Abstract

Each business faces large competition in the market, and it is necessary to adopt the most effective methodology as possible in order to obtain the best solution. Six Sigma (6σ) is a set of techniques and tools for process improvement. The tools of Six Sigma apply within a simple improvement model known as Define–Measure–Analyze–Improve–Control (DMAIC). This paper shows that implementing Six Sigma can be more effective in managing the vehicle fleet. The combination of mathematical, i.e., statistical basis and practice makes Six Sigma so successful. The Six Sigma project, implemented to reduce costs and increase the availability of a vehicle fleet in a selected company, can be widely applied in other similar enterprises.

1. Introduction

Today, in a time of technological progress, and in dynamic market, it is important to be adaptive to change, and to use new models in order to remain competitive in the market. To respond to these needs, various industrial engineering and quality management strategies such as series of standards ISO 9000, Total Quality Management, Kaizen, just-in-time manufacturing, Enterprise Resource Planning, Business Process Reengineering, Lean Management, etc., have been developed [1]. A new paradigm in this area of strategies is Six Sigma (6σ). The Six Sigma strategy is not just a quality management system. Its philosophy and vision has increased the profits of many organizations. The greatest news issued by Six Sigma concept is the quantification of indicators related to quality. The main benefit of a Six Sigma program is the elimination of subjectivity in decision making by creating a system where everyone in the organization collects, analyzes, and displays data in a consistent way [2]. This paper deals with application of Six Sigma Define–Measure–Analyze–Improve–Control (DMAIC) methodology on the optimization of the vehicle fleet of an enterprise. Any fleet within transport can optimize the use and enforcement of the model, whether in the case of cars, as in this paper, or in the case of various vessels in maritime transport.

2. The Concept of Six Sigma

2.1. Background of the Research

Six Sigma is a set of techniques and tools for process improvement. This statistical method is used in many companies whether they are manufacturing or giving services. Six Sigma methodology involves finding and eliminating the causes of errors or deficiencies. The focus is on the outputs that are of major importance to consumers. Six Sigma was developed in the early and mid 1980s by the Motorola Company. The company’s aim was to achieve business excellence. Thanks to the strategy, Motorola gained the leading position in the area of quality and was awarded the Malcolm National Quality Award [3]. In 1986, the engineers of Motorola, Bill Smith and Mikel J Harry, concluded that the previous method was not enough for measuring defects. After implementing the new methodology, better results were evident. Many companies like Toyota, Ford, BMW, Hilti, Shell, General Electric, Honey International, Caterpillar, Raytheon and Merrill Lynch also applied it successfully [3].

Sigma “σ” is a symbol for standard deviation that describes the degree of variation in a given set, i.e., the degree of product quality, services or processes [4]. The aim of Six Sigma is to reduce waste to the lowest possible level, as well as cost and time of production to increase business productivity. The basic measurement unit of Six Sigma is Defects per Million Opportunities (DPMO). Six Sigma is an indicator of the frequency of error/deviation occurrence. According to this model 3.4 errors per million are acceptable, which means a process shift of 1.5 σ [5,6]. Therefore, the goal of all companies is to accomplish that each process has an index value of Cp ≥ 2 [7]. In Figure 1, this condition corresponds to the main curve. The range between the Upper Specification Limit (USL) and the Lower Specification Limit (LSL) is named the specification range. The Six Sigma methodology is part of Statistical Process Control (SPC). A variational reduction in processes leads to higher profits and increases the quality of products and services [5].

Figure 1.

Six Sigma curve [8].

Six Sigma is a system for quality management, metrics and methodology, wherein quality indicators could be quantified [9]. Six Sigma methodology is basically focused on [7]:

- improving user satisfaction (customers);

- decreasing the product-making time (cycle time reduction);

- reducing the number of defects (errors) in products and services.

Improvements in these areas provide high levels of quality, large savings and high profits to companies, gaining new markets for the company and raising the company’s image. The application of Six Sigma reduces the cost of waste (from 20%-30% to less than 0.1%), the cycle-time, the cost and need for control, and increases the quality of products and customer satisfaction [10,11,12,13].

In recent years, there has been a renewed trend in the rise of Six Sigma methodology. It is associated with Lean Methodology and is called Lean Six Sigma. This package represents a set of tools within the structures set up under the name of Business excellence management. Its main purpose is achieving the highest possible financial and other benefits. The increased use of Six Sigma has contributed significantly to industrial expansion areas. The concept finds its application in high technology, the transport industry, machinery production and general purpose equipment.

2.2. Six Sigma Model

The Six Sigma strategy is not based solely on statistics and high technology, but also on proven methods and measurements that focus on improving processes and cost savings. It is currently one of the most popular quality management systems in the world [14].

DMAIC and Define–Measure–Analyze–Design–Verify (DMADV) are two models that use Six Sigma methodology. The tools of Six Sigma are often applied within a simple performance improvement model known as Define–Measure–Analyze–Improve–Control (DMAIC). DMAIC is used when the aim is to improve an existing product, process or service. Another approach, used for developing a new product, process or service is Define–Measure–Analyze–Design–Verify (DMADV) [15].

The major differences between DMAIC and DMADV are in the goals and outcomes of the completed project. The DMADV project has a more tangible outcome, but in reality, both methods give better quality, efficiency, more production and profits, and higher customer satisfaction [16]. The DMAIC model is used in this paper.

DMAIC has a Plan-Do-Check-Act (PDCA) model for the base, and is concerned with the life cycle of the project (exclusive orientation on projects). PDCA, as a tool, is used specifically in the management phase. DMAIC is an integral part of Six Sigma, but in general can be implemented as a standalone quality improvement procedure or as a part of other process improvement activities. In Figure 2, the letters in the acronym DMAIC represent five phases of the process.

Figure 2.

Six Sigma Define–Measure–Analyze–Improve–Control (DMAIC) roadmap [17].

The Define Phase is the first phase of the Lean Six Sigma improvement process. This phase finishes with signing a complete project assignment (Project Charter). Measurement is critical throughout the life of the project. There are two focuses: determining the starting point of the process and trying to understand the root cause of the process [18]. In the Analyze stage, the project team use data analysis tools and process analysis techniques to identify and verify the main causes of the problem [19]. The Improve phase consists of developing and selecting the optimal solutions for the best results and most robust performance [20]. The Control phase controls the solution implementation, and monitors the process and its operation.

DMAIC contains a number of various tools used by certain phases (Table 1). The method offers rough guidelines how to use tools at certain phases. Process owners and the team may use the tools they find to be the most responsive.

Table 1.

Six Sigma tools commonly used in each phase of a project [15].

3. Solution Approaches for Vehicle Fleet by DMAIC Method

This part of paper presents the process of applying the DMAIC model to the fleet in one selected profitable (successful) firm.

3.1. Problem Presentation

The selected company is one of the largest organizations, but its primary activity is not transport. It has a transport service, which includes a large number of passenger cars, buses, and other vehicles. It deals with heavy maintenance costs, low availability and a long process of purchasing spare parts. Two key processes are identified within DMAIC application: vehicle approval and vehicle fleet maintenance. The research data is from 2018. The research began in August 2019 and ended in February 2020.

3.2. Methodology

The suppliers, inputs, process, outputs, and customers (SIPOC) method was used to determine the process steps, customers (suppliers), as well as the inputs/outputs of the project [21]. By using another quality tool, Voice of the Customer (VOC), a transfer from the required to quantifiable specifications was made [22]. When analyzing interested parties, the following stakeholders are identified: management, internal and external users, and transport servicers.

The project goal is to reduce total costs by 20%.

A Swim lane map was a process map that separates process into lanes. The Swim lane workflow map also shows what performs each part of the process and the resources used in the performance [23]. The following areas are of utmost importance:

- non-defined vehicle class;

- reports (local order—a travel warrant for the narrow geographical area within facilities Q) on the use of the vehicle;

- procedures for updating the vehicle fleet;

- procedures for maintenance and use of official vehicles should include: travel plan (approval), the number of passengers per vehicle (optimal), report and maintenance plan, fault books;

- technical booklets.

The improvement process was measured by the total costs (Y). The total costs consist of the following: regular maintenance, replacement parts, vehicle registration and third-party services.

During the sampling, the following vehicle data was collected for all vehicles: type of vehicle, model of vehicle, registration number, year of production, total costs, kilometers travelled, fuel consumption in liters, consumption per 100 kilometers, fuel costs and maintenance costs.

3.3. Results and Discussion

Statistical data analysis was performed by using Minitab 17 (Minitab Inc., State College, PA, USA). A normality test for response variable (Y) was carried out. Figure 3 shows that the data for maintenance costs do not follow a normal distribution (Anderson–Darling test, p < 0.005).

Figure 3.

Normality test for maintenance costs.

Moving average and moving range control charts in Figure 4 show that the process is unstable/out of control. There are also ten points in the line (more than seven) emerging from the same side of the line, which are the mean values. It shows that there are variations in a specific cause, which should be removed [24]. Specific causes should not be ignored, but it is necessary to:

Figure 4.

Stability of the maintenance costs process.

- detect variations in specific causes quickly;

- stop activities until the process is rectified (reactively);

- identify and permanently eliminate specific causes (preventively);

- adjust the process if specific causes cannot be eliminated.

The Cause and Effect Matrix (Table 2) helped to prioritize the most important process inputs, i.e., Causes (X), which affect most (the highest rated) key process outputs (Y). Based on this Cause and Effect Matrix, Pareto analysis was performed (Figure 5).

Table 2.

Cause and Effect Matrix. Rating of importance to customer (1 = not important, 10 = very important). Key process outputs (Y): maintenance costs.

Figure 5.

Pareto chart.

The most important (critical) causes (X) were identified. They lead to 80% of the cost problems of the vehicle fleet, namely:

- the nonexistence of a technical book;

- too many external requirements;

- oversized exploitation;

- the type of the vehicle;

- kilometers travelled;

- inadequate procedures for maintenance;

- the age of the vehicle (year of production);

- the irresponsibility of the driver;

- the model of the vehicle.

Failure Mode and Effects Analysis (FMEA) applies in order to reduce the circle of potential causes. FMEA is a systematic method of identifying and preventing system, product and process problems before they occur [25]. The aim of FMEA analysis is to:

- detect errors and prevent them before they occur;

- reduce costs by identifying potential improvements early in the development cycle;

- evaluate the process/product from a new perspective.

The concept of FMEA analysis implies determining the ways in which errors can occur in the process or in the product. Therefore, it is necessary to plan how to avoid them.

Risk priority number (RPN) is an indicator of certain problems within FMEA analysis, consisting of the severity of the problem, the likelihood of occurrence and the probability of problem detection [26]:

RPN = Severity × Occurrence × Detection.

The higher the RPN is, the more likely it is concerned with a single error.

The FMEA contains a plan of activities/corrective measures that will prevent the occurrence of an error, i.e., reduce the RPN.

Following the proposed measures of FMEA analysis, (Table 3 and Table 4) risk reduction is expected. The recommended measures affected the risk reduction.

Table 3.

Failure Mode and Effects Analysis (FMEA).

Table 4.

Recommended actions and responsibilities.

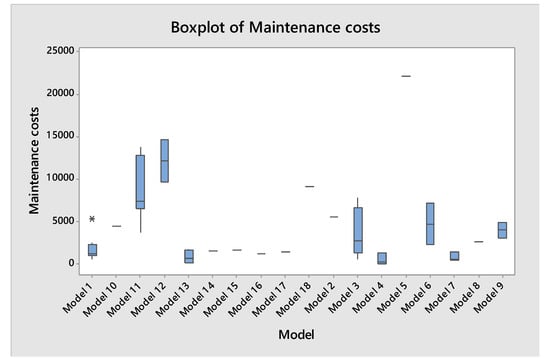

After identifying all inputs X that affect output Y (maintenance costs), collecting data and narrowing the circle of potential causes, the validation of critical causes is done. Validation takes the form of a tool that confirms critical causes. Figure 6 shows that the vehicle models 11, 12, 3 and 6 cause major maintenance costs.

Figure 6.

Boxplot of maintenance costs.

An analysis of variance (ANOVA) was used to test the effect or impact of X, which is an attribute data (vehicle model), on Y, which is a variable data (maintenance cost). Despite the non-normality of maintenance costs (Figure 3), the sample size is large (>30) and the ANOVA is “acceptable” [24]. Statistical software MINITAB has techniques for process capability measuring even in the case of non-normal distribution. How much a particular X affects Y is seen on R-sq (adj). Figure 7 shows that the P-value is 0.000. It is clear that the vehicle model affects maintenance costs of 75.17%.

Figure 7.

Interval plot of maintenance costs vs. model.

A regression analysis was performed to test whether the maintenance costs are affected by the kilometers travelled and the year of production (age of the vehicle). Figure 8 shows that kilometers travelled affect maintenance costs (Regression ANOVA, p < 0.001). It was also expected that the age of the vehicle would affect the maintenance costs (Regression ANOVA, p = 0.788) (Figure 9). However, these results are unexpected and introducing/applying all identified procedures is needed.

Figure 8.

Regression analysis: maintenance costs vs. travelled in km.

Figure 9.

Regression analysis: maintenance costs vs. year of production.

In Figure 10, the Pareto chart shows the total number of kilometers per vehicle model. It can be concluded that six vehicle models make up almost 80% of all kilometers travelled. In this regard, the vehicle fleet should be balanced in order to reduce maintenance costs, the number of training drivers and technicians and to increase the availability of spare parts.

Figure 10.

Pareto chart of model.

Table 5 and Table 6 explain the Improvement Plan for all samples identified (X). The improvement phase starts with brainstorming process that will accomplish further activity plans.

Table 5.

Improvement plan.

Table 6.

Improvement plan effects.

Table 7 and Table 8 show the Control Plan. Phase Control provides the transition from the state of the project into a stable condition. The Control plan is mandatory to ensure:

Table 7.

Control plan.

Table 8.

Control plan strategy.

- documents are updated;

- the training required due to the changes in the processes is carried out;

- an audit plan is created for control activities.

4. Conclusions

The Six Sigma methodology is based primarily on quantifiable data that aims to eliminate losses and improve the quality of products. The main purpose of the Six Sigma methodology is to implement strategies based on measurements that focus on improving processes and reducing variation. Six Sigma uses the process improvement methodology DMAIC, which has five phases: Define, Measure, Analyze, Improve and Control.

The optimization of the vehicle fleet in a profitable (successful) company in this paper precisely shows the application of the DMAIC model and the maintenance costs for 2018 were measured. The project started in 2019 and the available data for 2018 were taken into consideration. The Six Sigma (6σ) model was expected to reduce costs by 20%. The goal of a 20% reduction in costs was not attained, but the activities shown in the Improvement and Control Plans will reduce these costs by more than 20%.

By implementing the FMEA analysis, the following statistics were obtained. The vehicle model affects the maintenance costs by 75.17%, but the age of the vehicle was found not to affect maintenance costs.

Direct improvement measures were implemented due to the lack of technical booklets, procedures on vehicle maintenance and non-timely completion of the travel order. The expectations regarding the project relate to the implementation of recommended measures. This will lead to a reduction in the maintenance costs in general.

The advantages of the more efficient use of the vehicle fleet should be reducing maintenance and fuel costs, increasing the reliability and availability of the vehicle, defining responsibilities, etc. Accurate information about the history of repairs, shorter vehicle repair time and better control of exploitation costs may also be taken into consideration. The work on this project showed the remarkable importance of the existence of historical data. In addition, this project can also be applied in other similar enterprises. Moreover, the methods of fuzzy linear and dynamic programming combined with heuristic and metaheuristic methods find their place of application [27,28,29,30].

Author Contributions

T.S., T.G., J.Ž.M. and V.L. carried out research and methodology in the manuscript. T.S. and T.G. wrote original draft, interpreted the results, created tables and figures. T.S., T.G. and J.Ž.M. reviewed, edited and corrected the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This article is funded by University of Split, Faculty of Maritime Studies, R. Boškovića 37, 21000 Split, Croatia.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Desai, T.N.; Shrivastava, R.L. Six Sigma A New Direction to Quality and Productivity Management. In Proceedings of the World Congress on Engineering and Computer Science WCECS 2008, San Francisco, CA, USA, 22–24 October 2008; ISBN 978-988-98671-0-2. Available online: http://www.iaeng.org/publication/WCECS2008/WCECS2008_pp1047-1052.pdf (accessed on 1 March 2020).

- Kumar, S.; Satsangi, P.S.; Prajapati, D.R. Six Sigma an excellent tool for process improvement—A case study. Int. J. Scie. Eng. Res. 2011, 2, 1–10. [Google Scholar]

- Sujova, A.; Simanova, L.; Marcinekova, K. Sustainable Process Performance by Application of Six Sigma Concepts: The Research Study of Two Industrial Cases, Sustainability, Sustainable Business Models, Printed Edition of the Special Issue Published in Sustainability. Sustainability 2016, 8, 260. [Google Scholar] [CrossRef]

- Habul, A.; Pilav-Velić, A.; Kremić, E. Improvements of Business Process by Implementing Six Sigma Model. In Proceedings of the Scientific Conference with International Participation “Quality 2011”, Neum, Bosnia & Herzegovina, 01–04 June 2011; pp. 7–12. Available online: http://www.quality.unze.ba/zbornici/QUALITY%202011/002-Q11-017.pdf (accessed on 3 March 2020).

- Bratić, D.; Optimizing the Printing Concept on Six Sigma Principles. Ph. D. Thesis, University of Zagreb, Faculty of Graphic Arts, Zagreb, Croatia, 2015; p. 15. Available online: https://eprints.grf.unizg.hr/2249/1/Doktorski%20rad%20Bratic%20Diana.pdf (accessed on 15 January 2020).

- Kwak, Y.H.; Anbari, F.T. Benefits, obstacles, and future of six sigma approach. Technovation 2006, 26, 708–715. Available online: https://www.researchgate.net/publication/222518320_Benefits_obstacles_and_future_of_SixSigmaapproach (accessed on 14 March 2020). [CrossRef]

- Lazić, M. Six sigma—Methodology for quality improvement, Festival of quality 2011. In Proceedings of the National Conference on Quality, Faculty of Mechanical Engineering, Center for Quality, Kragujevac, Serbia, 19–21 May 2011; pp. 213–220, ISBN 978-86-86663-69-6. Available online: http://www.cqm.rs/2011/FQ2011/pdf/38/34.pdf (accessed on 12 March 2020).

- Gustafsson, V.; Davidsson, S. Streamlining the Invisible Value Chain Reduction of Losses within Administrative Processes: A Case Study. Bachelor’s Thesis, Linnaeus University, School of Engineering, Växjö, Sweden, 2011. Available online: http://www.diva-portal.org/smash/get/diva2:433853/FULLTEXT01.pdf (accessed on 14 February 2020).

- Lazibat, T.; Baković, T. Six Sigma System for Quality Management, Business Excellence, Zagreb, 2007; Volume 1, pp. 55–66. Available online: https://hrcak.srce.hr/38522 (accessed on 12 March 2020).

- Rajković, V. Lean Six Sigma Concept, Festival of quality 2012. In Proceedings of the National Conference on Quality, Faculty of Mechanical Engineering, Center for Quality, Kragujevac, Serbia, 07–09 June 2012; pp. 39–43, ISBN 978-86-86663-83-2. Available online: http://www.cqm.rs/2012/cd1/pdf/39/05.pdf (accessed on 10 March 2020).

- Anthony, P.; Behnoee, B.; Hassanpour, M.; Pamucar, D. Financial performance evaluation of seven Indian chemical companies. Decis. Mak. Appl. Manag. Eng. 2019, 2, 81–99. [Google Scholar] [CrossRef]

- Biswas, S.; Bandyopadhyay, G.; Guha, B.; Bhattacharjee, M. An ensemble approach for portfolio selection in a multi-criteria decision making framework. Decis. Mak. Appl. Manag. Eng. 2019, 2, 138–158. [Google Scholar] [CrossRef]

- Jankovic, A.; Popovic, M. Methods for assigning weights to decision makers in group AHP decision-making. Decis. Mak. Appl. Manag. Eng. 2019, 2, 147–165. [Google Scholar] [CrossRef]

- Russell, R.; Taylor, B. Operations Management—Creating Value along the Supply Chain; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; Available online: http://jtelen.free.fr/0MARINE%20bouquins/%5BRoberta_S._Russell,_Bernard_W._Taylor%5D_Operations(Bookos.org).pdf (accessed on 15 January 2020).

- Pyzdek, T.; Keller, P. The Six Sigma Handbook: A Complete Guide for Green Belts, Black Belts and Managers at all Levels, 3rd ed.; The McGraw-Hill Companies, Inc.: New York, NY, USA, 2009; ISBN 978-0-07-162337-7. [Google Scholar]

- The Council for Six Sigma Certification. Six Sigma—A Complete Step-by-Step Guide: A Complete Training & Reference Guide for White Belts, Yellow Belts, Green Belts, and Black Belts; The Council for Six Sigma Certification: Buffalo, WY, USA, 2018; ISBN 978-1732592650. Available online: https://www.sixsigmacouncil.org/wp-content/uploads/2018/08/Six-Sigma-A-Complete-Step-by-Step-Guide.pdf (accessed on 15 January 2020).

- Fung, P. Design for Six Sigma, Power Point Presentation. 2015. Available online: http://www.hksq.org/DFSS-STP-150124-Peter.pdf (accessed on 18 February 2020).

- Krishnan, R.; Prasath, A. Six Sigma Concept and DMAIC Implementation. IJBMR 2013, 3, 111–114. [Google Scholar]

- Sindha, N.; Suthar, K. Review on Implementation of Six Sigma DMAIC Methodology in Manufacturing Industries. IJSTE 2017, 3. Available online: http://www.ijste.org/articles/IJSTEV3I8064.pdf (accessed on 20 February 2020).

- Kaid, H.; Noman, M.; Nasr, E.; Alkahtani, M. Six Sigma DMAIC phases application in Y company: A case study. Int. J. Collab. Enterp. 2016, 5, 181–197. [Google Scholar] [CrossRef]

- Miski, A. Improving Customers Service at IKEA Using Six Sigma Methodology. Int. J. Sci. Eng. Res. 2014, 5, 1712–1720. Available online: https://www.ijser.org/researchpaper/Improving-Customers-Service-at-IKEA-Using-Six-Sigma-Methodology.pdf (accessed on 16 February 2020).

- Griffin, A.; Hauser, J. The Voice of the Customer. Mark. Sci. 1993, 12, 1–27. [Google Scholar] [CrossRef]

- Ezeonwumelu, E.P.; Ozuomba, S.; Kalu, C. Development of Swim Lane Workflow Process Map for Enterprise Workflow Management Information System (Wfmis): A Case Study of Comsystem Computer and Telecommunication Ltd (Cctl) Eket. Eur. J. Eng. Technol. 2015, 3. Available online: https://pdfs.semanticscholar.org/49fa/9f7f3585c2bf7223b6d334256b4d868eac0a.pdf (accessed on 20 January 2020).

- DaimlerChrysler Corporation, Ford Motor Company, and General Motors Corporation. Statistical Process Control (SPC) Reference Manual. 2005. Available online: https://www.academia.edu/7829906/AIAG_Statistical_Process_Control_SPC_2nd_Edition (accessed on 20 January 2020).

- Sharma, K.D.; Srivastava, S. Failure Mode and Effect Analysis (FMEA) Implementation: A Literature Review. J. Adv. Res. Aeronaut. Space Sci. 2018, 5, 1–17. Available online: https://www.researchgate.net/publication/333209894_Failure_Mode_and_Effect_Analysis_FMEA_Implementation_A_Literature_Review (accessed on 18 February 2020).

- Liu, H.; Deng, X.; Jiang, W. Risk Evaluation in Failure Mode and Effects Analysis Using Fuzzy Measure and FuzzyIntegral. Symmetry 2017, 9, 162. [Google Scholar] [CrossRef]

- Dobrosavljević, A.; Urošević, S. Analysis of Business Process Management Defining and Structuring Activities in Micro, Small and Medium—Sized Enterprises. Oper. Res. Eng. Sci. Appl. 2019, 2, 40–54. [Google Scholar] [CrossRef]

- Badi, I.; Shetwan, A.; Hemeda, A. A Grey-Based Assessment Model to Evaluate Health-Care Waste Treatment Alternatives in Libya. Oper. Res. Eng. Sci. Appl. 2019, 2, 92–106. [Google Scholar] [CrossRef]

- Petrovic, G.; Mihajlovic, J.; Cojbasic, Z.; Madic, M.; Marinkovic, D. Comparison of three fuzzy MCDM methods for solving the supplier selection problem. Facta Univ. Ser. Mech. Eng. 2019, 17, 455–469. [Google Scholar] [CrossRef]

- Sunny Diyaley, S.; Chakraborty, S. Optimization of multi-pass face milling parameters using metaheuristic algorithms. Facta Univ. Ser. Mech. Eng. 2019, 17, 365–383. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).