of the Usage Properties of the Parts Obtained by WEDM, Including by Using New Parts Materials

- -

- Conductive ceramics, characterized by electrical conductivity of at least 10–2 ohms.cm (titanium nitride TiN, titanium diboride TiN2) and which, with some small difficulties, can be processed by WEDM;

- -

- Nonconductive ceramics: for such materials, a so-called assisting electrode method was considered. There must be at least a thin conductive layer on the workpiece’s surface or immediately near this surface [131,132]. Under the action of high temperature developed by the electric discharges between the wire electrode and the conductive layer, cracks are developed, and this effect can contribute to the removal of material from the workpiece. The dielectric hydrocarbons can also be cracked. Some of the resulting conductive carbon compounds could adhere to the surface of the workpiece, ensuring a certain continuity of the conductive layer. Another WEDM way of non-conductive ceramics was based on an electrolyte in a hybrid WEDM process;

- -

- Semiconductive ceramics, whose WEDM process can take into account the version applicable in the case of conductive ceramics (with lower machining performance) or the one usable in nonconductive ceramics.

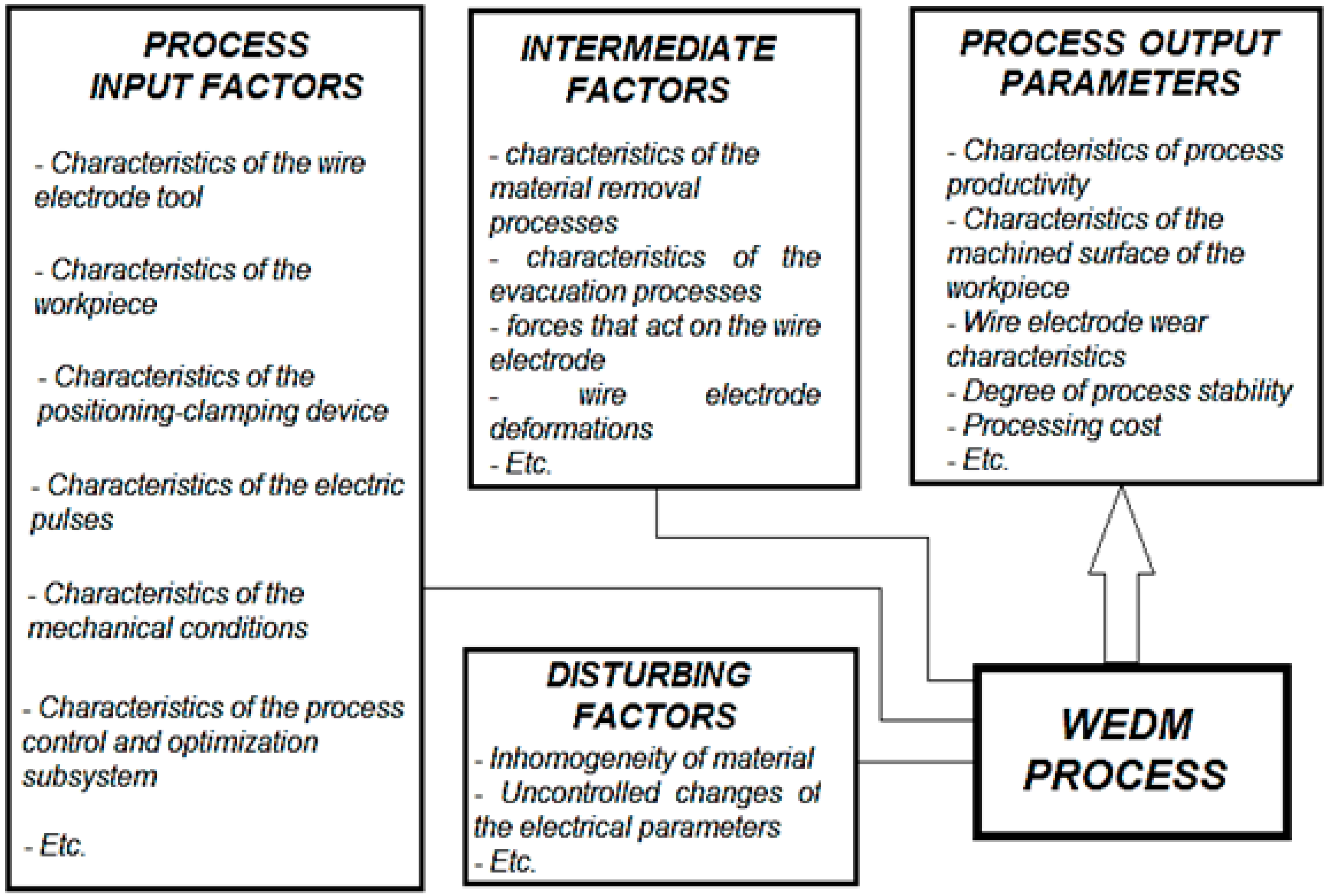

6. Input Factors and Output Parameters for WEDM

- -

- - Characteristics of the wire electrode tool: material, the chemical composition of wire electrode tool, resistivity, specific heat, thermal conductivity, melting temperature, latent heat of melting, vaporization temperature, latent heat of vaporization, specific mass, tensile strength, wire diameter, the shape of the wire (cross-section, structure), positioning accuracy of EF (angular positioning, coordinate error in the horizontal plane, etc.);

- -

- - Characteristics of the workpiece: thickness, material, chemical composition, electrical conductivity, specific heat, thermal conductivity, melting temperature, the accuracy of workpiece positioning, etc.;

- -

- Characteristics of the positioning-clamping device: positioning-clamping accuracy, clamping force, etc.;

- -

- Characteristics of the dielectric circulation subsystem: electrical conductivity of the dielectric liquid, chemical composition, impurities concentration, liquid viscosity, surface tension, specific heat, temperature, flow direction through the working gap, dielectric pressure, inlet flow, relative position of the electrodes pair to dielectric flow;

- -

- Characteristics of the electric pulses: voltage pulses shape, frequency and filling factor, pulse on-time, pulse off-time, cycle time, discharge frequency, peak or average voltage, peak or average current, pulse energy, electrodes polarity;

- -

- Characteristics of the mechanical conditions: stability of the wire electrode feed subsystem, sensitivity and reaction speed, the adjustment range of the wire electrode feed subsystem, running speed of wire electrode, axial tension of the wire electrode, distance between the guides of the wire electrode, the initial inclination of the wire electrode;

- -

- Characteristics of the process control and optimization subsystem: possibilities for the monitoring, adaptation, and optimization of parameters.

- -

- Characteristics of the material removal processes: the working gap size (front and lateral), kerf width, technological gap shape (kerf size in the upper workpiece zone, at the of workpiece bottom, at mid-height of workpiece, convexity, taper angle), length of the free path of particles expelled from the crater, percentage of pulse energy received by the working environment, by the workpiece material, the volume of removed material from the wire electrode tool by a single discharge, average depth of the crater in the electrode tool surface and in the workpiece surface, local average density of spurious pulses, and short-circuited pulses, local, average current intensity;

- -

- Characteristics of the evacuation processes: flow rate of solid waste and of gaseous waste from the gap, local density of erosive particles, average speed and pressure of shock waves, flow rate of erosive particles formation;

- -

- Forces that act on the wire electrode: electrostatic forces, electromagnetic forces, hydrostatic forces, hydrodynamic forces, forces due to the pressure in the plasma column, forces due to the pressure of the gas bubble;

- -

- Wire electrode deformations: dimensional deformation, vibration, position in the two directions, properties, structure.

- -

- Characteristics of process productivity: productivity, cutting speed evaluated in mm/min or mm2/min, totally removed volume, the total length of the machined kerf;

- -

- Characteristics of the machined surface of the workpiece: the physicochemical appearance of the machined surface (chemical composition, structure, properties), geometric appearance (dimensional accuracy, shape and position accuracy, maximum shape deviation, the roughness of rounding radii of the edges of the machined surfaces) [135];

- -

- Wire electrode wear characteristics: wire electrode wear rate, relative volume wear, specific consumption of wire electrode;

- -

- Degree of process stability;

- -

- Processing time: total working time, specific working time;

- -

- Processing cost: specific cost of used wire electrode, total specific machining cost.

7. Influence of Different Factors on the Values of the Parameters of Technological Interest in the Case of WEDM

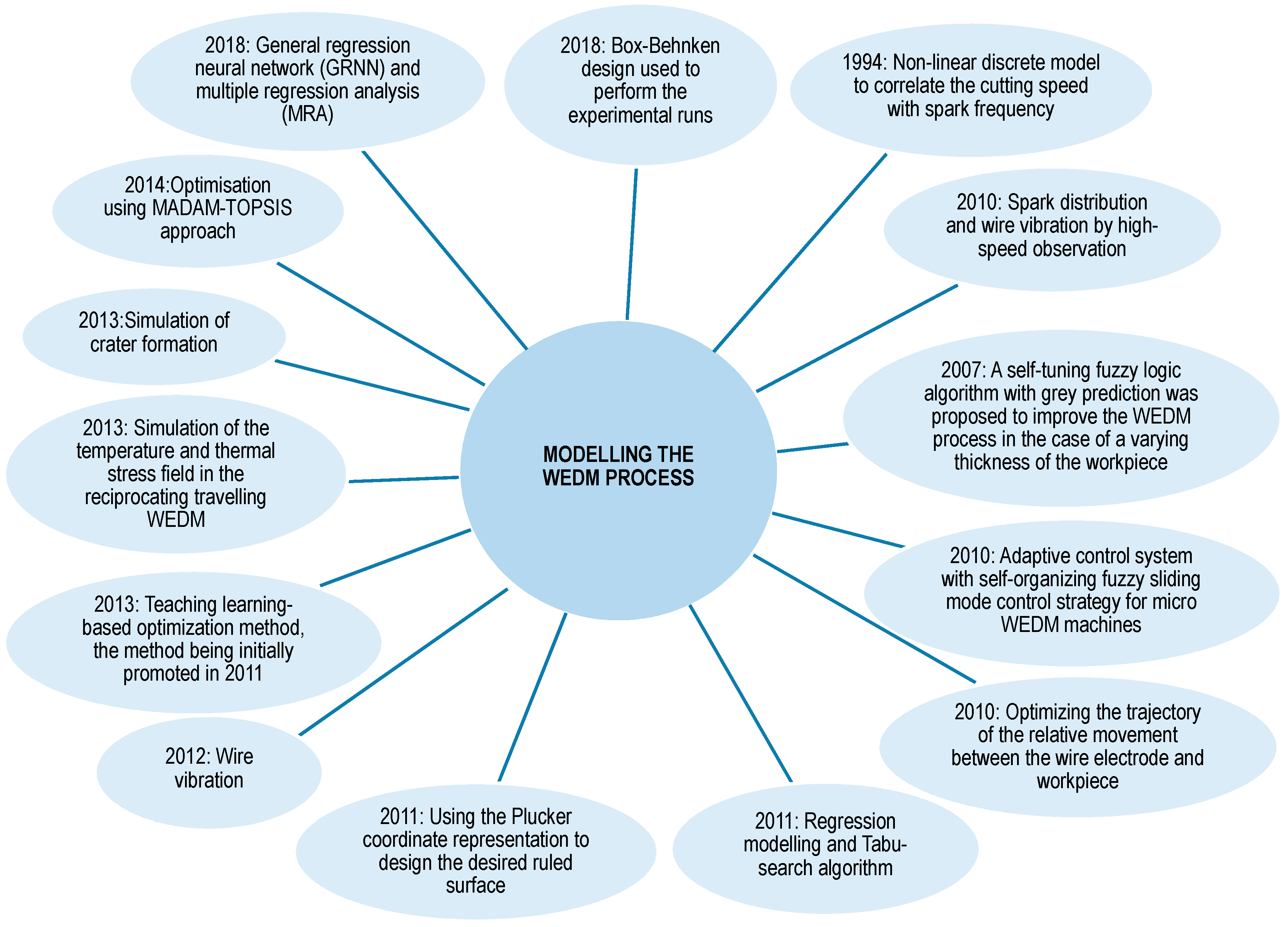

8. Modeling and Optimizing the WEDM Process

- -

- -

- -

- -

- -

- Grey-based response surface methodology [87];

- -

- Grey relational analysis [148];

- -

- Grey-fuzzy methodology [98];

- -

- Response surface methodology;

- -

- Response surface methodology coupled with grey relational analysis–Taguchi technique [152];

- -

- -

- Genetic algorithms [47];

- -

- Non-dominated sorting genetic algorithm approach and Pareto method [138];

- -

- Artificial neural networks [154];

- -

- -

- Analysis of the fractal dimension of the surface obtained by WEDM [158], etc.

9. Evolution Trends of WEDM Processes

10. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Balan, A.S.S.; Giridharan, A. A progress review in wire electrical discharge machining process. Int. J. Autom. Mech. Eng. 2017, 14, 4097–4124. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, V.; Kumar, J. A review on the state of the art in wire electric discharge machining (WEDM) process. Int. J. Mech. Eng. Res. Dev. 2011, 1, 23–39. [Google Scholar]

- Maher, I.; Sarhan, A.A.D.; Hamdi, M. Review of improvements in wire electrode properties for longer working time and utilization in wire EDM machining. Int. J. Adv. Manuf. Technol. 2015, 76, 329–351. [Google Scholar]

- Vala, U.H.; Sama, M.R. A review on different effects on flushing of dielectric fluid in WEDM. Int. J. Adv. Res. Sci. Eng. 2017, 6, 37–44. [Google Scholar]

- Bai, J.; Huang, H.; Lu, Z.; Feng, Y.; Guo, Y. Trajectory planning for the four axis WEDM machine and its implementation. In Proceedings of the 16th International Symposium on Electromachining, Shanghai, China, 19–23 April 2010; pp. 271–274. [Google Scholar]

- Kumar, S.; Mitra, B.; Dhanabalan, S. The state of Art: Revolutionary 5-Axis CNC Wire EDM & its recent developments. Int. J. Manag. IT Eng. 2018, 8, 328–353. [Google Scholar]

- Bergs, T.; Tombul, U.; Herrig, T.; Klink, A.; Welling, D. Influence of an additional indexing rotary axis on wire electrical discharge machining performance for the automated manufacture of fir tree slots. J. Eng. Gas Turbines Power 2020, 142, 091005. [Google Scholar] [CrossRef]

- Meena, K.I.; Manna, A.; Banwait, S.S. Effect of wire feed rate and wire tension during machining of PR-AL-SiC-MMC’s by WEDM. Eur. J. Eng. Technol. 2013, 1, 7–13. [Google Scholar]

- Okada, A.; Uno, Y.; Onoda, S.; Habib, S. Computational fluid dynamics analysis of working fluid flow and debris movement in wire EDMed kerf. CIRP Ann. 2009, 58, 209–212. [Google Scholar] [CrossRef]

- Zhang, C. Effect of machining fluid on the process performance of wire electrical discharge machining of nanocomposite ceramic. In Proceedings of the 2nd International Conference on Mechatronics and Mechanical Engineering (ICMME 2015), Singapore, 15–16 September 2015; Volume 34. [Google Scholar]

- Okada, A.; Uno, Y.; Nakazawa, M.; Yamauchi, T. Evaluations of spark distribution and wire vibration in wire EDM by high-speed observation. CIRP Ann. Manuf. Technol. 2010, 59, 231–234. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.; Xia, L.; Wang, W. Interelectrode discharge mechanism in high-speed wire electrical discharge machining. Int. J. Adv. Manuf. Technol. 2016, 84, 2637–2647. [Google Scholar]

- Prakash, C.P.S. A Study on the Machining Characteristic in Wire EDM Process. Ph.D. Thesis, Dr. MGR Educational and Research Institute, Chennai, India, 2008. [Google Scholar]

- Maher, I.A.S. Development of a New Performance Criteria for Higher Wire-Electrical Discharge Machining Performance Considering the Ecological and Economical Aspects. Ph.D. Thesis, University of Malaya, Kuala Lumpur, Malaysia, 2016. [Google Scholar]

- Schumacher, B.M. After 60 years of EDM; the discharge process remains still disputed. J. Mater. Process. Technol. 2004, 149, 376–381. [Google Scholar] [CrossRef]

- Jameson, E.C. Electrical Discharge Machining; Society of Manufacturing Engineers: Dearben, MI, USA, 2001; pp. 8–17. [Google Scholar]

- Jia, J.-Y.; Wang, Y.-Q.; Yang, S.-Q.; Li, W.-H. Study of the effects of important factors on the diameter accuracy of micro-shafts fabricated by TMTF-WEDG. Int. J. Adv. Manuf. Technol. 2020, 108, 3001–3020. [Google Scholar] [CrossRef]

- Tsuchiya, H.; Inoue, T.; Miyazaki, M. Wire electrochemical discharge machining of glass and ceramics. J. Jpn. Soc. Precis. Eng. 1985, 19, 73–74. [Google Scholar]

- Guo, Z.N.; Lee, T.C.; Yue, T.M.; Lau, W.S. Study on the machining mechanism of WEDM with ultrasonic vibration of the wire. J. Mater. Process. Technol. 1997, 69, 212–221. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Wang, W.M.; McGeough, J.A. WEDM identification and adaptive control for variable-height components. CIRP Ann. 1994, 43, 199–202. [Google Scholar] [CrossRef]

- Hanada, M.; Kunieda, M.; Araie, I. Development of micro EDM using electrostatic induction feeding. J. Jpn. Soc. Precis. Eng. 2006, 72, 636–640. [Google Scholar] [CrossRef]

- Yan, M.T.; Liao, Y.-S.; Chang, C.C. On-line estimation of workpiece height by using neural networks and hierarchical adaptive control of WEDM. Int. J. Adv. Manuf. Technol. 2001, 18, 884–891. [Google Scholar] [CrossRef]

- Dodun, O.; Gonçalves-Coelho, A.; Slătineanu, L.; Nagîţ, G. Using wire electrical discharge machining for improved corner cutting accuracy of thin parts. Int. J. Adv. Manuf. Technol. 2009, 41, 858–864. [Google Scholar] [CrossRef]

- Wang, W.; Liu, Z.D.; Tian, Z.J.; Huang, Y.H.; Liu, Z.X. High efficiency slicing of low resistance silicon ingot by wire electrolytic-spark hybrid machining. J. Mater. Process Technol. 2009, 209, 3149–3155. [Google Scholar] [CrossRef]

- Kapoor, J.; Kamba, J.S.; Sehijpal, S. Effect of cryogenic treated brass wire electrode on material removal rate in wire electrical discharge machining. Proc. IMechE C J. Mech. Eng. Sci. 2012, 226, 2750–2758. [Google Scholar] [CrossRef]

- Gotoh, H.; Tani, T.; Okada, M.; Goto, A.; Masuzawa, T.; Mohri, N. Wire electrical discharge milling using a wire guide with reciprocating rotation. Procedia CIRP 2013, 6, 199–202. [Google Scholar] [CrossRef]

- Zhang, C. Effect of wire electrical discharge machining (WEDM) parameters on surface integrity of nanocomposite ceramics. Ceram. Int. 2014, 40, 9657–9662. [Google Scholar] [CrossRef]

- Zhang, Z.; Ming, W.; Zhang, G.; Huang, Y.; Wen, X.; Huang, H. A new method for on-line monitoring discharge pulse in WEDM-MS process. Int. J. Adv. Manuf. Technol. 2015, 81, 1403–1418. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, G.; Yan, H. A high-precision constant wire tension control system for improving workpiece surface quality and geometric accuracy in WEDM. Precis. Eng. 2018, 54, 51–59. [Google Scholar] [CrossRef]

- Aspinwall, D.K.; Soo, S.L.; Berrisford, A.E.; Walder, G. Workpiece surface roughness and integrity after WEDM of Ti-6Al-4V and Inconel 718 using minimum damage generator technology. CIRP Ann. 2008, 57, 187–190. [Google Scholar] [CrossRef]

- Antar, M.T.; Soo, S.L.; Aspinwall, D.K.; Cuttell, M.; Perez, M.; Winn, A.J. WEDM of aerospace alloys using ‘clean cut’ generator technology. In Proceedings of the 16th International Symposium on Electromachining, Non-traditional Machining Society of CMES, Shanghai, China, 19–23 April 2010; pp. 285–290. [Google Scholar]

- Lee, W.M.; Liao, Y.S. Adaptive control of the WEDM process using a self-tuning fuzzy logic algorithm with grey prediction. Int. J. Adv. Manuf. Technol. 2007, 34, 527–537. [Google Scholar] [CrossRef]

- Conde, A.; Sánchez, J.A.; Plaza, S.; Olivenza, M.; Ramos, J.M. An industrial system for estimation of workpiece height in WEDM. Procedia Eng. 2015, 132, 647–654. [Google Scholar] [CrossRef][Green Version]

- Jia, Y.; Kim, B.S.; Hu, D.J. Parametric study on near-dry wire electrodischarge machining of polycrystalline diamond-coated tungsten carbide material. Proc. IMechE B J. Eng. Manuf. 2010, 224, 185–193. [Google Scholar] [CrossRef]

- Boopathi, S.; Sivakumar, K. Experimental comparative study of near-dry wire-cut electrical discharge machining (WEDM). Eur. J. Sci. Res. 2012, 75, 472–481. [Google Scholar]

- George, J.; Manu, R.; Mathew, J. Multi‑objective optimization of roundness, cylindricity and areal surface roughness of Inconel 825 using TLBO method in wire electrical discharge turning (WEDT) process. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 377. [Google Scholar] [CrossRef]

- Li, Z.; Bai, J.; Cao, Y.; Wang, Y.; Zhu, G. Fabrication of microelectrode with large aspect ratio and precision machining of micro-hole array by micro-EDM. J. Mater. Process. Technol. 2019, 268, 70–79. [Google Scholar]

- Bai, H.; Gao, F.; Shen, Y.; Zhu, C.; Wang, P. Forming method and experimental research on wire cutting of twist drill cone flank. Int. J. Adv. Manuf. Technol. 2019, 103, 4815–4823. [Google Scholar]

- Hernández, C.; Gella-Marín, R.M.; Huertas-Talón, J.-L.; Efkolidis, N.; Kyratsis, P. WEDM manufacturing method for noncircular gears, using CAD/CAM software. Stroj. Vestn. J. Mech. Eng. 2016, 62, 137–144. [Google Scholar]

- Masuzawa, T.; Tonshoff, H.K. Three-dimensional micromachining by machine tools. Ann. CIRP 1997, 46, 621–628. [Google Scholar]

- Liao, Y.S.; Chen, S.T.; Lin, C.S. Development of a high precision tabletop versatile CNC wire-EDM for making intricate micro parts. J. Micromech. Microeng. 2005, 15, 245–253. [Google Scholar]

- Di, S.; Chu, X.; Wei, D.; Wang, Z.; Chi, G.; Liu, Y. Analysis of kerf width in micro-WEDM. Int. J. Mach. Tool. Manuf. 2009, 49, 788–792. [Google Scholar]

- Gohil, V.; Puri, I.M. Turning by electrical discharge machining: A review. Proc. IMechE B J. Eng. Manuf. 2017, 231, 195–208. [Google Scholar]

- Patel, H.; Patel, D.M. Design a new wire cut EDM machine for turning operation. Int. J. Adv. Technol. Eng. Explor. 2019, 6, 84–91. [Google Scholar]

- Srivastava, A.K.; Nag, A.; Dixit, A.R.; Hloch, S.; Tiwari, S.; Scucka, J.; Pachauri, P. Surface integrity in wire-EDM tangential turning of in situ hybrid metal matrix composite A359/B4C/Al2O3. Sci. Eng. Compos. Mater. 2019, 26, 122–133. [Google Scholar]

- Rajurkar, K.P.; Wang, W.M. Thermal modeling and on-line monitoring of wire-EDM. J. Mater. Process. Technol. 1993, 38, 417–430. [Google Scholar]

- Li, C.J.; Bai, J.C.; Guo, Y.F.; Lu, Z.; Ding, J. Monitoring technology of gap discharge status based on floating threshold for WEDM. In Proceedings of the 16th International Symposium on Electromachining, Non-traditional Machining Society of CMES, Shanghai, China, 19–23 April 2010; pp. 271–274. [Google Scholar]

- Klocke, F.; Welling, D.; Klink, A.; Perez, R. Quality assessment through in-process monitoring of wire-EDM for fir tree slot production. Procedia CIRP 2014, 24, 97–102. [Google Scholar]

- Kumar, S.S.; Uthayakumar, M.; Kumaran, S.T.; Parameswaran, P.; Haneef, T.K.; Mukhopadhyay, C.K.; Rao, B.P.C. Performance monitoring of WEDM using online acoustic emission technique. Silicon 2018, 10, 2635–2642. [Google Scholar] [CrossRef]

- Yang, F.; Pan, C.; Shi, Y. Fabricating micro-texture on surface of cutting tool based on NC WEDM technology. IOP Conf. Ser. Earth Environ. Sci. 2020, 440, 022084. [Google Scholar]

- Zhang, J.; Li, Q.S.; Zhang, H.; Sui, Y.; Yang, H. Investigation of micro square structure fabrication by applying textured cutting tool in WEDM. Micromachines 2015, 6, 1427–1434. [Google Scholar]

- Klocke, F.; Kamenzky, S.; Dieckmann, J.; Klink, A. Investigations on the Influence of Powder Suspended Dielectrics in Wire-EDM. In Proceedings of the 16th International Symposium on Electromachining, Shanghai, China, 19–23 April 2010; pp. 279–284. [Google Scholar]

- Kumar, V.; Jangra, K.K.; Kumar, V. An experimental study on trim cutting operation using metal powder mixed dielectric in WEDM of Nimonic-90. Int. J. Ind. Eng. Comput. 2016, 7, 135–146. [Google Scholar]

- Chakraborty, S.; Mitra, S.; Bose, D. Modeling & analysis of B4C powder mixed wire EDM process for improving performance criteria of Ti6Al4V. IOP Conf. Ser. Mater. Sci. Eng. 2019, 653, 012006. [Google Scholar]

- Osypenko, V.; Plakhotnyi, O.; Timchenko, O. Surface forming features of new combined wire electrical discharge-electrochemical machining technology. Noncon. Technol. Rev. 2019, 23, 52–57. [Google Scholar]

- Ghiculescu, D.; Marinescu, N.I.; Nanu, S. Equipment for ultrasonic aiding of wire electrodischarge machining. Acad. J. Manuf. Eng. 2011, 9, 18–23. [Google Scholar]

- Kuo, K.-Y.; Wu, K.-L.; Yang, C.-K.; Yan, B.-H. Wire electrochemical discharge machining (WECDM) of quartz glass with titrated electrolyte flow. Int. J. Mach. Tool. Manuf. 2013, 72, 50–57. [Google Scholar]

- Wang, Y.; Wang, H.; Zhang, Y.; He, X.; Wang, Z.; Chi, G.; Chen, X.; Song, M. Micro electrochemical machining of array micro-grooves using in-situ disk electrode fabricated by micro-WEDM. Micromachines 2020, 11, 66. [Google Scholar] [CrossRef]

- Wu, X.; Li, S. Experimental investigations of a hybrid machining combining wire electrical discharge machining (WEDM) and fixed abrasive wire saw. Int. J. Adv. Manuf. Technol. 2018, 95, 2613–2623. [Google Scholar] [CrossRef]

- Ho, K.H.; Newman, S.T.; Rahimifard, S.; Allen, R.D. State of the art in wire electrical discharge machining (WEDM). Int. J. Mach. Tool. Manuf. 2004, 44, 1247–1259. [Google Scholar] [CrossRef]

- Tani, T.; Fukuzawa, Y.; Mohri, N.; Saito, N.; Okada, M. Machining phenomena in wEDM of insulating ceramics. J. Mater. Process. Technol. 2004, 149, 124–128. [Google Scholar] [CrossRef]

- Wang, J.; Jia, Z.; Guo, Y.B. Shape-cutting of quartz glass by spark discharge-assisted diamond wire sawing. J. Manuf. Proc. 2018, 34, 131–139. [Google Scholar] [CrossRef]

- Chu, W.-S.; Kim, C.-S.; Lee, H.-T.; Choi, J.-O.; Park, J.-I.; Song, J.-H.; Jang, K.-H.; Ahn, S.-H. Hybrid manufacturing in micro/nano scale: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 75–92. [Google Scholar] [CrossRef]

- Oßwald, K.; Lochmahr, I.; Schulze, H.-P.; Kröning, O. Automated Analysis of Pulse Types in High Speed Wire EDM. Procedia CIRP 2018, 68, 796–801. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Zhang, G.; Li, W. Reduction of energy consumption and thermal deformation in WEDM by magnetic field assisted technology. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 7, 391–404. [Google Scholar] [CrossRef]

- Yan, H.; Bakadiasa, K.D.; Chen, Z.; Yan, Z.; Zhou, H.; Han, F. Attainment of high corner accuracy for thin-walled sharp-corner part by WEDM based on magnetic field-assisted method and parameter optimization. Int. J. Adv. Manuf. Technol. 2020, 106, 4845–4857. [Google Scholar] [CrossRef]

- Menzies, I.; Koshy, P. Assessment of abrasion-assisted material removal in wire EDM. CIRP Ann. Manuf. Tech. 2008, 57, 195–198. [Google Scholar] [CrossRef]

- Sharma, H.; Goyal, K.; Kumar, S. Performance evaluation of cryogenically treated wires during wire electric discharge machining of AISI D3 die tool steel under different cutting environments. Multidiscip. Model. Mater. Struct. 2019, 15, 1318–1336. [Google Scholar] [CrossRef]

- Singh, N.; Kumar, P.; Goyal, K. Experimental investigation of WEDM variables on surface roughness of AISI D3 die steel by using two cryogenically treated different wires. Manuf. Sci. Technol. 2014, 2, 20–25. [Google Scholar]

- Tahir, W.; Jahanzaib, M.; Ahmad, W.; Hussain, S. Surface morphology evaluation of hardened HSLA steel using cryogenic-treated brass wire in WEDM process. Int. J. Adv. Manuf. Technol. 2019, 104, 4445–4455. [Google Scholar] [CrossRef]

- Singh, K.; Singh, S. Performance enhancement of material removal rate by using cryogenic treatment on zinc coated diffused brass wire in wire-cut EDM process. Int. J. Mech. Prod. Eng. 2019, 7, 36–41. [Google Scholar]

- Abyar, H.; Abdullah, A.; Akbarzadeh, A. Analyzing wire deflection errors of WEDM process on small arced corners. J. Manuf. Process 2018, 36, 216–223. [Google Scholar] [CrossRef]

- Abyar, H.; Abdullah, A.; Shafaroud, A.A. Theoretical and experimental analysis of machining errors on small arced corners during WEDM finishing stages. Mach. Sci. Technol. Int. J. 2019, 23, 734–757. [Google Scholar] [CrossRef]

- Liang, J.F.; Tsai, C.F.; Lin, M.H.; Liao, Y.S. Measurement of wire deflection in wire—Cut EDM machining. In Proceedings of the 16th International Symposium on Electromachining, Non-traditional Machining Society of CMES, Shanghai, China, 19–23 April 2010; pp. 223–226. [Google Scholar]

- Feng, X.; Wong, Y.S.; Hong, G.S. Modeling of Micro Wire EDM Process and Wire Vibration. In Proceedings of the 7th International Conference on MicroManufacturing, Evanston, IL, USA, 11–14 March 2012. [Google Scholar]

- Chen, Z.; Huang, Y.; Huang, H.; Zhang, Z.; Zhang, G. Three-dimensional characteristics analysis of the wire-tool vibration considering spatial temperature field and electromagnetic field in WEDM. Int. J. Mach. Tool. Manuf. 2015, 92, 85–96. [Google Scholar] [CrossRef]

- Parthiban, M.; Prabhukarthi, A.; Anthuvan, N. Development of a Mechanistic Model for WEDM. Int. J. Mod. Stud. Mech. Eng. 2019, 5, 1–9. [Google Scholar]

- Straka, L.; Čorný, I.; Pitel, J. Prediction of the geometrical accuracy of the machined surface of the tool steel EN X30WCrV9-3 after electrical discharge machining with CuZn37 wire electrode. Metals 2017, 7, 462. [Google Scholar] [CrossRef]

- Dodun, O.; Slătineanu, L.; Gherman, L. Improving the WEDM process acting on the tool electrode. Procedia Technol. 2014, 12, 427–432. [Google Scholar] [CrossRef][Green Version]

- Kruth, J.; Bleys, P. Measuring residual stress caused by wire EDM of tool steel. Int. J. Elect. Mach. 2000, 5, 23–28. [Google Scholar]

- Sudhakara, D.; Prasanthi, G. Optimization of dimensional deviation: Wire cut EDM of vanadis-4E (powder metallurgical cold worked toolsteel) by Taguchi method. In Proceedings of the 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) IIT Guwahati, Assam, India, 12–14 December 2014. [Google Scholar]

- Shihab, S.K. Optimization of WEDM process parameters for machining of friction-stir-welded 5754 aluminum alloy using Box–Behnken Design of RSM. Arab. J. Sci. Eng. 2018, 43, 5017–5027. [Google Scholar] [CrossRef]

- Che Nor, C.M.H.; Kasim, M.S.; Mohamad, E.; Sulaiman, M.A.; Ito, T. Study on cutting parameter on kerf width using wire electrical discharge machining of Inconel 718. In Proceedings of the Design & Systems Conference, Tokushima, Japan, 17–19 September 2014. [Google Scholar]

- Dabade, U.A.; Karidkar, S.S. Analysis of response variables in WEDM of Inconel 718 using Taguchi technique. Procedia CIRP 2016, 41, 886–891. [Google Scholar] [CrossRef]

- Gamage, J.R.; DeSilva, A.K.M.; Chantzis, D.; Antar, M. Sustainable machining: Process energy optimisation of wire electrodischarge machining of Inconel and titanium superalloys. J. Clean. Prod. 2017, 164, 642–651. [Google Scholar] [CrossRef]

- Klocke, F.; Welling, D.; Klink, A.; Veselovac, D.; Nöthe, T.; Perez, R. Evaluation of advanced wire-EDM capabilities for the manufacture of fir tree slots in Inconel 718. Procedia CIRP 2014, 14, 430–435. [Google Scholar] [CrossRef]

- Kumar, A.; Abhishek, K.; Vivekananda, K.; Maity, K.P. Effect of wire electrode materials on die-corner accuracy for Wire Electrical Discharge Machining (WEDM) of Inconel 718. Mater. Today Proc. 2018, 5, 12641–12648. [Google Scholar] [CrossRef]

- Ramakrishnan, R.; Karunamoorthy, L. Modeling and multi-response optimization of Inconel 718 on machining of CNC WEDM process. J. Mater. Process. Technol. 2008, 207, 343–349. [Google Scholar] [CrossRef]

- Sakar, A. Optimization of Quality Characteristic in Wire Electrical Discharge Machining of Incoloy 800 Using Taguchi Methods; National Institute of Technology: Kurukshetra, India, 2016. [Google Scholar]

- Sharma, P.; Chakradhar, D.; Narendranath, S. Evaluation of WEDM performance characteristics of Inconel 706 for turbine disk application. Mater. Des. 2015, 88, 558–566. [Google Scholar] [CrossRef]

- Saleh, M.; Anwar, S.; El-Tamimi, A.; Mohammed, M.K.; Ahmad, S. Milling microchannels in Monel 400 alloy by wire EDM: An experimental analysis. Micromachines 2020, 11, 469. [Google Scholar] [CrossRef]

- Selvakumar, G.; Sornalatha, G.; Sarkar, S.; Mitra, S. Experimental investigation and multi-objective optimization of wire electrical discharge machining (WEDM) of 5083 aluminum alloy. Trans. Nonferr. Mater. Soc. China (Engl. Ed.) 2014, 24, 373–379. [Google Scholar] [CrossRef]

- Tzeng, C.J.; Yang, Y.K.; Hsieh, M.H. Optimization of wire electrical discharge machining of pure tungsten using neural network and response surface methodology. Proc. IMechE B J. Eng. Manuf. 2011, 225, 841–852. [Google Scholar] [CrossRef]

- Markopoulos, A.P.; Papazoglou, E.-L.; Karmiris-Obratański, P. Experimental study on the influence of machining conditions on the quality of electrical discharge machined surfaces of aluminum alloy Al5052. Machines 2020, 8, 12. [Google Scholar] [CrossRef]

- Yang, R.T.; Tzeng, C.J.; Yang, Y.K. Optimization of wire electrical discharge machining process parameters for cutting tungsten. Int. J. Adv. Manuf. Technol. 2012, 60, 135–147. [Google Scholar] [CrossRef]

- Ahmed, N.; Mughal, M.P.; Shoaib, W.; Raza, S.F.; Alahmari, A.M. WEDM of copper for the fabrication of large surface-area micro-channels: A prerequisite for the high heat-transfer rate. Micromachines 2020, 11, 173. [Google Scholar] [CrossRef] [PubMed]

- Alias, A.; Abdullah, B.; Abbas, N.M. WEDM: Influence of machine feed rate in machining titanium Ti-6Al-4V using brass wire and constant current (4A). Procedia Eng. 2012, 41, 1812–1817. [Google Scholar] [CrossRef]

- Chalisgaonkar, R.; Kumar, J. Multi-response optimization using grey-fuzzy methodology for pure titanium in finish cut WEDM. Int. J. Adv. Multidiscip. Res. 2017, 9, 91–98. [Google Scholar]

- De, D.; Nandi, T.; Bandyopadhyay, A. Analysis of machining parameters for wire cut electrical discharge machining of pure titanium using response surface methodology. Mater. Today Proc. 2018, 5, 5374–5383. [Google Scholar] [CrossRef]

- Gautier, G.; Priarone, P.C.; Rizzuti, S.; Settineri, L.; Tebaldo, V. A contribution on the modelling of wire electrical discharge machining of a γ-TiAl alloy. Procedia CIRP 2015, 31, 203–208. [Google Scholar] [CrossRef]

- Kumar, A. Parametric Study and Optimization of WEDM Process Parameters of Pure Titanium. Ph.D. Thesis, Thapar University, Patiala, India, 2014. [Google Scholar]

- Majumder, H.; Maity, K.P. Predictive analysis on responses in WEDM of titanium grade 6 using general regression neural network (GRNN) and multiple regression analysis (MRA). Silicon 2018, 10, 1763–1776. [Google Scholar] [CrossRef]

- Nourbakhsh, F.; Rajurkar, K.P.; Malshe, A.P.; Cao, J. Wire electrodischarge machining of titanium alloy. Procedia CIRP 2013, 5, 13–18. [Google Scholar] [CrossRef]

- Antar, M.T.; Soo, S.L.; Aspinwall, D.K.; Jones, D.; Perez, R. Productivity and workpiece surface integrity when WEDM aerospace alloys using coated wires. Procedia Eng. 2012, 19, 3–8. [Google Scholar] [CrossRef]

- Magabe, R.; Sharma, N.; Gupta, K.; Davim, J.P. Modeling and optimization of wire-EDM parameters for machining of Ni55∙8Ti shape memory alloy using hybrid approach of Taguchi and NSGA-II. Int. J. Adv. Manuf. Technol. 2019, 102, 1703–1717. [Google Scholar] [CrossRef]

- Jangra, K.K. An experimental study for multi-pass cutting operation in wire electrical discharge machining of WC-5.3% Co composite. Int. J. Adv. Manuf. Technol. 2015, 76, 971–982. [Google Scholar] [CrossRef]

- Kim, C.H.; Kruth, J.P. Influence of the electrical conductivity of dielectric on WEDM of sintered carbide. KSME Int. J. 2001, 15, 1676–1682. [Google Scholar] [CrossRef]

- Shah, A.; Mufti, N.A.; Rakwal, D. Material removal rate, kerf, and surface roughness of tungsten carbide machined with wire electrical discharge machining. J. Mater. Eng. Perform. 2011, 20, 71–76. [Google Scholar] [CrossRef]

- Kozak, J.; Rajurkar, K.P.; Wang, S.Z. Material removal in WEDM of PCD blanks. J. Eng. Ind. Trans. ASME. 1994, 116, 363–369. [Google Scholar] [CrossRef]

- Dongre, G.; Zaware, S.; Dabade, U.; Joshi, S.S. Multi-objective optimization for silicon wafer slicing using wire-EDM process. Mater. Sci. Semicond. Process. 2015, 39, 793–806. [Google Scholar] [CrossRef]

- Pan, H.; Liu, Z.; Gao, L.; Qiu, M.; Tian, Z. Study of small holes on monocrystalline silicon cut by WEDM. Mater. Sci. Semicond. Process 2013, 16, 385–389. [Google Scholar]

- Joshi, K.; Padhamnath, P.; Bhandarkar, U.V.; Joshi, S. Surface quality and contamination on Si wafer surfaces sliced using wire-EDM. J. Eng. Mater. Technol. 2019, 141, 041013. [Google Scholar] [CrossRef]

- Yu, P.H.; Lee, H.K.; Lin, Y.X. Machining characteristics of polycrystalline silicon by wire electrical discharge machining. Mater. Manuf. Process. 2011, 26, 1443–1450. [Google Scholar] [CrossRef]

- Rakwal, D.; Bamberg, E. Slicing, cleaning and kerf analysis of germanium wafers machined by wire electrical discharge machining. J. Mater. Process. Technol. 2009, 209, 3740–3751. [Google Scholar] [CrossRef]

- Fard, R.K.; Afza, R.A.; Teimouri, R. Experimental investigation, intelligent modeling and multi-characteristics optimization of dry WEDM process of Al-SiC metal matrix composite. J. Manuf. Process. 2013, 15, 483–494. [Google Scholar]

- Garg, M.P.; Sharma, A. Examination of accuracy aspect in machining of ZrSiO4p/6063 aluminium MMC using CNC wire electrical discharge machining. Compos. Commun. 2017, 6, 6–10. [Google Scholar] [CrossRef]

- Jangra, K.; Grover, S.; Chan, F.T.S.; Aggarwal, A. Digraph and matrix method to evaluate the machinability of tungsten carbide composite with wire EDM. Int. J. Adv. Manuf. Technol. 2011, 56, 959–974. [Google Scholar]

- Kumar, S.S.; Uthayakumar, M.; Kumaran, S.T.; Parameswaran, P.; Mohandas, E.; Kempulraj, G.; Babu, B.S.R.; Natarajan, S.A. Parametric optimization of wire electrical discharge machining on aluminium based composites through grey relational analysis. J. Manuf. Process. 2015, 20, 33–39. [Google Scholar] [CrossRef]

- Liu, J.W.; Wu, Y.Z. An orthogonal experimental study of WEDM-HS of particle-reinforced 6061 Al matrix composites with 20-Vol% Al2O3. Appl. Mech. Mater. 2014, 563, 21–24. [Google Scholar]

- Patil, N.G.; Brahmankar, P.K. Semi-empirical modeling of surface roughness in wire electro-discharge machining of ceramic particulate reinforced Al matrix composites. Procedia CIRP 2016, 42, 280–285. [Google Scholar]

- Pramanik, A.; Basak, A.K. Degradation of wire electrode during electrical discharge machining of metal matrix composites. Wear 2016, 346, 124–131. [Google Scholar] [CrossRef]

- Saha, P.; Tarafdar, D.; Pal, S.K. Multi-objective optimization in wire-electro-discharge machining of TiC reinforced composite through Neuro-Genetic technique. Appl. Soft. Comput. 2013, 13, 2065–2074. [Google Scholar]

- Satishkumar, D.; Kanthababu, M.; Vajjiravelu, V. Investigation of wire electrical discharge machining characteristics of Al6063/SiCp composites. Int. J. Adv. Manuf. Technol. 2011, 56, 975–986. [Google Scholar]

- Shandilya, P.; Jain, P.K.; Jain, N.K. Modeling and analysis of surface roughness in WEDC of SiCP/6061 Al MMC through response surface methodology. Int. J. Eng. Sci. Technol. 2011, 3, 531–535. [Google Scholar]

- Shandilya, P.; Jain, P.K.; Jain, N.K. On wire breakage and microstructure in WEDC of SiCp/6061 aluminum metal matrix composites. Int. J. Adv. Manuf. Technol. 2012, 61, 1199–1207. [Google Scholar] [CrossRef]

- Lal, S.; Kumar, S.; Khan, Z.A.; Siddiquee, A.N. Multi-response optimization of wire electrical discharge machining process parameters for Al7075/Al2O3/SiC hybrid composite using Taguchi-based grey relational analysis. Proc. IMechE B J. Eng. Manuf. 2014, 229, 229–237. [Google Scholar] [CrossRef]

- Karthik, S.; Prakash, K.S.; Gopal, P.M.; Jothi, S. Influence of materials and machining parameters on WEDM of Al/AlCoCrFeNiMo0.5 MMC. Mater. Manuf. Process. 2019, 34, 759–768. [Google Scholar] [CrossRef]

- Trauth, D.; Klocke, F.; Welling, D.; Terhorst, M.; Mattfeld, P.; Klink, A. Investigation of the surface integrity and fatigue strength of Inconel718 after wire EDM and machine hammer peening. Int. J. Mater. Form. 2016, 9, 635–651. [Google Scholar] [CrossRef]

- Klocke, F.; Welschof, L.; Herrig, T.; Klink, A. Evaluation of contemporary wire EDM for the manufacture of highly loaded titanium parts for space applications. Procedia Manuf. 2018, 18, 146–151. [Google Scholar] [CrossRef]

- Sari, D.; Welling, D.; Löpenhaus, C.; Klocke, F.; Klink, A. Adjusting surface integrity of gears using wire EDM to increase the flank load carrying capacity. Procedia CIRP 2016, 45, 295–298. [Google Scholar] [CrossRef]

- Kozak, J.; Rajurkar, K.P.; Chandarana, N. Machining of low electrical conductive materials by wire electrical discharge machining (WEDM). J. Mater. Process. Technol. 2004, 149, 266–271. [Google Scholar]

- Hou, P.J.; Guo, Y.F.; Sun, L.X.; Deng, G.Q. Simulation of temperature and thermal stress filed during reciprocating traveling WEDM of insulating ceramics. Procedia CIRP 2013, 6, 410–415. [Google Scholar] [CrossRef]

- Smirnov, A.; Seleznev, A.; Pinargote, N.W.S.; Pristinskiy, Y.; Peretyagin, P.; Bartolomé, J.F. The influence of wire electrical discharge machining cutting parameters on the surface roughness and flexural strength of ZrO2/TiN ceramic nanocomposites obtained by spark plasma sintering. Nanomaterials 2019, 9, 1391. [Google Scholar] [CrossRef]

- Alduroobi, A.A.A.; Ubaid, A.M.; Tawfiq, M.A.; Elias, R.R. Wire EDM process optimization for machining AISI 1045 steel by use of Taguchi method, artificial neural network and analysis of variances. Int. J. Syst. Assur. Eng. Manag. 2020, 1–25. [Google Scholar] [CrossRef]

- Werner, A. Method for enhanced accuracy in machining curvilinear profiles on wire-cut electrical discharge machines. Precis. Eng. 2016, 44, 75–80. [Google Scholar] [CrossRef]

- Çaydaş, U.; Ay, M. WEDM cutting of Inconel 718 nickel-based superalloy: Effects of cutting parameters on the cutting quality. Mater.Technol. 2016, 50, 117–125. [Google Scholar]

- Prasad, D.V.S.S.S.V.; Krishna, G. Empirical modeling and optimization of kerf and wire wear ratio in wire electrical discharge machining. Int. J. Adv. Manuf. Technol. 2015, 77, 427–441. [Google Scholar] [CrossRef]

- Golshan, A.; Ghodsiyeh, D.; Izman, S. Multi-objective optimization of wire electrical discharge machining process using evolutionary computation method: Effect of cutting variation. Proc. IMechE B J. Eng. Manuf. 2015, 229, 75–85. [Google Scholar] [CrossRef]

- Ishfaq, K.; Ahmad, N.; Jawad, M.; Ali, M.A.; Al-Ahmari, A.M. Evaluating material’s interaction in wire electrical discharge machining of stainless steel (304) for simultaneous optimization of conflicting responses. Materials 2019, 12, 1940. [Google Scholar] [CrossRef]

- Chowdhury, A.G.K.; Ali, M.Y.; Banu, A. Analysis of corner radius in dry micro WEDM. Int. J. Mech. Eng. Robot. Res. 2020, 9. [Google Scholar] [CrossRef]

- Mouralova, K.; Zahradnicek, R.; Benes, L.; Prokes, T.; Hrdy, R.; Fries, J. Study of micro structural material changes after WEDM based on TEM lamella analysis. Metals 2020, 10, 949. [Google Scholar]

- Schulze, H.; Juhr, H. Influence of needle pulse shifting on the basis pulse for wire-EDM of hard metals. In Proceedings of the 16th International Symposium on Electromachining, Non-traditional Machining Society of CMES, Shanghai, China, 19–23 April 2010; pp. 249–253. [Google Scholar]

- Banu, A.; Bakar, M.A.; Ali, M.Y.; Adesta, E.Y.T. Analysis of WEDM process parameters on surface roughness and kerf using Taguchi method. Int. J. Eng. Mater. Manuf. 2017, 2, 103–109. [Google Scholar] [CrossRef]

- Ikram, A.; Mufti, N.A.; Saleem, M.Q.; Khan, A.R. Parametric optimization for surface roughness, kerf and MRR in wire electrical discharge machining (WEDM) using Taguchi design of experiment. J. Mech. Sci. Technol. 2013, 27, 2133–2141. [Google Scholar] [CrossRef]

- Roy, S.; Kumar, K.; Davim, J.P. Optimization of process parameters using soft computing techniques: A case with wire electrical discharge machining. In Handbook of Research on Soft Computing and Nature–Inspired Algorithms; IGI Global: Hershey, PA, USA, 2017; pp. 177–220. [Google Scholar]

- Singh, G. Fabrication of Micro Channels Using Wire EDM for Optimum Process Parameter Using MADAM-TOPSIS Approach. Ph.D. Thesis, Thapar University, Patiala, India, 2014. [Google Scholar]

- Kumar, K.; Ravikumar, R. Modeling and optimization of wire EDM process. Int. J. Mech. Mechatron. Eng. IJMME IJENS 2014, 14, 37–50. [Google Scholar]

- Kumar, B.; Suman, S.; Rakesh. Optimisation of process parameters of WEDM by Grey Relational method. Int. J. Eng. Dev. Res. 2017, 5, 1384–1395. [Google Scholar]

- Yan, M.T. An adaptive control system with self-organizing fuzzy sliding mode control strategy for micro wire-EDM machines. Int. J. Adv. Manuf. Technol. 2010, 50, 315–328. [Google Scholar] [CrossRef]

- Sadeghi, M.; Razavi, H.; Esmaeilzadeh, A. Optimization of cutting conditions in WEDM process using regression modelling and Tabu-search algorithm. Proc. IMechE B J. Eng. Manuf. 2011, 225, 1825–1834. [Google Scholar]

- Hsieh, J.F. Modelling tool path in wire electric discharge machining using Denavit-Hartenberg notation. Proc. IMechE B J. Eng. Manuf. 2011, 225, 1063–1072. [Google Scholar] [CrossRef]

- Datta, S.; Mahapatra, S.S. Modeling, simulation and parametric optimization of wire EDM process using response surface methodology coupled with grey-Taguchi technique. Int. J. Eng. Sci. Technol. 2010, 2, 162–183. [Google Scholar] [CrossRef]

- Santhiand, M.; Fakkir Mohamed, M. Optimization of wedm process parameters using DFA and TOPSIS for Inconel 600. Int. J. Appl. Eng. Res. 2015, 10, 3797–30802. [Google Scholar]

- Conde, A.; Arriandiaga, A.; Sanchez, J.A.; Portillo, E.; Plaza, S.; Cabanes, I. High-accuracy wire electrical discharge machining using artificial neural networks and optimization techniques. Robot. CIM Int. Manuf. 2018, 49, 24–38. [Google Scholar] [CrossRef]

- Rao, R.V.; Kalyankar, V.D. Parameter optimization of modern machining processes using teaching-learning-based optimization algorithm. Eng. Appl. Artif. Int. 2013, 26, 524–531. [Google Scholar]

- Devarasiddappa, D.; Chandrasekaran, M. Experimental investigation and optimization of sustainable performance measures during wirecut EDM of Ti-6Al-4V alloy employing preferencebased TLBO algorithm. Mater. Manuf. Process. 2020, 35, 1204–1213. [Google Scholar]

- Sen, R.; Choudhuri, B.; Barma, J.D.; Chakraborti, P. Optimization of wire EDM parameters using teaching learning based algorithm during machining of maraging steel 300. Mater. Today Proc. 2018, 5, 7541–7551. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Barman, T.K.; Sahoo, P.; Davim, J.P. Modeling and optimization of fractal dimension in wire electrical discharge machining of EN 31 steel using the ANN-GA approach. Materials 2019, 12, 454. [Google Scholar] [CrossRef] [PubMed]

| Input Factors | Output Parameters | |||||

|---|---|---|---|---|---|---|

| Material Removal Rate | Surface Roughness, Ra | Dimensional Deviation | Recast/White Layer Thickness | Wire Tool Electrode Wear | KerfWidth | |

| Pulse-on time |

|

|  [84,101] |  |  |  |

| Pulse-off time |

|  |  |  |  |  |

| Dis-charge current |  |  [35,82,101,136] |  |  |  [101] |  |

| Gap voltage |

|  |  (air pressure) |  [101] |  [101] |  |

| Flushing pressure? |  |  [35,136] |  [81] |  [136] |  [4] |  [136] |

| Wire feed |  |  [8] |  [84] |  [137] |  | |

| Wire tension |  [8] |  |  |  [8] | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slătineanu, L.; Dodun, O.; Coteaţă, M.; Nagîţ, G.; Băncescu, I.B.; Hriţuc, A. Wire Electrical Discharge Machining—A Review. Machines 2020, 8, 69. https://doi.org/10.3390/machines8040069

Slătineanu L, Dodun O, Coteaţă M, Nagîţ G, Băncescu IB, Hriţuc A. Wire Electrical Discharge Machining—A Review. Machines. 2020; 8(4):69. https://doi.org/10.3390/machines8040069

Chicago/Turabian StyleSlătineanu, Laurenţiu, Oana Dodun, Margareta Coteaţă, Gheorghe Nagîţ, Irina Beşliu Băncescu, and Adelina Hriţuc. 2020. "Wire Electrical Discharge Machining—A Review" Machines 8, no. 4: 69. https://doi.org/10.3390/machines8040069

APA StyleSlătineanu, L., Dodun, O., Coteaţă, M., Nagîţ, G., Băncescu, I. B., & Hriţuc, A. (2020). Wire Electrical Discharge Machining—A Review. Machines, 8(4), 69. https://doi.org/10.3390/machines8040069