Abstract

In this research, the modification of different polyester structures (fabrics and knits) by the biopolymer chitosan was studied to evaluate the effects of the polyester structure and treatments on the particulate pollution of wastewater. The pristine polyester and the chitosan-polyester fabric and polyester knit composites were washed cyclically with standard ECE A detergent at 60 °C. The laser diffraction technique was used to characterize the particle size of the washing wastewaters from the 1–5, 6–10 and 1–10 wash cycles. In addition, the total solids (TS), total suspended solids (TSS), total dissolved solids (TDS), turbidity and chemical oxygen demand (COD) were also determined, according to standard procedures. The obtained results show the influence of the polyester fabrics and polyester knit structures and chitosan-polyester composites on the particle size distribution (PSD) in the washing wastewater. Differences in the values of the characteristic parameters, especially the span value and shape factor (k) of the individual curves, are visible, indicating the release of particles during the washing process. The experimental results show that the laser diffraction technique is suitable for characterizing the particle dimensions of the washing wastewater for different pristine polyester structures and chitosan-polyester composites. Modification with chitosan has been shown to provide potential protection against the release of microplastic particles into the environment.

1. Introduction

A problem of global proportions, in the last decade, is the presence of microplastic particles (MP) in the environment (water, air, soil, rocks). Synthetic textiles containing polymers release microplastic particles and fibrils into wastewater posing a threat to the environment [1,2,3,4]. It is estimated that about 30% of these particles reach the environment through the washing process for polyester textiles [5] and through non-woven PP, PE, or HDPE fibers in flushable wet wipes and sanitary towels [6]. The tendency to release these particles depends on the properties of the textile, the technological and lifetime stages, and physical damage during the washing process.

In order to reduce the proportion of released particles, it is necessary to work on prevention and it is particularly important to choose a procedure to modify polyester textiles. Functional substances, for e.g., softener, pectin, chitosan, etc., create a film aimed at covering the surface and preventing the release of particles [7,8].

The prevention and reduction of particle release includes taking into account the influence on fibers, yarns and fabrics; functionalization, for example with the biopolymer chitosan; and the use of optimal conditions during the washing process, in accordance with the Sinner cycle [9,10,11]. Chitosan and chitosan-based compounds have adsorption abilities for heavy metals and the ability to remove phosphates, nitrate and heavy metals from wastewater [12,13,14,15,16,17,18]. Treating the textile material with chitosan increases the breaking force and its resistance to deformation, increases the wetting ability of the material and the hydrophilicity, the material acquires antimicrobial properties, static electricity charging and the amount of particles released from the material can be reduced [9,19].

Despite the protective effect of the material, functional particles can have multiple effects on the composition of washing wastewater as individual particles or potential vectors. Therefore, it is important to optimize their selection and modification processes to achieve good interaction with the material, biodegradability and non-toxicity. The importance of this approach is confirmed by the load level of textile washing wastewater, which contains organic, inorganic and biological components that may be present in the solution as soluble or suspended particles [20].

In the context of water pollution by microplastic particles, which is the subject of numerous pieces of research today, experimental data on the size distribution of the particles in different wastewaters can be an important parameter for the characterization, prevention of pollution and, finally, for the selection of wastewater treatments [21,22,23].

Since particle size distribution is a useful method for characterizing washing wastewater, it is possible to establish a relationship between the parameters in this curve and other parameters used to characterize wastewater, such as COD, suspended solids, color and turbidity [24]. Therefore, research efforts are focused on using particle size data to better understand numerous processes and describe various phenomena [25].

Consequently, the aim of this research is to compare the properties of washing wastewater from pristine polyester structures and chitosan-polyester composites resulting from the modification of polyester knit and polyester fabric, focusing on the content and distribution of the particles. The characteristic distribution diameters, namely D10, D50 and D90, obtained from the PSD curves were compared with other standard parameters (conductivity, turbidity, TS, TSS, TDS and COD) for wastewater characterization.

2. Materials and Methods

2.1. Materials

A standard white polyester fabric, PN-01, in plain weave (purchased from CFT, Center for Testmaterials BV, Vlaardingen, The Netherlands) and a polyester weft knit, MRF-0008 (from WFK, Germany), were used for the study.

The surface weight of the fabric was 156 g/m2, with a density of 27.7 threads/cm in the warp direction and 20 threads/cm in the weft direction.

The surface weight of the knit was 139 g/m2, with a horizontal density (Dh) of 16 stiches/cm and vertical density (Dv) of 21 stiches/cm.

A Sonowave ultrasonic cutter (TTS400, Rome, Italy) was used to prepare the samples, with a dimension of 30 × 50 cm, to avoid the influence of the protruding thread edges in the samples during the modification and washing processes.

Modification of Polyester Fabric and Knit with Chitosan

The polyester fabric and knit were modified with a chitosan solution (0.5%) by impregnation in a Benz stenter. Low molecular weight (LMW) chitosan in physical form at 85% deacetylatation (supplied by Aldrich®, San Diego, CA, USA), was prepared according to a step procedure [15]. After impregnation, the chitosan-polyester composites (fabric and knit) were dried at 90 °C for 40 s and cured at 130 °C for 20 s.

2.2. Washing Process

The washing process was carried out according to the standard HRN EN ISO 6330:2021 in a Rotawash device (SDL Atlas, Rock Hill, NC, USA), in a solution with 1.25 g/L standard detergent (ECE A phosphate-free reference detergent), the composition of which is shown in Table 1.

Table 1.

Composition of the reference detergent ECE A.

Each polyester fabric and knit was washed before and after modification with chitosan in different washing cycles at a bath ratio of 1:7 at 60 °C for 30 min, followed by four rinses with water at a bath ratio of 1:8. The collected composite washing wastewater after 1–5 washing cycles, 6–10 wash cycles and a total of 1–10 washing cycles, with detergent and rinse cycles with water were used for further analysis.

2.3. Methods

The standard methods (pH, conductivity, turbidity, TS, TSS, TDS and COD) [26] and particle size analysis [27] were used for the characterization of the washing wastewaters after the 1–5 washing cycles, the 6–10 washing cycles and the total of the 1–10 washing cycles for the pristine polyester structures and chitosan-polyester fabric and chitosan-polyester knit composites.

2.3.1. Standard Methods for Washing Wastewater Characterization

The pH and conductivity of the washing wastewater were measured with a multimeter (SevenCompact™ Duo S213), the pH was measured with an electrode from InLab Expert Pro-ISM® and the conductivity with InLab® 731-ISM. Calibration was performed with puffer pH 4.01, pH 7.00, pH 9.21, using InLab® Solutions, Mettler Toledo and a standard solution of 84 µS/cm from BDH Prolabo. The TSS, TS and TDS were determined according to standard filtration and gravimetric procedures. The turbidity was measured as NTU using the nephelometric method HRN EN ISO 7027-1: 2016 with a turbidity meter, Hach TL 2350. The chemical oxygen demand (COD) was determined with a Thermoreactor CR 2200 (WTW, Xylem Analytics) and a photometer (PhotoLab S6, WTW, Xylem Analytics, Germany GmbH, Bremen, Germany).

2.3.2. Laser Diffraction Method for Particle Size Characterization

A particle size analyzer (PSA 1090 LD, Anton Paar, Graz, Austria) was used for the diffraction of all the washing wastewater that was recorded and analyzed, which involves a complex algorithm that compares the measured values with the theoretical value based on the Fraunhofer diffraction theory. The result from the measurement is the distribution function presented as a statistical curve that allows for the determination of numerous parameters that provide important information about the particles present in the observed dispersed system. A detailed explanation of the parameters can be found in a previous study [25]. In this research, the characteristic diameters, D10, D50 and D90, the shape factor and span value determined from the PSD curve are used for particle characterization of the washing wastewater. All measurements were performed in replicate series with five measurements in water as a solvent, with the stirrer speed and pump speed set to medium.

3. Results and Discussion

This research focuses on particle content and particle size characterization to evaluate the particles of textile and non-textile origin released from pristine polyester fabric and polyester knit structures and chitosan-polyester fabric and knit composites, during the washing process with standard ECE A detergent at 60 °C. The analysis of the particle content and particle size using selected parameters was carried out in a detergent solution and wastewater after 1–5, 6–10 and a total of 1–10 washing and rinsing cycles.

Measuring solids and particles can be critical in assessing water quality profiles, especially washing wastewater as a dispersion system. When measuring solids to determine water quality, it is important to emphasize that solids come in a variety of physical forms and that different measurement principles can provide different types of information. This is particularly important for particulate matter in textile wastewater, which represents microfiber pollution. Parameters, such as turbidity, total suspended solids (TSS) and total dissolved solids (TDS), provide information about the type and amount of particles present in the solution.

Turbidity is an optical parameter to determine the clarity of water and is directly related to the amount of particles scattered throughout the water. Turbidity and TSS are related; turbidity can be used to indicate changes in the TSS concentration of water, but not to provide a particular measurement of those solids, because turbidity is purely a measurement of relative clarity. The TDS refers to the fraction of particles and ions that can pass through a filter with a pore size of 2 µm and represents the total concentration of these dissolved solids in a certain volume. Turbidity is the clarity of the water, expressed by the NTU, TDS and TSS measurements shown as the total concentration of the solids in a volume, but the PSD as a laser diffraction present results on the number, surface or volume distribution. The conversion from numbers to volume or vice versa is possible, but the conversion of volume results from laser diffraction to a numerical basis can lead to undefined errors. The results from this conversion show large differences in the mean sizes of the particles present in the system, especially for microfiber particles. The particle size distribution results in this paper were used as a superposition of five consecutive measurements for the volume distribution function [22,25].

The washing process is a complex system, and it is important to characterize the detergent solution to determine its influence on the particle content in washing wastewater. The standard ECE A detergent is a phosphate-free detergent, as shown in Table 1. It contains organic and inorganic substances necessary for the washing process. A non-soluble substance is sodium aluminosilicate, zeolite 4A as a builder, which is responsible for water softening and alkaline pH.

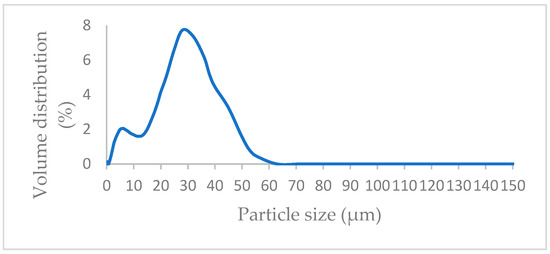

The results of the particle size distribution, as a volume distribution for the detergent solution, are shown in Figure 1.

Figure 1.

Particle size distribution function of detergent solution.

Based on the volume distribution function, the D10, D50, D90 for particles smaller than 10, 50 and 90 µm, the mean size, the shape factor (k) and span were determined. These results and the physicochemical properties of the reference detergent ECE A solution, as shown in Table 2, correspond to the composition of the detergent given in Table 1.

Table 2.

Physicochemical characteristics and parameters of the PSD function of the detergent solution.

The mean size of the particle diameters for the detergent solution is 22.715 µm, while the diameter ratio expressed as the span value is 1.61.

The detergent bath with 1.25 g/L consists mainly of soluble components, which is evident from the TDS/TSS ratio of 3.52. The other characterization parameters, pH, conductivity and turbidity, also agree with the composition as well. The detergent solution belongs to the easily degradable wastewaters, as shown by the COD value of 119 mg O2/L, and as such does not pose a major threat to the environment.

Washing wastewater where, in addition to detergents, there are also polyester fabrics exposed to all the parameters in the Sinner cycle, represent a more complex system for particle analysis.

3.1. Characteristics of Washing Wastewater from Pristine Polyester Fabric and Polyester Knit Structures

Pristine polyester fabric and polyester knit structures exposed for a certain time to the action of detergent components, mechanical agitation and temperature in the washing device release a certain amount of particles, which is reflected in the results of particle content and particle size analysis.

Washing wastewater from pristine polyester fabric and polyester knit characterizes the pH value in the range of 8.12–8.24, which corresponds to the alkaline medium created by the detergent ingredients, the conductivity values range from 717 to 733 µS/cm and the COD values indicate the readily degradable components in the wastewater, especially in the washing wastewater of the pristine polyester knit, Table 3.

Table 3.

Physicochemical characteristics of the washing wastewater from pristine polyester fabrics and polyester knit structures (expressed by basic parameters).

The results from the physicochemical analysis of the washing wastewater from the pristine polyester fabric and polyester knit, expressed by the particle content, are grouped in Table 4.

Table 4.

Physicochemical characteristics of the washing wastewater from pristine polyester fabrics and polyester knit structures (expressed by particle content).

Since the focus of the research is on the determination of the particle content in the complex system of washing wastewater, in which the composition of the detergent plays an important role, further analysis was carried out using the TDS/TSS ratio, which was compared with the same ratio in the detergent solution.

In contrast to the detergent solution, which consists mainly of soluble components, as can be seen from the TDS/TSS ratio of 3.52, the TDS/TSS ratio of the washing wastewater is 4.84, 6.52 and 5.43 for pristine polyester fabrics and 3.78, 3.43 and 3.93 for pristine polyester knit structures.

Considering the same parameters from the Sinner cycle for both systems, the obtained ratio can be related to the structural features and surface of the polyester fabric and polyester knit. The tactile properties of the fabric and knit structures are different, namely the rough surface of polyester fabric in comparison to the smooth polyester knit. This results in some differences in the observed relationships as the function of the number of wash cycles are specific, especially for polyester fabric. The turbidity values for the polyester knits are higher than that of the polyester fabric, which is consistent with its structural properties.

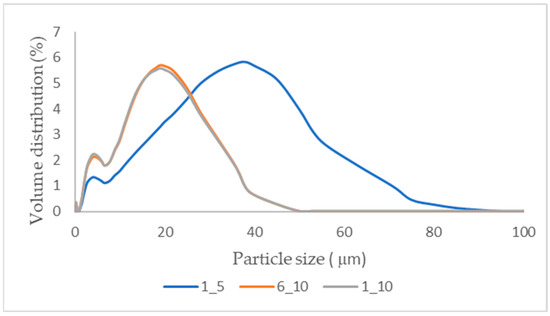

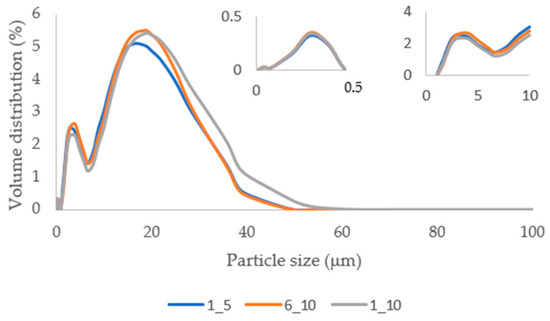

The results of the particle size distribution in the washing wastewater for the 1–5, 6–10 and 1–10 washing cycles for pristine polyester fabrics and polyester knit structures are shown as the volume distribution in Figure 2 and Figure 3.

Figure 2.

Particle size distribution function in washing wastewater of the pristine polyester fabrics.

Figure 3.

Particle size distribution function in washing wasteawater of the pristine polyester knits.

Both distribution curves are bimodal, and the differences are visible in the small particle size region. The particle size distribution curve for the pristine standard polyester fabrics in washing wastewater covers the particle range of 0–100 µm, with a larger range for the smaller number of wash cycles (1–5). Compared to the particle size range for the detergent solution, which extends up to 60 µm, a higher degree of particle contamination is observed in the first cycles, which is consistent with previous studies [28,29].

The range of particle sizes for the pristine standard polyester knit in the washing wastewater does not show large differences for the wash cycles. This is especially true for very small particle sizes of 0–2 µm, which are highlighted separately in Figure 3.

The characteristic parameters in the distribution curves for the pristine standard polyester fabrics and polyester knit structures in washing wastewater were determined, and the results for the values of D10, D50, D90, the shape factor (k), mean size and span are shown in Table 5 and Table 6, confirming the difference in the behavior of different materials in the washing process regardless of the same parameters in the Sinner cycle.

Table 5.

Parameters of the PSD function of washing wastewater from the pristine polyester fabric structure.

Table 6.

Parameters of the PSD function of washing wastewater from the pristine polyester knit structure.

The mean particle size for polyester fabrics is much higher in wastewater from the first wash cycles 1–5 than for the polyester knit. All the particle diameters for the polyester fabrics and polyester knit are the same in the washing wastewater for cycles 1–10. The diameter ratio, expressed as the span values (2.018 and 2.051), shows that it is consistent for knits and not significantly different for the number of cycles performed (1–5, 6–10) from the total number of 10 cycles. The span values for the range are greater than those for the detergent solution (1.609). This indicates that there are much fewer particles with a diameter of less than 10 µm. In the washing cycles analyzed, the polyester fabrics and knits are exposed to the action of the detergent, but since the structures are not soiled, undissolved particles from the detergent are adsorbed on the fabrics, or agglomeration and formation of larger particles in the bath occur.

Finally, it is important to emphasize that the detergent ingredients do not have a cleaning effect, but the result of their interaction with the polyester fabrics and knits may be agglomeration or the formation of deposits. Such deposits, formed by mechanical agitation, can be released from the surface as impurities of various origins.

3.2. Characteristics of Washing Wastewater from Chitosan-Polyester Fabric and Chitosan-Polyester Knit Composites

Numerous studies [8,11] have shown that polyester fabrics modified with chitosan have higher tensile strength and resistance to deformation, improved material wettability and hydrophilicity, have better antimicrobial properties, static electrical charging, and are less prone to fibril and the release of other particles. Given the interaction of chitosan with polyester, achieved by coating and thermal fixation, the gradual release of chitosan particles is expected, which does not represent an additional burden on wastewater. The proof of concept in this research was to evaluate the particle content in the effluent from washing chitosan-polyester fabric and chitosan-polyester knit composites through 1–5, 6–10 and 1–10 cycles. The standard characteristics of these wastewaters are listed in Table 7 and Table 8.

Table 7.

Physicochemical characteristics of washing wastewater from chitosan-polyester fabrics and knit composites (expressed by basic parameters).

Table 8.

Physicochemical characteristics of washing wastewater from chitosan-polyester fabrics and knit composites (expressed by particle content).

The results indicate differences in the TDS/TSS ratio, as well as the turbidity, which may be an indicator of contamination of these systems by potentially released particles.

The TDS/TSS ratio was calculated with the aim of determining the dominance of the influence of the structural features, surface area, and the influence of chitosan modification of the polyester fabric and polyester knit composites. The determined TDS/TSS ratios are significantly different from those of the pristine polyester fabric and knit and have different values depending on the number of washing cycles. The highest values of 7.96 and were obtained for the small number of washing cycles with chitosan-polyester fabric and 8 for the chitosan-polyester knit for the 1–10 cycles, respectively.

Considering the surface differences between the polyester fabric and polyester knit, the same effect of the modification was not expected, which these results confirm. The turbidity of the washing wastewater cycles 6–10 was higher for both chitosan-polyester composite structures than after the 1–5 and the total of 10 cycles. Such differences in the turbidity of the wastewater from the washing of polyester pristine fabrics, characterized by higher values, were not recorded/determined. This increase can be attributed to the washing resistance of the chitosan-polyester composite structures. After the 6–10 cycles, it is possible that the chitosan layer on the surface of the polyester fabric and knit hydrolyzes slightly and leads to an increase in turbidity.

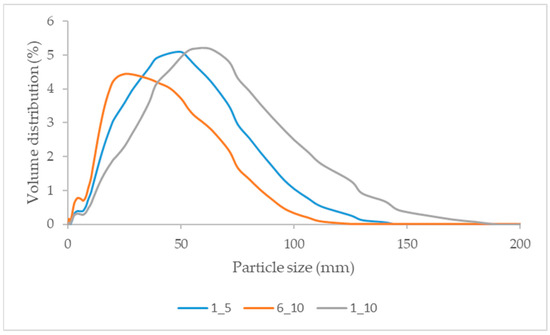

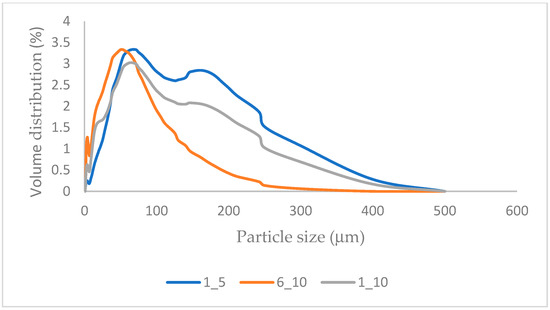

The results of the particle size distribution in the washing wastewater from the 1–5, 6–10 and 1–10 wash cycles from the chitosan-polyester composites (fabric and knit) are shown as the volume distribution in Figure 4 and Figure 5.

Figure 4.

Particle size distribution function in washing wastewater of the chitosan-polyester fabric composite.

Figure 5.

Particle size distribution function in washing wastewater of the chitosan-polyester knit composite.

The particle size distribution in the washing wastewater from chitosan-polyester composites differs significantly in shape from the previously presented curves. The distribution in particle size in the washing wastewater from chitosan-polyester knit structures ranges up to a particle size of 500 µm, indicating the presence of larger particles in the effluent.

Both distribution curves are multimodal, and differences are visible throughout the whole particle size range for both composites, fabric 0–200 µm and knit 0–500 µm. Compared to the particle size range for the detergent solution, which extends to 60 µm, a higher degree of particle contamination is observed in all washing cycles. The range of particle sizes for the chitosan-polyester knit composite in the washing wastewater shows large differences for the wash cycles. This is especially true for particle sizes at 120–500 µm, for the 1–5 and 1–10 wash cycles, where the bimodality of the curves is visible, see Figure 5.

The characteristic parameters in the distribution curves for chitosan-polyester composites (fabrics and knit) in the washing wastewater were determined, and the results for the values of D10, D50, D90, the mean size, shape factor (k) and span are shown in Table 9 and Table 10.

Table 9.

Parameters for the particle size distribution function in the washing wastewater from the chitosan-polyester fabric composites.

Table 10.

Parameters for the particle size distribution function in the washing wastewater from the polyester-chitosan knit composites.

The results confirm the differences in the behavior of chitosan-polyester fabric and knit composites in different washing cycles, regardless of the same parameters in the Sinner cycle.

Washing wastewater from chitosan-polyester fabric composites has much higher values for the D50, D90, and the mean size compared to the wastewater from chitosan-polyester knit composites for all washing cycles, except for the particle diameter D10, which is smaller for wash cycles 6–10 and 1–10. The diameter ratio, expressed as the span values, is much higher for the chitosan-polyester knit composite wastewater and increases with the wash cycles, while the shape factor decreases which confirms the presence of larger particles in the system.

Since it is a modification with a biopolymer, if particles are released, probably agglomerates, they will not create significant pollution because they are of biological origin and are easily degradable.

These results confirm the fact that the classical parameters for physicochemical analysis are not sufficient for the characterization of particulate matter. Therefore, it is also necessary to determine the size of the particles, so that this complex system can be influenced preventively by installing a filter in the washing machine, or if microfibers enter the sewage system, it is possible to remove them in pretreatments or in primary treatment.

4. Conclusions

This research is focused on modifying polyester fabrics and knits with chitosan to reduce the release of particles during the washing process. To evaluate the effectiveness of the modification, the particle content in the washing wastewater from the 1–5, 6–10 and 1–10 cycles for chitosan-modified and pristine polyester fabrics and knits were compared.

The TSS value was used as an indicator of the degree of solid particle loading in the washing wastewater and the laser diffraction method was used to determine the particle size distribution and characteristic parameters for the particles.

Comparing the obtained PSD functions in the washing wastewater from pristine and chitosan-modified polyester structures, differences in the values for the characteristic parameters of each curve become visible, indicating the release of particles during the washing process.

The variation of PSD in the washing wastewater from chitosan composites depends on the structure of the polymer, the interaction of chitosan with the structure, the durability of the modification through specific washing cycles, the suspended solids, the particle size distribution in the wash bath and the parameters for the washing process. Washing wastewater from chitosan-polyester fabric composites has much higher values for the D50, D90 and the mean size compared to the wastewater from chitosan-polyester knit composites. The shape factor is less than 1 for wash cycles 6–10 and 1–10, confirming the presence of larger particles in the washing wastewater from chitosan-polyester knit composites.

The presence of larger particles in the washing wastewater from chitosan-polyester composite sites can be considered a positive result, as the removal of larger particles is easier and already occurs during the pretreatment and initial treatment of effluent. It is also possible to retain larger MP and microfiber particles through filters in washing machines and in this way preventive measures are being taken to protect the environment.

Author Contributions

Conceptualization, M.Č. and T.P.; methodology, B.V., T.K. and A.Š.; validation, M.Č. and T.P.; formal analysis, B.V.; data curation, M.Č. and T.K.; writing—original draft preparation, M.Č. and T.P.; writing—review and editing, M.Č. and T.P.; project administration, T.P. and M.Č. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been fully supported by the Croatian Science Foundation under the project IP-2020-02-7575, Assessment of microplastic shedding from polyester textiles in washing process.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data are available.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Napper, I.E.; Thompson, R.C. Release of synthetic microplastic plastic fibres from domestic washing machines: Effects of fabric type and washing conditions. Mar. Pollut. Bull. 2016, 112, 39–45. [Google Scholar] [CrossRef] [PubMed]

- Browne, M.A.; Crump, P.; Niven, S.J.; Teuten, E.; Tonkin, A.; Galloway, T.; Thompson, R. The physical impacts of microplastics on marine organisms: A review. Environ. Sci. Technol. 2011, 45, 9175–9179. [Google Scholar] [CrossRef]

- Hernandez, E.; Nowack, B.; Mitrano, D.M. Polyester textiles as a source of microplastics from households: A mechanistic study to understand microfiber release during washing. Environ. Sci. Technol. 2017, 51, 7036–7046. [Google Scholar] [CrossRef] [PubMed]

- Palacios-Mateo, C.; Van der Meer, Y.; Seide, G. Analysis of the polyester clothing value chain to identify key intervention points for sustainability. Environ. Sci. Europe 2021, 33, 2. [Google Scholar] [CrossRef]

- Prefered Fiber & Materials, Market Report, Textile Exchange 2021. Available online: https://textileexchange.org/app/uploads/2021/08/Textile-Exchange_Preferred-Fiber-and-Materials-Market-Report_2021.pdf (accessed on 29 August 2022).

- Briain, O.Ó.; Mendes, A.R.M.; McCarron, S.; Healy, M.G.; Morrison, L. The role of wet wipes and sanitary towels as a source of white microplastic fibres in the marine environment. Water Res. 2020, 182, 116021. [Google Scholar] [CrossRef]

- De Falco, F.; Gennaro, G.; Roberto, A.; Emanuela, E.M.; Di Pace Emilia, D.P.; Ambrogi, V.; Maurizio, V.; Mariacristina, C. Pectin based finishing to mitigate the impact of microplastics released by polyamide fabrics. Carbohydr. Polym. 2018, 198, 175–180. [Google Scholar] [CrossRef]

- Koo, K.; Kim, S.; Park, Y.M.; Yu, J.Y.; Koo, B.S.; Yoo, S.C. Physicochemical characterization of PET fabrics treated with chitosan after exposure to O2 low temperature plasma—Especially by KES evaluation. Text. Color. Finish. 2005, 17, 25–36. [Google Scholar]

- Kang, H.; Park, S.; Lee, B.; Ahn, J.; Kim, S. Impact of Chitosan Pretreatment to Reduce Microfibers released from Synthetic Garments during Laundering. Water 2021, 13, 2480. [Google Scholar] [CrossRef]

- Fijan, S.; Fijan, R.; Šostar Turk, S. Implementing sustainable laundering procedure for textile in a comercial laundry and thus decreasing wastewater burden. J. Clean. Prod. 2008, 16, 258–263. [Google Scholar] [CrossRef]

- Sinner, H. Uber das Waschen mit Haushaltwaschmaschinen: In Welchem Umfange Erleichtern Haushaltwaschmaschinen und Geräte das Wäschehaben im Haushalt? Haus + Heim-Verlege: Hamburg, Germany, 1960. [Google Scholar]

- Omer, A.M.; Dey, R.; Eltaweil, A.S.; Abd El-Monaem, E.M.; Ziora, Z.M. Insights into recent advances of chitosan-based adsorbents for sustainable removal of heavy metals and anions. Arab. J. Chem. 2022, 15, 103543. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Y.; Yang, A.; Zhu, Q.; Sun, H.; Sun, P.; Yao, B.; Zang, Y.; Du, X.; Dong, L. Xanthate-Modified Magnetic Fe3O4SiO2-Based Polyvinyl Alcohol/Chitosan Composite Material for Efficient Removal of Heavy Metal Ions from Water. Polymers 2022, 14, 1107. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Shan, C.; Liu, Y.; Sun, H.; Yao, B.; Gong, G.; Jin, X.; Wang, S. Characterization and Mechanistic Study of Heavy Metal Adsorption by Facile Synthesized Magnetic Xanthate-Modified Chitosan/Polyacrylic Acid Hydrogels. Int. J. Environ. Res. Public Health 2022, 19, 11123. [Google Scholar] [CrossRef] [PubMed]

- Gamage, A.; Jayasinghe, N.; Thiviya, P.; Wasana, M.L.D.; Merah, O.; Madhujith, T.; Koduru, J.R. Recent Application Prospects of Chitosan Based Composites for the Metal Contaminated Wastewater Treatment. Polymers 2023, 15, 1453. [Google Scholar] [CrossRef]

- Politaeva, N.; Yakovlev, A.; Yakovleva, E.; Chelysheva, V.; Tarantseva, K.; Efremova, S.; Mukhametova, L.; Ilyashenko, S. Graphene Oxide-Chitosan Composites for Water Treatment from Copper Cations. Water 2022, 14, 1430. [Google Scholar] [CrossRef]

- Shanta, B.; Jannatun, F.; Debnath, T.; Rashid, T. Chitosan–Clay Composites for Wastewater Treatment: A State-of-the-Art Review. ACS EST Water 2021, 1, 1055–1085. [Google Scholar] [CrossRef]

- Candamano, S.; Sgambitterra, E.; Lamuta, C.; Pagnotta, L.; Sudip Chakraborty, S.; Crea, F. Graphene nanoplatelets in geopolymeric systems: A new dimension of nanocomposites. Mater. Lett. 2019, 236, 550–553. [Google Scholar] [CrossRef]

- Kaurin, T.; Pušić, T.; Čurlin, M. Biopolymer Textile Structure of Chitosan with Polyester. Polymers 2022, 14, 3088. [Google Scholar] [CrossRef]

- Periyasamy, A.P. Evaluation of microfiber release from jeans: The impact of different washing conditions. Environ. Sci. Pollut. Res. 2021, 28, 58570–58582. [Google Scholar] [CrossRef]

- Talvitie, J.; Mikola, A.; Koistinen, A.; Setälä, O. Solutions to microplastic pollution—Removal of microplastics from wastewater effluent with advanced wastewater treatment technologies. Water Res. 2017, 123, 401–407. [Google Scholar] [CrossRef]

- Cornacchia, M.; Moser, G.; Saturno, E.; Trucco, A.; Costamagna, P. Analysis of particle size distribution in municipal wastewater. Environ. Technol. Innov. 2022, 27, 102638. [Google Scholar] [CrossRef]

- Gharsallah, A.; Tahri, N.; Duplay, J.; Ben Amar, R. Performances of NF and RO applied in combined system and separately for the treatment and recycling of biologically pretreated real textile wastewater. J. Phase Chang. Mater. 2022, 2, 24–47. [Google Scholar] [CrossRef]

- Chavez, A.; Jimenez, B.; Maya, C. Particle size distribution as a useful tool for microbial detection. Water Sci. Technol. 2004, 50, 179–186. [Google Scholar] [CrossRef] [PubMed]

- Čurlin, M.; Pušić, T.; Vojnović, B.; Dimitrov, N. Particle Characterization of Washing Process Effluents by Laser Diffraction Technique. Materials 2021, 14, 7781. [Google Scholar] [CrossRef] [PubMed]

- American Public Health Association; American Water Works Association; Water Environment Federation. Standard Methods for the Examination of Water and Wastewater, 24th ed.; Lipps, W.C., Braun-Howland, E.B., Baxter, T.E., Eds.; APHA Press: Washington, DC, USA, 2023. [Google Scholar]

- Anton Paar. Available online: https://www.anton-paar.com/corp-en/products/details/psa-series/ (accessed on 11 July 2022).

- De Falco, F.; Gullo, M.P.; Gentile, G. Evaluation of microplastic release caused by textile washing processes of synthetic fabrics. Environ. Pollut. 2018, 236, 916–925. [Google Scholar] [CrossRef] [PubMed]

- Hartline, N.L.; Bruce, N.J.; Karba, S.N.; Ruff, E.O.; Sonar, S.U.; Holden, P.A. Microfiber masses recovered from conventional machine washing of new or aged garments. Environ. Sci. Technol. 2016, 50, 11532–11538. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).