Abstract

This document presents a proposal for designing an expert system in the Gabriela Mistral Division’s crushing plant belonging to Codelco (Chile) with the objective of maximizing stacked tonnage, allowing the improvement of operational variables that directly interact with the crushing process. In addition, this study considers the impact that occurs in both the process and operational continuity regarding the standardization of the system. In the first stage, a survey and analysis of historic operation data was carried out, which allowed the definition of benchmarking indicators. Subsequently, both modalities of operation were compared, monitoring processed tonnage and detentions related to operational failures. As a result, significant differences were observed in the performance of the critical line operating with expert control, with a 55% reduction in the detentions referred to operational failures. Added to this is the benefit of low cost and improved quality as the control provides an analysis of the variables in reduced time intervals, which is superior to human control.

1. Introduction

The mining industry has been forced to improve the efficiency of its operations to reduce both supplies and energy costs due to the abrupt fall in copper prices since 2015. The complexities of the copper production process include variability in the characteristics of the feed material and operational detentions, among others. This dynamic interaction of processes makes it necessary to incorporate advanced technologies in the production process, such as the expert system—a technology that seeks to reach an optimum point of operation to increase the efficiency of the process [1]. There are four main benefits of developing an expert system, as mentioned in Durkin [2]: improved productivity, low cost, improved quality, and improved image.

The Gabriela Mistral Division (Chile) produces 125 thousand tons of fine copper, with an average grade of 0.46% of total copper. This process is carried out by comminution operations (primary and secondary crushing), acidification, and stacking in dynamic stacks. In general terms, the amount of energy consumed in the crushing processes is closely related to the degree of reduction in size achieved by the particles; for the Gabriela Mistral Division, the energy cost corresponds to 30% of the total cost of operation. The variables that affect both the energy expenditure and the efficiency of the process were analyzed by Wei and Craig [3]. The ability to crush increasingly more material faster, more efficiently, and with an appropriate granulometry is one of the main challenges facing this process in the mining industry—a challenge that has also led to the search for best practices in design and maintenance. As part of its continuous improvement plan, Gabriela Mistral has designed a study analyzing the development and implementation of an expert system in the crushing plant that allows the critical variables of the process to be controlled on rules-based decisions that operate to maintain critical plant variables in preset stability ranges [4]. The system mimics the behavior of a human operator to provide continuity, efficiency, and safety [5]. The application of this system has been analyzed in several studies (e.g., [6,7,8,9,10,11]), showing its usefulness in various operations. It should be noted that one of the major advantages of operating the expert system is that it has the ability to process large amounts of information consistently with an optimal performance by operating day and night, thus minimizing operational problems that may be common with manual operation. This has been verified in various works (e.g., References [12,13,14,15]), where significant improvements in work efficiency were achieved. Taking into account the above, the present work aims to increase the stacking performance of the plant by 7% and then contribute to operational continuity and a controlled process by standardizing the operation in different shifts, thus increasing the useful life of the equipment.

To date, the Gabriela Mistral division crushing plant has been operating in manual mode with the assistance of room operators who have a thorough knowledge of the behavior of equipment that interacts directly with the plant. The experience of the operators is essential for designing optimal scheduling of the expert system to gather the best operational practices of different work shifts. It is worth mentioning that the system can improve over time, either with new operational maneuvers or with additional schedules, similar to what has been seen in three different studies (References [16,17,18,19]). The contribution of this work is that it applied methodological techniques for the development of the knowledge base in an industrial application of a multivariate and multiparametric process. In addition, yields in manual mode and expert mode were compared.

The main purpose of this study was to validate the operation of the technology implementation. For this, the operating data using the expert system was compared with those obtained using the common method of operation with a worker. The tests consisted of analyzing the impact in the plant when operated in both modes, evaluating the operational variables, and presenting detentions.

The focus of this study was on the knowledge base of the expert system, which expanded through interviews, questionnaires, and review of historical plant data among others to find optimum points of operation that could be used later to program the knowledge base in the K-UCN system (K. Arcos y C. Leiva, Antofagasta, Chile).

The comparison of both modes of operation indicated significant differences with respect to the performance of the critical line. The operation with expert control yielded an additional 159 tons/h, which presented an improvement of 2.17% and a stacking opportunity of 1,044,630 tons/year. The number of detentions decreased by 55%, allowing operational continuity and stability of the critical variables of the system.

2. Materials and Methodology

First, considering the study of the Gabriela Mistral Division production process, a survey was conducted of the conditions in which the plant was located in order to identify critical equipment in each area (secondary and tertiary crushing). In addition, a theoretical and bibliographic study of the Expert System 2013—which covers only the crushing plant—was carried out, evaluating both the operational parameters and the control logic used in order to analyze the behavior presented by the plant when it is operated automatically. At the same time, a list was made of the sensors required to operate with the expert system and their condition. With this, it was possible to design and operate the expert system K-UCN (Expert System Universidad Católica del Norte), which is the new system applied, as explained in this document, that seeks to improve the result obtained previously in the plant by a similar method. The system used previously (2013) consisted of a much smaller information base of knowledge than the K-UCN system, which uses a more extensive questionnaire to cover each situation presented in the plant operation. The Expert System 2013 failed to function properly in the plant, so it was replaced by the currently used manual operation system.

We hypothesized that the performance of the K-UCN system would be greater than the system’s performances in manual mode. Alternatively, the performance of K-UCN system might be greater than the Expert System 2013.

2.1. Specifications of the Crushing Plant

The mineral derived from both the open-cut and ground-based exploitation must be prepared in a crushing plant; then, if necessary, acid is added to achieve a controlled grain size to ensure a good permeability coefficient of the solution. Crushing is a unitary operation of size reduction by the application of compression forces whose main purpose is to carry out the necessary size reductions, until a product of a suitable granulometry is obtained that allows the development of leaching in stacks or deposits in an efficient way. The objective of crushing the ore is to produce particles of the appropriate size and shape for direct use, release valuable materials from the bargain so that they can be concentrated, and increase the surface area available for chemical reaction.

The crushing process is performed in two large stages, which require specific equipment to achieve proper granulometry. First there is a primary crushing or coarse crushing to crush big rocks. Second, there is a secundary grinding stage to achieve the right size.

For each of these stages, there is appropriate equipment with the following main characteristics: the opening of feed, capacity to different closures, sizes of products, power, etc. They are usually tabulated by the manufacturers of crushers based on density, grain size, and mineral hardness.

2.2. Instrumentation

In order to start and monitor the expert control system, field instrument reliability is required; the variables that interact with the system are shown in Table 1.

Table 1.

Critical Variables for Expert System, Crushing Plant.

These variables are defined because of the importance they have on reducing operational failures. In addition, the associated instrumentation presents reliability for the feedback required to take control. The ranges of these variables and the criterion of the rules used by the expert system can be seen in Table 2 and Table 3.

Table 2.

Established Operational Ranges: Secondary Crusher Line 1, Expert System K-UCN.

Table 3.

Established Operational Ranges: Tertiary Crusher Line 1, Expert System K-UCN.

There are a large number of system-related variables that are of great importance in the process. However, because of the poor reliability of associated instrumentation and the lack of measurement equipment, they do not interact in the expert control but are rather monitored by the operator.

2.3. Working Methodology

The methodology for the knowledge base develops the following activities:

- selection of the expert and expert domain;

- relationship with the expert and extraction of knowledge of the same, where special psychological techniques such as protocol analysis or interview techniques are of special importance. The professionals surveyed are shown in Table A1;

- acquisition of knowledge by the engineer and selection of the appropriate representation technique;

- selection of the most suitable tool for development.

- construction of incremental prototypes.

To design the philosophy of the K-UCN system, we started by taking interviews with operators and control room analysts in different shifts to form a knowledge base. This allowed us to define the operational variables, critical system variables, operating and prevailing rules, the dynamic time required by the system, and the analysis of the Expert System 2013. We performed tests by area and line as each of them presents different behaviors and therefore has different control logic. The behavior of the variables described below was evaluated:

Secondary crush:

- (a)

- percentage of current in belts;

- (b)

- tonnage straps;

- (c)

- percentage level of inclined plane;

- (d)

- current percentage of secondary crushers; and

- (e)

- percentage of tertiary tolvines level (average).

Tertiary crusher:

- (a)

- percentage level of inclined plane;

- (b)

- current percentage of tertiary crushers;

- (c)

- percentage level of tertiary feed hopper;

- (d)

- virtual tonnage; and

- (e)

- percentage level of fine silos (average).

In order to validate the results obtained from the tests mentioned above, a statistical analysis was carried out, which consisted of sampling the performance of each type of operation and comparing the average obtained during the total working time; this allowed us to evaluate the behavior of the manual operation in order to implement improvements in the control logic. In addition, a hypothesis test was performed to compare the operation of the first semester in manual mode 2016 versus the Expert System K-UCN. This was to analyze the effect when the plant was operated with the expert system, mainly in relation to the performance of the critical line and the number of operational detentions.

2.4. Design of the Expert System K-UCN

A knowledge base was formed by collecting information about different facts and experiences to analyze strategies used in different shifts. These were obtained through interviews, questionnaires, and direct conversations with analysts. The questionnaires were based on forms with predetermined questions, allowing the capture of abundant and basic information about the process and the problem under study. This allowed the formulation of initial hypotheses and guided the strategies for applying techniques of data collection on the most critical variables of the process. With respect to direct interviews, the experts responded extensively on the subject with the freedom to deviate from the interviewer’s objectives. This allowed us to learn how they faced and analyzed different situations occurring at the plant and the strategy they used to maintain operational stability, thereby creating a closer link with the experts.

For the collection and analysis of data, we designed sheets linked to the PI System—a platform that allowed us to obtain historical data of the plant and monitor the behavior of the operational variables that interact directly with the process, thus validating the knowledge base.

The distributed control system (DCS) used in the crushing plant is FOXBORO’s I/A Series System (Process & Machinery Control, Georgia, USA), which uses three software programs for the implementation of the expert system:

Software A: Shell: IACC (Integrated Automation Control Configurator), a software used in the creation and modification of rules that interact in the system with a programming language structured text;

Software B: FOXDRAW, where the screens are edited before the interaction with the operator; and

Software C: HMI, a man–machine interface, FOXVIEW, where the operator interacts with the expert control.

The main features of the K-UCN expert system are as follows:

- It is implemented in Line 1, 2, and 3 of the secondary and tertiary crushing area.

- The fine-tuning of the rules is independent for each line as they do not present the same behavior due to their location and the segregation that occurs in the stockpile.

- Its main control element is the speed regulation of the secondary and tertiary feeders.

- Its operating criteria are based on best operational practices.

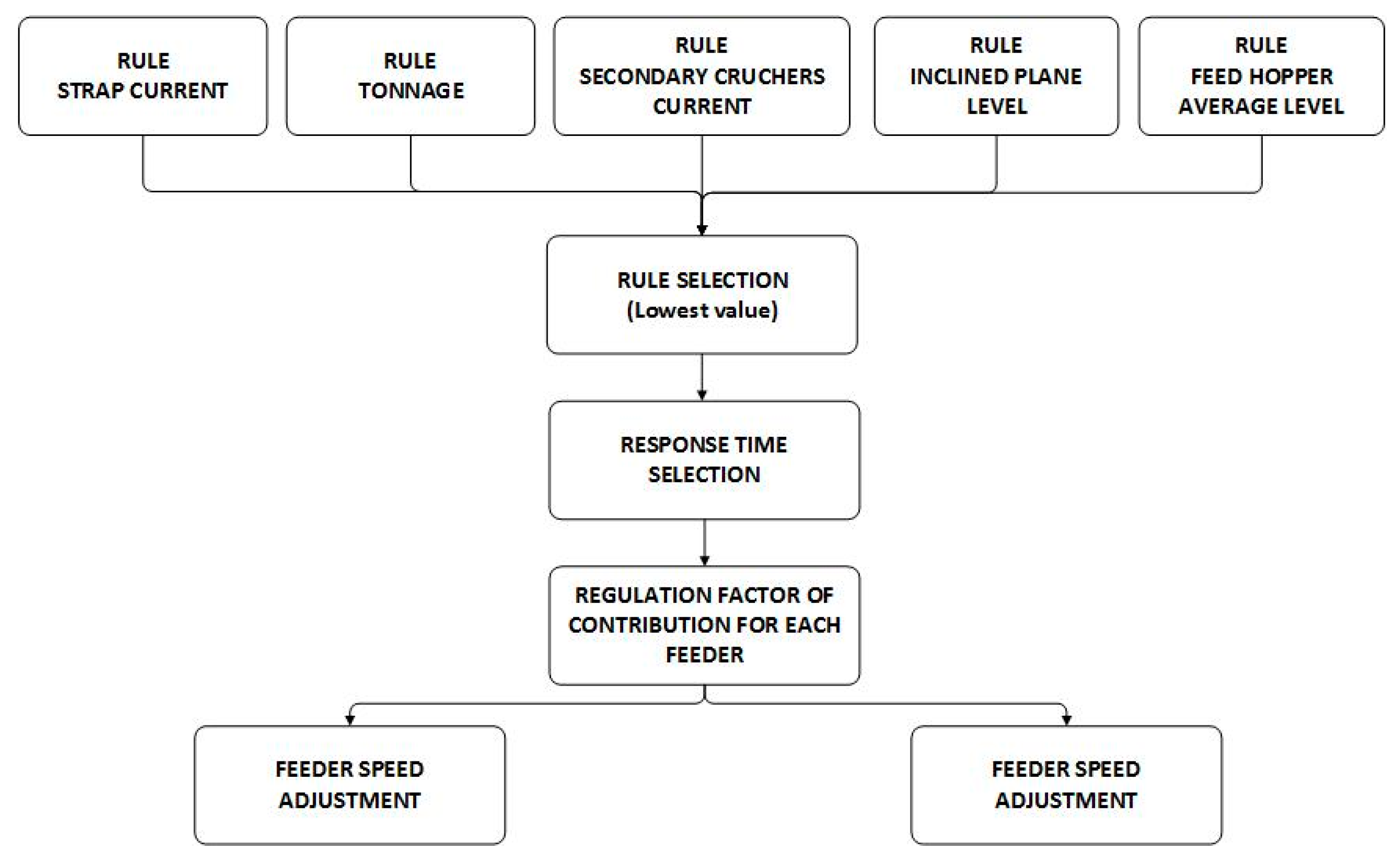

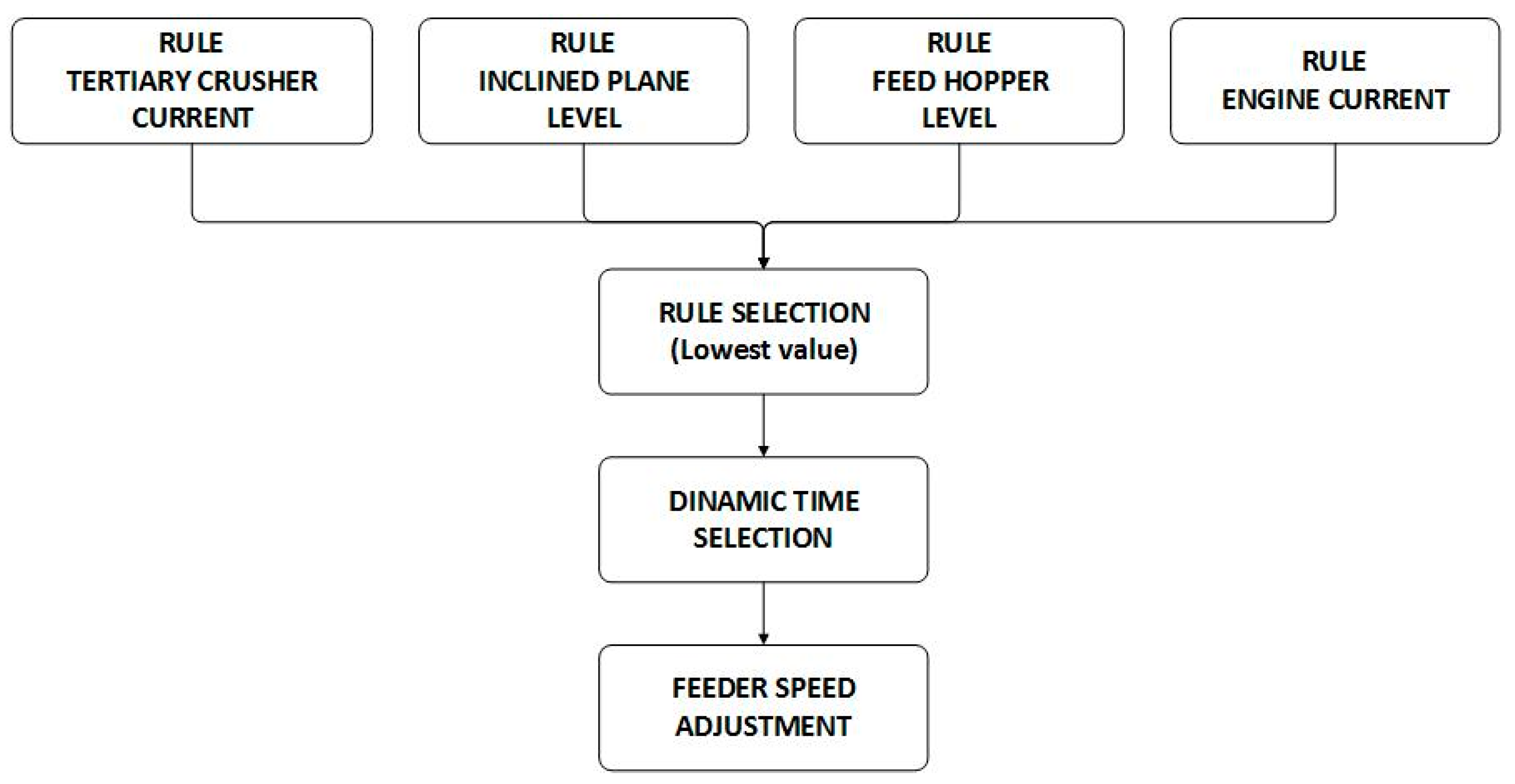

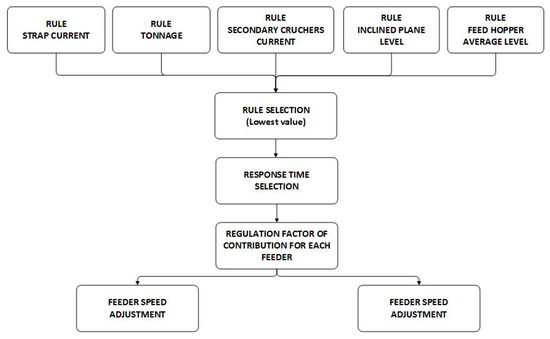

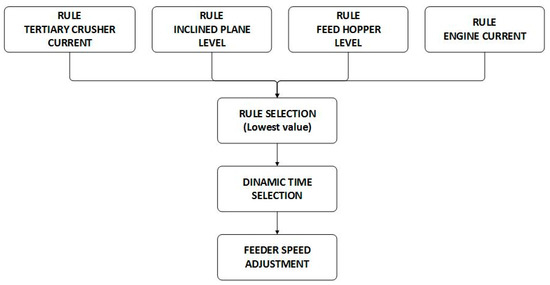

For each of the variables shown in Table 1, there is a range of values that determine the number of percentage points in which the speed of feeders is adjusted. The system is always controlled by the variable that is in a more critical value in order to maintain stability in the system. The main structures of expert control systems are shown in Figure 1 and Figure 2 and the ranges are shown in Table 2 and Table 3.

Figure 1.

Expert System K-UCN, Secondary Crusher.

Figure 2.

Expert system K-UCN—tertiary crusher.

Each rule makes a decision according to the variables controlled in each section depending on the interval they are in. Each variable that interacts in the expert system presents an associated dynamic time, i.e., the time it takes to make an impact when making a change, as shown in Table 4 and Table 5. This time was obtained from experimental tests in the plant by sampling each independent variable to obtain the median of the data.

Table 4.

Dynamic times K-UCN, Secondary Crusher.

Table 5.

Dynamic times, tertiary crushing.

To avoid a lack of control in the operational variables, restrictions were programmed as shown in Table 6.

Table 6.

Secondary and Tertiary Crushing Restrictions.

In addition, the expert system considers edge conditions that limit the speed of the secondary feeder, which is found in the three secondary crushing lines.

- If one of the tertiary feeders is stopped and the average tolvin exceeds 40% of the level for a time of 3 s, the speed of the secondary feeders must decrease by 40% of the set value.

- If both tertiary feeders are stopped and the tolvin average is higher than 45% of their level, the speed of the tertiary feeder or feeders should decrease by 40%.

Before any detention occurs during the use of the expert system, the control will begin to act 50 s after having given a condition to the feeder, allowing the line to stabilize; then, it will begin to maximize the variables. In case of an interlock, the feeder will start only after the alarm has been acknowledged by the analyst, and the same procedure will be performed.

The expert system considers edge conditions that limit the velocity of the tertiary feeder to any event occurring in the secondary crushing. This is applied for the six tertiary lines.

- The line is operative with a single secondary feeder with the contribution greater than 95%. If it stops and the level of the feed hopper is less than 50%, the speed of the tertiary feeders decreases by 40% of the set value.

- The line is operative with the two secondary feeders. If only one of the feeders stops and the level of the feed hopper is less than 50%, the tertiary feeders speed decreases by 20% of the set value.

- The line is operative with the two secondary feeders. Both stop when the level of the feed hopper is less than 50%, and the tertiary feeders speed decreases by 40% of the set value.

Unlike the secondary crushing, the expert system in the tertiary crushing plant operates with a stability band. This means that if the variables are within the ranges described in Table 7, it is activated above the decision rules presented by the expert control in order to maintain the stability of the variables, imitating the action performed by the analyst of the control room when it cannot continue to maximize performance. If one of these variables is outside of the ranges, they start to control again according to the programmed rules.

Table 7.

Stability Band Ranges.

2.5. Design of the Tests in the Crushing Plant

The tests were designed to mainly evaluate the behavior and operational impact caused in the crushing plant when operated with the expert control system so that it can be implemented in the Gabriela Mistral Division. Currently, the crushing plant operates in manual mode, and to review the behavior of the expert control system, three lines of the secondary crushing plant and six lines of the tertiary crushing plant were made available, with each line operating with two crushing lines. The evaluation process considered the following stages:

- Reconstruction of logic: This first stage corresponded to the analysis of existing logic, created for the Expert System 2013, with the aim of analyzing the operation of the system for that year. During this period, data was collected from the first half of 2016 to create the knowledge base.

- Parameter adjustments: During this stage, based on the knowledge base already created, the new operating strategy was designed for the K-UCN expert system, which recorded data without evaluation for the preliminary tests as it was treated of a net stage of operational adjustments.

- Feedback: During this period, the actual evaluation was carried out by taking a careful record of the conditions and operational variables. By means of feedback with the different shifts, fine adjustments were made to the parameters. For this stage, a minimum of three months of data was considered necessary so that the evaluation could be done under different operational conditions and type of mineral fed.

3. Results and Discussions

3.1. Critical Line Performance (KPI)

A comparison was made of the stacked performance—for manual operation versus expert system operation. Table 8 shows the hypothesis test with two independent samples performed in Minitab. Here, we observed that the mean of the operation with expert control was greater than that of the manual operation at a significance level of 0.05, representing a difference of 159 ton/h in favor of the operation with the expert system.

Table 8.

Hypothesis test: manual operation vs. operation expert system.

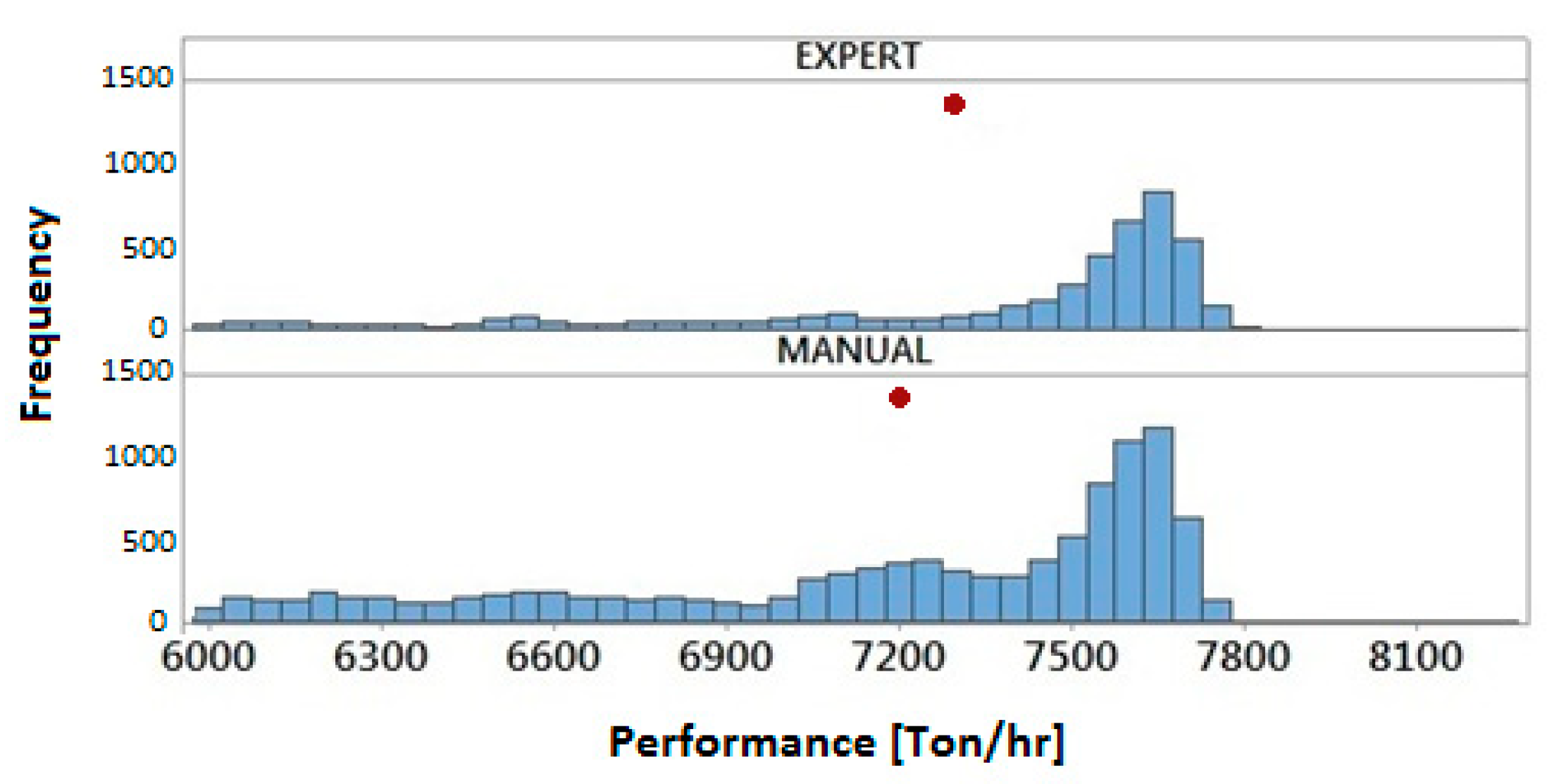

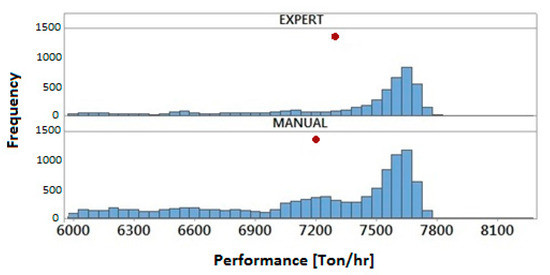

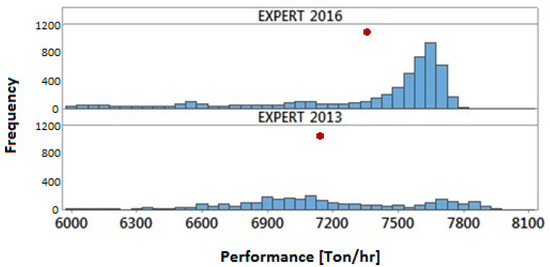

An increase of 2.17% in the amount of material processed could be seen, which followed the trend of other works where the use of an expert system generated a benefit in the processes. In Chen et al. [12], an increase of 10% was reported in the capacity of feeding; in Bouffard [6], a benefit of between 1 and 16% increase in processing capacity and 1% increase in recovery between various flotation and milling plants was achieved. Figure 3 shows the average performance for both the operation with an expert system of 7354 ton/h and a manual mode with 7195 ton/h. The behavior presented in the data showed a similar coefficient of variation, with a difference of 1% (6% versus 7%). The clear difference was the frequency of the yields obtained, with the expert system K-UCN showing a higher frequency in yields closer to 7500 ton/h (target crushed plant).

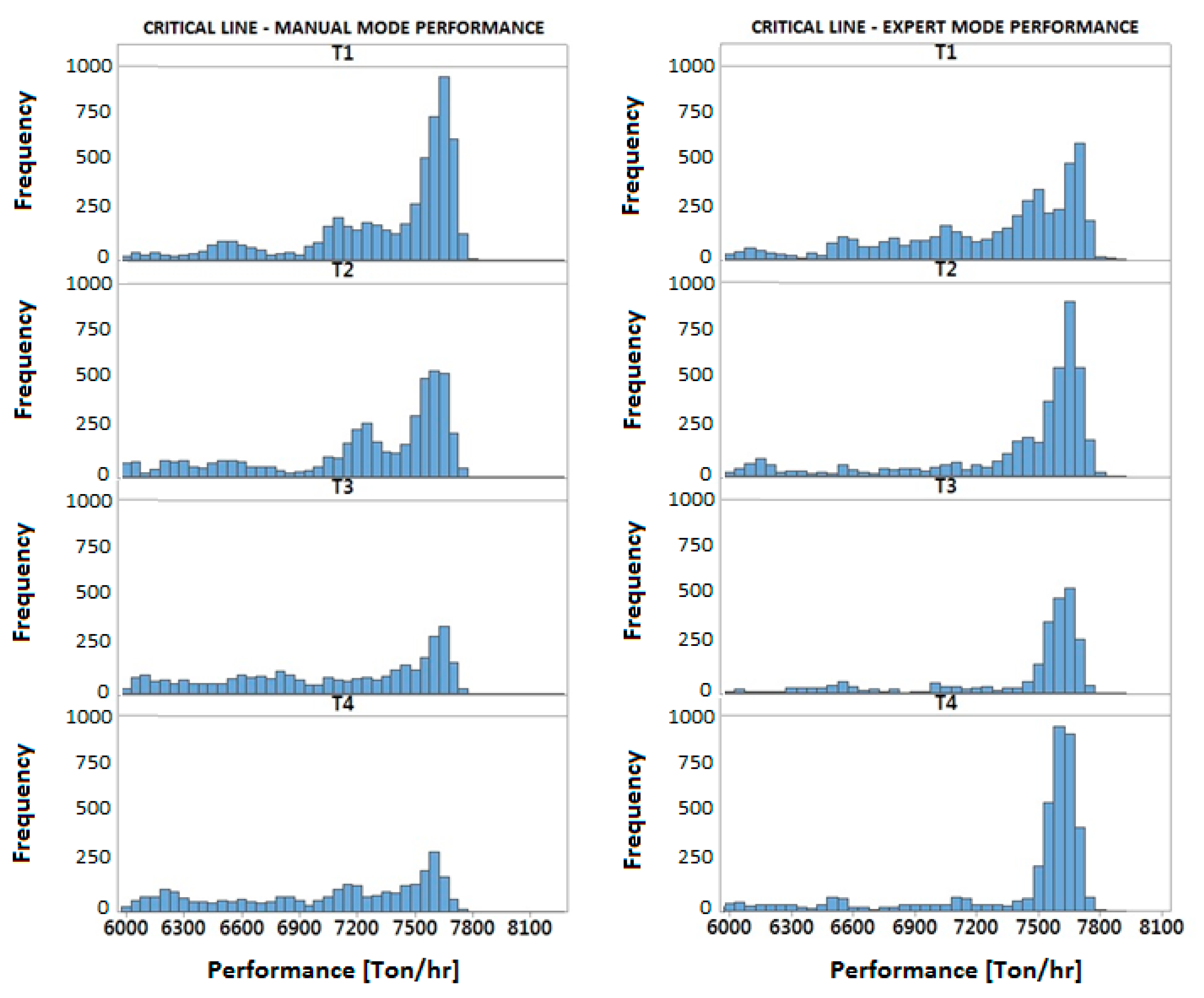

Figure 3.

Data Rate: Expert System vs. Manual Operation.

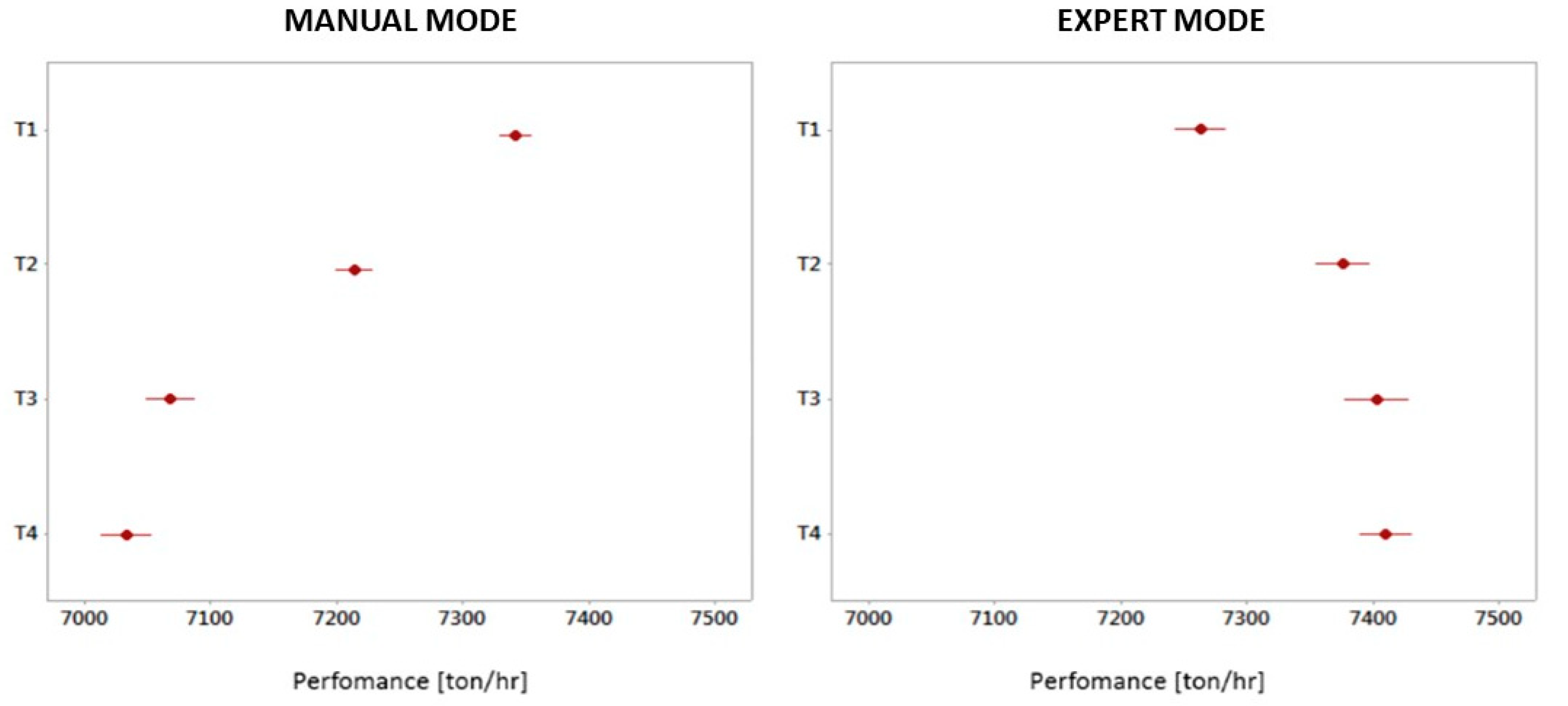

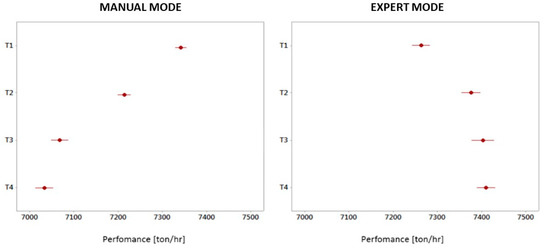

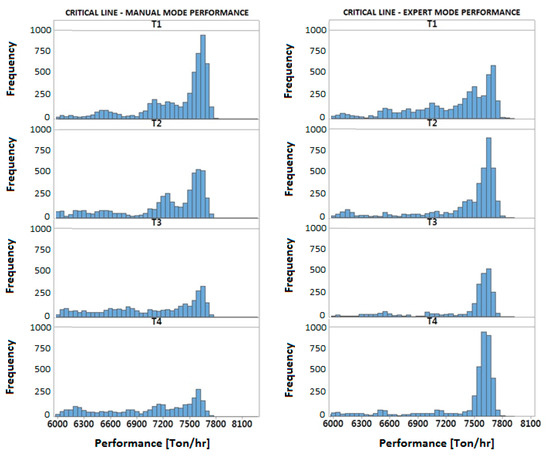

In turn, the behavior of four shifts in both modalities was analyzed, as can be seen in the Table 9 and Figure 4 and Figure 5. Here, the mean of expert system was greater than that of the manual system at the significance level of 0.05. The uncertainty quantified was associated with the estimation of the difference in means from the sample data, getting confidence intervals with 90% certainty that the true difference was between 149.33 and 194.67.

Table 9.

Turn-based performance in both modes.

Figure 4.

Anova hypothesis test, yields by turns in both modalities.

Figure 5.

Frequency of data, both modalities by turns.

It was observed that the best shifts that operate the plant in manual mode had an inverse behavior to the operation of the expert mode, indicating that a better control of the system—and of the variables that are directly associated in the system—is required. This presents an opportunity for improvement in the standardization of the plant operation plant.

3.2. Comparison between Expert Systems 2013 and 2016 K-UCN

In Table 10, it can be observed that the average performance in operation with K-UCN expert control was higher by 3% compared to the Expert System 2013, with a difference of approximately 200 ton/h. Taking into account the uncertainty associated with the estimation of the difference between the means from the sampled data, we had 90% certainty that the true difference was between 182 and 215.

Table 10.

Hypothesis test, expert system K-UCN vs. Expert System 2013.

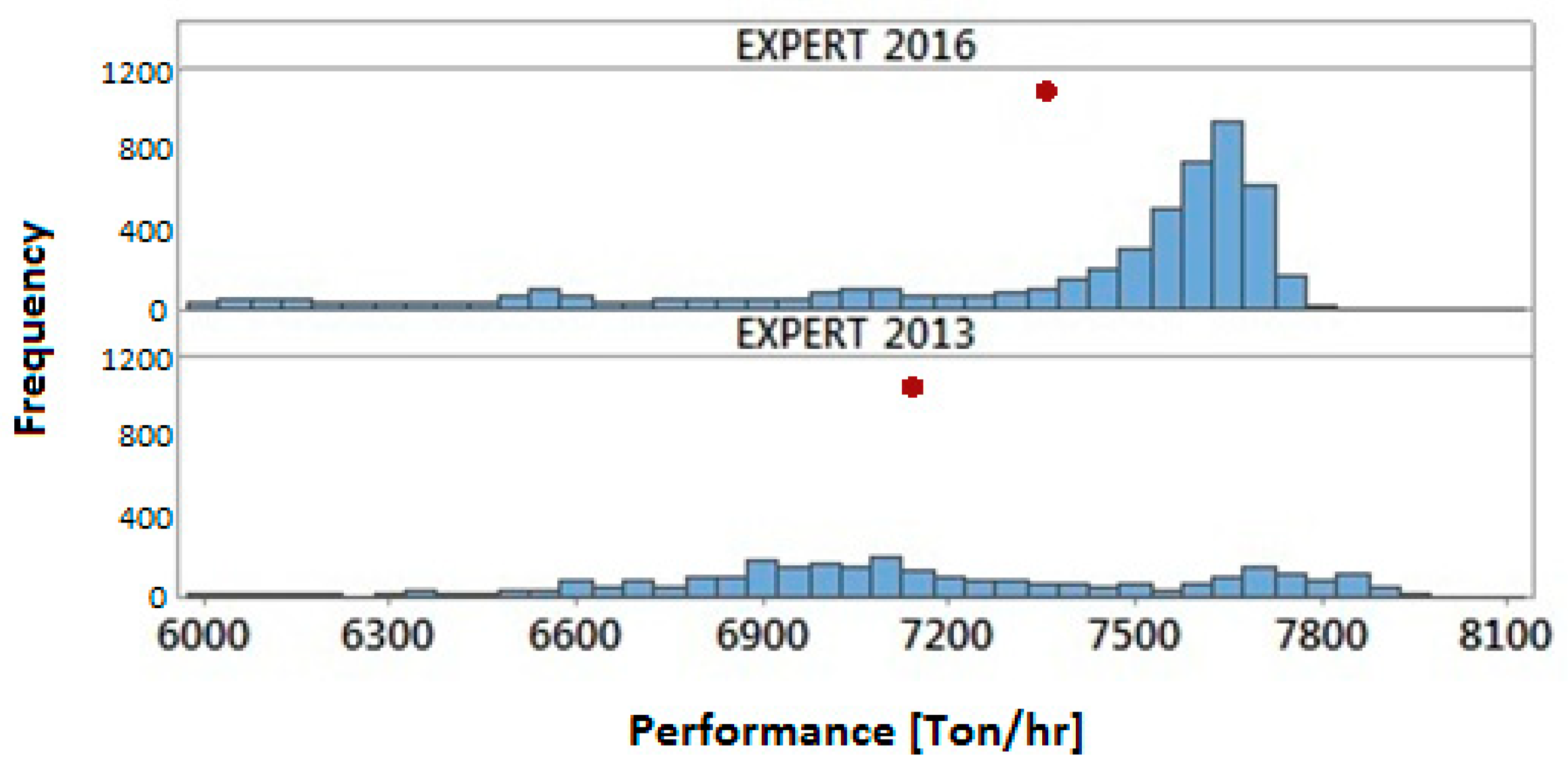

The K-UCN expert system presented a more controlled behavior—the trend was closer to the required target of 7500 ton/h as opposed to the Expert System 2013 in which the behavior of the performance was uniform in a wider range (Figure 6).

Figure 6.

Frequency of data between expert systems.

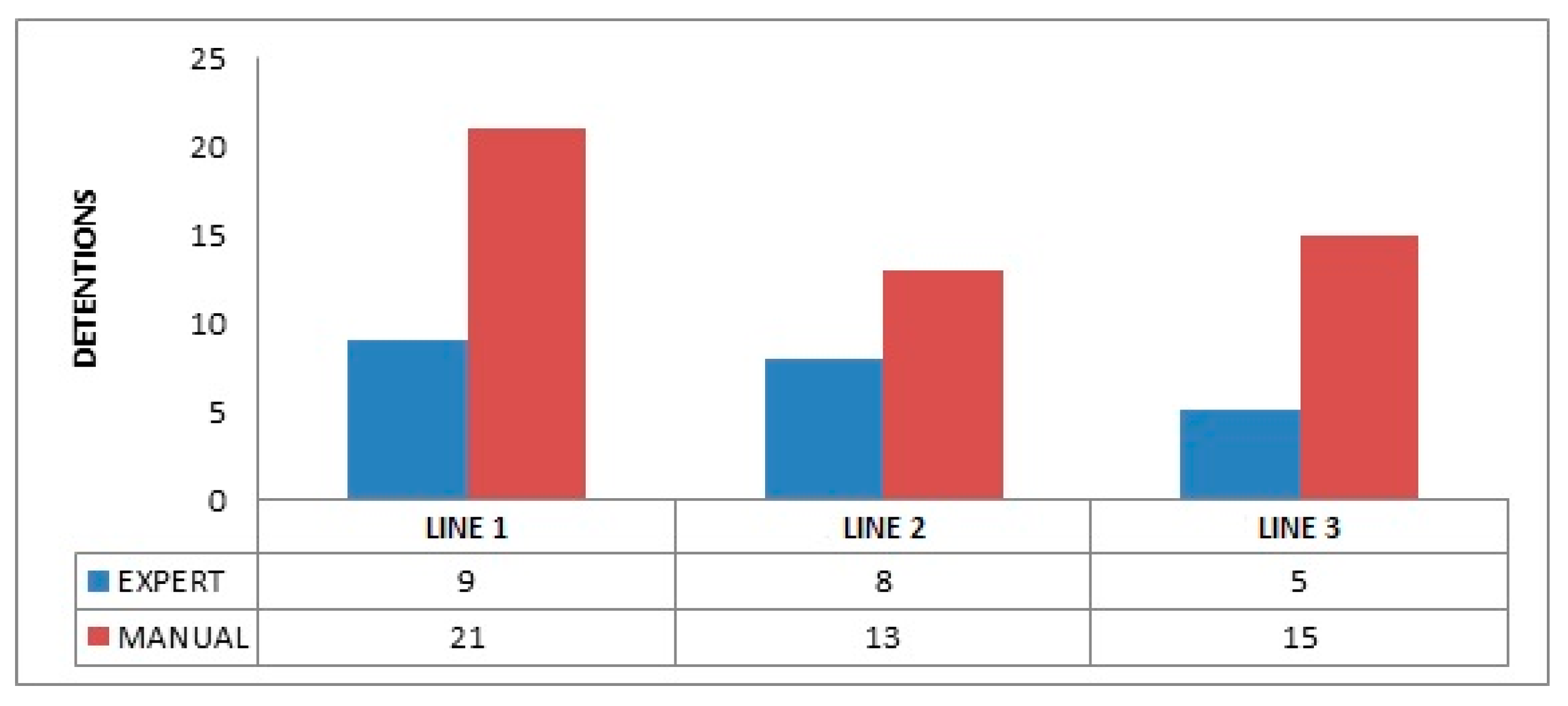

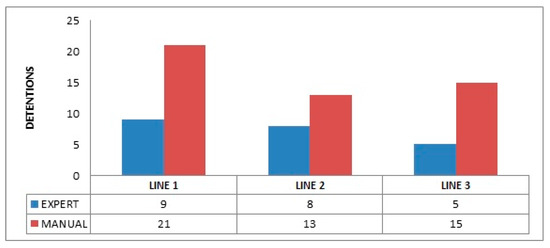

3.3. Plant Detentions

During the testing period, the number of detentions associated with the following variables that directly impacted the process and the expert control were monitored (Figure 7):

Figure 7.

Daily detentions in both modalities, by lines.

- overcurrent of the crushers;

- high level thin silos;

- low-level feed hopper;

- inclined plane; and

- extreme misalignment.

While evaluating the detentions of the complete plant, it was observed that in manual operation, 55% more detentions were present than when operating the plant with the expert system (22 versus 49). This shows that the implementation and use of the expert system presents a significant improvement opportunity. This was also seen in Fan et al. [7], where the application of a control system to support the existing one increased the stability of the process without altering production. The greatest percentage of the detentions was due to the extreme misalignment that occurred in the feeders and the low level of the feed hopper because this would increase the odds that the feeders became misaligned by the blows of the load in them.

4. Concluding Remark and Future Work

In this paper, it has been demonstrated, at an industrial level, that it is feasible to implement the expert control system in the crushing plant as it presents advantages in productivity and improved quality from a cost–benefit point of view, in addition to maintaining a controlled and standardized process.

The comparison of both modes of operation indicates significant differences with respect to the performance of the critical line. The operation with expert control yielded an additional 159 tons/h, which was an improvement of 2.17% and a stacking opportunity of 1,044,630 ton/y. The number of detentions decreased by 55%, allowing operational continuity and stability of the critical variables of the system.

As for the behavior of the shifts in the operation of the plant, it was observed that the shifts that resulted in the best practices while operating in manual mode showed an inverse behavior to operating in expert control. This is probably due to strong paradigms and the reluctance of using a new system. Currently, this problem is being dealt with by training for shifts that show major weaknesses.

The development of the incremental prototype significantly improved plant performance and unscheduled detention.

The authors of this paper consider the followings topics for future research:

- the implementation of the acidification process in the K-UCN system;

- analysis of the possibility of using the inference engine of the expert system with fuzzy logic.

Author Contributions

K.V.A. and C.A.L. conceived, designed, and performed the experiments; all the authors analyzed the data; K.V.A. also contributed the software that belongs to Gabriela Mistral Company; C.A.L., C.M.T., Y.G., and E.A.S. wrote the paper.

Funding

This research received no external funding.

Acknowledgments

The authors wish to acknowledge the material support provided by the Gabriela Mistral Division, Codelco and financial support provided by Universidad Católica del Norte.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

The expert system has been designed using interviews and questionnaires considering three professional positions (operator, process engineer, and senior engineer) as show in Table A1.

Table A1.

Number of professionals surveyed.

Table A1.

Number of professionals surveyed.

| Questions | Operator | Process Engineer | Senior Engineer |

|---|---|---|---|

| 1–10 | 8 | 2 | 1 |

| 11–20 | 8 | 2 | 1 |

| 21–30 | 8 | 2 | 1 |

| 31–42 | 8 | 2 | 1 |

The purpose of developing the questionnaire was to obtain information on how to operate the crushing plant. In order to update the knowledge base on the expert control system. The following questions were considered:

1. At what level of the stockpile should you begin to feed the plant?

2. What criterion is used to decide which feeder to operate—only one or both?

3. What is the optimum operating current of the secondary belts CV-002, 003, and 004?

4. How does the current of the belt relate to the performance of each line in secondary crushing?

5. What is the factor of the CV-002, 003, and 004 strap gauges used for? Is it necessary?

6. What is the optimal level of operating inclination of the secondary crushers?

7. What should be done when the inclined plane starts to rise? What is the percentage of filling where action should be taken?

8. What is the optimal rate of operation of the secondary crushers?

9. What should be done when the rate level from the secondary crushers increases or decreases? Indicate ranges

10. What is the optimal operating current of the secondary crushers?

11. Define high operating current in secondary crushers (ranges)—what should be done when currents are high?

12. Define low operating current in secondary crushers (ranges)—what should be done when currents are low?

13. Why do the crushers not operate with the currents to the limit (100%)?

14. What is the optimal level of the tertiary hopper for a secondary and tertiary feeder?

15. What should be done when the tertiary hoppers are full and empty? At what high hopper level should action be taken and what action should be taken?

16. What is the optimum current of the tertiary crushers?

17. Define high operating current for tertiary crushers (ranges)—what should be done when currents are high?

18. Define low operating current for tertiary crushers (ranges)—what should be done when currents are low?

19. What is the optimum operating pressure of the crushers? Is it the same for secondary and tertiary?

20. What should be done when the crushing pressure increases and when it decreases (ranges) for both secondary and tertiary?

21. What is the optimum vibration of the crushers? Is it the same for secondary and tertiary?

22. What should be done when the vibration of the crushers increases and decreases (ranges) for both secondary and tertiary?

23. What should be done when there is high temperature in the crusher? Is the temperature range operated by the crushers the same for secondary and tertiary?

24. What should be done when there is low temperature in the crusher? Is the temperature range operated by the crushers the same for secondary and tertiary?

25. Why is ring hopping caused in the crushers? Is it the same for secondary and tertiary crushing? What action is taken when this occurs?

26. What are the setting ranges in the secondary and tertiary crushers?

27. What steps should be followed to perform the measurement of the setting?

28. Evaluation to modify setting—in which case should the crusher be opened or closed?

29. What is the optimum percentage that the CV-010 and CV-011 belt should operate? What is the minimum and maximum percentage that both belts must operate?

30. According to the virtual tonnage of CV-012, should any action be taken?

31. Optimal level of fine silos—what action is taken when these are low and when they are high (ranges)?

32. What should be done when the belt current is optimal but the secondary crusher current is low?

33. What should be done when the belt current is low but the secondary crusher current is high?

34. What is the strategy to work with 5/6?

35. What should be done when the crushers are worn out? Is the same action taken for both the secondary and tertiary crushers?

36. What should be done when there is very hard or over-sized ore?

37. What should be done when there is thin material present?

38. What should be done in the presence of wet material?

39. What parameters or variables should be evaluated to increase tonnage?

40. What should be done when a secondary line is stopped?

41. What should be done when a tertiary line is stopped?

42. What should be done when the silo B or drum 02 is in maintenance?

References

- Bergh, L.G.; Yianatos, J.B.; Leiva, C.A. Fuzzy supervisory control of flotation columns. Miner. Eng. 1998, 11, 739–748. [Google Scholar] [CrossRef]

- Durkin, J.; Durkin, J. Expert Systems: Design and Development; Prentice Hall PTR: New York, NY, USA, 1998. [Google Scholar]

- Wei, D.; Craig, I.K. Grinding mill circuits—A survey of control and economic concerns. Int. J. Miner. Process. 2009, 90, 56–66. [Google Scholar] [CrossRef]

- Lucas, P.; Van Der Gaag, L. Principles of Expert Systems; Addision & Wesley: Boston, MA, USA, 1991. [Google Scholar]

- Parsaye, K.; Chignell, M. Intelligent Database Tools & Applications: Hyperinformation Access, Data Quality, Visualization, Automatic Discovery; Wiley: New York, NY, USA, 1993. [Google Scholar]

- Bouffard, S.C. Benefits of process control systems in mineral processing grinding circuits. Miner. Eng. 2015, 79, 139–142. [Google Scholar] [CrossRef]

- Fan, G.Q.; Rees, N.W. An intelligent expert system (KBOSS) for power plant coal mill supervision and control. Control. Eng. Pract. 1997, 5, 101–108. [Google Scholar] [CrossRef]

- Iqbal, A.; He, N.; Li, L.; Dar, N.U. A fuzzy expert system for optimizing parameters and predicting performance measures in hard-milling process. Expert Syst. Appl. 2007, 32, 1020–1027. [Google Scholar] [CrossRef]

- Torres-treviño, L.M.; Escamilla-salazar, I.G.; González-Ortíz, B.; Praga-Alejo, R. An expert system for setting parameters in machining processes. Expert Syst. Appl. 2013, 40, 6877–6884. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, Y.; Wang, C.; Li, X.; Ou, G. Design and evaluation of a high performance distributed expert system (HPDES) for aerospace ground verification system. Procedia Comput. Sci. 2012, 9, 1380–1389. [Google Scholar] [CrossRef]

- Taylor, N.K. An Expert System to Assist in Design. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 1990. [Google Scholar]

- Chen, X.; Li, Q.; Fei, S. Supervisory expert control for ball mill grinding circuits. Expert Syst. Appl. 2008, 34, 1877–1885. [Google Scholar] [CrossRef]

- Zhou, P.; Lu, S.; Yuan, M.; Chai, T. Survey on higher-level advanced control for grinding circuits operation. Powder Technol. 2016, 288, 324–338. [Google Scholar] [CrossRef]

- Festa, A.; Cornejo, F.; Orrante, F.; Alanís, R.; Gutiérrez, B. Expert System Implementation at Peñoles Group Concentrators; Technical Report; SGS Minerals Services: Geneva, Switzerland, 2009. [Google Scholar]

- Morgan, G.; Cheng, R.; Altintas, Y.; Ridgway, K. An expert troubleshooting system for the milling process. Int. J. Mach. Tools Manuf. 2007, 47, 1417–1425. [Google Scholar] [CrossRef]

- Chen, X.; Li, S.; Zhai, J.; Li, Q. Expert system based adaptive dynamic matrix control for ball mill grinding circuit. Expert Syst. Appl. 2009, 36, 716–723. [Google Scholar] [CrossRef]

- Iqbal, A.; He, N.; Dar, N.U.; Li, L. Comparison of fuzzy expert system based strategies of offline and online estimation of flank wear in hard milling process. Expert Syst. Appl. 2007, 33, 61–66. [Google Scholar] [CrossRef]

- Rubio, L.; De, M.; Longstaff, A.P.; Fletcher, S.; De La Sen, M.; Longstaff, A.P.; Fletcher, S.; De, M.; Longstaff, A.P.; Fletcher, S. Expert Systems with Applications Model-based expert system to automatically adapt milling forces in Pareto optimal multi-objective working points. Expert Syst. Appl. 2013, 40, 2312–2322. [Google Scholar] [CrossRef]

- Leiva, C.A.; Flores, V.M.; Salgado, F.; Poblete, D.; Acuña, C. Applying softcomputing for copper recovery in leaching process. Sci. Program. 2017, 2017, 6. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).