Abstract

Rice is a water-guzzling crop cultivated mostly through inefficient irrigation methods which leads to low water use efficiency and many environmental problems. Additionally, the export of virtual water through rice trading and the looming water crisis poses significant threats to the sustainability of rice production and food security. There are several alternative rice production methods to improve water use efficiency. These include aerobic rice, direct-seeded rice (DSR), alternate wetting and drying (AWD), saturated soil culture (SSC), drip-irrigated rice, a system of rice intensification (SRI), and smart irrigation with sensors and the Internet of Things (IoT). However, each method has its own advantages and disadvantages. For example, drip-irrigated rice and IoT-based automated irrigation are not feasible for poor farmers due to the high production costs associated with specialized machinery and tools. Similarly, aerobic rice, drip-irrigated rice, and the SRI are labor-intensive, making them unsuitable for areas with a shortage of labor. On the other hand, DSR is suitable for labor-scarce areas, provided herbicides are used to control weeds. In this article, the suitability of different water-saving rice production methods is reviewed based on factors such as climate, soil type, labor, energy, and greenhouse gas emissions, and their prospects and challenges are evaluated. Additionally, the article examines how cultural practices, such as seed treatment, weed control, and nutrition management, contribute to enhancing water use efficiency in rice production.

1. Introduction

Rice is the staple food for over half of the world’s population, and it requires a vast amount of water to grow [1]. However, the growing water crisis in rice-cultivating countries has become a matter of concern. The increase in demand for rice production coupled with the shortage of water supply has led to a severe water crisis in rice-cultivating countries. According to the Food and Agriculture Organization (FAO), rice cultivation accounts for 34–43% of global irrigation water use [2]. In countries such as India and China, where rice cultivation is a significant agricultural activity, water scarcity is a significant issue. The water availability in India has been declining, and projections suggest that the demand for water will exceed the supply by 50% by 2030 [3]. Similarly, in China, rice cultivation accounts for 40% of the country’s total water consumption. China is home to over a third of the world’s irrigated land and faces water scarcity issues. The per capita water availability in China is much lower than the global average, and it is projected that water scarcity will worsen in the future [4].

The growing water crisis in rice-cultivating countries poses a severe threat to food security [4]. Rice is a crucial crop for food security in many developing countries, and the shortage of water supply can lead to a decrease in rice production, thereby affecting food security [2]. Water scarcity also affects the quality of rice produced and can lead to increased prices, making it unaffordable for the poor. The depletion of water resources for rice cultivation can lead to soil degradation and reduced agricultural productivity. The overuse of water resources can also lead to increased salinization and waterlogging, further reducing agricultural productivity [2]. Additionally, climate change is expected to have significant impacts on water availability for rice cultivation. The changes in temperature and precipitation patterns are likely to alter the availability of water for irrigation, which could result in both water shortages and flooding. As global temperatures rise, it is expected that the hydrological cycle will intensify, resulting in more extreme rainfall events in some areas and more prolonged dry spells in others [5]. Higher temperatures are expected to increase evaporation rates and water loss from soil, which could lead to reduced soil moisture and more frequent droughts. This could affect the growth and productivity of rice crops, as they require adequate soil moisture to grow and produce high yields.

In addition to changing precipitation patterns, climate change is expected to increase the intensity and frequency of extreme weather events such as floods, storms, and cyclones [6]. These events could damage rice crops and infrastructure, such as irrigation systems, which could further reduce water availability for rice cultivation. Climate change will exacerbate existing water scarcity issues in many regions, and adaptation strategies will be needed to ensure the sustainable production of rice in the future [5]. In regions where rainfall is already scarce, this could lead to more frequent and severe droughts, making it harder for communities to access the water they need for agriculture, drinking, and other uses. As temperatures increase, so too does the rate of evaporation, which can lead to decreased soil moisture levels and reduced water availability for crops. This is particularly important for rice cultivation, which is one of the world’s most water-intensive crops. Rising temperatures are expected to increase the water requirements for rice cultivation, leading to increased demand for irrigation water in regions where water is already scarce [2]. Similarly, industrialization and urbanization can have significant impacts on freshwater availability for rice cultivation, as they increase competition for fresh water, contribute to water pollution and degradation, and lead to land-use changes that reduce the availability of surface water [7]. This increased demand can put pressure on freshwater resources, leading to over-extraction of groundwater and surface water, and potentially reducing the amount of water available for irrigation in rice cultivation areas. Industrialization and urbanization can also lead to water pollution and degradation, as wastewater and other pollutants are discharged into water bodies. This pollution can affect the quality of freshwater resources and reduce their suitability for rice cultivation [8].

Research on innovative irrigation management technologies to enhance water use efficiency in rice farming has been ongoing for almost two decades, but there are still some knowledge gaps that need to be addressed. These gaps include a lack of detailed review on the performance of various innovative irrigation management technologies on water use efficiency in rice farming. In addition to water use efficiency, it is essential to review the impact of these technologies on rice yield and quality comprehensively. Another vital gap to address is cost-effectiveness. Although innovative irrigation management technologies can be effective in saving irrigation water and improving water use efficiency, it is crucial to review the cost-effectiveness of these technologies. This review should include the return on investment and potential cost savings over time. Moreover, different regions have unique climatic conditions and soil characteristics that affect water use efficiency in rice farming. Therefore, it is necessary to identify suitable and effective methods of irrigation from the existing innovative irrigation management technologies based on the available research data. Finally, the success of innovative irrigation management technologies largely depends on farmer adoption, which requires the development of appropriate policies to promote the adoption of these new technologies. In light of these gaps, this article comprehensively reviewed the performance of innovative irrigation technologies on water use efficiency, cost-effectiveness, rice yield and quality, climatic and soil suitability, and policies to promote their adoption.

2. Improving Water Productivity and Water Use Efficiency of Rice

Feeding a growing population and meeting their water demands will become increasingly challenging in the future. Sustainability in agricultural water resource utilization is crucial for achieving global food security [9]. To address food scarcity caused by water scarcity, there are three approaches: (i) increasing water availability through wastewater recycling, (ii) enhancing water productivity through higher yields or better water use, or both, and (iii) addressing regional water scarcity through importing water in the form of food through virtual water trade [10]. The main objective of all three approaches is to maximize the use of available rainfall, make efficient use of limited irrigation water, and enhance crop water use efficiency through integrated techniques. Improving water efficiency in agriculture is a crucial approach for India to meet the growing demand for food. This can be achieved through various practices and technologies, including (i) upgrading and optimizing irrigation and drainage systems, (ii) building and lining field channels and waterways, (iii) land leveling and shaping, (iv) constructing field drains, (v) conjunctive use of surface and groundwater together, (vi) implementing and regulating appropriate cropping patterns, (vii) introducing and enforcing rotational water distribution systems (warabandi’s), (viii) developing plans for providing inputs such as credit, seeds, fertilizers, and pesticides, and (ix) strengthening current extension, training, and demonstration programs in farmers’ fields to conserve freshwater and increase irrigation efficiency.

2.1. Water-Saving Irrigation

The pressure on freshwater resources is growing in India, particularly in key rice-producing states. Improving agricultural water productivity (more produce or revenue per drop) is crucial in reducing the demand for freshwater. Rice cultivation traditionally involves continuously flooded (CF) conditions, which are highly productive but require a large amount of water and have negative environmental impacts such as degradation of soil health, increased methane emissions, and higher accumulation of harmful substances, such as mercury and arsenic [11,12]. Hence, agricultural research and development should aim to reduce the amount of water required for rice cultivation and find alternative methods to the conventional system [13]. To boost rice output, a variety of water-saving techniques have been tested and disseminated for adoption by farmers, which include (i) the alternate wetting and drying (AWD) method of irrigation, (ii) the aerobic rice system, (iii) the system of rice intensification (SRI), (iv) saturated soil culture (SSC), (v) direct seeded rice (DSR), and (vi) drip-irrigated DSR. The raised-bed system involves growing rice on raised beds, which are well-drained and not continuously flooded, allowing for less water usage and improved soil aeration. The system of ground cover rice production utilizes a shallow water depth with AWD to conserve water. Transplanting in non-puddled soil and using non-flooded mulching cultivation can also help reduce water consumption while maintaining crop yield. Intermittent dry spells and semi-dry cultivation involve strategic periods of drought to promote plant water use efficiency and reduce water usage in rice cultivation. These alternative methods are known for their reduced water consumption, improved soil health, lower greenhouse gas emissions, and reduced accumulation of harmful elements in rice grain. Implementing these techniques could play a crucial role in mitigating the water scarcity challenge in India’s agriculture sector.

2.2. Alternate Wetting and Drying

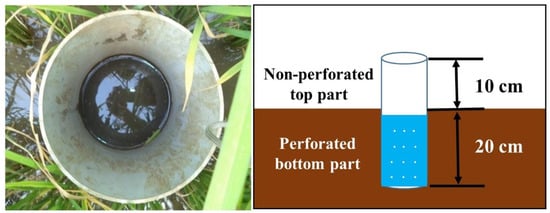

AWD irrigation was developed by the International Rice Research Institute (IRRI) and is a technically promising, realistically water-saving, and economically viable environmentally benign technique [14]. AWD has been extensively tested and is now being implemented in many Asian countries, including India, the Philippines, Vietnam, and Bangladesh. AWD irrigation subjects the field to alternating cycles of saturation (flooding) and drying (unsaturation), thereby saving irrigation water, improving water-use efficiency, reducing greenhouse gas emissions, and saving fertilizer, pesticide, and labor inputs. Once the soil reaches a specific lower moisture level, irrigation is provided. During the crop growing season, the fields are switched from a continually wet rice field to a field with occasional dry spells. After transplanting (or three to four weeks after sowing), the field is allowed to dry out for about two to three weeks until the water table reaches about 10–15 cm below the surface of the soil [13]. If no precipitation occurs, this could take anywhere from 1 to 7 days, depending on the soil. Once the threshold is met, irrigation water should be applied until the field receives 3–5 cm of standing water [15]. A sunk perforated plastic field tube (PVC pipe) allows examination of the below-ground water table and assists in making a decision to irrigate at the appropriate time (Figure 1). A safe level of 15 cm has been identified so that plants do not experience stress due to drought and yields do not suffer. The effect of AWD on rice yield and WUE is presented in Table 1.

Figure 1.

Perforated plastic field tube to examine the below-ground water table in AWD.

The AWD irrigation method can reduce water usage by up to 37% without affecting production. AWD has shown 23% less water use compared to continually flooded rice systems [16]. In addition to saving water, the AWD system has the potential to improve grain quality by lowering total arsenic (As) and mercury (Hg) content in rice grains by 50%, reducing greenhouse gas (GHG) emissions by 45–90%, boosting water efficiency, and keeping or even increasing grain output [17]. In rice cultivation, intermittent watering with AWD was found to decrease insect pests by 92% and diseases by 100% [11]. Additionally, the study by Duttarganvi et al. (2016) showed that the use of AWD in conjunction with cono-weeding resulted in significantly higher yields compared to other irrigation and weed management methods. This is due to the promotion of abundant root growth and an aerated growing environment [18].

Furthermore, the AWD method has also resulted in a 22% reduction in the frequency of watering compared to conventional rice production systems [19]. The significant decrease in irrigation water input in AWD is mainly due to a reduction in deep drainage, seepage, runoff, and evapotranspiration [20]. The absence of flooding in the AWD method minimizes water loss through seepage and percolation, although the rate of these processes is largely dependent on soil hydrological properties. The use of AWD under dry direct-seeded rice (DDSR) reduced the total water input by 27–29% and water productivity by 44–50% [11]. Another study by Sujono et al. (2011) reported that the practice of AWD in rice reduced the irrigation water input by 13.1%, increased the grain yield by 22.9%, and improved water productivity by 41.6% compared to shallow intermittent irrigation [21]. Likewise, Ceesay et al. (2006) also reported 60% water savings under AWD compared with continuous submergence [22]. The absence of standing water in the field under AWD is a key factor contributing to the reduced water input in this technique [23].

Based on the meta-analysis of 56 studies, Carrijo et al. (2017) established that severe AWD in rice saved 33.4% of water input with a 22.6% yield reduction, whereas mild AWD saved 25.7% of water input with increased rice productivity [24]. AWD promotes root growth, enabling better uptake of water and nutrients from deeper soil layers, which leads to increased grain productivity [25]. AWD plots received 57% less irrigation water than CF with a non-significant difference in grain yield, indicating that AWD could considerably enhance crop water use efficiency in Nepal [26]. In addition to reducing water usage and increasing yields, the use of AWD has also been found to modify plant hormone signaling, which in turn enhances grain filling rate, decreases the percentage of unfilled grain, and improves water use efficiency [27,28,29,30].

Research has found that the use of intermittent irrigation with three-day and seven-day intervals can save 55% and 74% of water, respectively, compared to CF irrigation. The seven-day intervals were found to have an irrigation water productivity of 0.48 kg grain/m3 and a total water productivity of 0.35 kg grain/m3 [31]. Maintaining a six-centimeter standing water depth at seven-day intervals has been shown to support plant growth while also boosting yields. Keeping soil moisture at optimum levels without inducing stress is crucial for the growth and development of the rice crop. While the adoption of AWD has proven to be effective in enhancing water use efficiency, saving water inputs, and increasing or maintaining yields, it is important to note that in some cases, particularly with light-textured sandy soils, the implementation of severe AWD may result in a sacrifice of yield for the sake of water savings and improved WUE. Additionally, the impact of soil characteristics on the effectiveness of AWD was found to be more pronounced in cases of severe AWD [24].

To prevent yield reductions in AWD, it is important to continuously irrigate crops during and after the start of the reproductive phase. Compared to CF, the AWD has been shown to significantly reduce water usage while maintaining or even improving yields [32]. The 34% reduction in water input in AWD, in turn, increased the water productivity of rice compared to continuous submergence [33]. Tan et al. (2013) found no significant decrease in yields under the AWD method, and the use of AWD resulted in a 17% increase in water productivity compared to CF irrigation. According to Islam et al. (2022), the AWD irrigation system mitigated GHG emissions by 27% compared to CF irrigation. The methane (CH4) emission for AWD was lower (1.67 kg ha−1 day−1) than that of CF (2.33 kg ha−1 day−1) [34]. The study conducted by Djaman et al. (2018) found that the implementation of AWD irrigation management with a pressure head of 30 kPa resulted in a substantial increase in rice yield and nitrogen use efficiency while reducing the need for irrigation applications by 27.3% compared to CF. The performance of AWD was found to be most effective in soils with a pH of less than 7 and a soil carbon content of at least 1% [35].

Although AWD reduced water input and gives a reasonable yield in many parts of the world, it has not been widely adopted due to its potential for reduced yields [24,36]. Adoption of AWD resulted in reduced rice productivity in certain conditions [24,26,37,38]. The significant disparities in grain yield across soils, climates, seasons, years, cultivars, and management practices pose a significant challenge to the widespread adoption of AWD [16,39]. Humphreys et al. (2012) found only a slight reduction in yield under AWD [40]. Similarly, Carrijo et al. (2017) reported a yield reduction of 5.4% under AWD. However, research has shown that under mild AWD, such as maintaining a soil water potential (SWP) of −20 kPa or higher or ensuring that the field water level does not drop below 15 cm from the soil surface, grain yields are not significantly impacted [24]. Despite the ability of the AWD method to conserve irrigation water, it is unlikely that this method will be widely adopted in Nepal, as the current water administration system is not providing any direct incentives to reduce irrigation water usage [26]. It should be noted that AWD may not be the most suitable approach for rice cultivation in sandy soils, as the water drains quickly and results in minimal water savings. Similarly, in soils with thick clay and shallow water tables, AWD may not be necessary, as the water table never drops below the lowest roots in these soils [41].

Table 1.

Paddy yield and water use efficiency (WUE) of rice under alternate wetting and drying (AWD) and continuously flooded (CF) methods.

Table 1.

Paddy yield and water use efficiency (WUE) of rice under alternate wetting and drying (AWD) and continuously flooded (CF) methods.

| S.No. | Season/Location | Paddy Yield (t/ha) | Increase in WUE than CF | Reference | ||

|---|---|---|---|---|---|---|

| AWD | CF | Percentage Increase over CF | ||||

| 1 | Northwestern Bangladesh (Boro, dry season) | 6.28 | 5.92 | 6.1 | 33.26 | [19] |

| 2 | Philippines (dry season) | 7.6 | 7.2 | 5.6 | 11.66 | [41] |

| 3 | Jingsu, China | 8.26 | 7.69 | 7.4 | 43.1–50.3 | [42] |

| 4 | China | 8.31 | 7.79 | 7.1 | 17.2 | [43] |

| 5 | Punjab, Pakistan (summer) | 4.03 | 4.18 | −3.6 | 21.0 | [44] |

2.3. The Effect of AWD on Grain Quality of Rice

The rice grain quality may change while transitioning from the conventional flooding system to water-saving rice production technologies [45]. The effect of AWD on rice grain quality is presented in Table 2. CF has been shown to have negative impacts on grain quality, as it accumulates harmful heavy metals such as arsenic and mercury [46,47]. On the other hand, the implementation of AWD irrigation has been found to improve grain quality by increasing protein content, milling recovery, and grain yield. However, excessive AWD can result in reduced protein content [48]. Song et al. (2021) reported that AWD improved the nutritional quality of milled rice by increasing amino acids and phenolic acids and decreasing lipids and alkaloids [49]. Rice plants grown under AWD showed higher levels of leaf abscisic acid and increased concentrations of foliar isopentenyladenine (37%), while leaf trans-zeatin concentrations decreased by 36% compared to CF [50]. In comparison to aerobic irrigation management, AWD irrigation reduced the number of opaque kernels (62%), abortive kernels (51%), and chalkiness (42%). Additionally, AWD irrigation decreased the kernel amylose levels by 15%, amylopectin by 6%, and mercury uptake by 21% compared to CF [51]. The nutritional quality of brown rice was improved under AWD water management, as there was an increase in grain antioxidants, flavonoids, γ-oryzanol, total tocopherols, grain iron, and zinc, as well as a significant decrease in grain arsenic compared to CF [52].

Table 2.

Influence of the alternate wetting and drying (AWD) production system on grain quality of rice.

AWD is a simple and low-cost method that can be easily adopted by smallholder farmers. AWD requires careful management to prevent damage to the rice crop and ensure optimal water and nutrient uptake by the plants. Additionally, the effectiveness of AWD may vary depending on local soil and climatic conditions, and it may not be suitable for all regions and climatic conditions. To further improve the adoption and effectiveness of AWD, some future research areas include Optimization of AWD practices: AWD is a complex agricultural technique that involves the manipulation of soil water dynamics. There is a need for further research to optimize AWD practices such as irrigation scheduling, drainage management, and water-saving technologies to maximize yields while minimizing water use. Soil health and nutrient management: AWD can have significant impacts on soil health and nutrient cycling. Future research should focus on understanding the long-term impacts of AWD on soil properties, nutrient availability, and GHG emissions, as well as developing strategies for managing soil health and fertility in AWD systems. Scaling up and dissemination: Despite the many benefits of AWD, adoption rates remain low in many regions. Future research should focus on identifying the barriers to adoption and developing strategies for scaling up and disseminating AWD practices to farmers, including training programs, farmer field schools, and extension services.

2.4. Aerobic Rice System

Aerobic rice cultivation is an innovative approach to growing rice in well-drained, non-flooded, and unsaturated soils without ponded water [56]. This method incorporates the use of specialized aerobic rice cultivars that are responsive to inputs and optimized water management techniques, resulting in an impressive yield of 4 to 6 tonnes per hectare with a water consumption rate of only 50 to 70% compared to traditional irrigated rice cultivation. This method is highly recommended for regions facing water scarcity or high water costs, as well as areas where there is a pressing need for labor and rising wages. The WUE and water productivity of rice under an aerobic system are presented in Table 3. The most serious barrier to the widespread adoption of aerobic rice is weed infestation. Various low-dose high-efficacy herbicides are available on the market to control weeds in the aerobic rice system. These herbicides also have a wider window of application. Shahane et al. (2019) reported that the aerobic rice system saved 37.4% and 50.8% of irrigation water during the first and second years of the experiment, respectively, over conventional transplanted rice [57]. More water is saved in the aerobic system than in puddled transplanted rice and the SRI due to the absence of nursery raising, puddling of fields, and maintenance of arable soil.

However, the aerobic rice system caused a significant yield penalty over puddled transplanted rice. In addition to water-saving, aerobic rice is known to reduce greenhouse gas emissions and lower global warming potential [58]. Changing rice cultivation from conventional flooded rice to an aerobic rice system emitted an average of 79.8% less CH4, whereas it emitted 14.4% more nitrous oxide (N2O) than transplanted paddy [59]. Aerobic rice cultivation resulted in lower yields, averaging 3 tonnes per hectare with 27% lower water use compared to traditional flooded conditions, which produced 5.8 tonnes per hectare [60]. Additionally, Kato et al. (2009) found that water productivity was 1.4 to 3.7 times higher in aerobic rice systems compared to transplanted rice (Table 3) [61]. The implementation of aerobic irrigation with DDSR increased water productivity by 22–30% and water savings by 49–55%, despite a decrease in paddy yield of 36–39% due to higher panicle sterility [11]. In a study conducted by Shahane et al. (2019), which compared the water productivity of aerobic rice, the system of rice intensification (SRI), and transplanted rice, it was found that aerobic rice saved 50.8% of the water used in transplanted rice [57]. Similar results were reported by Ramulu et al. (2020), who found that aerobic rice in sandy loam soil saved 50% of the irrigation water compared to transplanted rice [62].

Table 3.

Water use efficiency and water productivity of aerobic rice systems.

Table 3.

Water use efficiency and water productivity of aerobic rice systems.

| S.No | Season/Location | WUE or WP or % Water Saving | Reference |

|---|---|---|---|

| 1 | IRRI, Philippines | In aerobic rice, water productivity ranged from 0.88 to 1.13 compared to 0.54 to 0.66 kg grain m−3 under the alternate flooding method. The total water used in aerobic plots was 27% lower than the alternate flooding method of irrigation. | [60] |

| 2 | The University of Tokyo, Japan and Kyoto University, Osaka, Japan | Water productivity in the aerobic system ranged from 0.75 to 0.96 kg grain m−3 and 1.4 to 3.7 times higher than transplanted rice. The grain yield of aerobic and transplanted rice did not differ significantly in the clay loam soils of Japan. | [61] |

| 3 | IARI, New Delhi | The highest water productivity was recorded with the aerobic rice system (3.52 kg ha−1 mm−1) followed by the SRI method (3.07 kg ha−1 mm−1), and the lowest water productivity was noted with transplanted rice (2.28 kg ha−1 mm−1). The aerobic rice system saved 50.8% of water over transplanted rice. | [57] |

| 4 | Hyderabad, India | The aerobic rice system (0.70 kg grain m−3) has higher water productivity than transplanted rice (0.55 kg grain m−3). Aerobic management saved nearly 50% more water than conventional rice cultivation in sandy loam soils. | [62] |

| 5 | UAS, Banglore | Aerobic farms have a greater (3.84 q acre−1 inch) water use efficiency than traditional farmers (1.64 q acre−1 inch). Additionally, compared to conventional farms (₹ 269.41 acre inch−1), aerobic farms’ economic WUE was greater (₹ 1643.54 acre inch−1). | [63] |

Aerobic rice has several challenges, including, Nutrient deficiencies: The non-flooded aerobic soil conditions favor the development of nutrient deficiencies, such as iron and phosphorus which are typically more available under flooded conditions. Farmers must carefully manage nutrient inputs and may need to use fertilizer formulations that are specifically designed for non-flooded conditions. Weed control: Farmers may need to use more intensive weed control measures, such as herbicides or manual weeding, to maintain yields. Pest and disease management: Non-flooded conditions can also create favorable conditions for certain pests and diseases. For example, root-knot nematode infestation is more common under aerobic rice systems compared to flooded rice production systems.

2.5. The System of Rice Intensification

For more than a decade, the system of rice intensification (SRI) has been pushed as a set of agronomic management approaches for rice farming that increases output while lowering water usage. Henri de Laulanié invented the SRI in Madagascar in 1983 while working with peasant farmers [64,65]. The system has spread rapidly to dozens of rice-growing countries. It consists of several distinctive practices including transplanting young (13–15 days old) and single seedlings, wider and square planting, intermittent water management (irrigation after hair-like crack development), weed control with a cono-weeder/mechanical weeder for better weed control and soil aeration, and encouraging the use of organic nutrients and inorganic fertilizers.

It has been demonstrated that paddy farming using the SRI approach significantly increases land productivity while consuming less water. The SRI method of paddy cultivation saved up to 50% of irrigation water in comparison to the traditional method by avoiding evaporation and deep percolation losses. The SRI is the preferred method for rice cultivation on flat and irrigated land compared to uneven rainfed land [66]. This method is highly suitable for water-scarce regions, although this method slightly increases the need for human manpower initially.

The primary difference between the SRI and non-SRI irrigation techniques in terms of water use is that the former uses a dry-wetting irrigation system while the latter uses the more traditional inundation technique. Second, the SRI approach saves a significant quantity of water because it does not require deep or repetitive puddling. Third, irrigation is applied sparingly at the time of transplanting, contrasting with the typical procedure. Fourth, a simple wetting of the ground is sufficient to operate a hand-drawn cono-weeder or mechanical weeder efficiently in a paddy field. Extended root growth takes place due to the wide spacing followed during transplanting. This robust root system in the SRI facilitates the uptake of water and nutrients from a large volume of soil and results in higher yield. The SRI method can enhance rice grain yield with substantially less water input than the conventional method of rice cultivation [66]. Shahane et al. (2019) reported that the SRI method saved 21.9% and 27.4% of irrigation water without any reduction in yield during the first and second year of the experiment, respectively, over conventional transplanted rice [57]. When compared to normal transplanting, the SRI method saved 31 and 37 percent of irrigation water during the Kharif and Rabi seasons, respectively [67]. The saving of water with the SRI was due to the lower depth of irrigation water application in the SRI than in conventional transplanted rice during the early growth period. The SRI method of stand establishment saved irrigation water and has a greater WUE (70.8 kg rice equivalent yield/ha/cm) than the conventional transplanted rice (67.0 kg rice equivalent yield/ha/cm) and the alternate wetting and drying method of irrigation [68]. Farmers who use the SRI method instead of the usual inundation approach can save around 40% of irrigation water, enhance land yield by about 46%, and reduce cultivation costs by 23% [69].

According to Toungos (2018), the SRI method of rice production reduced 40% of irrigation water usage in Indonesia, 67% in the Philippines, and 25% in Sri Lanka when compared to traditional farming practices [70]. During the Kharif and Rabi seasons, the SRI method recorded 31% and 37% less water usage for irrigation compared to normal transplanting [71]. The SRI method had a higher irrigation water productivity (IWP) and economic water productivity (EWP) of 6.62 kg and ₹ 108, respectively, while the non-SRI method had a lower IWP and EWP of 2.70 kg and ₹ 45, respectively. The IWP was found to be 145% higher in the SRI method compared to the non-SRI method [69]. The higher IWP and EWP in the SRI method are due to the fact that farmers who adopt this approach generally save more water and produce more rice. SRI proponents suggest the use of cono-weeders for weeding and soil aeration, but poor farmers find the equipment to be too expensive and struggle to use it in field conditions [72].

The amount of water saved using the SRI approach was found to be higher in groundwater-irrigated areas (roughly 45 percent) than in canal-irrigated areas (about 33 percent) [69]. The reason for this variance is that farmers were able to closely adhere to a dry-wetting irrigation method since water availability was guaranteed in the groundwater-irrigated region. This allowed the farmers growing an SRI paddy to save a sizable amount of water. However, it was not feasible in the canal-irrigated area since farmers are not in charge of water management and are, therefore, prone to over-irrigate crops whenever water is available in plenty [69]. The SRI method improves the water and nutrient-holding capacity of soil as it adds more organic manure through the incorporation of weeds and promotes the use of organic nutrient sources (green manure, green leaf manure, farmyard manure, compost). Greenhouse gas emissions are also lower in the SRI method of cultivation, as it emitted an average of 26.8% less CH4 and 3.8% more N2O than the conventional flooded paddy [59]. The majority of farmers that adopted the SRI approach did not adhere to all of the suggested practices due to inadequate literacy and limited knowledge of the recommended irrigation practices. As a result, farmers have not used the SRI technique to its full potential [69]. Depending on local agronomic or institutional opportunities and constraints, partial implementations of SRI principles, i.e., adopting individual SRI practices, could provide some benefits to farmers but could not derive synergies between all of the principles [66].

The SRI may not be suitable for all farmers or all rice-growing conditions. Farmers must carefully weigh the advantages and disadvantages of the SRI and determine whether it is a suitable option for their specific situation. There are some challenges associated with the SRI system include Labor-intensive: The SRI requires more labor than traditional rice cultivation methods, particularly during the transplanting stage when seedlings are planted individually. This can be a challenge for smallholder farmers who may have limited labor resources. Water management: The SRI requires careful water management, and an area that has high rainfall may not be ideal as it does not allow better soil aeration for root growth and tiller development. Knowledge and skills: The SRI requires farmers to have a certain level of knowledge and skills, particularly in terms of transplanting, water management, and nutrient management. This can be a barrier to adoption for some farmers, particularly those with limited access to training and extension services. Time-consuming: The SRI requires more time and attention from farmers, particularly during the transplanting stage and in terms of soil management.

2.6. Saturated Soil Culture

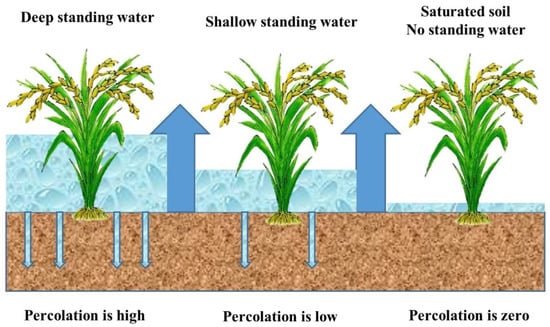

Saturated soil culture (SSC) entails providing shallow irrigation to achieve around 1 cm of ponded water depth for a day or two after the ponded water has vanished. In SSC, the soil is kept as close to saturation as feasible, lowering the ponded water’s hydraulic head, seepage, and percolation flow. In SSC (no standing water), the deep percolation losses are zero, while in continuously flooded conditions percolation of water is high (Figure 2). The percolation rate increases along with increasing irrigation water depth in the field [73]. The water depth above the soil is kept below 3 cm in SSC compared to other methods, where 5 cm is followed. The lower water depth reduces the percolation loss of water in SSC. The effect of SSC on rice yield and WUE is presented in Table 4. Tuong and Bhuiyan (1999) reported that SSC can reduce water losses, diminish water use, and maintain or increase productivity in rice-based systems. However, plants reduced evapotranspiration under severe water stress, which led to a decrease in photosynthesis, which in turn caused a decrease in chlorophyll, height, and tiller number [74]. Water stress during the tillering stage reduced the number of panicles per hill significantly [75]. Keeping the soil moisture in saturation avoids the problem of moisture stress and did not affect root growth, tiller production, and biomass accumulation. On average, SSC can decrease water input by 40% from the continuously flooded condition with a non-significant yield reduction of 6% [76].

Figure 2.

The saturated soil culture method of rice cultivation.

Among different irrigation water depths, viz., 5, 4, 3, and 2 cm, the application of 3 cm of irrigation at weekly intervals appeared suitable and beneficial to rice crops in loamy textured soil, as it recorded significantly higher total water productivity (0.35 kg/m3) and irrigation water productivity (0.79 kg/m3) with non-significant yield reduction [77]. Another study reported 32% less water usage under SSC compared to intermittent irrigation at a weekly interval [78]. According to Matsue et al. (2021), SSC irrigation significantly increased grain yield by increasing the percentage of filled grains compared to CF [79]. The quality of rice grains was also improved, with a higher percentage of head rice recovery and improved cooking quality due to a lower protein content and hardness/adhesion ratio. In the Philippines, SSC irrigation has been shown to save 30–60% of water compared to the CF system, with only a slight reduction in grain yield (4–9%) and an increase in WUE by 30–115% [27]. On the other hand, AWD saved 16–24% of irrigation water and 20–25% of production costs while maintaining the same yield as farmers’ practices [80]. Growing rice (cv. IR20) in the dry season under AWD saved 56% of irrigation water, whereas the yield was reduced from 7.9 t ha−1 to 3.4 t ha−1 [81].

In Australia, SSC used about 32% less water compared to traditional flooded rice production in both seasons (wet and dry), with no effect on grain yield and quality. Another study in Australia reported that SSC reduced water use by 16–28 percent and improved water use efficiency by up to 20 percent [82]. For growers in semi-arid tropical areas, SSC provides a practical substitute for flooded rice production [83]. Weekly irrigation at 120% soil saturation exhibited greater irrigation water productivity (0.69 kg/m3), rainwater productivity (1.02 kg/m3), and water-saving (90.53%), with less production penalty (5 × 10−3 kg/m3) compared to irrigation at 200% soil saturation (farmer practice) [84]. SSC facilitates maximum utilization of rainfall, thereby increasing the effective rainfall percentage during the crop season. Moreover, high effective rainfall is recorded from panicle initiation to physiological maturity, as the increased moisture content in this stage helps with faster crop recovery from moisture stress, better initiation of panicle, and higher panicle fertility. Thus, it will be more suitable for rainfed rice-growing areas. SSC has the ability to significantly reduce unnecessary water outflows while increasing water productivity. Compared to other water-saving irrigation methods, SSC is a low-cost technology that has greater potential to save available irrigation water. SSC reduces the number of irrigations required to raise the crop, thereby reducing the irrigation cost, energy required for irrigation, and irrigation water.

Table 4.

The effect of the saturated soil culture irrigation method on rice yield, water use efficiency, and irrigation water saving.

Table 4.

The effect of the saturated soil culture irrigation method on rice yield, water use efficiency, and irrigation water saving.

| S.No | Season/Location | Results | Reference |

|---|---|---|---|

| 1 | Irrigated field, Australia | Among four levels of soil saturation, viz., 120% (2 cm), 180% (3 cm), 240% (4 cm), and 300% (5 cm), the application of 180% (3 cm) was found effective, as it saved 40% irrigation with low yield sacrifice (6% of reduction). | [76] |

| 2. | Philippines | SSC saved 30–60% of water compared with the conventional flooded system with little reduction in grain yield (4–9%) and increased WUE by 30–115%. | [27] |

| 3. | National Pingtung University of Science and Technology in Southern Taiwan | Among different irrigation water depths, viz., 5, 4, 3, and 2 cm, the application of 3 cm of irrigation at weekly intervals appeared suitable and beneficial to rice crops, as it recorded significantly higher total water productivity (0.35 kg/m3) and irrigation water productivity (0.79 kg/m3) with non-significant yield reduction. | [77] |

| 4. | IRRI, Philippines | AWD saved 16–24% of irrigation water and 20–25% of production cost with the same yield as farmers’ practice. | [80] |

| 5. | Philippines/dry season | Growing rice (cv. IR20) under AWD saved 56% of irrigation water, whereas the yield was reduced from 7.9 t ha−1 to 3.4 t ha−1. | [81] |

| 6. | Eastern Burkina Faso. Semi-arid region. Irrigated field. | Weekly irrigation at 120% soil saturation exhibited greater irrigation water productivity (0.69 kg/m3), rainwater productivity (1.02 kg/m3), and water-saving (90.53%) with less production penalty (5 × 10−3 kg/m3) compared to irrigation at 200% soil saturation (farmers’ practice). | [74] |

| 7. | Millaroo Research Station, BRIA, Australia | SSC used about 32% less water compared to traditional flooded rice production in both seasons (wet and dry) with no effect on grain yield and quality. SSC is a viable alternative to flooded rice production for growers in semi-arid tropical environments. | [83] |

2.7. Direct-Seeded Rice

DSR is also an efficient resource conservation technology that holds great promise in rice-based cropping systems. DSR can be established by broadcasting or line-sowing at 20 cm row-to-row spacing, a 3–4 cm seeding depth, and using a mechanical seed-cum-fertilizer drill in unpuddled and well-prepared dry soil followed by light irrigation (2 cm) for germination. Thereafter, irrigation is somewhat delayed and given 20 days after the sowing to encourage a sturdy root system. Later irrigations are given by adopting the AWD cycle at the interval of 7–10 days depending on rainy events, soil type, crop growth stage, and ET demand. Alternatively, wet DSR involves the sowing of pre-germinated seeds (radicle 1–3 mm) on puddled wet soil.

The labor-intensive practice, viz., raising the nursery and transplanting the rice, is eliminated in DSR [85]. In the event of a monsoon delay or a water constraint, DSR allows the farmer to direct sow a paddy with an appropriate short-duration variety to fit within the cropping system. This also enables the timely seeding of succeeding wheat crop rice-wheat systems where delayed wheat sowing causes significant yield loss in the IGP region [86]. When compared to transplanted flooded rice, DSR uses less water and provides several other advantages such as reduced crop duration, cost of cultivation, etc. DSR is proven to yield more than conventional transplanted rice production if weeds are controlled properly at the right time. DSR is more prone to weed infestations than traditional transplanted rice, as the rice plants are initially smaller and weeds can more easily compete for resources. Herbicides are mostly used for weed control in DSR. The herbicides recommended for different rice production methods along with their rate and time of application are summarized by Saravanane et al. (2021) [87]. Poor seed germination and sub-optimal plant population are major causes of low yields in DSR. To ensure an optimum plant population, it is essential to use high-quality seeds with a high germination percentage. By doing so, farmers can increase the chances of successful germination and establish a healthy and uniform plant stand, ultimately resulting in higher yields.

The effect of DSR on WUE and water productivity is presented in Table 5. Dry direct-seeded rice produced higher yields (13–18%) and reduced the total water inputs (8–12%) in comparison to transplanted rice [11]. Gill et al. (2006) indicated that water productivity was improved to 0.46 from 0.36 by following the DSR compared to transplanted rice due to less irrigation water consumption (18%) and a similar yield [88]. Despite having more irrigation events, the average water input of DDSR was lower than that of transplanted rice for both rice seasons, as DSR omits the large amounts of early-season water input used to puddle the field. The extent of water savings in DDSR was relatively low (only 8–12%) in the sandy loam composition of the soil in comparison to transplanted rice, which might be attributed to the absence of a plow pan or a hard pan [11]. DSR with sesbania co-culture saved irrigation water (34%), increased water productivity (0.43 kg m), reduced labor requirements (24%), and saved electricity (29%) [89]. Similarly, when compared to transplanted rice, the global warming potential (GWP) of dry DSR rice was 76.2 percent lower than that of wet direct-seeded rice, which was 60.4 percent lower [90]. The new technology would not be widely used if it just served to save water without increasing the yield. Farmers would not use the technology if it was not profitable for them.

Table 5.

Water use efficiency and water productivity of direct-seeded rice.

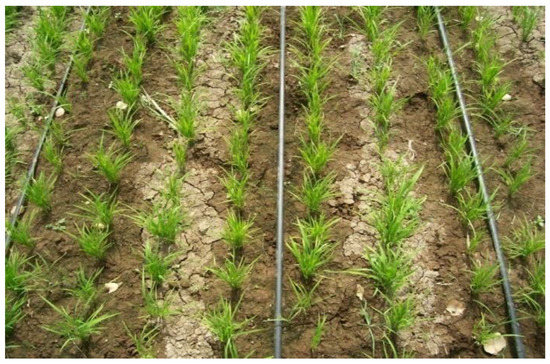

2.8. Drip-Irrigated Rice

Drip irrigation is a modern water-saving technology used in direct-seeded rice production (Figure 3). The water productivity in drip-irrigated rice under a direct-seeded system was significantly higher compared to transplanted rice under flood irrigation due to higher evaporation, deep percolation, runoff, and seepage in the later system. In drip irrigation, precise water application and ensuring consistent wetting of the rice field to meet crop evapotranspiration would be possible. Drip irrigation also promotes healthy crop development by reducing soil evaporation and deep percolation [91,92]. Furthermore, drip fertigation increases rice yield potential by administering divided fertilizer doses precisely at the proper moment according to crop developmental phases at the right place, i.e., the zone of maximum root activity. Additionally, the physiology of the rice crop was positively influenced by drip irrigation with enhanced water, nutrient, and resource use efficiency.

Figure 3.

Rice cultivation through drip irrigation.

Rice cultivation with drip irrigation resulted in longer and denser roots, which boosted canopy photosynthesis and tiller numbers [91]. Planting on either side of the dripline or one dripline feeding 2 to 3 rows on the bed was a preferred option by the farmers. The narrow dripline spacing gives farmers more flexibility and options for including a range of rotational crops. However, narrow spacing of 0.5 to 0.6 m also means more dripline, more connections, and higher costs. Emitter spacing used by researchers was mostly narrow and varied from 0.3 to 0.5 m, depending on soil characteristics. Seasonal irrigation requirements for drip-irrigated rice in the semi-arid region of Hyderabad, Telangana, India, were estimated to be 801 mm, which was 51.6% less than flooded irrigated rice. The quantity of irrigation water for drip-irrigated rice varied from 547 to 844 mm in the semiarid region of South India, 882 mm in Ludhiana, Punjab, 639 mm in Pantnagar, Uttarkhand, and 789 mm in Nashik, Maharashtra [93]. The continuous flood-irrigated rice across different agroecological conditions needed 150 to 853 mm more water (27.4 to 106.4%) than drip-irrigated rice. The water-saving in drip irrigation is mainly due to reduced evaporation, deep percolation, and conveyance losses. The WUE of surface drip-irrigated rice was 0.0576 t/ha-cm compared to 0.0181 t/ha-cm under conventional transplanted flooded rice [94]. In addition to saving 50–61 percent more water than the flood system, the drip system with fertigation also boosted yield and water productivity [95]. The effect of drip irrigation on WUE and water productivity is presented in Table 6.

However, the advantage of drip irrigation in terms of yield can vary based on environmental conditions. According to He et al. (2013), the decrease in yield with drip irrigation in rice is largely due to a reduction in the number of productive tillers [96]. Additionally, root length is also found to be reduced, with more roots distributed in deeper soil layers under drip irrigation compared to CF irrigation. On the other hand, Sharda et al. (2017) found that the higher grain yield in drip-irrigated DSR was mainly attributed to higher root density at deeper soil layers (15–30 cm), which in turn increased the irrigation WUE and the number of filled grains per panicle [97]. He et al. (2013) also found that drip irrigation with plastic mulch was more efficient in terms of water savings compared to furrow irrigation in rice cultivation [96]. This was attributed to two factors: (i) plastic mulching, which can effectively reduce evapotranspiration compared to bare land, and (ii) seepage, which was significantly lower in the drip irrigation treatment than in the furrow irrigation treatment in loamy soil. The adoption of water-saving practices in irrigated rice increased paddy productivity, promoted soil carbon sequestration, assisted in resource conservation (water, labor, energy, and time), and lowered greenhouse emissions [11].

Drip irrigation helped with the production of more roots in the topsoil layer than furrow-irrigated rice [96]. Spacing between the lateral should be kept optimum for higher yield along with water-saving. Ramesh et al. (2020) reported an 80 cm interval between the lateral optimum for hybrid rice [98]. In the changing climate scenario, a continuous flooding system contributes more methane gas to global warming; adopting drip irrigation for growing rice reduced methane and nitrous oxide emissions. According to Ramesh and Rathika (2020), an average of 68.6 and 34.4% less CH4 and N2O emissions were noticed under drip irrigation over a conventional flooded paddy [59]. Considering the seriousness of fast-depleting groundwater reserves and international commitments to address climate change issues, drip-irrigated rice would be of immense value to various stakeholders for saving water in agriculture. The evidence suggests that farmers do not embrace the drip fertigation technique in rice solely to conserve water, electricity, or other resources. In India, electricity is heavily subsidized, and water is not metered. The farming community will readily adopt the new technology only if it increases profits and is supported by farmer-friendly government policies that offer subsidies and other incentives. Installation and maintenance of the system. Drip irrigation systems require specialized installation and maintenance, including checking for leaks or clogs in the emitters, adjusting the water flow rate, and monitoring soil moisture levels. This can require additional labor input.

Table 6.

Water use efficiency and water productivity of drip-irrigated rice.

Table 6.

Water use efficiency and water productivity of drip-irrigated rice.

| S.No | Season/Location | WUE or WP or % Water Saving | Reference |

|---|---|---|---|

| 1 | G. B. Pant University of Agriculture and Technology | The WUE of drip-irrigated rice is 0.095 t/ha-cm compared to 0.021 t/ha-cm under transplanted rice with continuous submergence. | [94] |

| 2 | Multi-location with different varieties | Under drip fertigation, rice yields (13–28%) and water productivity (0.46 to 0.67 kg/m3) were higher across locations, irrespective of the cultivar compared to the conventional method. | [95] |

| 3 | Agricultural Drought Research Institute, China | The grain yield is reduced by 31.76–52.19% under drip irrigation with plastic mulch, although the WUE (0.38 kg grain m−3) is 1.52–2.12 times higher than the CF. Drip-irrigated rice has greater water-saving capacity (57.4–67.9%) and lower yield and economic benefit compared to CF. So, drip-irrigated rice is a better option for water-scarce areas. | [96] |

| 4 | PAU, Ludhiana | Drip-irrigated rice recorded higher WUE (0.81–0.88 kg m−3) and saved 42% of irrigation water compared to flood irrigation, which had a WUE of 0.42–0.52 kg m−3. | [97] |

| 5 | Research farm of Jain Irrigation, in Tamil Nadu | Drip irrigation in rice increased grain yield by 17–22% and saved irrigation water by 50–61%. Similarly, higher water productivity (0.365 to 0.714 kg/m3) was recorded in drip-irrigated rice compared to the flooded method of irrigation (0.097 to 0.224 kg/m3). | [99] |

2.9. Smart Irrigation

Sensor technology, the Internet of Things, wireless communications, public automatic weather station networks, improved crop evapotranspiration measurements, satellite and aerial imaging, and cloud computing technology are all promising areas for developing robust irrigation advisory tools to assist farmers in accurately determining and meeting crop water needs. Wireless networks can be used to collect data from soil moisture sensors, which can then be accessible via a web browser or smartphone app. Many of the computations involved in crop evapotranspiration-based irrigation scheduling have been automated using web and smartphone applications [100]. Smart irrigation apps are mobile-based irrigation scheduling tools that use weather data to determine irrigation scheduling protocols (when to apply and how much to apply) based on water losses from cropped fields. The weather data is obtained from the nearest automated weather monitoring network stations. A user’s new field is automatically associated with the nearest weather station when they register it in the smart irrigation apps; however, the user has the option of selecting any of the other available weather stations [101].

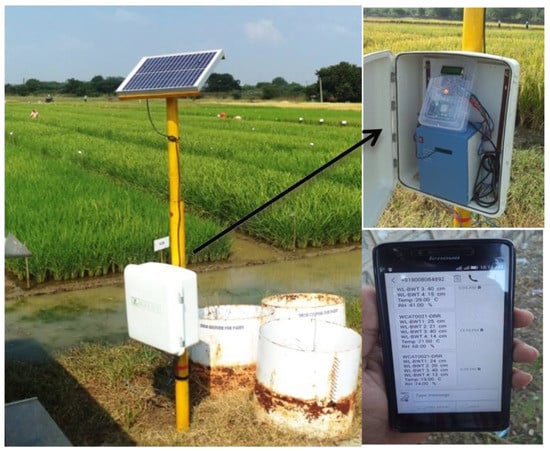

Around the world, agriculture automation is becoming more and more important. Irrigation systems can be automated to suit different crops, soil, climate, and other factors with the help of sensors (moisture, temperature, and humidity), IoT devices, and machine learning algorithms. The automation of irrigation systems increases crop output, quality, and water use efficiency while reducing irrigation water, time, cost, and electricity [102]. By measuring the level of water, soil temperature, nutrient content, and weather forecasting, smart irrigation technology increases production without requiring manpower. However, for an automated irrigation system to be implemented successfully, sensor installation is crucial [102]. Sensors need to be put in the area where plants’ roots extract water (ensuring that there are no air gaps around the sensor). This will guarantee that the crops obtain enough water. Solar-powered raindrops and soil moisture sensors were buried in the root zones of the crops, and all these sensors are managed by a wireless internet network. The GSM module is used in the soil moisture sensor and raindrop sensor to transmit SMS notifications on soil moisture to the farmer’s cell phone. As a result, the farmer may control the water supply using SMS (Figure 4).

Figure 4.

A smart irrigation device installed in the field.

The intelligent water-saving irrigation system based on the agricultural IoT enables the real-time remote monitoring of moisture content and the accurate management of irrigation in paddy fields. These intelligent automatic irrigation systems are simple to adopt, function perfectly, and have high reliability and low power consumption. Currently, the cost of sensors used for intelligent automatic irrigation is prohibitively high, making it unfeasible for small and marginal farmers to adopt this type of system in their farms [103]. Manufacturers are actively working to develop low-cost sensors that can be linked to nodes, thus facilitating the implementation of budget-friendly irrigation management systems and agriculture monitoring solutions. An IoT-based modern irrigation system has been found to reduce the water footprint by 40.29% and 29.22% compared to AWD and basin irrigation, respectively [104]. The water footprint of the IoT-based modern irrigation system, AWD, and basin irrigation was 2343, 3924, and 3310 m3/tonnes of paddy, respectively. The effect of smart irrigation on rice is presented in Table 7.

Table 7.

The effect of smart irrigation on rice cultivation.

Future research that could further improve the effectiveness of these systems includes Sensor accuracy and reliability: which is the idea that the accuracy and reliability of the sensors used in automated IoT sensor-based irrigation systems can affect the precision and efficiency of the irrigation process. Future research could focus on improving the accuracy and reliability of sensors to ensure that they provide accurate and timely data to the system. Crop modeling and prediction: Developing accurate crop models and prediction tools can help farmers optimize irrigation schedules and avoid over- or under-watering of their crops. Future research could focus on developing more accurate and sophisticated models for rice crops that take into account factors such as soil moisture, weather conditions, and plant growth stage. Optimization of water use efficiency: Automated IoT sensor-based irrigation systems can help farmers optimize their water use efficiency by providing real-time data on soil moisture levels and crop water requirements. Future research could focus on developing more efficient irrigation scheduling algorithms and control strategies to further improve water use efficiency. Integration with other technologies: Automated IoT sensor-based irrigation systems can be integrated with other technologies, such as weather forecasting or drone-based imaging, to further optimize the irrigation process. Future research could focus on developing more sophisticated and integrated technologies that provide farmers with a comprehensive and data-driven approach to crop management. Adoption and dissemination: Despite the potential benefits of automated IoT sensor-based irrigation systems, their adoption and dissemination in rice farming communities can be slow due to factors such as a lack of awareness, technical expertise, or financial resources. Future research could focus on developing effective dissemination strategies and outreach programs to promote the adoption and scaling up of these technologies.

2.10. Comparision of Different Water Saving Technologies with Conventional Flooding

Comparing water-saving rice production methods based on climate, soil type, labor, energy, and GHG is important for several reasons (Figure 5). Firstly, it helps farmers to select the most appropriate method based on the specific conditions of their farm, which can lead to higher yields, reduced costs, and improved WUE. Secondly, it allows policymakers to identify the most sustainable methods for a particular region, taking into account the local climate, soil type, and labor availability. This can help to reduce the environmental impact of rice cultivation while ensuring food security for local communities. Thirdly, comparing water-saving rice production methods based on energy and GHG emissions can contribute to the reduction in carbon footprints associated with rice production. Therefore, comparing water-saving rice production methods based on various factors is essential for sustainable rice production and achieving global food security and climate goals.

Figure 5.

A comparison of water-saving rice production methods.

Production cost: The adoption of DSR may result in lower cultivation costs when compared to traditional rice farming, as it eliminates the need for transplanting and reduces labor requirements for water management. Conversely, aerobic rice cultivation may incur higher production costs compared to traditional rice farming due to the additional inputs and equipment required. Similarly, the SRI may also lead to higher production costs due to its labor-intensive nature, including the need for manual labor in activities such as transplanting, weed control, and irrigation. Drip-irrigated rice may also have a higher cost of cultivation compared to traditional methods, as it requires the use of drip irrigation equipment and maintenance. Finally, the implementation of IoT-based automated irrigation may also incur higher cultivation costs than traditional rice farming due to the requirement for sensors, monitoring equipment, and maintenance.

Soil type: Aerobic rice is most suitable for well-drained soils, while heavy clay soils are not recommended. DSR, on the other hand, is not recommended for soils with high water tables, high soil pH, or salinity, as all of these factors can lead to poor seed germination. The SRI is not suitable for poorly drained or waterlogged soils as it can result in poor tiller and root development and higher seedling mortality. Similarly, drip irrigation may not be ideal for soils with high clay content as it can lead to clogging of the emitters. However, IoT-based automated irrigation can be implemented in any soil type as long as the sensors and monitoring equipment can be installed and function properly. GHG emissions: The implementation of practices that reduce water and fertilizer inputs while promoting soil aeration can significantly reduce methane emissions associated with rice cultivation. However, these practices increase nitrous oxide emissions, as alternate wetting and drying irrigation cycles promote the conversion of ammonia to nitrate. Similarly, the adoption of energy-intensive drip irrigation equipment may lead to an increase in GHG emissions during production and operation. This is also true for IoT-based automated irrigation systems.

Weed pressure: Weeds are a serious problem in aerobic rice, especially during early growth stages. Similarly, DSR faces weed competition due to limited water availability. The SRI requires more manual weeding because of a reduced number of plants per unit area. IoT-based automated irrigation and SSC also have weed control issues, but SSC uses stale seedbed preparation to reduce weed germination, and drip-irrigated rice reduces weed growth by minimizing soil moisture levels. Improved water-saving rice production systems have higher weed pressure than conventional flooded rice systems. However, the availability of broad-spectrum herbicides with a wider window of application helps the farmers to control weeds in these systems. Labor requirement: The labor requirement varies across different rice production methods. The SRI demands more manual labor due to transplanting single seedlings, maintaining wider spacing, weeding, and irrigation. Similarly, aerobic rice also requires more labor during the early growth stages for manual weed control. In contrast, drip-irrigated rice requires less labor for weeding but requires more labor for installation and maintenance of the drip irrigation system. DSR, on the other hand, requires less labor for land preparation and transplanting but more for weeding. Therefore, labor-intensive rice production systems are better suited for regions with ample and affordable labor resources. Climate: The SRI, aerobic rice, and DSR are not suitable for regions with high rainfall, as these methods require well-drained soil and do not perform well under flooded conditions. Drip-irrigated rice and SSC may not be suitable for arid regions where the availability of water for irrigation is limited.

3. Best Management Practices and Water Use Efficiency

Water use efficiency is a function of yield and evaporation. Any agronomic management practices that increase the grain yield will also increase the WUE. Along with these improved irrigation methods, smart irrigation technologies the adoption of other improved agronomic management practices is highly essential to achieve higher yield potential. Agronomic management practices such as the optimum time of sowing, adequate plant population establishment, timely control of weeds, balance and optimum fertilization, the proper control of insect pests and disease, and harvest are highly important to increase WUE. Additionally, various agronomic practices, including crop rotation, water conservation through minimum- or no-tillage, the use of plastic film or straw mulching, regulated deficit irrigation, fertigation, anti-transpirants, and soil amendments, can be employed to enhance soil water-holding capacity and WUE of rice-based cropping systems [14]. Engineering approaches such as rational exploitation of surface and groundwater resources, rainwater harvesting and storage for life-saving irrigation and groundwater recharge, the utilization of recycled sewage water or marginal quality saline water, the modernization of canal irrigation systems, low-pressure pipe conveyance, laser-controlled land leveling technology [14], improved surface irrigation by shortening or narrowing borders or furrows, and sprinkler irrigation implementation are highly recommended to increase water use efficiency [109].

3.1. Balanced and Efficient Nutrient Management

Vijayakumar et al. (2021) demonstrated that the application of nutrients based on the 4R principle of nutrient stewardship (right dose, right time, right place, and right method) led to increased water use efficiency in aerobic rice systems [110]. A supply of 100% of the recommended dose of fertilizer through drip fertigation was found optimum for higher yield and WUE [98]. Several new-age fertilizer carriers such as nano fertilizers, slow-release fertilizers, and organic nitrification inhibitors were found to be effective in reducing nutrient loss and increasing the recovery efficiency of nutrient and crop yield [111]. Similarly, Jinger et al. (2020) reported that the application of silicon fertilizer increased the yield and water use efficiency of rice [112,113]. Farmers can utilize tools such as decision support systems [67,114], riceNxpert [115], and other Android-based applications to adopt site-specific nutrient management in rice cultivation [116]. Nitrogen is a major key nutrient to rice, and response to nitrogen application is reported in all the rice growing ecosystems. The nitrogen use efficiency in rice is very low (~30%) and improving nutrient use efficiency directly increases rice yield and WUE. Subramanian et al. (2020) recommended the application of 175 kg N/ha in four equal splits at 10–12 days after emergence, at active tillering, panicle-initiation, and flowering for sustaining the aerobic rice yield [117]. Similarly, two to three split applications of the recommended dose of potassium were found to be more economical in the aerobic rice system [118]. In addition to macronutrient application, the need-based use of secondary micronutrients is also equally important. The application of iron foliar spray is important in DSR and aerobic rice, especially in the early stage of the crop to overcome iron deficiency [119]. Under surface drip irrigation with zinc fertigation (8 kg/ha), rice crops need 1246 L of water to produce one kg of rice compared to 4263 L under conventional transplanted rice with 25 kg Zn/ha application [94]. The water productivity is highest (1.13 g kg−1) in nitrogen-fertilized plots in comparison to no nitrogen (0.62 g kg−1) under aerobic rice [60].

3.2. Efficient Weed Control

As water scarcity becomes more acute, rice farmers may face limitations on the amount of water available for rice production and may not be able to rely on continuous flooding as a method for weed control in the future [120]. Though flooding helps in eliminating grass and sedges in rice cultivation, it failed to control broadleaf weeds [121]. Weed menace is the major problem in the SRI, DSR, aerobic rice, and drip-irrigated rice [119]. The occurrence of non-aquatic weeds increased in these systems due to the absence of flooding. The time of weed removal is more important in these methods. Early control of weeds helps with better crop establishment and turns crop weed competition in favor of rice plants [122]. The use of herbicides ensures that weeds are controlled at the time of germination. In direct-seeded rice systems, the use of a sequential approach consisting of a pre-emergence herbicide followed by a post-emergence herbicide was found to be more effective and cost-efficient than traditional hand weeding [87,123,124]. Several improved farm tools and implements were available for weed control in the SRI, line-sown DSR, and line-transplanted rice. The use of these tools improves soil aeration, root growth, and yield, in addition to better weed control [18,125].

DSR can reduce GHG emissions, improve soil quality, and save money on labor, water, and energy. However, weeds constitute a significant problem that could result in the total failure of the rice crop. To increase output and optimize resource utilization, effective weed management is vital. Compared to other weed control strategies, herbicides are a more efficient and cost-effective solution in the case of DSR. The sequential use of pendimethalin 1000 g/ha as a pre-emergence herbicide applied 1 day after sowing and penoxsulam + cyhalofop-butyl 130 g/ha as a post-emergence herbicide applied 25 days after sowing significantly increased grain yield, irrigation water productivity, and total water productivity by 378.9%, 378%, and 380%, respectively, compared to the unweeded control [126]. Effective weed control, which reduces competition for growth resources, such as water and nutrients, is essential for maximizing water use efficiency in direct-seeded aerobic rice systems. In aerobic rice, the herbigation with pretilachlor + bensulfuran methyl as pre-emergence, and bispyribac sodium as post-emergence at 20 days after sowing, resulted in higher water use efficiency (153.45 kg/ha cm) compared to the weedy check (7.07 kg/ha cm) [127]. This improvement was attributed to increased grain yield due to better weed management in the weed-free and herbigation treatments.

3.3. Seed Treatment

Seed priming is a pre-sowing seed treatment that helps rice seeds overcome various biotic and abiotic stressors, leading to improved seedling growth and an increase in crop productivity. Based on the substance/material used for priming, it is classified into hydro-priming (water), osmo-priming (osmotic agent), halo-priming (use of specific salts for priming), bio-priming (microbial bio-agents), and hormo-priming (plant growth regulators). Priming does not allow radical protrusion through the seed coat but allows the seeds to imbibe water and stay ready for quick germination. Seed priming has been shown to enhance plant germination even in adverse soil and weather conditions. It reduces the average time for seeds to sprout and increases the energy used for germination, resulting in a higher germination index and improved seedling vigor. This helps to ensure more robust plant growth and development, even in challenging environments [128]. The reduced imbibition lag time [129], osmotic adjustment [130], accumulation of germination-enhancing metabolites [131], enzyme activation [132], and metabolic repair during imbibition [133] ensure higher and uniform germination of primed seeds. Rice cultivation is possible with limited irrigation levels, even as low as −15 kPa and −30 kPa. In areas where it is challenging to maintain frequent irrigation and soil water levels drop below −15 kPa, seed priming with Trichoderma is advised, as this technique can result in a significant boost in grain yield, with an increase of 68% at −15 kPa and 77% at −30 kPa, as well as an improvement in water productivity, with a rise of 70% at −15 kPa and 66% at −30 kPa, compared to non-primed seeds [134].

The use of potassium nitrate as a seed priming agent is another promising option, especially when soil water levels fall below −15 kPa. This substance has the potential to improve seed performance in these challenging conditions. Seed priming with moringa leaf extracts (3.3%) or CaCl2 (2.2%) improved the direct-seeded rice performance when practiced with AWD irrigation [135]. According to research by Hussain et al. (2016), chemical priming with selenium and hormonal priming with salicylic acid were found to be more effective at mitigating the effects of chilling stress in rice seedlings [136]. These priming methods improved seedling performance and tolerance by enhancing starch metabolism, increasing respiration rates, reducing lipid peroxidation, and strengthening the plant’s antioxidant defense system. Seed priming can be a useful approach to improve rice germination and stand establishment in the rabi season, particularly in the eastern part of India where low temperatures can cause poor germination. Additionally, Dhillon et al. (2021) found that halo-priming with 2.0% potassium nitrate and hormo-priming with 50 ppm GA3 had the potential to improve rice crop establishment and yield by 7–11% in both conventional and soil mulch DSR systems [137]. The higher yields were attributed to faster and more successful germination and crop emergence, improved root growth, and enhanced yield attributes. The priming treatments also activate important enzymes such as superoxide dismutase, peroxidase, and catalase, and increase the accumulation of glutathione and free proline in rice seedlings, which protect the seedlings from chilling-induced oxidative stress.

3.4. The Water Footprint as an Indicator of the Best Rice Production Method

The water footprint (WF) is a comprehensive indicator of the environmental impact of rice cultivation and can help identify more sustainable and efficient irrigation practices to reduce water use and improve water quality. The WF in rice cultivation refers to the amount of water used for irrigating rice fields throughout its growth cycle, as well as the amount of water required to dilute pollutants, such as nitrogen and phosphorus, that may be released into the environment due to agricultural activities. It includes both the direct water consumption by the crop through evapotranspiration (green water) and the water used for irrigation (blue water), as well as the water required to dilute and transport pollutants in the environment (grey water). The worldwide WF of rice production is estimated to be 1308 Mm3 per year, with 707 Mm3 per year attributed to evaporation, of which 332 Mm3 per year is attributed to green water use and 374 Mm3 per year to blue water use. Furthermore, 64 Mm3 per year is related to pollution, while 538 Mm3 per year is lost through percolation and residual soil moisture after harvest [138]. In Thailand and Malaysia, the WF of rice cultivation was estimated to be 1665 m3 per ton and 2500 L/kg based on life cycle assessment, respectively [139,140]. Wu et al. compared the WF of paddy rice production under common flood irrigation (CFI) and water-saving irrigation (SWI) in Nanjing, East China, and found that the WF was 1000 m3/t for CFI and 910 m3/t for SWI, with a 9% reduction in WF for SWI compared to CFI. SWI reduced irrigation during non-critical periods, shifting the ratio of blue to green water fluxes in field water and using green water preferentially [141]. Another study evaluated the WF of rice production in the Walawe irrigation scheme of Sri Lanka over three years. Results showed that the average annual WFblue was found to be 2.27 m3/kg, which is higher than global and national WFtot, indicating that irrigation water usage in the area may be significantly higher due to relatively higher evapotranspiration in the area, suggesting the need to reduce excess water usage by shifting irrigation practices from flooded irrigation to the SRI [142]. In India, the WF of rice in 2014 was found to vary with region. Among the five rice-growing regions (south, north, east, west, and northeast), the western region showed the highest WF of 3.52 m3 per kilogram of rice due to the region’s high irrigation water usage [143]. This study also recommended large-scale promotion and adoption of water-saving irrigation techniques such as SRI, aerobic rice, AWD, DSR, etc., to reduce blue WF. Another interesting study in Indonesia compared the WF of conventional rice with organic rice cultivation, and the result showed that organic rice cultivation saves up to 52.8% of the WF compared to conventional flooded rice, demonstrating the potential of organic farming practices to promote sustainable water use in agriculture in Indonesia [144].

4. Conclusions