Abstract

This paper takes the dual-motor pure electric mining dump truck as the research object and designs a dual-motor rear-drive torque optimization allocation strategy in view of the problems such as the large load variation of the dump truck and the facts that the motor output torque cannot accurately express the driver’s dynamic intention and that the overall output efficiency of the dual motor is low. The strategy first divides the demand torque of the whole vehicle into two parts, the base torque and the compensation torque, which are determined by the accelerator pedal opening and the motor speed, and the compensation torque is fuzzy-controlled by taking the vehicle speed, the rate of change of the accelerator pedal opening, and the state of the battery charge as inputs. Subsequently, the dual-motor drive torque allocation is optimized using a particle swarm algorithm, with the objective of minimizing power loss in the dual motors. Furthermore, the energy-saving effect of the torque optimization allocation strategy proposed in this paper is compared with that of the traditional torque average allocation strategy under three working conditions: the driving conditions of Chinese dump trucks, the unloaded uphill movement of mining dump trucks, and the fully loaded downhill movement of mining dump trucks. The results show that the average efficiency of the dual-motor drive using the torque optimization allocation strategy is improved by 2.32%, 4.23%, and 2.24%, respectively, and battery energy savings are improved by 0.5%, 0.47%, and 0.24%, respectively.

1. Introduction

With the gradual improvement of China’s energy-saving and emission reduction requirements, the application of pure electric mining dump trucks will be the general trend. Since the pure electric mining dump truck adopts the electric motor as the power output device, improving the efficiency of the electric motor will help to improve the energy-saving effect of the whole vehicle and extend its driving range.

Combined with the actual needs of engineering, this paper carries out the research on the optimal allocation strategy of rear-drive torque for dual-motor pure electric mining dump trucks. Summarizing the previous research results, the domestic and foreign research on the rear drive torque allocation strategy of the dual motor is mostly focused on optimizing the motor efficiency and energy saving of the whole vehicle. For example, Wang C et al. [1] applied proportional–integral particle swarm optimization and deep deterministic policy gradient algorithms based on proportional integration to permanent magnet synchronous motors to obtain higher-quality parts using a fast compensation method for motor speeds. Wei H et al [2] a particle swarm optimization algorithm to solve an improved optimal efficiency allocation table with the objective of maximizing the overall efficiency of the two-motor system, and the simulation results show that this strategy can save battery power compared to other control strategies. Qiao Shuaipeng [3] proposed a multi-motor torque allocation strategy based on the optimization of the combined efficiency of the motor and battery. In order to maximize the service life of the battery, a maximum torque/current ratio torque allocation strategy was designed, and a multi-objective particle swarm optimization algorithm was used to improve the motor efficiency and driving range. Chixing et al. [4] proposed a motor torque allocation control strategy based on minimizing the dissipated power of tires. The strategy establishes an optimization objective based on the tire dissipated power and motor efficiency and solves the objective function using a genetic algorithm to obtain the motor torque allocation value when minimizing the tire dissipated power. The simulation results show that the strategy can effectively reduce the motor energy loss due to friction heat and improve the operating efficiency of the whole vehicle. Zeng Jianfeng et al. [5] employed a sequential quadratic programming algorithm to calculate the optimal efficiency at any speed and acceleration and projected the optimal efficiency of each drive mode on the speed–acceleration plane. By comparing the efficiencies, the optimal drive modes under specific operating conditions were determined, and the optimal power allocation schemes under torque-coupled and speed-coupled drive modes were developed. Wang W et al. [6] used a dynamic programming algorithm to solve an optimal energy management strategy problem for a two-motor coupled drive system, taking the battery SOC and the motor torque as the state and control variables, and defining the objective function as the minimum of the system error and the amplitude of the control variables, and the results of the study show that the control strategy derived from the dynamic programming can reduce the energy consumption more efficiently compared with the rule-based control strategy. Hu J et al. [7] proposed an energy management strategy based on driving pattern recognition, and designed a driving pattern recognizer based on a generalized neural network; in order to reasonably allocate the power between the dual motors, they formulated an energy management strategy based on dynamic planning based on the rule-based energy management strategy, and the research results show that the energy-saving effect of this strategy is better, and the economic improvement in the city mode is more obvious. Mu Baomao et al. [8] took the plug-in series hybrid bus as a research object to study the model’s predictive control strategy based on dynamic planning, and used the multi-step Markov chain model to realize the short-term speed prediction, and according to the principle of the dynamic planning algorithm, the inverse solution obtained the globally optimal energy allocation relationship in the prediction time domain.

However, in the previous research results, there is less research literature on the pure electric mining dump truck. Due to the special working conditions of mining dump trucks, considering the background of the electrification of engineering vehicles, this paper takes the dual-motor pure electric mining dump truck as the research object, and considers the problems such as large load changes of mining dump trucks, the facts that the motor output torque cannot accurately express the dynamic intention of the driver and that the overall output efficiency of the dual motor is low, etc., and divides the demanded torque of the mining dump truck into the two parts of the base torque and the compensating torque. The particle swarm algorithm is employed to optimize the allocation of dual-motor back-driving torque, with the objective of minimizing power loss in the dual motors.

2. Distribution Strategy of Base Torque and Compensation Torque for Dual Motors

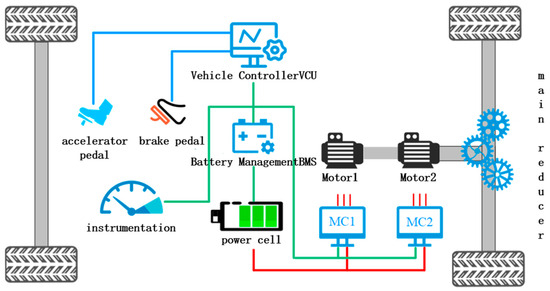

The pure electric mining dump truck studied in this paper belongs to the category of off-highway vehicles, and the drive form is the rear-axle drive, which adopts a dual-motor coaxial drive arrangement scheme. In order to meet the performance requirements of the vehicle, the mining dump truck uses two TZ530 permanent magnet synchronous drive motors, and the power battery is a lithium iron phosphate battery. The pure electric mining dump truck power unit arrangement schematic diagram is shown in Figure 1. The basic parameters of the whole vehicle of the pure electric mining dump truck are shown in Table 1, and the main technical parameters of the motor are shown in Table 2.

Figure 1.

Pure electric mining dump truck power plant layout diagram.

Table 1.

Pure electric mining dump truck permanent magnet synchronous motor parameter table.

Table 2.

Basic parameters of pure electric mining dump truck.

The operational context of mining dump trucks is characterized by frequent transitions between full load and no load, coupled with challenging and evolving road conditions. This dynamic operational environment gives rise to significant fluctuations in the vehicle’s overall load and presents a challenge for accurately representing the driver’s desired output torque. Accordingly, this paper distinguishes between the motor output torque, which is divided into base torque and compensation torque, and the demand torque of mining dump trucks. The base torque is determined by the accelerator pedal opening and the motor speed. The compensation torque is controlled in a fuzzy manner, taking the vehicle speed, the rate of change of the accelerator pedal opening, and the state of the battery charge as inputs.

2.1. Calculation of Base Torque

The base torque reflects the stabilized torque that the driver expects from the motor under the current operating conditions, and its value is determined by the combination of the driver-controlled accelerator pedal opening and the motor speed.

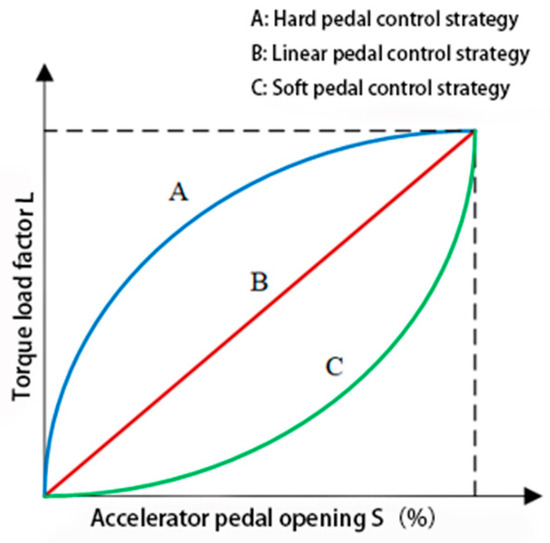

In the working process of the pure electric mining dump truck, the size of the motor output torque is related to the motor speed and torque load factor. While the motor speed is related to the vehicle speed demand, the torque load factor is related to the accelerator pedal opening. In terms of the accelerator pedal opening, according to the different driving modes, the accelerator pedal characteristics are mainly the three kinds of hard pedal control strategy, soft pedal control strategy, and linear pedal control strategy, and the accelerator pedal characteristics are schematically shown in Figure 2. Considering the simplicity of modeling and taking into account the power and economy of the pure electric mining dump truck, this paper chooses the linear pedal control strategy; then, the motor torque load factor is as follows:

Figure 2.

Schematic diagram of accelerator pedal characteristics.

In the above equation, is the linear pedal factor; is the accelerator pedal opening; and is the motor torque load factor.

In accordance with the rotational speed characteristics of the motor, as well as Equation (1), the base torque of the motor, the torque loading coefficient, and the relationships between the rotational speeds of the motor during the driving process of the pure electric mining dump truck are illustrated in Equation (2).

In the above equation, is the motor base torque (N·m); is the motor maximum torque (N·m); is the motor maximum power (W); is the motor speed (r/min); is the motor base speed (r/min); and is the motor maximum speed (r/min).

2.2. Compensating Torque Calculation

The substantial load variability observed in mining dump trucks presents a challenge for the motor base torque to align with the dynamic intentions of the operator. Accordingly, this paper proposes the addition of compensation torque to the base torque calculation, with the objective of enhancing the dynamic response capability of the motor torque.

The addition of compensating torque will cause the sudden change of driving torque of the mining dump truck, which will impact the whole vehicle and affect the driving experience. Therefore, this paper takes the whole vehicle impact degree as a limiting condition to determine the range of compensating torque, and the whole vehicle impact degree is defined as the rate of change of acceleration of the vehicle in the process of driving, and its expression is shown in Equation (3).

In the above equation, is the vehicle acceleration (m/s2); and is the vehicle speed (km/h).

Let the dump truck rotating mass conversion factor be δ = 1; the acceleration generated by the motor compensation torque is as in Equation (4).

In the above equation, is the motor compensation torque (N·m). is the mechanical transmission efficiency.

From Equations (3) and (4), the expression for the shock degree j is given by:

The variation of Equation (5) leads to Equation (6).

The standards for vehicle impact limits vary from country to country. This paper is based on the German impact limit standards in order to design and evaluate the vehicle braking system. The impact limit standards utilized are j ≤ 10m s−3, with a motor response time of 20 ms. The purely electric mining dump truck vehicle parameters are entered into Equation (6), which yields the maximum value of the motor compensation torque, 958 Nm [9].

According to the literature, the main factors affecting the compensating torque include vehicle speed, battery charge state, and accelerator pedal opening change rate [10]; therefore, the above three variables are taken as inputs to the fuzzy controller and the compensating torque is taken as output. S, M, and B denote small, middle, and big, respectively, which are used to describe the fuzzy size of the vehicle speed, the accelerator pedal change rate, and the battery charge state values. The fuzzy subsets and domains of the inputs and outputs are defined as follows: the fuzzy subset of the vehicle speed is {S, M, B}, and the domain is [0, 60]; the fuzzy subset of the battery charge state is {S, M, B}, and the domain is [0, 100]; the fuzzy subset of the rate of change of the accelerator pedal openness is {S, M, B}, and the domain is [0, 100]; and the fuzzy subset of the compensating torque value is {S, M, B}, and the domain is [0, 958].

Fuzzy rules take into account the following two main factors:

(1) When the vehicle speed is low and the rate of change of the accelerator pedal opening is large, this indicates that the driver needs more power to accelerate the vehicle, and the motor control system needs to increase the output value of the compensating torque; when the vehicle speed is high and the rate of change of the accelerator pedal is small, in order to avoid over-acceleration, the motor control system needs to reduce the output value of the compensating torque [11].

(2) When the charge state of the battery is low, the motor may not be able to provide a larger torque output and decrease the compensation torque output value, whereas when the charge state of the battery is high, the motor can provide a larger torque output and increase the compensation torque output value to improve the vehicle’s power performance. The fuzzy rules for compensating torque are shown in Table 3.

Table 3.

Fuzzy rules table for compensating torque.

3. Torque Allocation Strategy Based on Particle Swarm Optimization Algorithm

3.1. Dual-Motor Torque Distribution Input Power Model

Part of the power battery output power of the pure electric mining dump truck is used for the output power of the two motors, and the other part is used for the motor’s own power loss as well as the power loss in the process of the power transmission of each component. This paper takes the minimization of the total power loss of the two motors as the target for allocation; that is, under the condition that the output power of the motors is determined, the energy is allocated in a way that minimizes the input power of the two motors. The calculation of the input power of the two motors is shown in Equation (7).

In the above equation, is the overall input power of the two-motor system (kW); is the motor 1 input power (kW); and is the motor 2 input power (kW).

Combined with the motor output power calculation formula, Equation (7) is rewritten as:

In the above equation, is the motor 1 distribution torque; is the motor 2 distribution torque; is the motor 1 speed; is the motor 2 speed; is the motor 1 efficiency; and is the motor 2 efficiency.

From Equations (7) and (8), it can be observed that, under the premise of meeting the power demand of the entire vehicle, if the total input power of the two motors reaches the minimum value, the energy consumption of the motors is minimized. This paper adopts the torque distribution coefficient, which indicates the proportion of the motor 1 torque to the total demand torque, as a means of determining the working point of the two motors under the current rotational speed. When = 1, motor 1 is the sole driver; when = 0, motor 2 is the sole driver; and when 0 < < 1, both motors are engaged [12]. The dual-motor demand torque can be expressed as

In the above equation, is the total demanded torque of the dual motors.

During the driving process of the dual-motor pure electric mining dump truck, the rotational speeds of motor 1 and motor 2 are the same, i.e., n = n1 = n2. Based on the efficiency characteristics of the motors, the efficiency model of the two motors is established as shown in Equation (10).

In the above equation, , is the efficiency of motor 1 and motor 2 at the current speed and torque.

By substituting Equations (9) and (10) into Equation (8), the dual-motor torque distribution input power model established is shown in Equation (11).

In light of the aforementioned considerations, the minimum input power at the current speed can be expressed as follows:

In the torque allocation process, both to meet the overall vehicle demand torque, but also not to exceed the maximum torque range of each motor, we add constraints as shown in Equation (13) [13].

In the above equation, is the minimum speed of motor 1; is the minimum speed of motor 2; is the maximum speed of motor 1; is the maximum speed of motor 2; is the maximum torque of motor 1; and is the maximum torque of motor 2.

3.2. Torque Allocation Method Based on Particle Swarm Optimization Algorithm

The optimization of the electric mining dump truck’s dual-motor efficiency represents a multivariate input nonlinear optimization problem [14]. In consideration of the characteristics of the objective function, the particle swarm algorithm is the optimal choice for optimization, as it exhibits a faster computation speed and a stronger global search ability than traditional algorithms.

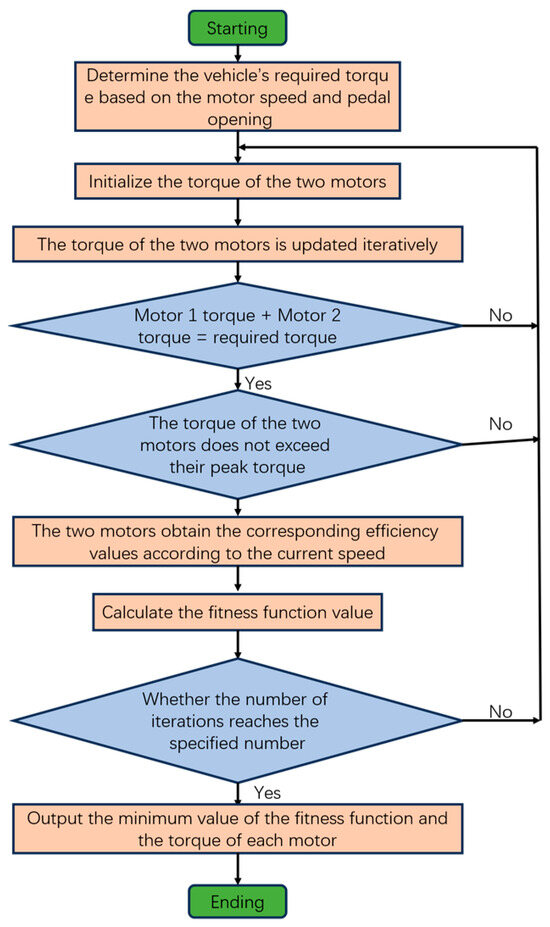

In accordance with the total input power calculation formula for dual motors, upon disregarding the coefficients within the formula and maintaining the same speed (n), the fitness function is reduced to Equation (14), which represents the objective function of particle swarm optimization. The number of initial populations was set to 45, and the number of iterations was set to 100. The specific sequence of operations that constitute the particle swarm algorithm-based torque allocation strategy for dual motors is depicted in Figure 3.

Figure 3.

The flow chart is optimized by particle swarm optimization.

In accordance with the principles of demand torque, the torque of the two motors is rationally distributed by integrating the current status of the vehicle and the efficiency characteristics of the motors. Subsequently, the merits and shortcomings of the existing torque allocation scheme are evaluated through the calculation of the value of the fitness function [15].

Upon completion of the prescribed number of iterations, the minimum value of the fitness function is output, which represents the minimum input power value of the pure electric mining dump truck. In the meantime, the solution that corresponds to the minimum value of the fitness function is the torque value assigned to both motors at the current speed.

3.3. Optimization Results of Torque Distribution Coefficients for the Dual Motors

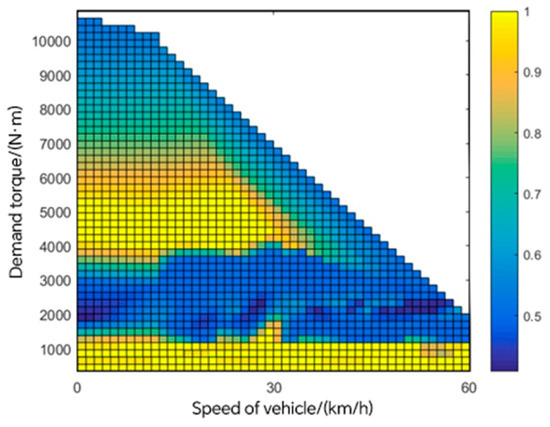

By employing the particle swarm optimization algorithm, the torque distribution coefficients of the dual motors can be ascertained under varying vehicle speeds and demanded torques, as illustrated in Figure 4.

Figure 4.

Dual-motor drive torque distribution coefficient.

As illustrated in Figure 4, when the demand torque falls within the 0–1200 N·m range, the total demand torque is relatively low, and the dual-motor torque distribution coefficient is largely situated around 1. This suggests that solely motor 1 is responsible for providing the demand torque for the entire vehicle. Conversely, when the demand torque is within the 1200–3900 N·m range, the dual-motor torque distribution coefficient is predominantly situated around 0.5, which suggests that motor 1 and motor 2 are close to the average distribution of the torque. In the event that the demand torque is approximately 3900–6400 N·m and the vehicle speed is relatively low, the majority of the driving torque is generated by motor 1, with only a minor contribution from motor 2. However, as the vehicle speed and torque increase gradually, the share of torque generated by motor 2 also increases, approaching the average distribution of torque.

4. Simulation Results Analysis of Optimal Torque Allocation Strategy for Dual Motors

4.1. Analysis of Particle Swarm Optimization Results Based on Simulink

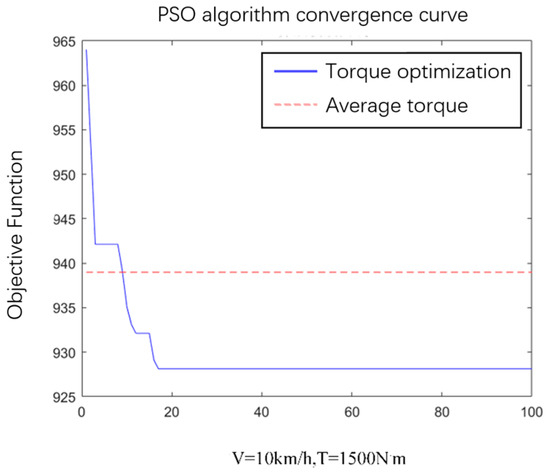

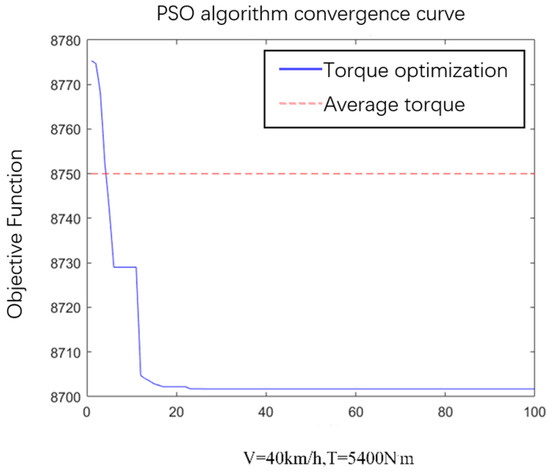

In order to analyze the effect of the optimal torque allocation of dual motors, this paper combines the working conditions of pure electric mining dump trucks, taking the speeds of 10 km/h and 40 km/h and the loads of 1500 N·m and 5400 N·m as an example. Subsequently, the objective function values of optimal torque allocation and average torque allocation are simulated and compared under varying speeds and loads, namely the total input power of the dual motors after each iteration. Figure 4 illustrates the simulation outcomes for low and high loads at a vehicle speed of 10 km/h, while Figure 5 depicts the simulation outcomes for low and high loads at a vehicle speed of 40 km/h.

Figure 5.

Simulation results of low and high load at 10 km/h.

As illustrated in Figure 5 and Figure 6, it can be observed that under varying vehicle speeds and loads, the objective function values of the torque optimal allocation are consistently lower than those of the torque average allocation. This suggests that when determining the torque demand of the entire vehicle, the implementation of the torque optimal allocation strategy requires less total input power from the dual motors than that of the torque average allocation strategy. Consequently, the dual-motor power loss is diminished.

Figure 6.

Simulation results of low and high loads at 40 km/h.

4.2. Performance Simulation Based on CRUISE under Different Working Conditions

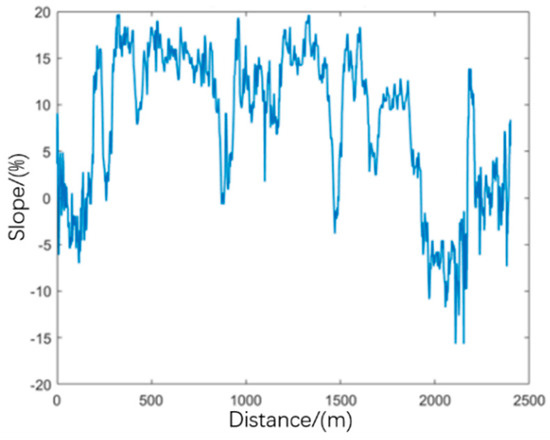

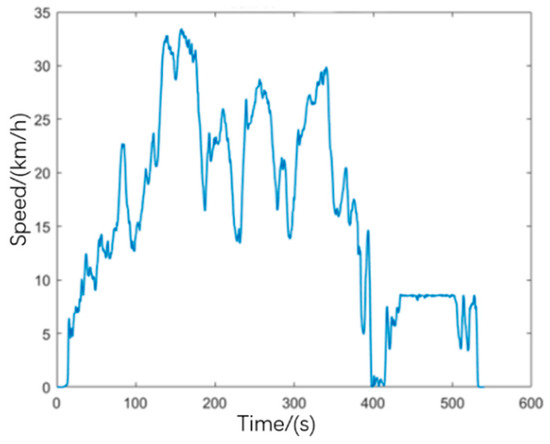

To more accurately reflect the actual driving conditions of pure electric mining dump trucks, this paper collected the actual road spectrum of mining dump trucks and established models for unloaded uphill and fully loaded downhill driving conditions, respectively.

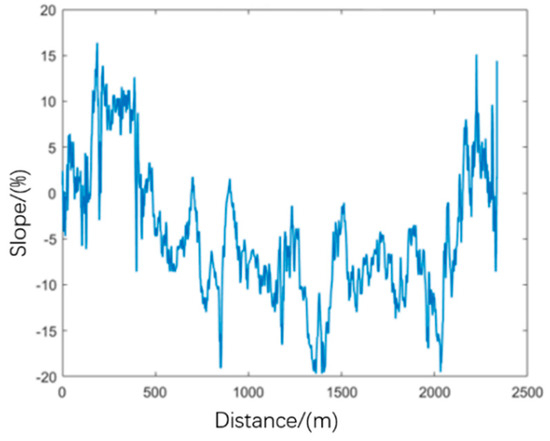

Figure 7 and Figure 8 illustrate the gradient–distance variation and vehicle speed–time variation, respectively, for an unloaded uphill slope.

Figure 7.

No-load uphill slope–distance condition.

Figure 8.

No-load uphill velocity–time condition.

A comprehensive analysis of the unloaded uphill conditions illustrated in Figure 7 and Figure 8 indicates that the mining dump truck departs from the unloading area in an unloaded state and traverses a distance of approximately 2.41 km in 540 s, reaching the loading location at an average speed of 20.24 km/h. It is noteworthy that in Figure 6, which depicts unloaded uphill conditions, a minor portion of the downhill conditions occurs due to the gradient change associated with the actual road conditions.

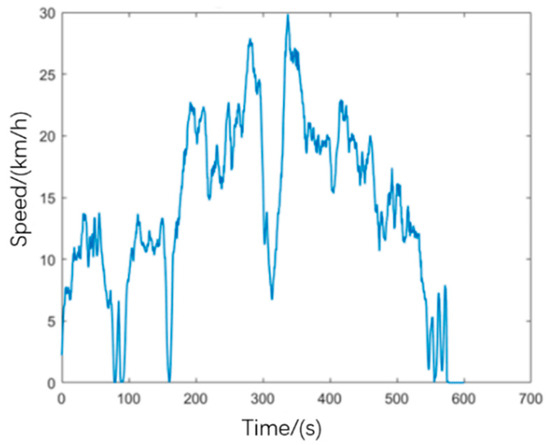

Figure 9 and Figure 10 illustrate the gradient–distance variation and vehicle speed–time variation, respectively, for a fully loaded downhill slope.

Figure 9.

Fully load downhill slope–distance condition.

Figure 10.

Fully loaded downhill velocity–time condition.

A comprehensive analysis of the fully loaded downhill conditions illustrated in Figure 9 and Figure 10 indicates that the mining dump truck departs the loading area with a fully loaded cargo and returns to the unloading area after approximately 576 s, traversing an average distance of 2.34 km at an average speed of 12.27 km/h. It is noteworthy that in Figure 8, which depicts the fully loaded downhill scenario, a minor portion of the uphill conditions can be observed. This is attributed to the gradient change encountered in the actual road conditions.

To further analyze the energy-saving effect of the dual-motor pure electric mining dump truck drive torque optimization distribution strategy, this paper employs CRUISE vehicle performance simulation software to simulate the three working conditions of Chinese dump truck driving. The simulation also includes the CHTC-D, a pure electric mining dump truck unloaded moving uphill, and a pure electric mining dump truck fully loaded moving downhill. The objective is to compare and analyze the motor efficiency distribution and battery SOC change values of the torque optimization distribution strategy and the torque equalization distribution strategy in the different working conditions. The distribution of motor efficiency and the change value of the battery SOC are compared and analyzed under different working conditions using the torque optimization distribution strategy and the torque average distribution strategy, respectively.

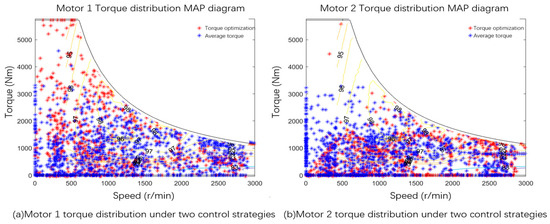

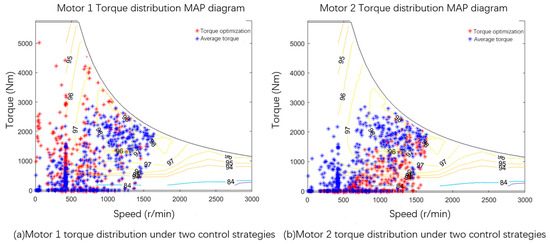

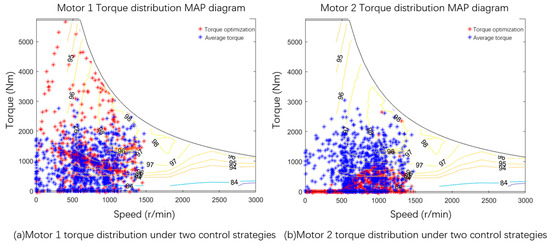

Figure 11, Figure 12 and Figure 13 show the operating points of motor 1 and motor 2 in the efficiency MAP diagram for the three operating conditions of the CHTC-D cycle condition, no-load uphill condition, and full-load downhill condition, respectively.

Figure 11.

The positions of motor 1 and motor 2 driving operating points under the CHTC-D cycle conditions.

Figure 12.

The operating points of motor 1 and motor 2 in the efficiency MAP diagram under the no-load uphill condition.

Figure 13.

The operating points of motor 1 and motor 2 in the efficiency MAP diagram under the full-load downhill condition.

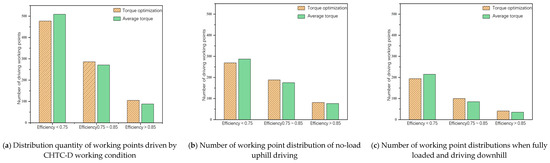

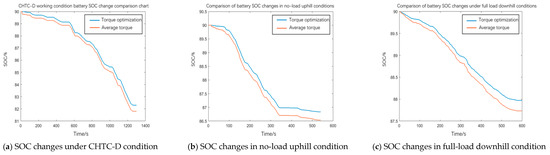

The distribution of motor efficiency is illustrated in Figure 14, and the variation curve of the battery SOC is presented in Figure 15.

Figure 14.

Distribution number of driving operating points in different efficiency intervals under three working conditions.

Figure 15.

SOC changes of the battery under three working conditions.

Figure 14a–c illustrate the distribution of the motor drive operating points across different efficiency intervals for the CHTC-D working condition, the real-vehicle no-load uphill, and the full-load downhill conditions, respectively. The mean efficiency of the motor with a torque optimization distribution strategy is 78.40%, 80.31%, and 78.32%, respectively, across the three working conditions. In comparison, the mean efficiency of the motor with an average torque distribution is 76.08%, 75.68%, and 74.12%, respectively. These results demonstrate that the dual motor’s efficiency can be enhanced more effectively through the implementation of a torque optimization allocation strategy.

The initial battery state of charge (SOC) value was set to 90%. Figure 15a–c illustrate the changes in the battery state of charge (SOC) of the dual-motor pure electric mining dump truck under the CHTC-D working condition, no-load uphill, and full-load downhill working conditions, respectively. Upon completion of the three working conditions, the battery state of charge (SOC) with the torque averaging strategy demonstrated decreases to 81.80%, 86.36%, and 87.73%, respectively, while the battery state of charge (SOC) with the torque optimization allocation strategy exhibited decreases to 82.30%, 86.83%, and 87.97%, respectively. It is evident that the dual-motor torque optimization strategy can reduce the energy consumption of the battery under diverse operational circumstances, thereby achieving an energy-saving effect and subsequently enhancing the vehicle’s operational range and prolonging the battery’s lifespan.

To verify the accuracy of the simulation model, this paper used real vehicle data for verification. In order to facilitate the comparison, the initial SOC of the battery of the dual-motor pure electric mining dump truck was first adjusted to 90%, and because the real vehicle adopted the torque equalization distribution strategy, only the changes of the battery SOC after the no-load uphill and full-load downhill conditions of this strategy were recorded, and the battery SOC was reduced to 86.5% and 87.5%, which is a better match with the simulation data, respectively. Due to the lack of experimental verification conditions for the model simulation, this paper only uses the SOC values recorded in the real vehicle for verification, because the on-board battery SOC data were based on the correction of the ampere-time method and the open-circuit voltage [16], so the on-board data are considered credible.

5. Conclusions

(1) This paper presents the findings of a study on the driving torque allocation strategy of a dual-motor pure electric mining dump truck. In consideration of the considerable variability in the load of a mining dump truck and the inability of the motor output torque to respond to the driver’s dynamic intention in a timely manner, it is necessary to divide the demand torque of the entire vehicle into two distinct categories: the basic torque and the compensation torque. The particle swarm algorithm is employed to optimize the torque distribution of the dual-motor drive, with the objective of minimizing the energy consumption of the dual motor.

(2) To more accurately simulate the actual driving conditions of pure electric mining dump trucks, this paper collected the actual road spectrum of mining dump trucks and established models for unloaded uphill and fully loaded downhill driving conditions, respectively. Moreover, the average efficiency of the dual motors and the battery energy-saving effect of the torque optimization allocation strategy and the torque average allocation strategy are compared and analyzed under the three working conditions of the CHTC-D working condition, unloaded uphill movement, and fully loaded downhill movement of the mining dump truck, using CRUISE software. The results demonstrate that the average efficiency of the dual motors exhibited increases of 2.32%, 4.23%, and 2.24%, respectively. Furthermore, the battery energy saving demonstrated increases of 0.5%, 0.47%, and 0.24%, respectively.

Author Contributions

Conceptualization, Y.C. and Z.W.; methodology, Z.W.; software, Z.W. and Z.P.; validation, Y.Z., Y.C. and Z.W.; formal analysis, Y.Z. and Z.P.; data curation, Z.W.; writing—original draft preparation, Y.C.; writing—review and editing, Y.Z.; supervision, Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data used to support the findings of this study are included within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, C.; Guo, C.; Tsay, D.; Perng, J.-W. PMSM speed control based on particle swarm optimization and deep deterministic policy gradient under load disturbance. Machines 2021, 9, 343. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, N.; Liang, J.; Ai, Q.; Zhao, W.; Huang, T.; Zhang, Y. Deep reinforcement learning based direct torque control strategy for distributed drive electric vehicles considering active safety and energy saving performance. Energy 2022, 238, 121725. [Google Scholar] [CrossRef]

- Qiao, S. Optimal Torque Distribution Strategy of Dual-Motor Four-Wheel-Drive Pure Electric Vehicle Based on the Efficiency Characteristics of Key Components. Master’s Thesis, Chongqing University, Chongqing, China, 2020. [Google Scholar] [CrossRef]

- Qi, X.; Wang, Q.; Chen, L.; Cao, J.; Zhang, Q.; Li, G. Optimization strategies of torque distribution for front and rear dual motor driven electric vehicles. Electr. Mach. Control 2020, 24, 62–70. [Google Scholar] [CrossRef]

- Zeng, J. Study on Drive Control Strategy for a Novel Dual-Motor Coupling Powertrain. Master’s Thesis, Chongqing University, Chongqing, China, 2015. [Google Scholar]

- Wang, W.; Shi, J.; Zhang, Z.; Lin, C. Optimization of a dual-motor coupled powertrain energy management strategy for a battery electric bus. Energy Procedia 2018, 145, 20–25. [Google Scholar] [CrossRef]

- Hu, J.; Niu, X.; Jiang, X.; Zu, G. Energy management strategy based on driving pattern recognition for a dual—Motor battery electric vehicle. Int. J. Energy Res. 2019, 43, 3346–3364. [Google Scholar] [CrossRef]

- Mu, B.; Ye, X. Research on model predictive control strategy based on dynamic planning. Heavy Truck 2023, 6, 6–8. [Google Scholar]

- Pan, C.; Yao, L.; Lai, J.; Cai, C.; Chen, X. Control Strategy of Dual-motor Nutation Coupling Drive System for Electric Bus. J. Mech. Transm. 2021, 45, 42–52+66. [Google Scholar]

- Ye, L.; Wu, Z.; Lv, W. Optimisation of braking energy recovery for rear-drive electric vehicles based on fuzzy control. Int. J. Veh. Des. 2023, 92, 93–112. [Google Scholar] [CrossRef]

- Wang, Y.; Qiao, M. Research on Driving Torque Optimization Control Strategy of Pure Electric Mine Car Based on Load Variation. Automob. Technol. 2023, 48, 36–42. [Google Scholar] [CrossRef]

- Li, J.; He, R. Energy management strategy of drive mode for dual-rotor in-wheel motor driven electric vehicle based on optimal system efficiency. J. Jilin Univ. (Eng. Technol. Ed.) 2024, 1671, 1–11. [Google Scholar] [CrossRef]

- Lin, Y.; Huang, Q.; Zhang, G. Torque Distribution Strategy Optimization of a Novel Dual-Motor Multi-Mode Drive System Using PSO Algorithm. Automot. Eng. 2022, 44, 1218–1225. [Google Scholar] [CrossRef]

- Li, B.; Zeng, L. Position Decoupling Control of Rigid Rotor of Active Magnetic Bearing. Mechanika 2023, 29, 292–301. [Google Scholar] [CrossRef]

- Ju, F.; Du, W.; Zhuang, W.; Li, B.; Wang, T.; Wang, W.; Ma, H. Profit-Effective Component Sizing for Electric Delivery Trucks with Dual Motor Coupling Powertrain. Energy. 2024, 296, 131055. [Google Scholar] [CrossRef]

- Xu, X.; Wang, Y.; Wang, Y. Influence of magnetic field on sound transmission loss of Magnetorheological fluids. Materials. 2022, 15, 6032. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).