Abstract

This paper presents the basic structural parts, a 3D model, and the overall design of a laboratory machine, which was created to detect vibrations generated by the casing of a conveyor roller rotating at different speeds. The intention of the authors was to verify whether plastic brackets inserted into the structurally modified trestles of a fixed conveyor idler can reduce the vibration values transmitted from the rotating conveyor roller to the trestle of a fixed idler. Experimental vibration measurements taken on the non-rotating parts of conveyor rollers, performed on a laboratory machine according to ISO 10816, are suitable for characterizing their operating conditions with regard to trouble-free operation. The aim of this paper is to detect the vibrations of a rotating conveyor roller on a laboratory machine in the defined places of a fixed conveyor idler and also on the steel frame of a laboratory machine that represents the supporting track of a belt conveyor. Vibrations detected by piezoelectric acceleration sensors were recorded by a measuring apparatus and displayed in the environment of Dewesoft X software (version 10). The measurements show that the vibration values grow with the increasing speed of the conveyor roller rotation. Experimental measurements have proven the correctness of the assumption that the vibrations transmitted to the trestle of a fixed conveyor idler are lower by up to 40% when using plastic brackets into which the axle of the conveyor roller is attached, compared to the solution where the axle of the conveyor roller is inserted into the notches of a steel trestle.

1. Introduction

Vibration [1,2] is defined as a process during which a material body oscillates around its equilibrium position. Vibration [3] is described by the amplitude and phase at a given point in time. Since in real situations, a body cannot be described as a single point of mass, the oscillation through the body spreads gradually from one particle to another—this phenomenon is called waves. Waves can be classified as non-periodic and periodic. Periodic waves [4] (harmonic vibrations) have a sinusoidal waveform and can be described by their speed, acceleration, and deflection. These three quantities are the basis for the description and measurement of vibrations [5]. We use speed mainly to determine the energy of vibrations, acceleration to determine the high-frequency components of vibrations, and deflection is used for low-frequency components.

The CSN ISO 10816 standard [6] establishes the general rules for measuring and evaluating machine vibrations, and these vibrations are measured on non-rotating parts (especially on bearings). The standard [6] stipulates that the measurement is generally broadband in order to cover the entire frequency range of a particular machine being measured. According to the standard [6], the measured values are the vibration deflection, vibration velocity, and vibration acceleration. In practice, the effective value of the vibration velocity is mainly used for vibration evaluation due to its relationship with the energy of these vibrations. Two criteria are decisive for the assessment of vibration strength (the highest measured value from a set of vibrations performed at multiple locations and in multiple directions). The first is the magnitude of the vibration, and the second is the magnitude of the change in the vibration [7].

By vibrations [8], we mean the mechanical oscillation of a body or elastic medium, where the individual points of the body/medium oscillate around an equilibrium position. The motion of the individual points of a body subjected to vibrations can be described by the time course of its deflection y(t) [m], velocity v(t) [m·s–1] [9], or acceleration a(t) [m·s–2] (1).

The effective value of vibration acceleration aRMS [m·s–2] can be expressed as (2).

In the article [10], by the authors Perun and Opasiak, vibration measurements of the cylinder shell installed on a laboratory stand were made. It contains the results of the assessment of the technical condition of the rollers of belt conveyors after a specified period of operation.

Klimenda et al. [11] deal with the measurement of noise and vibration of rollers for belt conveyors. In this article, the individual roller types that were measured are described. The process of noise and vibration measurement of the individual roller types is given. Part of the article concerns the noise and vibration measurement evaluation. The three highest acceleration values depending on the frequency of the vibration in individual directions (x, y, z) are given.

In the article [12], Svoboda et al. deal with measuring vibrations on the stand of a roller conveyor. The difference between the individual sets of rollers is used for the semi-finished product of the outer shell, but the design of the rollers is the same. One set has a shell from a convectional tube and the second set from an accuracy tube. The vibrations were measured by a six-channel Brüel & Kjær analyser (PULSE, Vibration Meters and vibration analyzer Type 2270-W). The and natural frequency were measured by using a three-axis accelerometer. In the conclusion of the article, there is an evaluation of the vibration. The three highest acceleration values depending on the frequency of the vibration in individual directions are given. From this evaluation, rollers with minimal and maximal acceleration are selected.

In the article [13], Bortnowski et al. created a device for a wireless measuring device that moves with the conveyor belt along the route, which records the signal of the transverse vibrations of the belt.

The roller is an important part of the belt conveyor in a sand carrier at sea, as presented by Peng et al. in the article [14]. In this paper, a novel intelligent fault diagnosis method for rollers is proposed by using audio wavelet packet decomposition and Convolutional Neural Networks (CNNs).

The article by M. Svoboda et al. [15] deals with the measurement of vibrations on the stand of a roller conveyor. The acceleration and natural frequency were measured by using a three-axis accelerometer. In the conclusion of the article, there is an evaluation of the vibration. The three highest acceleration values depending on the frequency of the vibration in individual directions are given.

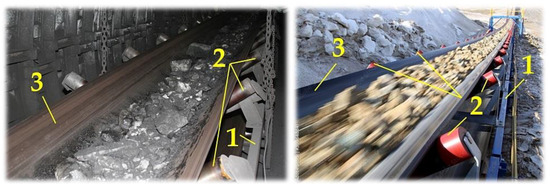

In many branches of industry, bulk materials are transported over short, medium, and long transport distances using continuously working conveyor systems, so-called belt conveyors [16,17,18]. The conveyor belt, see Figure 1, consists of a conveyor line 1 (assembled from steel assembled parts), which is fitted with conveyor rollers 2 [19] that support the conveyor belt 3 [20]. The endless loop of the conveyor belt circulates between two end drums. As a rule, on the upper surface of the conveyor belt, guided in the upper run of the belt conveyor [21], the conveyed material is transported towards the driving station.

Figure 1.

The endless loop of a conveyor belt supported by conveyor rollers. 1—conveyor line, 2—conveyor rollers, 3—conveyor belt.

On the drive drum of a conveyor belt driving station, the conveyor belt is carried away by frictional forces acting on the contact surface between the surface of the drive drum casing and the surface of the conveyor belt. The solution of the force ratios acting on the driving drums is based on the basic Euler (Eytelwein) relation [22,23]. The transmission capability [24,25] between the drive drum and the conveyor belt depends on the angle of the wrap, the coefficient of friction between the belt and the drive drum, and the belt tension (which generates the tension force of the conveyor belt).

Belt conveyor drives must be designed in such a way that the belt on the driving drums does not slip in the individual movement phases (start-up, steady running, and run-down phases). It is possible to increase the transmission capacity of belt conveyor drives by a number of technical measures, including, e.g., increasing the coefficient of friction between the belt and the drive drum, increasing the preload of the conveyor belt, and increasing the angle of the wrap (the implementation of two-drum and three-drum driving stations).

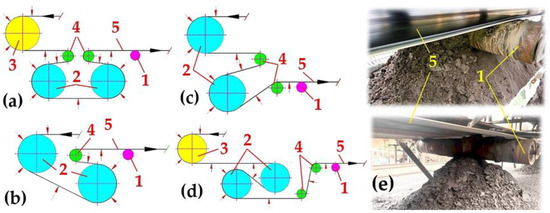

The disadvantage of both two-drum (Figure 2a,b) and three-drum drives is that the working run of the conveyor belt touches the casings of the conveyor rollers in the return run of the belt conveyor. An insufficiently cleaned surface of a conveyor belt from the adhered grains of the transported material causes the material to stick to the casings of the conveyor rollers, see Figure 2c. These then vibrate as a result of the unbalanced mass when the rollers rotate.

Figure 2.

Two-drum driving station (a) type Ω, (b) type C, (c) without a boom, (d) type S, (e) transported material stuck on the casing of the conveyor roller. 1—conveyor roller, 2—drive drum, 3—dump drum, 4—transmission drum, 5—conveyor belt.

In Figure 2a–d, the red arrows indicate the working surface of the conveyor belt, i.e., the surface on which the conveyed material is carried in the working (upper) run of the conveyor belt. In the return run of the conveyor belt, this dirty surface of the conveyor belt meets the casings of the conveyor rollers [26]. Despite the intensive brushing of dirt and adhered material grains from the working surface of the conveyor belt with devices called cleaners [27,28,29,30], dirt often remains on the surfaces of the conveyor belts, which accumulates on the rotating casings of the conveyor rollers.

Authors J Eliasson et al., in article [31], present an Internet of Things (IoT) architecture suitable for large-scale sensor networks for condition monitoring. The developed technology has been applied and demonstrated for rotating conveyor belt rolls.

Authors R. Li et al. propose, in article [32], to use radial grating vibration sensing technology for both belt conveyor and roller vibration monitoring. This can then be used to predict the fault state in the roller and its position, using distributed optical fibber temperature measurement technology, which can be used for “hot spot monitoring”.

The paper [33] presents a recent review of acoustic and vibration signal-based fault detection for belt conveyor idlers using ML models. It also discusses major steps in the approaches, such as data collection, signal processing, feature extraction and selection, and ML model construction.

The article [34] by X Liu et al. describes a test device for detecting the vibration of conveyor belt rollers.

Machine-learning-based techniques for the condition monitoring and fault diagnosis of industrial equipment were used in the paper [35] by authors J. Soares et al. Therefore, this paper presents a machine-learning-based method for fault diagnosis in belt conveyor idlers.

2. Materials and Methods

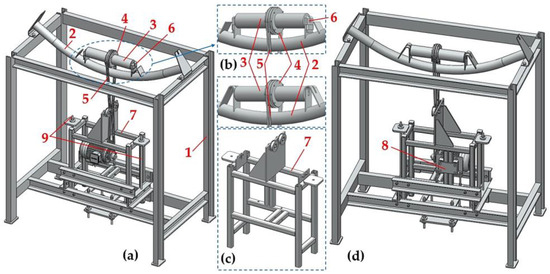

This article is a follow-up to the article [9], in which the effective values of the vibration velocity vRMS [m·s−1] were measured in three mutually perpendicular planes of a rotating (circumferential speed vr = 1.28 to 6.93 m·s−1) conveyor roller (with a casing diameter of 133 mm). The effective values of the vibration velocity vRMS [m·s−1] were measured for two different fittings of the conveyor roller axles. One is the traditional placement of the flattened ends of the roller axle in the notches of the trestles, see Figure 3b, on the fixed conveyor idler. The second way is to position these flattened ends of the roller axle in plastic brackets inserted into the specially designed steel trestles of the fixed conveyor idler.

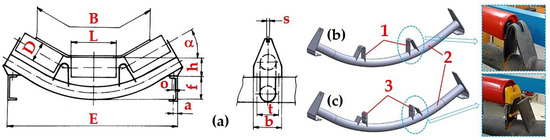

Figure 3.

(a) Structural 3D design of a laboratory machine—front view, (b) conveyor roller placed in the trestle of a fixed conveyor idler, (c) drive frame, (d) laboratory machine—rear view. 1—steel frame, 2—fixed conveyor idler, 3—conveyor roller, 4—driven pulley, 5—V-belt, 6—plastic bracket, 7—drive support frame, 8—electric motor support device, 9—threaded rod.

The measurement of the effective values of the vibration velocity vRMS [m·s−1] was carried out using a laboratory machine, see Figure 3a, which is located in a laboratory at the Department of Machine and Industrial Design, Faculty of Mechanical Engineering, VSB-Technical University of Ostrava. This device was designed by DvB-AF s.r.o., with its registered office at Meleček 227, 747-41 Hradec nad Moravicí, Žimrovice. A laboratory stand designed to measure the noise of a rotating roller is described in [36,37].

Research on idlers has rather focused on the rolling resistance, their energy consumption, load distribution, and failure analysis until now [38,39,40,41].

The aim of this paper is to specify an academic contribution, which is one of the possible recommendations to reduce the vibrations transmitted to the supporting structure of the belt conveyor excited by the rotating casing of the conveyor roller.

A 3D structural model of a laboratory machine created in SolidWorks®Premium 2012 × 64, SP5 is shown in Figure 3. The laboratory machine consists of a steel frame 1, to which a vertically sliding drive support frame is mechanically attached 7, see Figure 3c. The supporting device of the electric motor 8 is attached to the supporting frame of the drive 7, to which the electric motor is attached by screw connections (type 1AL90L-4,YASKAWA Electric Europe GmbH, Schwalbach am Taunus, Germany, power engine Pe = 1.5 kW, revolutions ne = 1445 min−1). A V-belt pulley with a calculated diameter of dw = 81.5 mm is positioned onto the shaft of an electric ϕ24 mm (with a tight key of 8 × 7 × 40 mm). This pulley transmits the pulling force of the drive by friction to one (or two) V-belts 5 [42] (type SPZ 2500 Lw 9.7 × 2513 La L = L). The revolutions of the electric motor ne [min−1] are controlled by an electric inverter (type YASKAWA VS-606 V7, YASKAWA Electric Europe GmbH, Schwalbach am Taunus, Germany).

Laboratory measurements were carried out on conveyor rollers with various diameters Dr [mm] (133, 108 and 89), at the same circumferential speeds vr [m·s−1] of their casings.

In Table 1, it is possible to read the required circumferential speed vr [m·s−1] of the conveyor roller, the required revolutions nr [min−1] of a roller with diameter Dr [m] and frequency fi [Hz], by which the revolutions nr [min−1] of a conveyor roller are controlled by a frequency converter.

Table 1.

Calculated values of the rotational speed nr [min−1] of a conveyor roller with a given diameter Dr [m] for circumferential speed vr [m·s−1] of the conveyor roller casings.

The theoretical magnitude of the rotational speed nr [m·s−1] of the conveyor roller with diameter Dr [m] can be expressed based on knowing the transmission ratio iw [-] and the constant ci [-] according to the relation (3). The transmission ratio iw [-] is defined by the ratio of the calculated diameter of the drive pulley dw [m] and the diameter of the driven pulley Dw [m]. The constant ci [-] expresses the ratio of the frequency value of f = 50 Hz (in Europe, a unified distribution grid of 400/230 V with a frequency of 50 Hz is used. In North America, it is a phase distribution system of 120 V at a frequency of 60 Hz) and the frequency fi [Hz] set on the display of the frequency converter.

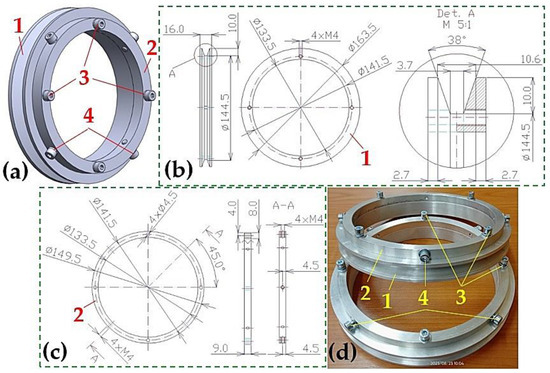

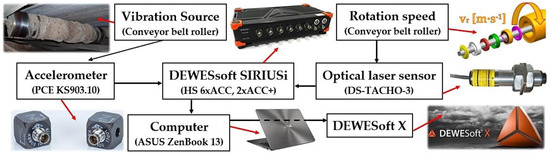

One or two so-called “V-belt pulley assembly” units are placed onto the tested conveyor roller (with a steel, plastic, or rubberized casing) with a diameter of Dr = 133 mm (or 108 mm or 89 mm), see Figure 4a. This assembly consists of a flange 2, with screw connections 3 attaching a pulley 1 with the calculated diameter of Dw = 153 mm. Prevention of this flange displacement 2 along the length of the conveyor roller casing, and prevention of flange rotation in relation to the circumference of the conveyor roller casing, is secured via screw connections 4.

Figure 4.

(a) A 3D model of V-belt pulley assembly, (b) the dimensions of the pulley, (c) the dimensions of the flange for the ϕ133 mm conveyor roller, (d) manufactured V-belt pulley assembly. 1—V-belt pulley, 2—flange, 3—screw M4 × 16 DIN 912, 4—screw M4 × 10 DIN 912.

An electric motor [43], on the shaft of which a V-belt is slid (calculated diameter dw = 81.5 mm), sets the V-belt into motion [42]. The V-belt rotates the test conveyor roller at a revolution nr [min−1] corresponding to the circumferential velocity vr [m·s−1] of the conveyor roller, see Table 1.

The design dimensions of the flange 2 slid onto the ϕ108 mm conveyor roller are shown in Figure 5b, and the design dimensions of flange 2 slid onto the ϕ89 mm conveyor roller are shown in Figure 5e.

Figure 5.

(a) A 3D model of the V-belt pulley assembly, (b) flange dimensions for ϕ108 mm conveyor roller, (c) manufacture V-belt pulley assembly, (d) a 3D model of the V-belt pulley assembly, (e) flange dimensions for ϕ89 mm conveyor roller, (f) manufactured V-belt pulley assembly. 1—V-belt pulley, 2—flange, 3—screw M4 × 16 DIN 912, 4—screw M4 × 25 DIN 912 (screw M4 × 35 DIN 933).

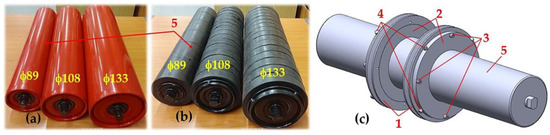

The steel casing, see Figure 6a, or rubberized, see Figure 6b, conveyor roller (ϕ133, ϕ108, or ϕ89 mm) rotates relative to the stable axle of the ϕ20 mm roller on 2 pcs of radial ball bearings 6204-2RS [44].

Figure 6.

Conveyor roller (a) steel, (b) rubberized, (c) a 3D model of a conveyor roller fitted with two pieces of the V-belt pulley assembly. 1—V-belt pulley, 2—flange, 3—screw M4 × 16 DIN 912, 4—screw M4 × 10 (25) DIN 912 (M4 × 35 DIN 933), 5—ϕ133 mm conveyor roller (or ϕ108 mm or ϕ89 mm).

In the article [45], the authors M. Vasić et al. analysed failures of belt conveyor tension roller bearings. The article also examines the effects of the tensioner pulley mounting position on bearing damage.

The plastic casing, see Figure 7a, of the conveyor roller (ϕ133, ϕ108, or ϕ89 mm) rotates relative to the ϕ20 mm roller axle on 2 radial ball bearings 6204-2RS [44].

Figure 7.

(a) Plastic conveyor roller, (b) conveyor roller fitted with two pieces of a V-belt pulley assembly, (c) roller axle placed in a plastic bracket. 1—V-belt pulley, 2—flange, 3—screw M4 × 16 DIN 912, 4—screw M4 × 10 (25) DIN 912 (M4 × 35 DIN 933), 5—ϕ133 mm conveyor roller (or ϕ108 mm, or ϕ89 mm), 6—plastic bracket to hold the roller axles.

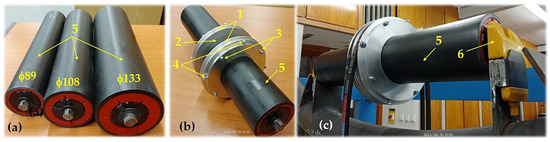

The axle of the tested conveyor roller is inserted into a cut-out in the steel (Figure 3b) or plastic (Figure 8d) trestle of the fixed conveyor idler, which is screwed to the top surface of the steel frame of the laboratory machine (Figure 3).

Figure 8.

Plastic bracket for the conveyor roller axle inserted into a modified trestle of a fixed roller idler (a) 3D structural design, (b) 3D structural design, (c) the implemented solution of the plastic bracket, plastic holder, (d) conveyor roller mounted in the trestle of a fixed roller idler. 1—conveyor roller, 2—plastic bracket.

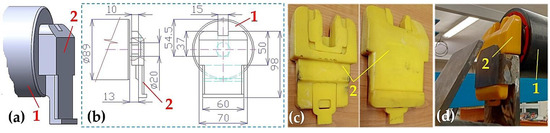

The vibrations generated by the rotating conveyor roller, transmitted to the sleeper of the fixed roller idler and the steel frame of the laboratory machine, were detected by two acceleration sensors PCE KS903.10 [46], see Figure 9. Signals from the acceleration sensors were recorded by Dewesoft SIRIUSi-HS 6 × ACC, 2 × ACC+ (DEWESoft Deutschland GmbH, Unterensingen, Germany) [47] measuring apparatus during the experimental measurements. Time records of the measured vibration values were used by the Dewesoft X [48] measuring program and transformed into effective vibration velocity values v(*)RMS(fi) [mm·s−1] in the range of 10–1 × 104 Hz (this frequency range is applied in the ISO 10816-3 standard [49]). The effective velocity values v(*)RMS(fi) [mm·s−1] (where * presents the x, y, or z axis of the coordinate system) with periodic courses were displayed using a PS monitor in the environment of the Dewesoft X measuring software.

Figure 9.

Measuring chain for detecting and recording the vibrations of rotating rollers on a laboratory machine.

The speed of the conveyor roller was scanned by an optical laser sensor DS-TACHO-3 (DEWESoft Deutschland GmbH, Unterensingen, Germany) [50,51].

3. Results

The experimental measurements of the vibration velocities v(*)RMS(fi) [mm·s−1] for a rotating conveyor roller with a diameter Dr [mm] were carried out using a laboratory machine, see Figure 3, under the same technical conditions, on two types of fixed conveyor idlers (where the basic dimensions comply with the standard CSN ISO 1537 [52]), see Figure 10a. The fixed roller idler support consists of rollers with diameter Dr [mm], with their axles firmly embodied in the cut-outs of trestles 1, placed on a sleeper 2 made of a tube with a circular cross-section.

Figure 10.

(a) Fixed conveyor idler—basic dimensions (in Table 2), (b) roller support with traditional trestles, (c) conveyor idler with plastic brackets in trestles. 1—trestle, 2—sleeper, 3—plastic bracket.

Table 2.

Basic dimensions of the conveyor idler according to [52].

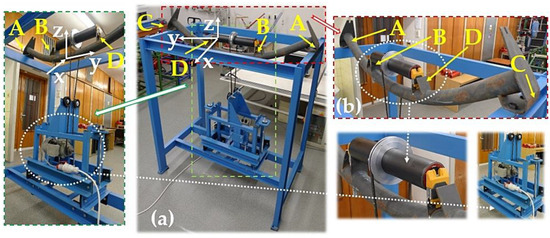

The experimental measurement of the vibration velocities v(*)RMS(fi) [mm·s−1] was carried out in a central roller (horizontally placed roller in a fixed idler), see Figure 10a, of our laboratory machine. A conveyor roller of a given diameter Dr [mm] fitted with a V-belt pulley assembly, see Figure 4a and Figure 5a,d, was rotated by means of a V-belt [42] with revolutions nr [min−1] (see Table 1). Using two acceleration sensors [46], the vibrations of the rotating conveyor roller positioned in the trestle were detected (B or D), see Figure 11, in the fixed conveyor idler and at the point of the mechanical attachment of the roller support to the upper beam of the steel frame of the laboratory machine (A or C), see Figure 11.

Figure 11.

(a) A laboratory machine used to measure the vibrations of the conveyor rollers; (b) measuring points A, B, C, and D on a fixed conveyor idler where accelerometers are placed.

3.1. The Plastic Trestle of a Fixed Conveyor Idler, the Plastic Casing of the Conveyor Roller

Table 3 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 89 mm plastic casing at the measuring points A and B for a fixed conveyor idler with plastic brackets (Figure 8) of our laboratory machine (Figure 11).

Table 3.

Roller axle placement—plastic trestle, measuring points A and B, roller casing—plastic, Dr = 89 mm.

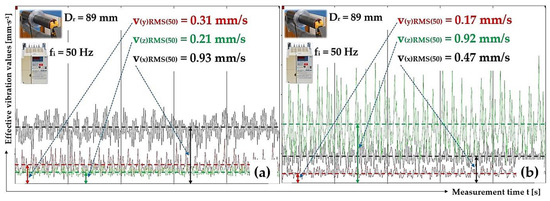

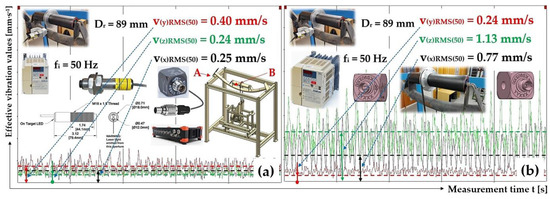

Figure 12 indicates the measured effective values of the vibration speed v(*)RMS(50) [mm·s−1] in the “x”, “y”, and “z” axes of the selected coordinate system at circumferential speed vr = 3.84 m·s−1 for a conveyor roller with a plastic casing of 89 mm diameter.

Figure 12.

Effective vibration values v(*)RMS(fi) [mm·s−1], ϕ89 mm plastic roller, the circumferential speed of the roller vr = 3.84 m·s−1, plastic trestle, (a) measuring point A, (b) measuring point B.

With regard to the scope of this paper, the measured graphs of the effective values of the vibration velocities v(*)RMS(fi) [mm·s−1] are not presented in this paper for circumferential speeds vr = 2.5 m·s−1 and vr = 1.25 m·s−1 for conveyor rollers with a diameter of 89 mm. In case of interest in these measured vibration waveforms, the author of this paper can supply the measured data sets with the graphic records of the measured vibration values for the conveyor rollers (with a steel or plastic casing), whose axles are placed in plastic brackets, Figure 10c, or on a steel trestle, Figure 10b, of the fixed conveyor idler. The measured courses of the effective values of the vibration velocities v(*)RMS(fi) [mm·s−1] are listed in the appendix with the title “Measured data” [53].

Table 4 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 89 mm plastic casing at the measuring points C and D for a fixed conveyor idler with plastic brackets.

Table 4.

Roller axle placement—plastic trestle, measuring points C and D, roller casing—plastic, Dr = 89 mm.

Table 5 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 89 mm plastic casing at the measuring points C and D for a fixed conveyor idler with plastic brackets.

Table 5.

Roller axle placement—plastic trestle, measuring points A and B, roller casing—plastic, Dr = 108 mm.

Table 6 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 108 mm plastic casing at the measuring points C and D for a fixed conveyor idler with plastic brackets.

Table 6.

Roller axle placement—plastic trestle, measuring points C and D, roller casing—plastic, Dr = 108 mm.

Table 7 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 133 mm plastic casing at the measuring points A and B for a fixed conveyor idler with plastic brackets.

Table 7.

Roller axle placement—plastic trestle, measuring points A and B, roller casing—plastic, Dr = 133 mm.

Table 8 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 133 mm plastic casing at the measuring points C and D for a fixed conveyor idler with plastic brackets.

Table 8.

Roller axle placement—plastic trestle, measuring points C and D, roller casing—plastic, Dr = 133 mm.

From Table 3, Table 4, Table 5, Table 6, Table 7 and Table 8, it is clear that the effective vibration values in individual coordinate axes, v(*)RMS(fi) [mm·s−1], measured at points A to D grow with the increasing speed vr [m·s−1] of the conveyor roller rotation with a plastic casing, the axle of which is mounted in a plastic support.

3.2. The Plastic Trestle of a Fixed Conveyor Idler, the Steel Casing of the Conveyor Roller

Table 9 displays the effective vibration velocity values v(*)RMS(fi) [mm·s−1] that were read from the DEWESoft X measurement software provided for the vibration measurements of a steel casing roller with a diameter of 89 mm. These were taken at measuring points A and B of the conveyor idler with plastic brackets on our laboratory device.

Table 9.

Roller axles placement—plastic trestle, measuring points A and B, roller casing—steel, Dr = 89 mm.

Figure 13 indicates the measured effective values of the vibration speed v(*)RMS(50) [mm·s−1] in the “x”, “y”, and “z” axes of the selected coordinate system at circumferential speed vr = 3.84 m·s−1 for a conveyor roller with a steel casing of 89 mm diameter. Vibration sensors have been placed at measuring points A and B. The measured courses of the effective values of the vibration velocities v(*)RMS(fi) [mm·s−1] are listed in the appendix with the title “Measured data” [53].

Figure 13.

Effective vibration values v(*)RMS(fi) [mm·s−1], ϕ89 mm steel roller, the circumferential speed of the roller vr = 3.84 m·s−1, plastic trestle, (a) measuring point A, (b) measuring point B.

Table 10 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 89 mm steel casing at the measuring points C and D for a fixed conveyor idler with plastic brackets.

Table 10.

Roller axles placement—plastic trestle, measuring points C and D, roller casing—steel, Dr = 89 mm.

Table 11 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 108 mm steel casing at the measuring points A and B for a fixed conveyor idler with plastic brackets.

Table 11.

Roller axles placement—plastic trestle, measuring points A and B, roller casing—steel, Dr = 108 mm.

Table 12 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 108 mm steel casing at the measuring points C and D for a fixed conveyor idler with plastic brackets.

Table 12.

Roller axles placement—plastic trestle, measuring points C and D, roller casing—steel, Dr = 108 mm.

Table 13 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 133 mm steel casing at the measuring points A and B for a fixed conveyor idler with plastic brackets.

Table 13.

Roller axles placement—plastic trestle, measuring points A and B, roller casing—steel, Dr = 133 mm.

Table 14 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 133 mm steel casing at the measuring points C and D for a fixed conveyor idler with plastic brackets.

Table 14.

Roller axles placement—plastic trestle, measuring points C and D, roller casing—steel, Dr = 133 mm.

From Table 9, Table 10, Table 11, Table 12, Table 13 and Table 14, it follows that the conveyor roller with a diameter of 108 mm has the highest effective vibration values in individual coordinate axes, v(*)RMS(fi) [mm·s−1], measured at points B and D of the steel casing, the axis of which is stored in a plastic support.

3.3. The Steel Trestle of the Fixed Conveyor Idler, the Plastic Casing of the Conveyor Roller

Table 15 lists the effective vibration velocity values v(*)RMS(fi) [mm·s−1] that were read from the DEWESoft X measurement software for the vibration values of a conveyor roller with a diameter of 89 mm plastic casing taken at measuring points A and B of a fixed conveyor idler with steel trestles, see Figure 10a, of the laboratory device (Figure 11).

Table 15.

Roller axles placement—steel trestle, measuring points A and B, roller casing—plastic, Dr = 89 mm.

Figure 14 shows the measured RMS values for the vibration velocity v(*)RMS(50) [mm·s−1] in axes “x”, “y”, and “z” for the selected coordinate system at circumferential speed vr = 3.84 m·s−1 of the conveyor roller with a plastic casing with an 89 mm diameter. With regard to the scope of this paper, the measured graphs of the effective values of the vibration velocities v(*)RMS(fi) [mm·s−1] are not presented in this paper for circumferential speeds vr = 2.5 m·s−1 and vr = 1.25 m·s−1. The measured courses of the effective values of the vibration velocities v(*)RMS(fi) [mm·s−1] are listed in the appendix with the title “Measured data” [53].

Figure 14.

Effective vibration values v(*)RMS(fi) [mm·s−1], ϕ89 mm plastic roller, the circumferential speed of the roller vr = 3.85 m·s−1, steel trestle, (a) measuring point A, (b) measuring point B.

Table 16 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 89 mm plastic casing at the measuring points C and D for a fixed conveyor idler with steel brackets.

Table 16.

Roller axles placement—steel trestle, measuring points C and D roller casing—plastic, Dr = 89 mm.

Table 17 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 108 mm plastic casing at the measuring points A and B for a fixed conveyor idler with steel brackets.

Table 17.

Roller axles placement—steel trestle, measuring points A and B roller casing—plastic, Dr = 108 mm.

Table 18 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 108 mm plastic casing at the measuring points C and D for a fixed conveyor idler with steel brackets.

Table 18.

Roller axles placement—steel trestle, measuring points C and D roller casing—plastic, Dr = 108 mm.

Table 19 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 133 mm plastic casing at the measuring points A and B for a fixed conveyor idler with steel brackets.

Table 19.

Roller axles placement—steel trestle, measuring points A and B roller casing—plastic, Dr = 133 mm.

Table 20 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 133 mm plastic casing at the measuring points A and B for a fixed conveyor idler with steel brackets.

Table 20.

Roller axles placement—steel trestle, measuring points C and D roller casing—plastic, Dr = 133 mm.

From Table 15, Table 16, Table 17, Table 18, Table 19 and Table 20, it is clear that the effective vibration values in individual coordinate axes, v(*)RMS(fi) [mm·s−1], measured at points A to D grow with the increasing speed vr [m·s−1] of the conveyor roller rotation with a plastic casing, the axle of which is mounted in a steel support.

3.4. The Steel Trestle of the Fixed Conveyor Idler, the Steel Casing of the Conveyor Roller

Table 21 lists the effective vibration velocity values v(*)RMS(fi) [mm·s−1] that have been read from the DEWESoft X software for the vibration values measured on the 89 mm diameter conveyor roller with the steel casing at the measuring points A and B of the fixed conveyor idler. The flattened ends of the conveyor roller axle are supported in the steel trestles of the fixed conveyor idler.

Table 21.

Roller axles placement—steel trestle, measuring points A and B roller casing—steel, Dr = 89 mm.

Figure 15 indicates the measured effective values of the vibration speed v(*)RMS(50) [mm·s−1] in the “x”, “y”, and “z” axes of the selected coordinate system at circumferential speed vr = 3.84 m·s−1 for a conveyor roller with a steel casing of 89 mm diameter. Vibration sensors have been placed at measuring points A and B. The measured courses of the effective values of the vibration velocities v(*)RMS(fi) [mm·s−1] are listed in the appendix with the title “Measured data” [53].

Figure 15.

Effective vibration values v(*)RMS(fi) [mm·s−1], ϕ89 mm steel roller, the circumferential speed of the roller vr = 3.84 m·s−1, steel trestle, (a) measuring point A, (b) measuring point B.

Table 22 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 89 mm steel casing at the measuring points A and B for a fixed conveyor idler with steel brackets.

Table 22.

Roller axles placement—steel trestle, measuring points C and D roller casing—steel, Dr = 89 mm.

Table 23 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 108 mm steel casing at the measuring points A and B for a fixed conveyor idler with steel brackets.

Table 23.

Roller axles placement—steel trestle, measuring points A and B roller casing—steel, Dr = 108 mm.

Table 24 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 108 mm steel casing at the measuring points C and D for a fixed conveyor idler with steel brackets.

Table 24.

Roller axles placement—steel trestle, measuring points C and D roller casing—steel, Dr = 108 mm.

Table 25 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 133 mm steel casing at the measuring points A and B for a fixed conveyor idler with steel brackets.

Table 25.

Roller axles placement—steel trestle, measuring points A and B roller casing—steel, Dr = 133 mm.

Table 26 indicates the effective vibration velocity values v(*)RMS(fi) [mm·s−1], which have been read from the DEWESoft X measurement software, for the vibration measurements of a conveyor roller with a diameter of 133 mm steel casing at the measuring points A and B for a fixed conveyor idler with steel brackets.

Table 26.

Roller axles placement—steel trestle, measuring points C and D roller casing—steel, Dr = 133 mm.

From Table 21, Table 22, Table 23, Table 24, Table 25 and Table 26, it follows that the conveyor roller with a diameter of 108 mm has the highest effective vibration values in individual coordinate axes, v(*)RMS(fi) [mm·s−1], measured at points B and D with speed vr = 2.5 m·s−1 of the conveyor roller rotation with a steel casing, the axis of which is stored in a plastic support.

4. Discussion

The aim of this paper was to detect vibrations transmitted by the rotating casing of the conveyor roller to the fixed conveyor idler and also to the steel frame of the laboratory machine to which the fixed conveyor idler is attached. The measurement of the vibrations of the roller casing installed on a laboratory stand, and an assessment of the technical condition of the belt conveyor rollers after the specified operating time, were also carried out in [33]. In the conclusions of the vibration measurements of the conveyor roller carried out by both laboratory machines, similar results were achieved.

From the measured time curves of the vibration value for conveyor rollers of 89 mm, 108 mm, and 133 mm diameters rotating at circumferential speeds of 1.25, 2.5, and 3.85 m·s−1, with the help of the DEWESoft X software, the effective values for the vibration velocities were determined, and these are listed in Table 3, Table 4, Table 5, Table 6, Table 7, Table 8, Table 9, Table 10, Table 11, Table 12, Table 13, Table 14, Table 15, Table 16, Table 17, Table 18, Table 19, Table 20, Table 21, Table 22, Table 23, Table 24, Table 25 and Table 26.

The vibration values of the conveyor rollers show that the effective values of the vibration velocity increase with the increasing speed (circumferential speed) of the conveyor roller casings. This assumption is confirmed in the findings presented in the article [9] by Klimenda et al., who deal in their article [11] with the measurement of the noise and vibration of rollers designed for belt conveyors. The three highest acceleration values depending on the frequency of the vibration in each direction (x, y, z) correspond to the measured effective vibration values v(*)RMS(fi) [mm·s−1] in the coordinate axes (x, y, z). For more information, see Section 3.1, Section 3.2, Section 3.3 and Section 3.4.

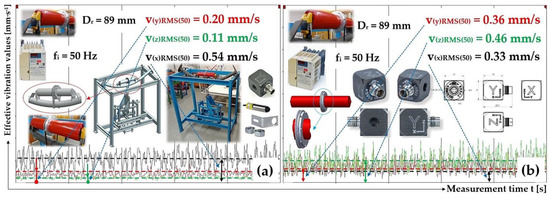

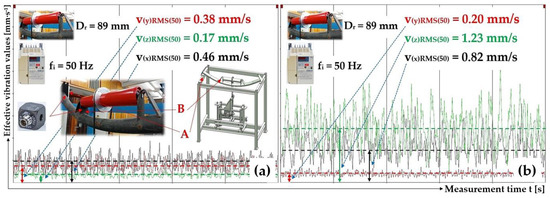

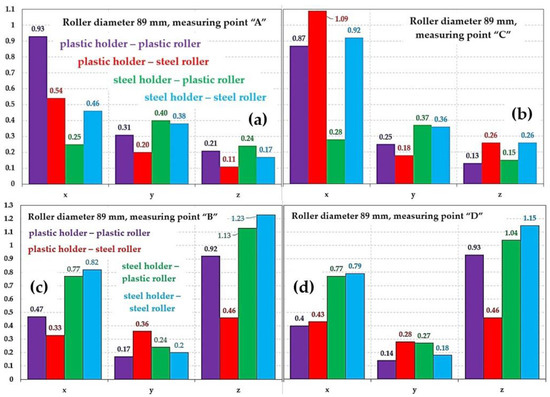

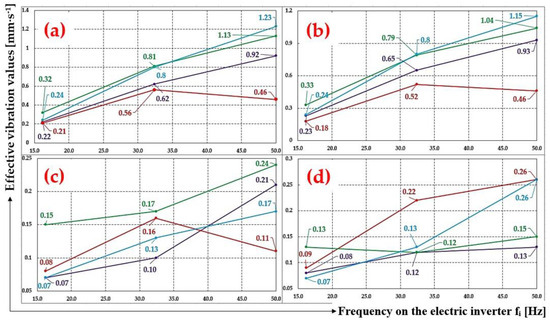

Figure 16c,d show that the highest effective values of the vibration velocity v(*)RMS(fi) [mm·s−1] reach the conveyor roller with an ϕ89 mm diameter placed in the steel trestle of a fixed conveyor idler, and that is in the “z” axis (vertical direction). This fact can be traced in the article [12], in which the three highest values of acceleration depending on the frequency of the vibration in each direction are described.

Figure 16.

The effective vibration values v(*)RMS(fi) [mm·s−1] of conveyor rollers with an 89 mm diameter, at revolutions of 825 min−1. Measuring point as in Figure 11 (a) A, (b) C, (c) B, (d) D.

At the revolutions of the steel casing conveyor roller nr = 825 min−1 and the roller axle placement of the conveyor with an 89 mm diameter into plastic brackets (see Figure 11 part B), the effective value of the vibration velocity v(*)RMS(fi) [mm·s−1] in axis “z” reaches 37.4% of the value v(*)RMS(fi) [mm·s−1], compared to placing this roller in a steel trestle.

When the axle of the steel conveyor roller with an ϕ89 mm diameter is fitted into the plastic brackets (see Figure 11 part D), the effective value of the vibration velocity v(*)RMS(fi) [mm·s−1] in the “z” axis reaches 40% of the value v(*)RMS(fi) [mm·s−1], unlike when placed in a steel trestle.

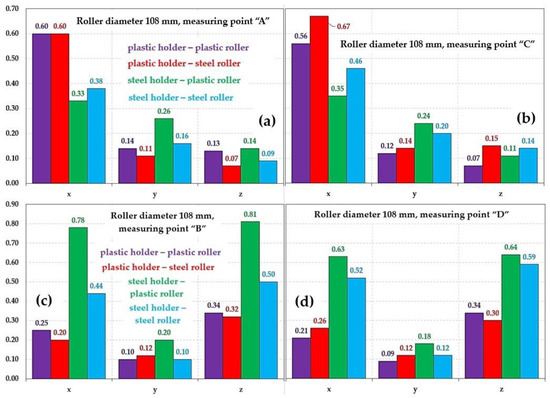

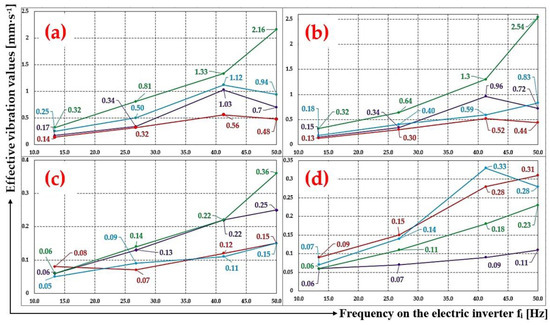

Figure 17c,d show that the highest effective values of the vibration velocity v(*)RMS(fi) [mm·s−1] reach the conveyor roller with a ϕ108 mm diameter placed in the steel trestle of a fixed conveyor idler, and that is in the “z” axis (vertical direction).

Figure 17.

The effective vibration values v(*)RMS(fi) [mm·s−1] of conveyor rollers with a 108 mm diameter, at revolutions of 442 min−1. Measuring point as in Figure 11 (a) A, (b) C, (c) B, (d) D.

At the revolutions of the steel casing conveyor roller nr = 442 min−1 and the roller axle placement of the conveyor with a 108 mm diameter into plastic brackets (see Figure 11 part B), the effective value of the vibration velocity v(*)RMS(fi) [mm·s−1] in axis “z” reaches 41.9% of the value v(*)RMS(fi) [mm·s−1], compared to placing this roller in a steel trestle.

When the axle of the steel conveyor roller with a ϕ108 mm diameter is fitted into the plastic brackets (see Figure 11 part D), the effective value of the vibration velocity v(*)RMS(fi) [mm·s−1] in the “z” axis reaches 46.9% of the value v(*)RMS(fi) [mm·s−1], unlike when placed in a steel trestle.

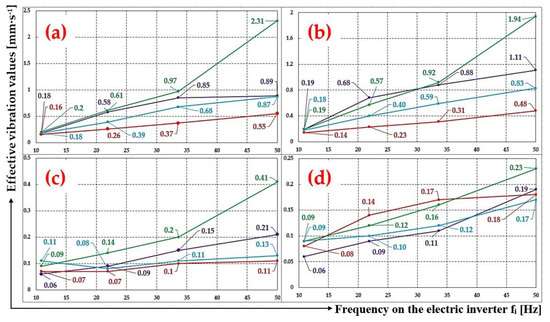

From Figure 18c,d, it is clear that the biggest differences in the effective values of the vibration velocity v(*)RMS(fi) [mm·s−1] are reached by the conveyor rollers with a 133 mm diameter, when these are placed in the fixed trestle of a conveyor idler, and these are reached in the “z” axis direction (vertical direction).

Figure 18.

The effective vibration values v(*)RMS(fi) [mm·s−1] of conveyor rollers with a 133 mm diameter, at revolutions 361 min−1. Measuring point as in Figure 11 (a) A, (b) C, (c) B, (d) D.

At the revolutions of the steel casing conveyor roller nr = 361 mim−1 and the roller axle placement of the conveyor with a 108 mm diameter into plastic brackets (see Figure 11 part B), the effective value of the vibration velocity v(*)RMS(fi) [mm·s−1] in axis “z” reaches 66.7% of the value v(*)RMS(fi) [mm·s−1], compared to placing this roller in a steel trestle.

When the axle of the steel conveyor roller with a ϕ133 mm diameter is fitted into the plastic brackets (see Figure 11 part D), the effective value of the vibration velocity v(*)RMS(fi) [mm·s−1] in the “z” axis reaches 57.5% of the value v(*)RMS(fi) [mm·s−1], unlike when placed in a steel trestle.

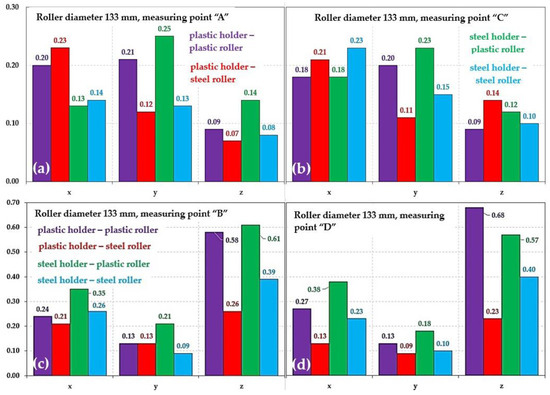

In Figure 19, we can see the effective vibration values v(*)RMS(fi) [mm·s−1] for the rotating conveyor rollers measured at the points A to D, of which the plastic or steel casing of a 133 mm diameter rotates at a circumferential speed of vr = 5.74 (3.84, 2.5, or 1.25) m·s−1, provided that the flattened ends of the conveyor roller axles are fitted into the steel or plastic trestle of the fixed conveyor idler.

Figure 19.

The effective vibration values v(*)RMS(fi) [mm·s−1] of ϕ133 mm conveyor rollers at different revolutions when red line is plastic trestle, roller casing—steel, blue line is steel trestle, roller casing—steel, fialová line is plastic trestle, roller casing—plastic, and green line is steel trestle, roller casing—plastic. Measuring point as in Figure 11 (a) B, (b) D, (c) A, (d) C.

Graphs (a) to (d) show that the effective vibration values v(*)RMS(fi) [mm·s−1] of the rotating conveyor rollers reach the highest values at higher frequencies set on the frequency converter (the speed of the driving electric motor was controlled by a frequency converter) corresponding to the revolutions of the conveyor rollers.

Research by K. Hicke at al. [54] focuses on monitoring the acoustic condition and detection of roller faults in industrial conveyor belts.

Graphs (a) to (d) also show that the higher effective vibration values v(*)RMS(fi) [mm·s−1] were measured at points A to D, in the case when the axles of the conveyor rollers were placed in a steel trestle (green and blue curves) than when the axles of the conveyor rollers were positioned in plastic brackets (purple and red colour curves).

In Figure 20, we can see the effective vibration values v(*)RMS(fi) [mm·s−1] for the rotating conveyor rollers measured at the points A to D, of which the plastic or steel casing of a 108 mm diameter rotates at a circumferential speed of vr = 4.66 (3.84, 2.5, or 1.25) m·s−1, provided that the flattened ends of the conveyor roller axles are fitted into the steel or plastic trestle of the fixed conveyor idler.

Figure 20.

The effective vibration values v(*)RMS(fi) [mm·s−1] of ϕ108 mm conveyor rollers at different revolutions when red line is plastic trestle, roller casing—steel, blue line is steel trestle, roller casing—steel, fialová line is plastic trestle, roller casing—plastic, and green line is steel trestle, roller casing—plastic. Measuring point as in Figure 11 (a) B, (b) D, (c) A, (d) C.

In Figure 21, we can see the effective vibration values v(*)RMS(fi) [mm·s−1] for the rotating conveyor rollers measured at the points A to D, of which the plastic or steel casing of an 89 mm diameter rotates at a circumferential speed of vr = 3.84 (2.5 or 1.25) m·s−1, provided that the flattened ends of the conveyor roller axles are fitted into the steel or plastic trestle of the fixed conveyor idler.

Figure 21.

The effective vibration values v(*)RMS(fi) [mm·s−1] of ϕ89 mm conveyor rollers at different revolutions when red line is plastic trestle, roller casing—steel, blue line is steel trestle, roller casing—steel, fialová line is plastic trestle, roller casing—plastic, and green line is steel trestle, roller casing—plastic. Measuring point as in Figure 11 (a) B, (b) D, (c) A, (d) C.

The provided vibration measurements of the rotating conveyor rollers with their axles fitted in the steel or plastic trestles of the fixed conveyor idler, performed on the non-rotating parts of our laboratory machine, are sufficient to appropriately characterize the operating conditions with regard to trouble-free operation. Measurements were made with regard to ISO 10816-1 [6], which specifies the general conditions and procedures for the measurement and evaluation of vibration by means of measurements carried out on non-rotating parts. The general evaluation criteria, which are presented in the form of both magnitude and vibration change, apply to both in-service monitoring and acceptance tests. The criteria were set primarily with regard to ensuring the reliable, safe, and long-term operation of the machine (i.e., a belt conveyor) while minimizing the adverse effects on the connected equipment.

Vibrations lead to fatigue failure or damage, which is harmful to engine-supporting structures [55].

Monitoring the health condition of rotating machinery in manufacturing systems usually requires vibration signals to be continuously collected, transmitted, and stored, states the article [56] by Lu, Y. and Wang, Y. Here, a new technique called physics-constrained dictionary learning is proposed to reduce the volume of data in storage and communication using compressed sensing. The proposed scheme is applied to compress the vibration signals of roller bearings.

The uninterrupted and trouble-free operation of induction motors (IMs) is the compulsion of modern industries, states the article [57] by Gangsar, P. and Tiwari, R.

5. Conclusions

This paper presents a design solution for an experimental machine on which the vibrations of a rotating casing of a conveyor roller can be detected in laboratory conditions. The laboratory machine was created to confirm the theoretical assumption that the magnitude of the vibration decreases when the axles of the conveyor roller are placed in plastic brackets. These plastic brackets were attached to the structurally modified trestles of a fixed conveyor idler. This theoretical assumption stated in the article was proved.

The tested conveyor rollers (casing diameter 133 mm, 108 mm, and 89 mm, casing length 465 mm), with a V-pulley fitted on their casing, were placed behind the axle into the support cut-outs on the cross bar of one of the two firm conveyor idlers.

One conveyor idler used in the experimental testing was of the standard design and the other one was of an atypical design. The atypical design consists of the modification of supports fitted with plastic holders, into whose cut-outs those flattened parts are inserted (with width 14 mm, length 10 mm, see Figure 4 and Figure 5 for both ends of the axle (the total length of 493 mm)) of the conveyor roller.

The authors of this article carried out experimental measurements based on the measurement of the vibrations of the rotating conveyor roller on the non-rotating parts, i.e., on the trestle of the fixed conveyor idler and in the place of the mechanical attachment of the conveyor idler to the steel frame of the laboratory machine. Vibrations were detected by acceleration sensors, recorded by a measuring apparatus, and displayed on a PC monitor in the environment of Dewesoft X software. With the help of the software, the measured vibration values were converted into the effective values of the vibration speed, and these were recorded in tables (see Table 3, Table 4, Table 5, Table 6, Table 7, Table 8, Table 9, Table 10, Table 11, Table 12, Table 13, Table 14, Table 15, Table 16, Table 17, Table 18, Table 19, Table 20, Table 21, Table 22, Table 23, Table 24, Table 25 and Table 26).

One so-called “V-belt pulley assembly” unit was placed onto the tested conveyor roller (with a steel or plastic casing) with a diameter of Dr [mm], see Figure 5. This assembly consists of a flange, with screw connections attaching a pulley with the calculated diameter of 141.5 mm.

The measured instantaneous values of the vibrations at time t [s] were presented in graphs (see Figure 12, Figure 13, Figure 14 and Figure 15). Due to the limited space for this article, in Section 3, only the selected measurement records are presented (in case of interest, all records are available from the authors of this article).

This article also describes the design modification of the fixed conveyor idler, the result of which is the installation of plastic brackets in the places where the flattened end parts of the conveyor roller axles are inserted into the notches created in the steel trestle of the traditional fixed conveyor idler. This modified fixed conveyor idler is characterized by two plastic brackets with notches, into which the flattened end parts of the conveyor roller axles are inserted.

The evaluation of the measured data made it possible to conclude that the use of plastic brackets can reduce the vibration values transmitted from the rotating casings of the conveyor rollers into the supporting structure of the belt conveyor.

When the axle of the steel conveyor roller with a diameter of ϕ89 mm (ϕ108 mm and ϕ133 mm) is fitted into the plastic brackets, the effective value of the vibration velocity in the “z” axis reaches 40% (46.9% and 57.5%) of the value, unlike when placed in a steel trestle. Vibrations generated by the rotating casings of the conveyor rollers in industrial plants with their casings covered with dirt produce excessive secondary noise, which is undesirable in the production hall.

Vibrations and noise are adversely manifested with the higher speed of the conveyor belt, which corresponds directly to the higher revolutions and circumferential speed of the conveyor rollers.

The limitations of this study are as follows:

- −

- The experimental measurement of the vibration velocities v(*)RMS(fi) [mm·s−1] was carried out in a central roller (horizontally placed roller in a fixed idler).

- −

- The effective values of the vibration velocity vRMS [m·s−1] were measured for two different fittings of the conveyor roller axles. One is the traditional placement of the flattened ends of the roller axle in the notches of the trestles, see Figure 3b on the fixed conveyor idler. The second way is to position these flattened ends of the roller axle in plastic brackets inserted into the specially designed steel trestles of the fixed conveyor idler.

- −

- Using two acceleration sensors, the vibrations of the rotating conveyor roller positioned in the trestle were detected (B or D) in the fixed conveyor idler and at the point of the mechanical attachment of the roller support to the upper beam of the steel frame of the laboratory machine (A or C).

- −

- Laboratory measurements were carried out on conveyor rollers with various diameters Dr [mm] (133, 108, and 89), at the same circumferential speeds vr [m·s−1] of their casings.

- −

- One or two so-called “V-belt pulley assembly” units were placed onto the tested conveyor roller (with a steel or plastic casing) with a diameter of Dr = 133 mm (or 108 mm or 89 mm). This assembly consists of a flange, with screw connections attaching a pulley with the calculated diameter of Dw = 153 mm.

- −

- The vibrations of the transport rollers were measured at the speed of rotation vr = 3.84 m·s−1, 2.5 m·s−1, and 1.25 m·s−1.

All the measured courses of the effective values of the vibration velocities v(*)RMS(fi) [mm·s-1], which are listed in Section 3 in Table 3, Table 4, Table 5, Table 6, Table 7, Table 8, Table 9, Table 10, Table 11, Table 12, Table 13, Table 14, Table 15, Table 16, Table 17, Table 18, Table 19, Table 20, Table 21, Table 22, Table 23, Table 24, Table 25 and Table 26, are listed in the appendix entitled “Measured data” [53].

It is intended to carry out more extensive experimental measurement analyses on this laboratory machine, the purpose of which is to obtain the vibration values of conveyor rollers with a rubberized casing, for the diameters of 133 mm, 108 mm, and 89 mm.

Author Contributions

Conceptualization, L.H. and Š.P.; methodology, L.H.; software, Š.P.; validation, E.N., T.M. and D.K.; formal analysis, L.H.; investigation, L.H.; resources, D.K.; data curation, E.N.; writing—original draft preparation, L.H.; writing—review and editing, L.H.; visualization, L.H. and E.N.; supervision, T.M.; project administration, L.H.; funding acquisition, L.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by “Research and innovation of modern processes and technologies in industrial practice”, grant number SP2023/003 and “Research and development of modern processes in industrial practice”, grant number SP2024/001 and was funded by MŠMT ČR (Ministry of education youth and sports).

Data Availability Statement

Measured data of effective vibration speed values v(*)RMS(fi) [mm·s−1], listed from Table 3, Table 4, Table 5, Table 6, Table 7, Table 8, Table 9, Table 10, Table 11, Table 12, Table 13, Table 14, Table 15, Table 16, Table 17, Table 18, Table 19, Table 20, Table 21, Table 22, Table 23, Table 24, Table 25 and Table 26 and processed using DEWESoft X software, can be sent in case of interest, by prior written agreement, in *.XLSX (Microsoft Excel) format.

Acknowledgments

This work has been supported by the Ministry of Education, Youth and Sports of the Czech Republic from the Specific Research Project SP2023/003 (SV3403351) and the Specific Research Project SP2024/001.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Singiresu, S.R. Mechanical Vibrations; Addison Wesley: Boston, MA, USA, 1995. [Google Scholar]

- Myklestad, N.O. Fundamentals of Vibration Analysis; Courier Dover Publications: Mineola, NY, USA, 2018. [Google Scholar]

- Weaver, W., Jr.; Timoshenko, S.P.; Young, D.H. Vibration Problems in Engineering; John Wiley & Sons: Stanford, CA, USA, 1991. [Google Scholar]

- Bachmann, H. Vibration Problems in Structures: Practical Guidelines; Springer Science & Business Media: Berlin, Germany, 1995. [Google Scholar]

- Buzdugan, G.; Mihailescu, E.; Rades, M. Vibration Measurement; Springer Science & Business Media: Berlin, Germany, 1986; Volume 8. [Google Scholar]

- ČSN ISO 10816-1; Mechanical Vibration—Evaluation of Machine Vibration by Measurements on Non-Rotating Parts—Part 1: General Guidelines (In Czech: Vibrace—Hodnocení Vibrací Strojů na Základě Měření na Nerotujících Částech—Část 1: Všeobecné Směrnice). Czech Office for Standards: Praha, Czech Republic, 1998. Available online: https://www.technicke-normy-csn.cz/csn-iso-10816-1-011412-158753.html (accessed on 17 September 2022).

- Perun, G. Attempt to evaluate the technical condition of the rollers of the belt conveyor by vibration measurements. Vibroengineering Procedia 2014, 3, 296–299. [Google Scholar]

- Smith, J.D. Vibration Measurement and Analysis; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Hrabovsky, L.; Pravda, S.; Sebesta, R.; Novakova, E.; Kurac, D. Detection of a Rotating Conveyor Roller Casing Vibrations on a Laboratory Machine. Symmetry 2023, 15, 1626. [Google Scholar] [CrossRef]

- Peruń, G.; Opasiak, T. Assessment of technical state of the belt conveyor rollers with use vibroacoustics methods-preliminary studies. Diagnostyka 2016, 17, 75–80. [Google Scholar]

- Klimenda, F.; Kampo, J.; Hejma, P. Vibration measurement of conveyor. Manuf. Technol. 2019, 19, 604–608. [Google Scholar]

- Svoboda, M.; Klimenda, F.; Kampo, J.; Soukup, J. Rollers Vibration of Conveyor Belt. Control and Stability; Department of Automation, Biomechanics and Mechatronics: Łódź, Polish, 2015. [Google Scholar]

- Bortnowski, P.; Krol, R.; Ozdoba, M. Roller damage detection method based on the measurement of transverse vibrations of the conveyor belt. Eksploat. I Niezawodn. 2022, 24, 510–521. [Google Scholar] [CrossRef]

- Peng, C.; Li, Z.; Yang, M.; Fei, M.; Wang, Y. An audio-based intelligent fault diagnosis method for belt conveyor rollers in sand carrier. Control. Eng. Pract. 2020, 105, 104650. [Google Scholar] [CrossRef]

- Svoboda, M.; LeComte, D.; Hayes, M.; Heim, R.; Gleason, K.; Angel, J.; Stephens, S. The drought monitor. Bull. Am. Meteorol. Soc. 2002, 83, 1181–1190. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, X. A new energy calculation model of belt conveyor. In AFRICON; IEEE Xplore: Piscataway, NJ, USA, 2009; pp. 1–6. [Google Scholar] [CrossRef]

- Alspaugh, M. Biannual Symposium on Bulk Material Handling by Conveyor Belt, Salt Lake City. Available online: https://www.osti.gov/etdeweb/biblio/20242523 (accessed on 9 December 2022).

- Havey, C.R. Belt Conveyors for Bulk Materials; Pennsylvania State University: State College, PA, USA, 1979. Available online: https://www.osti.gov/biblio/6407550 (accessed on 18 April 2023).

- Nascimento, R.; Carvalho, R.; Delabrida, S.; Bianchi, A.G.; Oliveira, R.A.R.; Garcia, L.G.U. An integrated inspection system for belt conveyor rollers. In Proceedings of the 19th International Conference on Enterprise Information Systems (ICEIS), Porto, Portugal, 26–29 April 2017; Volume 2, pp. 190–200. [Google Scholar]

- Hou, Y.F.; Meng, Q.R. Dynamic characteristics of conveyor belts. J. China Univ. Min. Technol. 2008, 18, 629–633. [Google Scholar] [CrossRef]

- Lozier, M.S. Deconstructing the conveyor belt. Science 2010, 328, 1507–1511. [Google Scholar] [CrossRef]

- Hrabovsky, L.; Nenicka, P.; Fries, J. Laboratory Machine Verification of Force Transmission Provided by Friction Acting on the Drive Drum of a Conveyor Belt. Machines 2023, 11, 544. [Google Scholar] [CrossRef]

- Stace, L.R.; Yardleym, E.D. Belt Conveying of Minerals; Elsevier: Oxford, UK, 2008. Available online: https://www.osti.gov/etdeweb/biblio/21036867 (accessed on 28 February 2022).

- Fiset, M.; Dussault, D. Laboratory simulation of the wear process of belt conveyor rollers. Wear 1993, 162, 1012–1015. [Google Scholar] [CrossRef]

- Hrabovsky, L.; Ucen, O.; Kudrna, L.; Cepica, D.; Frydrysek, K. Laboratory Device Detecting Tensile Forces in the Rope and Coefficient of Friction in the Rope Sheave Groove. Machines 2022, 10, 590. [Google Scholar] [CrossRef]

- Folta, Z.; Camlík, P. The conveyor rollers innovation and validation. Trans. VŠB Tech. Univ. Ostrav. Mech. Ser. 2009, 1, 1651. [Google Scholar]

- Hrabovsky, L.; Gaszek, J.; Kovar, L.; Fries, J. A Laboratory Device Designed to Detect and Measure the Resistance Force of a Diagonal Conveyor Belt Plough. Sensors 2023, 23, 3137. [Google Scholar] [CrossRef]

- Primary Belt Scraper. Available online: https://www.asgco.com/products/product_category/manufactured-products/conveyor-belt-cleaners/ (accessed on 2 May 2022).

- Secondary Belt Scraper. Available online: https://www.asgco.com/products/bc-2-conveyor-belt-cleaner/ (accessed on 9 December 2022).

- Rotary Brush Belt Cleaner. Available online: https://www.alibaba.com/showroom/rotary-brush-belt-cleaner.html (accessed on 20 January 2023).

- Eliasson, J.; Kyusakov, R.; Martinsson, P.E. An Internet of Things approach for intelligent monitoring of conveyor belt rollers. In Proceedings of the 10th International Conference on Condition Monitoring and Machinery Failure Prevention Technologies, Krakow, Poland, 18–20 June 2013; Volume 2, pp. 1096–1104. [Google Scholar]

- Malakhov, V.; Dyachenko, V. Rolling resistance coefficient of belt conveyor rollers as function of operating conditions in mines. Eurasian Min. 2022, 1, 67–71. [Google Scholar] [CrossRef]

- Alharbi, F.; Luo, S.; Zhang, H.; Shaukat, K.; Yang, G.; Wheeler, C.A.; Chen, Z. A brief review of acoustic and vibration signal-based fault detection for belt conveyor idlers using machine learning models. Sensors 2023, 23, 1902. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Pang, Y.; Lodewijks, G.; He, D. Experimental research on condition monitoring of belt conveyor idlers. Measurement 2018, 127, 277–282. [Google Scholar] [CrossRef]

- Soares, J.L.; Costa, T.B.; Moura, L.S.; Sousa, W.S.; Mesquita, A.L.; Mesquita, D.S. Machine Learning Based Fault Detection on Belt Conveyor Idlers. In Proceedings of the DINAME 2023—XIX International Symposium on Dynamic Problems of Mechanics, Pirenópolis, Brazil, 26 February–3 March 2023. [Google Scholar]

- Gondek, H.; Kolman, J.; Bohac, D. Results of belt conveyors noise reduction with the new construction of roller holders. Int. Multidiscip. Sci. GeoConference SGEM 2022, 22, 369–376. [Google Scholar]

- Kolman, J.; Bohac, D. Noise reduction of belt conveyor tracks. Int. Multidiscip. Sci. GeoConference SGEM 2020, 20, 195–202. [Google Scholar]

- Kulinowski, P.; Kasza, P.; Zarzycki, J. Influence of design parameters of idler bearing units on the energy consumption of a belt conveyor. Sustainability 2021, 13, 437. [Google Scholar] [CrossRef]

- Krol, R.; Kisielewski, W. Research of loading carrying idlers used in belt conveyor-practical applications. Diagnostyka 2014, 15, 67–74. [Google Scholar]

- Gładysiewicz, L.; Konieczna-Fuławka, M. Influence of idler set load distribution on belt rolling resistance. Arch. Min. Sci. 2019, 64, 251–259. [Google Scholar]

- Gładysiewicz, L.; Krol, R.; Kisielewski, W. Measurements of loads on belt conveyor idlers operated in real conditions. Meas. J. Int. Meas. Confed. 2019, 134, 336–344. [Google Scholar] [CrossRef]

- Klínový Řemen Typ SPZ 2500 Lw 9.7x2513 La L=L. Available online: https://www.prumex.cz/klinovy-remen-spz-2500-lw-9-7x2513-la-l-l-profiplus-rubena/ (accessed on 11 July 2023).

- Třífázový Elektromotor 1.5 kW, 1400 RPM. Available online: https://elektromotory-vybo.cz/obchod/elektromotor-1-5kw-1400ot-90l-4-elektricky-motor/ (accessed on 24 January 2023).

- Ball Bearings 6204 2RS. Available online: https://www.fersa.com/en/technical-details/6204%202RS (accessed on 29 April 2022).

- Vasic, M.; Stojanovic, B.; Blagojevic, M. Failure analysis of idler roller bearings in belt conveyors. Eng. Fail. Anal. 2020, 117, 104898. [Google Scholar] [CrossRef]

- Hand-Arm Acceleration Sensor KS903.10. Available online: https://www.pce-instruments.com/eu/pce-instruments-hand-arm-acceleration-sensor-ks903.10-det_5966162.htm (accessed on 26 September 2021).

- Sirius Modular Data Acquisition (DAQ) System. Available online: https://dewesoft.com/products/sirius (accessed on 16 February 2023).

- DeweSoft General Catalog. Available online: https://www.scribd.com/document/546764750/dewesoft-product-catalog-en-latest (accessed on 29 January 2023).

- ISO 10816-3; Mechanical Vibration—Evaluation of Machine Vibration by Measurements on Non-Rotating Parts—Part 3: Industrial Machines with Nominal Power above 15 kW and Nominal Speeds between 120 r/min and 15 000 r/min when Measured In Situ (In Czech: Vibrace—Hodnocení Vibrací Strojů na Základě Měření na Nerotujících Částech—Část 3: Průmyslové Stroje se Jmenovitým Výkonem nad 15 kW a Jmenovitými Otáčkami Mezi 120 1/min a 15,000 1/min Při Měření In Situ). Czech Office for Standards: Praha, Czech Republic, 2010. Available online: https://www.technicke-normy-csn.cz/csn-iso-10816-3-011412-158763.html (accessed on 28 June 2023).

- ROLS/ROLS24 Remote Optical Laser Sensor, Instruction Manual. Available online: https://monarchserver.com/Files/pdf/1071-4851-118_ROLS_ROLS24_Manual.pdf (accessed on 26 September 2021).

- DS-TACHO-3 Technical Reference Manual. Available online: https://downloads.dewesoft.com/manuals/dewesoft-ds-tacho3-manual-en.pdf (accessed on 14 March 2022).

- ČSN ISO 1537; Continuous Mechanical Handling Equipment for Loose Bulk Materials. Troughed Belt Conveyors (Other than Portable Conveyors). Idlers. (In Czech: Zařízení pro Plynulou Dopravu Sypkých Hmot. Pásové Dopravníky s Korýtkovým Dopravním Profilem (Jiné Než Přenosné) Válečky). Federal Bureau of Standards and Measurements: Gaithersburg, MD, USA, 1993. Available online: https://www.normservis.cz/download/view/csn/26/28648/28648_nahled.pdf (accessed on 13 November 2023).

- Measured Data. Available online: https://www.fs.vsb.cz/340/cs/veda-a-vyzkum/mereni-vysledky/ (accessed on 4 December 2023).

- Hicke, K.; Hussels, M.T.; Eisermann, R.; Chruscicki, S.; Krebber, K. Distributed Fibre Optic Acoustic and Vibration Sensors for Industrial Monitoring Applications. In Proceedings of the 15th International Conference on Infrared Sensors and Systems (IRS2 2017), Nuremberg, Germany, 30 May–1 June 2017; pp. 274–279. [Google Scholar]

- Ahirrao, N.S.; Bhosle, S.P.; Nehete, D.V. Dynamics and vibration measurements in engines. Procedia Manuf. 2018, 20, 434–439. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Y. A physics-constrained dictionary learning approach for compression of vibration signals. Mech. Syst. Signal Process. 2021, 153, 107434. [Google Scholar] [CrossRef]

- Gangsar, P.; Tiwari, R. Signal based condition monitoring techniques for fault detection and diagnosis of induction motors: A state-of-the-art review. Mech. Syst. Signal Process. 2020, 144, 106908. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).